1. Introduction

Debarking is a process that significantly affects other processing operations in the wood processing industry. Logs are only easily debarked when the adhesion at the interface of the wood/bark is low. Therefore, it can be declared that the main criterion for the debarking process is wood/bark adhesion [

1,

2,

3]. Adhesion of wood/bark is affected by several important factors such as moisture content, ambient air temperature, storage period, tree species and bark type as well as wood and bark density. The difficulty of the debarking process varies during the year. This is reflected for example in a higher proportion of bark in the wood chips. Debarking of logs with a lower temperature is more complicated due to a stronger bark adhesion and greater cohesiveness to the wood. It results in faster wear on the tool tip and increases the incidence of damage on the debarked logs. More importantly, the volume of wood fibers increases with the bark during the process. This leads, e.g., to the creation of a high bark particles content in the chips used in pulp mills, thus significantly increasing economic losses. Previous studies showed that soaking the logs in cold water (around 8 °C) for 20 minutes provided a positive improvement in debarking [

3]. The authors assessed the shear strength at the wood/bark interface in the debarking process in a drum debarker used mainly in pulp and paper production [

1,

4,

5]. In their research, the factors influencing the final value of adhesion were analyzed. Many authors [

1,

5,

6,

7] in their study found that the moisture content was the most important factor of wood/bark adhesion. Based on the study [

5], it can be stated that the lowest values of the shear strength at the wood/bark interface were measured particularly in the case of fresh logs. The highest values were measured in the case of the air-dried wood. The studies of several authors [

1,

4,

8] were aimed at monitoring the effect of storage time on log wood/bark adhesion. [

4] claimed that the infringement of inner bark occurred mainly on dried logs.

The next study [

8] was based on the use of thin-sized spruce and pine logs (thickness grades 5–10, 10–15, over 15 cm) in various climate conditions in Sweden for 14–15 weeks. The average moisture content of fresh log sapwood was about 55%, and after 14–15 weeks of storage it dropped to an average of 20%. At the same time, the shear strength at the wood/bark boundary increased three to five times due to the reduction of the sapwood moisture content during storage. From the point of increasing the shear strength at the wood/bark boundary, a critical storage period is considered to be six weeks. Within three weeks, the moisture content decreased, but the shear strength remained basically unchanged. After six weeks of storage, the sapwood moisture content decreased to 40%, but the shear strength at the wood/bark interface increased only slightly. Beyond this moisture content limit, or rather the mentioned time period, the shear strength increases remarkably. The results of a study by [

9] show a remarkably high variability of the wood moisture content in individual logs and parts of the log (more than 25% for spruce wood delivered to the processing plant). If the moisture content decreases to a low value, processing problems will increase. The issue of moisture content in wood processed into pulp is published in the literature mainly from a log debarking point of view. The research institutes in Canada [

10,

11], Australia [

12,

13], and Sweden [

8,

14] monitored how wood moisture content, harvesting period, location, tree species, tree age, trunk diameter, temperature, storage time, and other factors affected the debarking process, which was quantified by the shear strength at the wood/bark boundary. Based on research [

11,

15], the shear strength at the wood/bark boundary on four coniferous and four deciduous trees during the growing and dormant periods was observed. Their results showed an approximately three-fold increase in the shear strength at the wood/bark boundary in coniferous trees and a two- to eight-fold increase in the shear strength in deciduous trees. The authors attribute the increase in shear strength both to the changing structure of cambium during growing periods but also to the difference in the wood and bark moisture content in the vegetation and dormant periods. The authors [

11,

15,

16] discussed the measurement of wood/bark adhesion (shear strength). The measurement was taken during the growing and dormant periods in the longitudinal direction. Failures of the bark observed during the growing period came with small variations in the cambial zone. At a time when cambium entered a dormant state, a failure of the bark began to move into the phloem zone. The research also showed that oak bark was relatively fragile, and that during the dormant period adhesion of bark on a tree could be increased by bast rays.

The difference in the structure of wood and bark remarkable impacts on their physical, mechanical, and chemical properties. This is the main reason why many wood processing technologies first remove the bark. In particular, in the processing of wood pulp in the paper industry, bark is undesirable in semiproducts or final products (pulp, paper). When looking at the bark as an undesirable proportion of wood (logs), it is important to know the adhesion on wood and decrease the content of bark in the next processing.

The objective of this research was to evaluate the effect of the storage of beech and sessile oak logs on the shear strength on the wood/bark border.

2. Material and Method

The material to determine the adhesion of wood/bark based on shear strength was selected from oak (Quercus petraea (Matt.) Liebl.) and beech (Fagus sylvatica L.) growing in the research area of Včelien, the University Forest Enterprise of the Technical University in Zvolen at an altitude of about 450 m. a.s.l. in Kremnica Mountains (Slovakia, Region of Banská Bystrica). The research area was characterized as a mixed forest of hornbeam, oak and beech trees.

