The Use of Multilayer Perceptron (MLP) to Reduce Delamination during Drilling into Melamine Faced Chipboard

Abstract

:1. Introduction

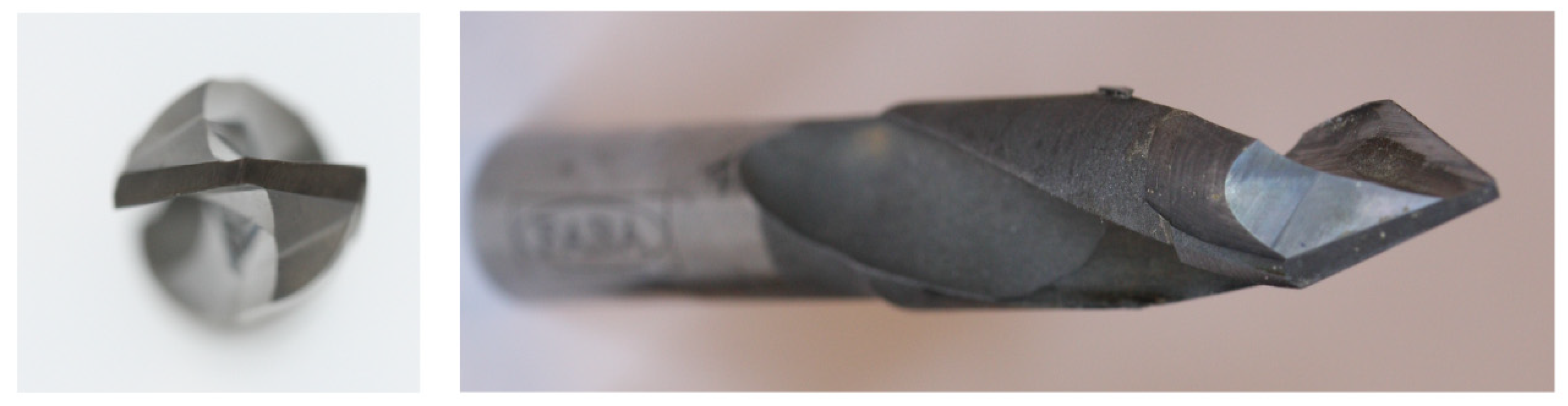

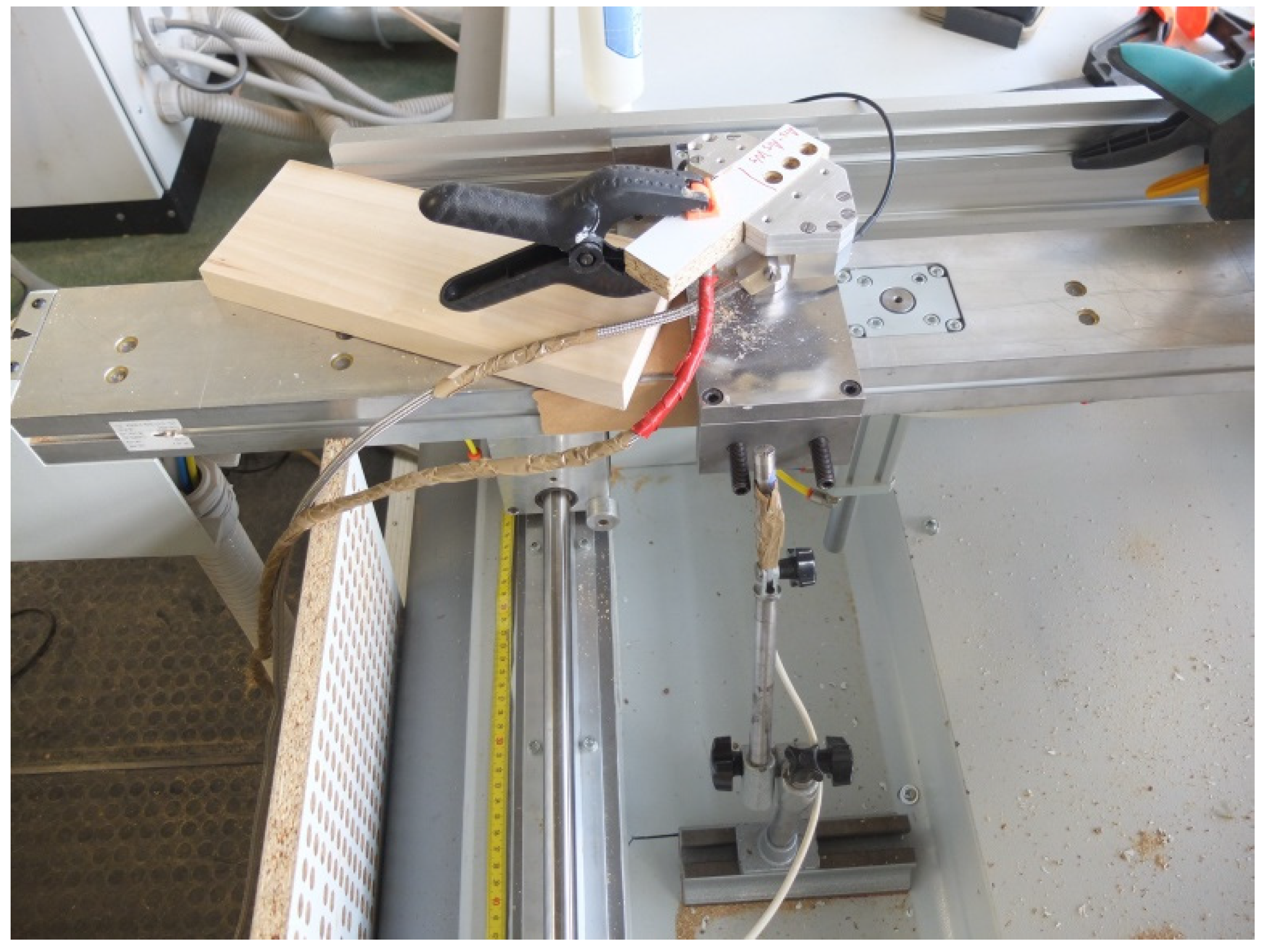

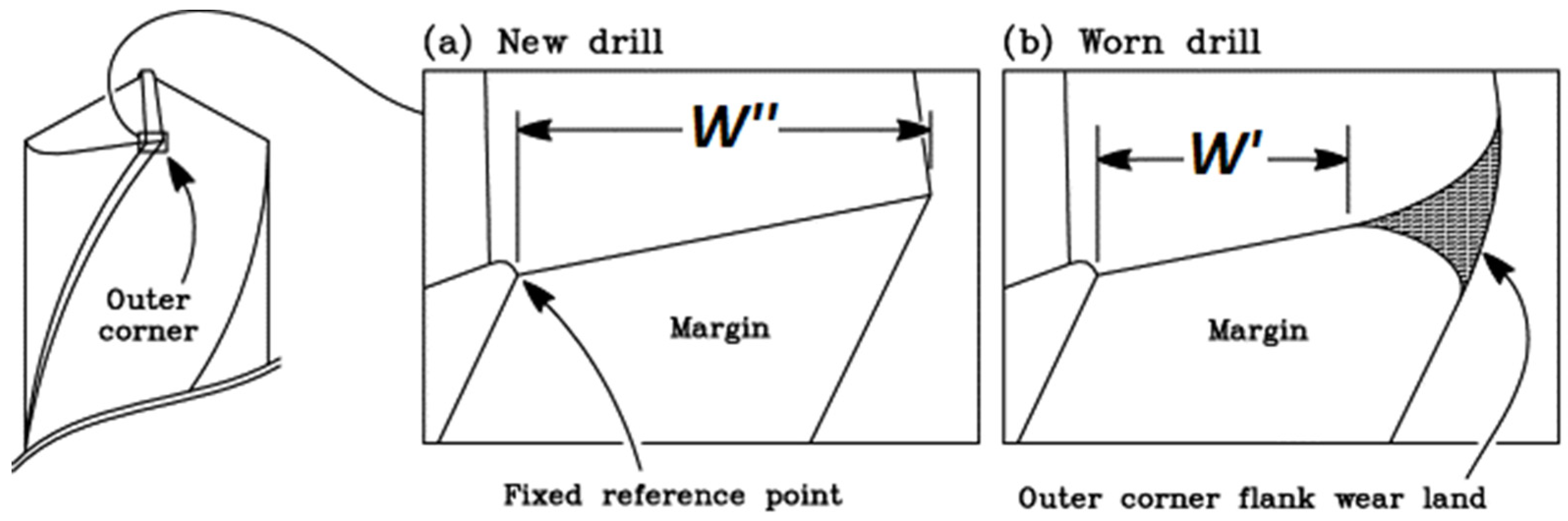

