A Comparison of the Environmental Performance between Construction Materials and Operational Energy of Nearly Zero-Energy Wood-Based Educational Building

Abstract

:1. Introduction

2. Materials and Methods

3. Results

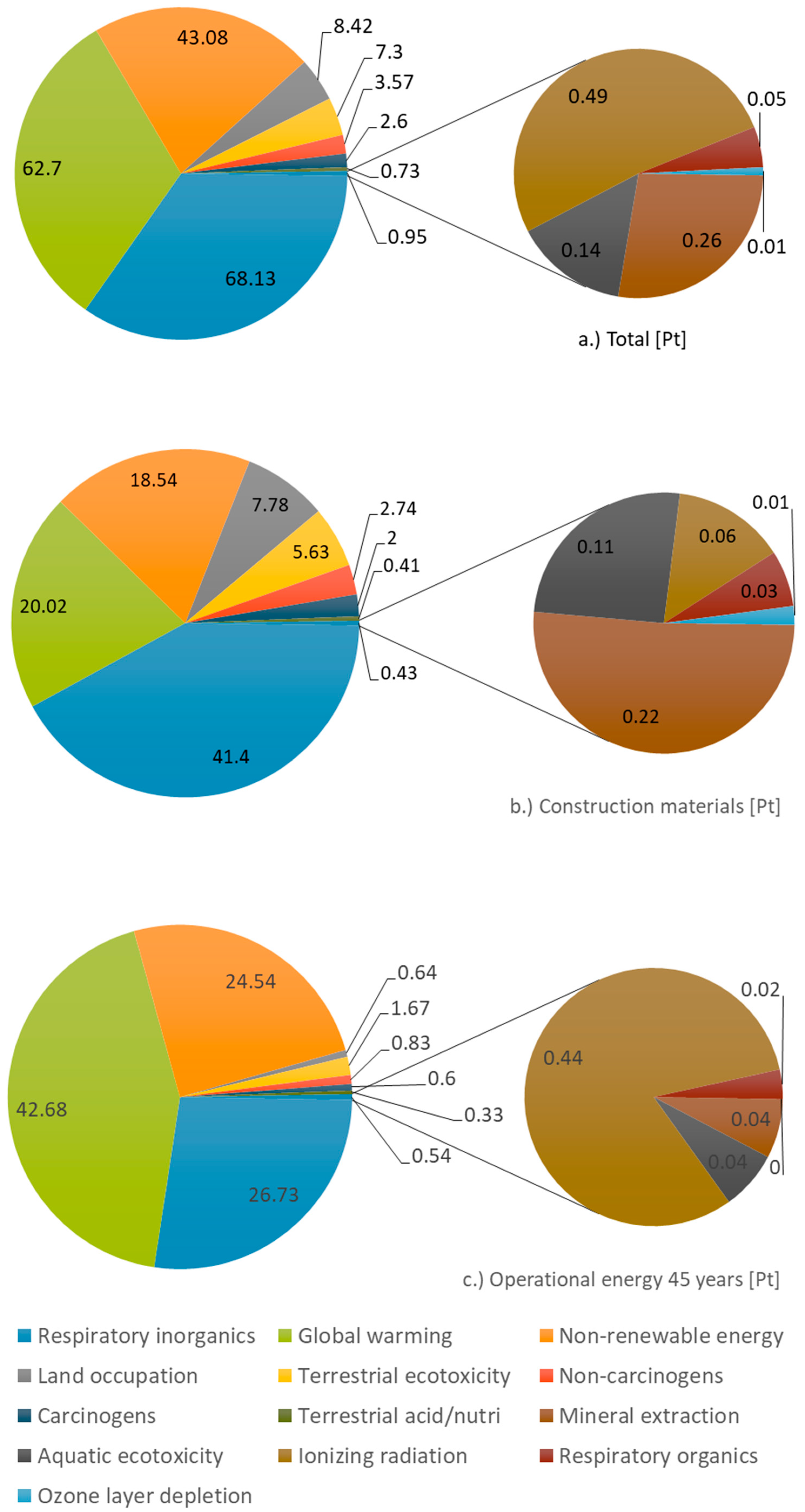

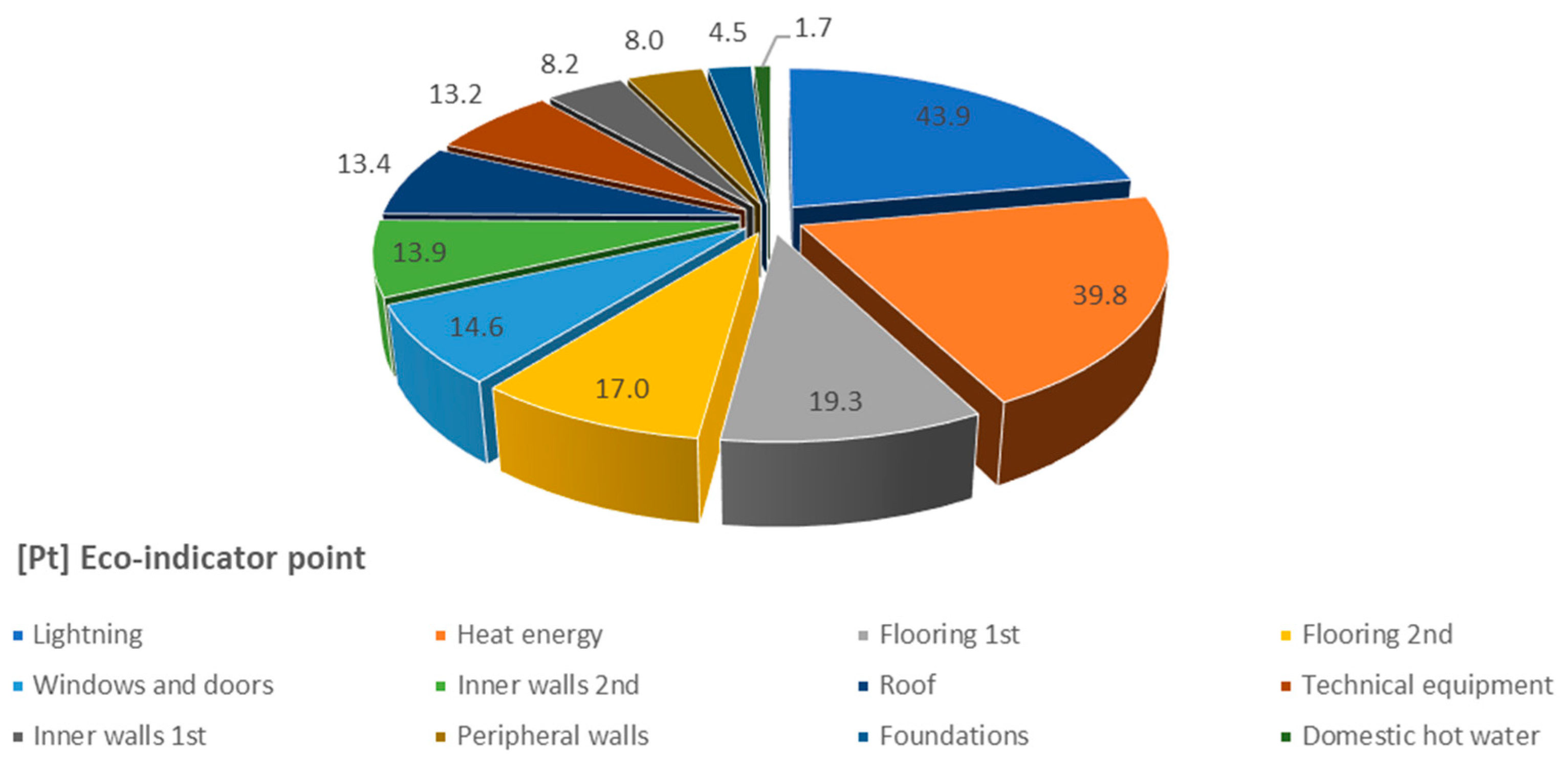

3.1. LCIA Construction Materials

3.2. LCIA Operational Energy

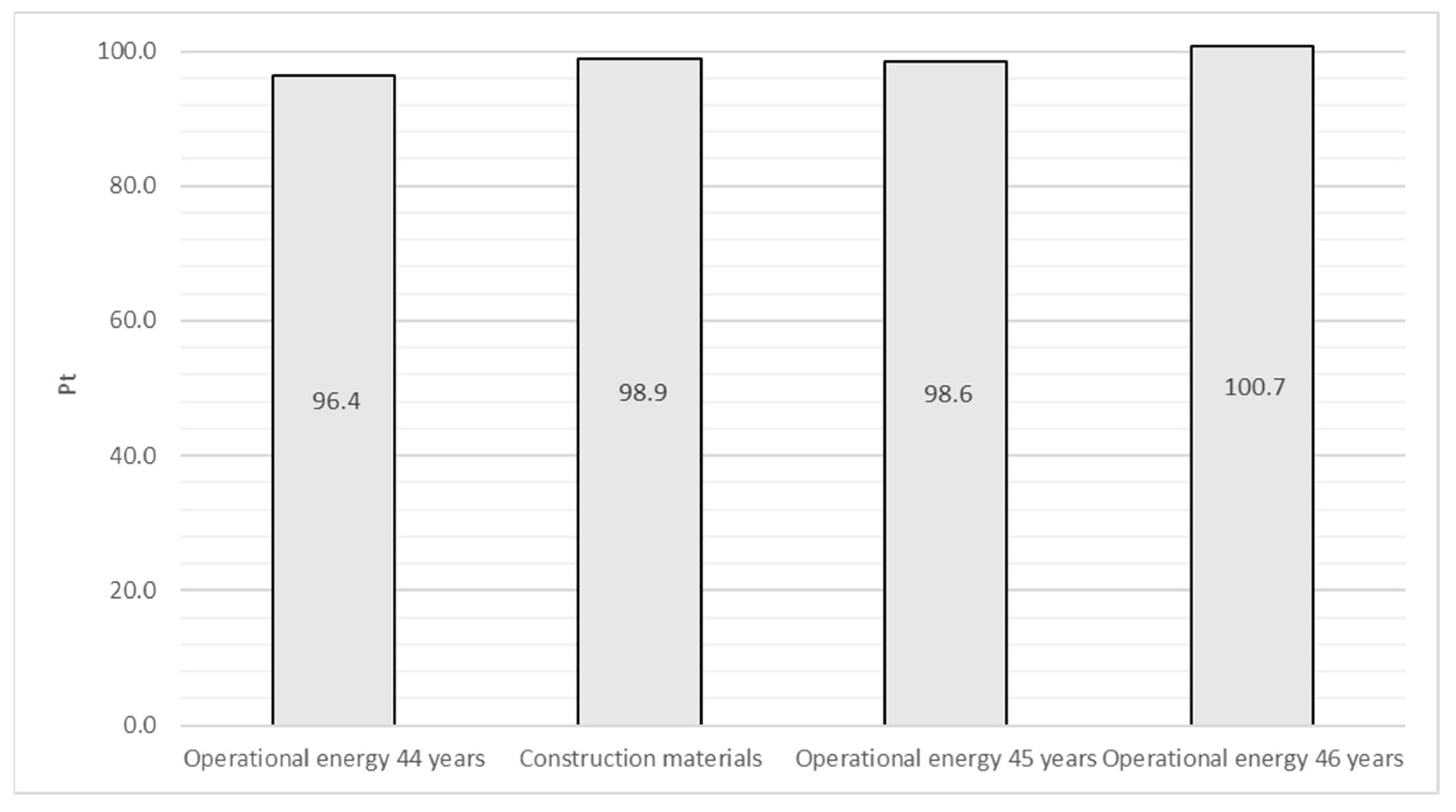

3.3. Lifespan of Building

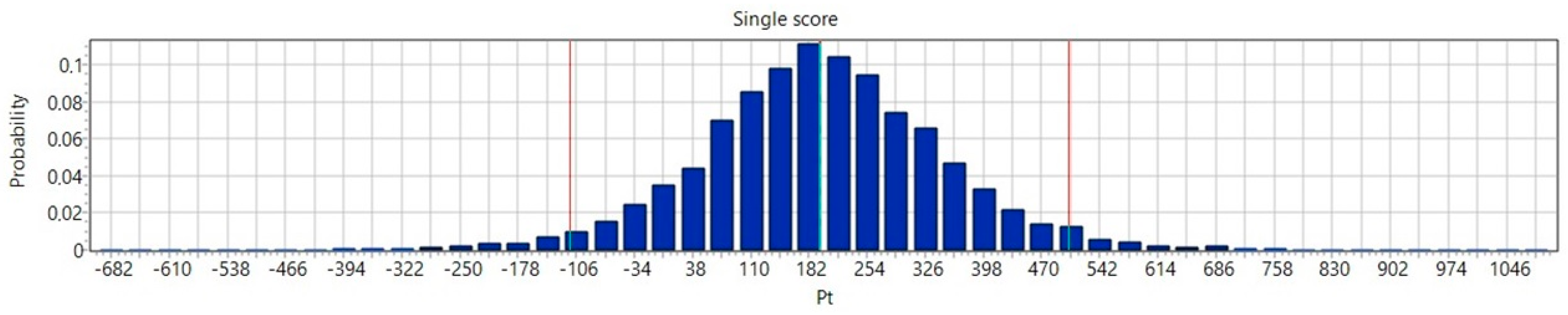

3.4. Uncertainty Analysis

3.5. Research Limitations

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Commission. Energy Efficiency in Buildings. 2020. Available online: https://ec.europa.eu/info/news/focus-energy-efficiency-buildings-2020-feb-17_en (accessed on 1 January 2022).

- European Parliament, Council of the European Union. Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32010L0031&from=EN (accessed on 1 January 2022).

- ISO 14040:2006; Environmental Management, Life Cycle Assessment-Principles and Framework; ISO: Geneva, Switzerland, 2006.

- ISO 14044:2006; Environmental Management, Life Cycle Assessment-Requirements and Guidelines; ISO: Geneva, Switzerland, 2006.

