Caveat emptor: On the Need for Baseline Quality Standards in Computer Vision Wood Identification

Abstract

:1. Introduction

1.1. The Central Dogma of ML

1.2. Core Tenets of CVWID

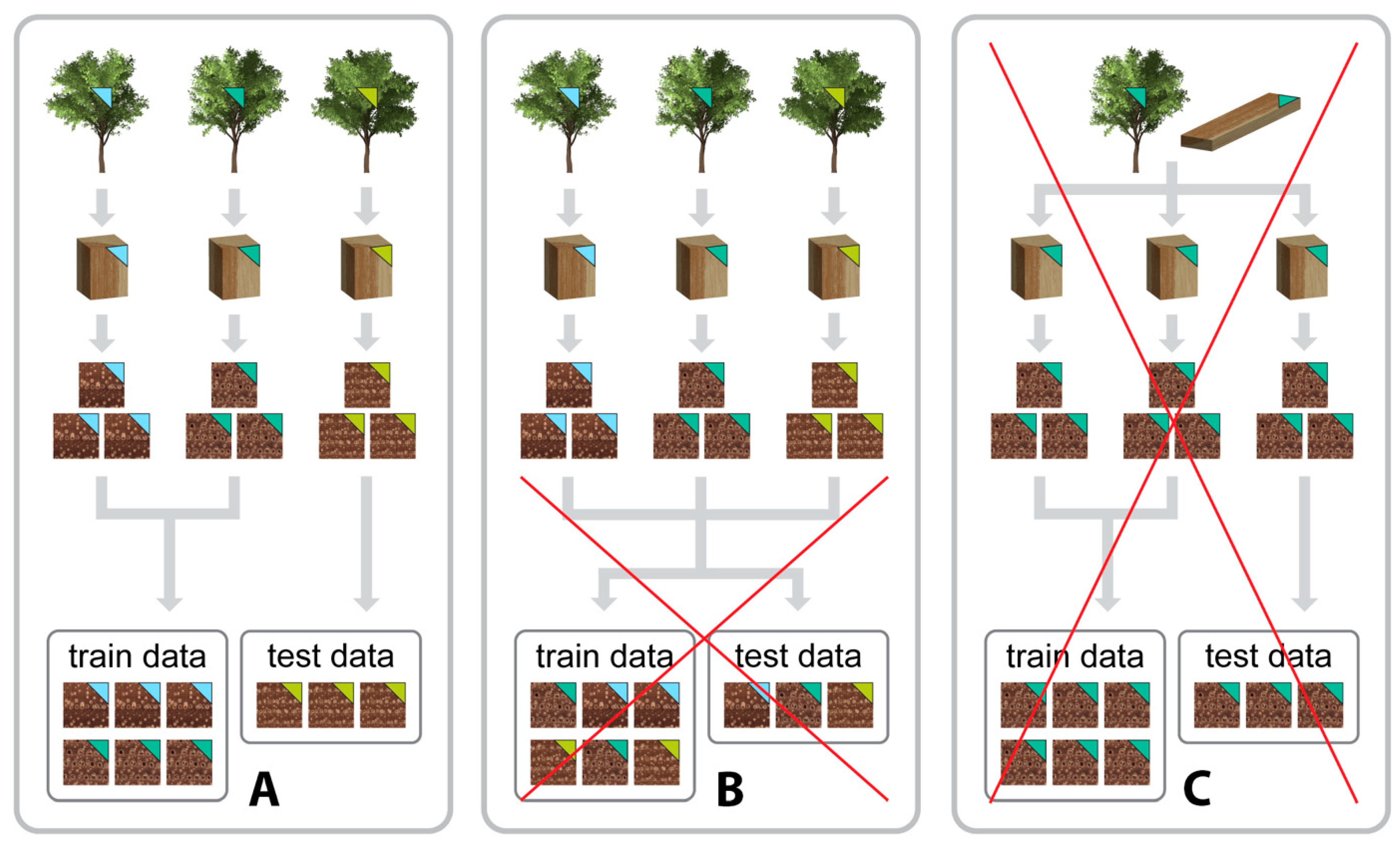

- Sample atomicity at the level of individual trees is mandatory for a valid training and evaluation methodology. Violation of this requirement leads to systems that are evaluated for the wrong functionality—individual tree recognition—instead of the desired wood species or genus identification functionality (see Figure 1 for example scenarios), and

