Effect of Bamboo Nodes on the Mechanical Properties of P. edulis (Phyllostachys edulis) Bamboo

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mechanical Properties Test and Calculation

2.3. Adjustment of Mechanical Properties

3. Results and Discussion

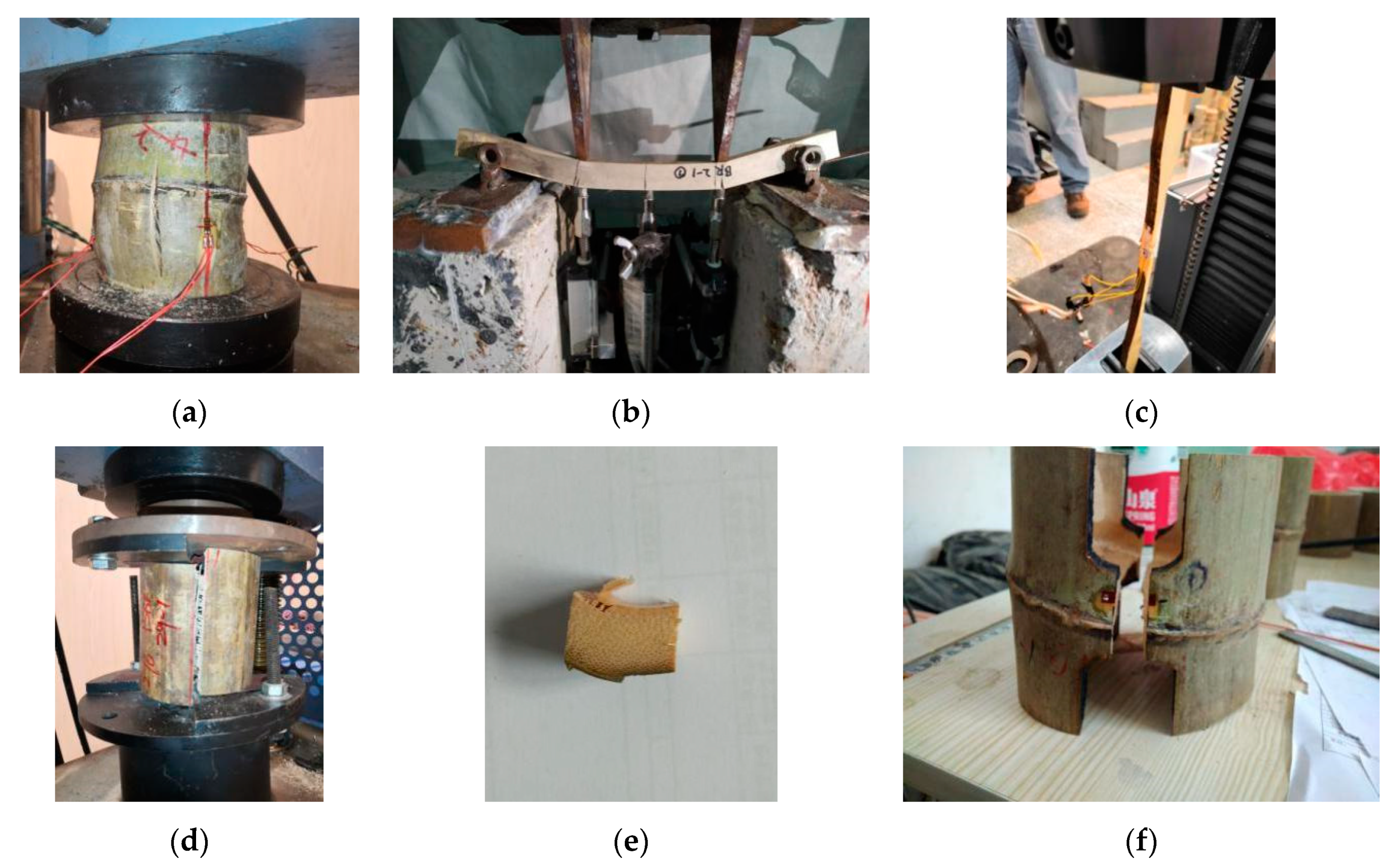