- CEN. EN 15978:2011; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation method; CEN: Brussels, Belgium, 2011. [Google Scholar]

- CEN. EN 15643:2021; Sustainability of Construction Works-Assessment of Buildings-General Framework; CEN: Brussels, Belgium, 2021. [Google Scholar]

- EN 15804+A2; Sustainability of Construction works-Environmental Product Declarations-Core Rules for the Product Category of Construction Products; CEN: Bruxelles, Belgium, 2013.

- ISO 15392; Sustainability in Building Construction-General Principles; ISO: Geneva, Switzerland, 2012.

- ISO 21929-1; Sustainability in Building Construction-Sustainability Indicators-Part 1: Framework for the Development of Indicators and a Core Set of Indicators for Buildings; ISO: Geneva, Switzerland, 2015.

- ISO 21930; Sustainability in Buildings and Civil Engineering Works-Core Rules for Environmental Product Declarations of Construction Products and Services; ISO: Geneva, Switzerland, 2018.

- ISO 21931-1; Sustainability in Building Construction-Framework for Methods of Assessment of the Environmental Performance of Construction Works-Part 1: Buildings; ISO: Geneva, Switzerland, 2015.

- Adalberth, K. Energy Use and Environmental Impact of New Residential Buildings; Byggnadsfysik LTH, Lunds Tekniska Högskola: Lund, Sweden, 2000; ISBN 91-88722-20-1. Available online: https://lucris.lub.lu.se/ws/files/4541413/8227876.pdf (accessed on 1 January 2022).

- Karimpour, M.; Belusko, M.; Xing, K.; Bruno, F. Minimising the life cycle energy of buildings: Review and analysis. Build. Environ. 2014, 73, 106–114. [Google Scholar] [CrossRef]

- Pajchrowski, G.; Noskowiak, A.; Lewandowska, A.; Strykowski, W. Materials composition or energy characteristic–What is more important in environmental life cycle of buildings? Build. Environ. 2014, 72, 15–27. [Google Scholar] [CrossRef]

- Goggins, J.; Moran, P.; Armstrong, A.; Hajdukiewicz, M. Life cycle environmental and economic performance of nearly zero energy buildings (NZEB) in Ireland. Energy Build. 2016, 116, 622–637. [Google Scholar] [CrossRef] [Green Version]

- Abergel, T.; Dean, B.; Dulac, J.; Hamilton, I.; Wheeler, T. Global Status Report-Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector. Global Alliance for Buildings and Construction. 2018. Available online: https://www.worldgbc.org/sites/default/files/2018%20GlobalABC%20Global%20Status%20Report (accessed on 1 January 2022).