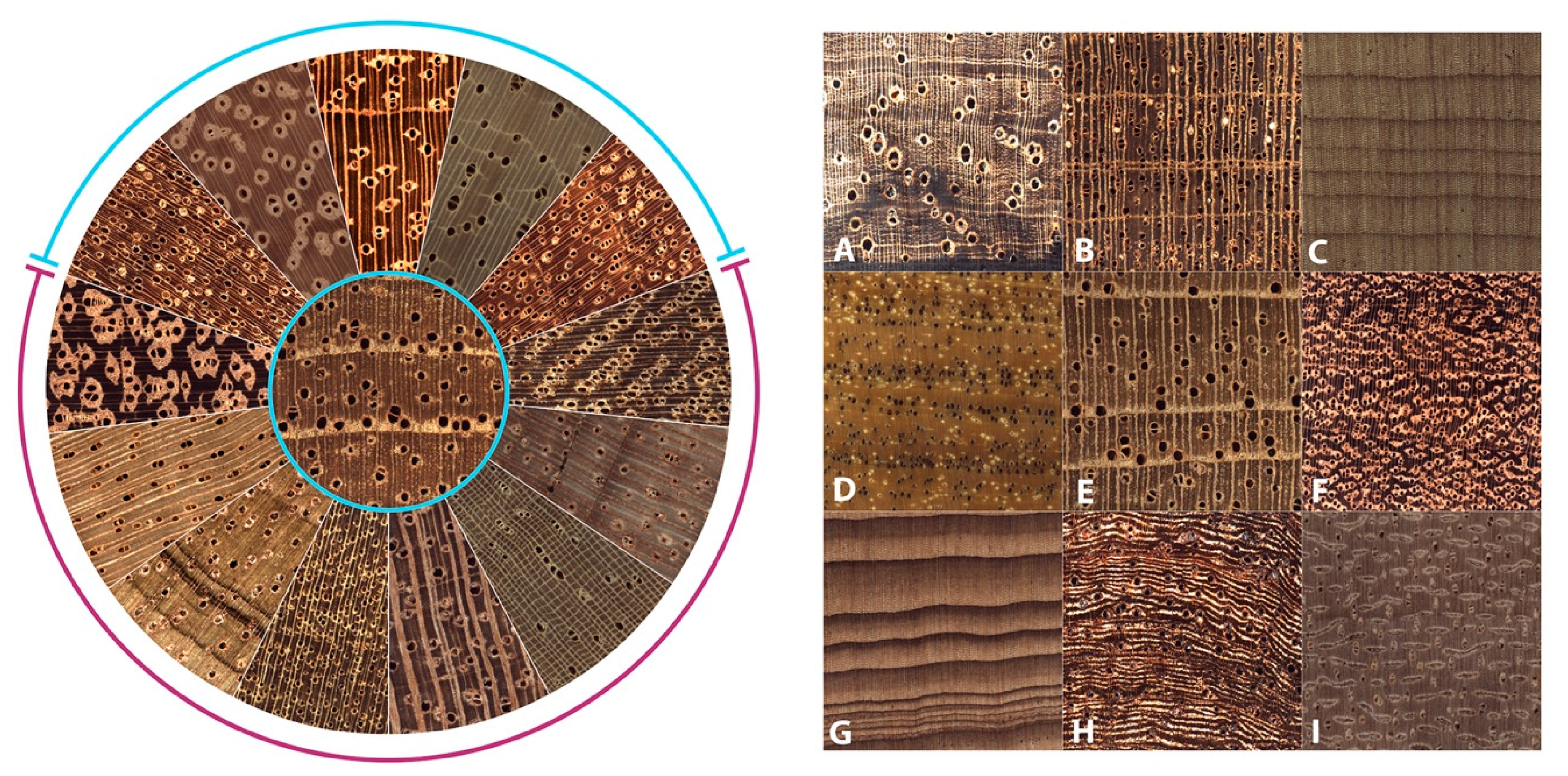

- Consistent sample preparation and imaging that enables the capture of images that show the relevant discriminative wood anatomy, thereby enabling models to learn and use robust features based on the arrangement, abundance, and structural patterns of wood anatomical features such as vessels, rays, and axial parenchyma, and reduces the chances of learning spurious or non-robust correlations (e.g., color, systematic defects in surface preparation).

