Abstract

In order to understand the physical and mechanical properties of poplar clones, and explore a method for their quick evaluation, the air dry density, modulus of rupture (MOR), modulus of elasticity (MOE), and compressive strength parallel to grains of three new bred poplar clones were explored and the prediction models with the highest accuracy were established by near infrared spectroscopy (NIRs). Clone 50 (Populus deltoides CL. ‘55/65′) had the highest air dry density, MOR, MOE, and compressive strength parallel to grains in the three clones. For clone 50 and 108 (Populus euramericana cv. ‘Guariento’), the mechanical properties of sapwood were better than those of heartwood, and the sapwood of clone 50 also had a better air dry density than that of heartwood. There were significant positive correlations between the air dry density and mechanical properties, with correlation coefficients above 0.68. Prediction models with better effects could be obtained by using information on the cross section for the air dry density and mechanical properties. First derivative+ Savitzky–Golay (S-G) smoothing methods were employed for the air dry density and MOR, and multiple scattering correction (MSC)+ S-G smoothing methods were used when establishing prediction models of MOE and compressive strength parallel to grains.

1. Introduction

Poplar (Populus spp.) has the advantage of a wide distribution and strong adaptability. It is the main species of fast-growing plantations in most countries of the world, such as those located in North America and Canada, and has been widely planted in China [1,2]. The poplar is huge in number and divided into five sections. It has excellent fiber features and displays fast growth and a high yield, so it has mainly been used in pulp and paper, and plywood manufacturing [3,4]. Compared with beech and oak [2,5], poplar wood has the characteristics of a low density and mechanical strength. In recent years, with the development of modification technology, such as wood surface hardening and high temperature heat treatment, the physical and mechanical properties of poplar wood have been improved continuously, so as to apply poplar wood to high value-added products, such as furniture, flooring, and interior decoration wood products [6,7]. Therefore, it is of great practical significance to evaluate the foundation material properties of poplar wood, in order to screen out poplar clones with excellent wood quality traits. In addition, due to the large variations of wood, it takes a lot of manpower and many material resources to test a large number of samples using the traditional wood physical and mechanical property testing methods. Therefore, finding a non-destructive testing method makes sense for quickly predicting the physical and mechanical properties with a range of wood samples, so as to realize the reasonable and value-added utilization of poplar and meet the social production demand.

Previous studies have shown that although the physical properties of poplar plantations have decreased compared with natural forests [8,9], a variety of new varieties of hybrid poplar have better chemical [10] and mechanical properties [11] than natural forests. The density is not only an important index in wood physical properties, but also an important parameter affecting the mechanical properties of wood [12,13]. One study found that four-year-old poplar P. × euramericana cv. ‘74/76′ clones growing under different environmental conditions had an air dry density that ranged from 400 to 403 kg·m−3 [14]. Additionally, 25-year-old Populus deltoides clones grown under the same environmental conditions had a basic density that ranged from 301 to 415 kg·m−3, and there were significant differences among different clones [15].

The mechanical properties of wood are important indexes for evaluating the bearing capacity of wood used in wood products, including the compressive strength, modulus of rupture (MOR), and modulus of elasticity (MOE) [16,17]. In a study of different poplar clones, it was found that there were differences among different clones, such as 9-year-old Populus x euramericanu, 5-year-old Populus x eurameriana (Dode) Guineir, and 10-year-old Qinbaiyang Series (Populus spp.), with the same age and habitat conditions [18,19,20,21]. Moreover, Zhao [14] found that the mechanical properties of P. × euramericana cv. ‘74/76′ increased from the pith to bark. There are also correlations between the mechanical properties of wood, such as MOR and MOE [22].

As a fast, accurate, and simple nondestructive testing method, near infrared spectroscopy (NIRs) technology has been applied to the rapid testing of wood material properties [23,24,25]. There have been some studies on the prediction of poplar density by using NIR technology. In a study on Populus tomentosa and other poplar species, it was found that the correlation and accuracy of the model were good using the partial least squares (PLS) method [26]. At present, research on the mechanical property prediction of wood by NIRs mainly focuses on the MOR/MOE of softwood. Most of the research on predicting the properties of poplar is focused on its fiber properties and physical properties [27,28]. There has been little research on the NIR prediction of mechanical properties of poplar and the effect of MOR prediction models was poor [29], so further research is needed. Studies on other wood species have shown that, when using different pretreatment methods, such as multiplicative scatter correction (MSC) and derivatives, the established models had a good prediction effect, and the accuracy was different with different methods [30].

For different poplar clones and the same clones bred in different environmental conditions, the physical and mechanical properties of wood are different. There has been little research on the physical and mechanical properties and their correlations for new poplar clones bred in recent years. Furthermore, few studies on the prediction of the physical and mechanical properties of poplar clones by NIRs could be found.

Therefore, taking three poplar clones introduced from different countries and bred in China as research objects, the air dry density, MOR, MOE, and compressive strength parallel to grains, including their radial variation, were explored. Additionally, the correlation coefficients between the density and mechanical properties were calculated by correlation analysis. Then, different pretreatment methods and spectra of different sections were compared to explore the prediction models with the highest accuracy regarding the physical and mechanical properties of three poplar clones by NIRs. The aim is to understand the physical and mechanical properties of the three poplar clones, and explore a method for quickly obtaining the physical and mechanical properties, so as to provide a scientific basis and theoretical guidance for the genetic improvement and utilization of poplar.