- Andrić, I.; Gomes, N.; Pina, A.; Ferrão, P.; Fournier, J.; Lacarrière, B.; Le Corre, O. Modeling the long-term effect of climate change on building heat demand: Case study on a district level. Energy Build. 2016, 126, 77–93. [Google Scholar] [CrossRef]

- Roux, C.; Schalbart, P.; Assoumou, E.; Peuportier, B. Integrating climate change and energy mix scenarios in LCA of buildings and districts. Appl. Energy 2016, 184, 619–629. [Google Scholar] [CrossRef]

- García-Gusano, D.; Garraín, D.; Dufour, J. Prospective life cycle assessment of the Spanish electricity production. Renew. Sustain. Energy Rev. 2017, 75, 21–34. [Google Scholar] [CrossRef]

- Kiss, B.; Kácsor, E.; Szalay, Z. Environmental assessment of future electricity mix–Linking an hourly economic model with LCA. J. Clean. Prod. 2020, 264, 121536. [Google Scholar] [CrossRef]

- Marszal, A.J.; Heiselberg, P. Life cycle cost analysis of a multi-storey residential Net Zero Energy Building in Denmark. Energy 2011, 36, 5600–5609. [Google Scholar] [CrossRef]

- Harkouss, F.; Fardoun, F.; Biwole, P.H. Multi-objective optimization methodology for net zero energy buildings. J. Build. Eng. 2018, 16, 57–71. [Google Scholar] [CrossRef]

- Hernandez, P.; Kenny, P. From net energy to zero energy buildings: Defining life cycle zero energy buildings (LC-ZEB). Energy Build. 2010, 42, 815–821. [Google Scholar] [CrossRef]

- D’Agostino, D.; Cuniberti, B.; Bertoldi, P. Energy consumption and efficiency technology measures in European non-residential buildings. Energy Build. 2017, 153, 72–86. [Google Scholar] [CrossRef]

- Fouquet, M.; Levasseur, A.; Margni, M.; Lebert, A.; Lasvaux, S.; Souyri, B.; Buhé, C.; Woloszyn, M. Methodological challenges and developments in LCA of low energy buildings: Application to biogenic carbon and global warming assessment. Build. Environ. 2015, 90, 51–59. [Google Scholar] [CrossRef]

- Bribián, I.Z.; Usón, A.A.; Scarpellini, S. Life cycle assessment in buildings: State-of-the-art and simplified LCA methodology as a complement for building certification. Build. Environ. 2009, 44, 2510–2520. [Google Scholar] [CrossRef]

- Mao-Qing, C.; Ting-Ting, L.; Yu-Hang, Z.; Jin-Cheng, S.; Mao-Sheng, C. Developing electromagnetic functional materials for green building. J. Build. Eng. 2022, 45, 103496. [Google Scholar] [CrossRef]

- Terzopoulou, P.; Kamperidou, V. Utilization of wooden biomass chemical components in bio-plastics production. Pro Ligno 2019, 15, 306–313. Available online: https://www.cabdirect.org/cabdirect/abstract/20203177421 (accessed on 1 January 2022).

- Tudor, E.M.; Dettendorfer, A.; Kain, G.; Barbu, M.C.; Réh, R.; Krišťák, Ľ. Sound-Absorption Coefficient of Bark-Based Insulation Panels. Polymers 2020, 12, 1012. [Google Scholar] [CrossRef]

- Jianjun, Z.; Shuang, L. Life cycle cost assessment and multi-criteria decision analysis of environment-friendly building insulation materials-A review. Energy Build. 2022, 254, 111582. [Google Scholar] [CrossRef]

- Rabbat, C.; Awad, S.; Villot, A.; Rollet, D.; Andrès, Y. Sustainability of biomass-based insulation materials in buildings: Current status in France, end-of-life projections and energy recovery potentials. Renew. Sustain. Energy Rev. 2022, 156, 111962. [Google Scholar] [CrossRef]

- Takano, A.; Hughes, M.; Winter, S. A multidisciplinary approach to sustainable building material selection: A case study in a Finnish context. Build. Environ. 2014, 82, 526–535. [Google Scholar] [CrossRef]

- Cole, R.J.; Kernan, P.C. Life-cycle energy use in office buildings. Build. Environ. 1996, 31, 307–317. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Safi, B.; Sebki, G.; Chahour, K. Recycling of Foundry Sand Wastes in Self-Compacting Mortars: Use as Cementitious Materials and Fine Aggregates. J. App. Eng. Sci. 2019, 9, 195–200. [Google Scholar] [CrossRef] [Green Version]

- Ondova, M.; Estokova, A. Environmental impact assessment of building foundation in masonry family houses related to the total used building materials. Environ. Prog. Sustain. Energy 2016, 35, 1113–1120. [Google Scholar] [CrossRef]

- STN EN 73 0540-2+Z1+Z2; Thermal Protection of Buildings. Thermal Performance of Buildings and Components. Part 2: Functional Requirements; Slovak Office of Standards: Bratislava, Slovakia, 2019.

- Ministry of Transport, Construction and Regional Development of the Slovak Republic. Ministerial Decree No. 364/2012 Coll. of 12th November 2012, Which Implements the Act No. 555/2005 Coll. on the Energy Performance of Buildings and on the Amendments to Certain Laws, as Amended. Available online: https://www.slov-lex.sk/pravne-predpisy/SK/ZZ/2012/364/ (accessed on 1 January 2022).

- Mitterpach, J.; Ileckova, R.; Stefko, J. Life cycle impact assessment of construction materials of a wood-based building in an environmental context. Acta Fac. Xylologiae Zvolen 2018, 60, 147–157. [Google Scholar] [CrossRef]

- PRé Consultants, SimaPro. Sustainability Software for Fact-Based Decisions, Introduction to LCA with SimaPro 2019. Available online: https://pre-sustainability.com/solutions/tools/simapro/ (accessed on 1 June 2021).

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A new life cycle assessment methodology. Int. J. Life Cycle Assess. 2003, 8, 324–330. [Google Scholar] [CrossRef] [Green Version]

- Ecoinvent.org. Available online: https://www.ecoinvent.org/database/database.html (accessed on 1 June 2021).

