This section presents the most relevant papers in the literature on experimental microwave wood technology treatment or modification, grouped according to their different applications. Although there are several uses, as mentioned above, most of these are correlated or occur concomitantly; thus, for each paper, the main objectives were identified. Hence, the research papers are presented in two major groups, MW for wood drying and MW for permeability modification, both with secondary objectives.

Using MW energy for either drying or increasing permeability is linked, and one can lead to the other. However, they are presented as separate topics because, although each paper had different objectives, they all converged toward an improvement in drying quality or an increase in permeability. Following the description of MW treatment applications for both primary groups, the main conclusions are stated, and a table with wood species, MW power, frequency, and exposure time from each article is provided.

2.1. Wood Drying

Antti [

37] found that using MW for wood drying has two main advantages; it reduces both drying time and problems in the wood. However, to have efficient drying with maximum benefits, MW energy needs to penetrate the entire wood material. Therefore, thicker wood samples require lower frequencies [

37]. Accordingly, Antti [

37] investigated the drying behavior of wood specimens of pine (

Pinus silvestris) and spruce (

Picea abies), analyzing the MW power, MC movement rates, steam pressure, and temperature while drying without causing degradation in the samples. Moreover, MC behavior during drying was studied. The MW intensities used were from 25 to 78 kW/m

3, and the internal temperatures obtained in the samples were up to 140 °C.

Antti [

37] concluded that the drying process is controlled by the MC movement rate, which is conditioned by the amount of generated steam pressure. The drying rates were higher with MC above the fiber saturation point (FSP), and spruce samples dried around 1.6 times quicker than pine ones. For instance, the drying efficiency decreased with the reduction in MC because a higher quantity of energy was reflected to the magnetrons, since the wood was losing its capacity to store energy. Under a constant temperature, nonquantifiable steam pressure was created when the MC was below 20%. The authors also suggested that with MC under the fiber saturation point, the temperatures of the wood could be higher than 110 °C, and this might have been prejudicial because internal color modification was observed inside the wood samples, related to the degradation of wood components. Lastly, it was found that steam pressure up to 20 kPa did not cause checking in the wood specimens [

37].

In the late 1990s, Zielonka and Dolowy [

38] investigated the use of MW for drying spruce samples to examine the MC, temperature, and energy distribution in the samples and establish an equation that correlates MC and heating time. The authors concluded that the energy distribution through the wood samples is constant; hence, compared with conventional wood drying techniques, MW drying is more efficient. Nasswettrová et al. [

39] explained that a more homogeneous distribution of MW energy led to better drying quality. Furthermore, most of the applied MW energy is absorbed by the surface, whereby the maximum temperature is placed a few millimeters above the surface, while the greatest MC loss is on the wood surface [

38].

Zielonka and Gierlik [

40] studied the temperature distribution of conventional and MW heating of spruce wood samples. The authors explained that the heat penetrates the wood through its surface and disperses inside it when using traditional drying techniques. On the other hand, MW heating transfers energy right into the wood, where it is captured mainly by the water molecules and converted to heat. Moreover, effective MW heating depends on the MW frequency, the intensity of applied load, and the dielectric loss factor ε″ of the medium. It was also observed that the MW energy penetrates inside the wood specimens very rapidly, causing a rapid increase in temperature [

40].

The conventional wood drying process may take long periods to occur, even when small samples are used in the laboratory [

12]. Accordingly, Oloyede and Groombridge [

12] investigated how the MW drying process affects the resistant properties of Caribbean pine (

Pinus caribaea) compared to two other wood drying methods. They found that the reduction in modulus of elasticity (MOE) and modulus of rupture (MOR) of dried specimens when using MW was significantly lower than those dried with a conventional oven. Although the time with MW was significantly shorter, the wood samples had a strength reduction of 60% during MW drying.

Table 1 shows the reduction in MOE and MOR in samples dried using 100% and 50% MW power capacity compared to ambient drying and conventional oven drying, at 50 and 103 °C, according to Oloyede and Groombridge [

12]. The authors dried the test specimens until they achieved 12% and 20% MC.

For 12% MC, ambient drying took approximately 7 days, the conventional oven took approximately 8 h, and MW drying took approximately 20 min. For 20% MC, ambient drying took roughly 5 days, the conventional oven took roughly 7 h, and MW drying took around 10 min [

12].

Hansson and Antti [

13] compared conventional drying with MW drying to investigate how both drying methods affect the wood strength of Norway spruce (

Picea abies) with respect to moisture content, density, and fiber direction. According to their conclusions, wood MC, the number of annual rings, weight, thickness, and width were the variables that affected the strength properties. Hansson and Antti [

13] showed that the MW drying time is considerably reduced compared to the conventional oven drying method. Similar results were presented by Oloyede and Groombridge [

12]. However, contrary to what Oloyede and Groombridge [

12] presented, Hansson and Antti [

13] argued that the drying method and time have little influence on the MOE and MOR of the studied samples of Norway spruce.

To provide a contribution to the MW drying technology field, Machado [

6] investigated the behavior of compressive strength parallel to the fibers of oak (

Quercus pyrenaica Wild) wood under two different MW exposure times, 5 and 10 min. According to the author, 10 min of exposure time led to a more drastic reduction than 5 min in compressive strength. The compressive strength loss for 5 min was 10%, while that for 10 min was 20% (compared to non-treated samples). The author, however, commented that, due to the reduced size of the samples, it was not clear if MW-treated wood elements may be used for structural purpose; thus, more studies are necessary in this field.

The drying process of

Eucalyptus species is time-demanding, and despite high accuracy and maintenance, the samples may still present cracks and other issues [

22]. Thus, Harris et al. [

22] studied the impacts of low-intensity MW pretreatment drying on flat sawn wood samples of messmate stringybark (

Eucalyptus obliqua L’Herit). Four MW energies were used, ranging from 70 to 89 kWh/m

3, in samples with initial MC ranging from 70% to 121%. A considerable decrease in the surface checking amount and depth of the MW-treated samples compared to control ones was observed. Moreover, MW pretreatment reduced the total number of checks in all samples. The control samples with one or more surface checks were 65%, of which 82% had depth extending for more than one-quarter the width. On the other hand, samples treated with 75 kWh/m

3 had fewer checks, compared to the other intensities of MW treatment; only 43% of these had one or more surface checks, of which only 25% expanded for more than one-quarter the width.

Studhalter et al. [

41] evaluated the temperature behavior of mountain ash (

Eucalyptus regnans) wood samples during and after the heating procedure to establish their MC distribution in the cross-section. The authors also studied the development of MW heating to define the optimized parameters for wood softening. Using three different values for MC, 20%, 35%, and green (80–120%), the authors concluded that initial MC impacts the temperature behavior substantially, affecting both heating and cooling stages. Furthermore, samples with higher MC were not heated as consistently as samples with lower MC, and they required higher amounts of MW energy, indicating that free water also plays a vital role in MW heating. The cooling rate of green specimens was greater than that of the other two specimens. Similar to the findings of Zielonka and Dolowy [

38], Studhalter et al. [

41] expected that higher temperatures would be found on the surface, but they were instead found in the center of the samples. Higher surface temperatures are better for the bending process; thus, they [

41] noted that higher surface temperatures can could obtained using proper MW devices and parameters. Contrary to what was presented by Antti [

37], Studhalter et al. [

41] pointed out that the fiber saturation point had no considerable impact on the heating development.

Ozarska and Daian [

42] explained that wood bending represents a way of obtaining and manufacturing curved timber elements, with the major advantage of improving strength and timber recovery, which leads to lower costs. In this context, the authors studied the use of MW energy for softening wood elements, making them malleable to bending for furniture elements. Using eight Australian wood species,

Eucalyptus saligna,

Atherosperma moschatum,

Eucalyptus marginata,

Eucalyptus diversicolor,

Eucalyptus nitens,

Nothofagus cunninghamii,

Acacia melanoxylon, and

Pinus radiata, the bending quality and the minimum bending radius were investigated.

According to the authors [

42], MW wood bending treatment involves three phases: (1) wood sample heating using MW to soften and prepare it for bending; (2) the bending process of softened wood samples to the specific dimension and shape, and reestablishing the bent component strains before MW drying; (3) fast MW drying and equilibrium of bent elements. The results supported the benefits of MW drying for wood bending, showing that the species in question could be used in the manufacturing of bent elements. The authors [

42] also identified the wood bending performance as follows, from the worst to the best:

E. saligna and

E. marginata, very bad (the defects were too high to be withdrawn by the machine)

; Acacia melanoxylon and N. cunninghamii, satisfactory (there were a few significant defects, but they were all eliminated by the machine);

P. radiata,

Atherosperma moschatum, and

E. nitens, decent (although the machine was necessary);

E. diversicolor, very good (the machine use was limited).

Gašparík and Barcík [

28,

43] studied how MW heating treatment can contribute to the plasticizing of beech tree wood (

Fagus sylvatica L.) so that wood bending processes may occur and be accelerated. In this sense, the authors indicated that total deformation plays an important role in this process. The wood samples had an initial MC of 20%, 30%, and 65%. Similar to Ozarska and Daian [

42], Gašparík and Barcík [

28,

43] concluded that using MW heating for wood plasticizing presents significant benefits compared to traditional methods. The benefits are temperature control, allowing the greatest treatment conditions, reduced plasticizing time, MW equipment mobility and straightforward operation without special or odd operational requirements, space and energy saving, and the sustainability of the process. According to the results, it was concluded that MC and plasticizing time have a critical impact on wood plasticizing, and the highest deformation was obtained for 65% MC. The heating achieved with MW treatment was appropriate for softening the lignin, i.e., suitable temperatures are obtained. Increased exposure time of samples to MW energy led to smaller deflections. This occurred because more energy was adsorbed, generating more steam pressure and higher temperatures in the wood core. However, Gašparík and Barcík [

28] explained that a decrease in MC alters the plasticity of the wood. It was also observed that the dimensions of wood samples affected the bending capability. Smaller samples had high reductions in MC, thus resulting in more difficulties for bending. The authors indicated that, to achieve optimum wood samples with softened behavior, it is necessary to choose a higher initial MC, reduce plasticizing times, or use another MW power level.