2. Materials and Methods

2.1. Materials

The three clones were collected from a forest farm in Jiaozuo County, He’nan province, China. Jiaozuo (113°13′ east longitude, 35°14′ north latitude) has a subtropical monsoon climate with an average temperature of 14.2–14.8 °C, 2200–2400 h of sunshine, annual average rainfall of 600–700 mm, and a 216–240-day frost-free period.

The three clones belong to different species of Sect. Aigeiros Duby and all were introduced from outside China: Clone 50 (Populus deltoides CL. ‘55/65′) was introduced from Yugoslavia in 1981; 108 (Populus euramericana cv. ‘Guariento’) from Italy (1984); and N179 (Populus nigra CL. ‘N179′) from Germany in the 20th century. They were cultivated with the same forest management at the same site in China and harvested nine years later. Five trees were selected from each clone. Basic information on the specimens is shown in Table 1.

Table 1.

Basic information on the experimental materials.

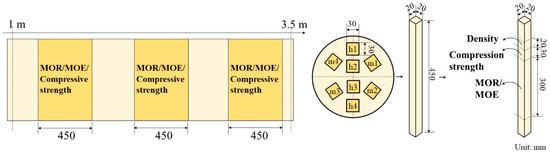

As shown in Figure 1, wood segments of each tree between 1 and 3.5 m in height were taken as research objects. Three 450 mm-long wood segments were cut and blank strips with an end-face size of 30 mm × 30 mm were prepared from them, wherein h1 and h4 samplings were close to the bark; h2 and h3 were nearby the pith; and m1, m2, m3, and m4 were taken from the middle of the discs. Then, wood strips with an end-face size of 20 mm × 20 mm were obtained by planing all around. In total, 71 (clone 50), 99 (clone 108), and 82 (clone N179) samples measuring 20 mm × 20 mm × 20 mm for density testing; 77 (clone 50), 102 (clone 108), and 93 (clone N179) samples measuring 300 mm × 20 mm × 20 mm (L × R × T) for MOR/MOE testing; and 77 (clone 50), 107 (clone 108), and 85 (clone N179) samples measuring 30 mm × 20 mm × 20 mm (L × R × T) for compressive strength parallel to grains testing were prepared, respectively. A sample of each was taken from a blank strip, realizing the integration of the sampling position.

Figure 1.

A diagram of the physical and mechanical properties of a prepared wood specimen.

2.2. Determination of the Density

The air dry density was measured according to GB/T 1933–2009“Method for Determination of the Density of Wood” [31]. First, the specimen was exposed to the conditions of a 20 ℃ temperature and 65% relative humidity to reach an equilibrium moisture content and its weight and radial, tangential, and longitudinal size were measured. Then, the samples were placed in an oven, maintained for 4 h at the temperature of 60 ℃, and baked until dry at 103 ℃. They were weighed every two hours, and when the difference was less than 0.5% of the sample weight, the weight and radial, tangential, and longitudinal size were measured and the air dry density was calculated. Then, it was converted into the air dry density under the condition of a 12% moisture content.

2.3. Determination of the Mechanical Properties

As for the mechanical properties, the moisture content of the samples was adjusted to almost 12% under the condition of a 20 ℃ temperature and 65% relative humidity. Then, the MOR, MOE, and compressive strength parallel to grains of samples were tested by the universal test machine Instron 5580 (Instron, Norwood, MA, USA). Referring to GB/T 1936.2–2009 “Method for Determination of The Modulus of Elasticity in Static Bending of Wood” [32], the MOE was measured by using the 2-point loading test method, the same test sample was loaded in the tangential direction three times, and the average value of the modulus of elasticity of the last two times was taken as the MOE of the test sample. According to GB/T 1936.1–2009 “Method of Testing in Bending Strength of Wood” [33], the MOR of poplar clones was tested by the 1-point loading test method in the tangential direction. Additionally, the compressive strength parallel to grains was obtained by referring to GB/T 1935–2009 “Method of Testing in Compression Strength Parallel to Grain of Wood” [34].

2.4. Acquisition of NIR Spectra

The NIR spectrum of each specimen was measured with an NIR spectrometer (ASD, North Sutton, NG, USA) at a wavelength between 350 and 2500 nm. All measurements were conducted by using a two bifurcated fiber optic sensor. The diameter of the spot on the surface of the sample was 5 mm. In total, 30 scans were collected and averaged to produce a single average spectrum.

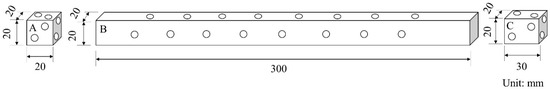

The NIR spectra of MOR and MOE samples were collected from radial sections and tangential sections, while those of the density and compressive strength along grain samples were collected from cross sections, radial sections, and tangential sections (Figure 2). All measurements were made in a conditioned atmosphere maintained at 30% relative humidity and 25 ℃.

Figure 2.

Diagram of the spectral collection position of the mechanical property samples. A: Density sample; B: bending sample; C: compressive strength parallel to grains sample.

2.5. Pretreatment and Analysis of NIR Spectra

The noise and irrelevant information in the NIR original spectrum will affect the final modeling result, so the first derivative method, second derivative method, multiple scattering correction (MSC), and Savitzky–Golay (S-G) smoothing method, which are common pretreatment methods for woods, were used for preprocessing.

