Meeting Challenges in Forestry: Improving Performance and Competitiveness

Abstract

1. Introduction

2. Materials and Methods

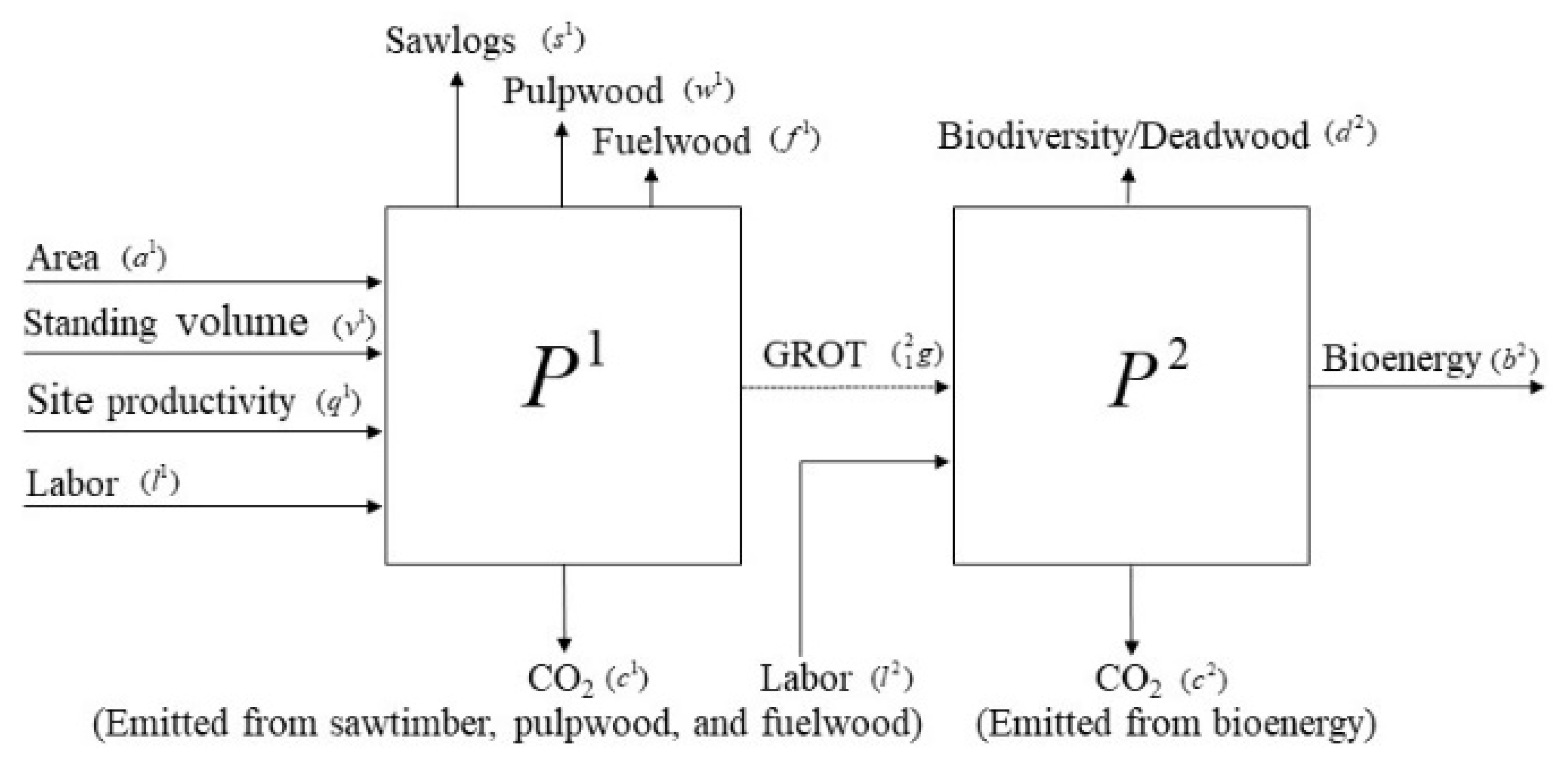

2.1. Efficiency Estimation (Network DEA)

2.2. Partial Equilibrium Forest Model

2.3. Data

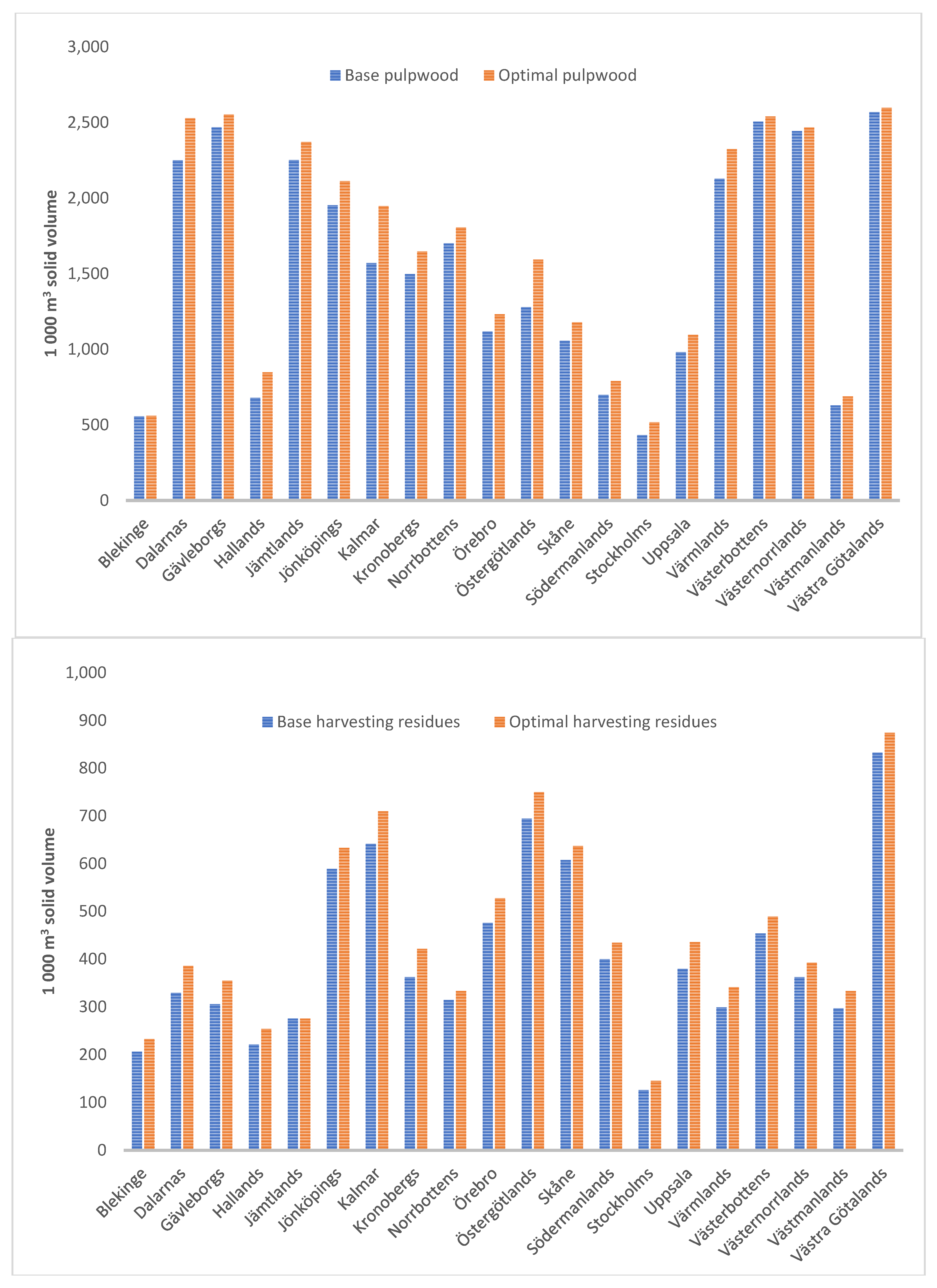

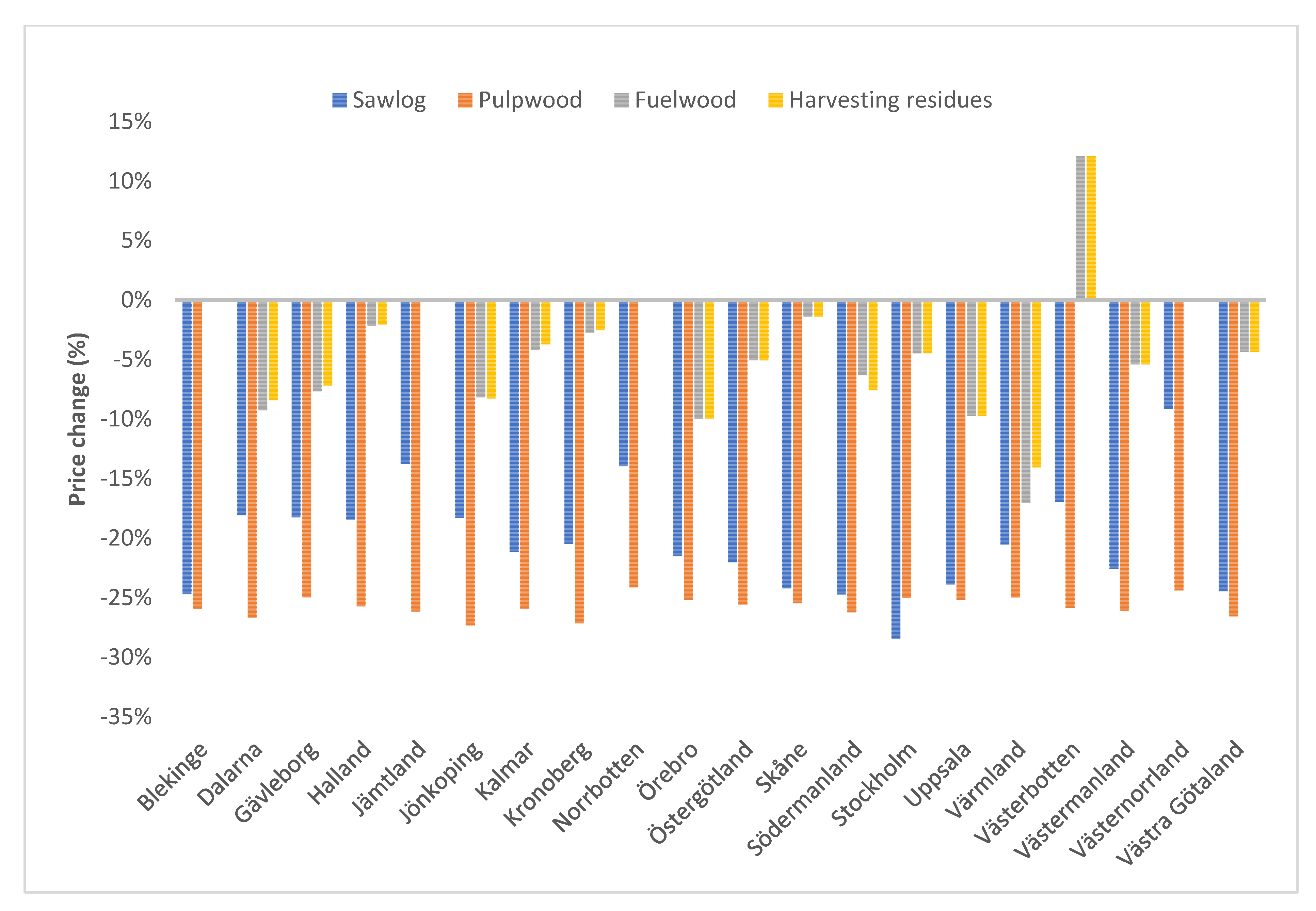

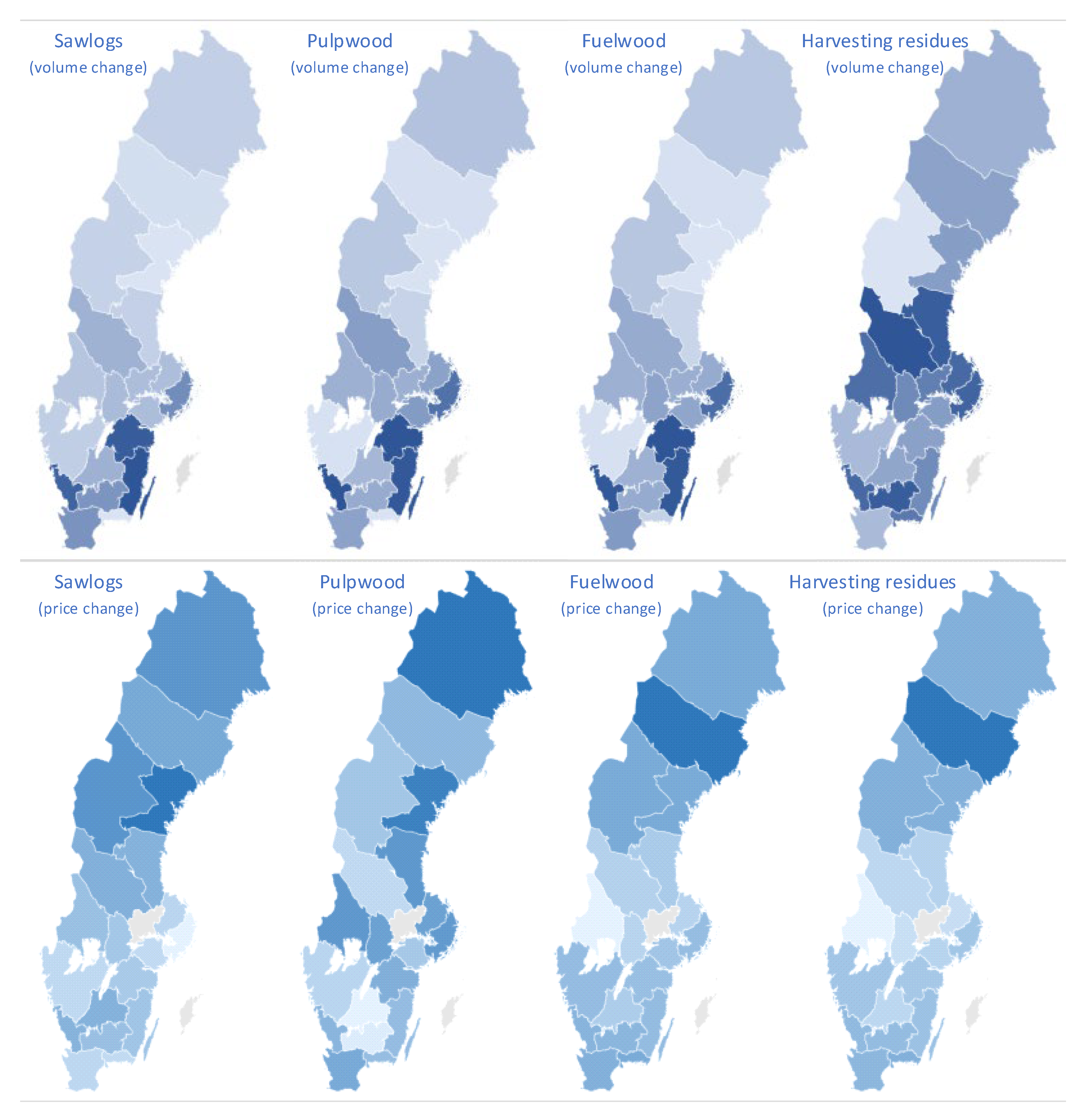

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Technology | Type | Variable | Definition |

|---|---|---|---|

| Input | Area of productive forest land (1000 ha) | ||

| Site productivity of productive forest land (m3 standing volume/ha/year) | |||

| Standing volume on productive forest land (million m3 standing volume) | |||

| Annual working units in forestry, which is the total number of working hours divided by 1800 h, i.e., 1 AWU = 1800 h | |||

| Output | Volume of sawtimber of annual fellings (1000 m3 solid volume under bark) | ||