Aiming to better understand the temperature behavior and the influence of MC on the wood plasticizing process using MW treatment, Gašparík and Gaff [

44] experimentally studied beech woods (

Fagus sylvatica L.). It was found that MW treatment supplies the necessary heating temperature to promote wood plasticizing, and the initial MC and exposure time demonstrated a strong effect on temperature behavior. The optimized temperature for plasticizing was obtained with 2 to 4 min of MW heating treatment. The dimensions of the wood specimens also influenced plasticizing because those with smaller dimensions lost more MC, as stated by Gašparík and Barcík [

43]. In conclusion, the authors argued that MW treatment for wood plasticizing to obtain correct temperatures is recommended, but they advised not using MW power over 700 W/magnetron because it may cause excessive MC loss and undesired reductions in flexural properties. Using wood samples with exact dimensions and 40% MC or more, along with an MW exposure time up to 4 min, may be sufficient to achieve optimum softened beech wood.

Koiš et al. [

45] developed laboratory MW equipment to evaluate the impact of MW energy on Norway spruce (

Picea abies) wood specimens with respect to the surface temperature and changes in MC, MOE, and MOR, using different MW power and conveyor speeds. The most significant average MC loss was found for the samples treated with 5 kW and a speed of 0.2 m/min, as shown in

Table 2. The maximum temperature was 87 °C with 5 kW and a speed of 0.4 m/min. The wood samples treated with 5 kW, 0.4 m/min, 3 kW, 0.2 m/min, and 5 kW, 0.2 m/min did not have their mechanical properties measured because they were too damaged after MW treatment. These results showed that, under the conditions used by Koiš et al. [

45], the maximum possible MW treatment was 3 kW, 0.4 m/min. Lastly, the authors argued that conveyor speed and generator output were the main factors affecting the MW treatment of Norway spruce samples. The most damaging effects on the mechanical properties and the most significant changes in the microstructure of the wood occurred with the highest MW power and the lowest speed [

45].

Peres et al. [

46] used MW heating on Persian lilac (

Melia azedarach L.) and jequitiba-rosa (

Cariniana sp.) wood to identify and analyze their physical and mechanical properties, aiming to efficiently obtain softened wood specimens so that they could be used for the industry. Three sets of specimens were used: one control and two treated, with 7 and 15 days of prior water immersion, exposed to MW for 90 s. Their results showed a decrease in MOE and MOR of both species studied, similar to the results presented by Oloyede and Groombridge [

12]. Furthermore, the mechanical properties of wood were partially reduced by heating and by moisture content; therefore, increasing moisture is needed for bending in hydrothermal treatments, as also indicated by Gašparík and Barcík [

28,

43] and Gašparík and Gaff [

44]. Upon analyzing both species individually, it was noted that each reacted differently to the MW treatment; however, for both species, MW heating promoted a plastic behavior in the wood samples, which was favorable for bending [

46].

Sethy et al. [

47] pointed out that drying the wood until 5% or 6% MC is not economically reasonable using conventional drying methods without causing undesirable drying problems. According to the authors, wood elements with lower MC need to be chemically modified. They studied the use of MW technology for drying radiata pine (

Pinus radiata) wood samples, allowing them to be further chemically modified. It was found that approximately 2 min is required to decrease the MC of the samples from 13% to 6% using MW energy of 55 kWh/m

3. As stated by other authors [

23,

38,

40], the drying was uniform within the specimens, generating fewer drying defects. The authors also suggested that MW technology may be used for this purpose in a reduced period and that further investigations using different wood species and dimensions are necessary [

47].

Since there are several parameters to be considered during MW treatment to produce different types of wood modification, it is essential to determine the appropriate level of modification to optimize the treatment by creating the necessary amount of steam pressure that will improve not only the drying quality but also the wood’s permeability [

3]. Accordingly, Xiao et al. [

3] studied how the wood temperature is affected by the initial MC and MW power by providing a temperature spectrum at different positions of the wood samples. To accomplish this, the authors set the MW power (20 kW), varying the MC (30%, 50%, and 70%), and then they set the MC (30%), using four different MC powers (5, 10, 15, and 20 kW).

First, Xiao et al. [

3] observed that the wood temperature behavior might have two patterns. The first is divided into three phases: (1) warming phase with quick temperature increase until 100 °C with low water loss; (2) water evaporation cycle with steady temperature; (3) rapid temperature rise in a brief period and decrease in MC. The second consisted of two phases: (1) warming; (2) constant temperature. Another conclusion made by Xiao et al. [

3] was that the maximum temperature and rate of temperature increase grew with the increase in MW power and decreased with the increase in MC, while the constant-temperature duration was reduced. For instance, in the 70% MC samples, the majority of MW power was employed to increase the temperature with no significant water evaporation. The authors [

3] found that the highest temperatures were on the upper surface (close to the MW applicator), followed by the center, the lower surface, and the end of the piece. In addition, the highest temperatures for 30%, 50%, and 70% MC were around 200, 150, and 100 °C, respectively. Their results are in accordance with previous studies [

37,

38,

40,

41].

Balboni et al. [

14] evaluated the impact of using MW treatment on drying defects, density, MOE, MOR, compression strength parallel to the grain, and shear strength of sawn timber red stringybark (

Eucalyptus macororhyncha) samples. The authors used two MW intensities, low microwave (LMW) and high microwave intensity (HMW), and they used a kiln to dry both wood group samples and the control one. The MW plant used by Balboni et al. [

14], at the University of Melbourne, Creswick Campus, had the following parts: a device in which the wood samples interact with the MW, a tunnel through which the wood enters and leaves, an MW generator, an autotuner, a waveguide, a conveyor belt that carries the wood samples, and a water load where the removed moisture is placed. According to the results, it was found that LMW performed best for MC with a more uniform distribution, no density decline, smaller check lengths on the surface (84%) and internally (50%), and greater capacity to recover from collapse (20%), while MOE and MOR values remained statistically unchanged. However, shear strength decreased by 13%, and compression parallel to the grain decreased by 10%, the same compressive reduction value found by Machado [

6] using a different wood species. HMW experienced more severe strength decreases and density reduction and more prolonged and deeper internal and superficial checks. Overall, because LMW had the best outcome, the authors [

14] stated that performing various detailed adjustments may promote drying advantages with a reduction in mechanical properties.

Ouertani et al. [

2] studied the drying kinetics of jack pine (

Pinus banksiana) wood boards using the specimen dimensions, MW power, and initial temperature to investigate the phytosanitary effectiveness, MW energy intake, and mechanical properties of treated samples. The MW equipment used by the authors was a BP-111 compact MW processor from Microwave Research and Applications, Inc. Laurel, MD. The samples used by the authors were at three different initial temperatures: −15, 4, and 18 °C.

Ouertani et al. [

2] concluded that thinner samples experienced shorter drying times and higher initial wood temperature and MC power. Results also showed that the initial MC of wood influenced its temperature in three main stages, as stated by Xiao et al. [

3]. The authors commented that samples with the same initial MC and mass had a reduction in energy consumption with enhanced MW power. For instance, green jack pine wood samples with a thickness of 12 mm needed 36.4 and 12.3 MJ/kg of water to be dried to 7% MC, using MW power from 300 to 1000 W, representing an energy economy of 65% [

2].

In addition to this, Ouertani et al. [

2] explained that there was no significant statistical reduction in mechanical properties compared to convective drying. However, as power was increased, there was a reduction of up to 28% in MOR and 18% in MOE at 1000 W. Considering “MW 300 W” as the MW treatment at 300 W power, “MW 500 W” as the MW treatment at 500 W power, and “MW 1000 W” as the MW treatment at 1000 W power, using the results obtained by Ouertani et al. [

2],

Figure 2 shows the variations in density, MOR, and MOE.

Using MW energy, Aksenov and Malyukov [

48] investigated the drying duration of both birch and aspen wood and the effect on the strength and hardness of wood samples. To do this, the authors [

48] used specimens with MC between 30% and 60% and created an innovative experimental installation with pulsed action. The results showed that MW drying could diminish the drying time of softwood species fivefold in comparison to conventional methods used during their experimental campaign. This result is in accordance with what Ouertani et al. [

2] and Oloyede and Groombridge [

12] found using different wood species. For instance, compared to Aksenov and Malyukov [

48], Oloyede and Groombridge [

12] found time reductions even greater for Caribbean pine.

It was also observed that the drying rate increases with the values of initial MC; for example, for the reduction in MC from 80% to 60%, the drying rate was 0.12%/s, whereas the rate was 0.08%/s for the reduction from 60% to 40% MC. The final MC found was on average 4.44%. Contrary to previous studies [

2,

6,

12,

13,

14,

45], the authors reported that the growth in hardness and strength of the surface of birch and aspen wood samples treated with MW represented a scientific innovation. According to these findings and the fact that both species are marginally used due to their low quality, with MW treatment, they could gain in terms of hardening, adding economic value to both species [

48].