The partial least squares (PLS) calibration model and prediction model for the actual value and spectral data of each sample were built by Unscrambler (CAMO, Trondheim, AS, Norway). When establishing the calibration models, the best principal component number was selected by Unscrambler. The PLS components (PCs), correlation coefficient of the calibration model (RC), and root mean square error of calibration (RMSEC) were used as the evaluation indexes of the calibration model effect, and the correlation coefficient of the prediction model (RP) was used as the evaluation index of the prediction model effect.

3. Results

3.1. Physical and Mechanical Properties of Three Kinds of Poplar Clones

3.1.1. Air Dry Density and Its Radial Variation

As Table 2 shows, the density of the three poplar clones ranged from 408 to 458 kg·m−3, so was higher than that reported previously for clones of P. × euramericana cv. ‘74/76′ [14]. Compared to different poplar clones, the density of clone 50 was the highest, while that of clone N179 was the lowest. The results of multiple comparisons also showed that there was a significant difference between clone 50 and the other two clones at the level of 0.05, but no significant difference between clone 108 and N179.

Table 2.

Air dry density of poplar clones.

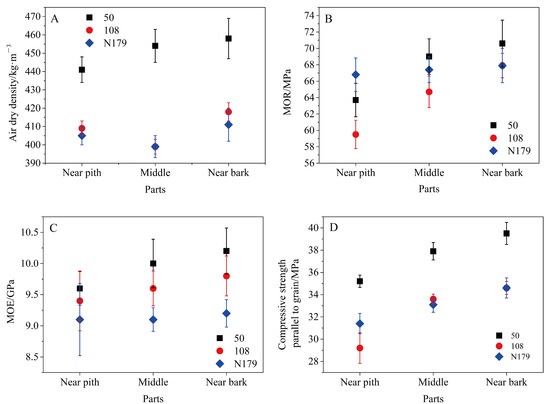

Material variation is one of the major characteristics of wood. The study of the radial variation of the physical and mechanical properties of wood is beneficial to the scientific processing and rational utilization of wood. Figure 3A shows the radial variation trend of the air dry density of three poplar clones from near the pith to near the bark. It can be seen that the air dry density values near the pith, middle, and near the bark of clone 50 were all higher than those of the other two clones. In the radial direction, the air dry density of clone 50 showed a gradually increasing trend from near the pith to near the bark, while clone 108 and N179 showed a trend that declined slightly from near the pith to the middle and increased slightly from the middle to near the bark, suggesting that there was no difference in the air dry density of clones 108 and N179 between heartwood and sapwood. The different clones should have different microstructures. Microstructures, such as the cell wall thickness and wall–lumen ratio, are the main impact factors of the density of wood [35]. The different radial variation trends of the air dry density of the three poplar clones may be due to their microstructures. The air dry density of clone 50 was higher than that of 108 and N179 for all three parts, so it might be that clone 50 had a thicker cell wall and higher wall–lumen ratio. This needs to be studied further.

Figure 3.

Radial variation of the physical and mechanical properties in three poplar clones. (A): air dry density; (B): modulus of rupture (MOR); (C): modulus of elasticity (MOE); (D): compressive strength parallel to grain.

3.1.2. Modulus of Rupture and Its Radial Variation

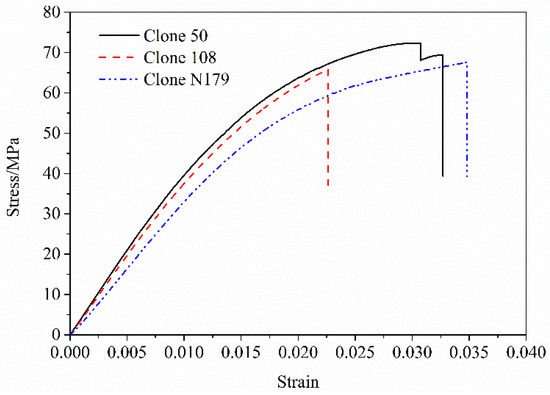

MOR is one of the most important indices of the mechanical properties that should initially be considered for making bending construction members. According to Table 3, the MOR of the three poplar clones ranged from 65.8 to 68.0 MPa. In the three poplar clones, the MOR of clone 50 was the highest, while that of clone 108 was the lowest. However, the results of multiple comparisons showed that there was no obvious difference among the three clones at the level of 0.05. Figure 4 shows the stress–strain curves of MOR of the three poplar clones. It can be seen that the trend of the curves was the same. With the increase of strain, the stress showed two stages of linear increase and slow growth until the specimen was broken.

Table 3.

Statistical results of MOR in three poplar clones.

Figure 4.

The stress–strain curves of MOR of three poplar clones.

Figure 3B shows the radial variation trend of MOR of three poplar clones from near the pith to near the bark. In the radial direction, the MOR of the three clones showed a trend of increasing gradually from near the pith to near the bark. Furthermore, for clone 50 and 108, the growth rate from near the pith to the middle was faster, and the growth rate from the middle to near the bark decreased. The MOR values of sapwood of clone 50 and 108 were 10.8% and 14.1% higher than that of heartwood, respectively. However, the overall change trend of clone N179 was not obvious, indicating that there was little difference in MOR between heartwood and sapwood. There was a great difference between heartwood and sapwood of clone 50 and 108.

3.1.3. Modulus of Elasticity and Its Radial Variation

As an important index of standing timber classification, the MOE reflects the wood performance in resisting bending deformation. As shown in Table 4, the MOE values of the three poplar clones were within the range of 9.18–9.97 GPa. Compared with the other two clones, the MOE of clone 50 was the highest, which was 9.97 GPa. Clone N179 had the lowest MOE of 9.18 GPa. Multiple analysis results showed that at the level of 0.05, there was no significant difference between clone 50 and clone 108, but there was a significant difference between clone 179 and the other two clones.