| Volume of pulpwood of annual fellings (1000 m3 solid volume under bark) | |||

| Volume of fuelwood of annual fellings (1000 m3 solid volume under bark) | |||

| Total harvesting residues associated with fellings (1000 tonnes dry matter) | |||

| Amount of carbon emitted from combustion of byproducts from sawtimber and pulpwood, and of fuelwood (1000 tonnes carbon) | |||

| Input | Total harvesting residues associated with fellings (1000 tonnes dry matter) | ||

| Overall cost of extracting harvesting residues to end customer (SEK), including labour, transport cost and machine cost | |||

| Output | Volume of deadwood left in forest (million m3 over bark) | ||

| Amount of bioenergy (1000 tonnes dry matter). | |||

| Amount of carbon emitted from combustion of bioenergy (1000 tonnes carbon) |

| Variables | Mean | s.d. | Minimum | Maximum |

|---|---|---|---|---|

| Forest land area | 1068 | 959 | 120 | 3591 |

| Site productivity | 7 | 2 | 3 | 11 |

| Standing volume | 144 | 95 | 14 | 333 |

| Annual working units | 748 | 439 | 91 | 2303 |

| Sawlogs | 1592 | 864 | 80 | 3662 |

| Pulpwood | 1470 | 794 | 74 | 2941 |

| Fuelwood | 284 | 153 | 14 | 582 |

| All harvesting residues | 554 | 314 | 26 | 1259 |

| Carbon stored in byproducts of sawtimber and pulpwood and fuelwood that would be used as biofuel | 352 | 191 | 18 | 756 |

| Cost of extracting harvesting residues | 75 | 48 | 7 | 217 |

| Dead wood | 8 | 7 | 0 | 28 |

| Harvesting residues | 67 | 41 | 7 | 193 |

| Carbon stored in extracted harvesting residues | 33 | 20 | 3 | 95 |

| Variable/Parameter | Description |

|---|---|

| CS | Consumer surplus |

| H | Roundwood harvesting rate |

| PSHR | Producer surplus harvesting residues |

| PSRW | Producer surplus roundwood |

| Q | Consumption quantity of end-good |

| R | Harvesting rate residues |

| TR | Tradable quantities |

| Welfare | Welfare |

| X | Input quantities |

| a | Reservation price roundwood |

| b | Reservation price harvesting residues |

| h | Observed harvesting rate of roundwood |

| k | Forest industry capacity constraint |

| l | Lower integral value |

| p | Observed price |

| q | Observed quantity end-good |

| r | Observed extraction rate of harvesting residues |

| tc | Unit transport cost |

| 𝜀 | Inverse elasticity of roundwood |

| 𝛳 | Input-output coefficient |

| 𝜇 | Inverse price elasticity of supply for harvesting residues |

| 𝜉 | Own-price elasticity of end-goods |

| 𝜑 | Shift parameter harvesting residues |

| 𝜔 | Shift parameter roundwood |

| 𝜂 | Roundwood supply elasticity |

| 𝜈 | Harvesting residues supply elasticity |

| Production Capacity | ||||||

|---|---|---|---|---|---|---|

| County | Sawmill1 (million m3) | Sulfate Pulp 1 (million tons) | Sulphite Pulp 1 (million tons) | Mechanical Pulp 1 (million tons) | Wood Pellets 2 (million tons) | Heat 3 (GWh) |