Chotikhun et al. [

4] argued that MW treatment is a novel technique that has become more popular because it has a more homogeneous heat distribution throughout wood specimens and saves time. Thus, the authors analyzed the physical and mechanical properties of MW treated rubberwood (

Hevea brasiliensis) specimens. The authors studied samples with 20% MC at three temperatures, 150, 180, and 220 °C. As presented by Xiao et al. [

3], wood samples with MC up to 30% were prone to having these temperature profiles with MW heating. The experimental tests revealed that MOE decreased 1.05-, 1.17-, and 1.64-fold under MW treatment compared to the control group for temperatures 150, 180, and 220 °C, respectively, while MOR decreased 1.44-, 2.37-, and 3.70-fold for the same temperatures. In addition, the density of the samples decreased with temperature increase, the dimensional stability was improved, and, at the temperature of 220 °C, there was a darkening of the specimens. Regarding the microstructural changes, it was observed that the cell walls were damaged, creating cracks on the samples. Lastly, the authors [

4] stated that, compared to traditional approaches, 20 min MW treatment provided noticeable energy saving.

Weng et al. [

15] explained that the damage generated in the wood microstructure by MW treatment allows an increase in permeability so that moisture can move more rapidly during the drying process, guaranteeing that the evaporative front remains at the wood surface for an extended period and that the water gradient in the thickness direction is diminished, thereby reducing drying stress. Therefore, this study developed by Weng et al. [

15] investigated the drying parameters, namely, drying time, rate, quality, and moisture dispersion, of Chinese fir (

Cunninghamia lanceolata (Lamb.) Hook.) wood samples under MW pretreatment.

Figure 3 shows the MW equipment used by the authors [

15].

As presented by previous studies [

2,

12], Weng et al. [

15] found that MW pretreatment could improve the conventional drying rate. The authors [

15] also concluded that MW pretreatment is more efficient during the phase in which the free moisture is migrating in the wood, as stated by Studhalter et al. [

41]. The dimensional stability of MW pretreated specimens increased because the residual stress and MW deviation in thickness were noticeably reduced. Modifications in the quality of the pretreated wood specimens were not identified.

On the basis of the previously presented studies, it is possible to draw certain conclusions. Compared to the traditional wood drying process, MW drying has a homogeneous and constant energy distribution, which implies a better drying process. In addition, MW drying is more effective, with fewer defects, and it is efficient, considerably reducing the drying time. The MW parameters that influence the drying rate and quality are the frequency, power, intensity of applied load, and the time of exposure to MW energy. Shorter times generate greater changes in the wood, which lead to reductions in its mechanical properties. A higher MW power results in less energy being required to dry the wood, whereby more damage is generated in the wood microstructure, which may also influence the mechanical properties.

Table 3 shows the percentage reductions or increases in MOE and MOR, with reference to studies that investigated the effects of MW treatment on wood strength. It is necessary to highlight that, although the results can be compared and used for further studies, it is important to analyze them on a paper-by-paper basis since wood MW modification depends on factors such as wood species, initial MC, exposure time, MW power, and intensity. Negative values indicate a decrease in the property, whereas positive values indicate an increase.

Initial MC and specimen thickness impact the drying rate and sample temperature; thus, each species may react differently to each MW treatment. For instance, a higher initial MC leads to lower temperatures of the tested samples. In general, the temperature behavior of MW-treated or -modified specimens follows three steps. First, there is a rapid increase in temperature until 100 °C, with slight water loss; second, the temperature remains constant, and there is intense water evaporation; third, there is a rapid temperature increase with MC reduction. Due to its proximity to the application, the surface temperatures of samples tend to be higher.

As explained above, different MW intensities can be used. Under low intensity, few checks are originated, and there are no significant losses in mechanical properties. If the parameters used for low-intensity MW modification are adequately studied and adjusted for the different species, ideal drying can be achieved to increase the permeability without reducing the mechanical properties of the wood. On the other hand, high-intensity MW modification causes severe changes in the wood, reducing the mechanical properties.

MW energy can also be used as a pretreatment for pre-drying and wood bending. For pre-drying, MW pretreatment increases the conventional drying rate and diminishes the drying defects. For wood bending, the benefit compared to conventional wood bending methods is that MW treatment allows the manufacturing of curved elements because of the reduced time, temperature control, and sustainability and quality of the process. In this context, better softening results are achieved when the initial MC is higher.

Table 4 briefly shows, for each work analyzed, the main objectives, the type of MW, as well as its power, frequency, and applied energy, and information concerning the MW processing time or speed.

2.2. Wood Permeability and Agent Retention and Impregnation

Due to the high commercial value of larch (

Larix olgensis) wood and its difficulty in drying, as well as related problems, Hong-Hain et al. [

20] evaluated the water permeability of both MW-treated and non-MW-treated larch wood samples, analyzing their mechanical properties and microscopic changes. It was observed that the critical elements for the treatment performance were the wood’s initial MC, MW intensity, and duration of treatment, in accordance with the conclusions of Hansson and Antti [

13]. Microwave treatment of larch wood fractured some pit membranes and parenchyma, creating new channels for liquid and gas transport within the wood. MOE and MOR diminished marginally but not significantly, as compared to untreated specimens. Lastly, the authors [

20] indicated that the highest permeability and mechanical properties for larch wood treated with MW were achieved with 25% MC, with a treatment scheme of 5 kW for 30 s, a delay of 25 to 30 s to allow the temperature of the specimens to achieve equilibrium, and then 9 kW for 50 s.

In another study, Scots pine (

Pinus sylvestris) heartwood and Norway spruce (

Picea abies) were tested under various MW parameters, evaluating their effect on water penetrability and impregnation [

16]. The wood samples were subjected to different intensities and treatment times (interactions, namely, 1, 3, 4, 5, and 7 min). Treu et al. [

16] observed that both species studied experienced an enhancement in permeability, and this effect was improved by the increase in MW treatment interactions, confirming the findings of Hong-Hain et al. [

20]. The authors also observed that each species reacted differently to the MW treatment. This influence on Scots pine heartwood specimens was more prominent than for spruce woods. As the authors [

16] used MW equipment with a conveyer belt, they were able to note that a higher conveyer belt speed reduced cracking formation and did not reduce the permeability properties compared to low speed.

Torgovnikov and Vinden [

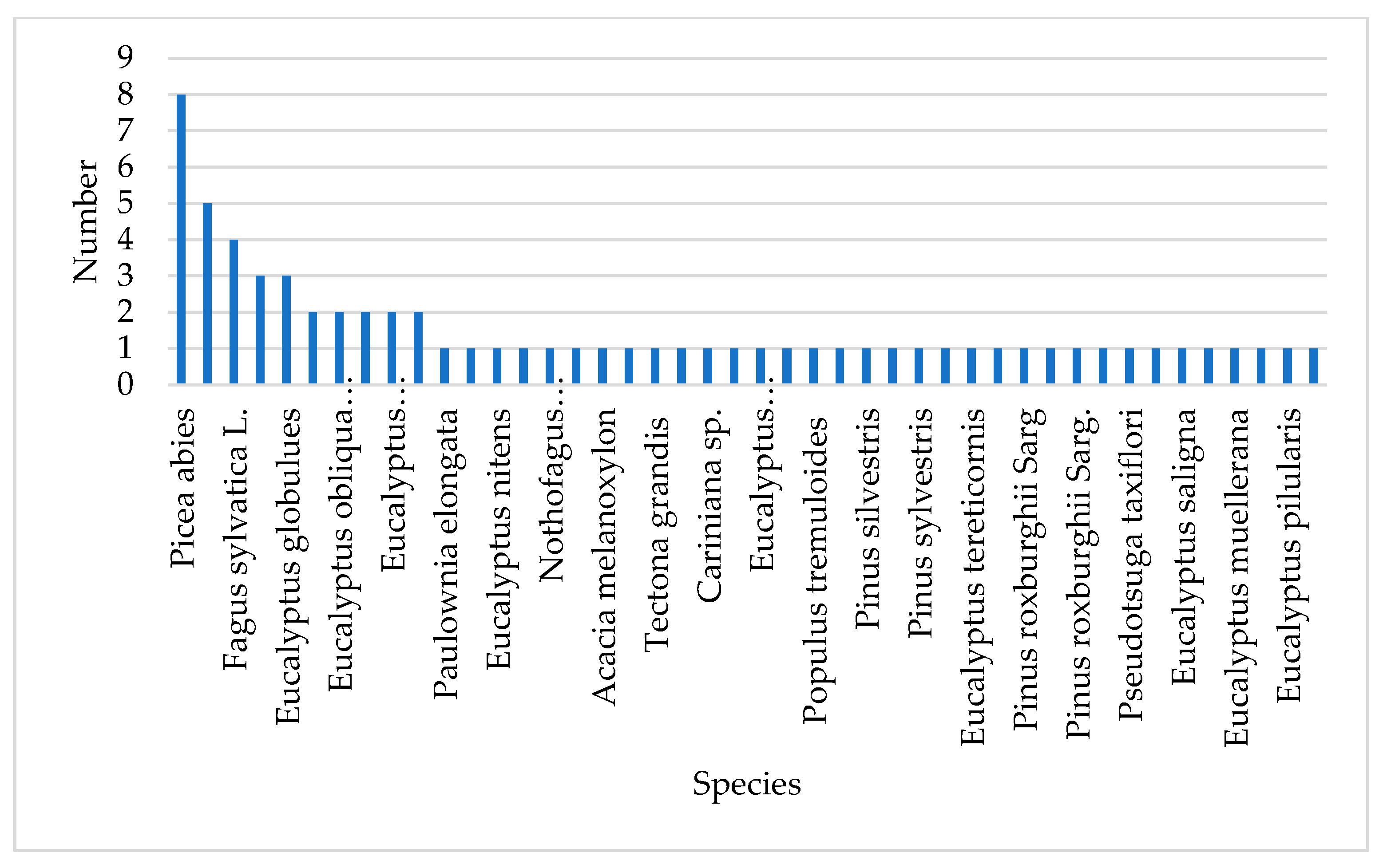

8] developed one of the most comprehensive studies of MW treatment and its effect on wood properties and structure. The authors researched the impact of MW wood treatment on wood structure and properties, the creation of MW wood treatment parameters, and potential commercial uses of modern MW technology. Sawn timber and logs samples were used, using one MW applicator only for sawn timber and another one for logs and sawn timber.