Table 4.

Statistical results of MOE in three poplar clones.

The radial variation of MOE in the three poplar clones (Figure 3C) showed that the MOE values of all three parts of clone 50 were always the largest, while that of clone N179 was the lowest, being the same as the average of three parts. Moreover, in the radial direction, the MOE of the three clones showed a trend of increasing gradually from near the pith to near the bark. Same as the MOR, the overall change trend of clone N179 was not obvious, and the difference between heartwood and sapwood was small. For clone 50 and 108, the growth rate from near the pith to the middle was faster, and the growth rate from the middle to near the bark decreased, for which the MOE values of sapwood were 6.25% and 4.26% higher than that of heartwood, respectively.

3.1.4. Compressive Strength Parallel to Grains and Its Radial Variation

The compressive strength parallel to grains of the three clones ranged from 33.0 to 37.9 MPa (Table 5). The highest was again recorded for clone 50 (37.9 MPa), with a value that was 13.4% higher than that of clone 108 and 14.8% higher than that of clone N179. Multiple analysis results showed that there was a significant difference between clone 50 and the other two clones at the 0.05 level, but no significant difference between clone 108 and clone N179.

Table 5.

Statistical results of the compressive strength parallel to grains in three poplar clones.

Figure 3D shows the radial variation of the compressive strength parallel to grains of three poplar clones. It could be seen that the compressive strength parallel to grains of clone 50 was the highest in all three parts, and there was not much difference between clone 108 and N179. On the whole, the compressive strength parallel to grains of the three clones showed an increasing trend from near the pith to near the bark. Among them, clone 50 and 108 increased faster from near the pith to the middle, while the increase rate slowed down from the middle to near the bark, showing a significant difference between heartwood and sapwood. For clone 50 and 108, the values of compressive strength parallel to grains of sapwood were 12.2% and 18.5% higher than that of heartwood, respectively. The increase trend of clone N179 was always slow.

3.2. Correlation between the Mechanical Properties and Air Dry Density of Poplar Clones

By comparing the radial variation of different properties, it can be seen that sapwood with a high air dry density also had a high MOR, MOE, and compressive strength parallel to grains. As there were no significant differences between heartwood and sapwood regarding the properties of N179, the correlations between the density and mechanical properties and different mechanical properties were analyzed (Table 6). The correlation coefficients for different clones exhibited some differences. There was a significant positive correlation between the air dry density and MOR/compressive strength parallel to grains, with correlation coefficients above 0.71 at the 0.01 level. The correlation coefficients between the density and MOE were lower overall. The correlation coefficients between the mechanical properties of the three clones ranged from 0.68 to 0.75 at the 0.01 level, among which the correlation coefficients between the MOR and compressive strength parallel to grains were the highest. On the whole, the correlation between the air dry density and MOE was slightly lower than that between the air dry density and MOR or compressive strength.

Table 6.

Correlation between the mechanical properties and air dry density of three poplar clones.

3.3. Prediction of the Physical and Mechanical Properties by NIRs

3.3.1. Spectra of NIR

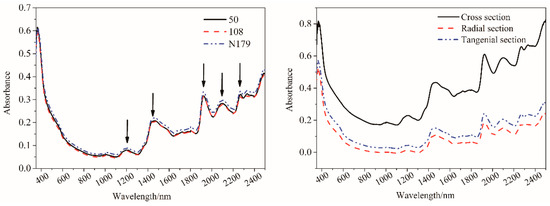

Figure 5 shows the original NIR spectra of three poplar clones and the spectra of different sections. As the figure shows, the near-infrared spectra of each clone were very similar, with strong absorption at 1208, 1461, 1923, 2099, and 2270 nm. Because the 350–400 nm bands contain much noise and less information, this part of the spectral information was not used in the subsequent study. In addition, by comparing the spectra of different sections in Figure 5, it was found that the spectral absorption intensity of the cross section was significantly higher than that of the radial section and tangential section. This rule was similar to previous studies of other species, such as Cunninghamia lanceolata and Eucalyptus pellita [36,37]. Therefore, when the spectral information of different sections is used, the accuracy of the NIR models will be different.

Figure 5.

Near infrared (NIR) spectra of three poplar clones and different sections.

3.3.2. Comparison of Calibration Models with Different Analysis Methods

Selecting clone N179 as the research object, the best modeling method of different properties was explored by using spectra of the cross section, radial section, tangential section, and average of three sections, combining first derivative, second derivative, MSC, and S-G smoothing methods. It was found that when three different sections were used to establish calibration models of the air dry density, the effect of models using information on the cross section was better than that of the radial section and tangential section.

The NIR calibration models of MOR and MOE established with spectra of the radial section or tangential section only had RC values below 0.52. The samples of the air dry density test and mechanical test were taken from adjacent parts of the same strips. Therefore, we used the spectra of cross sections of the air dry density to try to improve the effect of NIR calibration models of MOR and MOE. It is considered that the cross section of samples of the air dry density test is basically consistent with that of the mechanical test.

Table 7 shows the optimal modeling methods and relevant parameters of NIR calibration models with different properties. It can be seen that, for different properties, different methods should be used. For the air dry density and MOR, using the cross section, first derivative+ S-G smoothing methods were more suitable, with Rc of 0.88 and 0.67, respectively. Additionally, MSC+ S-G smoothing methods were suitable for the NIR prediction of MOE and compressive strength parallel to grains.