1.3. The CVWID Lifecycle

1.3.1. Context Definition

1.3.2. Data Collection

1.3.3. Model Training

1.3.4. Model Evaluation

1.3.5. Field Evaluation

1.4. Challenges and State-of-the-Practice in CVWID

1.4.1. Sourcing, Scarcity, and Data Quality of CVWID Data

1.4.2. Logistics of Field Testing

2. Materials and Methods

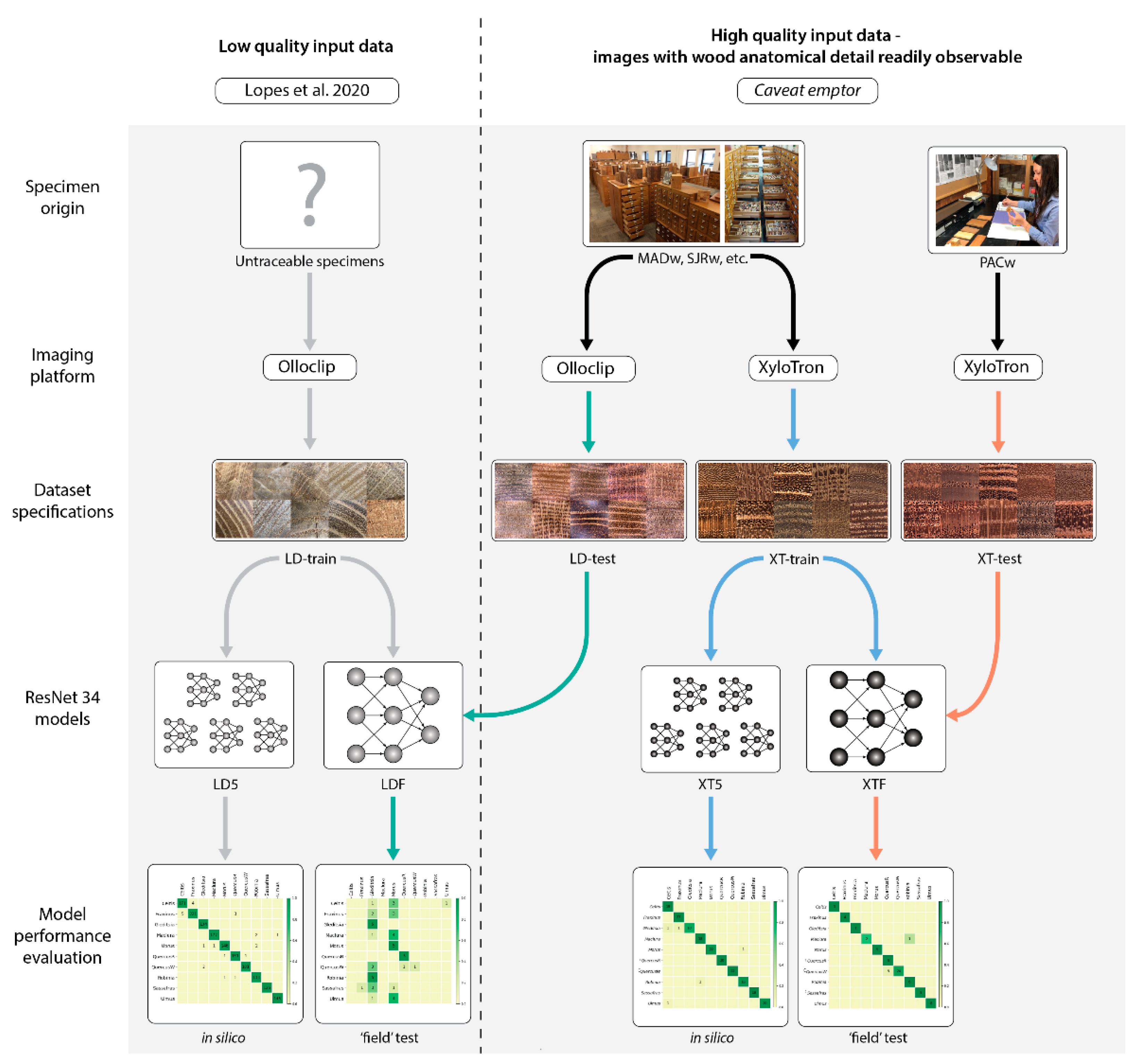

2.1. Datasets

2.1.1. LD-Train

2.1.2. LD-Test

2.1.3. XT-Train

2.1.4. XT-Test

2.1.5. Species Composition

2.2. Modeling and Evaluation

2.2.1. Evaluation of LD-Train

2.2.2. Model Architecture and Training

2.2.3. Performance Evaluation

Five-Fold Cross-Validation

Surrogate Field Testing

3. Results

3.1. Evaluation of LD-Train Image Quality

3.2. Evaluation of Models Trained on LD-Train

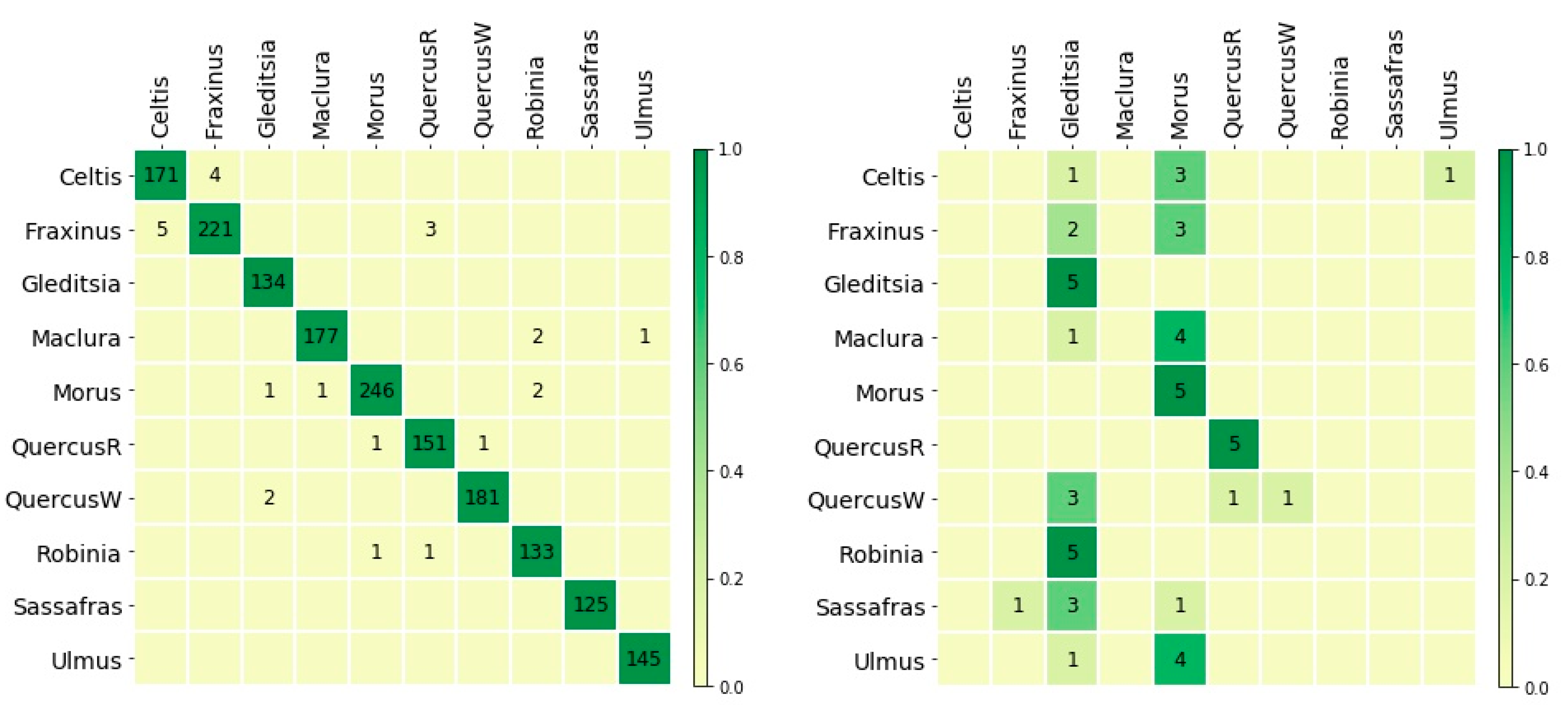

3.3. Evaluation of Models Trained on XT-Train

4. Discussion

4.1. High Accuracy Does Not a Valid Model Make

- The foundational requirement for a valid ML methodology is the clear separation between the training and testing sets. For CVWID this requires that every wood specimen must contribute images to exactly one of the cross-validation folds. The presence of sufficient numbers of duplicate images (rotated and cropped versions of images of the same wood tissue) in LD-train violates this foundational requirement both at the specimen and image levels, thereby not allowing scientifically valid evaluation such as cross-validation analysis.

- The lack of adequate specimen surface preparation to expose the relevant wood anatomy (use of saw-cuts instead of knife-prepared) and the presence of incorrectly labeled images (e.g., the majority of the images in class Morus were in fact images of Catalpa sp., a taxon not included in the study) are other reasons that make LD-train unsuitable for comparative model performance analyses, and this unsuitability extends to the validity of the initial work as published (Table 2). In contrast, the difference in cross-validation and proxy field testing accuracies for the models trained on XT-train, XT5, and XTF, is acceptable and the model(s) can be deemed practically functional, especially in human-mediated scenarios.