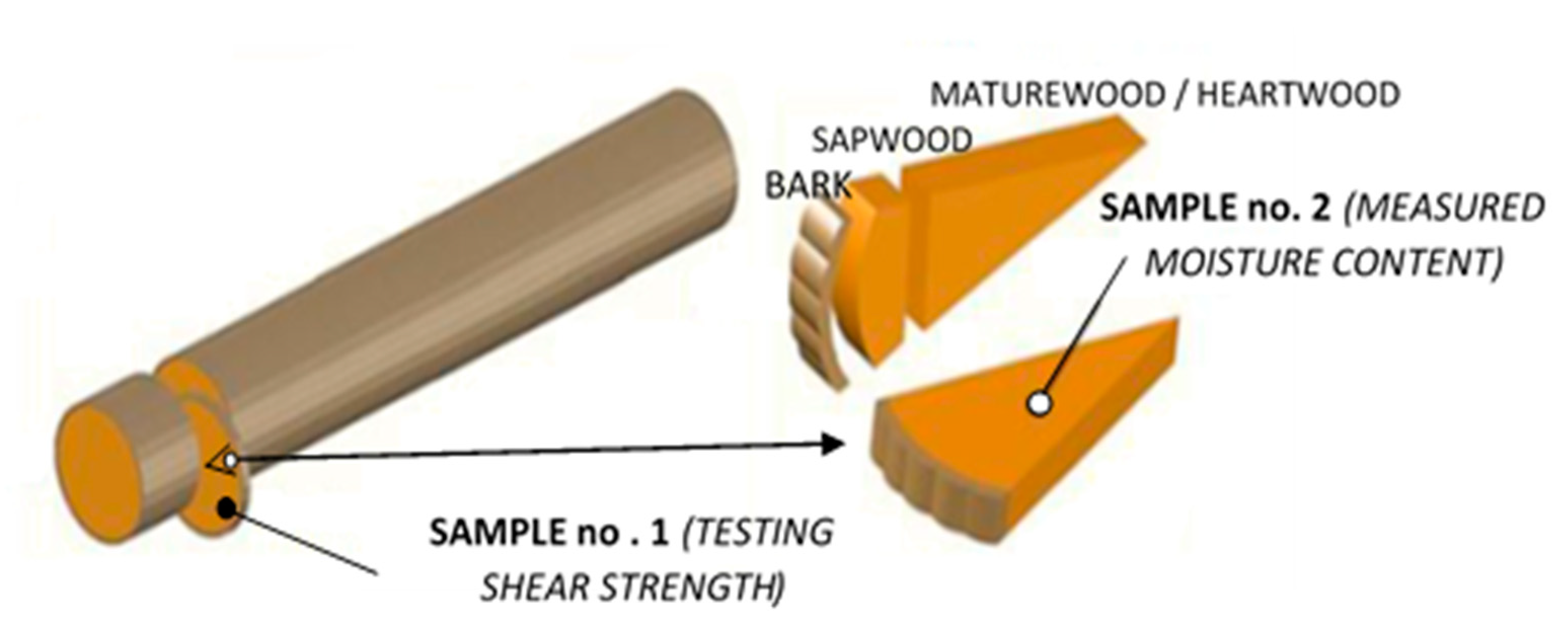

For the research, 4-meter-long freshly cut beech and oak logs were used. Logs were stored in an open space exposed to rain and snow without being covered. The logs were placed on concrete blocks at a height of about 30 cm above the ground. The storage period lasted half a year from July to December. The sampling from the sections began in July, the so-called "Zero take-off", where a disc was taken to determine the moisture content and shear strength in the tangential direction (

Figure 1). The surface of the shear (bark) was divided into two equal segments, which were used to test the shear strength during the storage of logs (

Figure 2). The shear strength was measured on 120 samples for beech and an equal number for sessile oak (

Figure 3). The cross-sections on both sides were coated with latex paint after each sample collection to prevent the logs from quickly drying. The samples, 50-mm thick, were taken monthly (

