Risk Factors and Occupational Safety Failures in Forest Work in the Southeast Asian Region

Abstract

1. Introduction

2. Materials and Methods

2.1. Data Sourcing and Categorization

2.2. Data Analysis

3. Results

3.1. FSC Certified Areas and Certifying Bodies

3.2. CARs and H&S Related Issues

3.3. Main Risk Factors of Forest Work

3.4. Risk Sub-Factor Groups of Forest Work

- Checking two harvesting teams, many harvesting team members did not wear appropriate PPE (hard hat and steel toe shoes), operated a chainsaw without face and ear protection, and did not wear steel toe shoes/boots: major CAR;

- PPE was not worn during the hand slashing operation at the compartment. Slashing was being carried out using a long-handled slasher. The worker was wearing no PPE. In an interview with a silvicultural contractor, it was noted that the incorrect PPE as set out in the “ILO document Safety and Health in Forestry Work” was being worn during brushing and cutting operations. The operator had ordinary rubber boots, a normal hat, no safety trousers and no visor: minor CAR;

- Only one set of PPEs for chainsaw operators (suitable with ILO Code Practice on H&S in Forestry) was presented in the office. No evidence was provided on how many sets were available, while there were at least four chainsaw operators in the harvesting team. At the interview with harvesting team members, they did not use PPE in accordance with ILO code practice requirements in practice: major CAR;

- Workers carrying logs and assisting on the harvesting site were wearing shoes without steel cups/toes and did not wear protection equipment for the shoulders when carrying logs: minor CAR.

- During audit at the office, there was an ILO code of practice OSH available in forestry work. However, during verification, the OSH procedure auditor found that there was no applicable ILO code of practice in their OSH procedure for workers who support forest activities. This may impact the effectiveness of OSH control. So, it was raised as a major CAR.

- SOP for OSH, handling of work accidents explained that if there is a work accident, they must provide first aid to the accident, but the procedure/aid program was not explained. Furthermore, no evidence was provided related to the training of workers: major CAR;

- Auditors reviewed the 2019 and 2020 accident record and found that there were no serious or fatal accidents. There were 12 light accidents in 2019, 9 light accidents and 1 medium accident in 2020. The auditor reviewed two samples of accidents from 2020 (chainsaw operator’s assistant and mechanic) and found that the organization had kept a record of accidents, including the victim data, including the name, gender, age, job, impact (dead, permanent disability, temporary not able to work, light wound), accident factor (location of wound, source of accident, type of accident, physical condition), loss estimate (material, day of work), and cause of accident. The chainsaw operator’s assistant injured his left leg (swollen and hurt) due to being hit by logs already cut that were suddenly broken into two. Additionally, the auditor found that both employees were brought to the hospital immediately to receive treatment after they obtained their first-aid kit. Details of all costs for treatment of both employees were reviewed and it was found that these were submitted to the social insurance. Based on interviews with managers, staff and workers, the organization was found to have revised their SOP on harvesting, induction training and safety briefing before workers arrived at the work area. However, the documentation of training of the revised SOP for harvesting had not been documented: minor CAR;

- The organization had SOP on H&S, which identifies appropriate safety equipment for each job category. It also includes the procedure of H&S equipment provision. The procedures clearly stated that the minimum standard of PPE for harvesting unit staff is helmet, rubber boots, cloth gloves, earplugs, long socks and a mask. Safety trousers and earmuffs were not mentioned in the organization’s procedures as required by the ILO Code of Practice for H&S in Forestry Work (chapter 7). Based on those findings, the auditors concluded to issue a minor CAR.

- The chainsaw operator and his support worker in the organization were both situated one next to the other and it was detected that the stumps were not in line (missing felling hinge and kerf) with the requirements of the national regulations and ILO-code of practice: major CAR;

- The tree stumps observed did not comply with good practice in terms of cutting technique and, thus, safety requirements: minor CAR;

- The cutting technique observed in the field was not in compliance with best practices. This nonconformity was already identified during the main audit (minor CAR 2018-04). As the former minor CAR could not be closed due to the observation made during the first surveillance audit, the former minor CAR was upgraded to a major CAR.

