Change in Micromechanical Behavior of Surface Densified Wood Cell Walls in Response to Superheated Steam Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

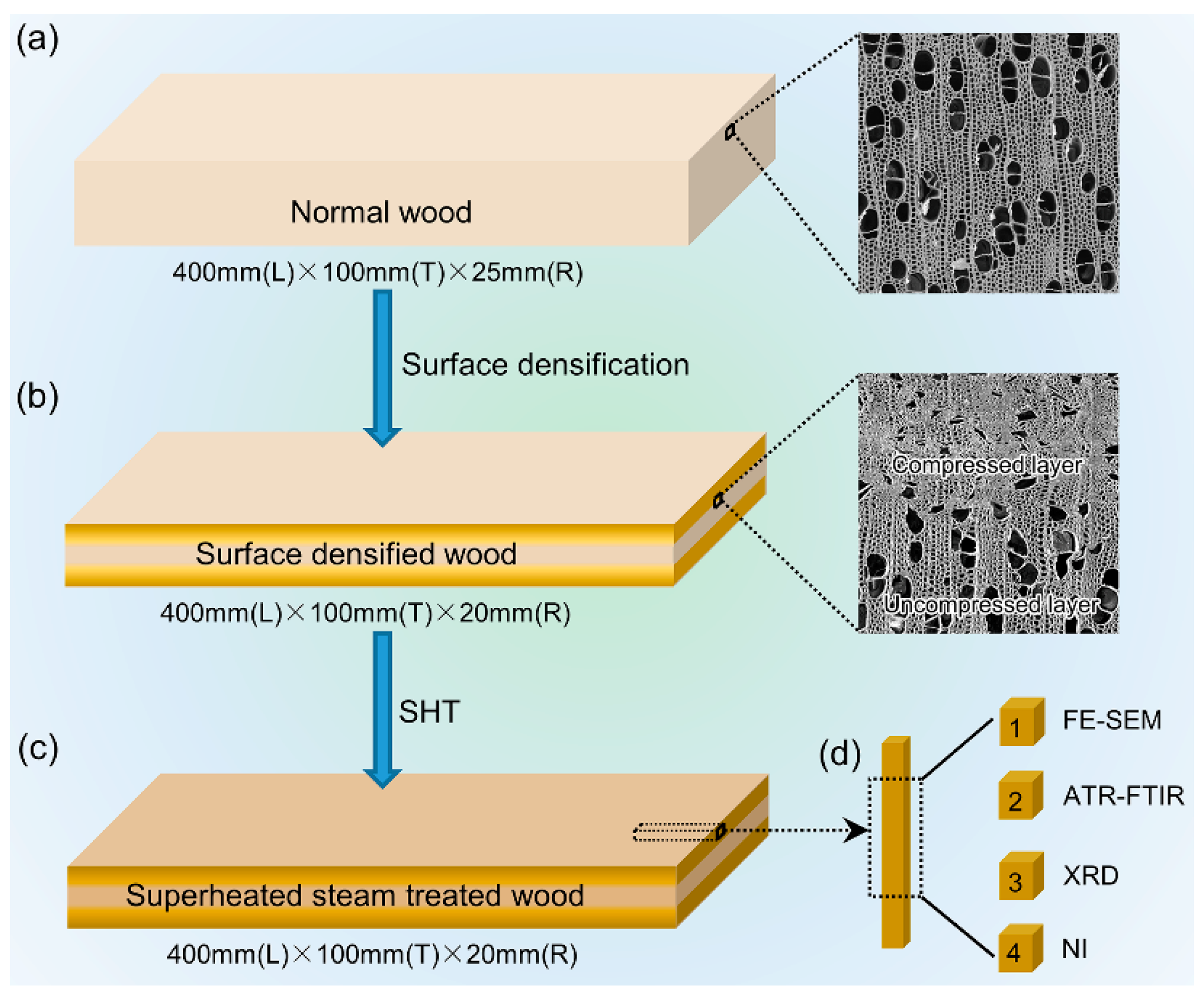

2.2. Surface Densification and Superheated Steam Treatment (SHT) Process

2.3. SEM Observation

2.4. XRD Analysis

2.5. ATR-FTIR Analysis

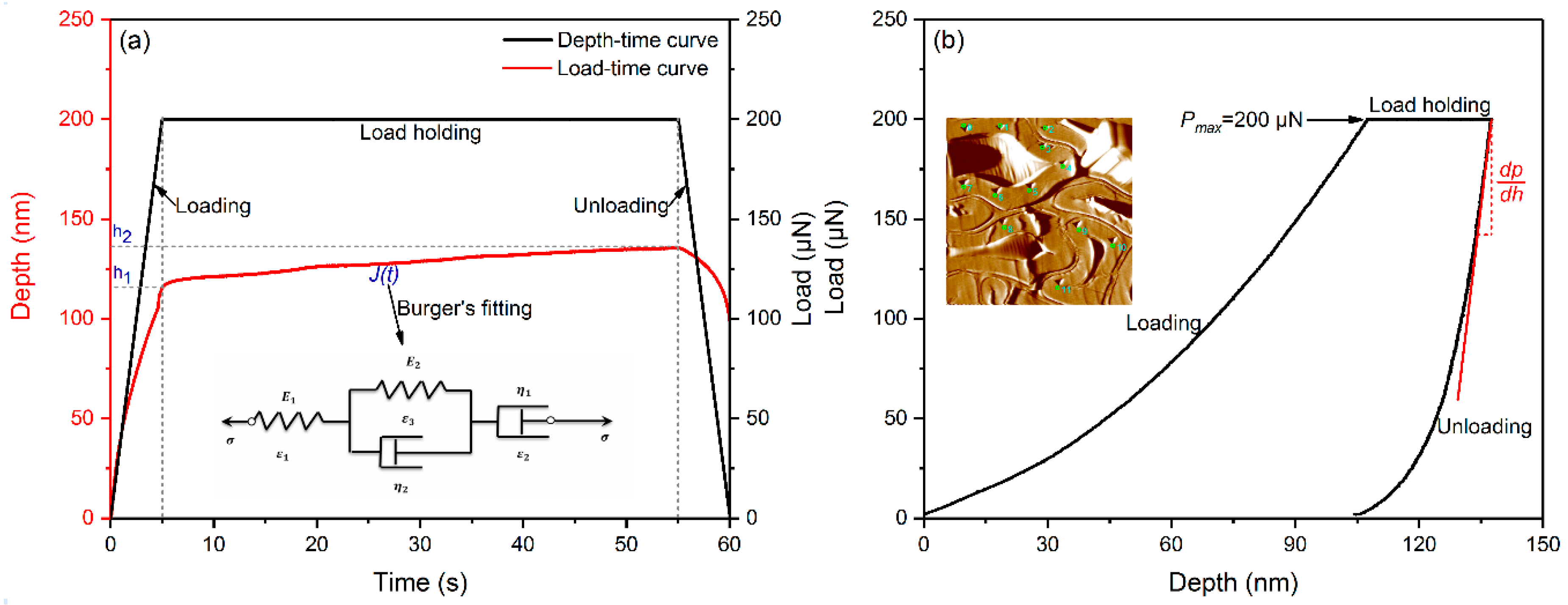

2.6. NI Test

2.7. Statistical Analysis

3. Results and Discussion

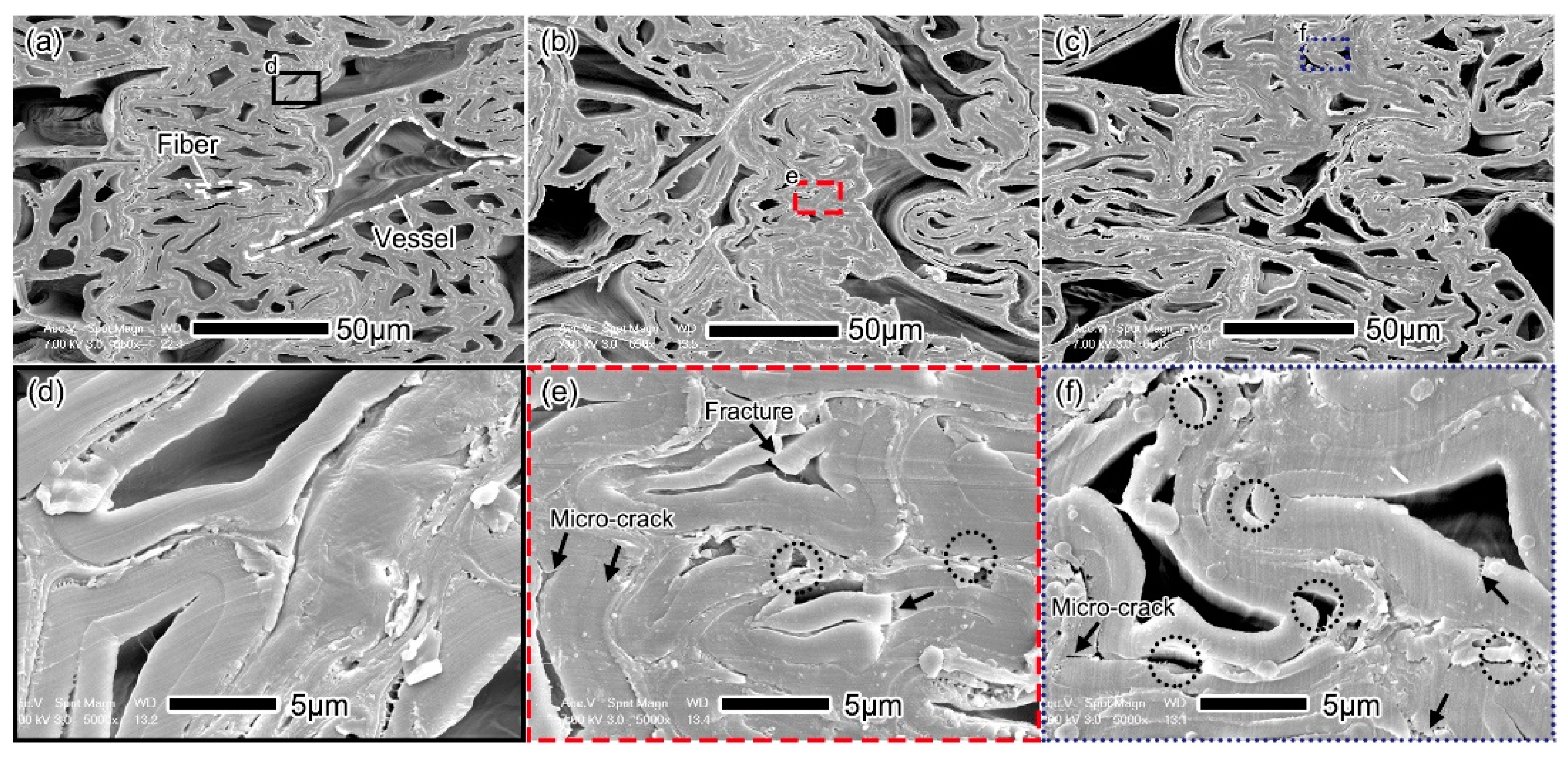

3.1. Microstructure of Cell Wall

3.2. Chemical Composition

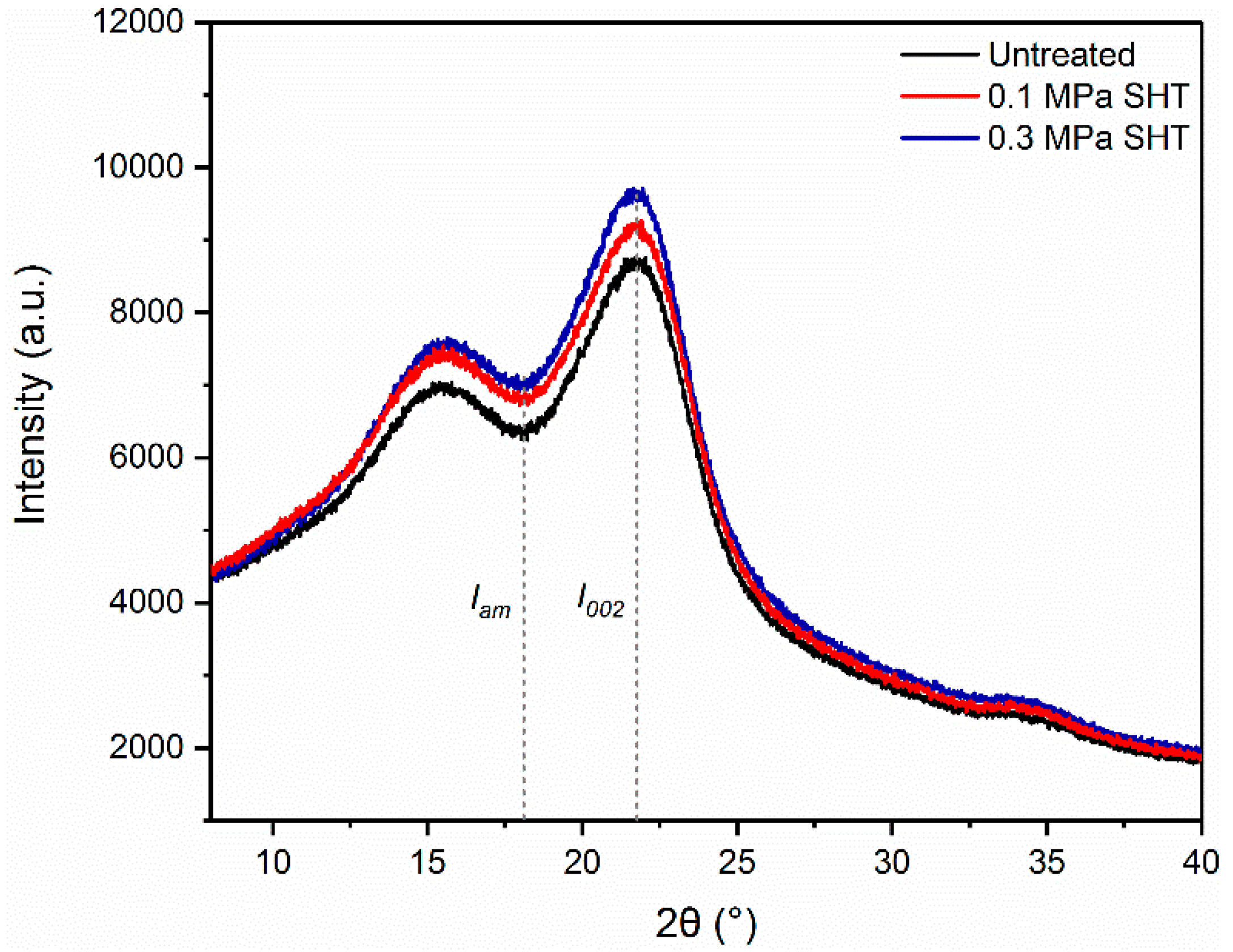

