Relation between Energy Efficiency and GHG Emissions in Drying Units Using Forest Biomass

Abstract

1. Introduction

2. Materials and Methods

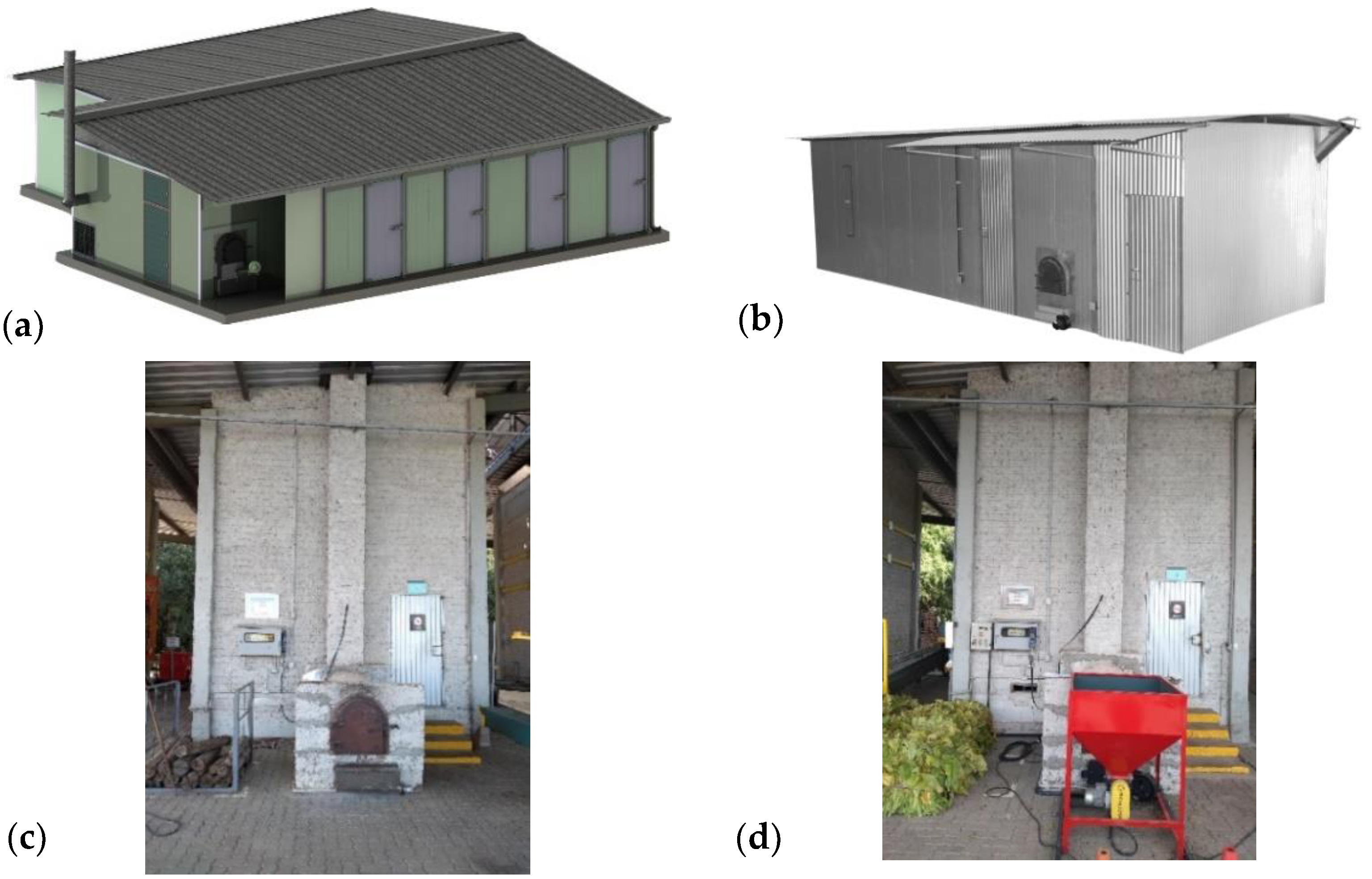

2.1. Drying Units

2.2. Biomass Types

2.3. Analysis and Characterization

2.3.1. Biomass Characterization

2.3.2. Biomass Consumption

2.3.3. Energy Efficiency

- where:

- EPC = energy from the fuel, kJ;

- QC = amount of fuel, kg;

- PCI = lower calorific value of fuel, kJ.kg−1.