| Blekinge | 0.00 | 0.49 | 0.00 | 0.00 | 0.000 | 0.235 |

| Dalarna | 2.20 | 0.00 | 0.00 | 0.99 | 0.200 | 0.841 |

| Gotland | 0.04 | 0.00 | 0.00 | 0.00 | 0.004 | 1.115 |

| Gävleborg | 1.55 | 1.49 | 0.00 | 0.00 | 0.271 | 0.197 |

| Halland | 1.16 | 0.49 | 0.00 | 0.29 | 0.153 | 0.417 |

| Jämtland | 0.77 | 0.00 | 0.00 | 0.00 | 0.123 | 0.693 |

| Jönköping | 1.94 | 0.00 | 0.00 | 0.19 | 0.264 | 0.932 |

| Kalmar | 1.80 | 0.79 | 0.00 | 0.00 | 0.150 | 0.807 |

| Kronoberg | 1.02 | 0.00 | 0.00 | 0.00 | 0.001 | 1.012 |

| Norrbotten | 1.12 | 1.29 | 0.00 | 0.00 | 0.171 | 0.624 |

| Örebro | 0.65 | 0.59 | 0.00 | 0.10 | 0.109 | 0.987 |

| Östergötland | 1.07 | 0.45 | 0.00 | 0.59 | 0.085 | 1.871 |

| Skåne | 0.30 | 0.00 | 0.39 | 0.00 | 0.000 | 2.316 |

| Södermanland | 0.30 | 0.00 | 0.00 | 0.00 | 0.058 | 1.349 |

| Stockholm | 0.00 | 0.00 | 0.00 | 0.69 | 0.0005 | 4.943 |

| Uppsala | 0.55 | 0.59 | 0.00 | 0.00 | 0.001 | 1.155 |

| Värmland | 1.17 | 1.59 | 0.10 | 0.19 | 0.149 | 0.854 |

| Västerbotten | 2.00 | 0.29 | 0.00 | 0.00 | 0.168 | 1.514 |

| Västernorrland | 0.67 | 0.00 | 0.00 | 0.00 | 0.110 | 1.170 |

| Västmanland | 2.05 | 1.69 | 0.29 | 0.80 | 0.177 | 1.080 |

| V. Götaland | 0.55 | 0.10 | 0.00 | 0.00 | 0.175 | 2.373 |

| County | Sawlogs 1 (m3fub) | Pulpwood 1 (m3fub) |

|---|---|---|

| Blekinge | 0.509 | 0.315 |

| Dalarna | 0.462 | 0.285 |

| Gotland | 0.462 | 0.285 |

| Gävleborg | 0.462 | 0.285 |

| Halland | 0.509 | 0.315 |

| Jämtland | 0.456 | 0.292 |

| Jönköping | 0.509 | 0.315 |

| Kalmar | 0.509 | 0.315 |

| Kronoberg | 0.509 | 0.315 |

| Norrbotten | 0.456 | 0.292 |

| Örebro | 0.462 | 0.285 |

| Östergötland | 0.462 | 0.285 |

| Skåne | 0.509 | 0.315 |

| Södermanland | 0.462 | 0.285 |

| Stockholm | 0.462 | 0.285 |

| Uppsala | 0.462 | 0.285 |

| Värmland | 0.462 | 0.285 |

| Västerbotten | 0.456 | 0.292 |

| Västernorrland | 0.462 | 0.285 |

| Västmanland | 0.456 | 0.292 |

| Västra Götaland | 0.509 | 0.315 |

| All counties | ||

| Fuelwood 2 (m3fub) | 0.204 | |

| Harvesting residues 2 (m3fub) | 0.485 | |

| Sawnwood 1 (m3) | ||

| Sawnwood 1 (m3) | 1.913 | |

| Sulphate pulp 1 (ton) | 4.501 | |

| Sulphite pulp 1 (ton) | 4.810 | |

| Mechanical pulp 1 (ton) | 3.951 | |

| Wood pellets 1 | 0.293 | |

| Heat 3 (MWh) | 0.700 |

| Sawlogs 1 | Pulpwood 1 | Fuelwood 1 | Harvesting Residues 1 | Sawnwood 2 |

|---|---|---|---|---|

| 0.47 | 0.28 | 0.11 | 0.11 | −0.16 |

| Sulphate pulp 2 | Sulphite pulp 2 | Mechanical pulp 2 | Wood pellet 2 | Heat 2 |

