Magnetron Sputtering Construction of Nano-Al Metallized Wood and Its Functional Research

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

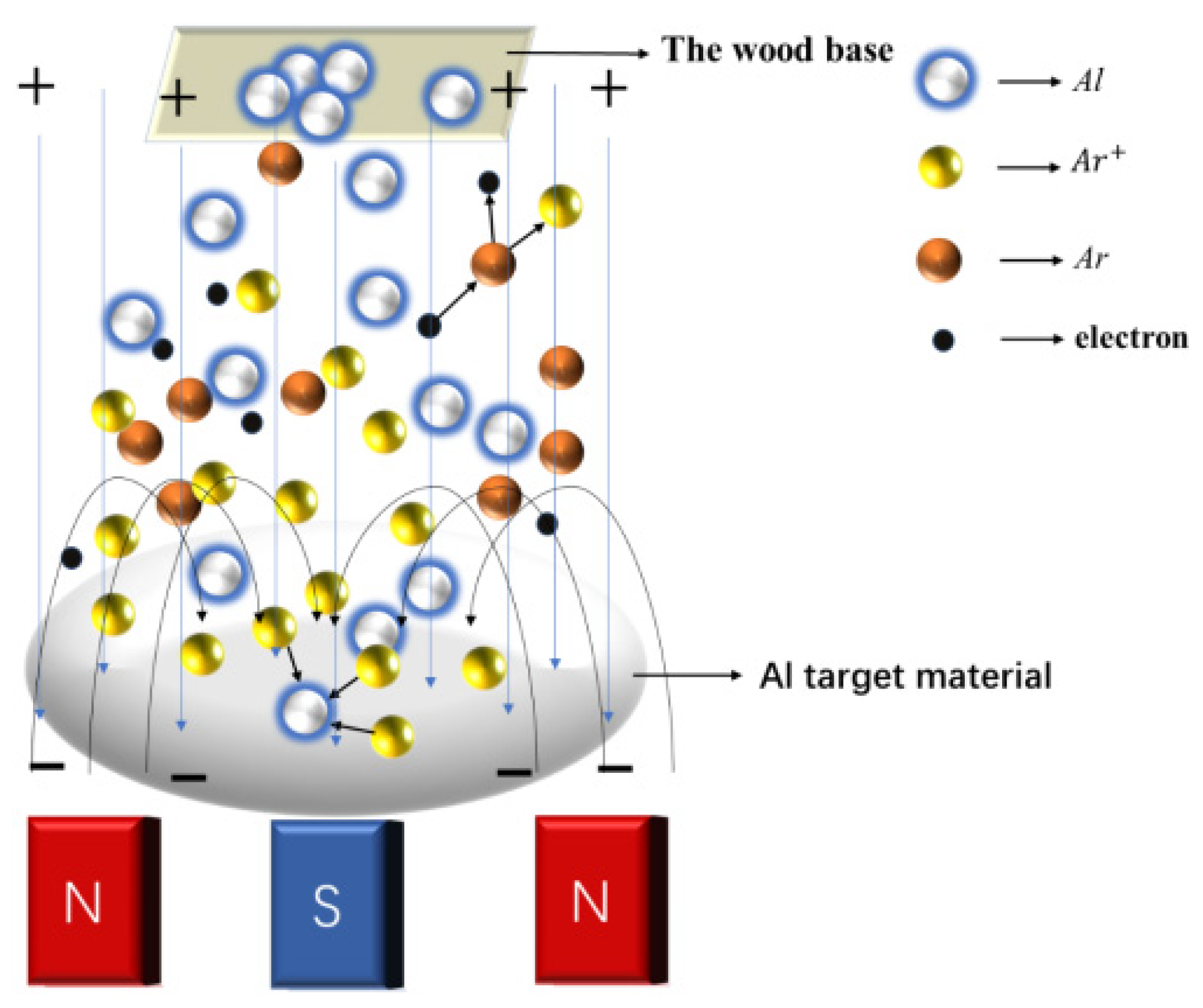