- where:

- PCI = lower calorific value of fuel, kJ.kg−1;

- PCS = fuel superior calorific power, kJ.kg−1;

- UC = fuel moisture content, % b.u. (35%).

- where:

- EEs = energy efficiency related to drying, kJ.kg−1;

- EPC = energy consumed in the form of fuel, kJ;

- Mi = initial product mass, kg; and

- Mf = final product mass, kg.

2.3.4. GHG Quantification

2.3.5. Emission Factors

- where:

- Vchimney − total = total volume of gases flowing through the chimney (m3);

- []X = average concentration of X (ppmv) at 8% oxygen [23];

- MX = molar mass (g/mol);

- M (dry − basis fuel) = mass of dry − basis fuel (kg);

- Vx = molar volume of 1 mol at 0 °C and 1 atm (L/mol) (=0.0224 m3).

- where:

- CO₂-eq = GHG emissions.

- PAG = Global warming potential of gas i;

- GEE = Mass of gas i; and,

- i = greenhouse gas.

2.3.6. Firewood Consumption and Emissions Scenarios

3. Results and Discussions

3.1. Biomass Characterization

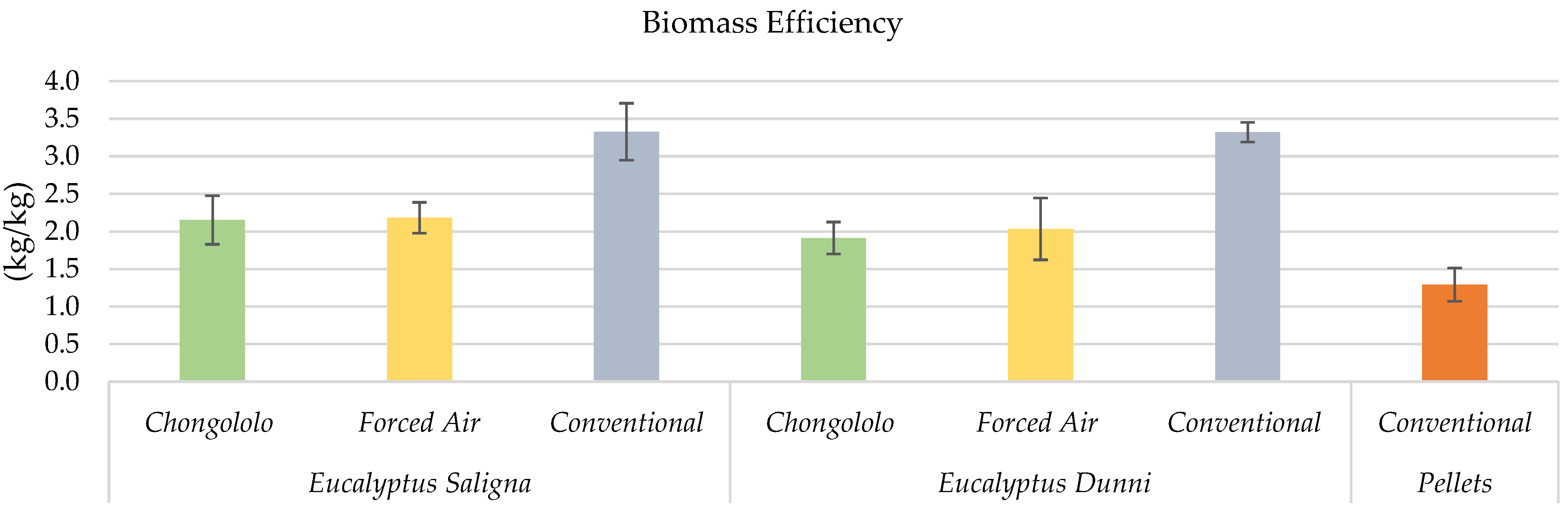

3.2. Efficiency in Biomass Consumption

3.3. Energy Efficiency

3.4. GHG Emissions

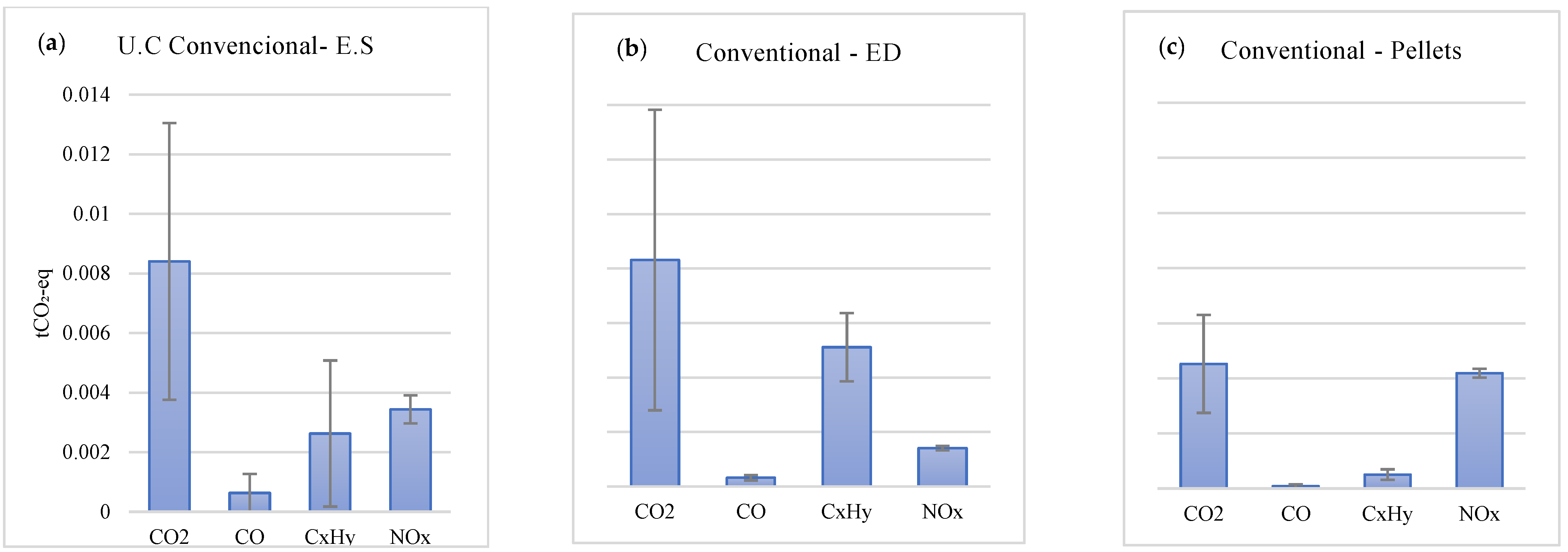

3.5. Emission Factor in Tons of Carbon Equivalent (tCO₂-eq)

3.6. Scenarios

3.6.1. Efficiency in Forest Biomass Consumption