4.2. Towards Effective Field Testing and Deployment

4.3. A Baseline Quality Standards Checklist

- the use of multiple unique wood specimens of a sufficient number to capture the wood anatomical variation inherent to the taxa considered, with uniqueness interpreted as being sourced from distinct trees, (see Figure 1 for valid and invalid scenarios),

- the consistent, repeatable, and adequate preparation of specimen surface(s) (e.g., sanding, razor cuts) to expose the relevant wood anatomy needed for identification,

- the use of an imaging sensor with a sufficient (and reported) spatial resolution to enable the capture of coarse and fine, taxon-dependent, discriminating wood anatomical features,

- the acquisition of in-focus images with controlled, repeatable, and consistent illumination,

- minimal to no overlap among multiple images from a specimen so that intra-specimen variation is optimally and maximally captured,

- the label space design, i.e., the classes (sub-generic, multi-generic, individual species, anatomical characters, character states, etc.) into which the taxa are categorized (model outputs), represent the wood anatomy of the considered taxa while being relevant to the deployment context for the model,

- the evaluation of trained models, at the specimen level, on specimens that did not contribute images for model training and/or testing on a completely new set of verified specimens, and,

- the parsing of model evaluation results (e.g., confusion matrices) using domain expertise (not all errors are considered equal e.g., out-of-genus identification errors may be worse than congeneric errors [14]), in addition to reporting standard metrics such as (specimen level) accuracies, precision-recall, F1 score—these latter metrics do not provide class-wise information about which errors were made.

