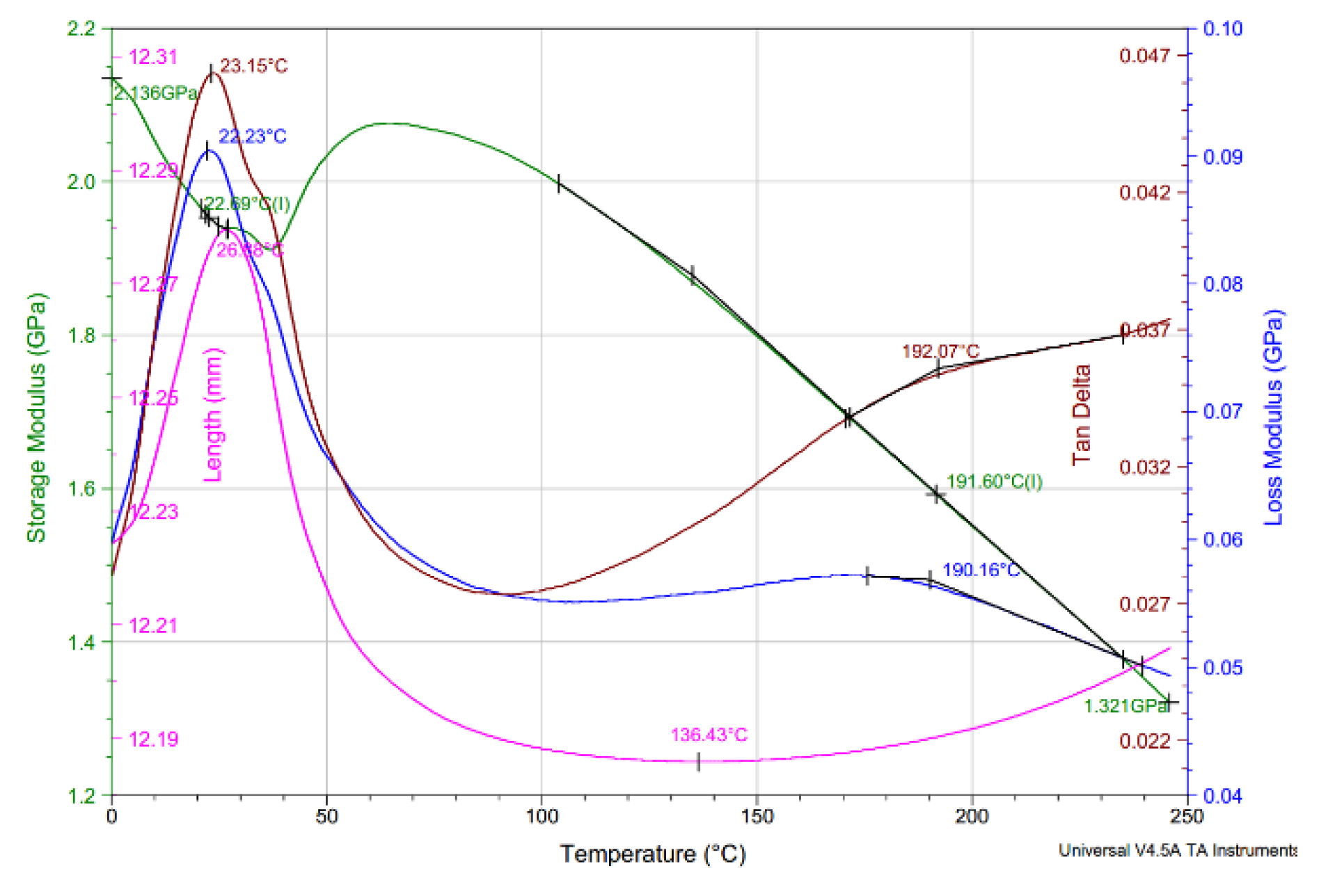

3.3.3. Dynamic Mechanical (Viscoelastic) Properties

Since the relaxation state of the strong cellulose crystallites does not change until the melting point, which is above the temperature of thermal decomposition [

51], the relaxation transitions of the cellulose composite take place in the weak non-crystalline domains. There are three structural components responsible for the viscoelastic behavior of cellulose paper: lignin, hemicellulose (

Table 4) and disordered parts of the macromolecular chains of cellulose, all of which represent the amorphous domains on the complex semi-crystalline cellulose composite. These components are also responsible for the other structural properties that have an influence on viscoelasticity, such as the bonding and association of the cellulose fibers with the surrounding environmental factors (particularly moisture contact due to ambient relative humidity and temperature) [

52,

53], which are also mentioned further in this chapter of the paper. The viscoelastic curves, i.e., storage modulus E′, loss modulus E′′, damping factor tanδ, and dimension L of the samples are shown in

Figure 3,

Figure 4,

Figure 5,

Figure 6,

Figure 7 and

Figure 8, while the storage modulus values at 20 °C and the temperature of the relaxation transitions T

r are shown in

Table 10. The storage modulus E′ (marked as green curves in

Figure 6,

Figure 7,

Figure 8 and

Figure 9) is proportional to the energy stored by the material in one deformation cycle and represents the elastic response of the material. The loss modulus E′′ (marked as blue curves in

Figure 6,

Figure 7,

Figure 8 and

Figure 9) is proportional to the energy (heat) dissipated by the material in one cycle and represents the viscous response of the material. The damping factor tanδ (marked as brown curves in

Figure 6,

Figure 7,

Figure 8 and

Figure 9), represents the ratio of the viscous to elastic response and is a measure of damping in the material. The length L (marked as pink curves in

Figure 6,

Figure 7,

Figure 8 and

Figure 9), represents the change in dimensions of the sample (shrinking or expanding).

As shown in

Figure 4,

Figure 5,

Figure 6 and

Figure 7, the temperature relaxation behavior of the cellulose structure is very complex because of its heterogeneity, and sometimes it is impossible to determine which component (or mixture thereof) is responsible for the overall behavior of the structure. The relaxation transitions are of different nature and occur in a wide temperature range below the temperature of thermal decomposition [

54,

55]. However, there are some features that stand out and can be discussed. All samples show a slow decrease in storage modulus E′ throughout the heated region, indicating the semi-crystalline structure of COP, as well as for KW–GR.

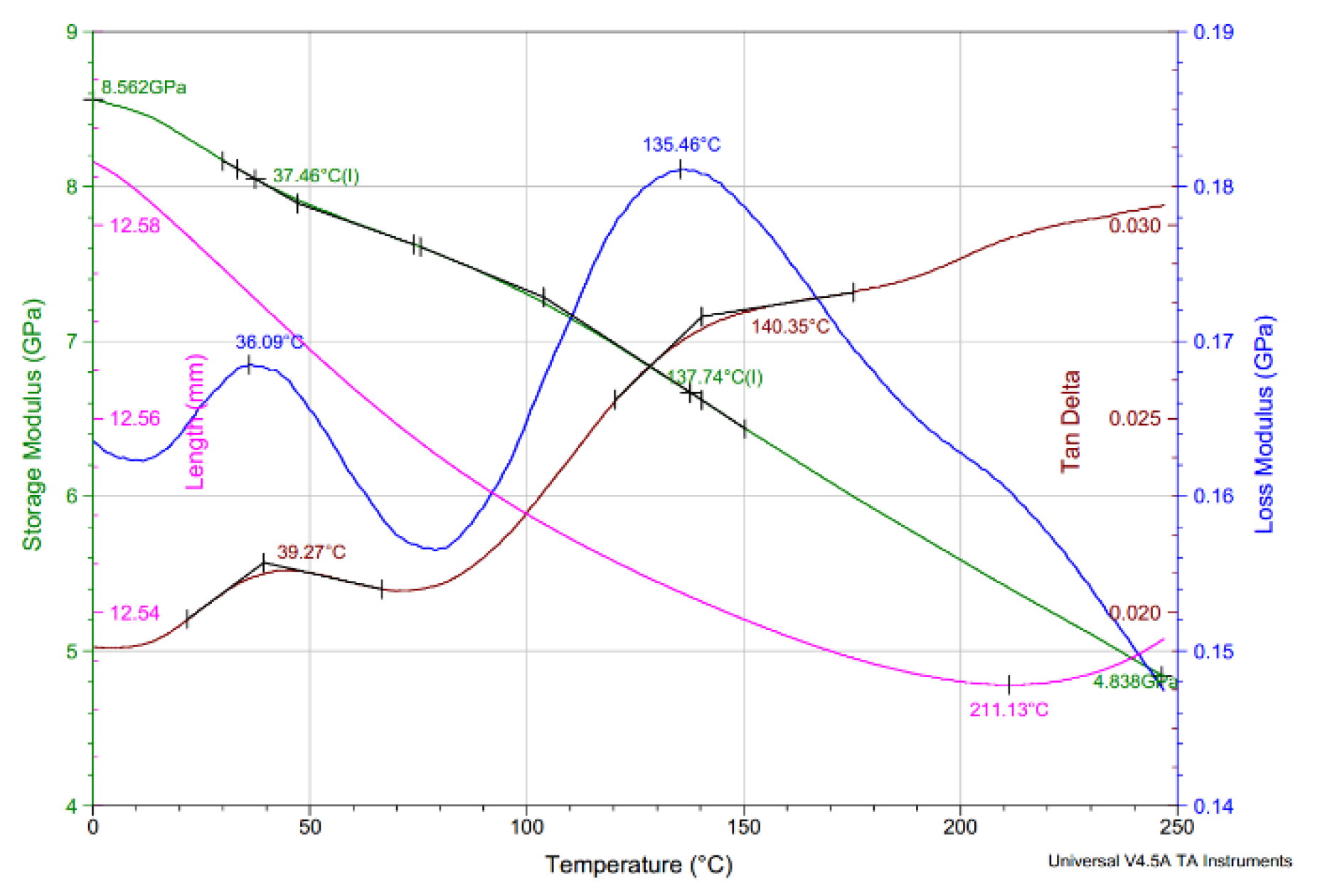

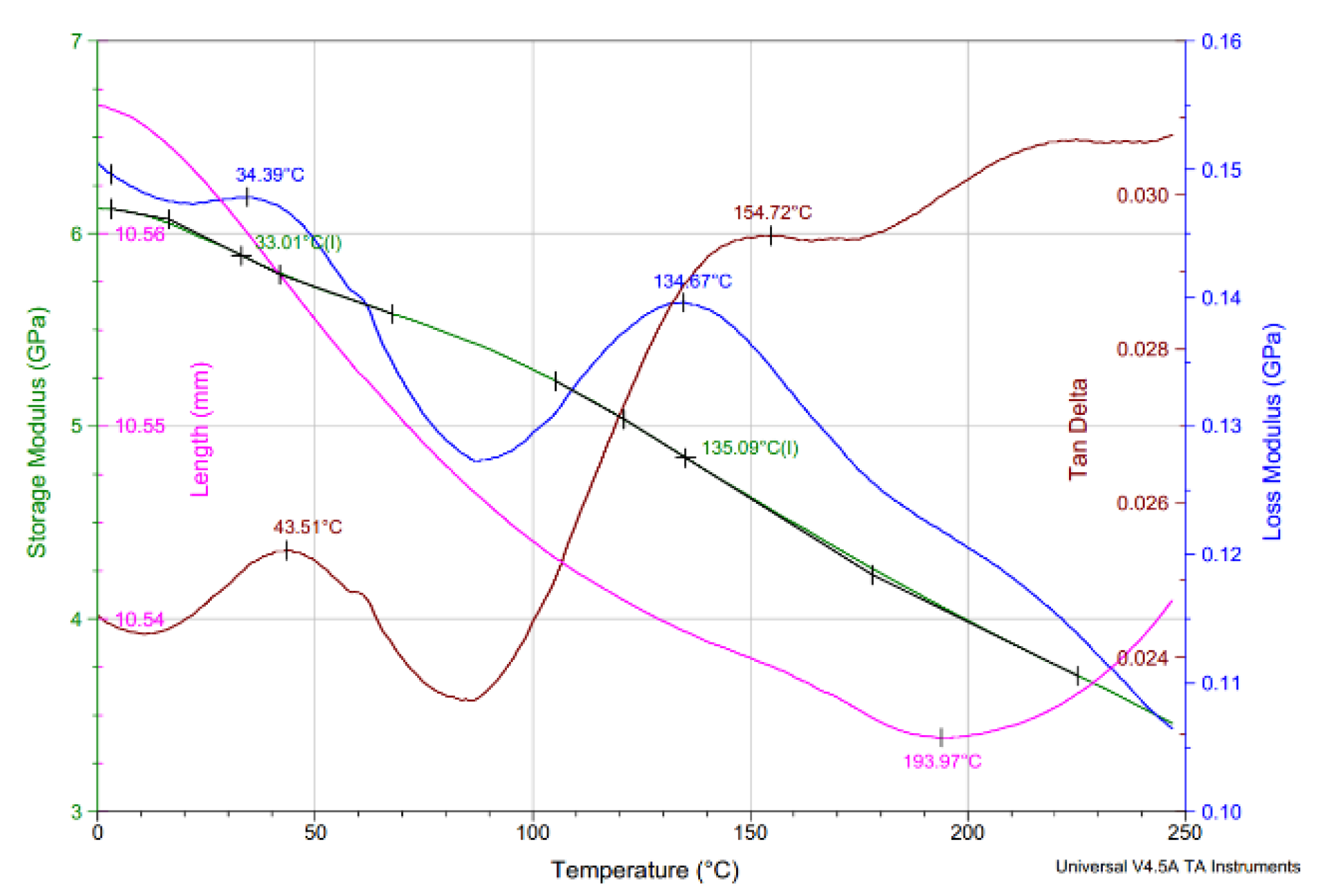

The viscoelastic curves of COP (

Figure 7) show two relaxation regions indicated by the intensity of the tanδ curves. The first region is located between 20 and 70 °C with T

r = 37.46 °C and the larger, broader one between 80 and 170 °C with T

r = 137.74 °C. The storage modulus, which stores the applied energy after the release of the sample and uses it to restore the deformation to the initial state, decreases from an initial 8.562 GPa at 0 °C to 4.838 GPa at 250 °C (43.5%). As mentioned, the decrease in modulus is slow and almost linear throughout the heated region. Up to room temperature (ca. 20 °C), the modulus decreases by 2.6%. With the decrease in the elastic modulus and due to the applied heat, the segmental vibration of the structure segments occurs, which leads to the occurrence and increase in the mechanical loss modulus E′′. The maximum value of E” represents the beginning of the fluctuation of the molecular segments and consequently there is the scattering of the thermal energy (heat scattering of the sample). The scattering reaches its peak at 36.09 and 135.46 °C. The intensity of the molecular fluctuations is reflected in the height of the tanδ curve and illustrates the internal friction of the structure. It peaks at 37.27 °C, followed by a peak at 140.35 °C. The sample stops shrinking at 211.13 °C and shrinks by 0.5%. The final increase in length is the result of the thermal expansion of the structure due to the viscous component of the sample that has occurred and is shown for all samples.