2.2. Magnetron Sputtering Construction of Nano-Al Metallized Wood

2.3. Characterization of Structure and Morphology of Nano-Al Metallized Wood

2.4. Physical Performance Test of Nano-Al Metallized Wood

3. Results and Analysis

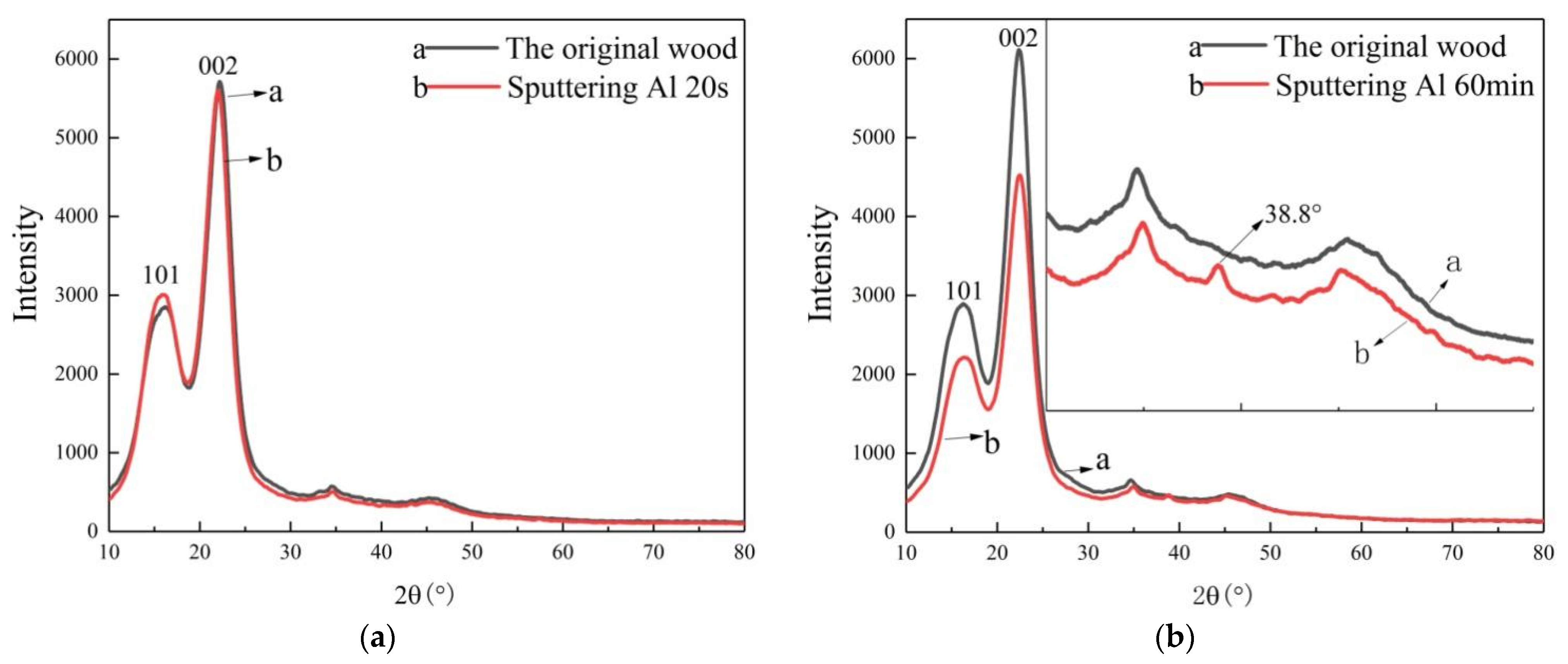

3.1. The Structure of Nano-Al Metallized Wood

3.2. Nanometer Al Metallized Wood Fluorescence Effect

3.3. Load–Displacement Curve of Nano-Al Metallized Wood