3.3. Cellulose Crystalline Structure

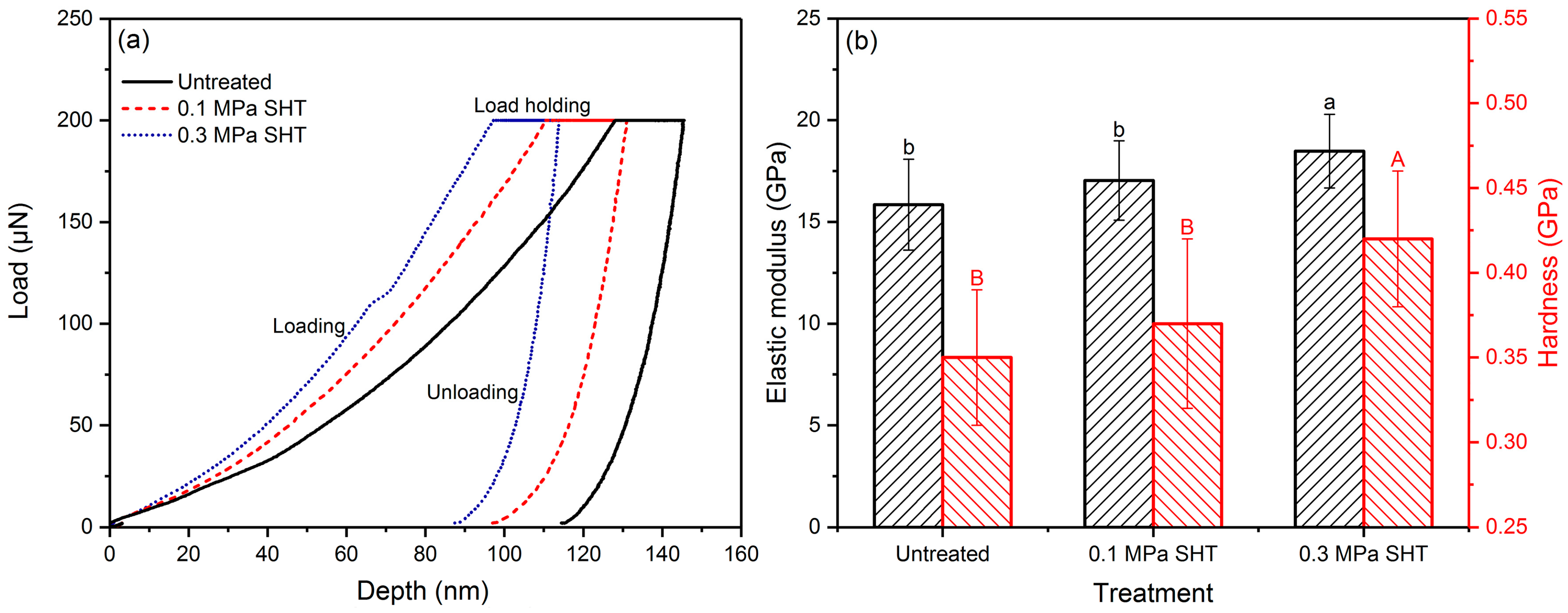

3.4. Elastic Modulus and Hardness of Cell Wall

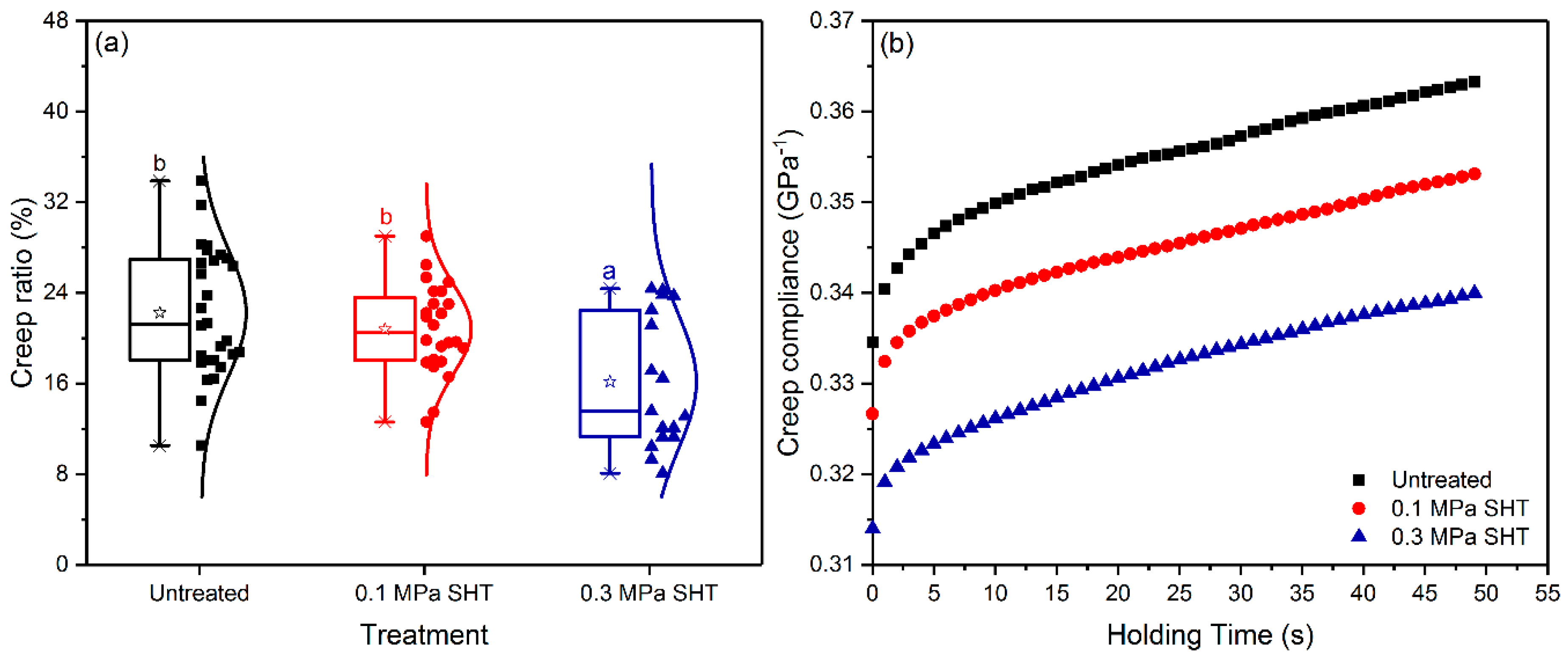

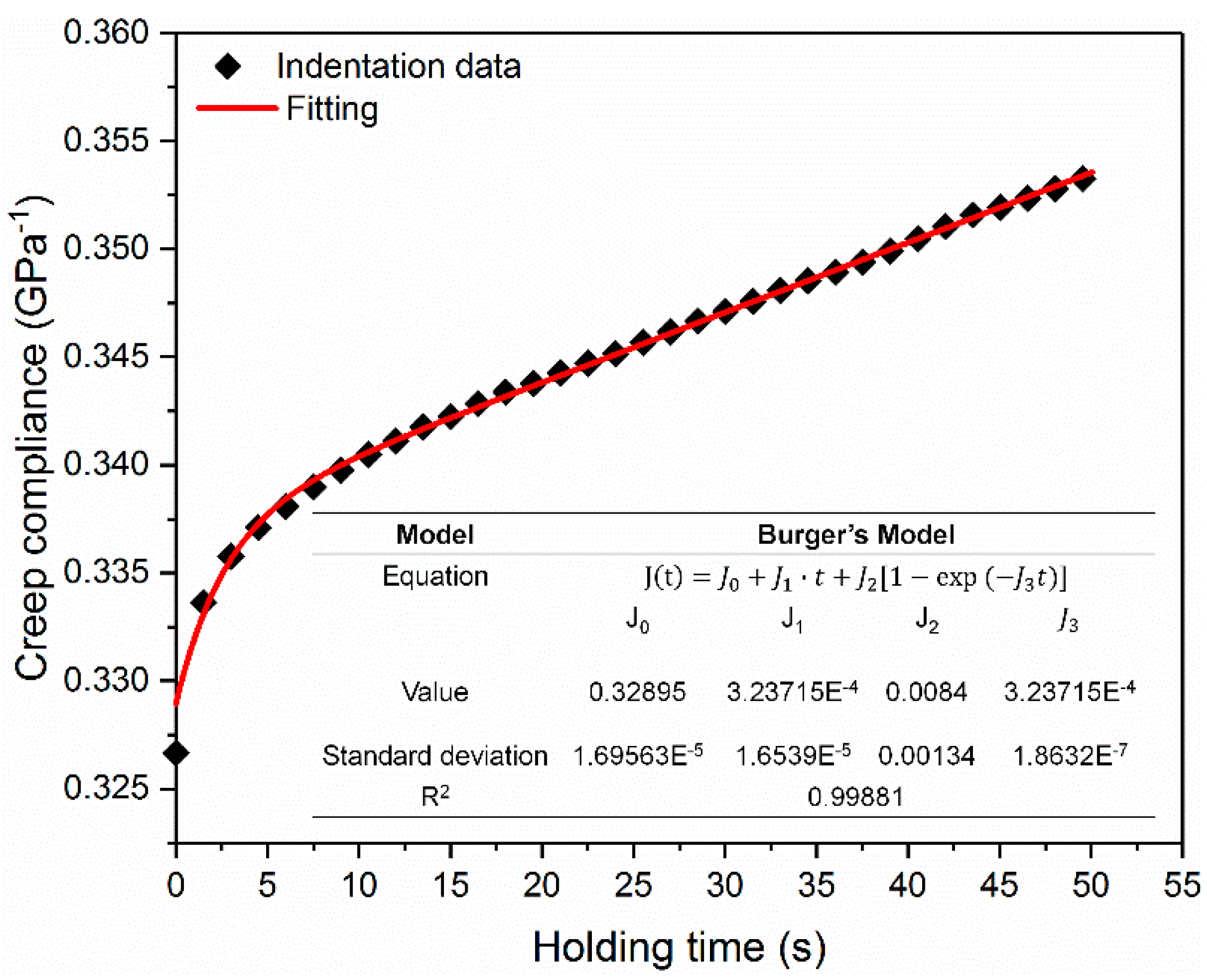

3.5. Creep Behaviours of Cell Wall

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Research Institute of Wood Industry. Wood Physical and Mechanical Properties of Main Tree Species in China; Forestry Publishing House: Beijing, China, 1982. [Google Scholar]