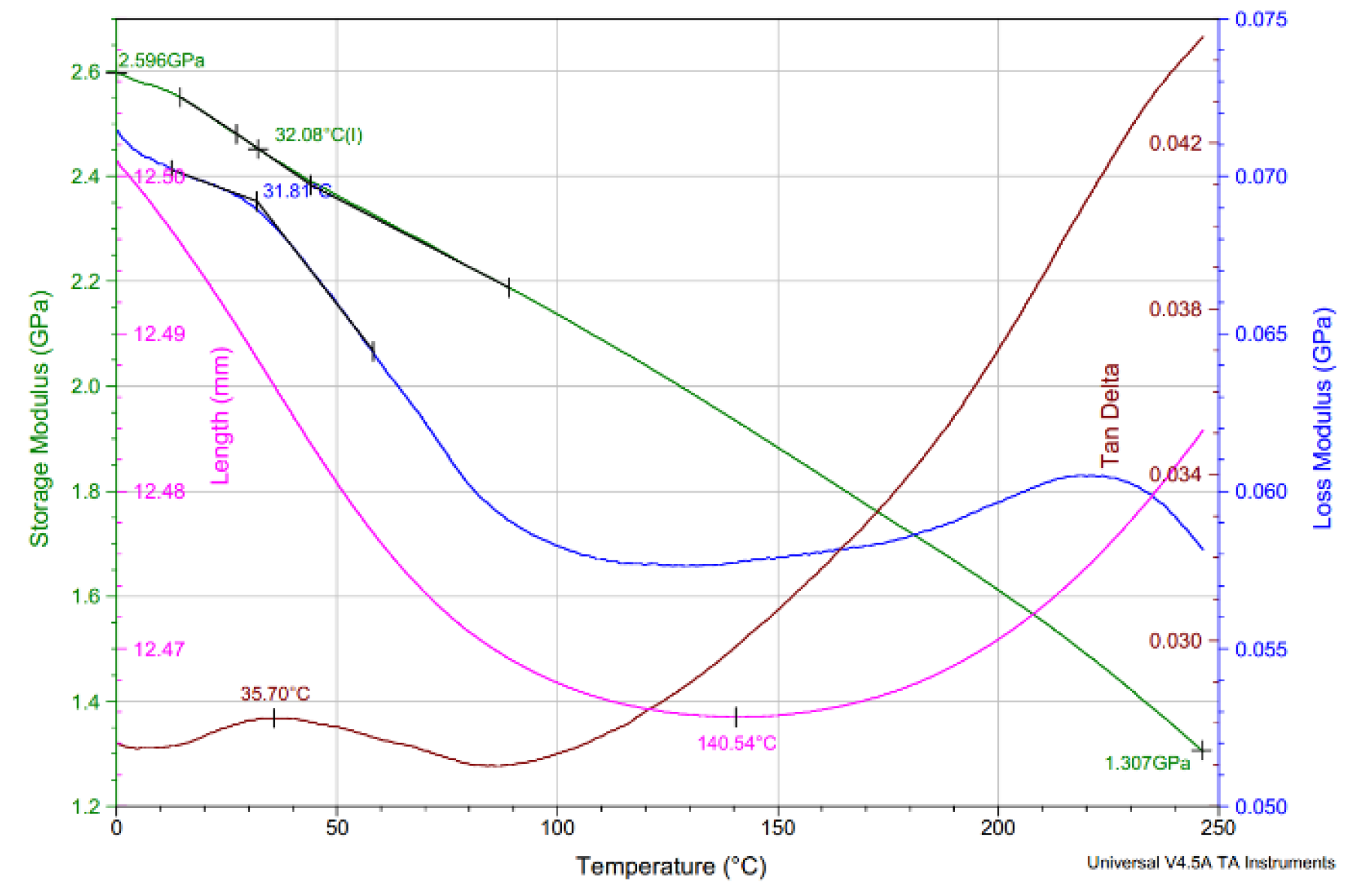

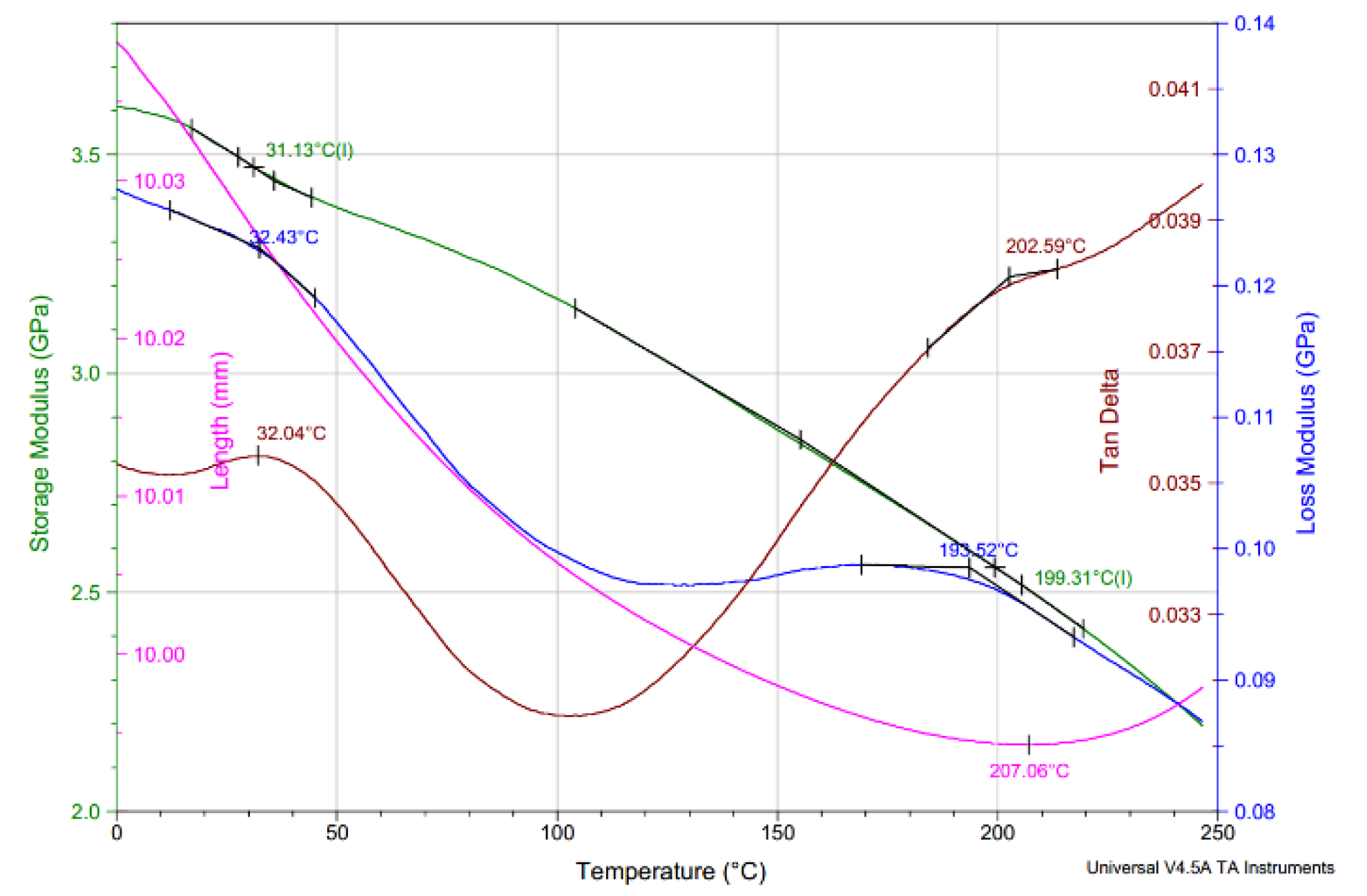

Similar to COP, GR also shows a slow and linear decrease in its storage modulus throughout the heated region (

Figure 6). The storage modulus drops from the initial 2.596 GPa at 0 °C to 1.307 GPa at 250 °C (49.6%). By room temperature, the modulus decreases by 2.9%. The relaxation range is given between 10 and 80 °C, with the relaxation transition temperature at 32.08 °C, and above 90 °C. The sample stops shrinking at 140.54 °C and shrinks by 0.240%.