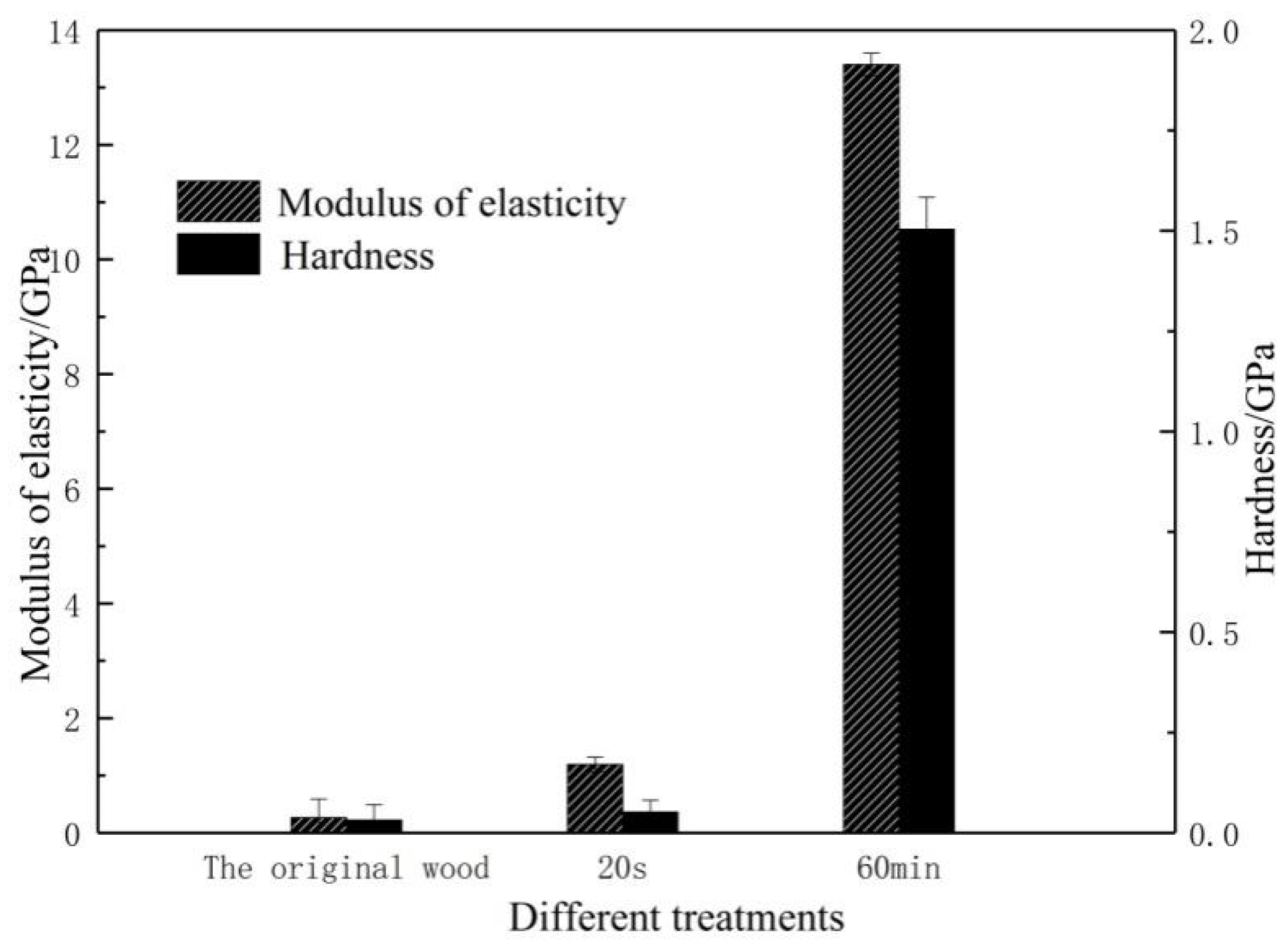

3.4. Nano-Al Metallized Wood Hardness and Elastic Modulus

3.5. Electrical Conductivity of Nano-Al Metallized Wood

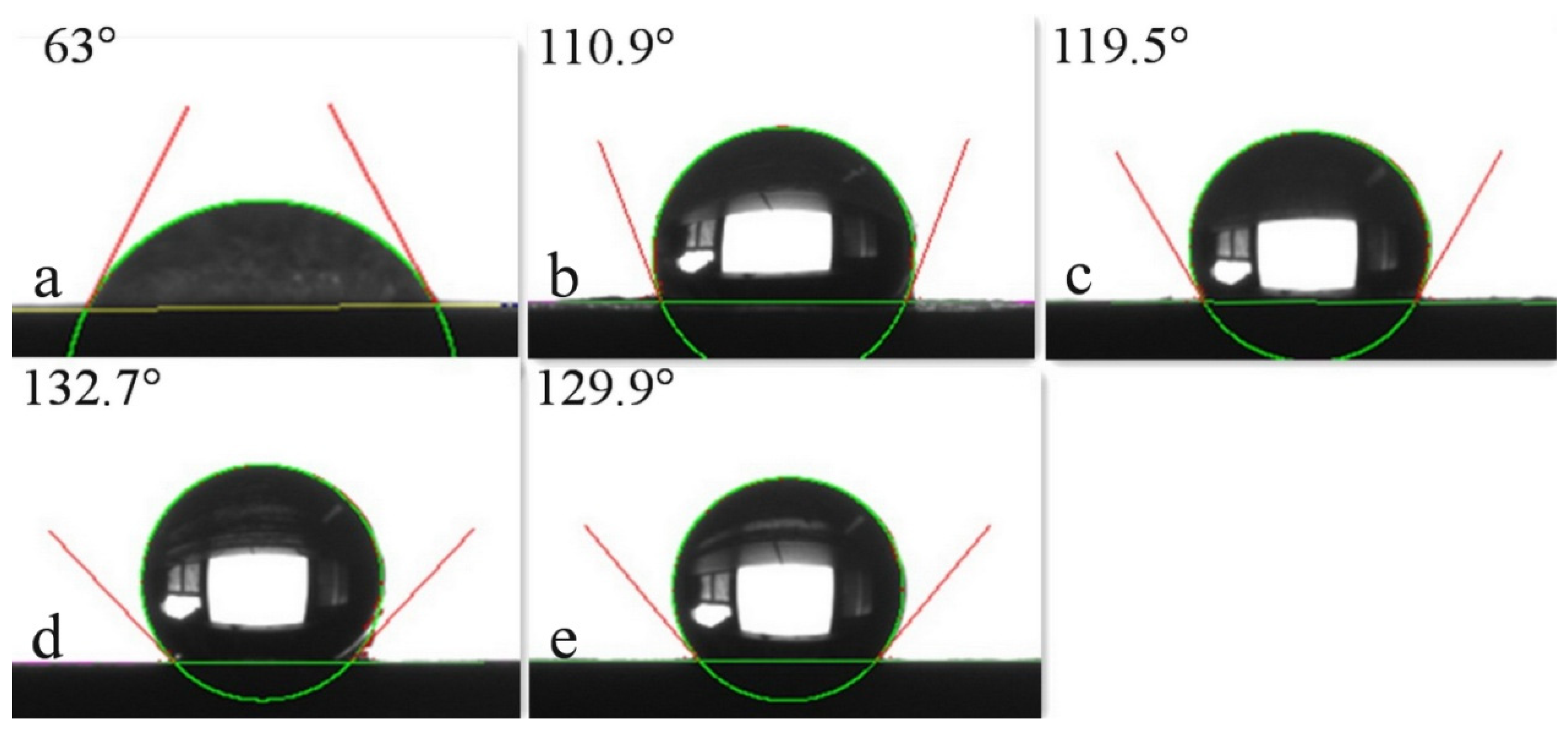

3.6. Hydrophobic Effect of Metallized Wood