3.1. Failure Process and Morphology Analysis

3.2. Location Distribution of the Bamboo Nodes

3.3. Effect of Bamboo Nodes on Moisture Content

3.4. Influence of Bamboo Nodes on Bearing Capacity

3.5. Effect of the Nodes on Mechanical Properties

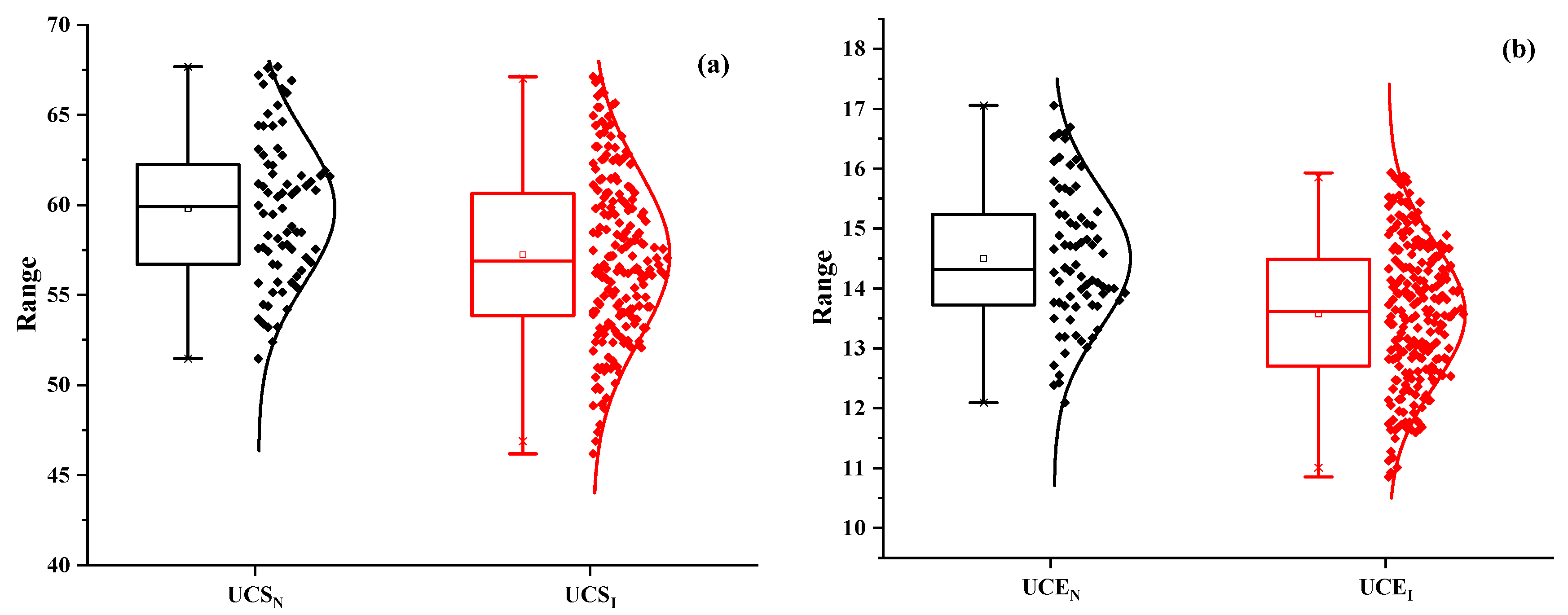

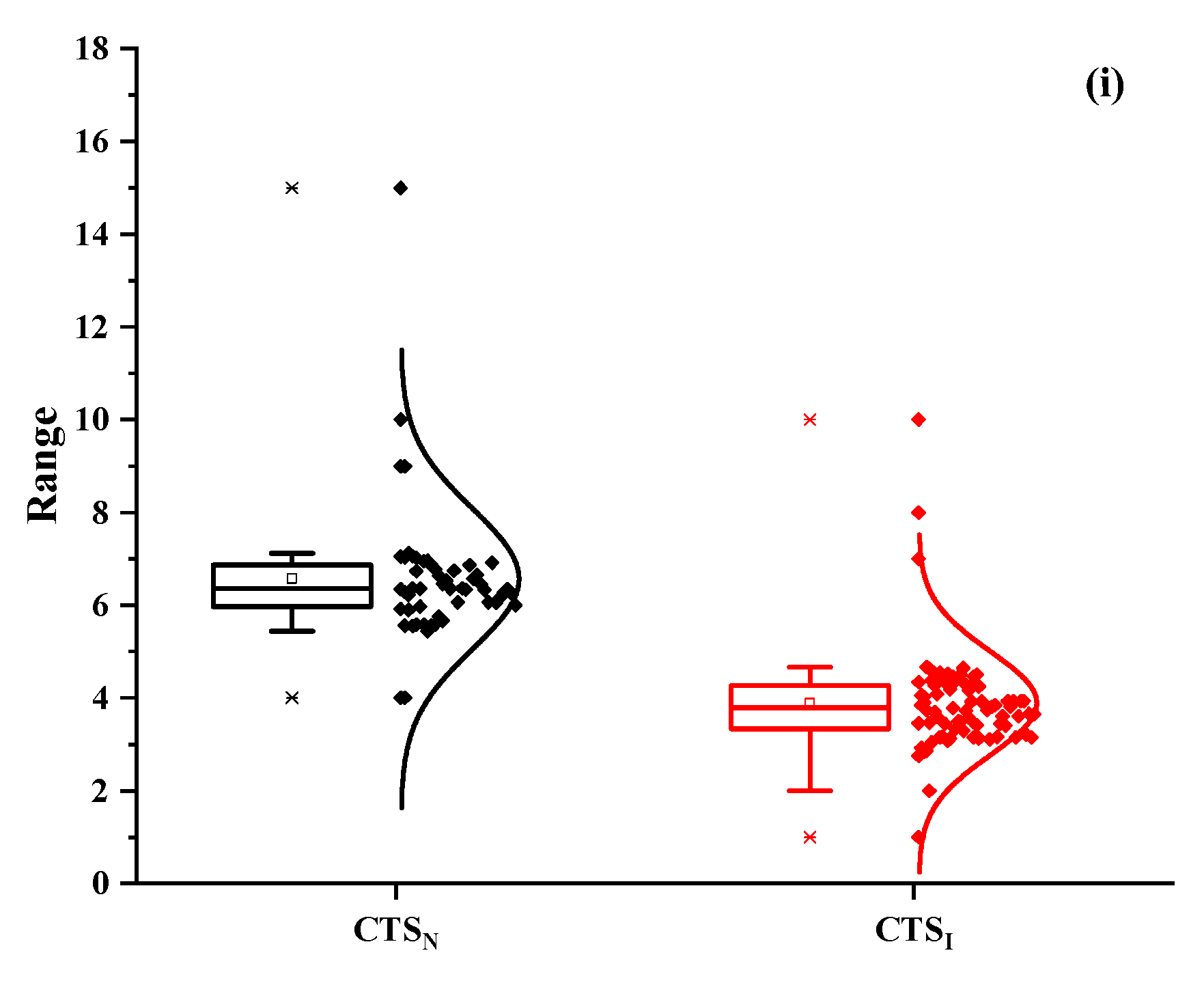