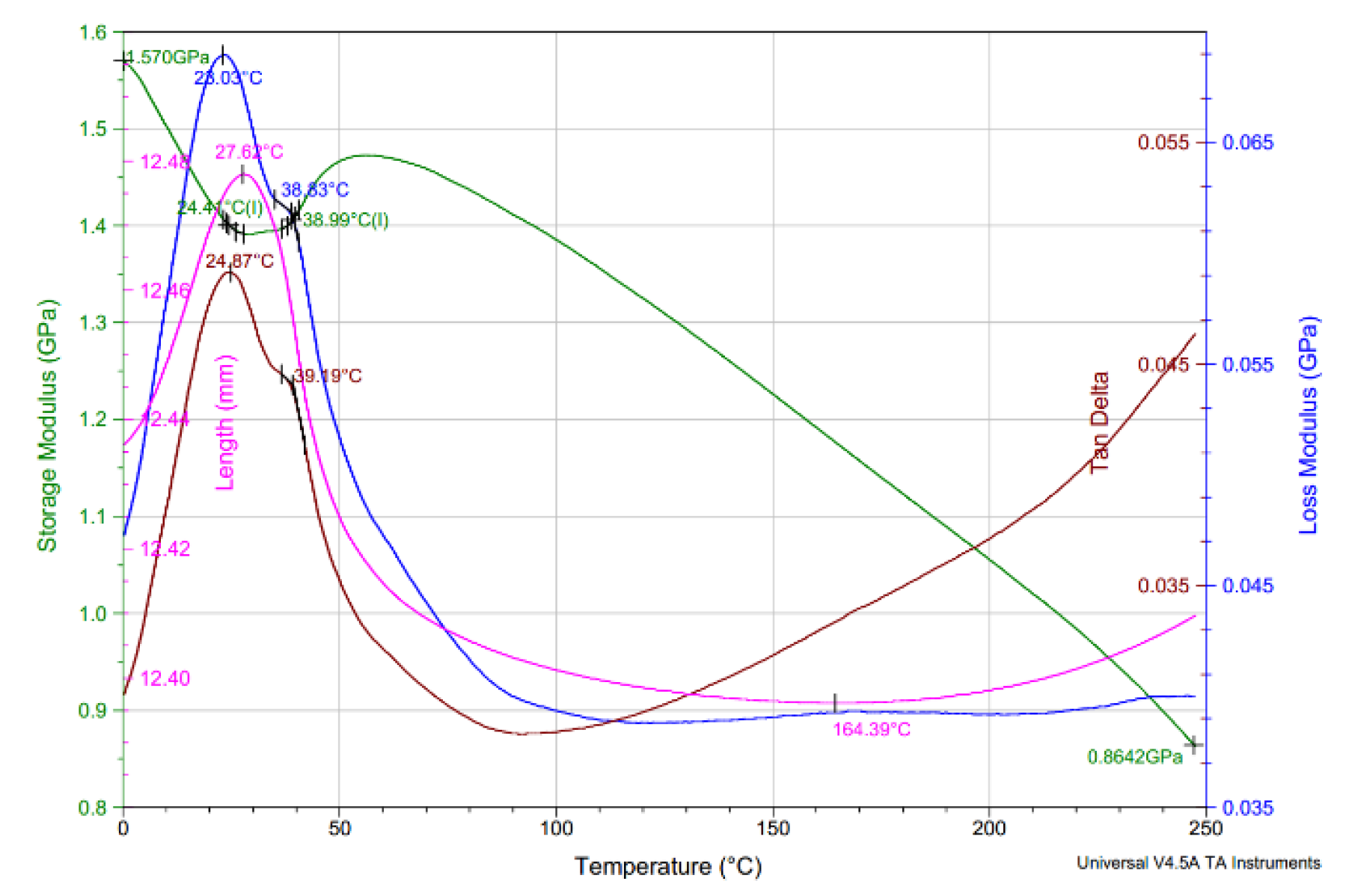

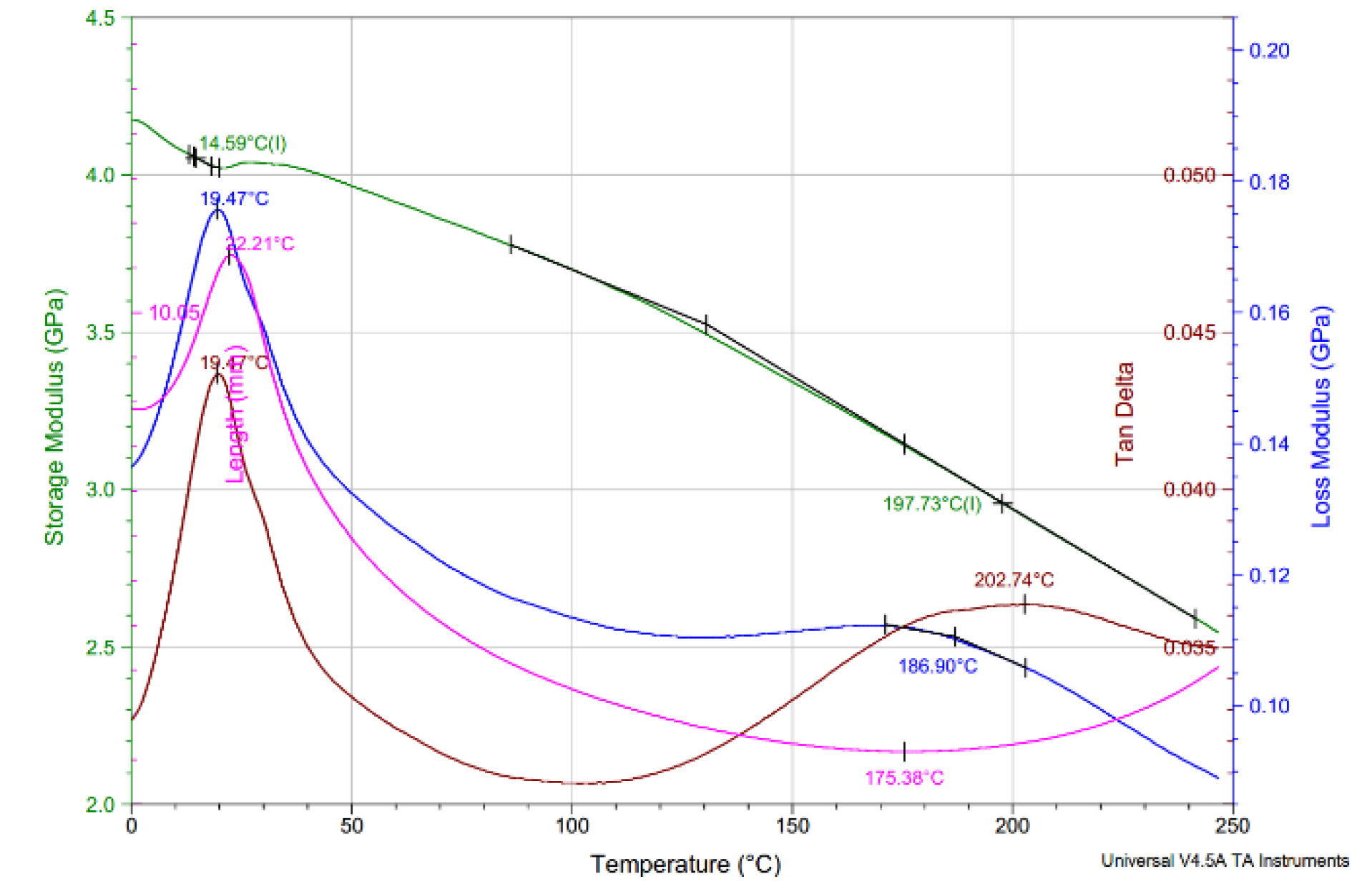

KW and BL show similar viscoelastic behavior and deviate slightly from the behavior of GR and COP in the initial heated region up to 70 °C (

Figure 4 and

Figure 5), where the storage modulus E′ and sample length initially decrease, then increase, and finally begin to gradually decrease. The decrease could be the result of the bound moisture, while the increase could result from the cellulose in the non-crystalline region of the cell wall, assuming a crystallized form to some extent. Thus, the storage modulus decreases from an initial 2.136 GPa at 0 °C to 1.321 GPa at 250 °C (38.2%), and from 1.570 GPa at 0 °C to 0.8642 GPa at 250 °C (45.0%) for KW and BL, respectively. Up to room temperature, the modulus decreases by 7.8 and 9.2% for KW and BL, respectively. The first given relaxation range can be considered as the main transition range for KW and BL, since the dispersion of mechanical heat (loss modulus E′′) and the damping (tanδ) of the structure are the strongest here. The relaxation transition temperatures for KW and BL are 22.69 and 24.41 °C, respectively.

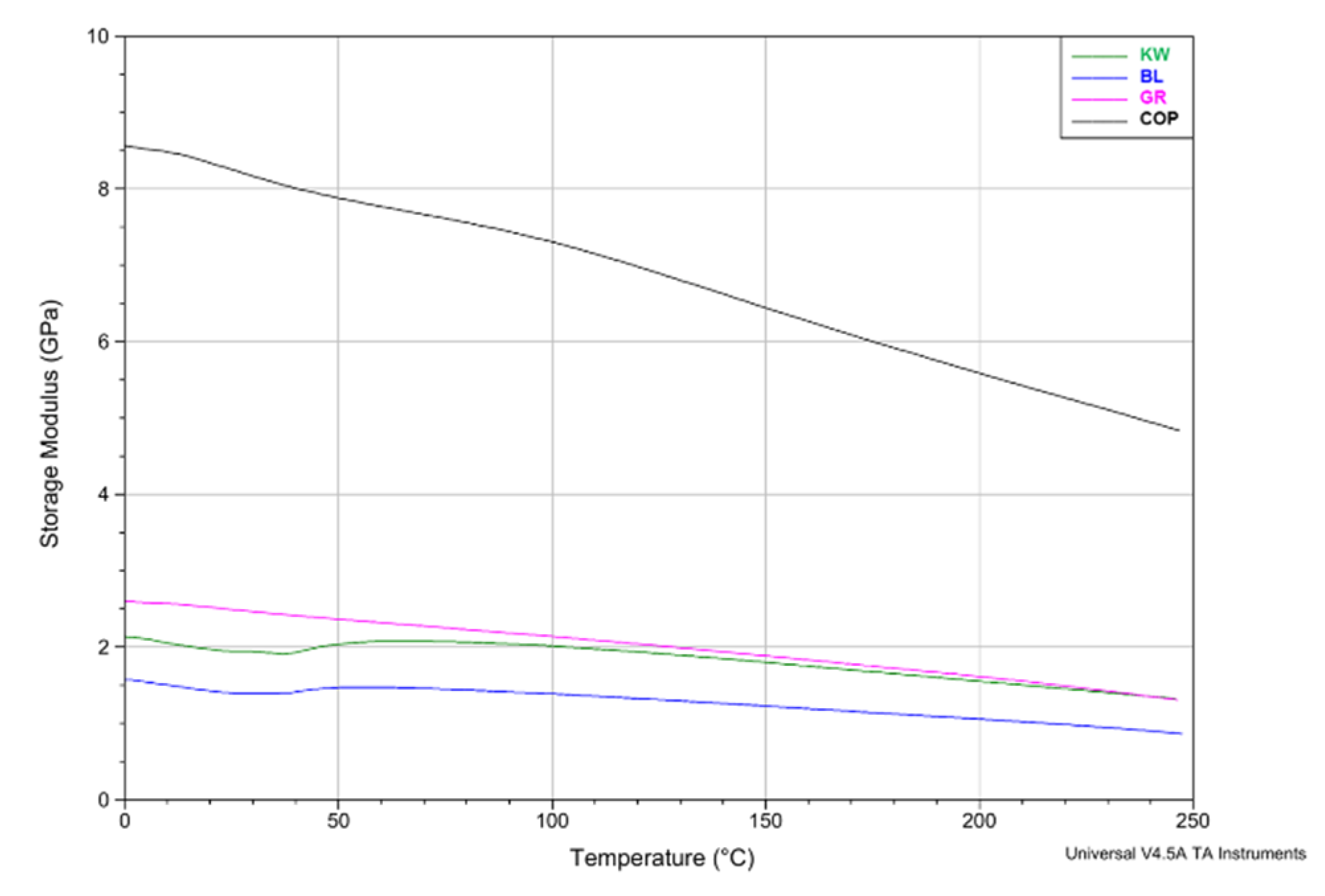

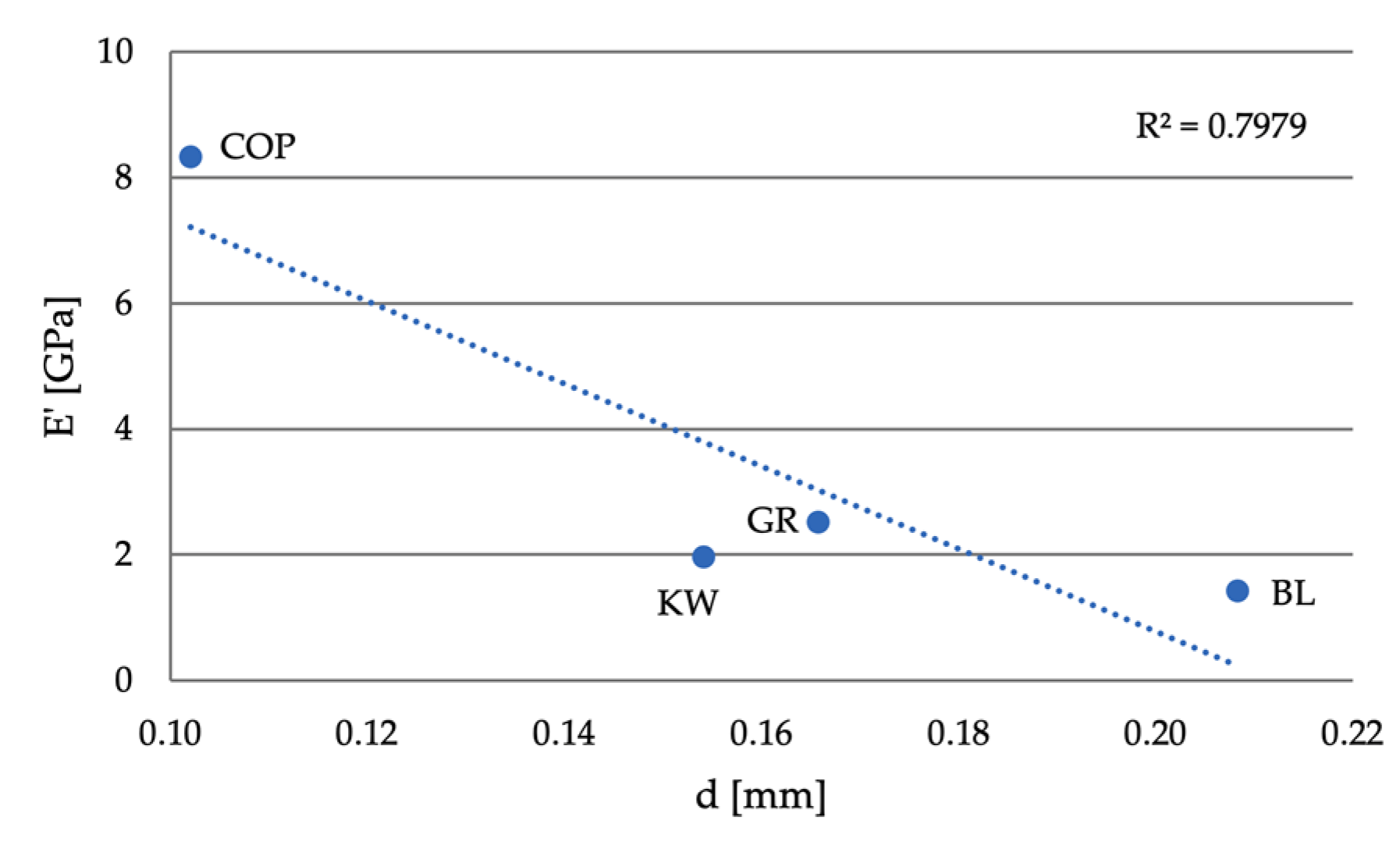

The comparison of storage elasticity (

Figure 8), which is an indicator of the bonding properties in the cellulose network, shows that papers made from IAPS (KW, BL, and GR) are less stiff compared to commercial office paper (COP). Thus, commercial office paper has a higher ability to store the stress energy, i.e., it behaves more elastically, i.e., with E′ = 8.338 GPa at T = 20 °C. The papers of IAPS: KW, BL, and GR show much lower elasticity, i.e., their storage modulus decreases from 69.7% to up to 82.9% for BL and GR, respectively. BL shows the lowest elasticity, i.e., E′ = 1.425 GPa, while GR behaves as the stiffest, i.e., 2.521 GPa. The reason for this difference in elasticity between the commercial office paper and papers from IAPS can be found in many factors. For example, the higher elasticity of COP could be the result of the following parameters and a mixture of them:

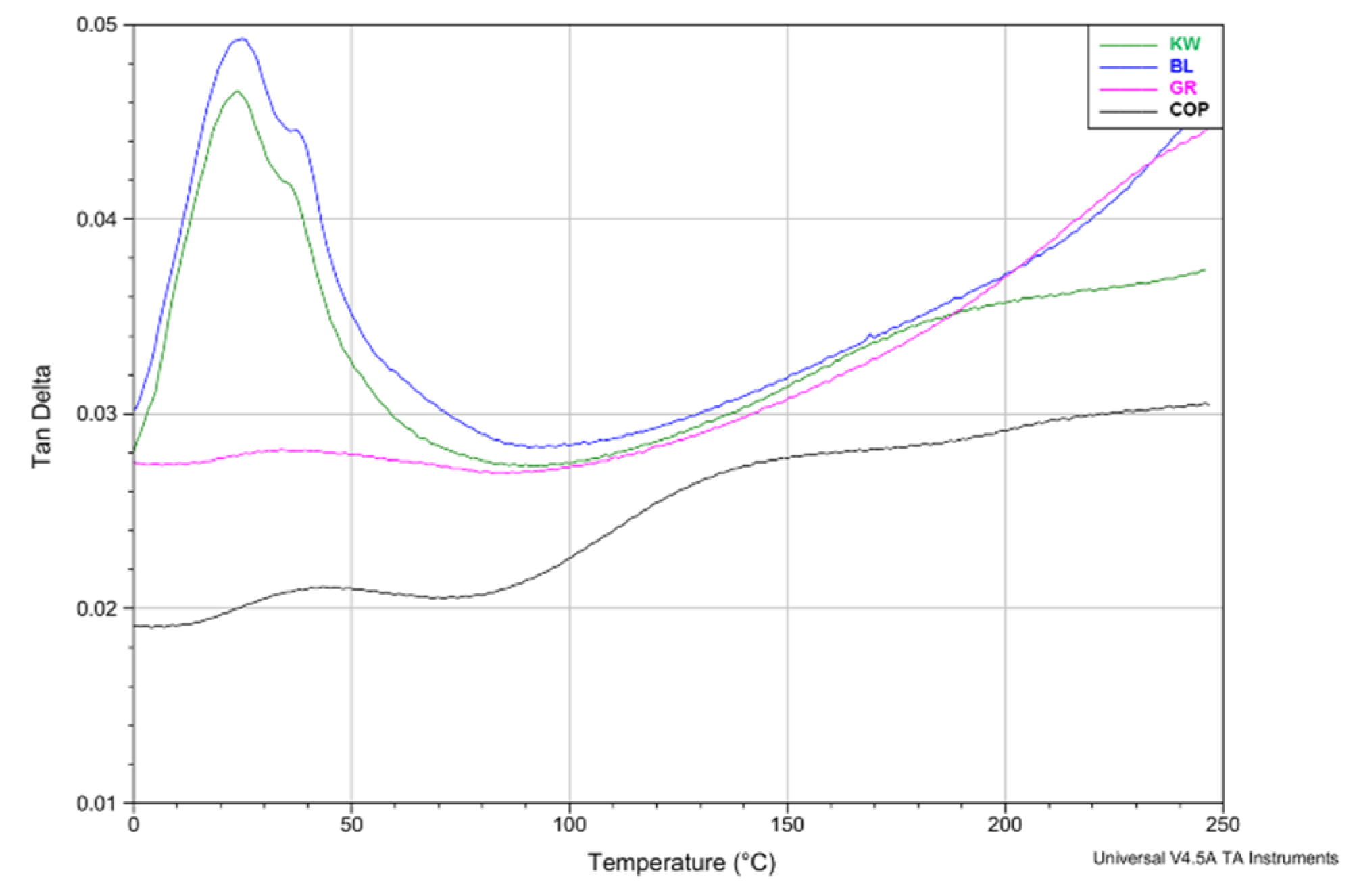

Comparison of the values of the damping factor tgδ (

Figure 9) shows that KW and BL are much more susceptible to the mobility of the molecular segments, resulting in greater macromolecular fluctuation and increased heat release, which can lead to microcracks in the structure. Therefore, aggressive mechanical loading during papermaking in the range of 10 to 50 °C is not recommended for KW and BL.

Another factor that also specifies the viscoelastic behavior of the paper is the relaxation transition temperature, i.e., T

r. Papers from IAPS show lower T

r (KW = 22.69 °C, BL = 24.41 °C, GR = 32.08 °C, and COP = 37.46 and 137.74 °C) compared to commercial office papers, as can be seen in

Table 10. The reason can again be explained by the higher moisture content of KW, BL, and GR (

Table 7), which leads to a decrease in intra- and inter-cellulose macromolecular bonds and makes the structure more susceptible to segment mobility under the influence of applied heat. The lower relaxation transition temperature T

r may also be correlated with the hollower structure of KW, BL, and GR (

Table 6), which is more prone to the mentioned segment mobility.

Some studies [

56], even suggest that the relaxation transition temperature of paper depends mainly on the structural mobility of hemicellulose and lignin under the influence of ambient heat and moisture. As Olsson notes, lignin plays the main role in this phenomenon: its massive three-dimensional structure with large lateral methoxyl groups prevents its covalent self-crosslinking, while at the same time its large volume prevents its entanglement. This increases the mobility of its segments, leading to a decrease in the softening temperature. This observation could be the explanation for the lowest relaxation temperature T

r of KW, which contains the highest proportion of lignin and hemicellulose mixture compared to BL and GR (63.3% in KW, 57% in BL, and 55% in GR). KW even contains the highest proportion of lignin (27% for KW, 22% for BL, and 19% for GR) (

Table 4). Placet et al., further explains that the relaxation that occurs at lower temperatures is the consequences of the relaxation of hemicellulose, while at higher temperatures it belongs to the relaxation of lignin [

57]. As studied in his research, ambient moisture shows different affinity to lignin and hemicellulose: the affinity for hemicellulose is high due to the presence of hydroxyl and carboxyl groups, which leads to an improvement in the flexibility of the cellulose network and a decrease in its stiffness. Thus, the relaxation takes place at lower temperatures. In contrast, the water affinity to lignin is low due to its massive molecular structure, which leads to relaxation occurring at higher temperatures.

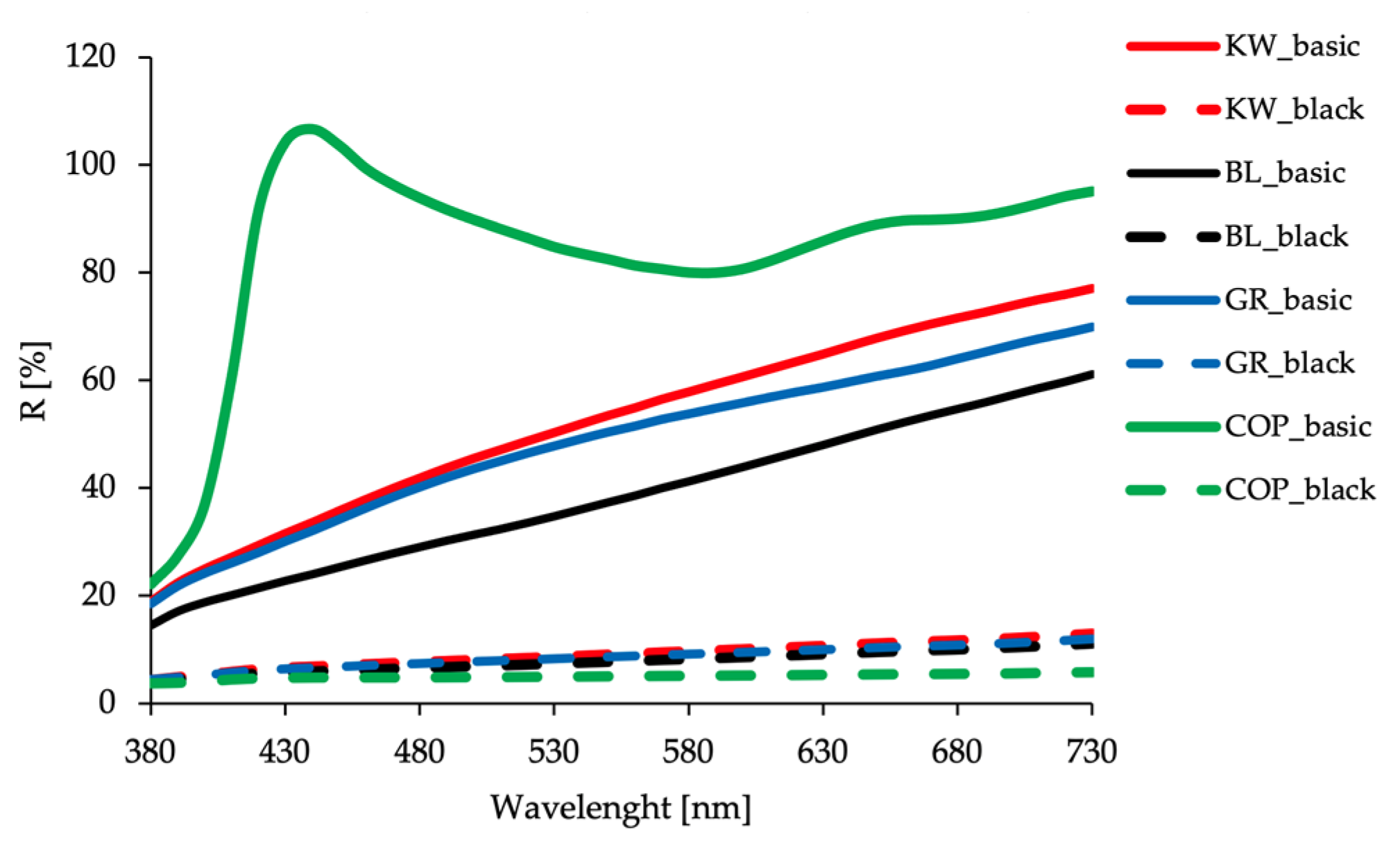

UV Impact on Dynamic Mechanical Properties

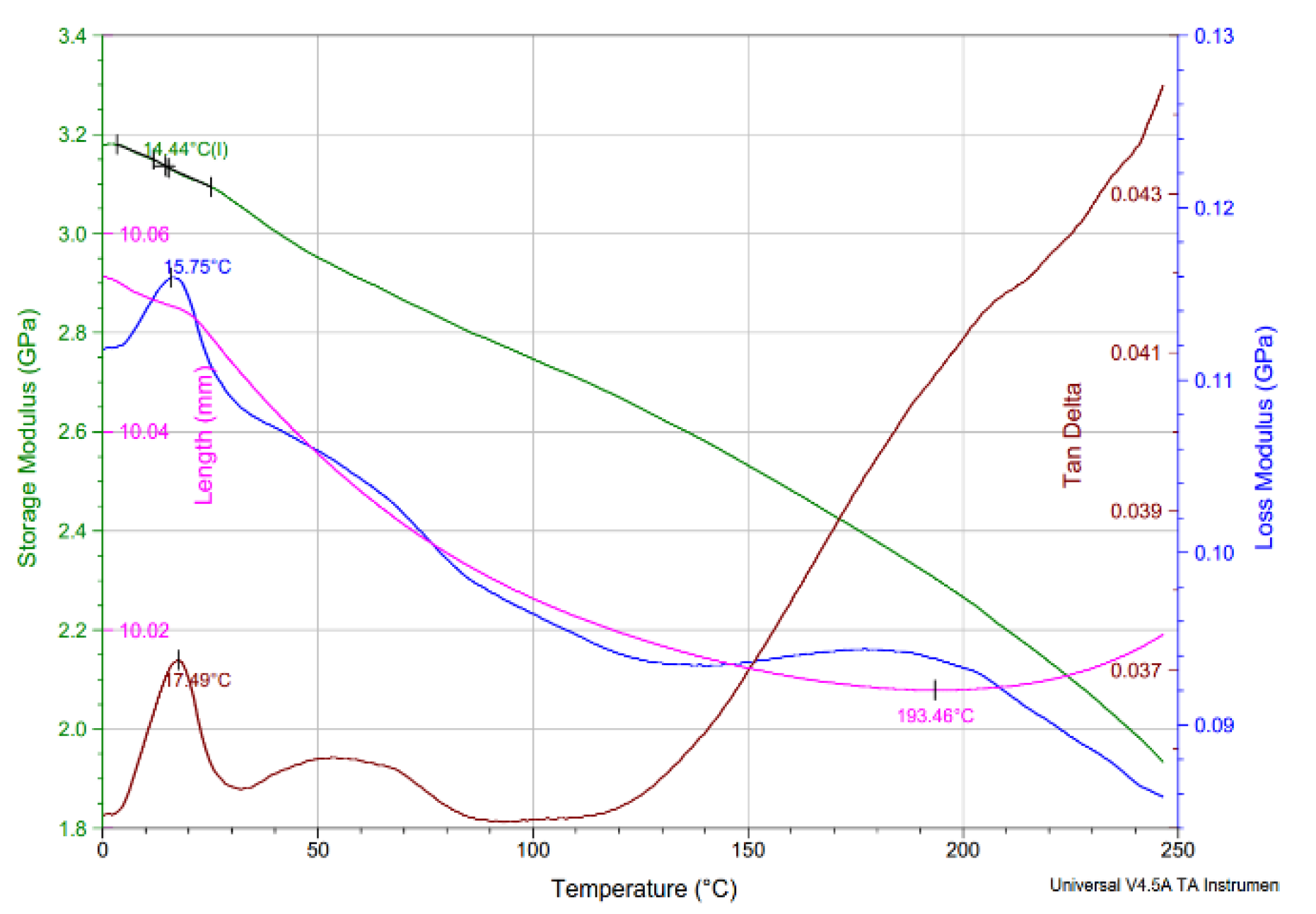

After UV exposure (

Figure 10,

Figure 11,

Figure 12 and

Figure 13 and

Table 11), the elasticity of KW, BL, and GR at 20 °C increases significantly: by about 104% for KW, 23% for BL, and 148% for the GR sample, while it decreases by 26.7% for the COP sample.

In general, UV light causes gradual degradation of paper, which has been shown for commercial office paper (COP). However, UV irradiation is the only type of cellulose degradation that affects only the amorphous regions, i.e., hemicellulose and lignin, and does not involve degradation of the crystalline fibril portion of the semi-crystalline cellulose structure. As suggested by Karlovits [

58], the UV-exposed degraded amorphous domains form a more ordered structure, leading to covalent cross-linking through additional bonds. The more ordered structure is the result of the reduction in the “free volume”, i.e., the molecules adjust their positions over time and consequently a tighter structure is formed, increasing the storage modulus E′. The cross-linking formed occurs in the wall of the cellulose fibers and in the fiber–fiber bonding surfaces [

59]. The increase in elastic modulus of papers during natural and accelerated ageing is also suggested by Graminski [

60]. The author adds that the increase in paper elasticity during ageing is probably also related to the crystallization processes and not only to the cross-linking reactions of the semicrystalline structure.