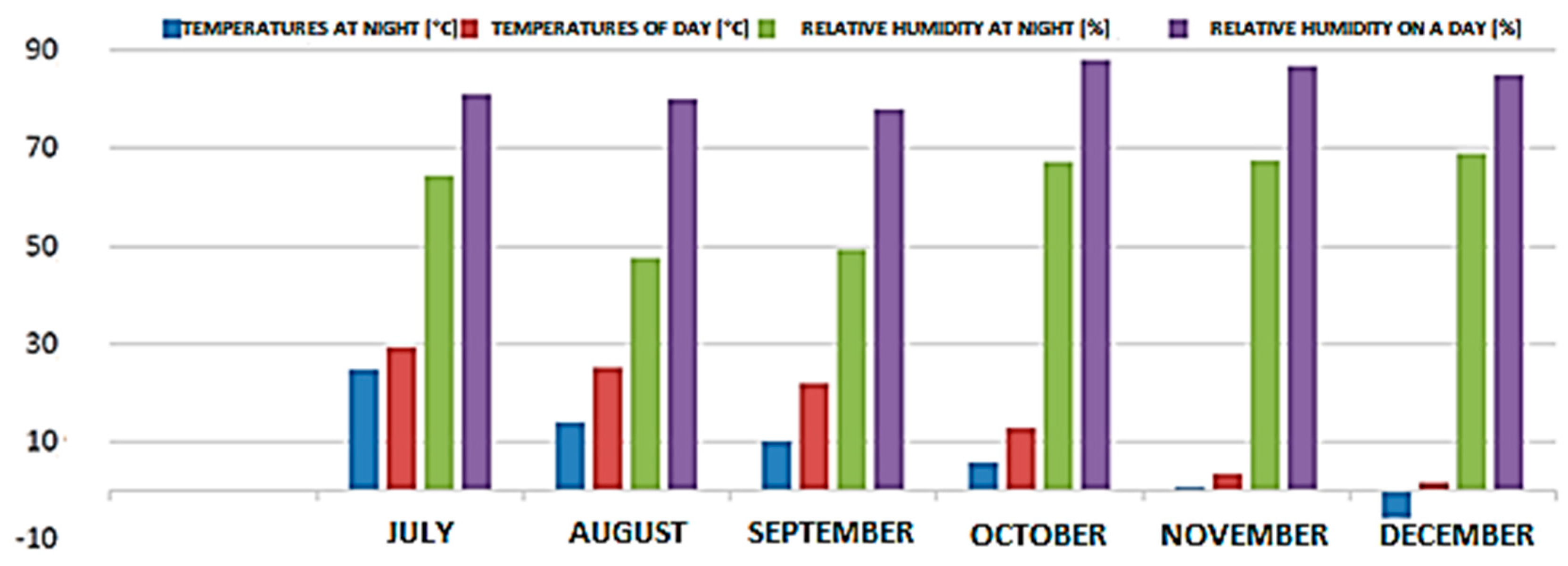

Figure 1). During storage, weather conditions such as the highest and lowest daily air temperature (°C) and relative humidity (%) were recorded (

Figure 4).