Table 7.

Partial least squares (PLS) calibration models for different properties.

3.3.3. Comparison of Prediction Models of the Physical and Mechanical Properties

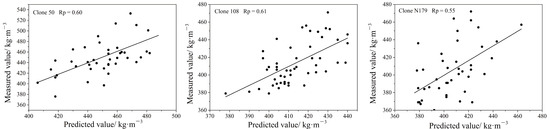

Using the methods obtained in Table 7, the NIR prediction models of four properties of the three clones were established with the full-cross validation method. As shown in Table 8, the Rc of the air dry density NIR calibration models were higher than those of other properties, and the effects of the prediction models differed little from those of the other properties. The prediction model of clone 108 was the best, with RP of 0.61 and RMSEP of 0.019. The correlation between the NIR predicted value and measured value of the air dry density of the three clones is shown in Figure 6. The results showed that NIR could achieve the prediction on the air dry density of the three poplar clones.

Table 8.

PLS calibration and prediction model statistical table for four properties of three clones.

Figure 6.

Correlation between the NIR predicted value and measured value of the air dry density of three clones.

For NIR prediction models on mechanical properties, the RP were between 0.51 and 0.75, except for the prediction model on the MOR of clone N179 (Table 8). The accuracy of the MOR prediction model of clone 50 was the best among the three clones, for which RP was 0.71 and RMSEP was 4.722. For MOE and compressive strength parallel to grains, the effects of the prediction of clone N179 were better than those of clone 50 and 108. Taking into account the physical and mechanical properties, such a prediction accuracy is acceptable. RP of the MOR prediction model of clone N179 was only 0.18, indicating that the prediction of MOR of clone N179 cannot be realized with the current samples. Therefore, it may be necessary to add new samples with larger variability to further improve the prediction model effect. Other studies have also shown that the correlation coefficient of the prediction model for MOR of poplar 72 was poor [29]. Compared with the NIR prediction models of different mechanical properties in the same clone, it was found that for clone 50 and 108, RP of MOR prediction models were the highest (0.71 and 0.69, respectively). However, for clone N179, the prediction model of the compressive strength parallel to grains had best accuracy, with RP of 0.75.

4. Discussion

4.1. The Physical and Mechanical Properties of Three Poplar Clones

The three clones were introduced from three different countries in the 20th century and were cultivated in He’nan province, China. As three clones from the same forest farm were planted and cut at the same time, there was no difference in age and habitat conditions among them. The same forest management was used during their growth period. The density, MOR, MOE, and compressive strength parallel to grains of the three clones are listed in Table 2, Table 3, Table 4 and Table 5. Compared with other poplar clones, such as 9-year-old Populus × euramericanu collected in Quebec, Canada [18], the three clones 50, 108, and N179 had higher MOE values. Additionally, compared with 10-year-old Qinbaiyang collected from Gansu province, China, these three clones had lower MOR, MOE, and compressive strength parallel to grains values [20]. However, they had better mechanical properties than a 9-year-old Populus × tomentosa triploid clone [37]. For the three clones, clone 50 had the best physical and mechanical properties. As there was no influence of age, forest management, and habitat conditions, the effect of the genotype itself on the physical and mechanical properties of poplar clones is revealed [38]. Based on their wood properties, clone 50 should have excellent wood quality traits when it is applied to high value-added products, such as furniture, flooring, and interior decoration wood products. Microstructures can influence the physical and mechanical properties of wood [39,40,41]. The poplar clones should have different microstructures for their different genotypes. They will be further explored and discussed later for the three poplar clones.

For different hardwood species, the radial variation of wood properties law is different. The mechanical properties of some tree species increase gradually from near the pith to near the bark, such as Quercus petraea and Q. robur [42], while some decrease in the radial direction, such as Toona ciliata [39]. However, for the three clones we studied, there has been little research thus far. The physical and mechanical properties of clone 50 showed a radial variation law of increasing from near the pith to near the bark, and the same law was recorded for the mechanical properties of clone 108. This indicated that the properties of sapwood were better than those of heartwood, and this is similar to the radial variation laws of mechanical properties of P. × euramericana cv. ‘74/76′ found by Zhao [14]. Although clone N179 had almost the lowest physical and mechanical properties among the three clones, the properties of clone N179 were relatively stable in the radial direction. It is very important for wood processing and utilization to reveal whether there are differences among different parts of wood regarding the physical and mechanical properties. Especially for the tree species with different properties of heartwood and sapwood, the difference of their properties should be considered in processing and utilization to achieve suitable wood application. For clone 50 and 108, the radial variation of properties should be noted.

4.2. Positive Correlations between the Air Dry Density and Mechanical Properties

There were positive correlations between the air dry density and mechanical properties, such as MOR, MOE, and compressive strength parallel to grains, and also positive correlations among different mechanical properties (Table 6). Similar laws were also obtained in Lv’s [15] study of 17 poplar clones harvested at a shipping forest farm of Jiangsu Province, China. The correlation coefficients between the air dry density and mechanical properties of the three clones in our study were higher than those of clones in Lv’s [15] study, but the correlation coefficients between the different mechanical properties of the three clones were lower. Moreover, for different hardwood, such as American red oak (Quercus nuttallii, Quercus shumardii, and Quercus nigra) and Eucalyptus camaldulensis, there were also positive correlations between the density and mechanical properties, and different mechanical properties, respectively [43,44]. Compared with these two kinds of hardwood, the correlations between the physical and mechanical properties of the three poplar clones were higher. Density samples are small in size and easy to obtain, and can be obtained from living wood. The results of correlation analysis showed that the air dry density can be used to predict the mechanical properties of the three poplar clones. Therefore, nondestructive testing of mechanical properties can be realized by measuring the air dry density.