4.4. Revisiting Context-Dependency in CVWID and Other Modalities

5. Conclusions: Caveat emptor

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Johnson, A.; Laestadius, L. New laws, new needs: The role of wood science in global policy efforts to reduce illegal logging and associated trade. IAWA J. 2011, 32, 125–136. [Google Scholar] [CrossRef]

- Wiedenhoeft, A.C.; Simeone, J.; Smith, A.; Parker-Forney, M.; Soares, R.; Fishman, A. Fraud and misrepresentation in retail forest products exceeds U.S. forensic wood science capacity. PLoS ONE 2019, 14, e0219917. [Google Scholar] [CrossRef] [PubMed]

- Schmitz, N.; Braga, W.; Deklerck, V.; Espinoza, E.; Groening, M.; Koch, G.; Pastore, T.; Ramananantoandro, T.; Schröder, H.; Watkinson, C.; et al. (Eds.) Scientific methods for taxonomic and origin identification of timber. In Global Timber Tracking Network; GTTN Secretariat, European Forest Institute and Thünen Institute: Braunschweig, Germany, 2020. [Google Scholar] [CrossRef]

- Khalid, M.; Lew, E.; Lee, Y.; Yusof, R.; Nadaraj, M. Design of an intelligent wood species recognition system. Int. J. Simul. Syst. Sci. Technol. 2008, 9, 9–19. Available online: https://ijssst.info/Vol-09/No-3/paper2.pdf (accessed on 13 April 2022).

- Martins, J.; Oliveira, L.S.; Nisgoski, S.; Sabourin, R. A database for automatic classification of forest species. Mach. Vis. Appl. 2013, 24, 567–578. [Google Scholar] [CrossRef]

- Filho, P.L.P.; Oliveira, L.S.; Nisgoski, S.; Britto, A.S., Jr. Forest species recognition using macroscopic images. Mach. Vis. Appl. 2014, 25, 1019–1031. [Google Scholar] [CrossRef]

- Figueroa-Mata, G.; Mata-Montero, E.; Valverde-Otárola, J.C.; Arias-Aguilar, D. Automated Image-based Identification of Forest Species: Challenges and Opportunities for 21st Century Xylotheques. In Proceedings of the 2018 IEEE International Work Conference on Bioinspired Intelligence, San Carlos, CA, USA, 18–20 July 2018; pp. 1–8. [Google Scholar] [CrossRef]

- Ravindran, P.; Costa, A.; Soares, R.; Wiedenhoeft, A.C. Classification of CITES-listed and other neotropical Meliaceae wood images using convolutional neural networks. Plant Methods 2018, 14, 25. [Google Scholar] [CrossRef]

- Tang, X.J.; Tay, Y.H.; Siam, N.A.; Lim, S.C. MyWood-ID: Automated macroscopic wood identification system using smartphone and macro-lens. In Proceedings of the 2018 International Conference on Computational Intelligence and Intelligent Systems, Phuket, Thailand, 12–14 March 2018; pp. 37–43. [Google Scholar] [CrossRef]

- Damayanti, R.; Prakasa, E.; Krisdianto; Dewi, L.M.; Wardoyo, R.; Sugiarto, B.; Pardede, H.F.; Riyanto, Y.; Astutiputri, V.F.; Panjaitan, G.R.; et al. LignoIndo: Image database of Indonesian commercial timber. IOP Conf. Ser. Earth Environ. Sci. 2018, 374, 012057. [Google Scholar] [CrossRef]

- de Andrade, B.G.; Basso, V.M.; de Figueiredo Latorraca, J.V. Machine vision for field-level wood identification. IAWA J. 2020, 41, 681–698. [Google Scholar] [CrossRef]

- Souza, D.V.; Santos, J.X.; Vieira, H.C.; Naide, T.L.; Nisgoski, S.; Oliveira, L.E.S. An automatic recognition system of Brazilian flora species based on textural features of macroscopic images of wood. Wood Sci. Technol. 2020, 54, 1065–1090. [Google Scholar] [CrossRef]

- Ravindran, P.; Owens, F.C.; Wade, A.C.; Vega, P.; Montenegro, R.; Shmulsky, R.; Wiedenhoeft, A.C. Field-Deployable Computer Vision Wood Identification of Peruvian Timbers. Front. Plant Sci. 2021, 12, 647515. [Google Scholar] [CrossRef]

- Ravindran, P.; Wiedenhoeft, A.C. Comparison of two forensic wood identification technologies for ten Meliaceae woods: Computer vision versus mass spectrometry. Wood Sci. Technol. 2020, 54, 1139–1150. [Google Scholar] [CrossRef]

- Arévalo, R.; Pulido, E.N.R.; Solórzano, J.F.G.; Soares, R.; Ruffinatto, F.; Ravindran, P.; Wiedenhoeft, A.C. Image based identification of Colombian timbers using the XyloTron: A proof of concept international partnership. Colomb. For. 2021, 24, 5–16. [Google Scholar] [CrossRef]

- Ravindran, P.; Ebanyenle, E.; Ebeheakey, A.A.; Abban, K.B.; Lambog, O.; Soares, R.; Costa, A.; Wiedenhoeft, A.C. Image based identification of Ghanaian timbers using the XyloTron: Opportunities, risks and challenges. In Proceedings of the 2019 Workshop on Machine Learning for the Developing World, Vancouver, BC, Canada, 9–14 December 2019. [Google Scholar] [CrossRef]

- Ravindran, P.; Thompson, B.J.; Soares, R.K.; Wiedenhoeft, A.C. The XyloTron: Flexible, Open-Source, Image-Based Macroscopic Field Identification of Wood Products. Front. Plant Sci. 2020, 11, 1015. [Google Scholar] [CrossRef] [PubMed]

- Wiedenhoeft, A.C. The XyloPhone: Toward democratizing access to high-quality macroscopic imaging for wood and other substrates. IAWA J. 2020, 41, 699–719. [Google Scholar] [CrossRef]

- Bradski, G. The OpenCV Library. Dr. Dobb’s J. Softw. Tools Prof. Progra. 2000, 25, 120–123. Available online: https://github.com/opencv (accessed on 13 April 2022).