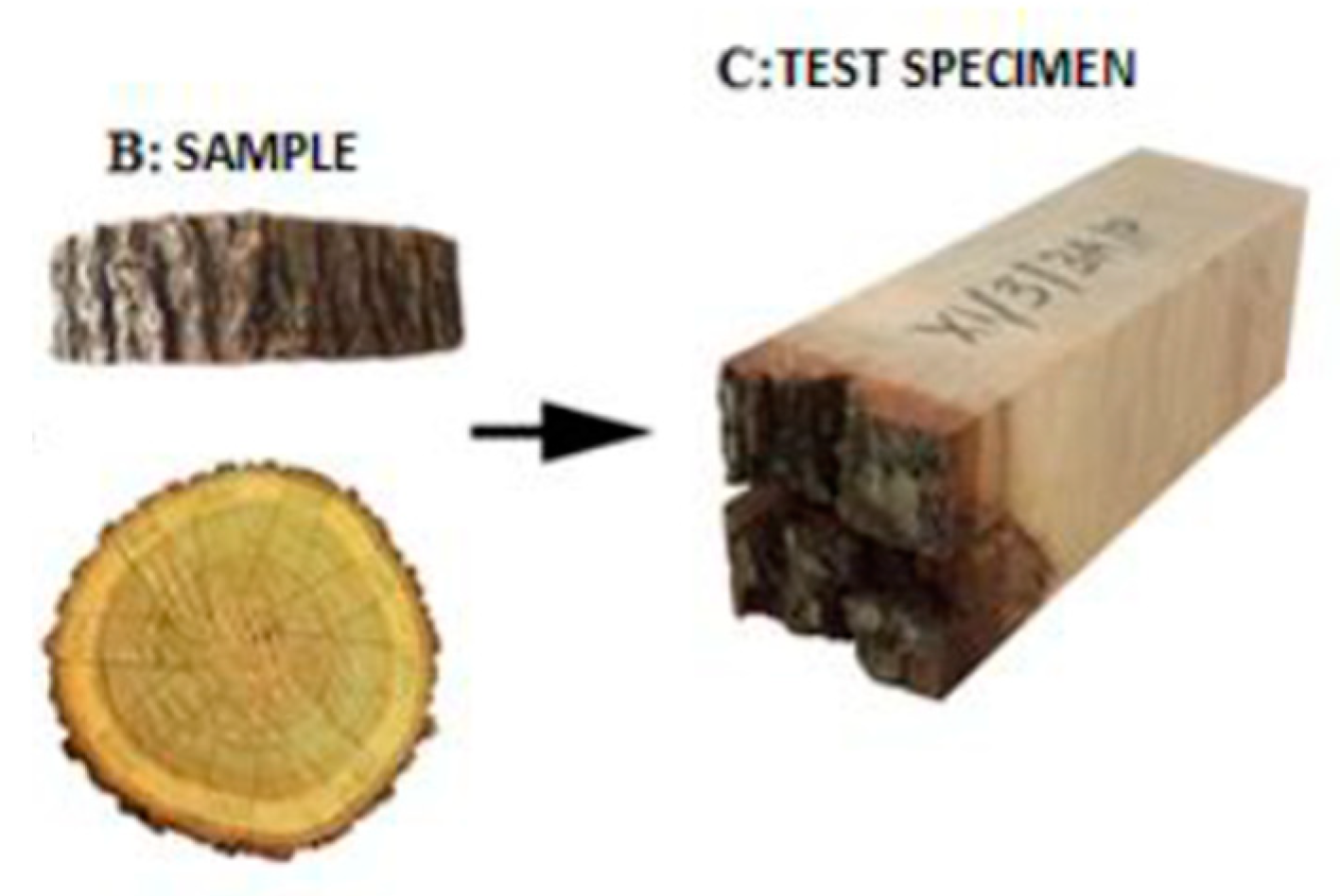

Subsequently, fresh samples for testing the shear strength were cut into dimensions of about 30 × 30 × 60 mm (

Figure 2). The bark surfaces were cut into two identical areas with dimensions of about 30 × 13 mm. Then, the shear strength was measured in a fresh state on the areas that were created this way. The shear strength was measured in the tangential direction (

Figure 3).

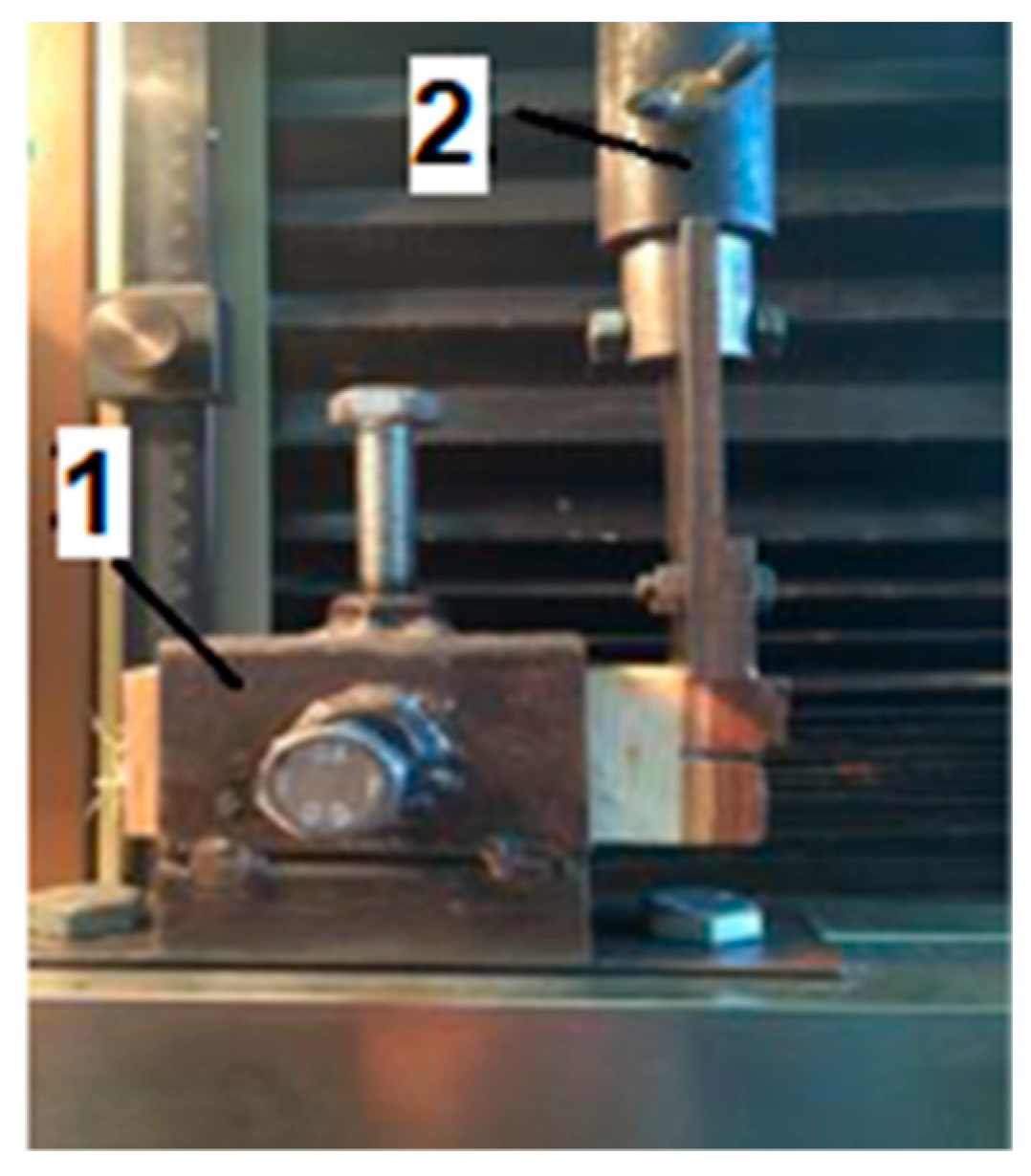

Adhesion testing at the wood/bark interface was performed using the testing device TIRATEST. The samples were fixed with anchoring screws. The loading arm of the testing device was equipped with a special thorn with a shape similar to the wood/bark interface (