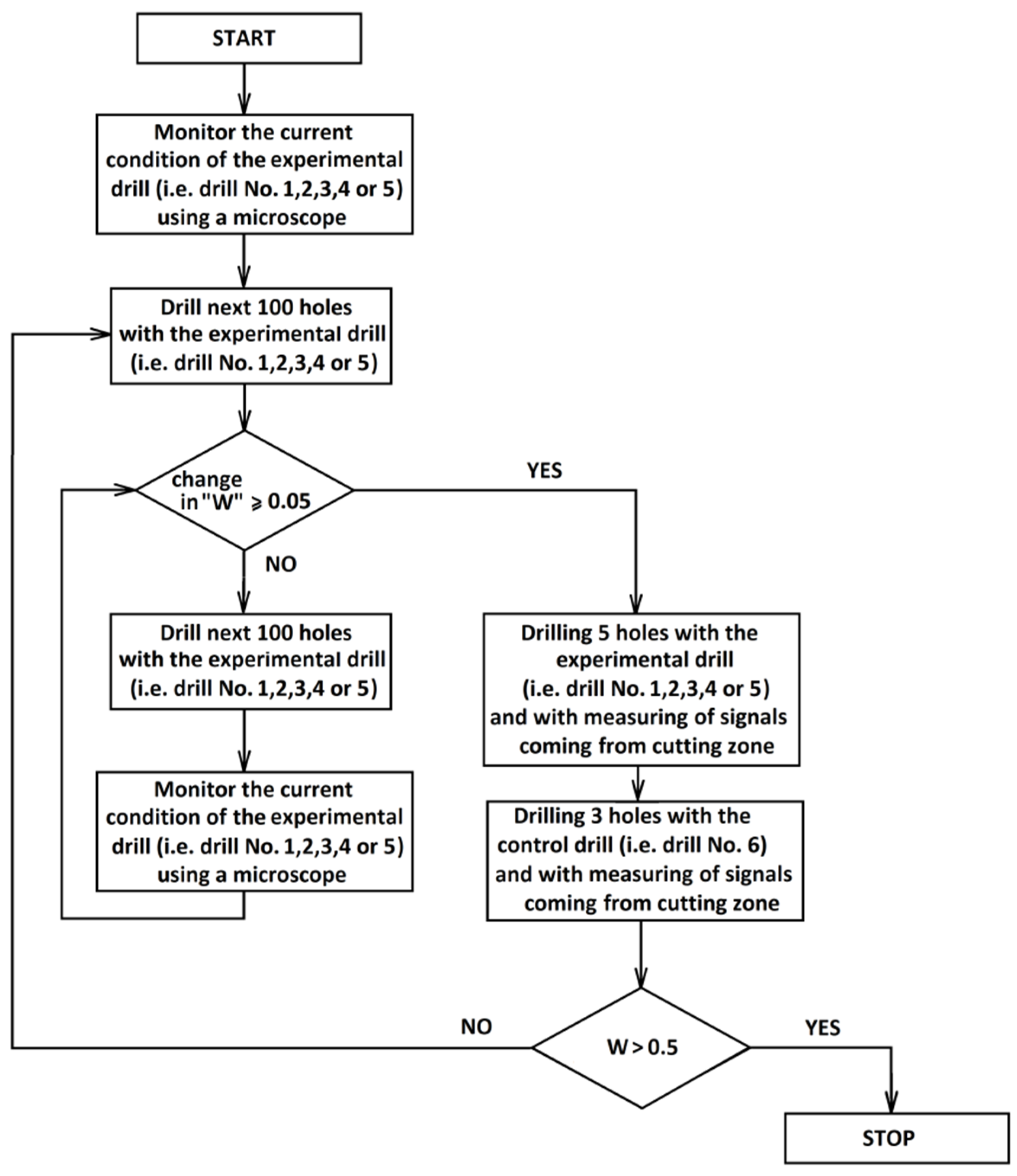

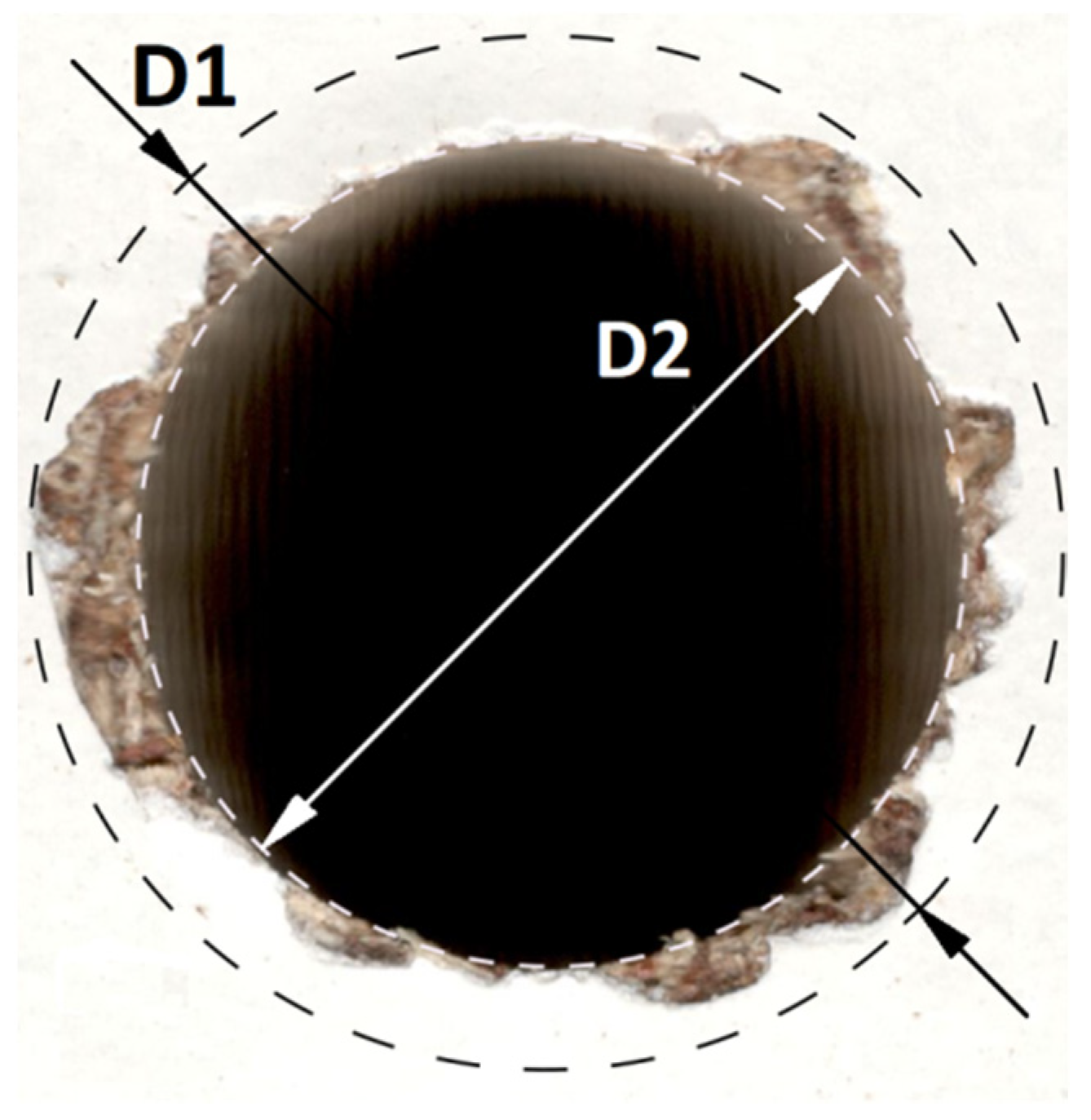

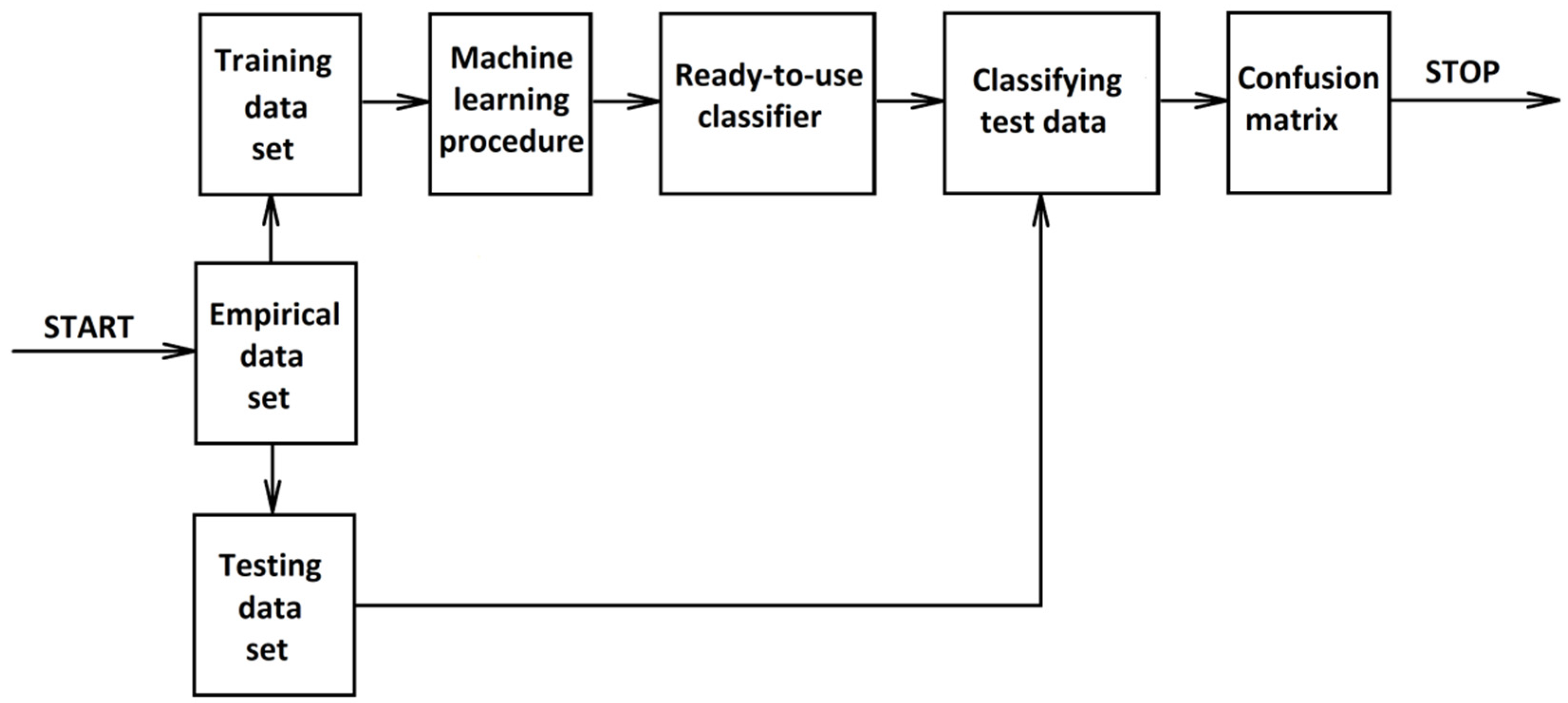