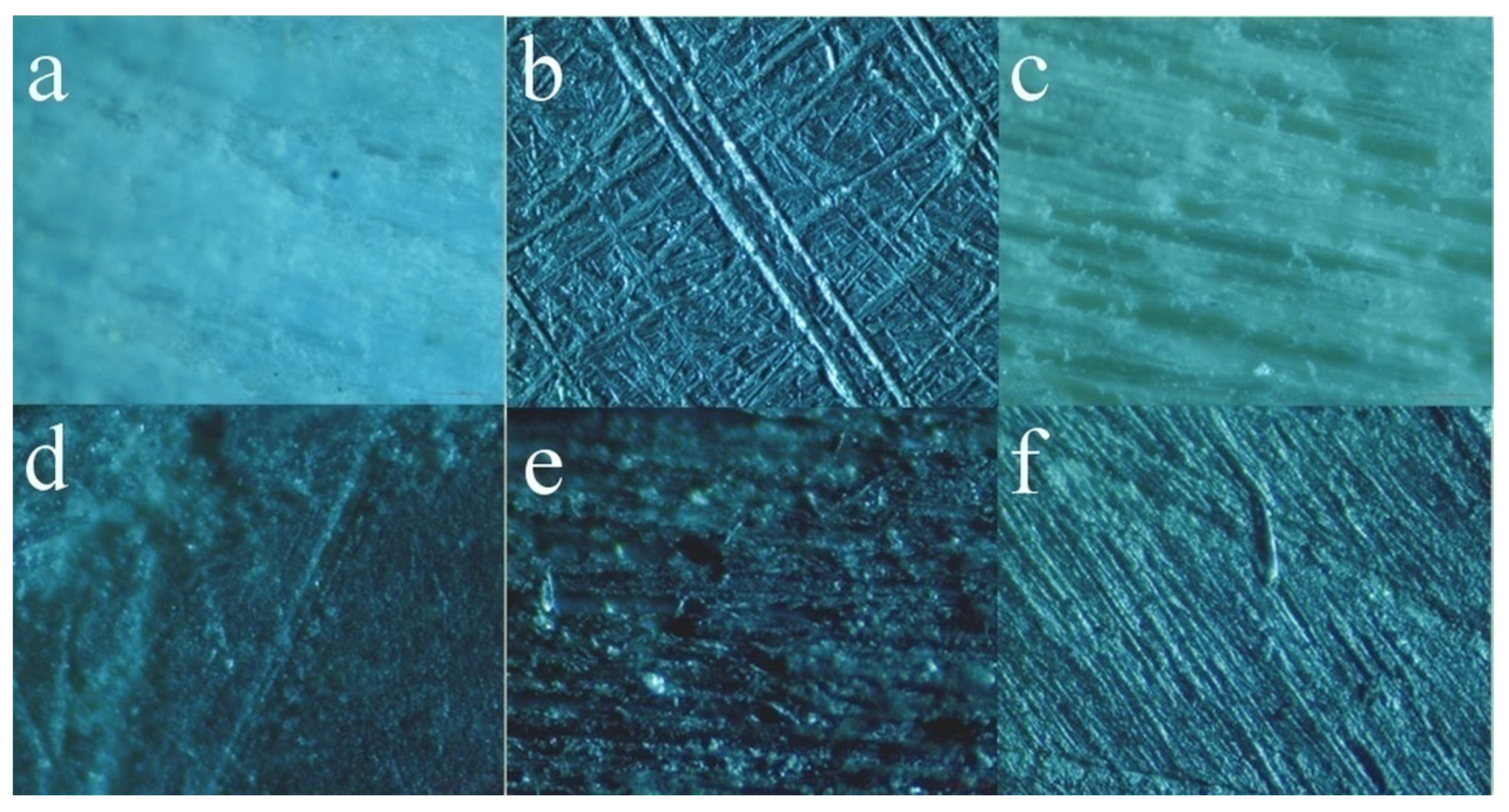

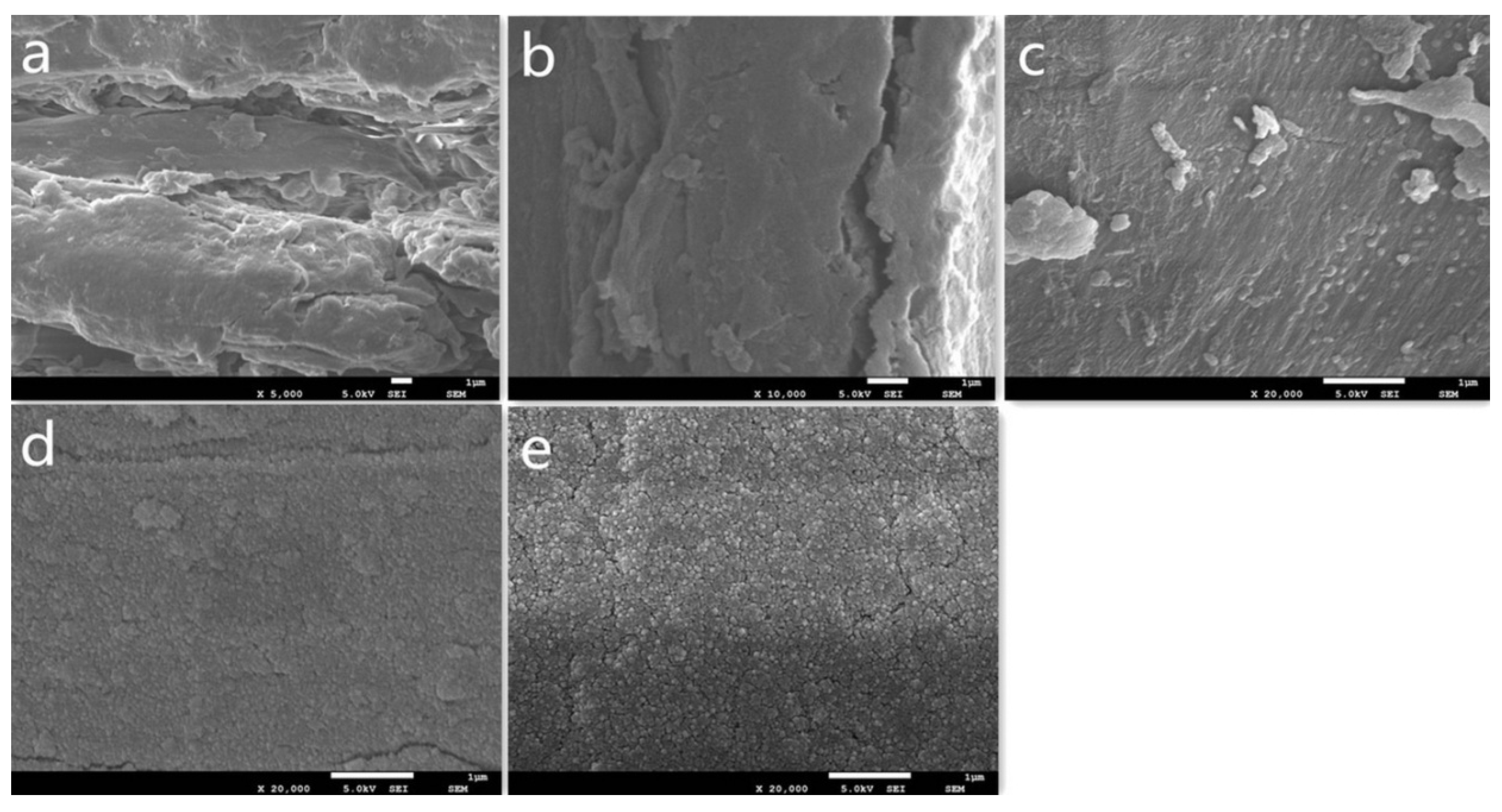

3.7. Micro Morphology of Metallized Wood

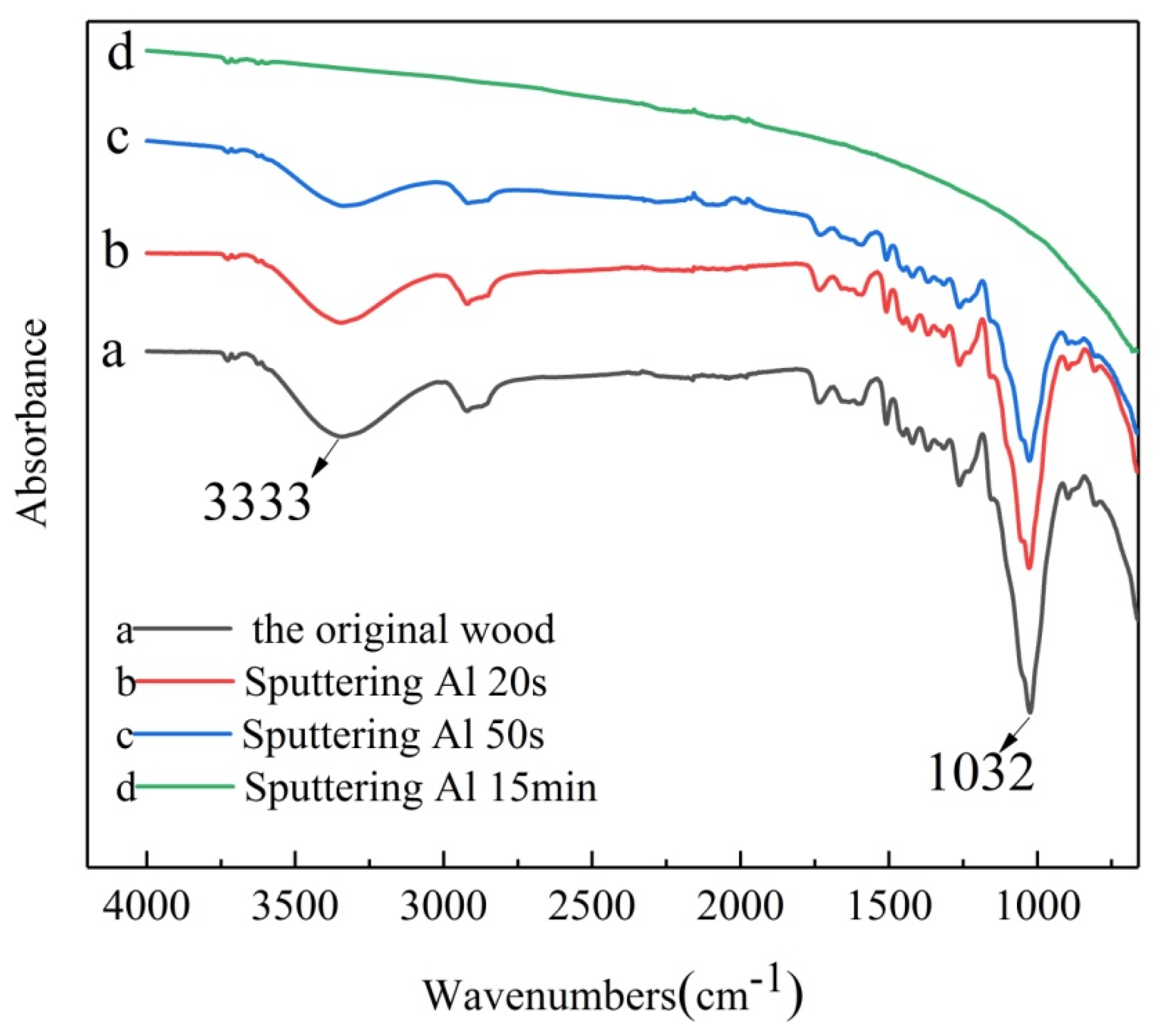

3.8. Fourier Transform Infrared Spectroscopy Analysis

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mark, J.E.; Calvert, P.D. Hybrid and in situ composites. Mater. Sci. Eng. C 1994, 1, 159–170. [Google Scholar] [CrossRef]