Figure 3). A tension–deformation diagram was recorded from every sample, from which the maximum loading force needed to rupture the wood/bark interface was determined. The value of the maximum shear strength for the tangential direction in a fresh state was calculated using the Equation (1):

where: τ

tangential—limit of the shear strength in the longitudinal and tangential direction [MPa], F—maximum loading force [N], and S—shear area [mm

2].

The initial (wi) and final (wf) moisture content (MC) of wood and bark was determined using the gravimetric method [

17]. The moisture content was calculated using Equation (2):

where: m

w is the weight of the wet sample (g), and m

0 is the weight of the absolutely dry sample (g)

The statistical evaluation was realized by a descriptive graph (Box and whisker plot). The type of the descriptive graph was median/quartile/range. The results were evaluated by the method of analysis of variance (ANOVA). The method was based on the tested criteria (p < 0.05) the interval variable (shear strength) and nominal variables (month).

3. Results and Discussion

During the storage of beech and oak logs, noticeable changes during the six-month storage cycle were recorded. The average climate conditions during the storage of beech and oak logs are shown in

Figure 4. The changes mainly concerned the decrease in shear strength, the distribution of moisture content across the cross-section, as well as the biological degradation of the cambial zone and the sapwood. Similar changes were described in the research of [

8,

9], which stored spruce, pine, and beech logs.

3.1. Beech Wood

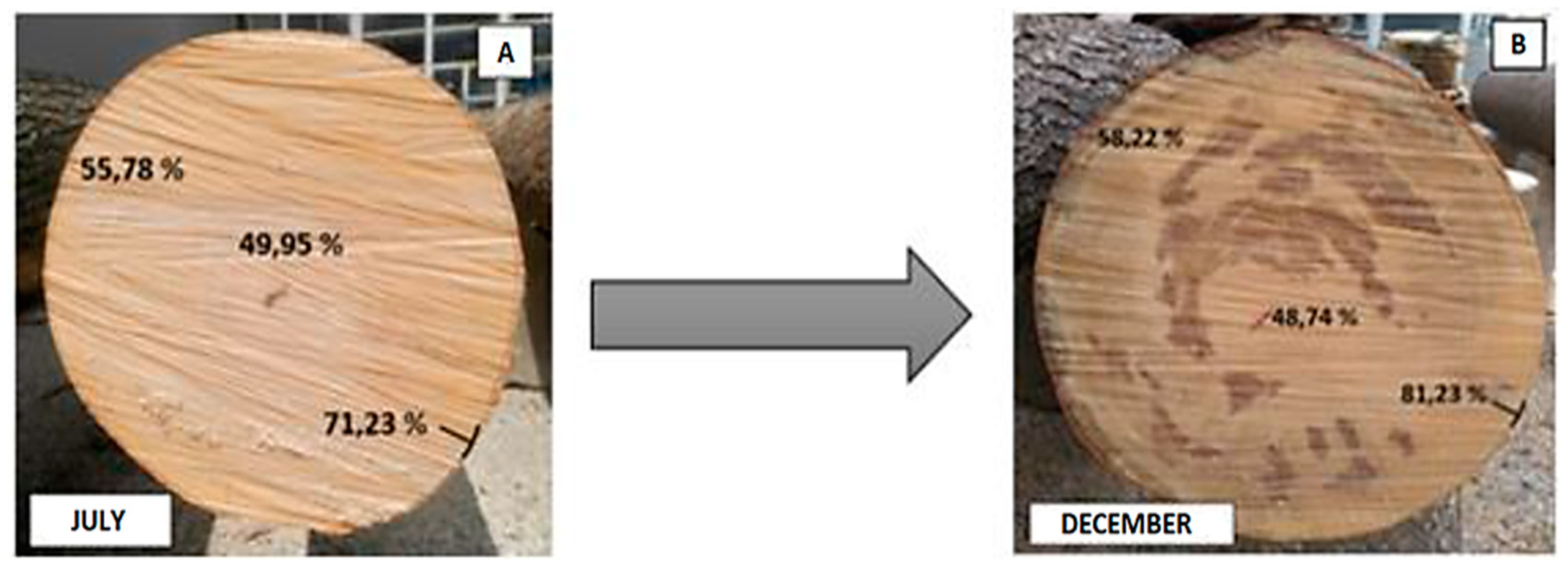

The beech (

Figure 5A) moisture content distributed over the cross-section at the beginning of the storage was as follows: bark 71.2%, sapwood zone 55.8%, and mature wood 49.95%. At the end of the cycle, its moisture content in the cross-section changed, mainly due to a change in conditions during storage, which led to the biological degradation of cambium and sapwood and the formation of red heartwood throughout the cross-section (

Figure 5B).