4.3. Best Methods for Establishing NIR Prediction Models of Different Properties

The first derivative, second derivative, MSC, and S-G smoothing methods are commonly used in the NIR prediction of wood properties, especially the first derivative method, which is also used in the prediction of poplar mechanical properties [29]. Whilst the first derivative method and second derivative method can resolve overlapping peaks and improve the spectral resolution and sensitivity [45,46], MSC can correct the spectral noise in each spectral curve, and eliminate the spectral scattering effect caused by the particle size and uneven distribution of the particles on the surface of the measured object [47,48]. Moreover, the S-G smoothing method can remove noise and improve the signal-to-noise ratio of the signal, while preserving useful information on the spectral boundary [46]. The accuracy of NIR models is different when using different pretreatment methods.

For the air dry density and MOR of these three poplar clones, the accuracies were better when first derivative+ S-G smoothing methods were adopted. Furthermore, MSC+ S-G smoothing methods were more suitable for NIR prediction based on the MOE and compressive strength parallel to grains. The effect of the second derivative method was not as good as that of the first derivative and MSC methods on the prediction of these four properties of three poplar clones. Models established with spectra of the cross section had better effects, which was consistent with the results presented in previous research on Eucalyptus pellita [36]. This is because the cross section has higher absorbance. Compared with other hardwood, such as Acacia melanoxylon [49] and Eucalyptus robusta [50], the correlation coefficients of physical and mechanical property calibration models of the three poplar clones were not very high. The reason for this may be that the samples used in this experiment were taken from trees between 1 and 3.5 meters high, causing a lower coefficient of variation of physical and mechanical properties [51]. Moreover, poplar wood has a lower density and larger porosity, making it hard to obtain perfect NIR prediction models on physical and mechanical properties.

5. Conclusions

The physical and mechanical properties, such as the density, MOR, MOE, and compressive strength parallel to grains of the three poplar clones and rapid prediction of the properties by NIRs were studied. Clone 50 had the best physical and mechanical properties of the three clones. There were significant differences between sapwood and heartwood in terms of the physical and mechanical properties of clone 50 and between sapwood and heartwood of mechanical properties of clone 108, respectively, which should be considered in the processing and utilization of these two clones. The properties of clone N179 were relatively stable in the radial direction. There was a positive correlation between the air dry density and mechanical properties, with correlation coefficients between 0.68 and 0.81. The above results indicated that the density property can be used to estimate and indirectly select the mechanical properties of MOR, MOE, and compressive strength parallel to grains in the three poplar clones. When different pretreatment methods and spectra of different sections were used, the effects of NIR prediction models on the wood density and mechanical properties exhibited differences. Except for the MOR prediction model of clone N179, NIRs can basically realize the prediction of poplar properties when information on the cross section is used.

Author Contributions

Y.W. designed the experiments. R.J. completed the test and data analysis. R.W. completed the test and data analysis of MOE. X.C. completed the test and data analysis of compressive strength parallel to grain. R.J. wrote the manuscript. Y.W. reviewed and edited the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to gratefully acknowledge the financial support from the National Key Research and Development Program of China (No. 2017YFD0600201) and Central Public Interest Scientific Institution Basal Research Fund (No. CAFYBB2018GD001).

Acknowledgments

We acknowledge Shengquan Liu and Liang Zhou of Anhui Agricultural University for selecting and collecting poplar clones.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Liu, H.Z.; Liu, S.Q. Preliminary report on selection and breeding of poplar hybrid clones. J. Hebei For. Sci. Technol. 1994, 12, 12–14. [Google Scholar]

- Ding, W.D.; Koubaa, A.; Chaala, A. Mechanical properties of MMA-hardened hybrid poplar wood. Ind. Crop. Prod. 2013, 46, 304–310. [Google Scholar] [CrossRef]

- Seman, B.; Geffert, A.; Geffertova, J. The influence of the long-term storage of hardwood on the selected physical and mechanical properties in view of pulping. Key Eng. Mater. 2016, 688, 10–16. [Google Scholar] [CrossRef]

- Balatinecz, J.J.; Kretschmann, D.E.; Leclercq, A. Achievements in the utilization of poplar wood—Guideposts for the future. For. Chron. 2001, 77, 265–269. [Google Scholar] [CrossRef]

- Kurt, R.; Merıç, H.; Aslan, K.; Çıl, M. Laminated veneer lumber (lvl) manufacturing using three hybrid poplar clones. Turk. J. Agric. For. 2012, 36, 237–245. [Google Scholar]

- Wu, G.F.; Lang, Q.; Wang, B.; Jiang, Y.F.; Pu, J.W. Chemical modification of poplar wood on the mechanical properties. Adv. Mater. Res. 2011, 1815–1818. [Google Scholar] [CrossRef]

- Guo, Y.G.; Liu, X.Y. Design and research of modified poplar furniture. Art Sci. Technol. 2019, 32, 53–54. [Google Scholar]

- Beaudoin, M.; Hernandez, R.E.; Koubaa, A.; Poliquin, J. Interclonal, intraclonal, and within-tree variation in wood density of poplar hybrid clones. Wood Fiber Sci. 1992, 24, 147–153. [Google Scholar]