| −0.18 | −0.18 | −0.18 | −0.62 | −0.25 |

| County | Base Values | |||

|---|---|---|---|---|

| Sawlog | Pulpwood | Fuelwood | Harvesting Residues | |

| Blekinge | 603.2 | 556.7 | 107.4 | 76.3 |

| Dalarna | 2433.0 | 2250.6 | 433.9 | 122.0 |

| Gotland | 2673.0 | 2468.2 | 475.9 | 113.1 |

| Gävleborg | 104.2 | 93.1 | 20.2 | 42.4 |

| Halland | 735.1 | 680.3 | 131.4 | 81.9 |

| Jämtland | 2441.1 | 2252.4 | 434.5 | 101.9 |

| Jönköping | 2111.8 | 1952.5 | 377.6 | 218.0 |

| Kalmar | 1704.3 | 1569.7 | 302.9 | 237.5 |

| Kronoberg | 1612.7 | 1496.9 | 289.0 | 134.1 |

| Norrbotten | 1839.4 | 1700.6 | 327.8 | 116.3 |

| Örebro | 1208.6 | 1118.4 | 215.7 | 176.2 |

| Östergötland | 1389.6 | 1278.3 | 246.5 | 256.9 |

| Skåne | 1141.5 | 1056.9 | 203.7 | 224.8 |

| Södermanland | 757.7 | 699.8 | 134.9 | 148.0 |

| Stockholm | 471.3 | 432.8 | 83.4 | 46.8 |

| Uppsala | 1062.9 | 981.9 | 189.2 | 140.5 |

| Värmland | 2305.0 | 2128.3 | 410.2 | 110.6 |

| Västerbotten | 2714.9 | 2506.2 | 483.5 | 167.8 |

| Västernorrland | 678.3 | 628.3 | 121.1 | 109.9 |

| Västmanland | 2660.3 | 2443.1 | 471.0 | 134.0 |

| Västra Götaland | 2785.1 | 2568.4 | 495.6 | 308.1 |

References

- Li, Y.; Mei, B.; Linhares-Juvenal, T. The economic contribution of the worldߣs forest sector. For. Policy Econ. 2019, 100, 236–253. [Google Scholar] [CrossRef]

- Hurmekoski, E.; Hetemäki, L. Studying the future of the forest sector: Review and implications for long-term outlook studies. For. Policy Econ. 2013, 34, 17–29. [Google Scholar] [CrossRef]

- Sowlati, T. Efficiency studies in forestry using data envelopment analysis. For. Prod. J. 2005, 55, 49–57. [Google Scholar]

- Kao, C.; Yang, Y.C. Reorganization of forest districts via efficiency measurement. Eur. J. Oper. Res. 1992, 58, 356–362. [Google Scholar] [CrossRef]

- Kao, C. Measuring the performance improvement of Taiwan forests after reorganization. For. Sci. 2000, 46, 577–584. [Google Scholar]

- Kao, C. Malmquist productivity index based on common-weights DEA: The case of Taiwan forests after reorganization. Omega—Int. J. Manag. Sci. 2010, 38, 484–491. [Google Scholar] [CrossRef]

- Kao, C.; Chang, P.L.; Hwang, S.N. Data envelopment analysis in measuring the efficiency of forest management. J. Environ. Manag. 1993, 38, 73–83. [Google Scholar] [CrossRef]

- Kao, C. Measuring the efficiency of forest districts with multiple working circles. J. Oper. Res. Soc. 1998, 49, 583–590. [Google Scholar] [CrossRef]

- Kao, C. Efficiency measurement for parallel production systems. Eur. J. Oper. Res. 2009, 196, 1107–1112. [Google Scholar] [CrossRef]

- Kao, C. Congestion measurement and elimination under the framework of data envelopment analysis. Int. J. Prod. Econ. 2010, 123, 257–265. [Google Scholar] [CrossRef]

- Ke, S.F.; Chen, Z.C.; Robson, M.; Wen, Y.L.; Tian, X.H. Evaluating the implementation efficiency of the Natural Forest Protection Program in ten provinces of western China by using Data Envelopment Analysis (DEA). Int. For. Rev. 2015, 17, 469–476. [Google Scholar] [CrossRef]

- Li, L.; Hao, T.; Chi, T. Evaluation on China’s forestry resources efficiency based on big data. J. Clean. Prod. 2017, 142, 513–523. [Google Scholar] [CrossRef]

- Lin, B.; Ge, J. Carbon sinks and output of China’s forestry sector: An ecological economic development perspective. Sci. Total. Environ. 2019, 655, 1169–1180. [Google Scholar] [CrossRef] [PubMed]

- Viitala, E.J.; Hänninen, H. Measuring the efficiency of public forestry organizations. For. Sci. 1998, 44, 298–307. [Google Scholar]

- Gutiérrez, E.; Lozano, S. Avoidable damage assessment of forest fires in European countries: An efficient frontier approach. Eur. J. For. Res. 2013, 132, 9–21. [Google Scholar]

- Kovalcik, M. Efficiency of the Slovak forestry in comparison to other European countries: An application of Data Envelopment Analysis. Cent. Eur. For. J. 2018, 64, 46–54. [Google Scholar]

- Marinescu, M.V.; Sowlati, T.; Maness, T.C. The development of a timber allocation model using data envelopment analysis. Can. J. For. Res. 2005, 35, 2304–2315. [Google Scholar] [CrossRef]

- Pukkala, T. Which type of forest management provides most ecosystem services? For. Ecosyst. 2016, 3, 9. [Google Scholar] [CrossRef]

- Ning, Y.; Liu, Z.; Ning, Z.; Zhang, H. Measuring Eco-Efficiency of State-Owned Forestry Enterprises in Northeast China. Forests 2018, 9, 455. [Google Scholar] [CrossRef]

- Obi, O.F.; Visser, R. Operational efficiency analysis of New Zealand timber harvesting contractors using data envelopment analysis. Int. J. For. Eng. 2017, 28, 85–93. [Google Scholar] [CrossRef]