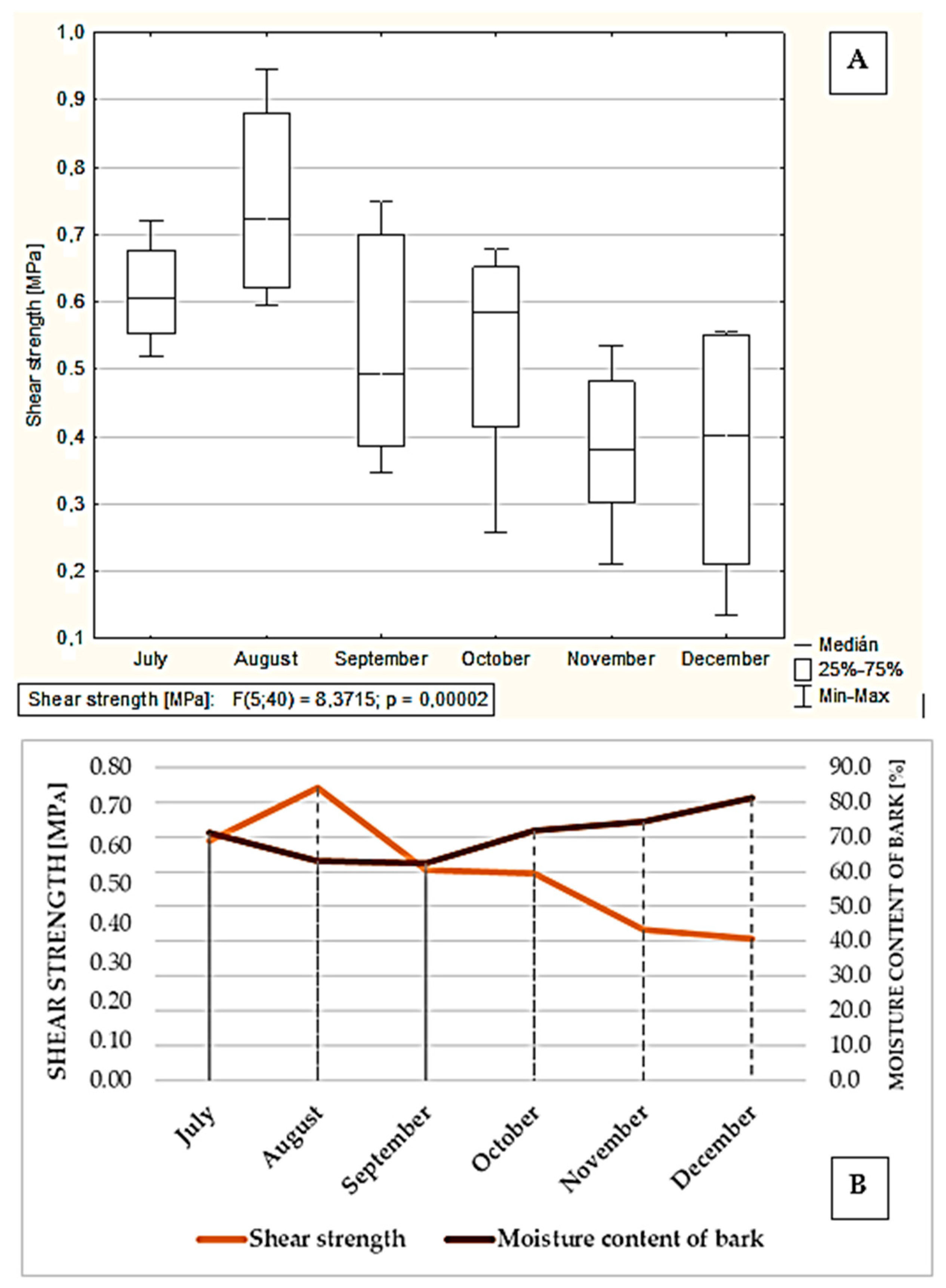

The bark moisture content increased to 81.2%, that of sapwood to 58.2%, and only mature wood showed a decrease to 48.7%. An increase in the moisture content in the bark and sapwood could be explained by frequent precipitation (rain, snow) and fluctuations in the temperature and relative humidity, especially from October to December, which also led to the red heartwood formation. These changes in humidity, especially in the areas of bark and sapwood, also led to changes in the shear strength at the wood/bark interface.

During the storage of the beech logs, significant differences in the measured values of the shear strength in specific months were shown. Changes in the moisture content of bark led to a 52% decrease in the shear strength. The exception was recorded in August, characterized by high daily temperatures (

Figure 4) resulting in the measurement of the highest average value of the shear strength, i.e., 0.75 MPa (

Figure 6A). The same results were found in studies [

1,

4,

8]. Similar results were found in other studies [

2,

3,

6,

7,

8], where the wood and bark moisture content were the most important factor affecting the shear strength values. The shear strength values in monthly intervals decrease throughout the storage period (from 0.61 to 0.35 MPa).