Fourteen different species were used in the study, eight of them from the

Eucalyptus genus, two

Paulownia, one

Pinus, one oak, one Douglas fir, and one Sitka spruce: radiata pine (

Pinus radiata), Douglas fir (

Pseudotsuga taxifloria), Sitka spruce (

Picea sitchensis), messmate (

Eucalyptus obliqua), mountain ash (

Eucalyptus regnans), blue gum (

Eucalyptus globulus), Sydney blue gum (

Eucalyptus saligna), shining gum (

Eucalyptus nitens), yellow stringybark (

Eucalyptus muellerana), jarrah (

Eucalyptus margina- ta), karri (

Eucalyptus diversicolor), black butt (

Eucalyptus pilularis), Paulownia (

Paulownia fortunei and

Paulownia elongata), and oak (

Quercus robur). Using the data provided by Torgovnikov and Vinden [

8],

Table 5 presents information regarding MW specifications, wood sample dimensions, and initial MC.

As shown in

Table 5, Torgovnikov and Vinden [

8] analyzed the modification of wood in three categories: (1) low degree: wood cell pore membranes were ruptured, the resin was melted and replaced in tubes, and tyloses were partially ruptured in hardwood species; (2) moderate degree: wood cell pore membranes and ray cells were ruptured, the resin was boiled and replaced, and tyloses were destroyed in hardwood species; (3) high degree: wood cell pore membranes were ruptured, the resin was boiled and replaced, and the tyloses were destroyed in hardwood species; moreover, ray cells, vessels walls, and main cells walls, such as tracheids, libriform, parenchyma, were ruptured with the formation of cavities in the radial–longitudinal direction. In addition, a frequency of 2.45 GHz was indicated for wood pieces with thickness up to 90 mm, whereas 0.922 GHz was indicated for samples with thickness up to 280 mm.

On the basis of the results, Torgovnikov and Vinden [

8] stated that, when high-intensity MW power is transferred to wet wood, it can have a major influence on the wood’s micro- and macrostructure, and distinct components of the wood structure may be broken at different rates, resulting in varying degrees of alteration. Similar to Hain et al. [

20], Torgovnikov and Vinden [

8] stated that each species reacts differently to the MW treatment, mainly depending on the MW applied energy. Even though MW-treated wood displayed an improvement in permeability for all studied samples, a higher MW intensity led to a greater gain in terms of permeability, as well as a greater reduction in mechanical properties. To illustrate,

Table 6 shows the reduction in MOE and MOR of blue gum and

Paulownia woods, both treated at a frequency of 0.922 GHz.

Torgovnikov and Vinden [

8] explained that the density may decrease according to the wood species and the MW modification intensity, as shown in

Table 7The authors [

8] summarized by stating that the major advantages of using MW treatment for commercial uses and applications are pre-drying treatment of hardwoods for faster drying, preservative treatment of refractory wood species, growth and drying stress relief in timber, acceptable costs for the wood industry, enhancement of wood pulping properties by MW treatment of sawn timber, logs, and woodchips, and the production of novel wood products, one that the authors called Torgvin, which is a very porous material after MW modification, and another called Vintorg, which is Torgvin impregnated with resin to enhance some of the physical and mechanical properties [

8].

Vinden et al. [

49] explained that hardwood timber is commonly used for railway sleepers in Australia, but one species of softwood, radiata pine, can be used instead. However, radiata pine (

Pinus radiata) heartwood has very low permeability, which is a drawback since railway sleepers need preservative treatment to last longer. Accordingly, their research had five primary objectives: (1) to experimentally study the effects of MW treatment using a four-port MW applicator on radiata pine sleepers; (2) to investigate how MW parameters influence the preservative distribution and retention, culminating with the identification of optimized MW treatment parameters; (3) to estimate the impacts on the mechanical properties of MW treatment; (4) to analyze the preservative impregnation parameters necessary to have optimum retention by the railway sleepers; (5) to propose technical references for MW treatment and technology to be used for railway sleepers.

Vinden et al. [

49] used logs with an average percentage of 60% to 70% of heartwood. Due to the rupture of some wood cells, there was a reduction in wood mechanical resistance, similar to that shown by Torgovnikov and Vinden [

8]. According to the results, using MW power of 60 kW with samples at 17% MC led to an MOE equal to 8.1 GPa and MOR equal to 31.9 MPa. The authors [

49] pointed out that those values are within those allowed for railway sleepers. Additionally, for the studied species, the specific applied MW energy could range from 75 to 110 kWh/m

3 without causing damage to the sleepers using green density samples with 600 and 800 kg/m

3. Those specimens with larger amounts of heartwood presented significant enhancements in permeability and preservative retention. On the basis of these outcomes, the authors proposed and designed a 400 kW commercial MW plant that could process 100,000 sleepers annually; according to them, the costs for treating the railway sleepers would be affordable for the industry.

He et al. [

50] researched how MC, MW intensity, and exposure time modified the liquid permeability of Chinese fir (

Cunninghamia lanceolata) wood without considerably compromising the mechanical properties. The study revealed that an MW intensity of 20 kW, with 60 s of processing time and MC varying from 40% to 60%, promoted an enhancement in liquid permeability without a noticeable drawback in the mechanical properties. Equally important, it was found that the microstructural modifications, such as the destruction of pit membranes, as well as micro-checks in the longitudinal tracheids and the intercellular layer of ray cells, played an essential role in the permeability increase. The mercury intrusion porosimetry (MIP) test results demonstrated that the pore diameter range was enlarged, and new pores were generated.

He et al. [

50] also concluded that the MC had no relevant impact on the MOE and MOR of the studied specimens of Chinese fir wood. The processing times of 30 and 60 s that the researchers used did not influence MOE; only the time of 90 s showed a noticeable difference compared to the control group. As shown in

Table 8, the MW intensity variation had no considerable effect on those mechanical properties, whose presented values were statistically similar, and these findings agree with those of Hong-Hain et al. [

20]. On the other hand, there were significant MOE and MOR reductions in the studies carried out by Torgovnikov and Vinden [

8] of wood samples under high-intensity MW treatment.

MW-treated beech wood (

Fagus sylvatica L.) was analyzed regarding axial permeability for distilled water [

51]. Nasswettrová et al. [

51] used the sample’s initial MC above the fiber saturation point and two different MW exposure times (two different groups), the first for 240 s, followed by 60 s of relaxation, and the second for 120 s, followed by 120 s of relaxation. On the basis of the results, the authors stated that the mean coefficient of permeability for distilled water for specimens processed with MW energy was greater than the control group samples (without MW treatment). In addition, the permeabilities of groups 1 and 2 were, respectively, 2.3- and 2.8-fold higher than the control one. Similar to He et al. [

50], Nasswettrová et al. [

51] confirmed that higher initial MC positively impacts permeability.

Assuming that, at high degrees of MW treatment, wood becomes a highly porous material, as shown by Torgovnikov and Vinden [

8,

21], Torgovnikov et al. [

52] developed an investigation aiming to analyze the impacts of MW treatment on the microstructure and properties of blue gum (

Eucalyptus globulues) wood and to determine the characterization of the MW-modified wood samples following metal alloy impregnation. The authors used the terms Torgvin and Vintorg, in which Torgvin refers to the highly porous wood after MW treatment, and Vintorg is the wood composite material made from Torgvin. The same nomenclature was used by Torgovnikov and Vinden [

8,

21]. The initial MC of the MW-treated wood samples ranged from 78% to 108%, and a metal alloy (Company Belmont alloy No. 2431, bismuth/lead/tin/cadmium) was used for the impregnation.

First, Torgovnikov et al. [

52] analyzed the Torgvin wood element structure and identified severe damage to wood cells, specifically, destruction of tyloses, rupture of libriform fiber walls, ray cells, vessels, and wood pore membranes, and the generation of voids in the radial–longitudinal plane. Voids with less than 1.0 mm width accounted for 96% of the total, those with less than 10 mm length in the radial direction accounted for 93% of the total, and those with less than 20 mm length in the longitudinal direction accounted for 76% of the total. The MW intensity of 990 MJ/m

3 caused significant reductions in MOR and MOE, as shown in

Table 9. The authors explained that the more noticeable decrease in strength values in the tangential direction in relation to the radial one was due to the formation of radial–longitudinal cavities.

With respect to the Vintorg material, Torgovnikov et al. [

52] explained that the metal alloy used penetrated the wood voids, cracks, and ruptured cells. At 8% to 12% MC, nontreated samples of blue gum had an average density of 697 kg/m

3. On the other hand, the blue gum manufactured wood had 637 kg/m

3 average density, highlighting that the density reduction depends on the wood species and degree of MW treatment. The average density was enhanced, achieving 3275 kg/m

3, which could be explained by the occupation of the metal alloy (density of 7400 kg/m

3) in the created voids. The strength properties also increased compared to both nontreated and Torgvin types of wood, as shown in

Table 10.