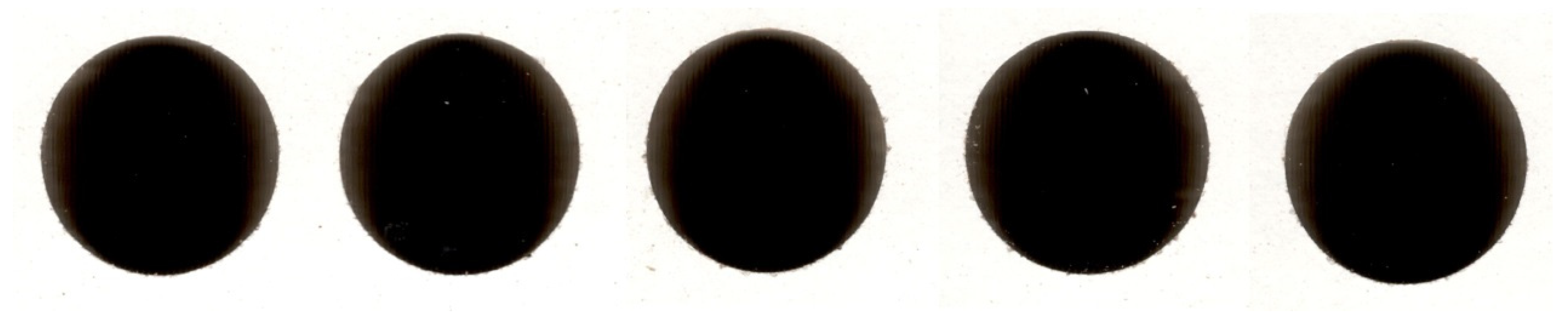

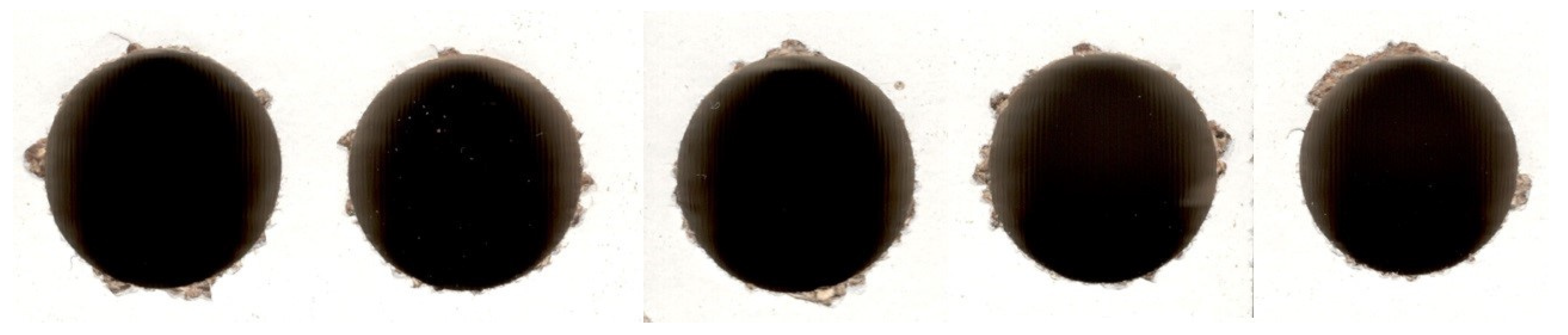

2. Materials and Methods

- Contact sensor of acoustic emission (AE) signal (Kistler 8152B; Kistler Group, Winterthur, Switzerland), which was mechanically pressed against the workpiece;