- Greil, P.; Lifka, T.; Kaindl, A. Biomorphic cellular silicon carbide ceramics from wood: II. mechanical properties. J. Eur. Ceram. Soc. 1998, 18, 1975–1983. [Google Scholar] [CrossRef]

- Sun, J.A.; Yang, Y.S.; Dang, B.K.; Chen, Y.P.; Wang, Y.Y.; Zhang, J.Y.; Qiu, J. Research progress of the preparation of biomimetic superhydrophobic wood surface micro-nano structures. J. For. Eng. 2021, 6, 1–11. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Qu, L.J.; Qian, J.; He, Z.B.; Yi, S.L. Effects of the ultrasound-assisted pretreatments using borax and sodium hydroxide on the physicochemical properties of Chinese fir. Ultrason. Sonochem. 2018, 50, 200–207. [Google Scholar] [CrossRef]

- Wang, Q.W.; Yi, X.; Shen, J. Tailoring wood-plastic composites for furniture production: Possibilities and opportunities. J. For. Eng. 2016, 1, 1–8. [Google Scholar] [CrossRef]

- Félix, J.S.; Domeño, C.; Nerín, C. Characterization of wood plastic composites made from landfill-derived plastic and sawdust: Volatile compounds and olfactometricanalysis. Waste Manag. 2013, 33, 10–15. [Google Scholar] [CrossRef] [PubMed]

- Shah, S.M.; Zulfiqar, U.; Hussain, S.Z.; Ahmad, I.; Habib, U.R.; Hussain, I.; Subhani, T. A durable superhydrophobic coating for the protection of wood materials. Mater. Lett. 2017, 203, 17–20. [Google Scholar] [CrossRef]

- Guo, H.Z.; Klose, D.; Hou, Y.H.; Jeschke, G.; Burgert, I. Highly Efficient UV Protection of the Biomaterial Wood by A Transparent TiO2/Ce Xerogel. ACS Appl. Mater. Interfaces 2017, 9, 39040–39047. [Google Scholar] [CrossRef]

- Gaff, M.; Kacik, F.; Gasparik, M. Impact of thermal modification on the chemical changes and impact bending strength of European oak and Norway spruce wood. Compos. Struct. 2019, 216, 80–88. [Google Scholar] [CrossRef]

- Chaiwutthinan, P.; Chuayjuljit, S.; Srasomsub, S.; Boonmahitthisud, A. Composites of poly(lactic acid)/poly(butylene adipate-co-terephthalate) blend with wood fiber and wollastonite: Physical properties, morphology, and biodegradability. J. Appl. Polym. Sci. 2019, 136, 47543. [Google Scholar] [CrossRef]

- Chai, Y.; Fu, F.; Liang, X.Q. Progress of wood based metal functional composites. J. Beijing For. Univ. 2019, 41, 151–160. [Google Scholar] [CrossRef]

- Klimowicz, T.F. The largescale commercialization of aluminummatrix composites. JOM 1994, 46, 49–53. [Google Scholar] [CrossRef]

- Schuster, D.M.; Skibo, M.D.; Bruski, R.S.; Provencher, R.; Riverin, G. The recycling and reclamation of metal-matrix composites. JOM 1993, 45, 26–30. [Google Scholar] [CrossRef]

- Lucchetta, G.; Marinello, F.; Bariani, P.F. Aluminum sheet surface roughness correlationwith adhesion in polymer metal hybrid overmolding. CIRP Ann. 2011, 60, 559–562. [Google Scholar] [CrossRef]

- Zhang, Q.; Ning, L.P.; Wang, C.Y.; Wang, M.; Shen, Y.Z.; Yan, Y.R. Fabrication and characterization of bio-based shielding material with dissimilar surface resistivity prepared by electroless Ni–Fe–P alloy plating on bamboo (N. affinis). J. Mater. Sci. Mater. Electron. 2019, 30, 21064–21078. [Google Scholar] [CrossRef]

- Xie, X.Q.; Cheng, M.J.; Dai, V.D.; Jia, H.L.; Wang, L.J. Study of Electroless Plating of Ni⁃Fe Alloy on Triplochiton Sclexcylon Veneer. Furniture 2019, 231, 57–61. [Google Scholar] [CrossRef]