Torgovnikov et al. [

52] concluded by stating that this new wood composite material, Vintorg, has novel properties compared to nontreated wood, such as elevated density, excellent thermal and electroconductivity, and different swelling and shrinkage properties, which enable a variety of possible uses and applications. However, they suggested that further studies and analyses with different wood species and impregnation agents are necessary.

In accordance with Torgovnikov et al. [

52], Xu et al. [

53] commented that the upgraded transverse permeability due to MW pretreatment leading to subsequent impregnation is not clearly identified. Thus, the authors analyzed the influence of impregnating the plantation poplar wood (

Populus deltoides), with an initial MC of 56%, using phenol–formaldehyde resin with a low molecular weight. The results supported the authors’ hypothesis that, by using a suitable MW pretreatment, the radial and longitudinal wood permeability could be significantly improved, due to the breakup of the wood ray cells and cell pore membranes. The average density of samples impregnated at 0.9 MPa for 1.5 h was 46.5% higher than that of the nontreated samples. In addition, it was observed that the resin had a consistent distribution in the intercellular spaces, vessel elements, and the wood fiber’s lumens, as also observed by Torgovnikov et al. [

52]. Lastly, the present study indicated that the wood-based composites analyzed may be employed for indoor and outdoor decoration, as well as for the manufacture of high-quality furniture.

Because studies have indicated that MW treatment can improve wood permeability, drying efficiency, hardwood drying rate, and the manufacture of new wood composite products [

18], Kumar et al. [

18] used MW treatment to increase the air permeability and preservative retention of chir pine (

Pinus roxburghii) wood heartwood. Their study demonstrated that the heartwood samples treated with MW increased air permeability and preservative uptake remarkably, as shown in

Table 11. The authors [

18] stated that this technology can be validated and applied on a small scale to see if it has promise in the wood preservation industry for improving wood permeability and shortening treatment times.

Hermoso and Vega [

7] investigated various MW treatment energies to increase the permeability in

Eucalyptus globulus heartwood, a refractory species, while also assessing the effect on mechanical properties. Samples with an initial MC of 12% and higher than 30% were used. The results demonstrated an improvement of 89.98% in uptake and of 88.24% in retention of 2% water-soluble solution salts TANALITH E, considering 12% MC, in accordance with the results obtained by Kumar et al. [

18]. With respect to 30% MC, the uptake increase was 148.66%, and the retention was 147.06%.

The results also showed that the volume of MW energy transmitted has a substantial impact on stiffness, and this influence was more evident in specimens with an MC of 12% [

7], since samples with higher MC, during the same period of exposure to MW, tend to use the MW energy to evaporate the water without achieving high internal temperatures, as shown by Xiao et al. [

3].

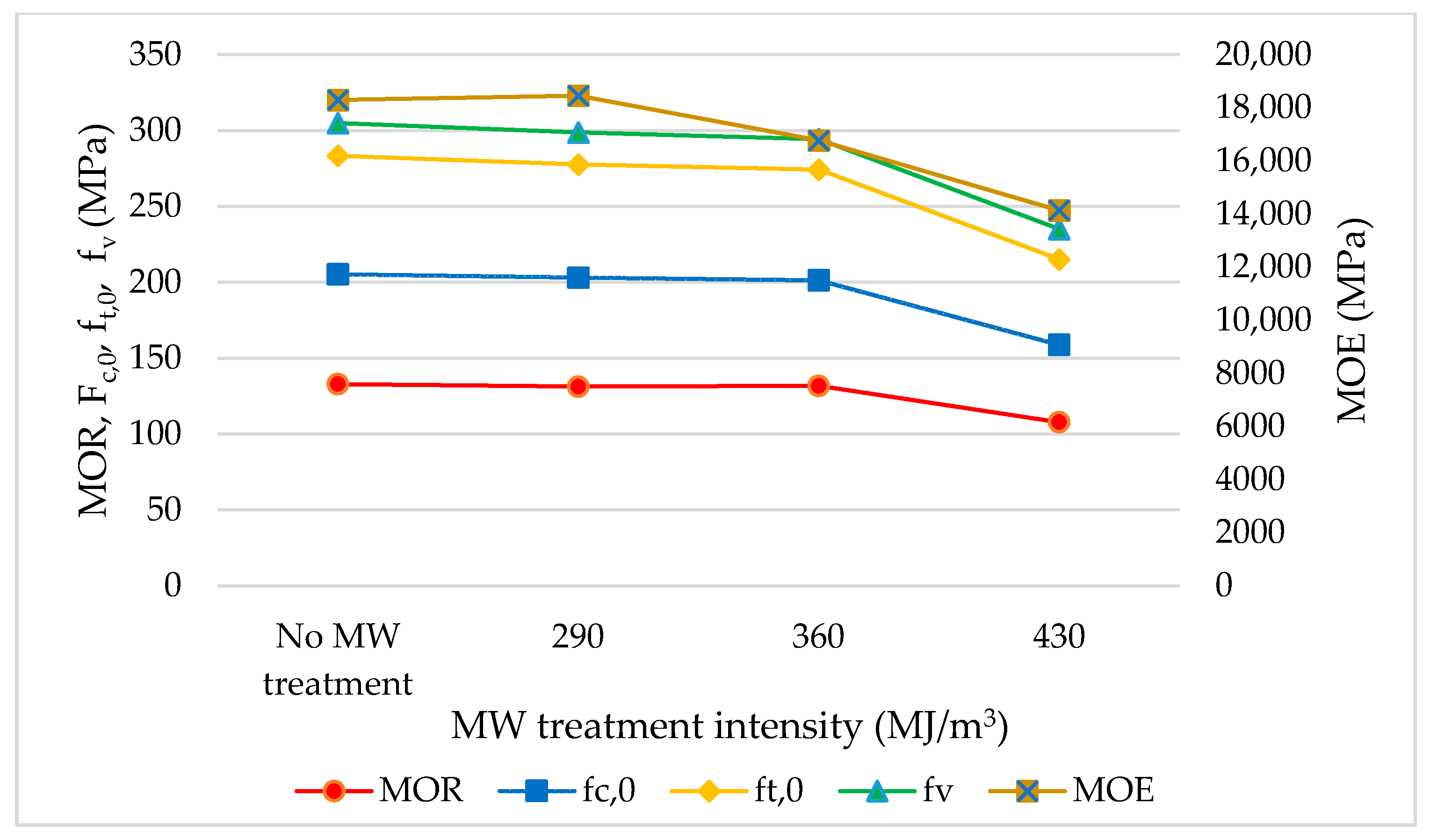

The authors [

7] also found that, in low-intensity MW treatment (290 MJ/m

3), either with 12% or 30% initial MC, the MOE, MOR, shear (f

v), compressive (f

c,0), and tension (f

t,0) parallel to grain strengths were statistically equivalent to the control group with no MW treatment, which is in accordance with Balboni et al. [

14].

Figure 4 and

Figure 5 show the mechanical resistance values for 12% and 30% MC, respectively.

Hermoso and Vega [

7] also stated that the highest temperatures were obtained with 12% MC. Compared to the control group samples, the MW treatment of

Eucalyptus globulus heartwood with 430 MJ/m

3 demonstrated the most significant improvement in impregnation (2.28-fold greater) and retention (2.50-fold higher). Lastly, the results suggested that the energy spectrum of 360 to 430 MJ/m

3 offers a balance between enhancing impregnability and maintaining wood mechanical properties [

7].