3.6.2. Emissions-tCO₂-eq

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Biomass | CU | Analysis | Biomass Quantity | Capacity | Drying Hours | Green Tobacco CU | Dry Tobacco by CU (kg) | kg/kg ¹ | EE 2 (kJ.kg) | Cs 3 (kg/h) |

|---|---|---|---|---|---|---|---|---|---|---|

| E. saligna | Chongololo | 01 | 4397.17 | 608,00 | 168,00 | 11,639.82 | 1988.16 | 2.21 | 8023.34 | 69.28 |

| 02 | 4631.89 | 608,00 | 168,00 | 11,639.82 | 1988.16 | 2.33 | 8451.63 | 69.28 | ||

| 03 | 3806.87 | 608,00 | 168,00 | 11,639.82 | 1988.16 | 1.91 | 6946.24 | 69.28 | ||

| Average | 4278.64 | 608,00 | 168,00 | 11,639.82 | 1988.16 | 2.15 | 7807.07 | 69.28 | ||

| DP | 425.09 | 0.00 | 0.00 | 0.00 | 0.00 | 0.21 | 775.64 | 0.00 | ||

| Forced Air | 01 | 2004.98 | 270,00 | 168,00 | 5556.53 | 882.90 | 2.27 | 7555.10 | 33.07 | |

| 02 | 2244.77 | 270,00 | 168,00 | 5556.53 | 882.90 | 2.54 | 8458.67 | 33.07 | ||

| 03 | 1532.05 | 270,00 | 168,00 | 5556.53 | 882.90 | 1.74 | 5773.02 | 33.07 | ||

| Average | 1927.27 | 270,00 | 168,00 | 5556.53 | 882.90 | 2.18 | 7262.26 | 33.07 | ||

| DP | 362.66 | 0.00 | 0.00 | 0.00 | 0.00 | 0.41 | 1366.56 | 0.00 | ||

| Conventional | 01 | 2508.48 | 500,00 | 168,00 | 5065.00 | 765.00 | 3.28 | 10,273.68 | 30.15 | |