- Wang, Y.N.; Wu, X.T.; Wang, Y.B.; Tian, Y.Q.; Mu, H.B.; Li, J.K. Hydrophobic and UV-resistant properties of environmentally friendly nano-ZnO-coated wood. Holzforschung 2020, 75, 138–147. [Google Scholar] [CrossRef]

- Li, J.K.; Wang, Y.N.; Zhao, H.Z.; Qi, D.W. Research on the gradual process of the structure and mechanical properties of NanoZnO-coated veneer. Wood Sci. Technol. 2021, 55, 243–255. [Google Scholar] [CrossRef]

- Wang, Q.L.; Xiao, S.L.; Shi, S.Q.; Xu, S.Y.; Cai, L.P. Self-bonded natural fiber product with high hydrophobic and EMI shielding performance via magnetron sputtering Cu film. Appl. Surf. Sci. 2019, 475, 947–952. [Google Scholar] [CrossRef]

- Nouveau, C.; Djouadi, M.A.; Decès, P.C. The influence of deposition parameters on the wear resistance of CrxNy magnetron sputtering coatings in routing of oriented strand board. Surf. Coat. Technol. 2003, 174, 455–460. [Google Scholar] [CrossRef]

- Wang, Q.L.; Tang, J.; Xiao, S.L.; Wang, M.; Shi, S.Q. Natural fiber-based composites with high hydrophobic, magnetic, and EMI shielding properties via iron oxide in situ synthesis and copper film deposition. BioResources 2020, 15, 8384–8402. [Google Scholar] [CrossRef]

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. Surf. Coat. Technol. 2010, 204, 1661–1684. [Google Scholar] [CrossRef]

- Wan, C.; Jiao, Y.; Li, J. A cellulose fibers-supported hierarchical forest-like cuprous oxide/copper array architecture as a flexible and free-standing electrode for symmetric supercapacitors. J. Mater. Chem. A 2017, 5, 17267–17278. [Google Scholar] [CrossRef]

- Alexeeva, O.K.; Fateev, V.N. Application of the magnetron sputtering for nanostructured electrocatalysts synthesis. Int. J. Hydrogen Energy 2016, 41, 3373–3386. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, Z.S.; Xu, J.; Zhang, Z.; Wang, H.C.; Zhu, J.T.; Wang, F.L.; Wang, B.; Qin, S.J.; Chen, L.Y. Characterization of low-Z material layer profiles in bilayer structures by X-ray reflectivity measurement. Opt. Precis. Eng. 2007, 15, 1838–1843. [Google Scholar]

| Sample Name | Cross-Grain Sheet Resistance (mΩ) | Along-Grain Sheet Resistance (mΩ) | Average Cross-Grain Sheet Resistance (mΩ) | Average Along-Grain Sheet Resistance (mΩ) | ||||

|---|---|---|---|---|---|---|---|---|

| The original wood | - | - | - | - | - | - | - | - |

| (Al) 20 s | - | - | - | - | - | - | - | - |

| (Al) 50 s | - | - | - | - | - | - | - | - |

| (Al) 15 min | 316.70 | 328.10 | 334.50 | 141.90 | 135.80 | 137.30 | 326.43 | 138.33 |

| (Al) 60 min | 697.20 | 682.00 | 708.70 | 226.60 | 220.70 | 234.30 | 695.9 | 227.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Jin, C.; Wang, X.; Li, Q.; Li, W.; Xu, Q.; Li, J. Magnetron Sputtering Construction of Nano-Al Metallized Wood and Its Functional Research. Forests 2021, 12, 1564. https://doi.org/10.3390/f12111564

Wang Y, Jin C, Wang X, Li Q, Li W, Xu Q, Li J. Magnetron Sputtering Construction of Nano-Al Metallized Wood and Its Functional Research. Forests. 2021; 12(11):1564. https://doi.org/10.3390/f12111564

Chicago/Turabian StyleWang, Yanan, Chengzhu Jin, Xinyi Wang, Qiushuang Li, Wenxuan Li, Qiang Xu, and Jingkui Li. 2021. "Magnetron Sputtering Construction of Nano-Al Metallized Wood and Its Functional Research" Forests 12, no. 11: 1564. https://doi.org/10.3390/f12111564

APA StyleWang, Y., Jin, C., Wang, X., Li, Q., Li, W., Xu, Q., & Li, J. (2021). Magnetron Sputtering Construction of Nano-Al Metallized Wood and Its Functional Research. Forests, 12(11), 1564. https://doi.org/10.3390/f12111564