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-Learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. Available online: https://www.jmlr.org/papers/volume12/pedregosa11a/pedregosa11a.pdf (accessed on 13 April 2022).

- Abadi, M.; Barham, P.; Chen, J.; Chen, Z.; Davis, A.; Dean, J.; Devin, M.; Ghemawat, S.; Irving, G.; Isard, M.; et al. TensorFlow: A system for large-scale machine learning. In Proceedings of the 12th USENIX Symposium on Operating Systems Design and Implementation, Savannah, GA, USA, 2–4 November 2016; pp. 265–283. Available online: https://research.google/pubs/pub45381/ (accessed on 13 April 2022).

- Paszke, A.; Gross, S.; Massa, F.; Lerer, A.; Bradbury, J.; Chanan, G.; Killeen, T.; Lin, Z.; Gimelshein, N.; Antiga, L.; et al. Pytorch: An imperative style, high-performance deep learning library. Adv. Neural Inf. Process. Syst. 2019, 32, 8026–8037. [Google Scholar] [CrossRef]

- Hwang, S.W.; Sugiyama, J. Computer vision-based wood identification and its expansion and contribution potentials in wood science: A review. Plant Methods 2021, 17, 47. [Google Scholar] [CrossRef]

- Domingos, P. A few useful things to know about machine learning. Commun. ACM 2012, 55, 78–87. [Google Scholar] [CrossRef] [Green Version]

- Halevy, A.; Norvig, P.; Pereira, F. The Unreasonable Effectiveness of Data. IEEE Intell. Syst. 2009, 24, 8–12. [Google Scholar] [CrossRef]

- O’Mahony, N.; Campbell, S.; Carvalho, A.; Harapanahalli, S.; Velasco-Hernandez, G.; Krpalkova, L.; Riordan, D.; Walsh, J. Deep Learning vs. Traditional Computer Vision. In Advances in Computer Vision. CVC 2019. Advances in Intelligent Systems and Computing; Arai, K., Kapoor, S., Eds.; Springer: Cham, Switzerland, 2019; Volume 943. [Google Scholar] [CrossRef] [Green Version]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef] [PubMed]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; The MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Daintith, J.; Wright, E. A Dictionary of Computing; Oxford University Press: Oxford, UK, 2008; ISBN 13:9780199234004. [Google Scholar] [CrossRef]

- Shen, Z.; Liu, J.; He, Y.; Zhang, X.; Xu, R.; Yu, H.; Cui, P. Towards Out-Of-Distribution Generalization: A Survey. arXiv 2021, arXiv:2108.13624. [Google Scholar] [CrossRef]

- Zhou, K.; Liu, Z.; Qiao, Y.; Xiang, T.; Loy, C.C. Domain Generalization in Vision: A Survey. arXiv 2021, arXiv:2103.02503. [Google Scholar] [CrossRef]

- Shorten, C.; Khoshgoftaar, T.M. A survey on Image Data Augmentation for Deep Learning. J. Big Data 2019, 6, 60. [Google Scholar] [CrossRef]

- He, T.; Lu, Y.; Jiao, L.; Zhang, Y.; Jiang, X.; Yin, Y. Developing deep learning models to automate rosewood tree species identification for CITES designation and implementation. Holzforschung 2020, 74, 1123–1133. [Google Scholar] [CrossRef]

- Hedrick, B.P.; Heberling, J.M.; Meineke, E.K.; Turner, K.G.; Grassa, C.J.; Park, D.S.; Kennedy, J.; Clarke, J.A.; Cook, J.A.; Blackburn, D.C.; et al. Digitization and the Future of Natural History Collections. BioScience 2020, 70, 243–251. [Google Scholar] [CrossRef]

- Pearson, K.D.; Nelson, G.; Aronson, M.F.J.; Bonnet, P.; Brenskelle, L.; Davis, C.D.; Denny, E.G.; Ellwood, E.R.; Goëau, H.; Heberling, J.M.; et al. Machine Learning Using Digitized Herbarium Specimens to Advance Phenological Research. BioScience 2020, 70, 610–620. [Google Scholar] [CrossRef]

- von Baeyer, M.; Marston, J.M. Best practices for digitizing a wood slide collection: The Bailey-Wetmore Wood Collection of the Harvard University Herbaria. Quat. Int. 2021, 593–594, 50–59. [Google Scholar] [CrossRef]

- Lopes, D.J.V.; Burgreen, G.W.; Entsminger, E.D. North American Hardwoods Identification Using Machine-Learning. Forests 2020, 11, 298. [Google Scholar] [CrossRef] [Green Version]

- Available online: https://globaltimbertrackingnetwork.org/products/iawa-index-xylariorum/ (accessed on 13 April 2022).