- Chen, C.; Tu, D.; Zhou, Q.; Zhou, J.; Wang, X.; Cherdchim, B.; Ou, R. Development and evaluation of a surface-densified wood composite with an asymmetric structure. Constr. Build. Mater. 2020, 242, 118007. [Google Scholar] [CrossRef]

- Laine, K.; Rautkari, L.; Hughes, M.; Kutnar, A. Reducing the set-recovery of surface densified solid Scots pine wood by hydrothermal post-treatment. Eur. J. Wood Wood Prod. 2013, 71, 17–23. [Google Scholar] [CrossRef]

- Rautkari, L.; Properzi, M.; Pichelin, F.; Hughes, M. Properties and set-recovery of surface densified Norway spruce and European beech. Wood Sci. Technol. 2010, 44, 679–691. [Google Scholar] [CrossRef]

- Belt, T.; Rautkari, L.; Laine, K.; Hill, C.A.S. Cupping behaviour of surface densified Scots pine wood: The effect of process parameters and correlation with density profile characteristics. J. Mater. Sci. 2013, 48, 6426–6430. [Google Scholar] [CrossRef]

- Rautkari, L.; Laine, K.; Laflin, N.; Hughes, M. Surface modification of Scots pine: The effect of process parameters on the through thickness density profile. J. Mater. Sci. 2011, 46, 4780–4786. [Google Scholar] [CrossRef]

- Navi, P.; Heger, F. Combined densification and thermo-hydro-mechanical processing of wood. MRS Bull. 2004, 29, 332–336. [Google Scholar] [CrossRef]