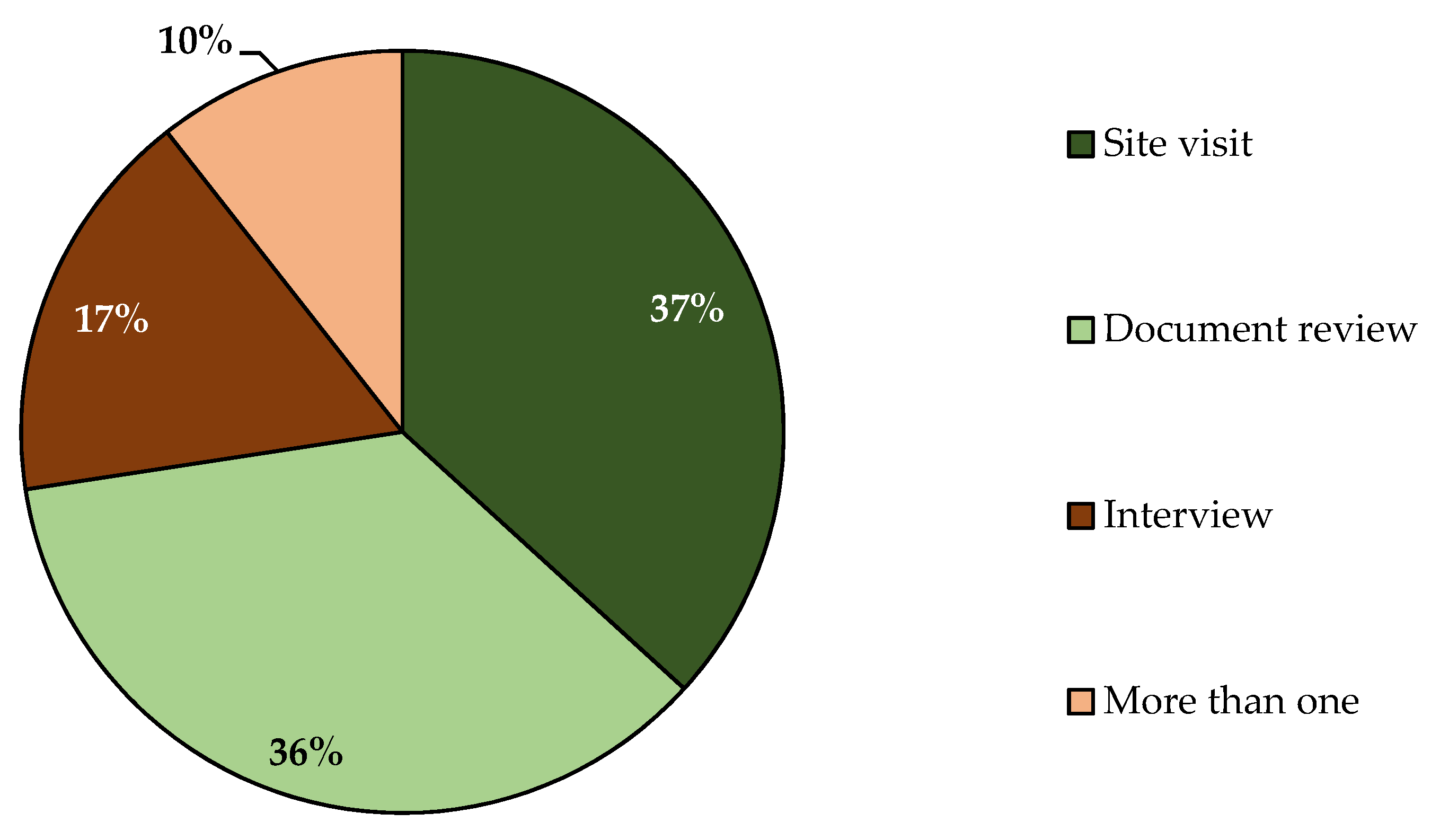

3.5. Sources of CARs and Observations

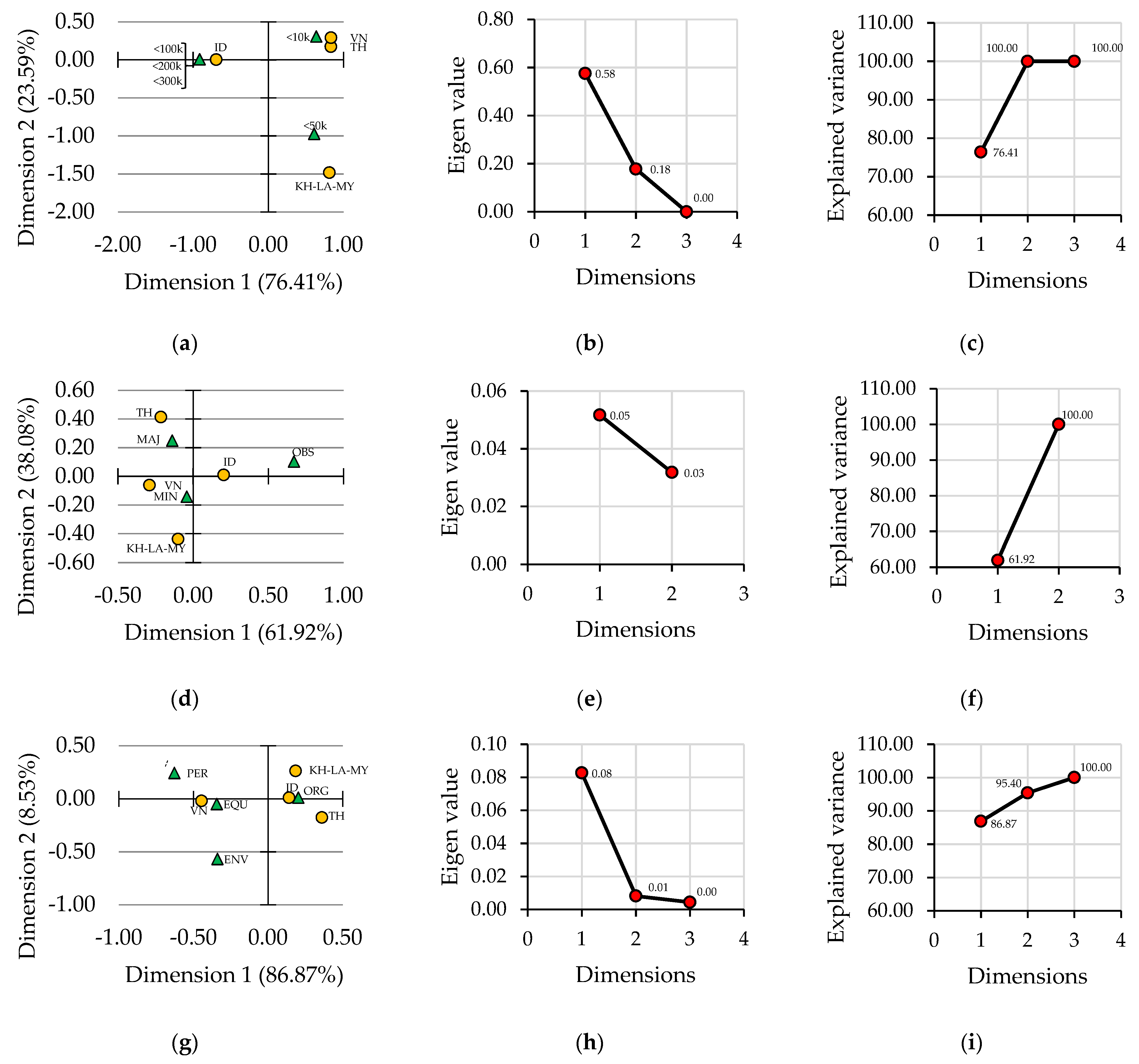

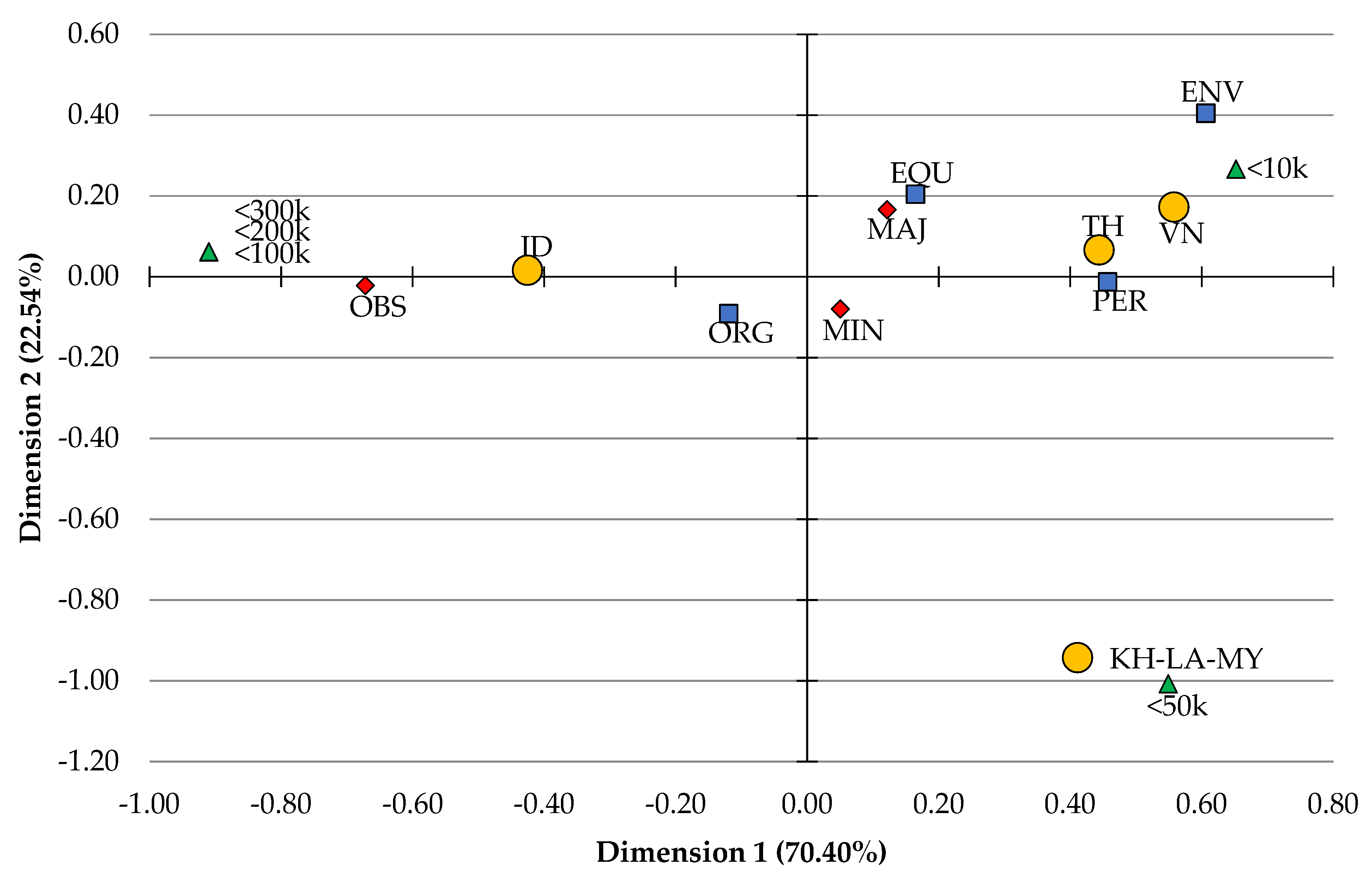

3.6. Dependencies in Data

4. Discussion

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Potočnik, I.; Poje, A. Forestry ergonomics and occupational safety in high ranking scientific journals from 2005–2016. Croat. J. For. Eng. 2017, 38, 291–310. [Google Scholar]

- Laflamme, L.; Cloutier, E. Working condition and safety in forestry work. In Encyclopeadia of Occupational Health and Safety, 4th ed.; Stellman, J.M., Ed.; International Labour Office: Geneva, Switzerland, 1998; Volume 3. [Google Scholar]

- Jankovský, M.; Allman, M.; Allmanová, Z. What Are the Occupational Risks in Forestry? Results of a Long-Term Study in Slovakia. Int. J. Environ. Res. Public Health 2019, 16, 4931. [Google Scholar] [CrossRef] [PubMed]

- Lindroos, O.; Burström, L. Accident rates and types amoung self-employed private forest owners. Accid. Anal. Prev. 2010, 42, 1729–1735. [Google Scholar] [CrossRef] [PubMed]