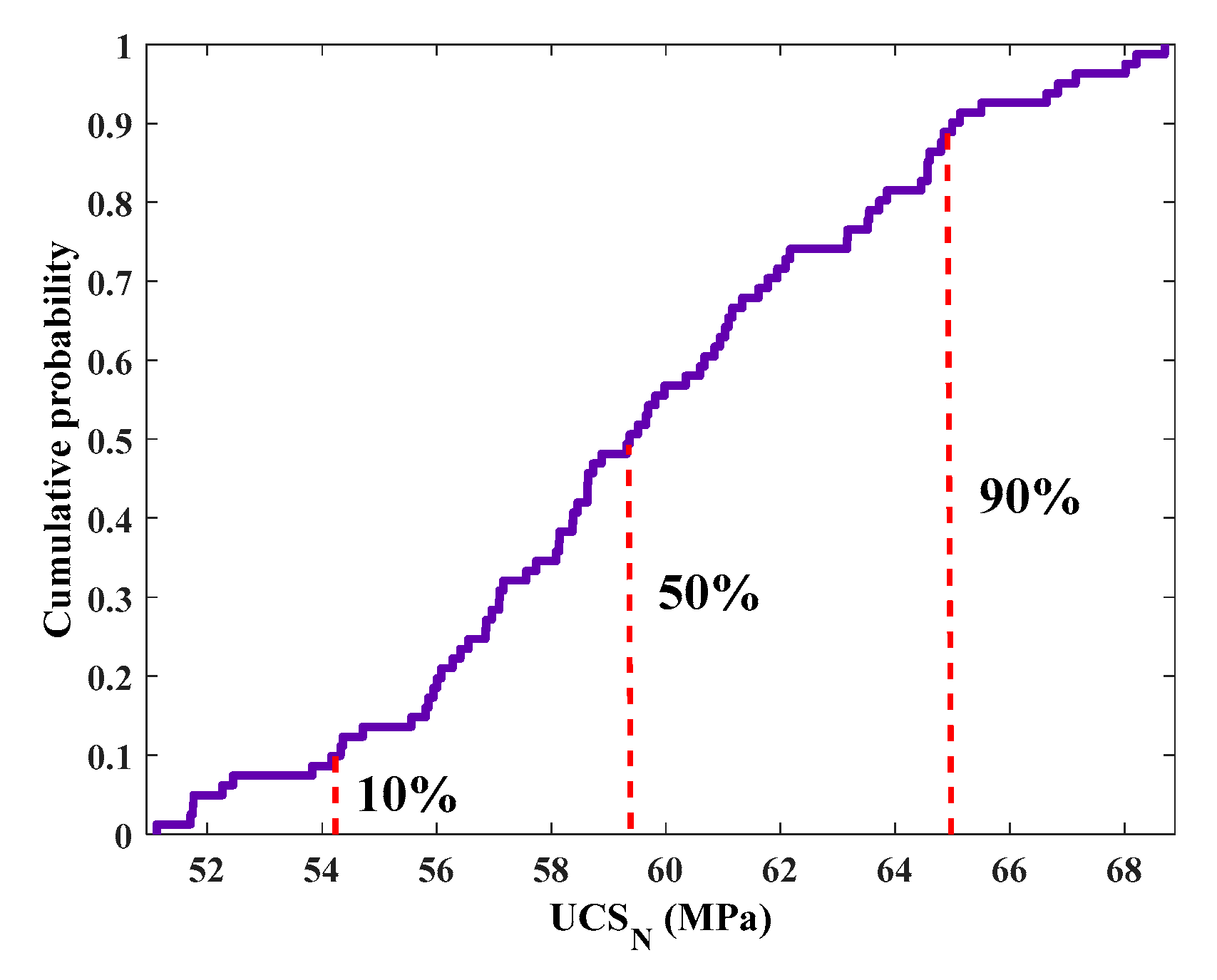

3.5.1. Characteristic Values of the Mechanical Properties of Entire Bamboo Stalks

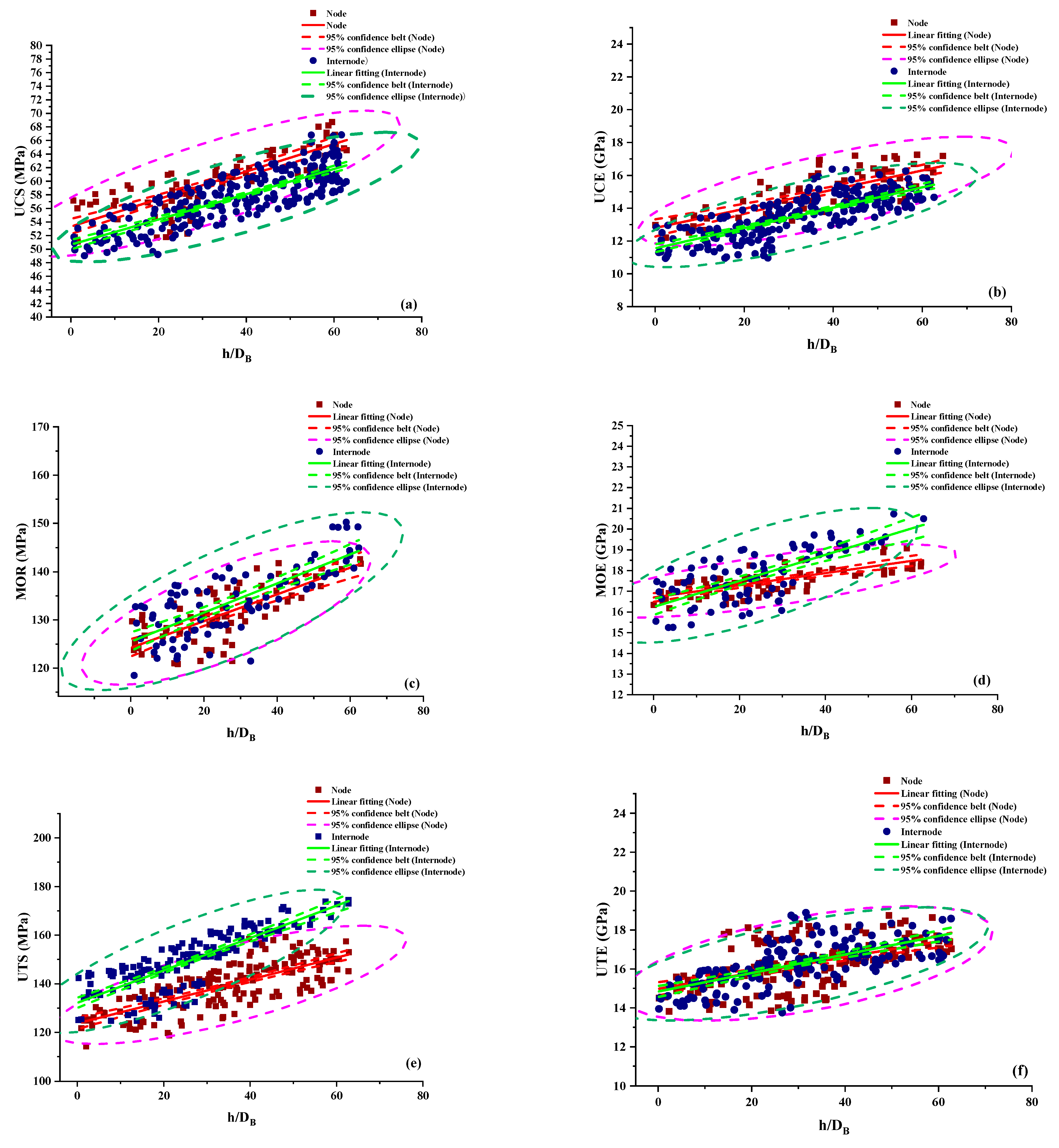