As can be seen in

Table 11, UV irradiation shifts the relaxation transition temperatures for KW, GR, and COP to the lower temperature and raises them for BL. The highest shift occurs for the GR sample (T

r decreases by 8 °C), indicating the higher structural mobility and sliding of the macromolecules due to the applied heated oscillation stress.

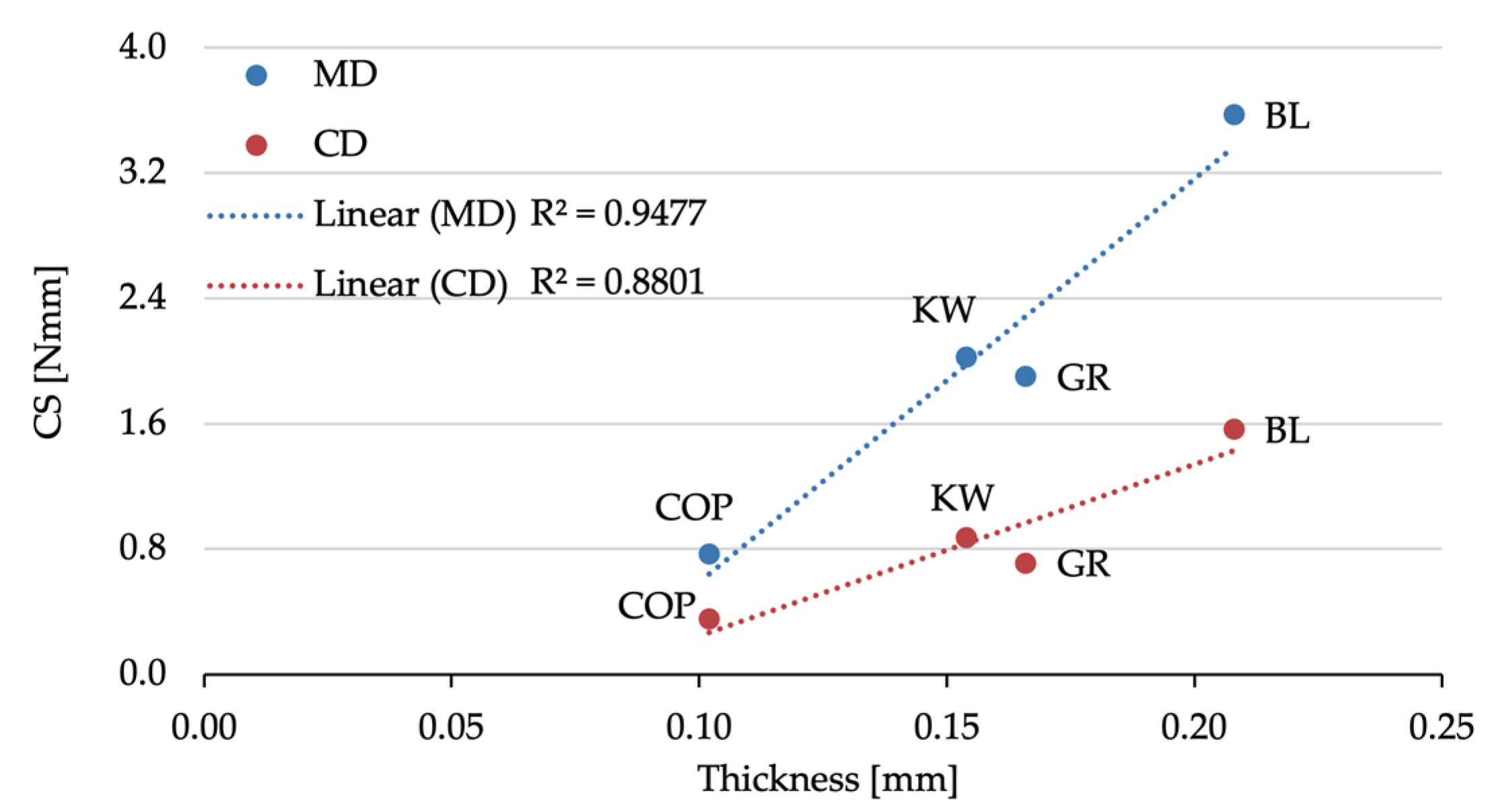

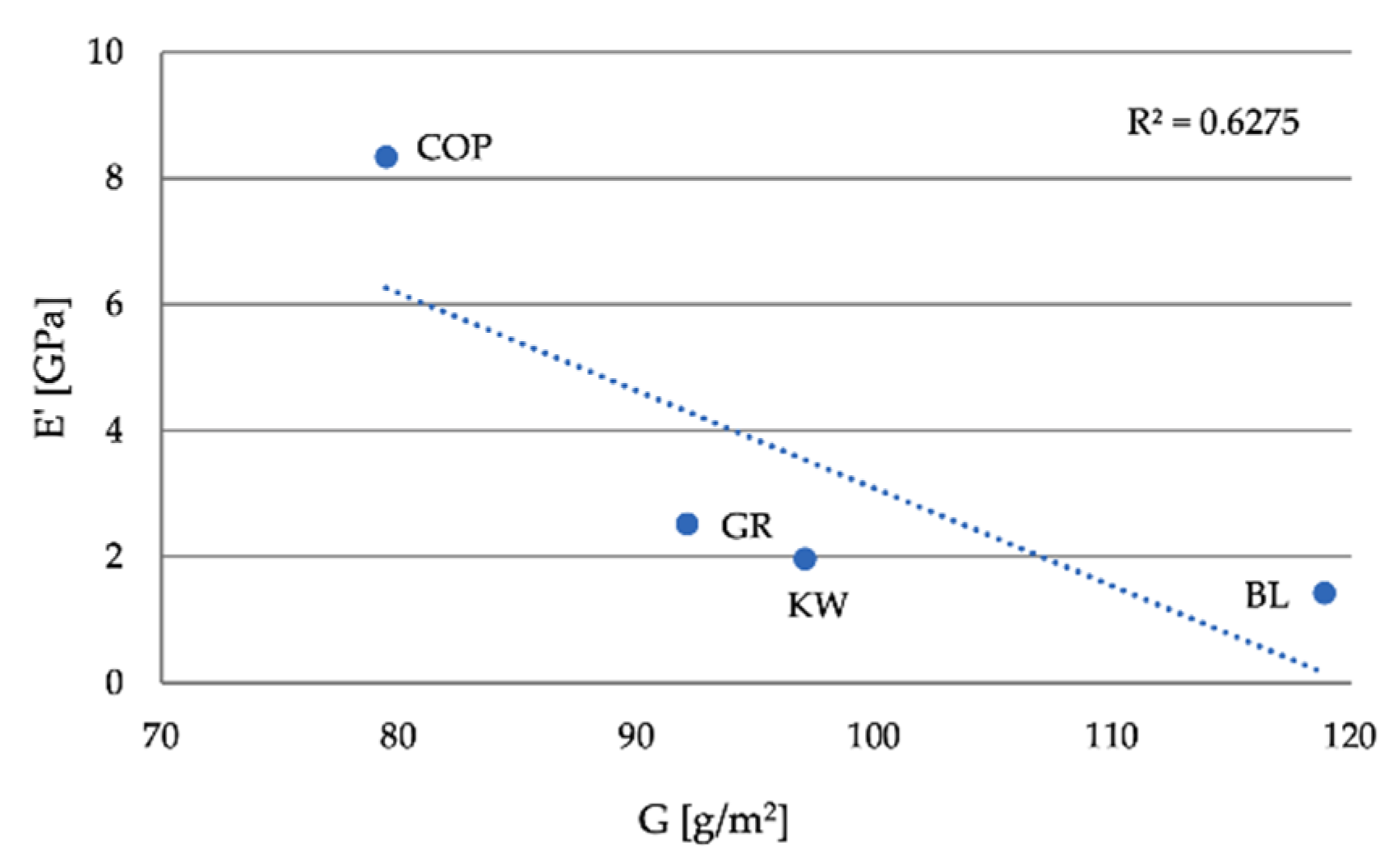

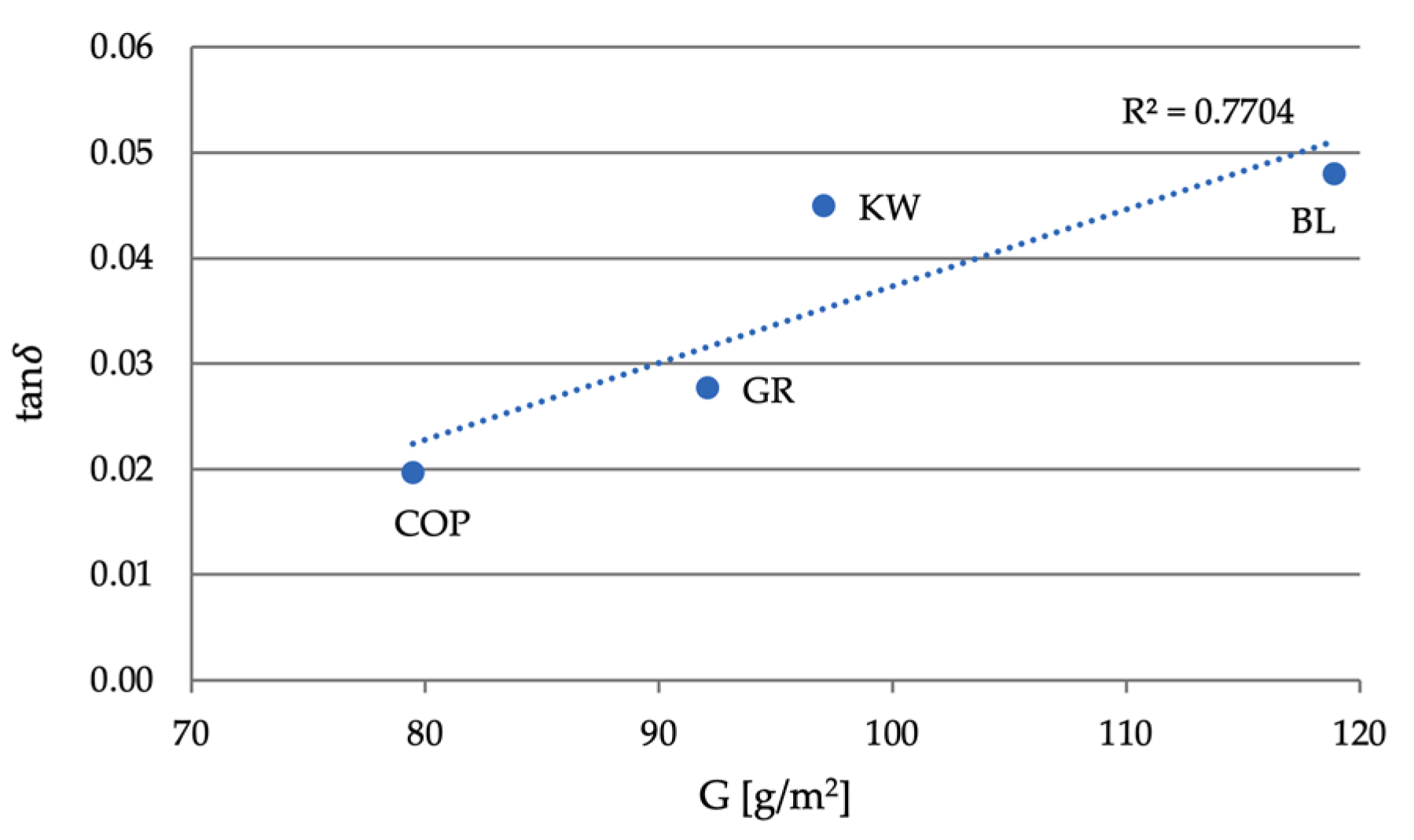

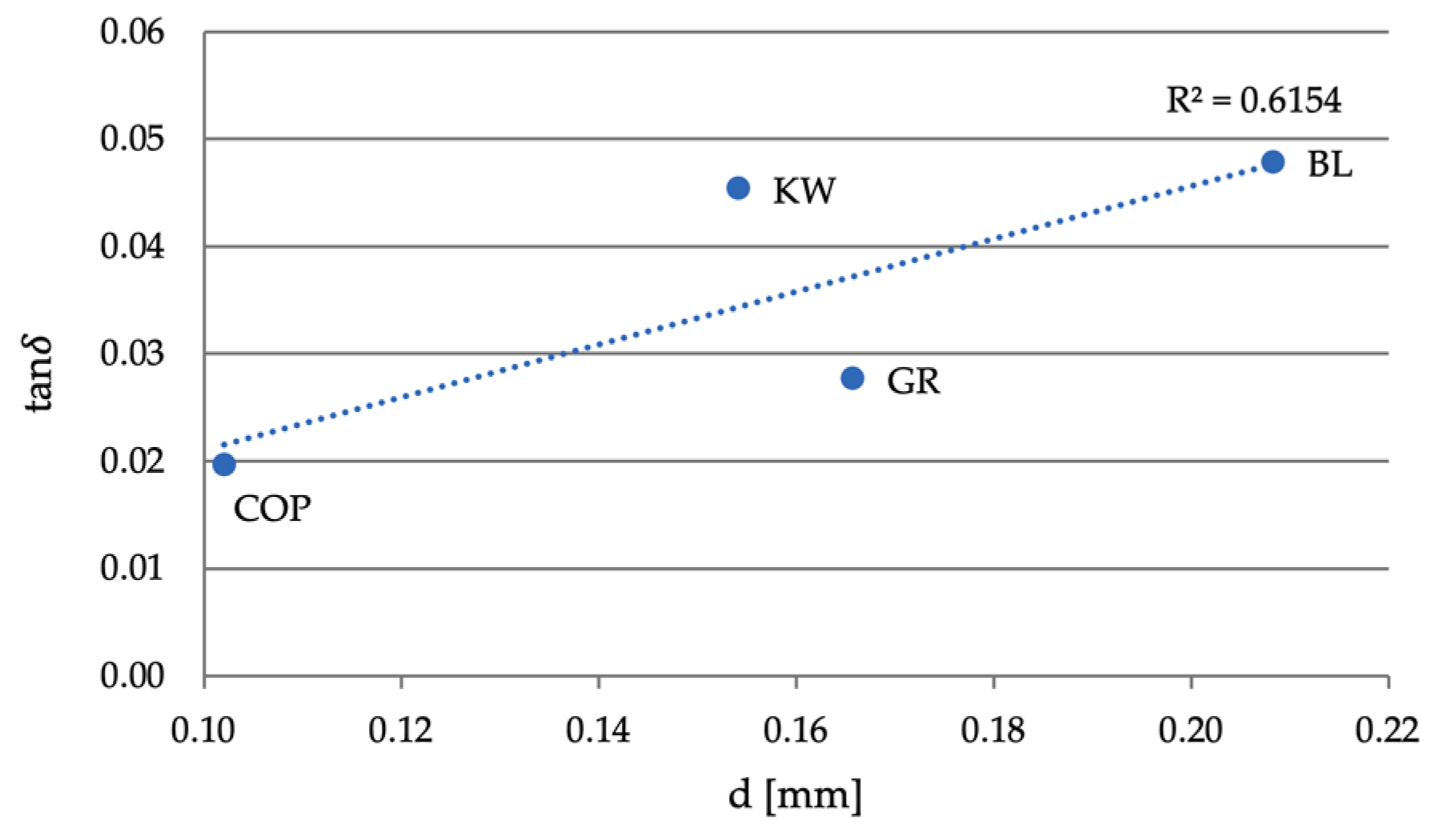

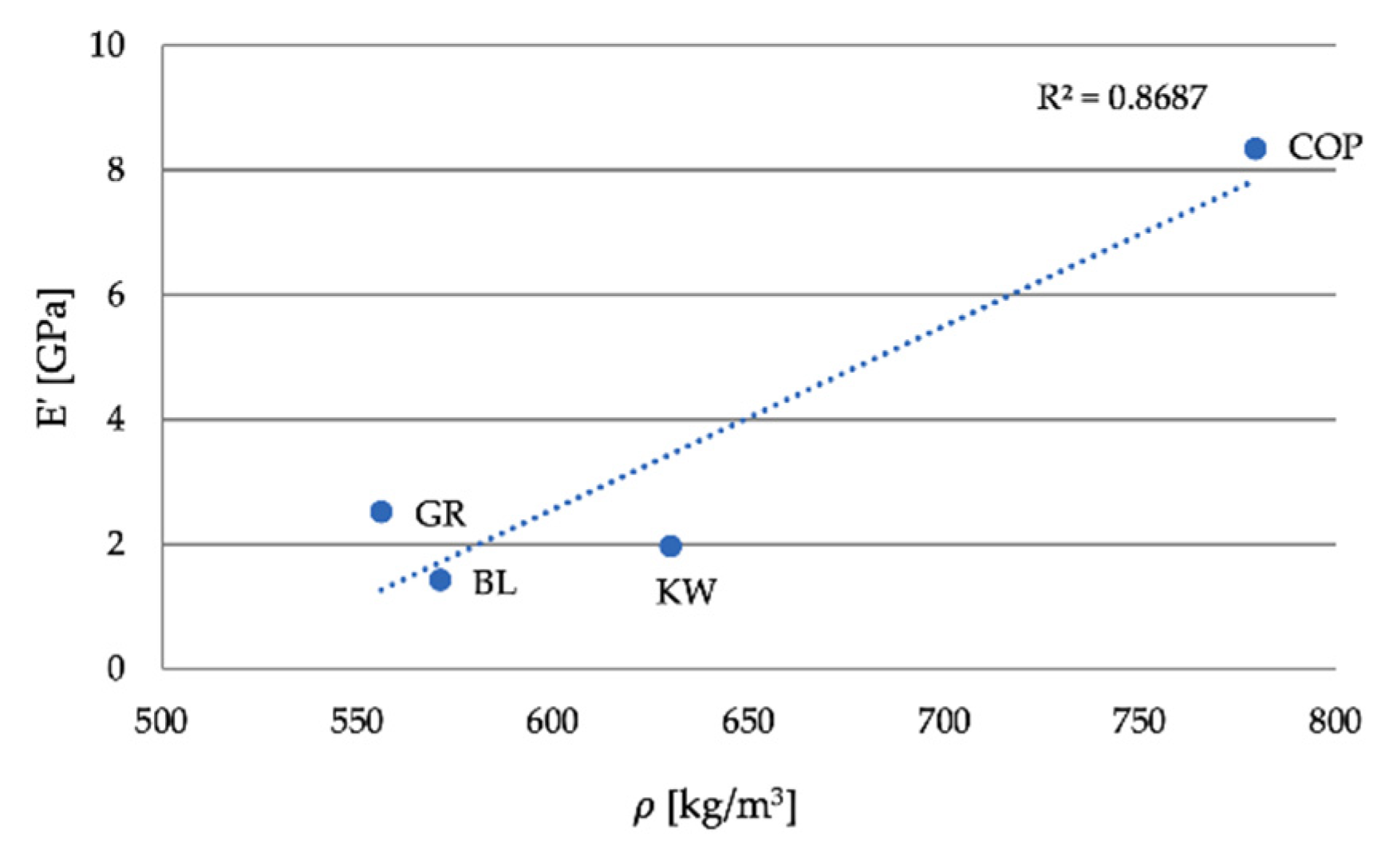

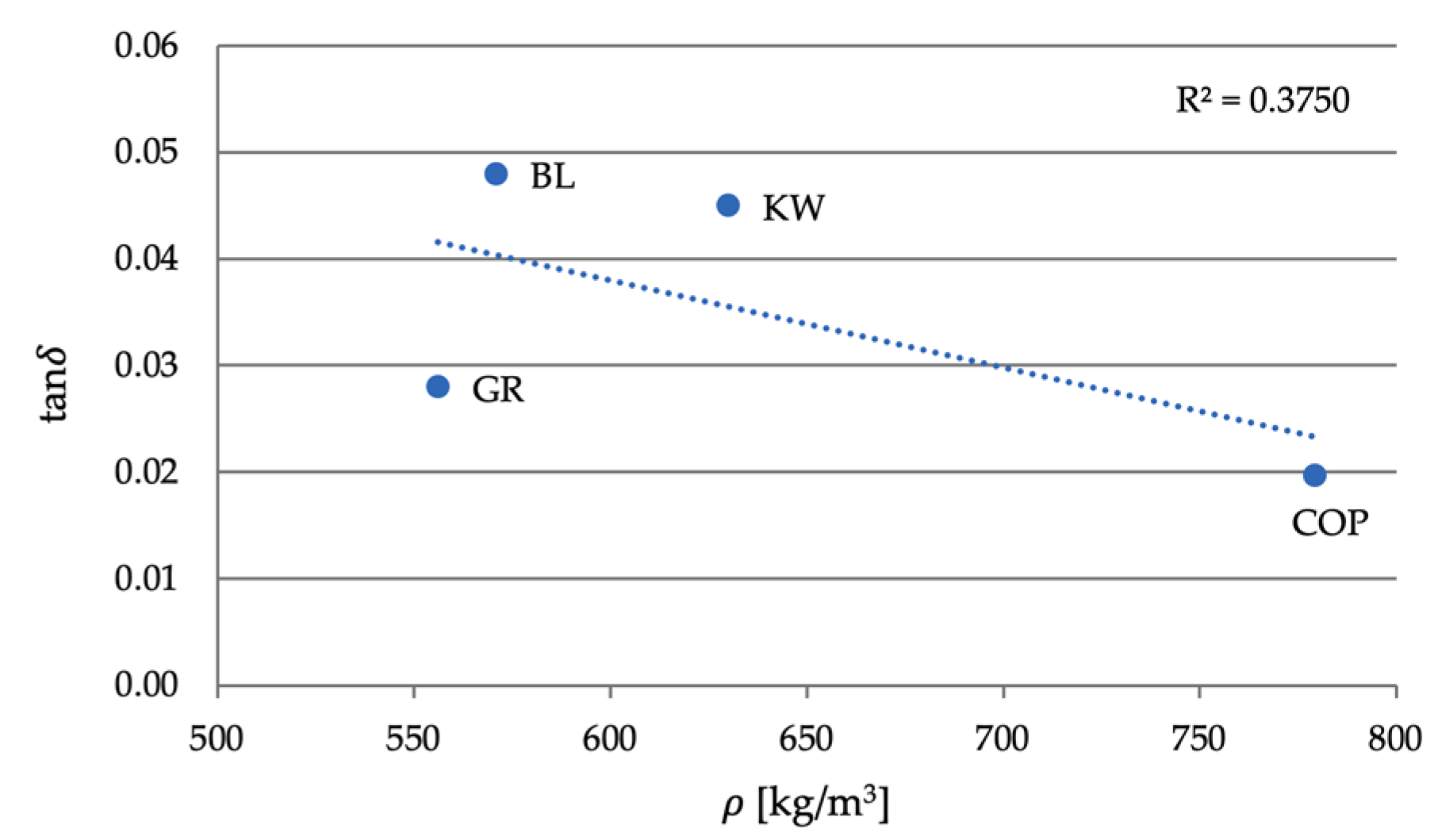

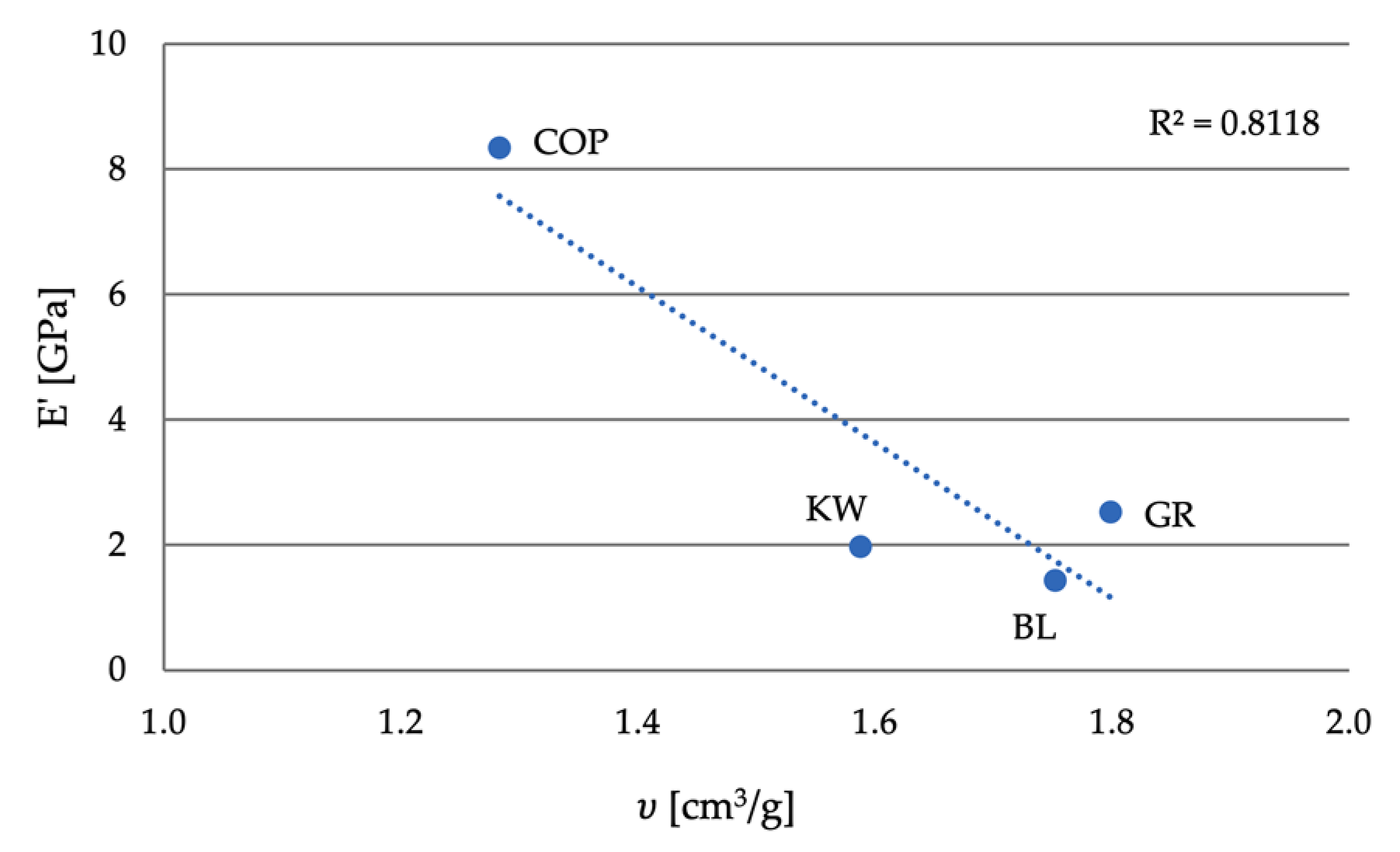

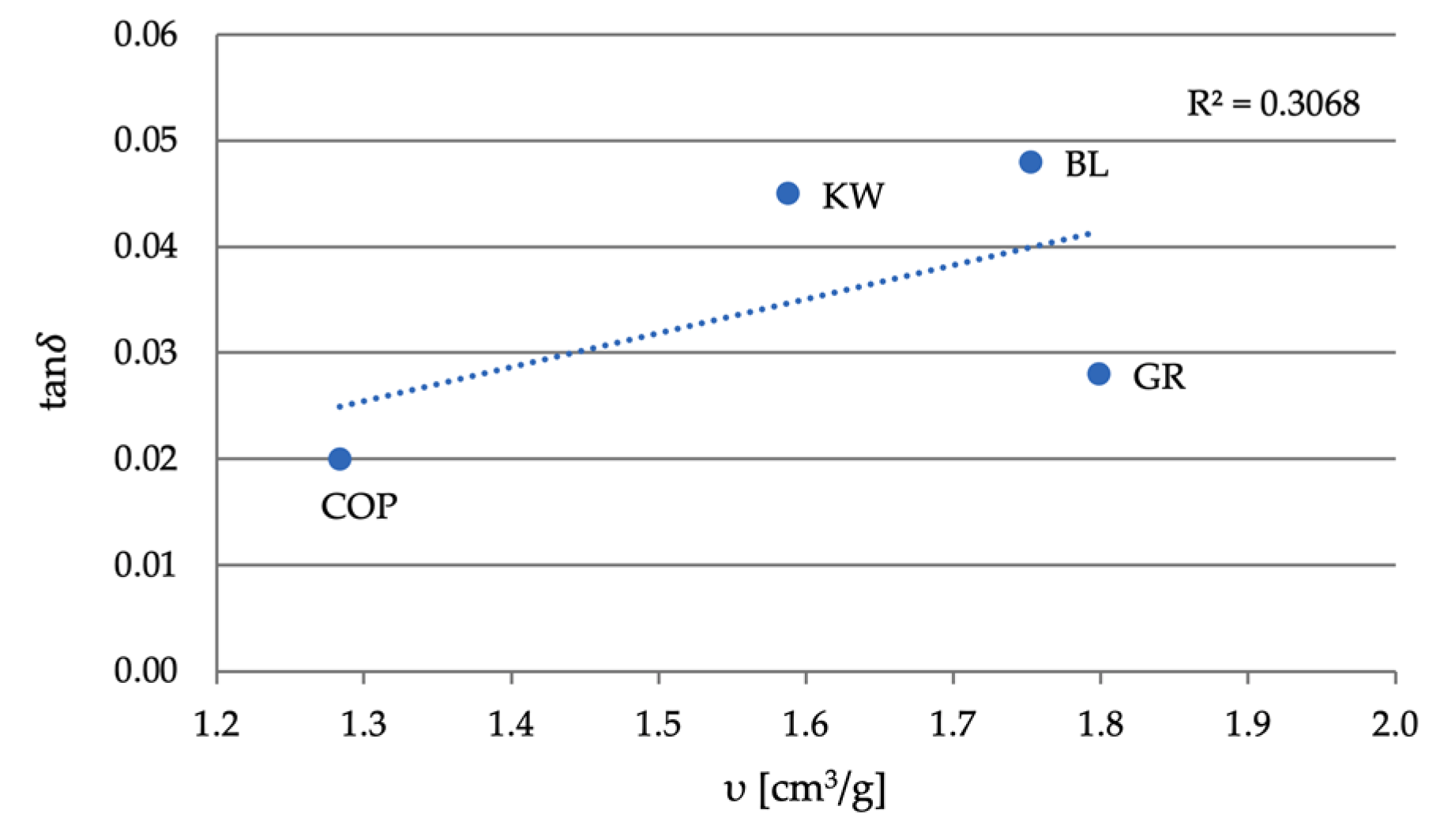

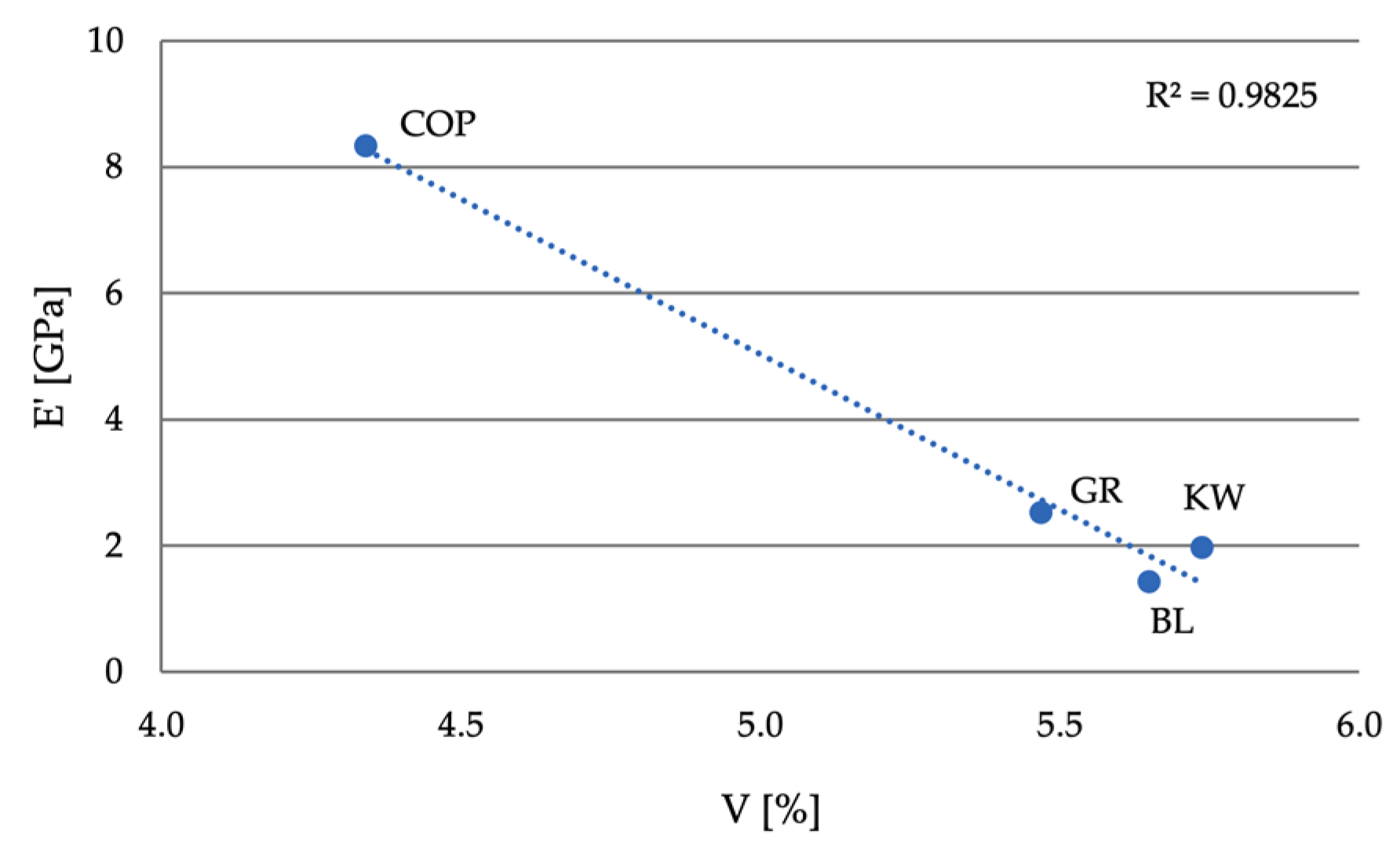