- Obi, O.F.; Visser, R. Including Exogenous Factors in the Evaluation of Harvesting Crew Technical Efficiency using a Multi-Step Data Envelopment Analysis Procedure. Croat. J. For. Eng. 2018, 39, 153–162. [Google Scholar]

- Susaeta, A.; Adams, D.C.; Carter, D.R.; Gonzalez-Benecke, C.; Dwivedi, P. Technical, allocative, and total profit efficiency of loblolly pine forests under changing climatic conditions. For. Policy Econ. 2016, 72, 106–114. [Google Scholar] [CrossRef]

- He, H.; Weng, Q. Ownership, autonomy, incentives and efficiency: Evidence from the forest product processing industry in China. J. For. Econ. 2012, 18, 177–193. [Google Scholar] [CrossRef]

- Buongiorno, J. Forest sector modeling: A synthesis of econometrics, mathematical programming, and system dynamics methods. Int. J. Forecast. 1996, 12, 329–343. [Google Scholar] [CrossRef]

- Latta, G.S.; Sjolie, H.K.; Solberg, B. A review of recent developments and applications of partial equilibrium models of the forest sector. J. For. Econ. 2013, 19, 350–360. [Google Scholar] [CrossRef]

- Kallio, A.M.; Dykstra, D.P.; Binkley, C.S. The Global Forest Sector: An Analytical Perspective; John Wiley & Sons: Chichester, UK, 1987. [Google Scholar]

- Buongiorno, J.; Zhu, S.; Zhang, D.; Turner, J.; Tomberlin, D. The Global Forest Products Model: Structure, Estimation and Applications; Academic Press: San Diego, CA, USA, 2003. [Google Scholar]

- Toppinen, A.; Kuuluvainen, J. Forest sector modelling in Europe: The state of the art and future research directions. For. Policy Econ. 2010, 12, 2–8. [Google Scholar] [CrossRef]

- Olsson, A.; Lundmark, R. Modelling the competition for forest resources: The case of Sweden. J. Energy Nat. Resour. 2014, 3, 11–19. [Google Scholar] [CrossRef][Green Version]

- Bolkesjø, T.F. Modeling Supply, Demand and Trade in the Norwegian Forest Sector. Ph.D. Thesis, Agricultural University of Norway, Ås, Norway, 2004. [Google Scholar]

- Olofsson, E. Regional effects of a green steel industry: Fuel substitution and feedstock competition. Scand. J. For. Res. 2019, 34, 29–52. [Google Scholar] [CrossRef]

- Mustapha, W. The Nordic Forest Sector Model (NFSM): Data and Model Structure; INA Fagrapport 38; Norwegian University of Life Sciences: Ås, Norway, 2016. [Google Scholar]

- Kallio, A.M.; Moiseyev, A.; Solberg, B. Economic impacts of increased forest conservation in Europe: A forest sector model analysis. Environ. Sci. Policy 2006, 9, 457–465. [Google Scholar] [CrossRef]

- Trømborg, E.; Bolkesjø, T.F.; Solberg, B. Second-generation biofuels: Impacts on bioheat production and forest products markets. Int. J. Energy Sect. Manag. 2013, 7, 383–402. [Google Scholar] [CrossRef]

- Bolkesjø, T.F. Projecting pulpwood prices under different assumptions on future capacities in the pulp and paper industry. Silva Fenn. 2005, 39, 103–116. [Google Scholar] [CrossRef][Green Version]

- Turner, J.; Buongiorno, J.; Zhu, S. Effects of the Free Trade Area of the Americas on Forest Resources. Agric. Resour. Econ. Rev. 2005, 34, 1–15. [Google Scholar] [CrossRef]

- Trømborg, E.; Buongiorno, J.; Solberg, B. The global timber market: Implications of changes in economic growth, timber supply, and technological trends. For. Policy Econ. 2000, 1, 53–69. [Google Scholar] [CrossRef]

- Mustapha, W.; Trømborg, E.; Bolkesjø, T.F. Forest-based biofuel production in the Nordic countries: Modelling of optimal allocation. For. Policy Econ. 2019, 103, 45–54. [Google Scholar] [CrossRef]

- Wenchao, Z.; Bostian, M.; Färe, R.; Grosskopf, S.; Lundgren, T. Efficient and Sustainable Bioenergy Production in Swedish Forests—A Network DEA Approach. The Data Envelopment Analysis Journal. Forthcoming Theme Issue on the Measurement of Environmental Efficiency. See pre-print in CERE Working Paper Series 2019:12. 2020. Available online: www.cere.se (accessed on 4 May 2020).

- Färe, R.; Grosskopf, S. New Directions: Efficiency and Productivity; Springer Science & Business Media Inc.: New York, NY, USA, 2004. [Google Scholar]

- Olofsson, E. An Introduction to the Norrbotten County Forest Sector Model. Technical Report for a Regional Partial Equilibrium Model. 2018. Available online: http://ltu.divaportal.org/smash/get/diva2:1198792/FULLTEXT01.pdf (accessed on 17 September 2019).