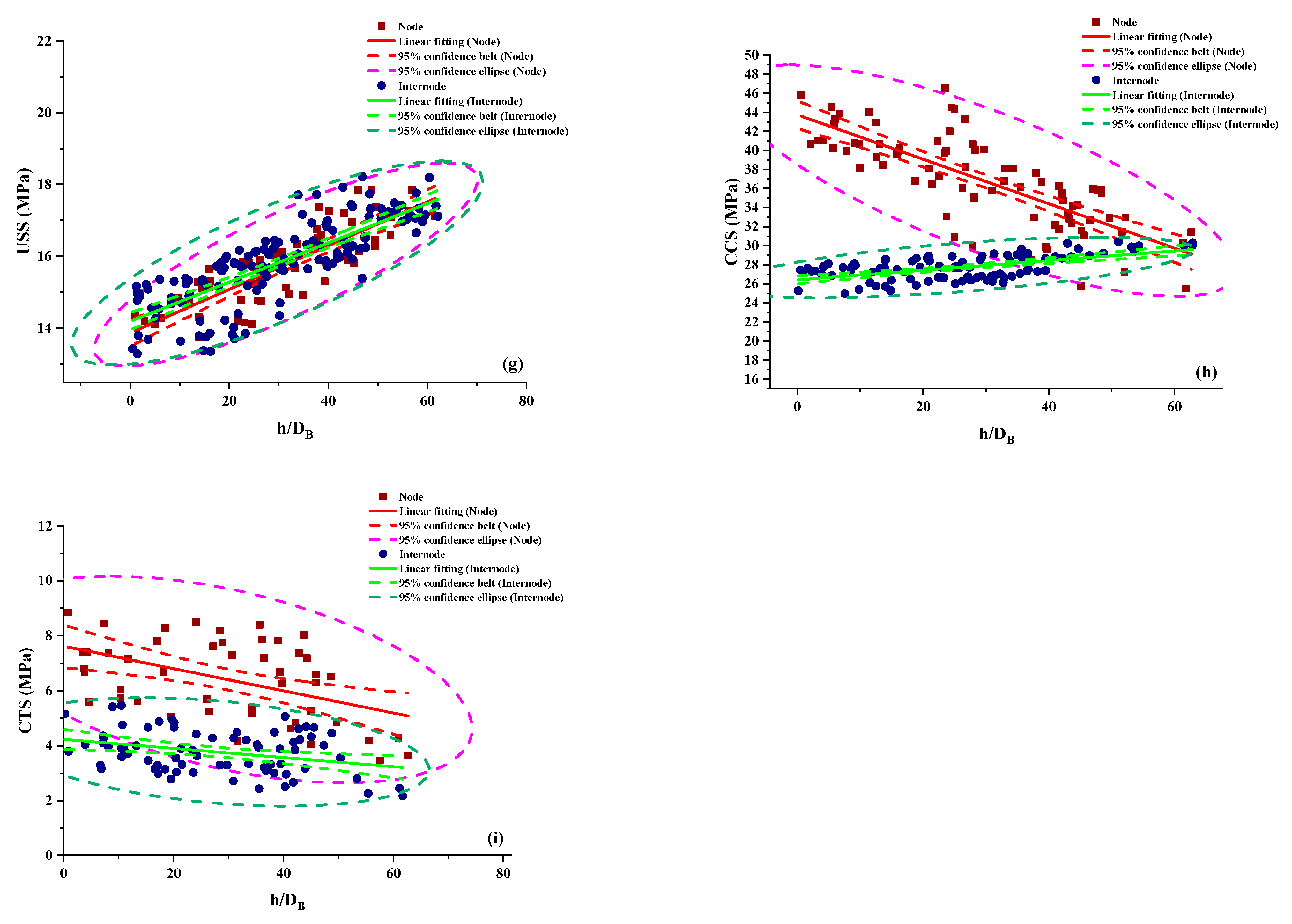

3.5.2. Relationship between Bamboo Mechanical Properties and Standardized Parameters Considering the Effect of Bamboo Nodes