- Tsioras, P.A.; Khooshdonbat, M.; Nikooy, M.; Naghdi, R.; Heidari, M. The impact of body posture on heart rate strain during tree felling. Int. J. Environ. Res. Public Health 2022, 19, 1198. [Google Scholar] [CrossRef] [PubMed]

- Staal Wästerlund, D. Managing Heat in Agricultural Work: Increasing Worker Safety and Productivity by Controlling Heat Exposure; Forestry Working Paper No. 1; FAO: Rome, Italy, 2018; 53p, Available online: https://www.fao.org/sustainable-forest-management/toolbox/tools/tool-detail/en/c/1126610/ (accessed on 9 November 2022).

- Social Security Office. Occupational Accident Statistics and Sicknesses 2015. Available online: https://www.sso.go.th/wpr/assets/upload/files_storage/sso_th/32ad74534d1c43ed7e322128308ec49f.pdf (accessed on 14 August 2022).

- Noor, J.; Syafinie, M.; Marinah, M.; Najidah, M.; Juliana, Y.; Nasrul, A.A. Occupational accidents in forestry and agricultural sectors in Malaysia. Borneo J. Sci. Technol. 2021, 3, 16–19. [Google Scholar]

- Yovi, E.Y.; Yamada, Y. Strategy to disseminate occupational safety and health information to forestry workers: The felling safety game. J. Trop. For. Sci. 2015, 27, 213–221. [Google Scholar]

- Yovi, E.Y.; Abbas, D.; Takahashi, T. Safety climate and risk perception of forestry workers: A case study of motor-manual tree felling in Indonesia. Int. J. Occup. Saf. Ergon. 2021, 1–33. [Google Scholar] [CrossRef]

- Garland, J.; Cedergren, J.; Eliasson, L.; van Hensbergen, H.; McEwan, A.; Wästerlund, D. Occupational Safety and Health in Forest Harvesting and Silviculture—A Compendium for Practitioners and Instructors; Forestry Working Paper No. 14; FAO: Rome, Italy, 2020; 110p, Available online: https://www.fao.org/documents/card/en/c/ca8773en/ (accessed on 16 August 2022).

- Rhee, K.Y.; Choe, S.W.; Kim, Y.S.; Koo, K.H. The trend of occupational injuries in Korea from 2001 to 2010. Saf. Health Work 2013, 4, 63–70. [Google Scholar] [CrossRef]

- Hălălișan, A.F.; Popa, B.; Borz, S.A.; Abrudan, I.V. Health and Safety Issues in Romanian Forests: Findings from FSC Certification Audits. Forests 2022, 13, 714. [Google Scholar] [CrossRef]

- Tsioras, P.A.; Rottensteiner, C.; Stampfer, K. Wood harvesting accidents in the Austrian state forest enterprise 2000–2009. Saf. Sci. 2014, 62, 400–408. [Google Scholar] [CrossRef]

- Harwood, C.E.; Nambiar, E.K.S. Sustainable Plantation Forestry in South-East Asia; ACIAR Technical Reports 84; Australian Centre for International Agricultural Research: Canberra, Australia, 2014. [Google Scholar]

- Anon. Appropriate Small-Scale Forest Harvesting Technologies, a Guidebook for Southeast Asia; RECOFTC: Bangkok, Thailand, 2015. [Google Scholar]

- Lundback, M.; Häggström, C.; Nordfjell, T. Worldwide trends in methods for harvesting and extracting industrial roundwood. Int. J. For. Eng. 2021, 32, 202–215. [Google Scholar] [CrossRef]

- Kaakkurivaara, N.; Stampfer, K. Assessment for Improvement: Harvesting Operations in Small-Scale Forest on Thai Steep Terrain. Small-Scale For. 2017, 17, 259–276. [Google Scholar] [CrossRef]

- Robb, W.; Zemánek, T.; Kaakkurivaara, N. An analysis of chainsaw operator safety between Asian and European countries. Croat. J. For. Eng. 2022, 43, 373–389. [Google Scholar] [CrossRef]