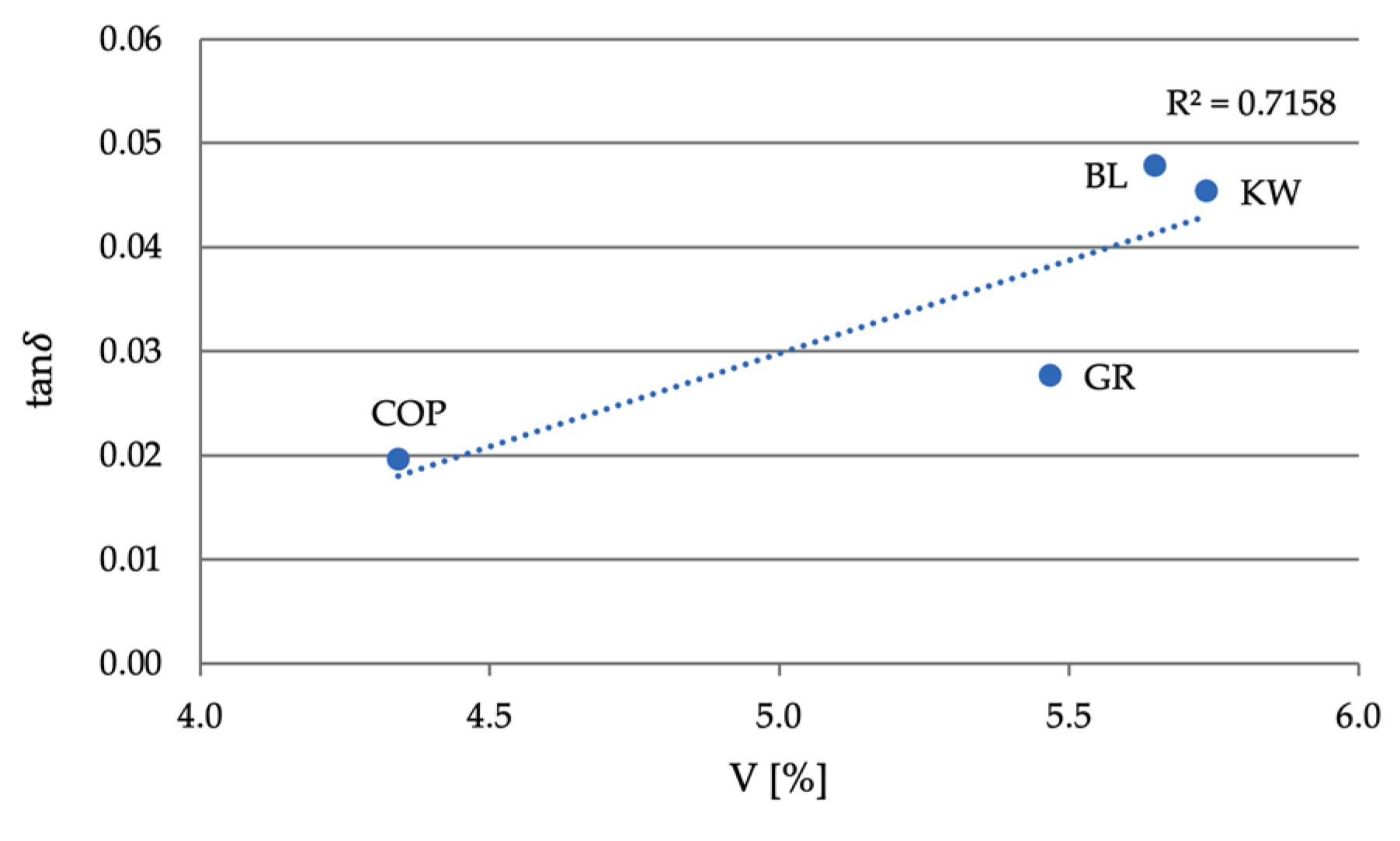

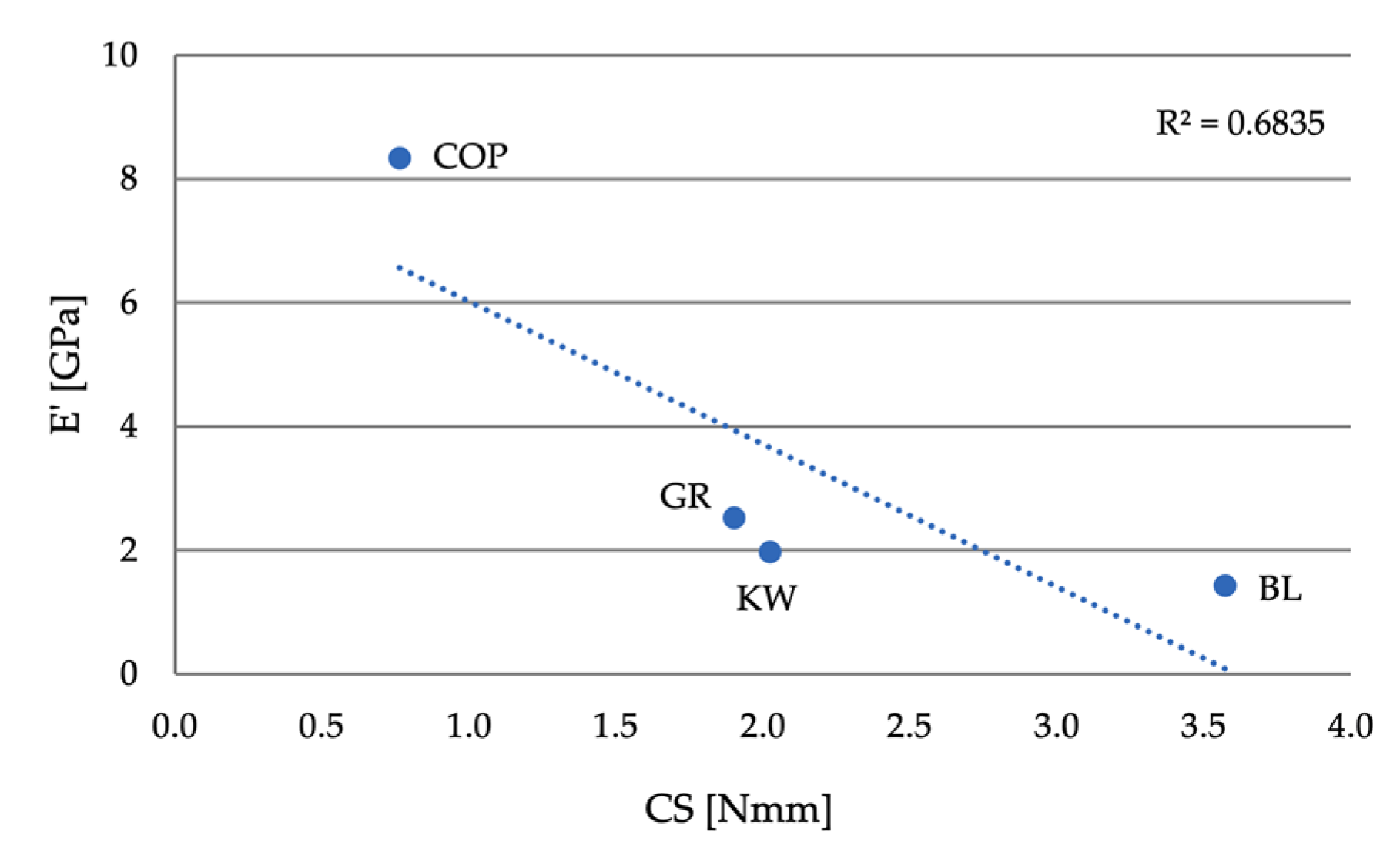

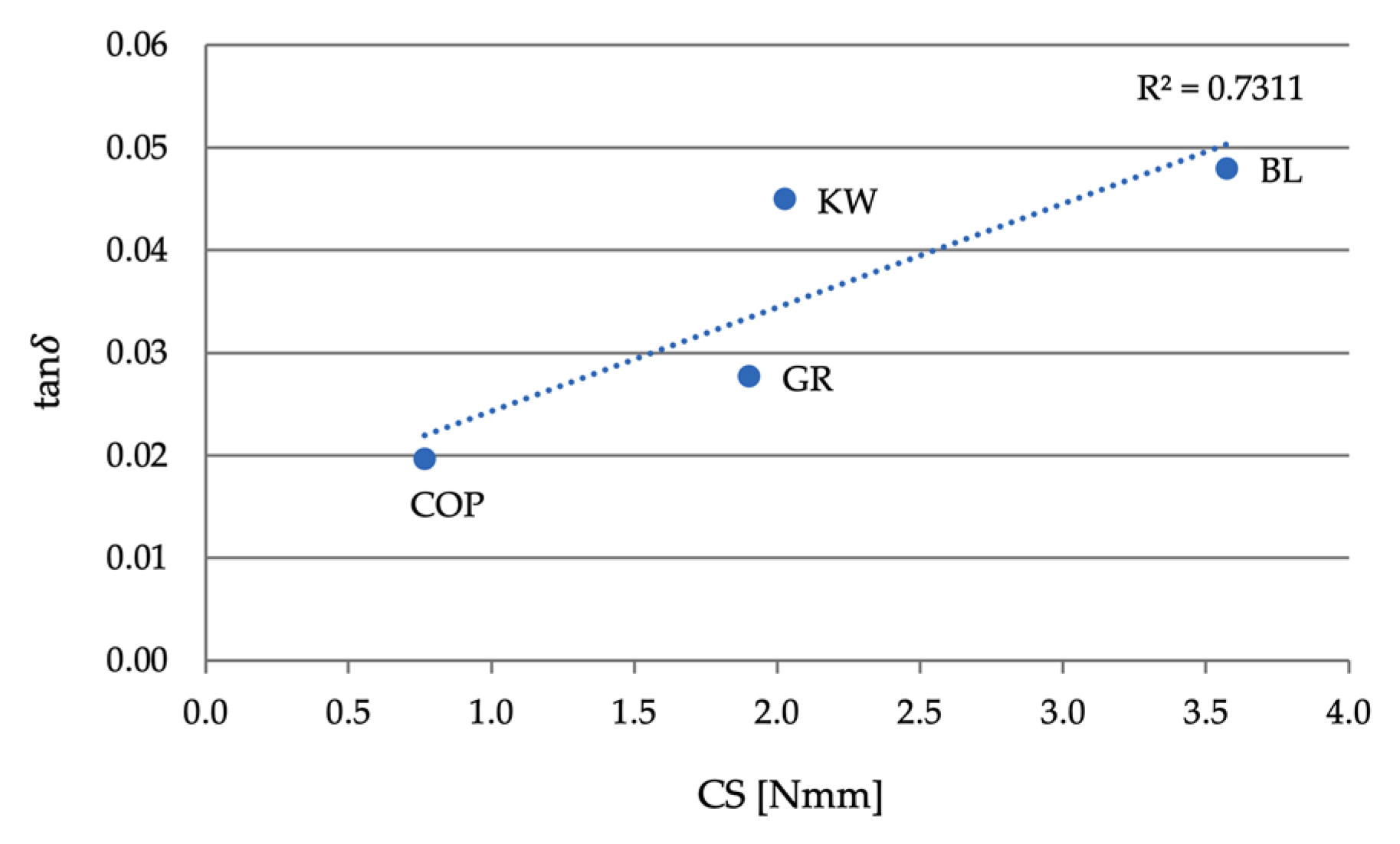

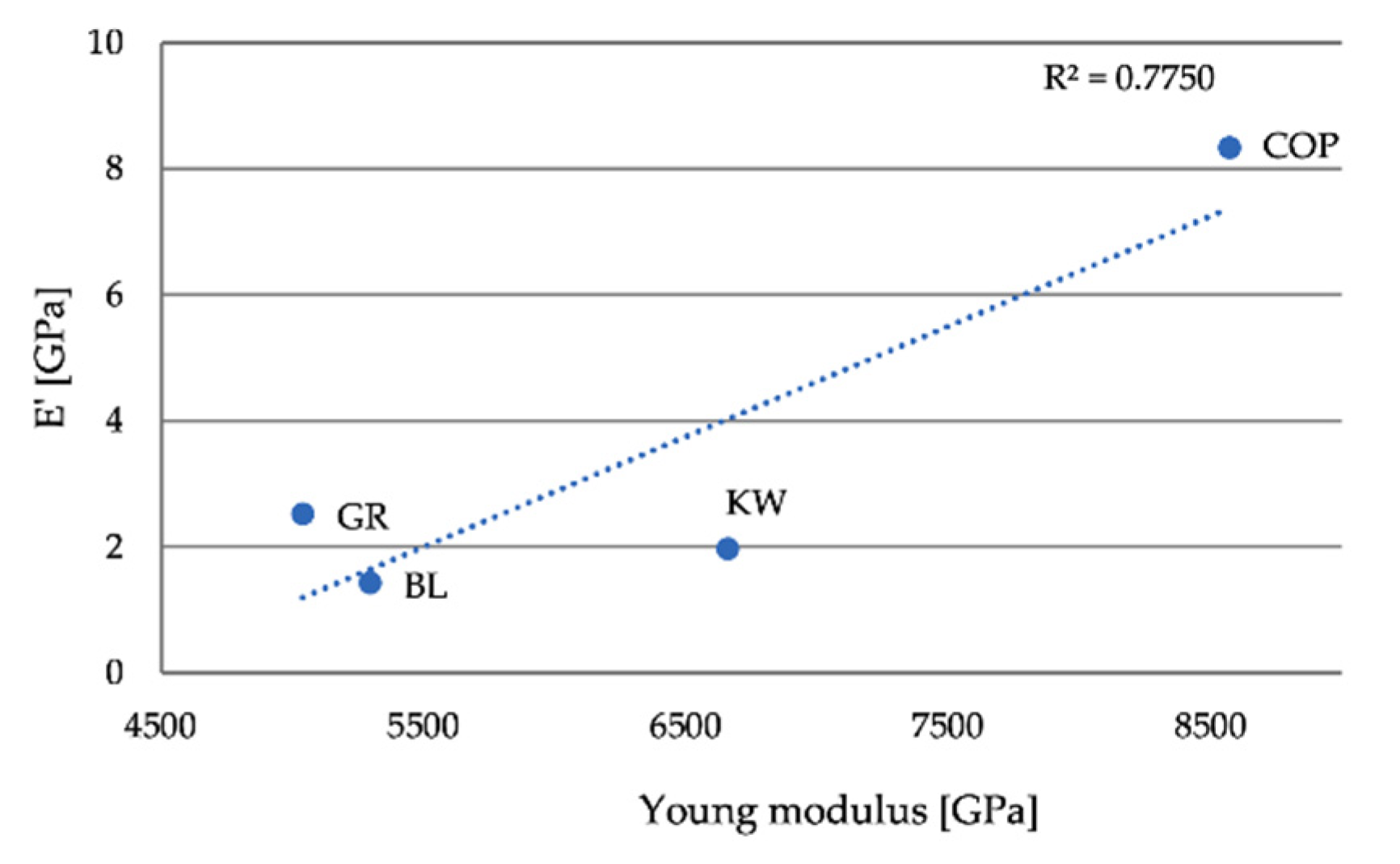

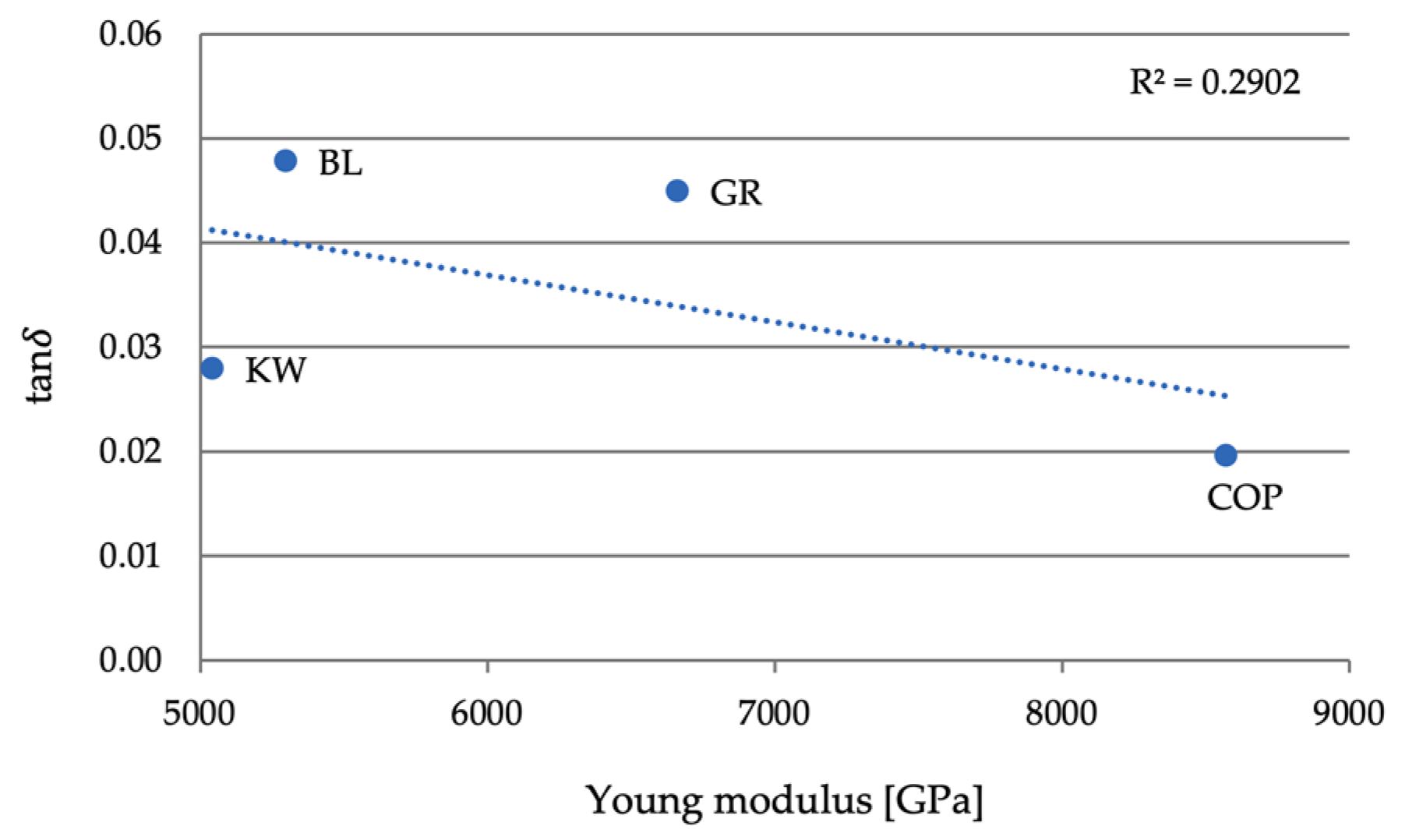

3.3.4. Linear Correlations between Structural, Physical, and Dynamic Properties

By comparing the structural and physical-mechanical properties with the viscoelastic properties, such as storage modulus, i.e., elastic fraction, E′, and phase difference, tanδ, interesting linear correlations between the measured values can be observed (

Figure 14,

Figure 15,

Figure 16,

Figure 17,

Figure 18,

Figure 19,

Figure 20,

Figure 21,

Figure 22,

Figure 23,

Figure 24,

Figure 25,

Figure 26 and

Figure 27). The viscoelastic behavior of the papers is mainly influenced by the moisture content, i.e., for the influence of the moisture content in the paper that it has on the elastic fraction, the linear correlation between the studied papers is 98.25% (

Figure 22), while the influence on the phase difference is 71.58% (

Figure 23). The lowest degree of linear correlation of the basic and physical-mechanical properties on the viscoelastic properties, i.e., mainly on the phase difference, has the Young’s modulus, 29.02% (

Figure 27), the specific volume, 30.68% (

Figure 21) and the paper density, 37.50% (

Figure 19). In all cases of comparison of basic and physical-mechanical properties with viscoelastic properties, GR is closest to COP, which directly indicates less use of cellulose fibers from invasive alien plants and more use of wood fibers in papermaking. We can also conclude that European goldenrod cellulose fibers (GR) are the closest to tree fibers in terms of basic and physical-mechanical properties and that they can be more integrated into papermaking for production purposes, which is an alternative to reducing the proportion of wood species in cellulose fibers. It is also encouraging that Japanese knotweed fibers (KW), one of the most widespread alien invasive plants, are relatively close to European goldenrod fibers (GR) in all cases of viscoelastic response, while acacia fibers (BL) are the most prominent and consequently the least suitable for the mechanical papermaking process.