- Accelerometer for vibration measurement (Kistler 8141B; Kistler Group, Winterthur, Switzerland), which was mounted to the sample holder (jig);

- Force gauge based on 2-component sensor (Kistler 9345A; Kistler Group, Winterthur, Switzerland) for the simultaneous measurement of feed force as well as machining torque;

- Microphone for noise (acoustic pressure) measurement (B&K 4189; Brüel and Kjær, Nærum, Denmark) mounted on the stand near the machining zone.

- TP: the number of true positive predictions;

- TN: the number of true negative predictions;

- FP: the number of false positive predictions;

- FN: the number of false negative predictions.

3. Results and Discussion

4. Conclusions

- The classification effects (with an overall accuracy above 70%) were ultimately fairly decent but slightly worse than those of the classification algorithms tested earlier (i.e., “nearest neighbors” or “support vector machine” algorithms). The most troublesome, however, is the fact that serious errors (mistakes between extreme classes “Green” and “Red”) were occasionally noted (for about 1% of the analyzed cases).

- The most important and the best news is that the “Green” class (which is the most important one from a practical point of view) was identified quite accurately (accuracy: 0.84; Fscore: 0.77). This is very beneficial because the main job of the tool condition monitoring system is to identify tools which should not yet be changed.

- Thinking about future research, we plan to consider the drilling of various wood-based materials (e.g., MDF), testing other classification algorithms and analyzing the problem of selecting signal features for their usefulness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kun, W.; Qi, S.; Cheng, W. Influence of pneumatic pressure on delamination factor of drilling medium density fiberboard. Wood Res. 2015, 60, 429–440. [Google Scholar]

- Szwajka, K.; Trzepieciński, T. Effect of tool material on tool wear and delamination during machining of particleboard. J. Wood Sci. 2016, 62, 305–315. [Google Scholar] [CrossRef]

- Szwajka, K.; Trzepieciński, T. An examination of the tool life and surface quality during drilling melamine faced chipboard. Wood Res. 2017, 62, 307–318. [Google Scholar]

- Śmietańska, K.; Podziewski, P.; Bator, M.; Górski, J. Automated monitoring of delamination factor during up (conventional) and down (climb) milling of melamine-faced MDF using image processing methods. Eur. J. Wood Wood Prod. 2020, 78, 613–615. [Google Scholar] [CrossRef] [Green Version]

- Lemaster, R.L.; Tee, L.B.; Dornfeld, D.A. Monitoring tool wear during wood machining with acoustic emission. Wear 1985, 101, 273–282. [Google Scholar] [CrossRef]

- Lemaster, R.L.; Lu, L.; Jackson, S. The use of process monitoring techniques on a CNC wood router. Part 1. Sensor selection. For. Prod. J. 2000, 50, 31–38. [Google Scholar]

- Lemaster, R.L.; Lu, L.; Jackson, S. The use of process monitoring techniques on a CNC wood router. Part 2. Use of vibration accelerometer to monitor tool wear and workpiece quality. For. Prod. J. 2000, 50, 59–64. [Google Scholar]

- Zhu, N.; Tanaka, C.; Ohtani, T.; Usuki, H. Automatic detection of a damaged cutting tool during machining I: Method to detect damaged bandsaw teeth during sawing. J. Wood Sci. 2000, 46, 437–443. [Google Scholar] [CrossRef]

- Zhu, N.; Tanaka, C.; Ohtani, T. Automatic detection of damaged bandsaw teeth during sawing. Holz Roh Werkst. 2002, 60, 197–201. [Google Scholar] [CrossRef]

- Zhu, N.; Tanaka, C.; Ohtani, T.; Takimoto, Y. Automatic detection of a damaged router bit during cutting. Holz Roh Werkst. 2004, 62, 126–130. [Google Scholar] [CrossRef]

- Suetsugu, Y.; Ando, K.; Hattori, N.; Kitayama, S. A tool wear sensor for circular saws using wavelet transform signal processing. For. Prod. J. 2005, 55, 79. [Google Scholar]

- Szwajka, K.; Górski, J. Evaluation tool condition of milling wood on the basis of vibration signal. J. Phys. Conf. Ser. 2006, 48, 1205–1209. [Google Scholar] [CrossRef]

- Wilkowski, J.; Górski, J. Vibro-acoustic signals as a source of information about tool wear during laminated chipboard milling. Wood Res. 2011, 56, 57–66. [Google Scholar]