- Banciu, T.; Borz, S.A.; Marcu, M.V.; Iordache, E.; Liampas, S.-A.G.; Drosos, V.C. An evaluation of risk-taking behavior in motor-manual tree felling and processing operations. Bull. Transilv. Univ. Bras. II For. Wood Ind. Agric. Food Eng. 2018, 11, 1–21. [Google Scholar]

- Paluš, H.; Parobek, J.; Dzian, M.; Šimo-Svrček, S.; Krahulcová, M. How companies in the wood supply chain perceive the forest certification. Acta Fac. Xylologiae 2019, 61, 155–165. [Google Scholar] [CrossRef]

- Paluš, H.; Parobek, J.; Šulek, R.; Lichý, J.; Šálka, J. Understanding Sustainable Forest Management Certification in Slovakia: Forest Owners’ Perception of Expectations, Benefits and Problems. Sustainability 2018, 10, 2470. [Google Scholar] [CrossRef]

- Malaysian Timber Certification Council. Available online: https://mtcc.com.my (accessed on 3 October 2022).

- IFSS. Sustainable Forest Management Certificate Holder. Available online: https://ifcc-ksk.org/documents/PEMEGANG%20SERTIFIKAT%20PHL.pdf (accessed on 3 October 2022).

- Gutierrez Garzon, A.R.; Bettinger, P.; Siry, J.; Abrams, J.; Cieszewski, C.; Boston, K.; Mei, B.; Zengin, H.; Yeşil, A. A Comparative Analysis of Five Forest Certification Programs. Forests 2020, 11, 863. [Google Scholar] [CrossRef]

- FSC. Certification Training Forest Management Course Manual, 20–24 November 2017 NEPCon, FSC A000535; Preferred by Nature: Bogor, Indonesia, 2017; 384p. [Google Scholar]

- International Labour Office. Safety and Health in Forestry Work: An ILO Code of Practice; International Labour Office: Geneva, Switzerland, 1998. [Google Scholar]

- Ghaffariyan, M.R. Analysis of forestry work accidents in five Australian forest companies for the period 2004 to 2014. J. For. Sci. 2016, 62, 545–552. [Google Scholar] [CrossRef]

- Heinrich, H.W.; Petersen, D.; Roos, N. Industrial Accident Prevention: A Safety Management Approach; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Marsden, E. Heinrich’s Domino Model of Accident Causation. Available online: https://risk-engineering.org/concept/Heinrich-dominos#ref-Heinrich1931 (accessed on 25 August 2022).

- Forest Stewardship Council. FSC Certificates Public Dashboard. Available online: https://fsc.org/en/fsc-public-certificate-search (accessed on 25 August 2022).

- Melemez, K. Risk factor analysis of fatal harvesting accidents: A case study in Turkey. Saf. Sci. 2015, 79, 369–378. [Google Scholar] [CrossRef]

- Bendixen, M. A Practical Guide to the Use of Correspondence Analysis in Marketing Research. Mark. Bull. 2003, 14, 15, Technical note 2. Available online: http://marketing-bulletin.massey.ac.nz (accessed on 8 November 2022).

- Yelland, P.M. An introduction to Correspondence Analysis. Math. J. 2010, 12, 23. [Google Scholar] [CrossRef]

- Greenacre, M. The Use of Correspondence Analysis in the Exploration of Health Survey Data; © Fundación BBVA: Bilbao, Spain, 2002; 39p. [Google Scholar]

- Forest Stewardship Council. FSC International Standard Forest Management Evaluations FSC-STD-20-007 (V3-0) EN. Available online: https://ic.fsc.org/download.fsc-std-20-007-v3-0-en-forest-management-evaluations.a-524.pdf (accessed on 10 November 2022).

- CA Data Analysis Tool in Real Statistics. Available online: https://www.real-statistics.com/multivariate-statistics/correspondence-analysis/ca-data-analysis-tool/ (accessed on 8 November 2022).

- Global Forest Resources Assessments, FAO. Available online: https://www.fao.org/forest-resources-assessment/fra-2020/country-reports/en/ (accessed on 24 November 2022).