- Najjar, M.; Figueiredo, K.; Hammad, A.W.A.; Haddad, A. Integrated optimization with building information modeling and life cycle assessment for generating energy efficient buildings. Appl. Energy 2019, 250, 1366–1382. [Google Scholar] [CrossRef]

- Estokova, A.; Vilcekova, S.; Porhincak, M. Analyzing Embodied Energy, Global Warming and Acidification Potentials of Materials in Residential Buildings. Procedia Eng. 2017, 180, 1675–1683. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Barreneche, C.; Miró, L.; Morera, J.M.; Bartolí, E.; Fernández, I.A. Low carbon and low embodied energy materials in buildings: A review. Renew. Sustain. Energy Rev. 2013, 23, 536–542. [Google Scholar] [CrossRef]

- Hafner, A.; Schäfer, S. Comparative LCA study of different timber and mineral buildings and calculation method for substitution factors on building level. J. Clean. Prod. 2017, 167, 630–642. [Google Scholar] [CrossRef]

- Petrovic, B.; Myhren, J.A.; Zhang, X.; Wallhagen, M.; Eriksson, O. Life cycle assessment of a wooden single-family house in Sweden. Appl. Energy 2019, 251, 113253. [Google Scholar] [CrossRef]

- Vilčeková, S.; Harčárová, K.; Moňoková, A.; Burdová, E.K. Life Cycle Assessment and Indoor Environmental Quality of Wooden Family Houses. Sustainability 2020, 12, 10557. [Google Scholar] [CrossRef]

- Carla Rodrigues, C.; Freire, F. Environmental impacts and costs of residential building retrofits—What matters? Sustain. Cities Soc. 2021, 67, 102733. [Google Scholar] [CrossRef]

- Luo, L.; Chen, Y. Carbon emission energy management analysis of LCA-Based fabricated building construction. Sustain. Comput. Inform. Syst. 2020, 27, 100405. [Google Scholar] [CrossRef]

- Röck, M.; Saade, M.R.M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG emissions of buildings–The hidden challenge for effective climate change mitigation. Appl. Energy 2020, 258, 114107. [Google Scholar] [CrossRef]

- Belucio, M.; Rodrigues, C.; Antunes, C.H.; Freire, F.; Dias, L.C. Eco-efficiency in early design decisions: A multimethodology approach. J. Clean. Prod. 2021, 283, 124630. [Google Scholar] [CrossRef]

- Saade, M.R.M.; Guest, G.; Amor, B. Comparative whole building LCAs: How far are our expectations from the documented evidence? Build. Environ. 2020, 167, 106449. [Google Scholar] [CrossRef]

- Mequignon, M.; Ait Haddou, H.; Thellier, F.; Bonhomme, M. Greenhouse gases and building lifetimes. Build. Environ. 2013, 68, 77–86. [Google Scholar] [CrossRef]

- Safari, K.; AzariJafari, H. Challenges and opportunities for integrating BIM and LCA: Methodological choices and framework development. Sustain. Cities Soc. 2021, 67, 102728. [Google Scholar] [CrossRef]

- Häfliger, I.F.; John, V.; Passer, A.; Lasvaux, S.; Hoxha, E.; Saade, R.M.R.; Habert, G. Buildings environmental impacts’ sensitivity related to LCA modelling choices of construction materials. J. Clean. Prod. 2017, 156, 805–816. [Google Scholar] [CrossRef] [Green Version]

- de Souza, D.M.; Lafontaine, M.; Charron-Doucet, F.; Bengoa, X.; Chappert, B.; Duarte, F.; Lima, L. Comparative Life Cycle Assessment of ceramic versus concrete roof tiles in the Brazilian context. J. Clean. Prod. 2015, 89, 165–173. [Google Scholar] [CrossRef]

- Robati, M.; Daly, D.; Kokogiannakis, G. A method of uncertainty analysis for whole-life embodied carbon emissions (CO2-e) of building materials of a net-zero energy building in Australia. J. Clean. Prod. 2019, 225, 541–553. [Google Scholar] [CrossRef]

- Hasan, U.; Whyte, A.; Al Jassmi, H. Life cycle assessment of roadworks in United Arab Emirates: Recycled construction waste, reclaimed asphalt pavement, warm-mix asphalt and blast furnace slag use against traditional approach. J. Clean. Prod. 2020, 257, 120531. [Google Scholar] [CrossRef]

- Owsianiak, M.; Laurent, A.; Bjørn, A.; Hauschild, M.Z. IMPACT 2002+, ReCiPe 2008 and ILCD’s recommended practice for characterization modelling in life cycle impact assessment: A case study-based comparison. Int. J. Life Cycle Assess. 2014, 19, 1007–1021. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Giannoulis, C.; Papacharalampopoulos, A.; Foteinopoulos, P.; Chryssolouris, G. Life cycle analysis: Comparison between different methods and optimization challenges. Procedia CIRP 2016, 41, 626–631. [Google Scholar] [CrossRef] [Green Version]

- Alyaseri, I.; Zhou, J. Handling uncertainties inherited in life cycle inventory and life cycle impact assessment method for improved life cycle assessment of wastewater sludge treatment. Heliyon 2015, 5, e02793. [Google Scholar] [CrossRef]

- Mitterpach, J.; Hroncová, E.; Ladomerský, J.; Štefko, J. Quantification of Improvement in Environmental Quality for Old Residential Buildings Using Life Cycle Assessment. Sustainability 2016, 8, 1303. [Google Scholar] [CrossRef] [Green Version]