- Laine, K.; Segerholm, K.; Wålinder, M.; Rautkari, L.; Hughes, M. Wood densification and thermal modification: Hardness, set-recovery and micromorphology. Wood Sci. Technol. 2016, 50, 883–894. [Google Scholar] [CrossRef]

- Biziks, V.; Bicke, S.; Militz, H. Penetration depth of phenol-formaldehyde (PF) resin into beech wood studied by light microscopy. Wood Sci. Technol. 2019, 53, 165–176. [Google Scholar] [CrossRef]

- Lykidis, C.; Kotrotsiou, K.; Tsichlakis, A. Reducing set-recovery of compressively densified poplar wood by impregnation–modification with melamine–formaldehyde resin. Wood Mater. Sci. Eng. 2019, 15, 269–277. [Google Scholar] [CrossRef]

- Buchelt, B.; Dietrich, T.; Wagenführ, A. Testing of set recovery of unmodified and furfurylated densified wood by means of water storage and alternating climate tests. Holzforschung 2014, 68, 23–28. [Google Scholar] [CrossRef]

- Pfriem, A.; Dietrich, T.; Buchelt, B. Furfuryl alcohol impregnation for improved plasticization and fixation during the densification of wood. Holzforschung 2012, 66, 215–218. [Google Scholar] [CrossRef]