- Borz, S.A.; Ignea, G.; Vasilescu, M.M. Small gains in wood recovery rate when disobeying the recommended motor-manual tree felling procedures: Another reason to use proper technical prescriptions. Bioresources 2014, 9, 6938–6949. [Google Scholar] [CrossRef]

- Landekić, M.; Martinić, I.; Mijoč, D.; Bakarić, M.; Šporčić, M. Injury Patterns among Forestry Workers in Croatia. Forests 2021, 12, 1356. [Google Scholar] [CrossRef]

- Axelsson, S.-Å. The mechanization of logging operations in Sweden and its effect on occupational safety and health. Int. J. For. Eng. 1998, 9, 25–31. [Google Scholar]

- Klun, J.; Medved, M. Fatal accidents in forestry in some European countries. Croat. J. For. Eng. 2007, 28, 55–62. [Google Scholar]

- Potočnik, I.; Pentek, T.; Poje, A. Severity analysis of accidents in forest operations. Croat. J. For. Eng. 2009, 30, 171–184. [Google Scholar]

- Gyekye, S.A.; Salminen, S. Educational status and organizational safety climate: Does educational attain influence workers’ perceptions of workplace safety? Saf. Sci. 2009, 47, 20–28. [Google Scholar] [CrossRef]

- Brachetti Montorselli, N.; Lombardini, C.; Magagnotti, N.; Marchi, E.; Neri, F.; Picchi, G.; Spinelli, R. Relating safety, productivity and company type for motor-manual logging operations in the Italian Alps. Accid. Anal. Prev. 2010, 42, 2013–2017. [Google Scholar] [CrossRef]

| Risk Factor | Description of Typical Characteristics |

|---|---|

| Environmental | Unsafe working conditions |

| Improper weather conditions, extreme heat/cold, rain, dust | |

| Density of trees | |

| Equipment-related | Use of inappropriate tool/machine |

| Use of non-standard tool/machine | |

| Use of old machine | |

| Insufficient maintenance and repair | |

| Absence of machinery protectors | |

| Not using personal protective equipment | |

| Not using communication tools | |

| Insufficient PPE and/or first aid kit and/or fire extinguisher | |

| PPE and/or first aid kit and/or fire extinguisher are not available at working place | |

| Job-related | Heavy physical workload |

| Job structure spread over a large terrain, necessity of communication among workers | |

| Mobile objects (tree, logs) | |

| Long and heavy objects | |

| Various phases of work in the same field | |

| Limited visibility, obligation to complete work in a short time, limiting the choice of workers | |

| Organizational | Incorrect working system (laws and regulations, communication, written SOP, etc.) |

| Insufficient number of workers | |

| Unsuitable selection of workers | |

| Insufficient training of workers | |

| Inadequate control | |

| Lack of warning signs | |

| Overtime hours | |

| Insufficient rest breaks | |

| Difficulties in supplying protective equipment | |

| Inadequate supervising, monitoring, and recording | |

| Inadequate wages, welfare, and other benefits | |

| Personal | Carelessness |

| Inexperience | |

| Insufficient knowledge on the job | |

| Unsuitability to the work | |

| Fatigue | |

| Tendency to act quickly | |

| Disorderly behavior | |

| Positioning in dangerous zones | |

| Lack of motivation |

| Country | BV | CU | GFA | NC | SA | SCS | SGS | Total |

|---|---|---|---|---|---|---|---|---|

| Cambodia | 1 | 1 | ||||||

| Indonesia | 1 | 5 | 7 | 10 | 11 | 3 | 37 | |

| Laos | 3 | 1 | 4 | |||||

| Malaysia | 2 | 2 | 4 | |||||

| Thailand | 13 | 11 | 2 | 7 | 33 | |||

| Vietnam | 2 | 33 | 6 | 10 | 51 | |||

| Total | 16 | 18 | 39 | 8 | 16 | 13 | 20 | 130 |

| Country | Total Forest Area, ha | Certificate Holders | Area Size, ha | Share | |||