| 02 | 2378.00 | 500,00 | 168,00 | 5065.00 | 765.00 | 3.11 | 9739.29 | 30.15 | ||

| 03 | 2577.16 | 500,00 | 168,00 | 5065.00 | 765.00 | 3.37 | 10,554.97 | 30.15 | ||

| Average | 2487.88 | 500,00 | 168,00 | 5065.00 | 765.00 | 3.25 | 10,189.32 | 30.15 | ||

| DP | 101.17 | 0.00 | 0.00 | 0.00 | 0.00 | 0.13 | 414.33 | 0.00 | ||

| E. dunnii | Chongololo | 01 | 4712.00 | 608,00 | 168,00 | 11,639.82 | 1988.16 | 2.37 | 8608.44 | 68.04 |

| 02 | 3345.40 | 608,00 | 168,00 | 11,639.82 | 1988.16 | 1.68 | 5046.41 | 83.24 | ||

| 03 | 3345.40 | 608,00 | 168,00 | 11,639.82 | 1988.16 | 1.68 | 5098.99 | 83.24 | ||

| Average | 3800.93 | 608,00 | 168,00 | 11,639.82 | 1988.16 | 1.91 | 6251.28 | 78.17 | ||

| DP | 789.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.32 | 2041.53 | 8.78 | ||

| Forced Air | 01 | 1586.68 | 270,00 | 168,00 | 5556.53 | 882.90 | 1.80 | 6996.52 | 28.59 | |

| 02 | 1893.36 | 270,00 | 168,00 | 5556.53 | 882.90 | 2.14 | 6953.89 | 34.57 | ||

| 03 | 1904.10 | 270,00 | 168,00 | 5556.53 | 882.90 | 2.16 | 6418.03 | 38.16 | ||

| Average | 1794.71 | 270,00 | 168,00 | 5556.53 | 882.90 | 2.03 | 6789.48 | 33.77 | ||

| DP | 180.24 | 0.00 | 0.00 | 0.00 | 0.00 | 0.20 | 322.39 | 4.83 | ||

| Conventional | 01 | 2232.83 | 500,00 | 168,00 | 5065.00 | 765.00 | 2.92 | 11,086.36 | 23.85 | |

| 02 | 2583.08 | 500,00 | 168,00 | 5065.00 | 765.00 | 3.38 | 12,289.14 | 27.00 | ||

| 03 | 2807.46 | 500,00 | 168,00 | 5065.00 | 765.00 | 3.67 | 9070.97 | 39.63 | ||

| Average | 2541.13 | 500,00 | 168,00 | 5065.00 | 765.00 | 3.32 | 10,815.49 | 30.16 | ||

| DP | 289.6 | 0.00 | 0.00 | 0.00 | 0.00 | 0.38 | 1626.10 | 8.35 | ||

| Pellets | Conventional | 01 | 879.4 | 500,00 | 168,00 | 5065.00 | 765.00 | 1.15 | 3700.81 | 30.15 |

| 02 | 1185.00 | 500,00 | 168,00 | 5065.00 | 765.00 | 1.55 | 4986.88 | 30.15 | ||

| 03 | 900 | 500,00 | 168,00 | 5065.00 | 765.00 | 1.18 | 3787.50 | 30.15 | ||

| Average | 988.13 | 500,00 | 168,00 | 5065.00 | 765.00 | 1.29 | 4158.40 | 30.15 | ||

| DP | 170.80 | 0.00 | 0.00 | 0.00 | 0.00 | 0.22 | 718.79 | 0.00 |

Appendix B

| Biomass | Curing Unit | O2 | CO2 | CO | CxHy | NOx | Speed | |

|---|---|---|---|---|---|---|---|---|

| % | 8% | 8% mg/m3 | 8% | 8% mg/m3 | m/s | |||

| E. saligna | Chongololo | Average | 15.8 | 11.55 | 29,577.55 | 1.55 | 140.58 | 10.65 |

| DP | 0.92 | 0.04 | 7451.80 | 0.3 | 178.89 | 0.75 | ||

| Forced Air | Average | 11.92 | 10.02 | 15,557.85 | 1.05 | 130.86 | 7.9 | |

| DP | 4.36 | 1.37 | 5542.56 | 0.51 | 84.8 | 0.19 | ||

| Conventional | Average | 14.27 | 11.6 | 7230.73 | 0.56 | 173.51 | 7.11 | |

| DP | 0.99 | 0.02 | 4711.87 | 0.42 | 18.95 | 0.58 | ||

| E. dunnii | Chongololo | Average | 13.36 | 11.54 | 14,896.03 | 1.86 | 218.22 | 7.21 |