- Gasson, P. How precise can wood identification be? Wood anatomy’s role in support of the legal timber trade, especially CITES. IAWA J. 2011, 32, 137–154. [Google Scholar] [CrossRef]

- LeCun, Y.; Boser, B.; Denker, J.S.; Henderson, D.; Howard, R.E.; Hubbard, W.; Jackel, L.D. Backpropagation applied to handwritten zip code recognition. Neural Comput. 1989, 1, 541–551. [Google Scholar] [CrossRef]

- Russakovsky, O.; Deng, J.; Su, H.; Krause, J.; Satheesh, S.; Ma, S.; Huang, Z.; Karpathy, A.; Khosla, A.; Bernstein, M.; et al. Imagenet: Large scale visual recognition challenge. Int. J. Comput. Vis. 2015, 115, 211–252. [Google Scholar] [CrossRef] [Green Version]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Delving deep into rectifiers: Surpassing human-level performance on ImageNet classification. In Proceedings of the 2015 International Conference on Computer Vision, Santiago, Chile, 7–13 December 2015; pp. 1026–1034. [Google Scholar] [CrossRef] [Green Version]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep Residual Learning for Image Recognition. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 1–26 July 2016; pp. 770–778. [Google Scholar] [CrossRef] [Green Version]

- Pan, S.J.; Yang, Q. A survey on transfer learning. IEEE Trans. Knowl. Data Eng. 2010, 22, 1345–1359. [Google Scholar] [CrossRef]

- Howard, J.; Gugger, S. Fastai: A layered API for deep learning. Information 2020, 11, 108. [Google Scholar] [CrossRef] [Green Version]

- Kingma, D.; Ba, J. Adam: A method for stochastic optimization. In Proceedings of the 2015 International Conference on Learning Representations, San Diego, CA, USA, 7–9 May 2015. [Google Scholar] [CrossRef]

- Smith, L. A Disciplined Approach to Neural Network Hyper-Parameters: Part 1—Learning Rate, Batch Size, Momentum, and Weight Decay. arXiv 2018, arXiv:1803.09820. [Google Scholar] [CrossRef]

- Devries, T.; Taylor, G.W. Improved Regularization of Convolutional Neural Networks with Cutout. arXiv 2017, arXiv:1708.04552. [Google Scholar] [CrossRef]

- Lens, F.; Liang, C.; Guo, Y.; Tang, X.; Jahanbanifard, M.; da Silva, F.S.C.; Ceccantini, G.; Verbeek, F.J. Computer-assisted timber identification based on features extracted from microscopic wood sections. IAWA J. 2020, 41, 660–680. [Google Scholar] [CrossRef]

- Ravindran, P.; Owens, F.C.; Wade, A.C.; Shmulsky, R.; Wiedenhoeft, A.C. Towards Sustainable North American Wood Product Value Chains, Part I: Computer Vision Identification of Diffuse Porous Hardwoods. Front. Plant Sci. 2022, 12, 758455. [Google Scholar] [CrossRef]

- Florsheim, S.M.B.; Ribeiro, A.P.; Longui, E.L.; Faria, E.; Andrade, I.M.; Oliveira, J.S.; Gouveia, T.C.; Marques, V.N. State of Sao Paulo Friend of Amazonia “Online Identification”. In Proceedings of the Forest Legality Alliance 12th Semi-annual Membership Meeting, World Resources Institute, Washington, DC, USA, 27–28 January 2015. [Google Scholar]

- Recht, B.; Roelofs, R.; Schmidt, L.; Shankar, V. Do ImageNet Classifiers Generalize to ImageNet? arXiv 2019, arXiv:1902.10811. [Google Scholar] [CrossRef]

- UNODC. Best Practice Guide for Forensic Timber Identification; United Nations: New York, NY, USA, 2016. [Google Scholar]

- Wang, Y.; Yao, Q.; Kwok, J.; Ni, L.M. Generalizing from a Few Examples: A Survey on Few-Shot Learning. arXiv 2020, arXiv:1904.05046. [Google Scholar] [CrossRef]

- Bendre, N.; Marín, H.T.; Najafirad, P. Learning from Few Samples: A Survey. arXiv 2020, arXiv:2007.15484. [Google Scholar] [CrossRef]

- Jing, L.; Tian, Y. Self-supervised Visual Feature Learning with Deep Neural Networks: A Survey. arXiv 2019, arXiv:1902.06162. [Google Scholar] [CrossRef]

- Jaiswal, A.; Babu, A.R.; Zadeh, M.Z.; Banerjee, D.; Makedon, F. A Survey on Contrastive Self-supervised Learning. arXiv 2021, arXiv:2011.00362. [Google Scholar] [CrossRef]

- de Geus, A.R.; Backes, A.R.; Gontijo, A.B.; Albuquerque, G.H.Q.; Souza, J.R. Amazon wood species classification: A comparison between deep learning and pre-designed features. Wood Sci. Technol. 2021, 55, 857–872. [Google Scholar] [CrossRef]