|---|---|---|---|---|---|---|---|

| No. | Min | Max | Average | Total | % | ||

| Cambodia | 58,714,510 | 1 | 7896 | 7896 | 0.2 | ||

| Indonesia | 92,133,200 | 37 | 148 | 298,710 | 85,073 | 3,147,695 | 86.2 |

| Laos | 16,595,500 | 4 | 3483 | 41,259 | 23,449 | 93,796 | 2.6 |

| Malaysia | 19,114,040 | 4 | 6476 | 23,344 | 14,289 | 57,154 | 1.6 |

| Thailand | 19,873,000 | 33 | 29 | 29,790 | 3514 | 115,946 | 3.2 |

| Vietnam | 14,643,090 | 51 | 780 | 20,282 | 4498 | 229,374 | 6.3 |

| Total | 221,073,340 | 130 | 23,120 | 3,651,860 | 100 | ||

| Type | Major | Minor | Observations | Total | ||||

|---|---|---|---|---|---|---|---|---|

| Country | n | % | n | % | n | % | n | % |

| Cambodia | - | - | 3 | 1.5 | - | - | 3 | 0.9 |

| Indonesia | 47 | 48.0 | 100 | 51.5 | 28 | 87.5 | 175 | 54.0 |

| Laos | 3 | 3.1 | 13 | 6.7 | - | - | 16 | 4.9 |

| Malaysia | - | - | 3 | 1.5 | 1 | 3.1 | 4 | 1.2 |

| Thailand | 18 | 18.4 | 15 | 7.7 | 2 | 6.3 | 35 | 10.8 |

| Vietnam | 30 | 30.6 | 60 | 30.9 | 1 | 3.1 | 91 | 28.1 |

| Total | 98 | 100 | 194 | 100 | 32 | 100 | 324 | 100 |

| Risk Factor | Subfactor | n | % |

|---|---|---|---|

| Environment | |||

| Unsafe working condition | 1 | 25.0 | |

| Insufficient weather conditions, extreme heat, rain, dust | 2 | 50.0 | |

| Density of trees | 1 | 25.0 | |

| Total | 4 | 100 | |

| Equipment | |||

| Use of inappropriate tool/machine | 10 | 9.7 | |

| Use of non-standard tool/machine | 13 | 12.6 | |

| Use of old machine | 2 | 1.9 | |

| Insufficient maintenance and repair | 11 | 10.7 | |

| Absence of machinery protectors | 3 | 2.9 | |

| Not using PPE | 34 | 33.0 | |

| Not using communication tools | 1 | 1.0 | |

| Insufficient PPE and/or first aid kit and/or fire extinguisher | 19 | 18.4 | |

| PPE and/or first aid kit and/or fire extinguisher are not available at working place | 10 | 9.7 | |

| Total | 103 | 100 | |

| Organization | |||

| Incorrect working system (laws and regulations, communication, written SOP, etc.) | 64 | 27.0 | |

| Unsuitable selection of workers | 3 | 1.3 | |

| Insufficient training of workers | 26 | 11.0 | |

| Inadequate control | 47 | 19.8 | |

| Lack of warning signs | 4 | 1.7 | |

| Difficulties in supplying protective equipment | 37 | 15.6 | |

| Inadequate supervising, monitoring, and recording | 39 | 16.5 | |

| Inadequate wages, welfare, and other benefits | 17 | 7.2 | |

| Total | 237 | 100 | |

| Personal | |||

| Carelessness | 5 | 20.8 | |

| Inexperience | 5 | 20.8 | |

| Insufficient knowledge on the job | 10 | 41.7 | |

| Positioning in dangerous zones | 4 | 16.7 | |

| Total | 24 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaakkurivaara, T.; Borz, S.A.; Kaakkurivaara, N. Risk Factors and Occupational Safety Failures in Forest Work in the Southeast Asian Region. Forests 2022, 13, 2034. https://doi.org/10.3390/f13122034

Kaakkurivaara T, Borz SA, Kaakkurivaara N. Risk Factors and Occupational Safety Failures in Forest Work in the Southeast Asian Region. Forests. 2022; 13(12):2034. https://doi.org/10.3390/f13122034

Chicago/Turabian StyleKaakkurivaara, Tomi, Stelian Alexandru Borz, and Nopparat Kaakkurivaara. 2022. "Risk Factors and Occupational Safety Failures in Forest Work in the Southeast Asian Region" Forests 13, no. 12: 2034. https://doi.org/10.3390/f13122034

APA StyleKaakkurivaara, T., Borz, S. A., & Kaakkurivaara, N. (2022). Risk Factors and Occupational Safety Failures in Forest Work in the Southeast Asian Region. Forests, 13(12), 2034. https://doi.org/10.3390/f13122034