- Carlsson, M. Bioenergy from the Swedish Forest Sector. (Licentiate thesis), Swedish University of Agricultural Sciences. 2012. Available online: https://pub.epsilon.slu.se/9117/ (accessed on 17 September 2019).

- Hazell, P.B.R.; Norton, R.D. Mathematical Programming for Economic Analysis in Agriculture; Macmillan: New York, NY, USA, 1986. [Google Scholar]

- SFA. Swedish Forest Agency—Statistics. Online Database. 2018. Available online: https://www.skogsstyrelsen.se/en/statistics/ (accessed on 10 February 2020).

- NFI. Swedish National Forest Inventory—Official Statistics about the Status and Changes in Sweden´s Forests. 2018. Available online: https://www.slu.se/en/Collaborative-Centres-and-Projects/the-swedish-national-forest-inventory/ (accessed on 10 February 2020).

- Claesson, S.; Duvemo, K.; Lundström, A.; Wikberg, P.E. Skogliga Konsekvensanalyser 2015—SKA15 (Forest Impact Analysis); (In Swedish (No. 10)); Skogsstyrelsen and SLU: Jönköping, Sweden, 2015. [Google Scholar]

- SDC. Biometria. Online Database. 2018. Available online: https://www.sdc.se/default.asp?id=1107&ptid= (accessed on 10 February 2020).

- Skogforsk. 2018. Available online: https://www.skogforsk.se/english/ (accessed on 10 February 2020).

- Nordzell, H. Costs and Benefits of Reducing Greenhouse Gas Emissions Through Conversion of Wetlands into Forest; Avancerad nivå, A2E; SLU Institutionen för Ekonomi: Uppsala, Sweden, 2015. [Google Scholar]

- Skogsindustrierna Här Finns våra Medlemmar (“Here are Our Members”). 2018. Available online: https://www.skogsindustrierna.se/skogsindustrin/vara-medlemmar/karta/ (accessed on 10 February 2020).

- Bioenergi. Pellets i Sverige (Pellets in Sweden). 2018. Available online: https://bioenergitidningen.se/e-tidning-kartor/pelletskartan (accessed on 10 February 2020).

- SCB. Fjärrvärmeproduktion Och Bränsleanvändning (MWh), Efter län Och Kommun, Produktionssätt Samt bränsletyp (”District Heating Production and Fuel Use (MWh), by County and Municipality, Mode of Production and Fuel Type”). 2018. Available online: http://www.statistikdatabasen.scb.se/pxweb/sv/ssd/START__EN__EN0203/?rxid=de3bc7a4-823a-4041-84aa-bbb0fd86d7bf (accessed on 10 February 2020).

- Swedish Energy Agency. Trädbränsle- Och Torvpriser (“Tree Fuel and Peat Prices”). Number 1/2018. Available online: http://www.energimyndigheten.se/globalassets/statistik/priser/tradbransle_och_torvpriser_en0307_2018-03-05.pdf (accessed on 10 February 2020).

- Skogskunskap. Kostnader för skogsbränsle (“Costs for Forest Fuel”). 2018. Available online: https://www.skogskunskap.se/aga-skog/priser--kostnader/kostnader-for-skogsbransle/ (accessed on 10 February 2020).

- Energiföretagen. Fjärrvärmepriser (“District Heating Prices”). 2018. Available online: https://www.energiforetagen.se/statistik/fjarrvarmestatistik/fjarrvarmepriser/ (accessed on 10 February 2020).

- Geijer, E.; Andersson, J.; Bostedt, G.; Brännlund, R.; Hjältén, J. Safeguarding species richness vs. increasing the use of renewable energy—The effect of stump harvesting on two environmental goals. J. For. Econ. 2014, 20, 111–125. [Google Scholar] [CrossRef]

| Forest Product | Average Volume Change (DEA) | Average Price Change (FSM) |

|---|---|---|

| Sawlogs | 9.2 | −20.3 |

| Pulpwood | 8.5 | −25.8 |

| Fuelwood | 7.8 | −4.3 |

| Harvesting residues | 9.7 | −4.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lundmark, R.; Lundgren, T.; Olofsson, E.; Zhou, W. Meeting Challenges in Forestry: Improving Performance and Competitiveness. Forests 2021, 12, 208. https://doi.org/10.3390/f12020208

Lundmark R, Lundgren T, Olofsson E, Zhou W. Meeting Challenges in Forestry: Improving Performance and Competitiveness. Forests. 2021; 12(2):208. https://doi.org/10.3390/f12020208

Chicago/Turabian StyleLundmark, Robert, Tommy Lundgren, Elias Olofsson, and Wenchao Zhou. 2021. "Meeting Challenges in Forestry: Improving Performance and Competitiveness" Forests 12, no. 2: 208. https://doi.org/10.3390/f12020208

APA StyleLundmark, R., Lundgren, T., Olofsson, E., & Zhou, W. (2021). Meeting Challenges in Forestry: Improving Performance and Competitiveness. Forests, 12(2), 208. https://doi.org/10.3390/f12020208