- Popescu, M.-C.; Lisa, G.; Froidevaux, J.; Navi, P.; Popescu, C.-M. Evaluation of the thermal stability and set recovery of thermo-hydro-mechanically treated lime (Tilia cordata) wood. Wood Sci. Technol. 2014, 48, 85–97. [Google Scholar] [CrossRef]

- Inoue, M.; Kadokawa, N.; Nishio, J.; Norimoto, M. Permanent fixation of compressive deformation by hygro-thermal treatment using moisture in wood. Wood Res. Tech. Notes 1993, 29, 54–61. [Google Scholar]

- Rautkari, L.; Honkanen, J.; Hill, C.A.S.; Ridley-Ellis, D.; Hughes, M. Mechanical and physical properties of thermally modified Scots pine wood in high pressure reactor under saturated steam at 120, 150 and 180 °C. Eur. J. Wood Wood Prod. 2014, 72, 33–41. [Google Scholar] [CrossRef]

- Kutnar, A.; Kamke, F.A. Compression of wood under saturated steam, superheated steam, and transient conditions at 150 °C, 160 °C, and 170 °C. Wood Sci. Technol. 2010, 46, 73–88. [Google Scholar] [CrossRef]

- Gao, Z.; Huang, R.; Chang, J.; Li, R.; Wu, Y. Effects of pressurized superheated-steam heat treatment on set recovery and mechanical properties of surface-compressed Wood. Bioresources 2019, 14, 1718–1730. [Google Scholar]

- Xiang, E.; Feng, S.; Yang, S.; Huang, R. Sandwich compression of wood: Effect of superheated steam treatment on sandwich compression fixation and its mechanisms. Wood Sci. Technol. 2020, 54, 1529–1549. [Google Scholar] [CrossRef]

- Ding, T.; Gu, L.; Li, T. Influence of steam pressure on physical and mechanical properties of heat-treated Mongolian pine lumber. Eur. J. Wood Wood Prod. 2011, 69, 121–126. [Google Scholar] [CrossRef]

- Gao, Z.; Huang, R.; Chang, J.; Li, R.; Wu, Y.; Wang, Y. Sandwich compression of wood: Effects of preheating time and moisture distribution on the formation of compressed layer(s). Eur. J. Wood Wood Prod. 2019, 77, 219–227. [Google Scholar] [CrossRef]

- Meng, Y.; Xia, Y.; Young, T.M.; Cai, Z.; Wang, S. Viscoelasticity of wood cell walls with different moisture content as measured by nanoindentation. RSC Adv. 2015, 5, 47538–47547. [Google Scholar] [CrossRef]

- Wang, D.; Lin, L.; Fu, F. The difference of creep compliance for wood cell wall CML and secondary S2 layer by nanoindentation. Mech. Time Depend. Mater. 2019, 9, 1–12. [Google Scholar] [CrossRef]

- Xing, D.; Li, J.; Wang, X.; Wang, S. In situ measurement of heat-treated wood cell wall at elevated temperature by nanoindentation. Ind. Crop. Prod. 2016, 87, 142–149. [Google Scholar] [CrossRef]

- Engelund, E.T.; Svensson, S. Modelling time-dependent mechanical behaviour of softwood using deformation kinetics. Holzforschung 2011, 65, 231–237. [Google Scholar] [CrossRef]

- Roszyk, E.; Mania, P.; Moliński, W. The influence of microfibril angle on creep of Scotch pine wood under tensile stress along the grains. Wood Res. 2012, 57, 347–358. [Google Scholar]

- Wang, J.; Zhao, G. Creep of compressed wood of Chinese fir heat treated in air. J. Beijing For. Univ. 2002, 24, 52–58. [Google Scholar]

- Wang, X.; Deng, Y.; Wang, S.; Min, C.; Meng, Y.; Pham, T.; Ying, Y. Evaluation of the effects of compression combined with heat treatment by nanoindentation (NI) of poplar cell walls. Holzforschung 2014, 68, 167–173. [Google Scholar] [CrossRef]

- Li, Y.; Huang, C.; Li, W.; Wang, S.; Wang, X. The effects of thermal treatment on the nanomechanical behaviour of bamboo (Phyllostachys pubescens Mazel ex H. de Lehaie) cell walls observed by nanoindentation, XRD, and wet chemistry. Holzforschung 2017, 71, 129–135. [Google Scholar] [CrossRef]

- Zhang, T.; Bai, S.; Zhang, Y.; Thibaut, B. Viscoelastic properties of wood materials characterized by nanoindentation experiments. Wood Sci. Technol. 2011, 46, 1003–1016. [Google Scholar] [CrossRef][Green Version]