- Li, D.G. Study on physical and mechanical properties of new clones of poplar. J. Jiangsu For. Sci. Technol. 2001, 28, 10–13. [Google Scholar]

- Zhao, Y.G.; Zhou, Y.Q.; Zhang, Y.H.; Chai, S.F. Biomass and wood property analysis on Qinbaiyang of stump grafting. Shanxi For. Sci. Technol. 2014, 43, 16–18. [Google Scholar]

- Lu, Z.Y.; Sun, L.E. Studies on the mechanical properties of poplar hybrid mew breeds. J. Beijing For. Univ. 1995, 17, 68–71. [Google Scholar]

- Wang, C.X. The influence of dry shrinkage and wetting on solid wood furniture design was analyzed. Heilongjiang Sci. Technol. Inf. 2015, 21, 267–268. [Google Scholar]

- Dobner, M.; Huss, J.; Tomazello Filho, M. Wood density of loblolly pine trees as affected by crown thinnings and harvest age in southern Brazil. Wood Sci. Technol. 2018, 52, 465–485. [Google Scholar] [CrossRef]

- Zhao, R.J.; Yao, C.L.; Cheng, X.B.; Lu, J.X.; Fei, B.H.; Wang, Y.R. Anatomical, chemical and mechanical properties of fast-growing Populus × Euramericana cv. ‘74/76′. IAWA J. 2014, 35, 158–169. [Google Scholar]

- Lv, Y.; Liu, Y.; Fang, S.Z.; Tian, Y.; Xu, X.Z. Genetic differences in growth traits and wood quality among clones of southern type poplar. J. Nanjing For. Univ. 2018, 42, 24–30. [Google Scholar]

- Gong, M.X.; Cheng, R.X.; Song, Y.T.; Liang, H.L. Methods of inorganic modification of wood. For. Eng. 2013, 29, 65–68. [Google Scholar]

- Cavalli, A.; Cibecchini, D.; Togni, M.; Sousa, H.S. A review on the mechanical properties of aged wood and salvaged timber. Constr. Build. Mater. 2016, 114, 681–687. [Google Scholar] [CrossRef]

- Hernández, R.E.; Koubaa, A.; Beaudoin, M.; Fortin, Y. Selected mechanical properties of fast-growing poplar hybrid clones. Wood Fiber Sci. 1998, 30, 138–147. [Google Scholar]

- Tong, Z.K.; Yu, Y.M.; Zheng, Y.P. A study on timber physical and mechanical properties of new Aigeiros clones. For. Res. 2002, 15, 450–456. [Google Scholar]

- Chen, L.Y.; Shi, X.J.; Fan, J.F. Study on properties and fiber morphology of Qinbaiyang series yarieties Woods. J. Northwest For. Univ. 2017, 32, 253–258. [Google Scholar]

- Zhang, Y.J.; Feng, D.J.; Dou, Y.G. Timber physical and mechanical properties of Populus pyramidalias Rozier and Populus × canadensis cv. ‘Regenerata’. J. West China For. Sci. 2017, 46, 35–38, 49. [Google Scholar]

- Xu, Y.M.; Liu, Z.X. Their elastic modulus correlations with modulus of rupture. J. Huazhong Agric. Univ. 1996, 15, 79–85. [Google Scholar]

- Fujimoto, T.; Yamamoto, H.; Tsuchikawa, S. Estimation of wood stiffness and strength properties of hybrid larch by near-infrared spectroscopy. Appl. Spectrosc. 2007, 61, 882–888. [Google Scholar] [CrossRef]

- Tham, V.T.H.; Inagaki, T.; Tsuchikawa, S. A novel combined application of capacitive method and near-infrared spectroscopy for predicting the density and moisture content of solid wood. Wood Sci. Technol. 2018, 52, 115–129. [Google Scholar] [CrossRef]

- Diniz, C.P.; Grattapaglia, D.; Mansfield, S.D.; Figueiredo, L.F.A. Near-infrared-based models for lignin syringyl/guaiacyl ratio of Eucalyptus benthamii and E. pellita using a streamlined thioacidolysis procedure as the reference method. Wood Sci. Technol. 2019, 53, 521–533. [Google Scholar] [CrossRef]

- Wu, T.; Fang, G.G.; Liang, L.; Xiong, Z.X. Four Kinds of algorithms used for the determination of pulpwood properties by near infrared spectroscopy. Chem. Ind. For. Prod. 2016, 36, 63–70. [Google Scholar]

- Gebreselassie, M.N.; Ader, K.; Boizot, N.; Millier, F.; Charpentier, J.P.; Alves, A.; Simões, R.; Rodrigues, J.C.; Bodineau, G.; Fabbrini, F.; et al. Near-infrared spectroscopy enables the genetic analysis of chemical properties in a large set of wood samples from Populus nigra (L.) natural populations. Ind. Crop. Prod. 2017, 107, 159–171. [Google Scholar] [CrossRef]

- Liang, L.; Wei, L.; Fang, G.; Xu, F.; Deng, Y.; Shen, K.; Tian, Q.; Wu, T.; Zhu, B. Prediction of holocellulose and lignin content of pulp wood feedstock using near infrared spectroscopy and variable selection. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2020, 225, 117515. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.Q.; Zhao, R.J.; Fu, F.; Fei, B.H.; Jiang, Z.H. Use of near infrared spectroscopy to measure mechanical properties of solid wood. Chin. For. Sci. Technol. 2007, 22, 14–19. [Google Scholar]