- Modahl, I.S.; Askham, C.; Lyng, K.A.; Skjerve-Nielssen, C.; Nereng, G. Comparison of two versions of an EPD, using generic and specific data for the foreground system, and some methodological implications. Int. J. Life Cycle Assess. 2013, 18, 241–251. [Google Scholar] [CrossRef]

- Röder, M.; Whittaker, C.; Thornley, P. How certain are greenhouse gas reductions from bioenergy? Life cycle assessment and uncertainty analysis of wood pellet-to-electricity supply chains from forest residues. Biomass Bioenergy 2014, 79, 50–63. [Google Scholar] [CrossRef]

| Product stage | Raw material supply | A1 | included |

| Transport to manufacturer | A2 | included | |

| Manufacturing | A3 | included | |

| Construction stage | Transport to construction site and transport on site | A4 | excluded |

| Construction and installation process | A5 | excluded | |

| Use stage | Use | B1 | excluded |

| Maintenance | B2 | excluded | |

| Repair | B3 | excluded | |

| Replacement | B4 | excluded | |

| Refurbishment | B5 | excluded | |

| Operational energy use | B6 | included | |

| Operational water use | B7 | excluded | |

| End of life stage | Deconstruction and demolition | C1 | excluded |

| Transport | C2 | excluded | |

| Waste processing for reuse, recovery or recycling | C3 | excluded | |

| Waste disposal | C4 | excluded | |

| Benefits and loads beyond the system boundaries | Reuse, Recovery, Recycling potential | D | excluded |

| Built-up area | 572.16 m2 |

| Heated area | 528.72 m2 |

| Heated volume | 1679.05 m3 |

| Floor area | 550.23 m2 |

| Load-bearing walls | 122.5 m2 |

| Partitions | 267.4 m2 |

| Window area | 121.15 m2 |

| Door area | 23 m2 |

| Lightning area | 544.4 m2 |

| Electricity consumption for lightning | 9.05 kWh /m2/year |

| Lightning * | 4926.82 kWh/year * |

| Electricity consumption for technical equipment | 1478.05 kWh/year |

| Energy consumption for hot water preparation | 8.60 kWh/m2/year |

| Energy consumption for heating | 21.59 kWh/m2/year |

| Structural Units | Subtitle | m3 | kg/m3 | kg |

|---|---|---|---|---|

| Foundation | Concrete C 20/25 | 30 | 2250 | 67,500 |

| Rolled steel 4 mm thick | 0.192 | 7850 | 1507.2 | |

| Solid wood Spruce C24 | 15.174 | 420 | 6373.08 | |

| Flooring—1st floor | HDF fiberboard | 7.77 | 600 | 4662 |

| Box beam Spruce short | 1.55 | 420 | 650.64 | |

| Box beam OSB short | 1.15 | 550 | 631.14 | |

| Box beam Spruce long | 2.09 | 420 | 876.19 | |

| Box beam OSB long | 1.55 | 550 | 849.92 | |

| Straw insulation | 108.98 | 90 | 9808.56 | |

| Grate Spruce | 0.84 | 420 | 354.06 | |

| Isover DOMO | 28.98 | 120 | 3477.60 | |

| Flex glue | 4.64 | 1600 | 7418.88 | |

| Ceramic paving | 6.96 | 2000 | 13,910.40 | |

| Exterior stairs | 0.35 | 420 | 145.15 | |

| Flooring—2nd floor | CLT board | 104.33 | 470 | 49,034.16 |

| Epoxy resin | 1.16 | 1750 | 2028.60 | |

| Ceramic paving | 0.34 | 2000 | 686.88 | |

| Paving BK | 2.16 | 380 | 821.94 | |

| Peripheral walls—1st floor | Facade cladding Larch | 3.06 | 550 | 1684.38 |

| Grate Spruce | 1.18 | 420 | 493.92 | |

| HDF fiberboard | 1.84 | 600 | 1102.50 | |

| Box beam Spruce | 2.57 | 420 | 1079.57 | |

| Box beam OSB | 1.90 | 420 | 799.68 | |

| Straw insulation | 49 | 90 | 4410 | |

| CLT board | 12.25 | 470 | 5757.50 | |

| PU lacquer | 0.06 | 950 | 58.19 | |

| Inner walls—1st floor | CLT board | 14.42 | 470 | 6777.40 |

| Glazed walls | 0.34 | 2600 | 891.80 | |

| GLT columns | 7.87 | 420 | 3306.24 | |

| Ceiling beams | GLT | 5.03 | 420 | 2112.08 |

| Inner walls—2nd floor | CLT board | 12.32 | 470 | 5790.45 |

| Glazed walls | 0.78 | 2600 | 2022.12 | |

| GLT columns | 6.74 | 420 | 2830.46 | |

| Roof | Roof beams GLT | 15.98 | 420 | 6713.28 |

| Cement board | 4.12 | 1300 | 5359.58 | |

| Isover plus | 19.24 | 130 | 2501.14 | |

| Box beam Spruce | 5.24 | 420 | 2199.96 | |

| Box beam OSB | 3.88 | 550 | 2134 | |

| Straw insulation | 109.94 | 90 | 9894.60 | |

| HDF fiberboard | 8.96 | 600 | 5374.56 | |

| Grate Spruce | 4.59 | 420 | 1923.37 | |

| OSB III board | 14.28 | 550 | 7856.4 | |

| Folded sheet metal roofing | 0.32 | 7140 | 2308.53 |

| Impact Category | Unit | Total | Construction Materials | Operational Energy 45 Years |