| DP | 0.64 | 0.41 | 3037.96 | 1.39 | 37.89 | 1.25 | ||

| Forced Air | Average | 11.77 | 11.65 | 11,069.44 | 2.08 | 291.3 | 7 | |

| DP | 3.41 | 2.28 | 1994.16 | 0.31 | 105.98 | 0.77 | ||

| Conventional | Average | 12.97 | 11.62 | 4679.00 | 1.31 | 85.12 | 6.37 | |

| DP | 1.83 | 1.13 | 841.49 | 0.65 | 10.35 | 0.87 | ||

| Pellets | Conventional | Average | 16.62 | 11.5 | 954.99 | 0.15 | 293.53 | 5.66 |

| DP | 1.33 | 0.02 | 1029.02 | 0.16 | 31.72 | 0.80 |

Appendix C

| Biomass | Curing Unit | tCO₂-eq Per kg of Cured Tobacco | Sum | tCO₂-eq Per Curing Unit | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CO2 | CO | CxHy | NOx | CO2 | CO | CH4 | N2O | Total | tCO₂-eq /kg Tobacco | ||||

| E. saligna | Chongololo | Average | 0.005169 | 0.001644 | 0.004240 | 0.001628 | 0.012681 | 9.051969 | 2.722440 | 2.253041 | 4.311375 | 18.338825 | 0.009230 |

| DP | 0.002845 | 0.001280 | 0.000053 | 0.000133 | 0.004312 | 2.113565 | 1.332999 | 0.740527 | 1.417057 | 2.526774 | 0.004125 | ||

| Forced Air | Average | 0.008047 | 0.001389 | 0.005991 | 0.003163 | 0.018589 | 5.265811 | 0.859394 | 0.875335 | 1.675023 | 8.675563 | 0.011239 | |

| DP | 0.003809 | 0.000831 | 0.000229 | 0.000160 | 0.005029 | 0.391185 | 0.231816 | 0.434920 | 0.832254 | 1.544437 | 0.004618 | ||

| Conventional | Average | 0.008404 | 0.000631 | 0.002625 | 0.003435 | 0.015095 | 5.383625 | 0.374547 | 0.900900 | 1.723944 | 8.383016 | 0.010552 | |

| DP | 0.004643 | 0.000635 | 0.002454 | 0.000474 | 0.008205 | 0.440633 | 0.246379 | 0.501592 | 0.959837 | 1.958491 | 0.005212 | ||

| E. dunnii | Chongololo | Average | 0.002029 | 0.000279 | 0.002696 | 0.001339 | 0.006343 | 4.070167 | 0.560477 | 2.275258 | 1.275818 | 8.181719 | 0.004078 |

| DP | 0.000510 | 0.000262 | 0.000664 | 0.000077 | 0.001512 | 0.575603 | 0.383738 | 0.364834 | 0.611185 | 1.935361 | 0.006016 | ||

| Forced Air | Average | 0.004813 | 0.000622 | 0.007131 | 0.004228 | 0.016792 | 4.445313 | 0.574095 | 1.047476 | 1.713841 | 7.780725 | 0.008423 | |

| DP | 0.000906 | 0.000393 | 0.000124 | 0.000180 | 0.001603 | 0.473395 | 0.335219 | 0.201204 | 0.626260 | 1.636078 | 0.009221 | ||

| Conventional | Average | 0.008309 | 0.000316 | 0.005110 | 0.001406 | 0.015140 | 6.347137 | 0.241551 | 0.866250 | 0.754940 | 8.209879 | 0.010748 | |

| DP | 0.005518 | 0.000098 | 0.001254 | 0.000085 | 0.006954 | 0.726216 | 0.045740 | 0.405511 | 0.017314 | 1.194781 | 0.003341 | ||

| Pellets | Conventional | Average | 0.004523 | 0.000085 | 0.000505 | 0.004185 | 0.009298 | 3.582398 | 0.067517 | 0.898260 | 1.595012 | 6.143187 | 0.007755 |

| DP | 0.001778 | 0.000071 | 0.000192 | 0.000161 | 0.002203 | 0.430214 | 0.036707 | 0.407519 | 0.347953 | 1.222393 | 0.003401 | ||