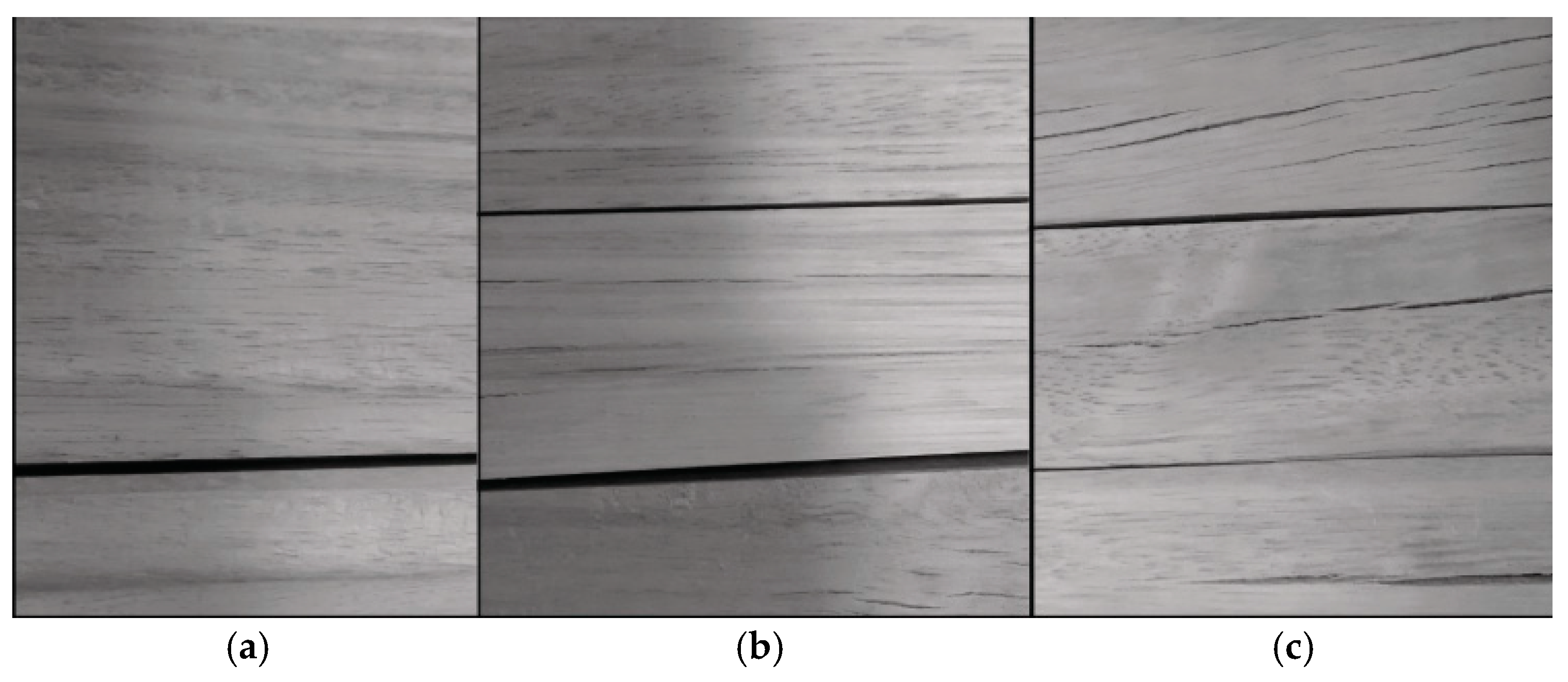

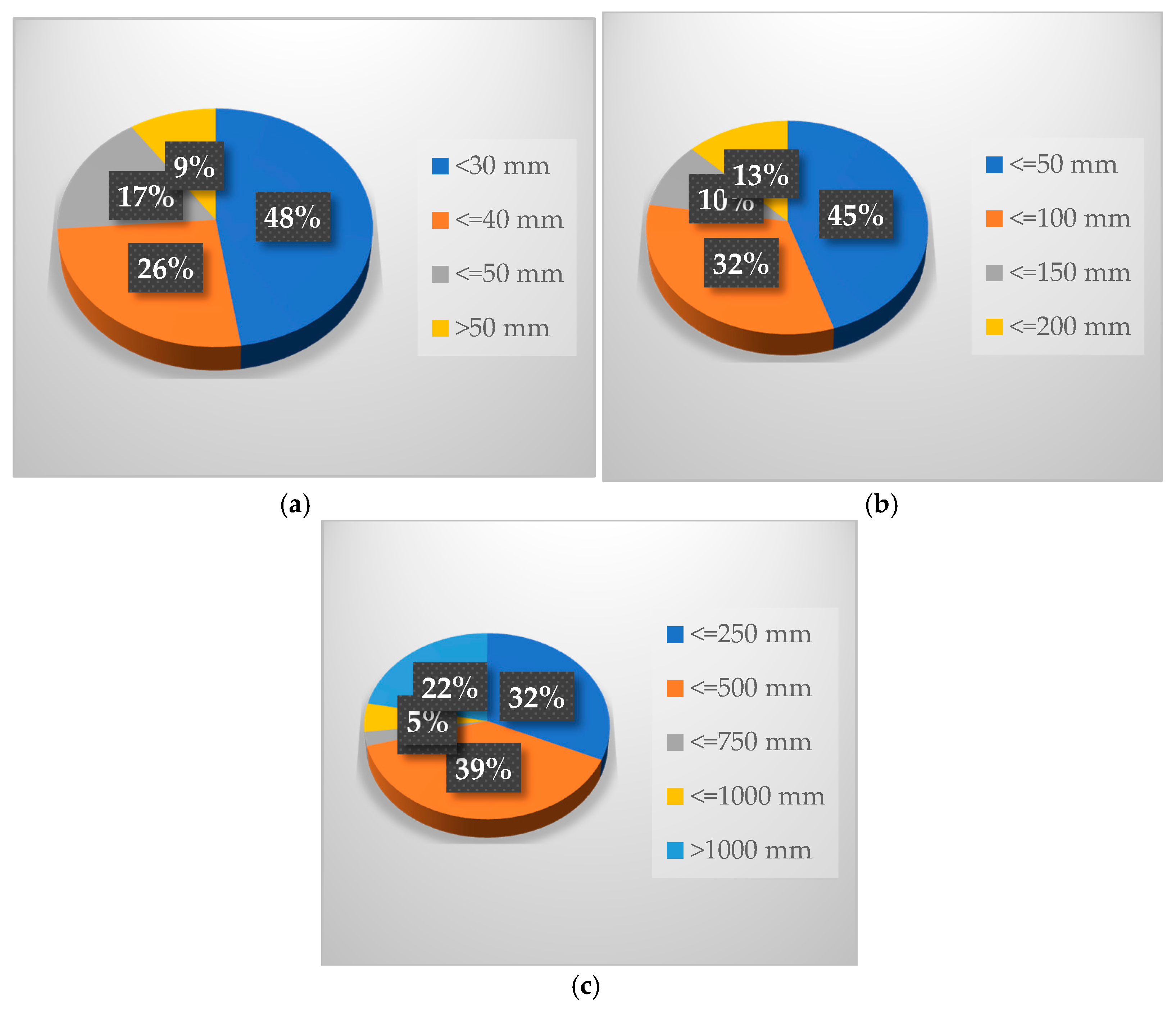

Figure 6 shows the surface appearance of MW-treated wood samples under three intensities: (a) 290 MJ/m

3, (b) 360 MJ/m

3, and (c) 430 MJ/m

3.

The pH is a relevant factor for wood elements because acid wood can cause corrosion in steel connections, for example, in fasteners and nails [

54]. From that perspective, Poonia and Tripathi [

54] investigated the effects of MW treatment for 3 and 5 min on preservative uptake, pH modification, and durability against termites in samples of

Eucalyptus tereticornis wood. Four MW intensities were used (lower and higher), and, under lower intensity (95.57 W/cm

2) for 3 min, no cracks or checks were found on the specimens. However, under higher intensity (143.35 W/cm

2) and time (5 min), both cracks and checks were observed. Controls samples had a pH equal to 3.9; however, as the treatment intensity and time increased, the pH decreased. For instance, under the highest MW intensity (143.35 W/cm

2) for 5 min, the pH of the samples was equal to 3.2. Bahmani et al. [

55] pointed out that an acid environment is favorable for wood durability against fungi and insects. The preservative retention improved with the intensification of MW treatment and time [

54], as shown in previous studies [

7,

8,

16,

18,

52], but termite resistance was not altered. Nevertheless, if there was a combination of MW treatment and copper chromate preservative, the authors stated that the termite resistance was higher [

54].

He et al. [

56] claimed that it has not been established yet how MW treatment parameters, such as initial MC and processing time, affect the drying and permeability features. Hence, their study aimed to understand clearly how the drying and the transverse and longitudinal permeability of

Eucalyptus urophylla is affected by the initial MC, MW power, and exposure time. They also intended to establish a primary relationship for submitting wood-based composite materials to MW treatment. It was found that MW treatment was noticeably responsible for increasing the wood samples’ transverse and longitudinal permeability. As found in previously described studies [

12,

13,

14,

37], this study proved that MW treatment effectively decreased the drying time, and that the drying quality was not affected.

Furthermore, the increase in MW power and exposure time also improved the permeability, while a smaller initial MC led to a higher permeability [

56]. Xiao et al. [

3] explained that there is a rapid increase in temperature in samples with smaller initial MC, generating more steam pressure, which is the main factor responsible for increasing the permeability [

8]. In addition, the drying rate of MW-treated samples was enhanced by 171% and the drying time decreased by 65% compared to nontreated samples, while the transverse and longitudinal permeability increased by 58% and 135%, respectively, compared to nontreated specimens. Moreover, using a

Eucalyptus species, Hermoso and Vega [

7] obtained similar results for improvement in permeability. The authors [

56] suggested that favorable circumstances for manufacturing high-value-added usable wood-based composites materials are feasible according to these results.

Pinus roxburghii wood was studied to determine the pH and the termite resistance of samples after MW treatment using four different intensities for 5 min [

57]. Poonia and Tripathi [

57] remarked that no cracks or checks were found in the MW-treated samples. The MC content of the samples diminished as the MW intensity increased. For instance, under the highest intensity, samples with an initial MC of 40.60% decreased by 14%. As described by Poonia and Tripathi [

54], under the maximum MW intensity, the pH decreased from 4.6 to 3.9. Lastly, an enhancement in preservative retention was observed, but the termite resistance was not affected by the MW treatment under any intensity. The same results for termite resistance were found by Poonia and Tripathi [

54] using

Eucalyptus species.