- Górski, J.; Szymanowski, K.; Podziewski, P.; Śmietańska, K.; Czarniak, P.; Cyrankowski, M. Use of cutting force and vibro-acoustic signals in tool wear monitoring based on multiple regression technique for compreg milling. BioResources 2019, 14, 3379–3388. [Google Scholar] [CrossRef]

- Nasir, V.; Cool, J.; Sassani, F. Intelligent Machining Monitoring Using Sound Signal Processed With the Wavelet Method and a Self-Organizing Neural Network. IEEE Trans. Robot. Autom. 2019, 4, 3449–3456. [Google Scholar] [CrossRef]

- Nasir, V.; Sassani, F. A review on deep learning in machining and tool monitoring: Methods, opportunities, and challenges. Int. J. Adv. Manuf. Technol. 2021, 115, 2683–2709. [Google Scholar] [CrossRef]

- Zbieć, M. Application of Neural Network in Simple Tool Wear Monitoring and Indentification System in MDF Milling. Drv. Ind. 2011, 62, 43–54. [Google Scholar] [CrossRef]

- Tratar, J.; Pušavec, F.; Kopac, J. Tool wear in terms of vibration effects in milling medium-density fibreboard with an industrial robot. J. Mech. Sci. Technol. 2015, 28, 4421–4429. [Google Scholar] [CrossRef]

- Nasir, V.; Dibaji, S.; Alaswad, K.; Cool, J. Tool wear monitoring by ensemble learning and sensor fusion using power, sound, vibration, and AE signals. Manuf. Lett. 2001, 30, 32–38. [Google Scholar] [CrossRef]

- Jegorowa, A.; Górski, J.; Kurek, J.; Kruk, M. Initial study on the use of support vector machine (SVM) in tool condition monitoring in chipboard drilling. Eur. J. Wood Wood Prod. 2019, 77, 957–959. [Google Scholar] [CrossRef] [Green Version]

- Jegorowa, A.; Górski, J.; Kurek, J.; Kruk, M. Use of nearest neighbors (k-NN) algorithm in tool condition identification in the case of drilling in melamine faced particleboard. Maderas-Cienc. Tecnol. 2020, 22, 189–196. [Google Scholar] [CrossRef] [Green Version]

- Górski, J. The Review of New Scientific Developments in Drilling in Wood-Based Panels with Particular Emphasis on the Latest Research Trends in Drill Condition Monitoring. Forests 2022, 13, 242. [Google Scholar] [CrossRef]

- EN 310; Wood-Based Panels: Determination of Modulus of Elasticity in Bending and of Bending Strength. CEN: Brussels, Belgium, 1994.

- EN 1534; Wood Flooring and Parquet: Determination of Resistance to Indentation—Test Method. CEN: Brussels, Belgium, 2002.

- Czarniak, P.; Szymanowski, K.; Panjan, P.; Górski, J. Initial Study of the Effect of Some PVD Coatings (“TiN/AlTiN” and “TiAlN/a-C:N”) on the Wear Resistance of Wood Drilling Tools. Forests 2022, 13, 286. [Google Scholar] [CrossRef]

- Haykin, S. Neural Networks: A Comprehensive Foundation; Macmillan College Publishing Company, Inc.: New York, NY, USA, 1994. [Google Scholar]