|---|---|---|---|---|

| Respiratory inorganics | kg PM2.5 eq | 6.90 × 102 | 4.19 × 102 | 2.71 × 102 |

| Global warming | kg CO2 eq | 6.21 × 105 | 1.98 × 105 | 4.23 × 105 |

| Non-renewable energy | MJ primary | 6.55 × 106 | 2.82 × 106 | 3.73 × 106 |

| Land occupation | m2org.arable | 1.06 × 105 | 9.78 × 104 | 8.03 × 103 |

| Terrestrial ecotoxicity | kg TEG soil | 1.26 × 107 | 9.75 × 106 | 2.89 × 106 |

| Non-carcinogens | kg C2H3Cl eq | 9.05 × 103 | 6.94 × 103 | 2.11 × 103 |

| Carcinogens | kg C2H3Cl eq | 6.59 × 103 | 5.07 × 103 | 1.52 × 103 |

| Terrestrial acid/nutri | kg SO2 eq | 9.67 × 103 | 5.35 × 103 | 4.32 × 103 |

| Mineral extraction | MJ surplus | 3.97 × 104 | 3.38 × 104 | 5.97 × 103 |

| Aquatic ecotoxicity | kg TEG water | 3.93 × 107 | 2.97 × 107 | 9.63 × 106 |

| Ionizing radiation | Bq C-14 eq | 1.67 × 107 | 1.94 × 106 | 1.48 × 107 |

| Respiratory organics | kg C2H4 eq | 1.75 × 102 | 1.13 × 102 | 6.23 × 101 |

| Ozone layer depletion | kg CFC-11 eq | 4.16 × 10−2 | 1.52 × 10−2 | 2.64 × 10−2 |

| Aquatic eutrophication | kg PO4 P-lim | 1.04 × 102 | 4.00 × 101 | 6.43 × 101 |

| Aquatic acidification | kg SO2 eq | 2.62 × 103 | 1.37 × 103 | 1.26 × 103 |

| Impact Category | Unit | Domestic Hot Water | Flooring 1st | Flooring 2nd | Foundations | Heat Energy | Inner Walls 1st | Inner Walls 2nd | Lightning | Peripheral Walls | Roof | Technical Equipment | Windows and Doors |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Carcinogens | kg C2H3Cl eq | 6.7 × 101 | 7.8 × 102 | 5.6 × 102 | 2.6 × 102 | 6.0 × 102 | 4.3 × 102 | 8.1 × 102 | 6.5 × 102 | 4.0 × 102 | 6.9 × 102 | 2.0 × 102 | 1.1 × 103 |

| Non-carcinogens | kg C2H3Cl eq | 1.4 × 102 | 6.5 × 102 | 7.6 × 102 | 3.1 × 102 | 9.4 × 102 | 6.7 × 102 | 1.2 × 103 | 8.0 × 102 | 5.2 × 102 | 1.7 × 103 | 2.4 × 102 | 1.1 × 103 |

| Respiratory inorganics | kg PM2.5 eq | 8.3 | 1.4 × 102 | 64 | 15 | 78 | 31 | 53 | 1.4 × 102 | 26 | 42 | 43 | 43 |

| Ionizing radiation | Bq C-14 eq | 9.3 × 103 | 1.8 × 105 | 2.3 × 105 | 8.5 × 104 | 2.9 × 105 | 2.1 × 105 | 3.8 × 105 | 1.1 × 107 | 2.5 × 105 | 3.5 × 105 | 3.3 × 106 | 2.6 × 105 |

| Ozone layer depletion | kg CFC-11 eq | 2.7 × 10−3 | 1.6 × 10−3 | 2.1 × 10−3 | 9.4 × 10−4 | 2.7 × 10−3 | 1.5 × 10−3 | 2.6 × 10−3 | 1.6 × 10−2 | 1.7 × 10−3 | 3.0 × 10−3 | 4.8 × 10−3 | 1.8 × 10−3 |

| Respiratory organics | kg C2H4 eq | 3.6 | 9.4 | 20 | 6.5 | 41 | 7.4 | 12 | 14 | 7.8 | 17 | 4.1 | 34 |

| Aquatic ecotoxicity | kg TEG water | 1.2 × 105 | 2.5 × 106 | 4.8 × 106 | 1.1 × 106 | 1.3 × 105 | 3.9 × 106 | 6.3 × 106 | 7.2 × 106 | 2.2 × 106 | 5.8 × 106 | 2.2 × 106 | 3.0 × 106 |

| Terrestrial ecotoxicity | kg TEG soil | 1.7 × 105 | 7.6 × 105 | 1.8 × 106 | 4.4 × 105 | 5.2 × 105 | 9.6 × 105 | 1.3 × 106 | 1.7 × 106 | 6.0 × 105 | 2.4 × 106 | 5.1 × 105 | 1.5 × 106 |

| Terrestrial acid/nutri | kg SO2 eq | 3.1 × 102 | 4.3 × 102 | 1.0 × 103 | 2.6 × 102 | 1.8 × 103 | 4.5 × 102 | 7.8 × 102 | 1.7 × 103 | 4.5 × 102 | 8.3 × 102 | 5.2 × 102 | 1.1 × 103 |

| Land occupation | m2org.arable | 6.2 × 103 | 4.7 × 103 | 3.4 × 104 | 4.8 × 103 | 0.0 | 1.1 × 104 | 1.4 × 104 | 1.4 × 103 | 1.4 × 104 | 1.4 × 104 | 4.2 × 102 | 1.2 × 103 |

| Aquatic acidification | kg SO2 eq | 42 | 1.3 × 102 | 2.1 × 102 | 59 | 2.8 × 102 | 1.3 × 102 | 2.5 × 102 | 7.2 × 102 | 1.3 × 102 | 1.9 × 102 | 2.2 × 102 | 2.6 × 102 |

| Aquatic eutrophication | kg PO4 P-lim | 5.3 × 10−1 | 4.0 | 6.4 | 1.6 | 1.2 | 3.9 | 7.1 | 48 | 3.6 | 4.7 | 14 | 8.7 |