The storage time under real conditions has an effect on reducing the adhesion of wood/bark, which can be seen in the diagram (

Figure 6A). These findings confirmed that the storage time, associated with the changed moisture content, reduced the shear strength value. As is also shown in the research [

8], the shear strength does not change at the beginning of the storage but only after a remarkable drop in humidity. Another method, based on the study [

4], discovered that the bark disruption occurred only during very dry incisions. Additionally, the research [

5] stated that the highest shear strength values were measured in the case of wood that was dried under external conditions.

The observations during the storage of the logs showed that the value of the shear strength was more affected by the change in the moisture content of the bark than the sapwood (

Figure 6B). As the moisture content of the bark decreased, the shear strength of the wood/bark increased and vice versa. The shear strength was also affected by biotic and abiotic factors near the bark, which in particular caused the degradation of the cambial zone.

3.2. Oak Wood

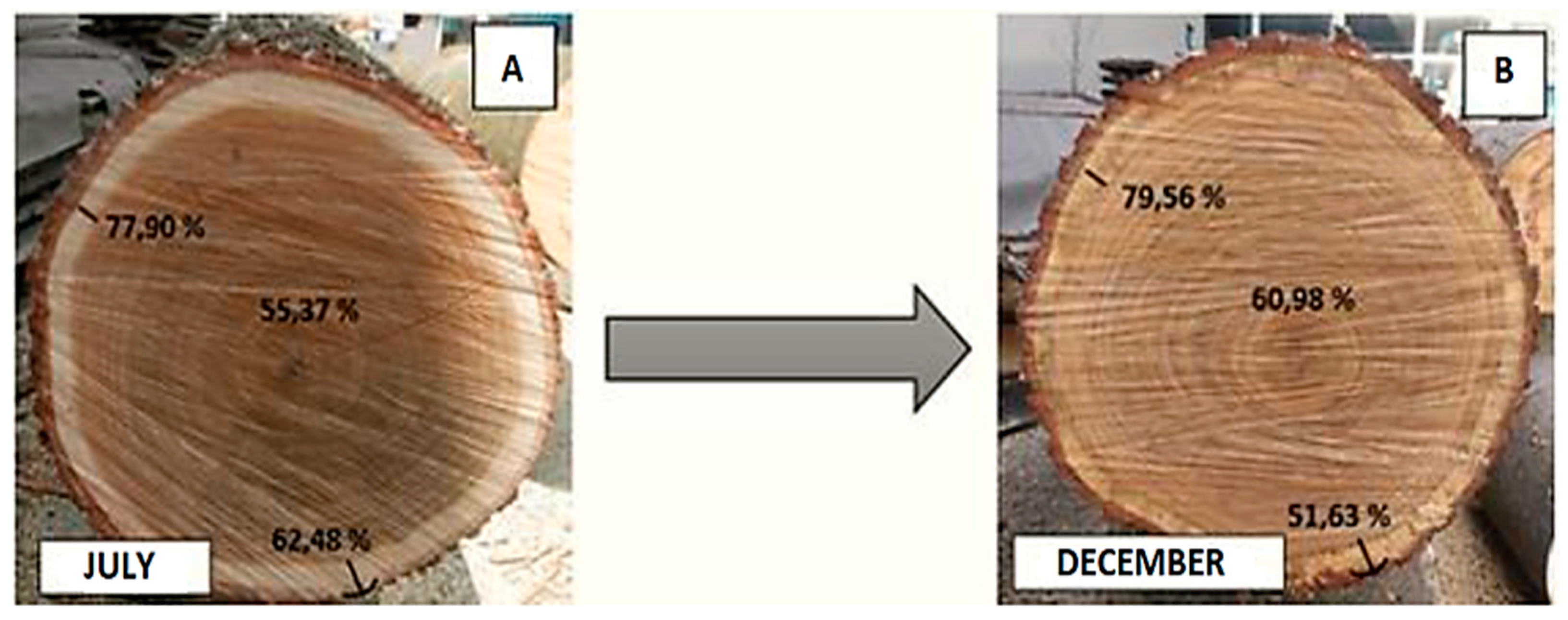

Oak, which belongs to the group of durable tree species, proved to be highly resistant even during storage. The moisture content (

Figure 7A) of the bark (62.5%), sapwood (77.9%), and heartwood (55.4%) changed, similarly to beech in all three zones of the trunk at the end of storage. The effect of the change in the moisture content of wood and bark during storage on the value of the shear strength was similarly studied by the following studies [

11,

15]. The authors [

11,

15] attribute an increase in shear strength both to the changing structure of cambium but also to the difference in the wood and bark moisture content.

In the case of oak, the biological degradation was not observed in the heartwood zone, which can be explained by the high content of tannins in the central part. Only the sapwood zone was degraded at the end of the experiment (

Figure 7B).