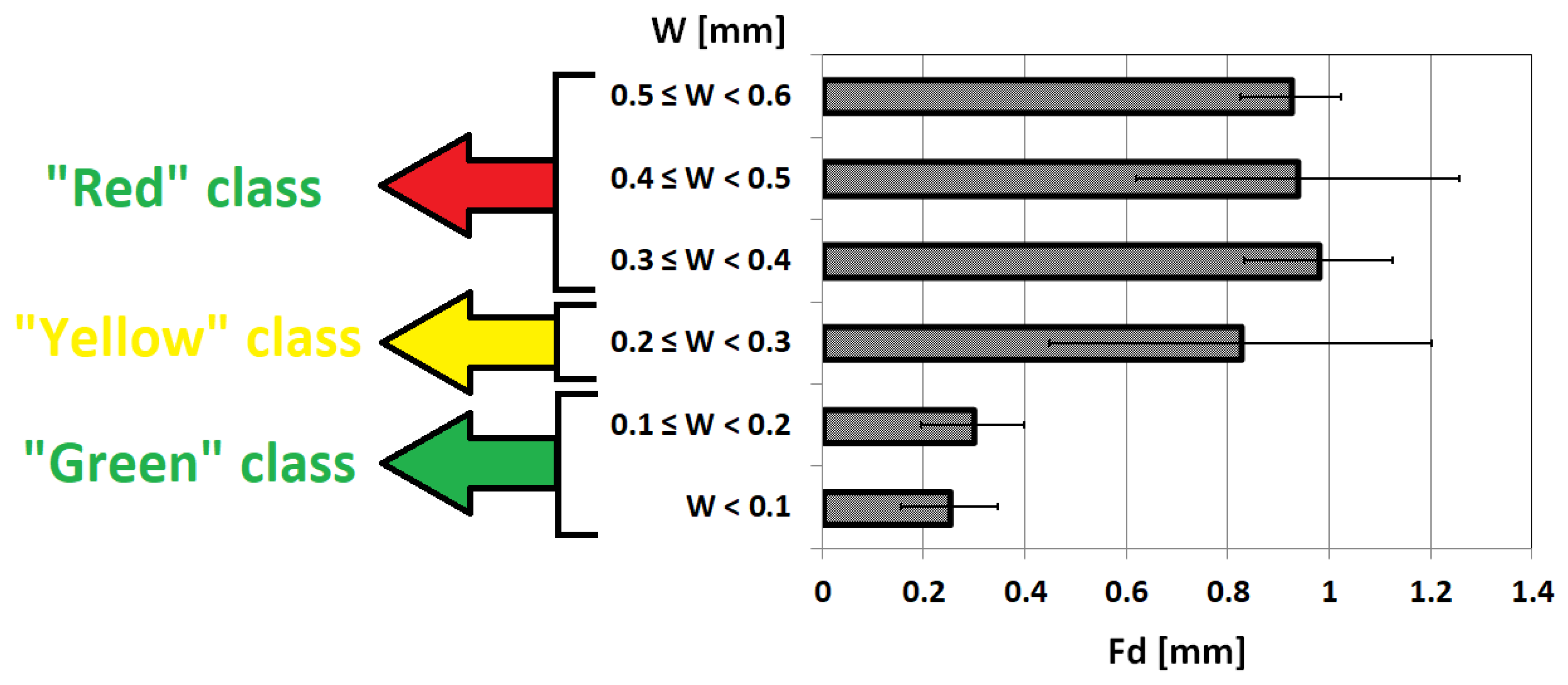

| Ranges of W (mm) | Class Name |

|---|---|

| ≤0.2 | Green |

| 0.2–0.35 | Yellow |

| >0.35 | Red |

| No. of Variant | Number of Hidden Layers | Number of Neurons in Each Hidden Layer |

|---|---|---|

| 1 | 1 | 10 |

| 2 | 2 | 10 |

| 3 | 3 | 10 |

| 4 | 1 | 15 |

| 5 | 2 | 15 |

| 6 | 3 | 15 |

| 7 | 1 | 20 |

| 8 | 2 | 20 |

| 9 | 3 | 20 |

| Real Class | ||||

|---|---|---|---|---|

| Green | Yellow | Red | ||

| Predicted Class | Green | KGG (%) | KGY (%) | KGR (%) |

| Yellow | KYG (%) | KYY (%) | KYR (%) | |

| Red | KRG (%) | KRY (%) | KRR (%) | |

| Predicted Class | Green | 26.0% | 7.0% | 0.0% |

| Yellow | 7.9% | 11.2% | 4.2% | |

| Red | 0.9% | 9.8% | 33.0% | |

| Green | Yellow | Red | ||

| Real class | ||||

| Class Name | Accuracy (Acc) | Sensitivity (Sn) | Specificity (Sp) | Precision (Pr) | Fscore |

|---|---|---|---|---|---|

| Green | 0.84 | 0.75 | 0.89 | 0.79 | 0.77 |

| Yellow | 0.71 | 0.40 | 0.83 | 0.48 | 0.44 |

| Red | 0.85 | 0.89 | 0.83 | 0.75 | 0.82 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jegorowa, A.; Kurek, J.; Kruk, M.; Górski, J. The Use of Multilayer Perceptron (MLP) to Reduce Delamination during Drilling into Melamine Faced Chipboard. Forests 2022, 13, 933. https://doi.org/10.3390/f13060933

Jegorowa A, Kurek J, Kruk M, Górski J. The Use of Multilayer Perceptron (MLP) to Reduce Delamination during Drilling into Melamine Faced Chipboard. Forests. 2022; 13(6):933. https://doi.org/10.3390/f13060933

Chicago/Turabian StyleJegorowa, Albina, Jarosław Kurek, Michał Kruk, and Jarosław Górski. 2022. "The Use of Multilayer Perceptron (MLP) to Reduce Delamination during Drilling into Melamine Faced Chipboard" Forests 13, no. 6: 933. https://doi.org/10.3390/f13060933

APA StyleJegorowa, A., Kurek, J., Kruk, M., & Górski, J. (2022). The Use of Multilayer Perceptron (MLP) to Reduce Delamination during Drilling into Melamine Faced Chipboard. Forests, 13(6), 933. https://doi.org/10.3390/f13060933