| Global warming | kg CO2 eq | 1.2 × 103 | 1.9 × 104 | 2.8 × 104 | 1.3 × 104 | 2.8 × 105 | 1.7 × 104 | 3.2 × 104 | 1.1 × 105 | 1.8 × 104 | 3.5 × 104 | 3.3 × 104 | 3.6 × 104 |

| Non-renewable energy | MJ primary | 1.6 × 104 | 2.5 × 105 | 5.1 × 105 | 1.2 × 105 | 4.4 × 105 | 2.3 × 105 | 4.2 × 105 | 2.5 × 106 | 2.5 × 105 | 3.3 × 105 | 7.6 × 105 | 7.1 × 105 |

| Mineral extraction | MJ surplus | 1.3 × 102 | 2.6 × 103 | 1.0 × 103 | 7.1 × 102 | 2.4 × 102 | 2.8 × 103 | 5.9 × 103 | 4.3 × 103 | 2.3 × 103 | 7.1 × 103 | 1.3 × 103 | 1.1 × 104 |

| Impact Category | Unit | Mean | Median | SD | CV | 2.5% | 97.5% | SEM |

|---|---|---|---|---|---|---|---|---|

| Global warming | kg CO2 eq | 6.21 × 105 | 6.20 × 105 | 1.27 × 104 | 2.05 | 5.99 × 105 | 6.49 × 105 | 1.27 × 102 |

| Aquatic acidification | kg SO2 eq | 2.62 × 103 | 2.61 × 103 | 1.39 × 102 | 5.31 | 2.37 × 103 | 2.92 × 103 | 1.39 |

| Respiratory inorganics | kg PM2.5 eq | 6.89 × 102 | 6.86 × 102 | 4.54 × 101 | 6.59 | 6.11 × 102 | 7.88 × 102 | 4.54 × 10−1 |

| Terrestrial acid/nutri | kg SO2 eq | 9.66 × 103 | 9.62 × 103 | 6.84 × 102 | 7.08 | 8.42 × 103 | 1.11 × 104 | 6.84 |

| Mineral extraction | MJ surplus | 3.94 × 104 | 3.90 × 104 | 4.42 × 103 | 1.12 × 101 | 3.19 × 104 | 4.91 × 104 | 4.42 × 101 |

| Respiratory organics | kg C2H4 eq | 1.75 × 102 | 1.72 × 102 | 2.00 × 101 | 1.14 × 101 | 1.50 × 102 | 2.25 × 102 | 2.00 × 10−1 |

| Non-renewable energy | MJ primary | 6.55 × 106 | 6.43 × 106 | 8.02 × 105 | 1.22 × 101 | 5.32 × 106 | 8.48 × 106 | 8.02 × 103 |

| Carcinogens | kg C2H3Cl eq | 6.61 × 103 | 6.41 × 103 | 1.17 × 103 | 1.77 × 101 | 4.94 × 103 | 9.42 × 103 | 1.17 × 101 |

| Ozone layer depletion | kg CFC-11 eq | 4.16 × 10−2 | 4.12 × 10−2 | 1.58 × 10−2 | 3.79 × 101 | 1.16 × 10−2 | 7.41 × 10−2 | 1.58 × 10−4 |

| Land occupation | m2org.arable | 1.07 × 105 | 9.40 × 104 | 5.03 × 104 | 4.72 × 101 | 4.79 × 104 | 2.36 × 105 | 5.03 × 102 |

| Aquatic eutrophication | kg PO4 P-lim | 1.05 × 102 | 8.58 × 101 | 7.10 × 101 | 6.77 × 101 | 3.76 × 101 | 2.86 × 102 | 7.10 × 10−1 |

| Ionizing radiation | Bq C-14 eq | 1.67 × 107 | 1.06 × 107 | 2.21 × 107 | 1.33 × 102 | 4.51 × 106 | 6.50 × 107 | 2.21 × 105 |

| Non-carcinogens | kg C2H3Cl eq | 8.32 × 103 | 8.44 × 103 | 7.56 × 104 | 9.09 × 102 | 1.44 × 105 | 1.58 × 105 | 7.56 × 102 |

| Aquatic ecotoxicity | kg TEG water | 3.90 × 107 | 3.58 × 107 | 4.97 × 108 | 1.27 × 103 | −9.54 × 108 | 1.03 × 109 | 4.97 × 106 |

| Terrestrial ecotoxicity | kg TEG soil | 1.10 × 107 | 8.71 × 106 | 2.24 × 108 | 2.04 × 103 | −4.43 × 108 | 4.68 × 108 | 2.24 × 106 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mitterpach, J.; Vaňová, R.; Šedivka, P.; Štefko, J. A Comparison of the Environmental Performance between Construction Materials and Operational Energy of Nearly Zero-Energy Wood-Based Educational Building. Forests 2022, 13, 220. https://doi.org/10.3390/f13020220

Mitterpach J, Vaňová R, Šedivka P, Štefko J. A Comparison of the Environmental Performance between Construction Materials and Operational Energy of Nearly Zero-Energy Wood-Based Educational Building. Forests. 2022; 13(2):220. https://doi.org/10.3390/f13020220

Chicago/Turabian StyleMitterpach, Jozef, Rozália Vaňová, Přemysl Šedivka, and Jozef Štefko. 2022. "A Comparison of the Environmental Performance between Construction Materials and Operational Energy of Nearly Zero-Energy Wood-Based Educational Building" Forests 13, no. 2: 220. https://doi.org/10.3390/f13020220

APA StyleMitterpach, J., Vaňová, R., Šedivka, P., & Štefko, J. (2022). A Comparison of the Environmental Performance between Construction Materials and Operational Energy of Nearly Zero-Energy Wood-Based Educational Building. Forests, 13(2), 220. https://doi.org/10.3390/f13020220