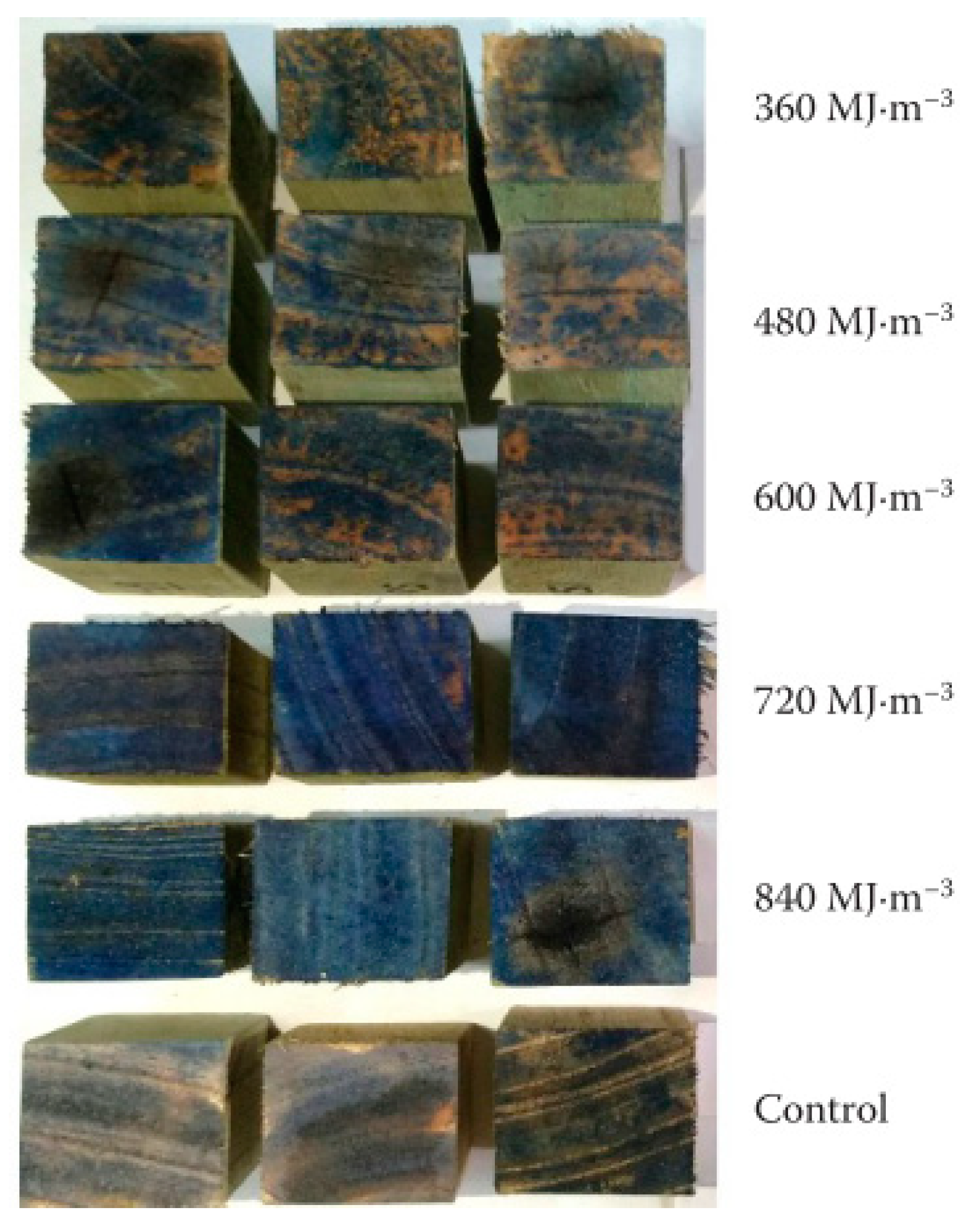

Preserving a wood element means eliminating its replacement or doing so as little as possible [

58]. However, this is not easy to do; hence, this is an issue that causes concern because the scarcity of species with good natural durability has caused an increase in the use of less durable species. Therefore, these species require preservative treatment, which can be more complex in species with low permeability [

58]. Therefore, Samani et al. [

58] treated

Melia composita wood samples under different intensities in order to analyze the microstructure modification and the permeability changes using different preservative treatments, namely, 6% solution of copper/zinc borate (ZiBOC), borax boric acid, copper chrome arsenate (CCA), and copper chrome boron (CCB) for 24 h immersion. The tests showed a substantial increase in the uptake of preservative agents compared to nontreated samples, highlighting an MW intensity of 840 MJ/m

3 as that which most improved the retention.

Figure 7 shows the samples under different MW intensities impregnated with CCA. The anatomical assessment showed that the vessel diameters increased and damaged cells, contributing to permeability increases and preservative uptake. Lastly, as shown by Vinden et al. [

49], the results found by Samani et al. [

58] indicate an important path to be followed in the MW treatment of refractory species so that other species may be experimentally tested to expand and validate the possible commercial and industrial applications of this technology.

Once high-intensity MW treatment is applied to the wood, it boils the water and creates steam pressure, which causes damage and leads to the rupture of wood cells, vessels, and microstructures, thereby enhancing gas and liquid permeability [

8]. Thus, the physical and mechanical properties of woods may diminish [

33], which, in some situations, can be an advantage, as highlighted by Peres et al. [

46]. Terziev et al. [

33] explained that, in certain situations, MW treatment led to temperatures around 160 °C, in agreement with other studies [

3,

4]. Accordingly, the authors [

33] intended to show the changes in micro- and ultrastructure levels of Norway spruce and radiata pine wood using two MW frequencies, 0.922 and 2.45 GHz.

For both wood species samples, permeability was doubled compared to nontreated samples, and this was due to the high-intensity MW treatment that caused severe damage in pit membranes, ray cells, and middle lamellae of the cell wall, as could be seen in the surface and internal cracks [

33]. The temperature in and microwave heating of lignin and hemicelluloses are expected to influence the dissolution and bond degradation between cellulose and lignin, as well as between cellulose and hemicelluloses. Lastly, the authors noted that recognizing how MW treatment impacts wood microstructure can create prospects for expanding and increasing the use of this innovative technology [

33].

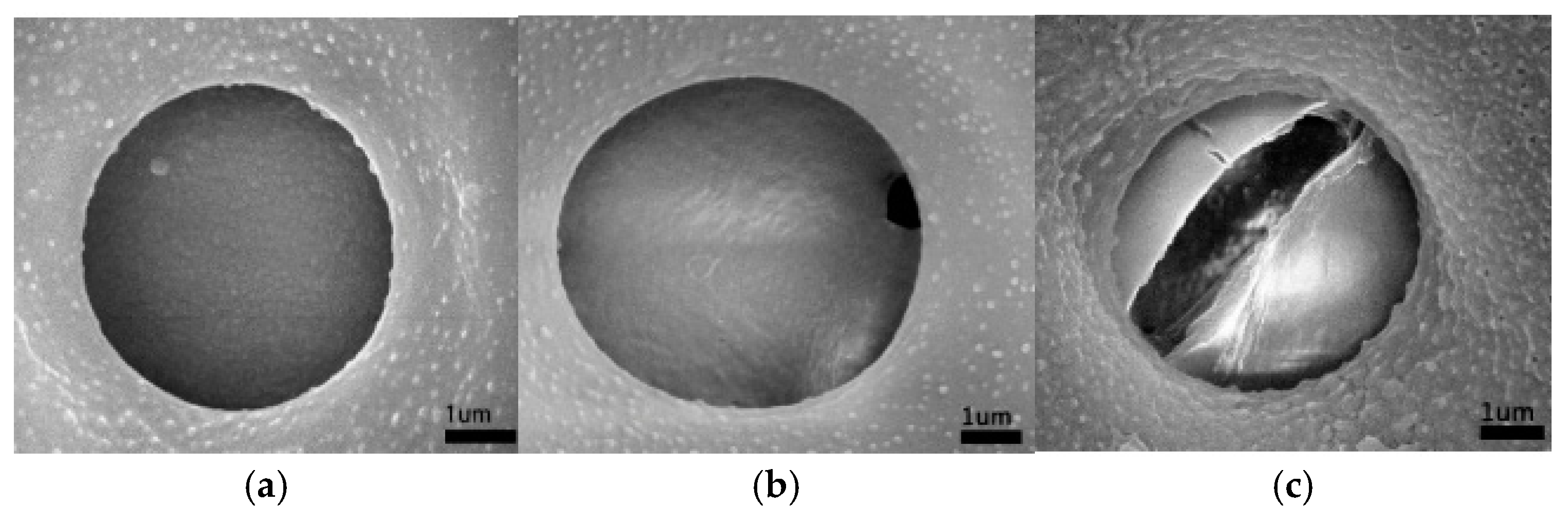

Weng et al. [

19] investigated the microstructural modifications and pore size distribution of Chinese fir (

Cunninghamia lanceolata) lumber under two MW intensities (low and high intensity), aiming to provide further academic background for using MW treatment to improve wood permeability. As proposed by other authors, it was found that, under low MW intensity, the damage is not prominent, observed as the beginning of the deterioration of pit membranes and the appearance of micro-cracks, whose range was 1–25 μm. The micro-fibrils on the margo of the pit membranes were broken, while the torus continued unchanged. Once high MW treatment was applied, the damage became more evident and acute, with larger cracks in the torus, ranging from 100–130 μm. The results also revealed a rupture of the middle lamella between longitudinal tracheids and ray parenchyma cells, as shown in