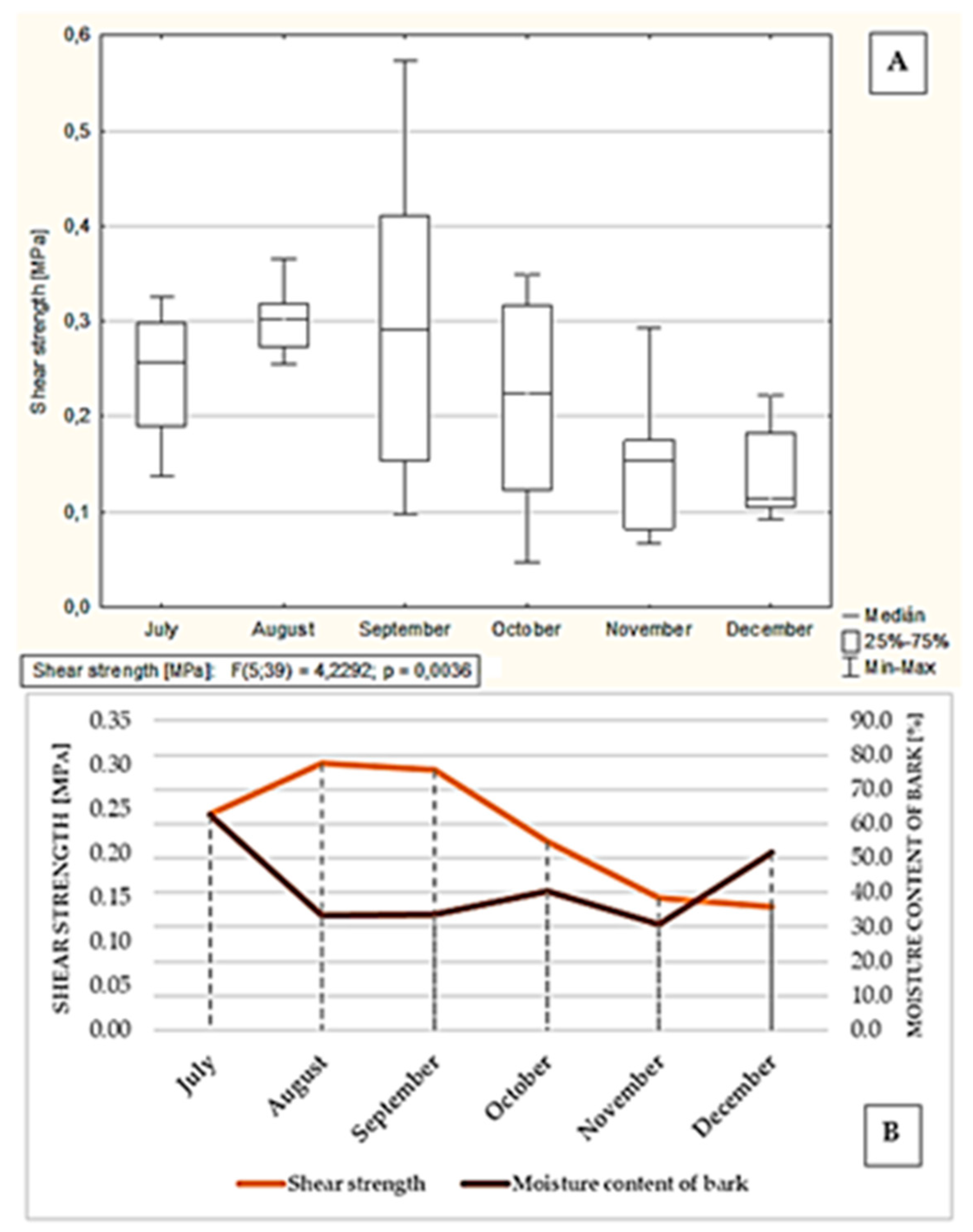

In the case of oak, the shear strength also decreased by a value equal to 50%. On average, shear strength values ranged from 0.24 MPa in July to 0.14 MPa in December. A similar study on the shear strength of oak bark was carried out by [

2,

11,

15], which studied the development of bark/wood adhesion during the growing and dormant periods. In both studies, the oak bark was shown to be relatively fragile, and the phloem rays affected the shear strength remarkably, especially during the growing period.

The overall trend of the shear strength during the six months of storage usually had a decreasing tendency. Similar findings were discovered in the studies [

8,

9]. The relationship between the bark moisture content and the values of the shear strength was also similar for beech wood (

Figure 8B). As the moisture content of the bark increased, the strength decreased. However, in oak, the changes in the moisture content of bark became evident in November and December, leading to the assumption that oak with a thicker bark tolerated the moisture changes better than beech with a thinner bark. Overall, we can confirm that the bark moisture content is proving to be one of the most important factors affecting the shear strength of the bark/wood interface. Based on the research [

1,

4,

5,

7,

8], the dependence of the shear strength on the value of the bark moisture content for other can be confirmed.