- Kothiyal, V.; Bhandari, S.; Ginwal, H.S.; Gupta, S. Multi-species NIR calibration for estimating holocellulose in plantation timber. Wood Sci. Technol. 2015, 49, 769–793. [Google Scholar] [CrossRef]

- GB/T 1933-2009. Method for Determination of the Density of Wood; Standards Press of China: Beijing, China, 2009. [Google Scholar]

- GB/T 1936.2-2009. Method for Determination of the Modulus of Elasticity in Static Bending of Wood; Standards Press of China: Beijing, China, 2009. [Google Scholar]

- GB/T 1936.1-2009. Method of Testing in Bending Strength of Wood; Standards Press of China: Beijing, China, 2009. [Google Scholar]

- GB/T 1935-2009. Method of Testing in Compressive Strength Parallel to Grain of Wood; Standards Press of China: Beijing, China, 2009. [Google Scholar]

- Hu, J.Q.; Qi, Q.; Zhao, Y.L.; Tian, X.M.; Lu, H.; Gai, Y.; Jiang, X. Unraveling the impact of Pto4CL1 regulation on the cell wall components and wood properties of perennial transgenic Populus tomentosa. Plant Physiol. Biochem. 2019, 139, 672–680. [Google Scholar] [CrossRef]

- Jiang, Z.H.; Huang, A.M.; Wang, B. Near infrared spectroscopy of wood sections and rapid density prediction. Spectrosc. Spect. Anal. 2006, 26, 1034–1037. [Google Scholar]

- Zhao, R.J.; Huo, X.M.; Shangguan, W.W.; Wang, Y.R. Influence factor for prediction of air-dry density of Eucalyptus pellita by near infrared spectroscopy. Spectrosc. Spect. Anal. 2011, 31, 2948–2951. [Google Scholar]

- Xing, X.T.; Zhang, Z. Genetic control of air-dried wood density, mechanical properties and its implication for veneer timber breeding of new triploid clones in Populus tomentosa Carr. For. Stud. Chin. 2002, 4, 52–60. [Google Scholar]

- Xia, L.M.; Qi, J.Q.; Huang, X.Y.; Xie, J.L.; Xiao, H.; Luo, J.X.; Xiao, X.C.; Song, L.M. Physical-mechanical properties of heartwood and sapwood in Toona sp. wood (Toona ciliata M. Roem.) before and after accelerated aging treatment. BioResources 2018, 13, 8409–8420. [Google Scholar] [CrossRef]

- Tian, G.L.; Wang, H.K.; Yu, Y.; Shui, Y.Y. Study the effect of MFA to the elastic modulus and hardness of wood cell wall. Nanosci. Nanotechnol. 2010, 7, 63–66. [Google Scholar]

- Fan, W.J.; Tu, D.Y.; Peng, C.; Han, Y.H.; Cai, J.B. Influence of heat treatment on mechanical properties of Populus tomentosa wood. J. Northeast For. Univ. 2015, 43, 88–91. [Google Scholar]

- Merela, M.; Cufar, K. Density and mechanical properties of oak sapwood versus heartwood. Drvna Ind. 2014, 64, 323–334. [Google Scholar] [CrossRef]

- Shang, X.H.; Zhang, P.J.; Luo, J.Z.; Wu, Z.H. Physical and mechanical properties of Eucalyptus camaldulensis juvenile wood. J. Northwest A&F Univ. 2019, 47, 32–41. [Google Scholar]

- Bi, Y.J.; Wang, H.; Pan, B.; Huang, L.B. Physical and mechanical properties of introduced American red oaks juvenile wood. J. Northwest A&F Univ. 2020, 48, 37–43. [Google Scholar]

- Sun, H.X. Study on Pest Detection of Fresh Jujube Based on Near Infrared Spectroscopy and X-ray Diffraction Image. Master’s Thesis, Shanxi Agricultural University, Jinzhong, China, 2014. [Google Scholar]

- Savitzky, A.; Golay, M.J.E. Smoothing and differentiation of data by simplified least squares procedures. Anal. Chem. 1964, 36, 1627–1639. [Google Scholar] [CrossRef]

- Xue, J.X. Study on Online Detection Technology and Method of Fresh Jujube Quality Based on Spectral and Imaging Technology. Ph.D. Thesis, Shanxi Agricultural University, Jinzhong, China, 2016. [Google Scholar]

- Tu, W.J. Detection Method of Basic Density of Solid Wood Based on Near Infrared Spectroscopy. Master’s Thesis, Northeast Forestry University, Harbin, China, 2017. [Google Scholar]

- Santos, A.J.A.; Alves, A.M.M.; Simões, R.M.S.; Pereira, H.; Rodrigues, J.; Schwanninger, M. Estimation of wood basic density of Acacia melanoxylon (R. Br.) by near infrared spectroscopy. J. Near Infrared Spectrosc. 2012, 20, 267. [Google Scholar] [CrossRef]

- Zhao, R.J.; Zhou, X.W.; Ren, H.Q.; Wang, Y.R. Prediction and correlation analysis of wood air-dry density and elastic modulus for Eucalyptus pellita. J. Northeast For. Univ. 2013, 41, 68–71. [Google Scholar]

- Hoffmeyer, P.; Pedersen, J.G. Evaluation of density and strength of Norway spruce wood by near infrared reflectance spectroscopy. Holz Roh Werkstoff 1995, 53, 165–170. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).