- Talebi, H.; Milanfar, P. Learning to Resize Images for Computer Vision Tasks. arXiv 2021, arXiv:2103.09950. [Google Scholar] [CrossRef]

- Olschofsky, K.; Köhl, M. Rapid field identification of CITES timber species by deep learning. Trees For. People 2020, 2, 100016. [Google Scholar] [CrossRef]

- Shugar, A.N.; Drake, B.L.; Kelley, G. Rapid identification of wood species using XRF and neural network machine learning. Sci. Rep. 2021, 11, 17533. [Google Scholar] [CrossRef]

- Nisbet, E.G.; Dlugokencky, E.J.; Bousquet, P. Methane on the rise—Again. Science 2014, 343, 493–495. [Google Scholar] [CrossRef] [Green Version]

- Espinoza, E.O.; Wiemann, M.C.; Barajas-Morales, J.; Chavarria, G.D.; McClure, P.J. Forensic analysis of CITES protected Dalbergia timber from the Americas. IAWA J. 2015, 36, 311–325. [Google Scholar] [CrossRef]

| Class Label | LD-Train | LD-Test | XT-Train | XT-Test |

|---|---|---|---|---|

| Celtis | 175 | 25 (5) | 300 (19) | 14 (3) |

| Fraxinus | 229 | 25 (5) | 300 (27) | 18 (4) |

| Gleditsia | 134 | 25 (5) | 121 (12) | 15 (3) |

| Maclura | 180 | 25 (5) | 203 (18) | 23 (5) |

| Morus | 250 | 25 (5) | 300 (23) | 25 (5) |

| QuercusR | 153 | 25 (5) | 300 (30) | 126 (27) |

| QuercusW | 183 | 25 (5) | 300 (33) | 40 (8) |

| Robinia | 135 | 25 (5) | 249 (17) | 15 (3) |

| Sassafras | 125 | 25 (5) | 262 (19) | 33 (7) |

| Ulmus | 145 | 25 (5) | 300 (21) | 30 (6) |

| Total | 1709 | 250 (50) | 2635 (219) | 339 (71) |

| Celtis | Fraxinus | Gleditsia | Maclura | Morus | Robinia | QuercusR | QuercusW | Sassafras | Ulmus | Average | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Correct taxon | 0.96 | 1 | 1 | 1 | 0.44 | 0.99 | 1 | 1 | 1 | 1 | 0.94 |

| Knife/razor-cut | 0.99 | 0.07 | 0.90 | 0 | 0.80 | 0.02 | 0.18 | 0.05 | 0.94 | 1 | 0.50 |

| No anatomy evident | 0 | 0.88 | 0.08 | 0.04 | 0.39 | 0.81 | 0.77 | 0.83 | 0.06 | 0 | 0.39 |

| Wood anatomy evident | 0.97 | 0.04 | 0.48 | 0 | 0.18 | 0.01 | 0.06 | 0.04 | 0.11 | 0.97 | 0.29 |

| Image in focus | 0.85 | 0.93 | 0.59 | 0.95 | 0.28 | 0.94 | 0.88 | 0.89 | 0.79 | 0.96 | 0.81 |

| Image size 3024 × 3024 | 1 | 0.98 | 0.98 | 0.83 | 0.76 | 1 | 0.08 | 0.94 | 1 | 1 | 0.86 |

| Prop. of all claims | 0.95 | 0.61 | 0.79 | 0.56 | 0.49 | 0.59 | 0.44 | 0.58 | 0.77 | 0.98 | 0.68 |

| Duplicate image pairs * | 0 | 19 | 0 | 16 | 5 | 0 | 13 | 14 | 0 | 0 |

| Training Dataset | Model | Testing Dataset | Reporting Level | % Accuracy |

|---|---|---|---|---|

| LD-train | LD5 | LD-train | Image | 98.5 |

| LD-train | LDF | LD-test | specimen | 32.0 |

| XT-train | XT5 | XT-train | Image | 96.1 |

| XT-train | XT5 | XT-train | specimen | 97.1 * |

| XT-train | XTF | XT-test | specimen | 94.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ravindran, P.; Wiedenhoeft, A.C. Caveat emptor: On the Need for Baseline Quality Standards in Computer Vision Wood Identification. Forests 2022, 13, 632. https://doi.org/10.3390/f13040632

Ravindran P, Wiedenhoeft AC. Caveat emptor: On the Need for Baseline Quality Standards in Computer Vision Wood Identification. Forests. 2022; 13(4):632. https://doi.org/10.3390/f13040632

Chicago/Turabian StyleRavindran, Prabu, and Alex C. Wiedenhoeft. 2022. "Caveat emptor: On the Need for Baseline Quality Standards in Computer Vision Wood Identification" Forests 13, no. 4: 632. https://doi.org/10.3390/f13040632

APA StyleRavindran, P., & Wiedenhoeft, A. C. (2022). Caveat emptor: On the Need for Baseline Quality Standards in Computer Vision Wood Identification. Forests, 13(4), 632. https://doi.org/10.3390/f13040632