References

- Nicolletti, X.M.; Lefèvre, G.B. Precificação de carbono no Brasil: Perspectivas e aprendizados a partir de uma simulação de mercado cap-and-trade. Cad. Adenauer XVII 2016, 2, 145–169. [Google Scholar]

- Zhao, Q.; Ding, S.; Wen, Z.; Toppinen, A. Energy Flows and Carbon Footprint in the Forestry-Pulp and Paper Industry. Forests 2019, 10, 725. [Google Scholar] [CrossRef]

- Pinsky, V.; Kruglianskas, I. Inovação tecnológica para a sustentabilidade: Aprendizados de sucessos e fracassos. Estud. Av. 2017, 31, 107–126. [Google Scholar] [CrossRef][Green Version]

- Tolmasquim, M.T.; Gorini, R.; Matsumura, R.E.; Soares, J.B.; Oliveira, L.B.; Lisboa, M.L.V.; G. Faria, G.V.R.; Conde, R.M.; Moraes, N.G. The Brazilian Commitment to Combating Climate Change: Energy Production and Use; Empresa de Pesquisa Energética-EPE: Rio de Janeiro, Brazil, 2016; p. 96. [Google Scholar]

- Brasil, C.N.A. Confederação da Agricultura e Pecuária do Brasil—CNA PIB do Agronegócio; CNA: Arlington County, VA, USA, 2020; p. 18. [Google Scholar]

- Industria Brasileira de Árvores—IBÁ—Relatório 2019. 2019. Available online: https://iba.org/datafiles/publicacoes/relatorios/iba-relatorioanual2019.pdf (accessed on 10 October 2020).

- Kumar, A.; Sharma, M.P.; Taxak, A.K. Effect of vegetation communities and altitudes on the soil organic carbon stock in Kotilbhel-1A catchment, India. Soil Air Water 2017, 8, 1600650. [Google Scholar] [CrossRef]

- Sheikh, M.A.; Kumar, M.; Todaria, N.P.; Bhat, J.A.; Kumar, A.; Pandey, R. Contribution of Cedrus Deodara Forests for Climate Mitigation along Altitudinal Gradient in Garhwal Himalaya, India. Mitig. Adapt. Strateg. Glob. Chang. 2021, 26, 5. [Google Scholar] [CrossRef]

- Beling, R.R. Anuário Brasileiro do TABACO 2018; Editora Gazeta: Curitiba, Brazil, 2018; p. 69. [Google Scholar]

- Greff, H.P.; de Farias, J.A.; Schulte, T.F. Mercado de lenha voltado ao beneficiamento de grãos e tabaco na região central do Rio Grande Do Sul. Cad. Pesqui. 2015, 27, 16. [Google Scholar]

- Campos, A.T.; Saglietti, J.R.C.; Bueno, O.D.C.; Campos, A.T.D.; Klosowski, E.S.; Gasparino, E. Balanço energético na produção de feno de alfafa em sistema intensivo de produção de leite. Ciênc. Rural 2004, 34, 245–251. [Google Scholar] [CrossRef][Green Version]

- Segura, M.A.; Andrade, H.J. Huella de carbono en cadenas productivas de café (Coffea arabica L.) con diferentes estándares de certificación en Costa Rica. Rev. Luna Azul 2012, 35, 18. [Google Scholar]

- Gomes, A.F.; Martins, M.A.; Pereira, E.G. Simulação computacional de dispositivos de mistura em câmara de combustão para gases de carbonização. Ciênc. Florest. 2019, 29, 673–684. [Google Scholar] [CrossRef]

- Pérez, J.F.; Graciano, D.S.; Gómez, J.A. Caracterización energética y emisiones de una estufa de cocción ecoeficiente con biomasa a diferentes altitudes. Ingeniería Mecánica. Ing. Mec. 2013, 16, 227–237. [Google Scholar]

- Dessbesell, L.; Farias, J.A.D.; Roesch, F. Complementing Firewood with Alternative Energy Sources in Rio Pardo Watershed, Brazil. Ciênc. Rural 2017, 47. [Google Scholar] [CrossRef][Green Version]

- Hernandez Solorzano, L.C.; Forero Nuñez, C.A.; Sierra, F.E. Biomass Densification: A Review of the Market and Recent R&D Trends. TECCIENCIA 2017, 12, 81–92. [Google Scholar]

- Japan Tobacco JT Strengthens Commitment to Climate Action with Approved Science Based Target. 2020. Available online: https://www.jti.com/jt-strengthens-commitment-climate-action-approved-science-based-target (accessed on 5 January 2021).