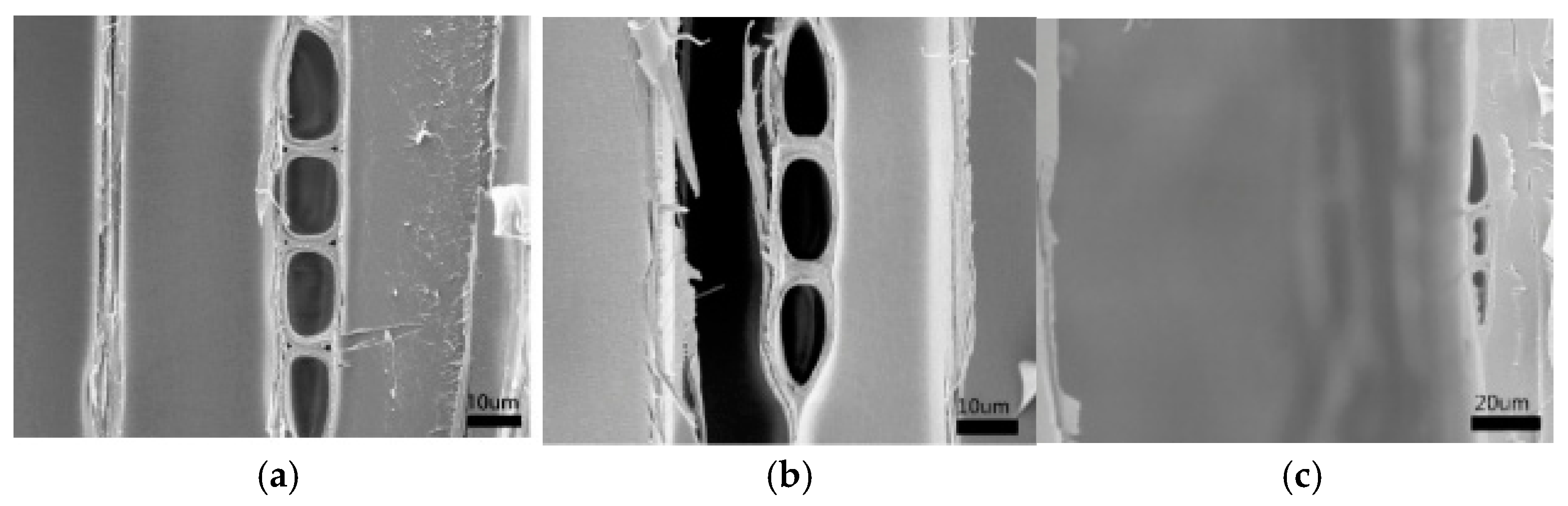

Figure 8.

New pathways for the fluid commute were identified due to the enlargement of pore dimensions (as indicated by Samani et al. [

58]). The diameter dropped from 647.7 nm to 831.8 nm for low intensity, whereas, for high intensity, it increased to 1047.6 nm. This cell damage, associated with the creation of macro-cracks and the rise in pore diameter, generated favorable conditions for moisture commute, thus enhancing the radial, tangential, and longitudinal permeability of Chinese fir wood.

Figure 9 shows the SEM micrographs of cracks between ray parenchyma cells and longitudinal tracheids for different MW treatments. Lastly, the authors reported that all these microstructural modifications may negatively affect the physical and mechanical properties of the studied wood, a finding which was shown in previous studies using different wood species [

19].

Ganguly et al. [

59] explained that wood modification has recently become the most searched-for technology in the fields of wood science and technology, as the global supply of durable wood species has forced the wood industry and consumers to seek out nondurable species (a point of view also presented by Samani et al. [

58]). Hence, the authors [

59] investigated the effect of MW modification on the treatability, preservative uptake of 2% copper chrome borate, and anatomical properties of yellow poplar (

Liriodendron tulipifera) and

Tectona grandis wood specimens. From the results, the authors proposed that MW treatment can be used to enhance the permeability and treatability of various refractory and nondurable wood species, decreasing their constant replacement during their service life. MW treatment is time-saving, representing a reduction in energy consumption, in addition to being economically affordable. With respect to the wood samples, preservative agent retention increased about 5–6-fold for both species, compared to non-MW-treated samples. Concerning the anatomical modifications, similar to findings presented by previous studies [

19], it was found that the pore diameters increased with the rupture of wood cells, leading to the formation of microcracks and checks, which could reduce the mechanical properties.

Poonia et al. [

60] investigated the impacts of MW treatment on bamboo (

Bambusa vulgaris Schrad.) specimens to identify their viability for treating wood-decaying fungi, namely, white rot (

Trametes versicolor) and brown rot (

Rhodonia placenta) fungi. Three exposure times were used, 60, 120, and 180 s. The results indicated that the control samples experienced a greater weight loss in both types of fungi, an average of 47.88%, while under 60, 120, and 180 s of MW treatment, the weight losses averaged 30.27%, 17.21%, and 8.28%. These data show that the fungus viability diminished with the increase in processing time. Thus, the authors suggested that MW technology can be used for fungal control.

To investigate the effects of MW treatment on the microstructure of

Picea abies (L.) Karst wood samples, analyze the volume of their pores, and establish an efficient MW treatment (in terms of MW energy) with the least damage possible in the wood microstructure, Ganguly et al. [

61] carried out experimental tests on the heartwood and sapwood of wood samples. Two MW intensities were used, moderate (700 MJ/m

3) and high (1260 MJ/m

3). Results showed that the volume of pores was enhanced by increasing the MW intensity; thus, this might contribute to increasing wood permeability, for example, facilitating the uptake of preservative agents. However, the authors explained that the mechanical properties may be negatively affected, as shown in [

4,

7,

14],

Using SEM images and light microscopy, Ganguly et al. [

61] analyzed the anatomical structure of specimens, visualizing the damage in the anatomical structure of Norway spruce. The samples treated under both intensities exhibited delamination between the walls of the cells and distortions in the tissues of earlywood of heartwood specimens. In the comparison of MW treatment on the heartwood and sapwood of Norway spruce samples, it was found that each was affected differently. The heartwood of spruce suffered more than sapwood due to MW energy, mainly under high intensity. Tracheids of samples under high intensity collapsed in earlywood for both heartwood and sapwood spruce. Under the same conditions, the tracheids of the sapwood of spruce were partially damaged in latewood, while the heartwood of spruce exhibited middle lamella detachment between latewood tracheids [

61].

Ganguly et al. [

61] concluded that the sapwood of Norway spruce under moderate and high MW intensity could be used without generating serious damage to the wood structure. On the other hand, heartwood under high intensity experienced severe anatomical issues; thus, it was not recommended. Lastly, the authors stated that these results might contribute to the development and best use of MW technology for wood treatment and modification.

Kol and Çayır [

62] studied how the MW parameters of power (925 and 1850 W) and intensity (1156 and 1542 MJ/m

3), as well as the initial MC (55 and 83%) of samples, affect the mechanical properties and impregnability of Oriental spruce (

Picea orientalis (L.) Link) wood in terms of MW pretreatment. On the basis of the results, the authors concluded that there was an increase in percentual loss of weight after the MW pretreatment (

Table 12). Using the commercial wood preservative Tanalith-E 8000 (Lonza Wood Protection, Alpharetta, GA, USA), an improvement was found in the retention capacity of the wood samples, as shown in

Table 12. This can be explained by the damage caused in the wood structure due to the steam pressure, which ruptured the aspiration of bordered pits, while micro and macro checks were practically not formed. Because the initial MC of the samples used was above the FSP, the authors also explained that most MW energy was used to evaporate the free water instead of the water in the wood cells. The same results were shown by Studhalter et al. [

41] using a

Eucalyptus species.

In terms of mechanical properties, namely, compression parallel to the grain, MOE, and MOR, significate changes were not identified (

Table 13). The authors [

62] stated that this was due to the optimum MW parameters used.

In light of the research papers presented here and their respective results, conclusions can be stated. MW treatment has a significant impact on the longitudinal and transverse permeability of the wood, i.e., for the various wood species studied, there was an enhancement in liquid and gas permeability and good retention and uptake of preservative agents. Refractory species display a considerable growth in permeability. Depending on the MW intensity, more steam pressure is generated, which can cause severe damage to the cells and microstructures of the wood. Due to the steam pressure, pit membranes, parenchyma cells, and ray cells are ruptured, and new voids are created, contributing to an increase in the diameter of existent pores and the formation of new ones. Furthermore, depending on the MW energy and achieved temperature, the lignin and hemicellulose can be dissolved. Hence, all these phenomena establish novel pathways for fluids.

In addition to each wood species reacting differently to each MW treatment, the initial MC, MW intensity, and duration of the treatment influence how intense the modification and the micro- and macrostructural changes are. For instance, higher initial MC in wood samples is favorable for the improvement in permeability without causing an undesirable reduction in strength properties. Moreover, reduced times can cause fewer defects in the wood, but can also dimmish the permeability improvement. Concerning MW intensity, a greater value intensifies the structural modification of wood and increases permeability.

In addition, the combination of longer exposure times and higher MW intensity may reduce the pH in the wood, which can provide protection against the attack of certain biological agents. Studies have also shown that, while termite resistance is unchanged by MW treatment, fungal attacks can be reduced. Density is another factor that may be reduced depending on the wood species and MW intensity.

Using low-intensity MW treatment could increase permeability without compromising mechanical properties, namely, MOE, MOR, f

c,0, f

t,0, and f

v. That said, high-intensity MW treatment led to reduced mechanical properties, creating an extremely porous wood.

Table 14 presents the percentage variations in MOE and MOR according to those papers whose objective was to use MW energy to increase permeability and investigate the mechanical properties of wood specimens. As stated for

Table 3, although the results can be compared and used for further studies, it is necessary to analyze them on a paper-by-paper basis since wood MW modification depends on the wood species, initial MC, exposure time, MW power, and intensity. Negative values indicate a reduction in the property, whereas positive ones indicate an increase.

Highly porous wood samples may have further applications, for example, for indoor and outdoor wood elements. It is possible to impregnate such wood with resins and produce high-quality and value-added wood-based materials with satisfactory and favorable mechanical properties. The density of this new material depends on the resin used; additionally, improvements in thermal and electrical conductivity and dimensional stability can be seen, depending on the resin’s physical and mechanical properties.

Table 15 summarizes the key goals, wood species, MW type, power, frequency, applied energy, and processing time or speed for the previously analyzed studies.