- Li, R.; Gao, Z.; Feng, S.; Chang, J.; Wu, Y.; Huang, R. Effects of preheating temperatures on the formation of sandwich compression and density distribution in the compressed wood. J. Wood Sci. 2018, 64, 751–757. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray difractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Wei, L.; McDonald, A.G.; Stark, N.M. Grafting of bacterial polyhydroxybutyrate (PHB) onto cellulose via in situ reactive extrusion with dicumyl peroxide. Biomacromolecules 2015, 16, 1040–1049. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Wei, X.; Tao, D.; Sheng, X.; Zhang, M. Modification of poplar wood using polyhexahydrotriazine and its effect on hygroscopicity. J. Wood Chem. Technol. 2018, 38, 214–223. [Google Scholar] [CrossRef]

- Yin, Y.; Berglund, L.; Salmén, L. Effect of steam treatment on the properties of wood cell wall. Biomacromolecules 2011, 12, 194–202. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Song, K.; Salmén, L.; Yin, Y. Changes of wood cell walls in response to hygro-mechanical steam treatment. Carbohydr. Polym. 2015, 115, 207–214. [Google Scholar] [CrossRef]

- Guo, J.; Rennhofer, H.; Yin, Y.; Lichtenegger, H.C. The influence of thermo-hygro-mechanical treatment on the micro- and nanoscale architecture of wood cell walls using small- and wide-angle X-ray scattering. Cellulose 2016, 23, 2325–2340. [Google Scholar] [CrossRef]

- Yin, J.; Yuan, T.; Lu, Y.; Song, K.; Li, H.; Zhao, G.; Yin, Y. Effect of compression combined with steam treatment on the porosity, chemical compositon and cellulose crystalline structure of wood cell walls. Carbohydr. Polym. 2017, 155, 163–172. [Google Scholar] [CrossRef]

- Stanzl-Tschegg, S.; Beikircher, W.; Loidl, D. Comparison of mechanical properties of thermally modified wood at growth ring and cell wall level by means of instrumented indentation tests. Holzforschung 2009, 63, 443–448. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.; Deng, Y.; Yu, W.; Xie, X.; Wang, S. Contributions of basic chemical components to the mechanical behaviour of wood fiber cell walls as evaluated by nanoindentation. Bioresources 2016, 11, 6026–6039. [Google Scholar] [CrossRef]

- Yu, Y.; Fei, B.; Wang, H.; Tian, G. Longitudinal mechanical properties of cell wall of Masson pine (Pinus massoniana Lamb) as related to moisture content: A nanoindentation study. Holzforschung 2011, 65, 121–126. [Google Scholar] [CrossRef]

- Gril, J.; Hunt, D.; Thibaut, B. Using wood creep data to discuss the contribution of cell-wall reinforcing material. Comptes Rendus Biol. 2004, 327, 881–888. [Google Scholar] [CrossRef]

| Treatment | CrI (%) | Crystalline Thickness (nm) | Crystalline Length (nm) |

|---|---|---|---|

| Untreated | 43.31 b | 2.71 b | 20.28 b |

| 0.1 MPa SHT | 44.14 b | 3.53 a | 20.52 ab |

| 0.3 MPa SHT | 46.78 a | 3.81 a | 20.87 a |

| Treatment | Burger’s Model | Mathematical Expression of Burger’s Model | ||||

|---|---|---|---|---|---|---|

| Ee | η1 | η2 | Ed | R2 | ||

| Untreated | 2.97 | 3036.55 | 342.65 | 97.18 | 0.9985 | Y(t) = 0.3371 + 0.010 × (1 − e−0.28362 × t) + 3.29 × 10−4 × t) |

| 0.1 MPa SHT | 3.04 | 3089.13 | 315.37 | 119.05 | 0.9988 | Y(t) = 0.32895 + 0.008 × (1 − e−0.37749 × t) + 3.24 × 10−4 × t) |

| 0.3 MPa SHT | 3.15 | 3096.59 | 886.45 | 145.14 | 0.9969 | Y(t) = 0.3176 + 0.007 × (1 − e−0.16373 × t) + 3.23 × 10−4 × t) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiang, E.; Huang, R.; Yang, S. Change in Micromechanical Behavior of Surface Densified Wood Cell Walls in Response to Superheated Steam Treatment. Forests 2021, 12, 693. https://doi.org/10.3390/f12060693

Xiang E, Huang R, Yang S. Change in Micromechanical Behavior of Surface Densified Wood Cell Walls in Response to Superheated Steam Treatment. Forests. 2021; 12(6):693. https://doi.org/10.3390/f12060693

Chicago/Turabian StyleXiang, Elin, Rongfeng Huang, and Shumin Yang. 2021. "Change in Micromechanical Behavior of Surface Densified Wood Cell Walls in Response to Superheated Steam Treatment" Forests 12, no. 6: 693. https://doi.org/10.3390/f12060693

APA StyleXiang, E., Huang, R., & Yang, S. (2021). Change in Micromechanical Behavior of Surface Densified Wood Cell Walls in Response to Superheated Steam Treatment. Forests, 12(6), 693. https://doi.org/10.3390/f12060693