- Associação dos Fumicultores do Brasil—Afubra Dados Sobre o Setor Tabacaleiro. 2020. Available online: https://afubra.com.br/fumicultura-brasil.html (accessed on 20 January 2021).

- de Farias, J.A. Atividade Florestal No Contexto da Fumicultura: Oportunidade de Desenvolvimento Regional, Diversificação, Geração de Emprego e Renda; Tese de Doutorado, Universidade Federal de Santa Maria: Santa Maria, Brazil, 2010. [Google Scholar]

- Osório, A.G.S. Projeto e Construção de Um Secador Intermitente de Fluxo Concorrente e Sua Avaliação Na Secagem de Café; Universidade Federal de Viçosa: Viçosa, Brazil, 1982; p. 57. [Google Scholar]

- Amorim, E.B. de Gases de Efeito Estufa Produzidos Pela Combustão de Biomassa; Universidade Estadual Paulista “Júlio de Mesquita Filho”: Guaratinguetá, Brazil, 2012. [Google Scholar]

- França, D.D.A.; Longo, K.M.; Neto, T.G.S.; Santos, J.C.; Freitas, S.R.; Rudorff, B.F.T.; Cortez, E.V.; Anselmo, E.; Carvalho, J.A. Pre-Harvest Sugarcane Burning: Determination of Emission Factors through Laboratory Measurements. Atmosphere 2012, 3, 164–180. [Google Scholar] [CrossRef]

- Conselho Nacional Do Meio Ambiente-CONAMA. Resolução No 436, de 22 de Dezembro de 2011. 2011. Available online: https://www.novaconcursos.com.br/blog/pdf/resolucao-436-2011.pdf (accessed on 20 January 2021).

- Purohit, A.N.; Nautiyal, A.R. Fuelwood Value Index of Indian Mountain Tree Species. Int. Tree Crops J. 1987, 4, 177–182. [Google Scholar] [CrossRef]

- Garcia, D.P.; Caraschi, J.C.; Ventorim, G. Caracterização energética de pellets de madeira. Rev. Madeira 2013, 24, 14–16. [Google Scholar]

- Roman, K.; Barwicki, J.; Hryniewicz, M.; Szadkowska, D.; Szadkowski, J. Production of Electricity and Heat from Biomass Wastes Using a Converted Aircraft Turbine AI-20. Processes 2021, 9, 364. [Google Scholar] [CrossRef]

- Foelkel, C. Utilização da Biomassa do Eucalipto para Produção de Calor, Vapor e Eletricidade. 2016. Available online: https://www.eucalyptus.com.br/eucaliptos/PT44_Geracao_Calor_Vapor_Eletricidade.pdf (accessed on 20 January 2021).

- Welter, C.A.; Farias, J.A.D.; Silva, D.A.D.; Rech, R.D.S.; Teixeira, D.D.S.; Pedrazzi, C. Consumption and Characterization of Forestry Biomass Used in Tobacco Cure Process. Floresta E Ambient. 2019, 26. [Google Scholar] [CrossRef]

- Welter, C.A. Uso da Biomassa Florestal Como Estratégia de Redução dos Gases de Efeito Estufa: Estudo de Caso na Fumicultura do Sul do Brasil; Universidade Federal De Santa Maria Centro De Ciências Rurais Programa De Pós-Graduação Em Engenharia Florestal: Santa Maria, Brazil, 2017. [Google Scholar]

- Tippayawon, N.; Tantakitt, C.; Thavornun, S. Investigation of Lignite and Firewood Co-Combustion in a Furnace for Tobacco Curing Application. Am. J. Appl. Sci. 2006, 3, 1775–1780. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Q.; Wei, Y.; Yang, G.; Wei, F. Integrated Furnace for Combustion/Gasification of Biomass Fuel for Tobacco Curing. Waste Biomass Valoriz. 2019, 10, 2037–2044. [Google Scholar] [CrossRef]

- Amaral, M.C.F. Estudo Sobre a Emissão de NOX por Turbinas a Gás. 2014; Volume 1, p. 71. Available online: http://www.uezo.rj.gov.br/tcc/cn/Maria-Carolina-Francisco-Amaral.pdf (accessed on 20 January 2021).

- Gioda, A. Comparação dos níveis de poluentes emitidos pelos diferentes combustíveis utilizados para cocção e sua influência no aquecimento global. Quím. Nova 2018, 8, 839–848. [Google Scholar] [CrossRef]

- Francisco, R.P. Estudo Termoquímico da Queima de Combustíveis em Caldeiras Usando Balanços de Energia. Dissertação de Mestrado; Universidade Federal De São João Del-Rei: São João Del Rei, Brazil, 2012. [Google Scholar]

- Garcia, R. Combustíveis e Combustão Industrial; Editora Interciência: Rio de Janeiro, Brazil, 2002. [Google Scholar]

| CU | Capacity | Main Technological Caracteritics | Structure | Chimney Useful Area | n of Greenhouses 2 |

|---|---|---|---|---|---|

| Continuous load (Chongololo) | 608 clamps | Fan Double-firing system Temperature and humidity control | Steel | 0.045 m2 | 28 |

| Forced air 1 | 207 clamps | Fan Temperature and humidity control | Steel | 0.049 m2 | 9532 |

| Conventional with firewood | 500 sticks | Automatic damper Temperature and humidity control | Masonry | 0.045 m2 | 6015 |

| Conventional adapted for pellets | 500 sticks | Fan Temperature and humidity control | Masonry | 0.045 m2 | 3 |

| Biomass | Moisture Content | Ash (%) | Extractives (%) | Lignin (%) | DB (g/cm3) | CV (Kcal/kg) | ED (Gcal/m3) |

|---|---|---|---|---|---|---|---|

| Eucalyptus saligna firewood | 25–35% b.u | 0.41 | 2.73 | 15.96 | 0.44 | 4686.60 | 2.07 |

| Eucalyptus dunnii firewood | 25–35% b.u | 0.54 | 2.69 | 21.64 | 0.56 | 4715.00 | 2.62 |

| Pinus sp. Pellets | 8% b.u | 0.33 | 6.54 | 28.02 | 0.70 | 4728.00 | 3.30 |

| Biomass | Curing Unit | kg of Firewood per 2020/2021 Harvest |

|---|---|---|

| E. saligna | Chongololo | 133,428,783.03 ± 13,256,339.90 |

| Forced Air | 135,339,654.92 ± 25,467,270.99 | |

| Conventional | 201,633,535.51 ± 8,199,087.37 | |

| E. dunnii | Chongololo | 118,531,475.87 ± 24,605,048.68 |

| Forced Air | 126,031,279.12 ± 12,657,258.45 | |

| Conventional | 205,948,712.10 ± 23,471,298.98 | |

| Pellets | Conventional | 80,084,577.05 ± 13,842,905.58 |

| Curing Unit | Means | Groups | Biomass | Means | Groups |

|---|---|---|---|---|---|

| Conventional | 162555608 | a | Wood E. saligna | 156800658 | a |

| Forced Air | 130685467 | b | Wood E.dunnii | 150170489 | a |

| Chongololo | 125980129 | b | Pellets Pinus sp. | 80084577 | b |

| Biomass | Curing Unit | tCO2-eq in the 2020/2021 Harvest |

|---|---|---|

| E. saligna | Chongololo | 627,221.23 ± 255,733.12 |

| Forced Air | 789,861.02 ± 286,295.15 | |

| Conventional | 765,012.20 ± 323,115.42 | |

| E. dunnii | Chongololo | 252,030.91 ± 67,919.43 |

| Forced Air | 522,256.56 ± 74,448.80 | |

| Conventional | 666,348.32 ± 379,930.40 | |

| Pellets | Conventional | 480,838.66 ± 160,333.43 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pasa, D.L.; Dessbesell, L.; de Farias, J.A.; Hermes, D. Relation between Energy Efficiency and GHG Emissions in Drying Units Using Forest Biomass. Forests 2021, 12, 1056. https://doi.org/10.3390/f12081056

Pasa DL, Dessbesell L, de Farias JA, Hermes D. Relation between Energy Efficiency and GHG Emissions in Drying Units Using Forest Biomass. Forests. 2021; 12(8):1056. https://doi.org/10.3390/f12081056

Chicago/Turabian StylePasa, Débora Luana, Luana Dessbesell, Jorge Antonio de Farias, and Dionatan Hermes. 2021. "Relation between Energy Efficiency and GHG Emissions in Drying Units Using Forest Biomass" Forests 12, no. 8: 1056. https://doi.org/10.3390/f12081056

APA StylePasa, D. L., Dessbesell, L., de Farias, J. A., & Hermes, D. (2021). Relation between Energy Efficiency and GHG Emissions in Drying Units Using Forest Biomass. Forests, 12(8), 1056. https://doi.org/10.3390/f12081056