3.5.3. Relationship between the Node and Internode Mechanical Properties

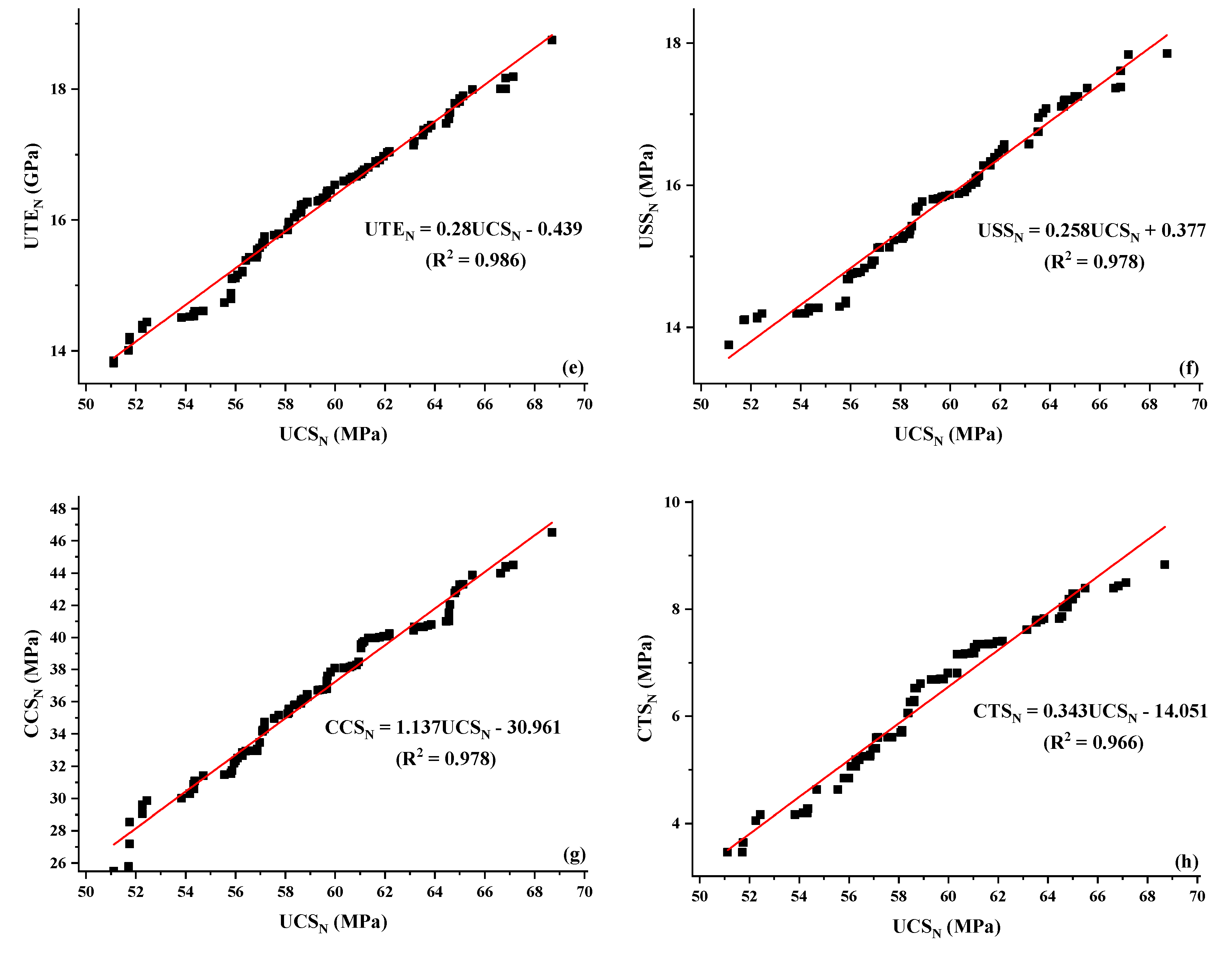

3.5.4. Mutual Relationship of Bamboo Mechanical Properties Considering the Effect of Bamboo Nodes

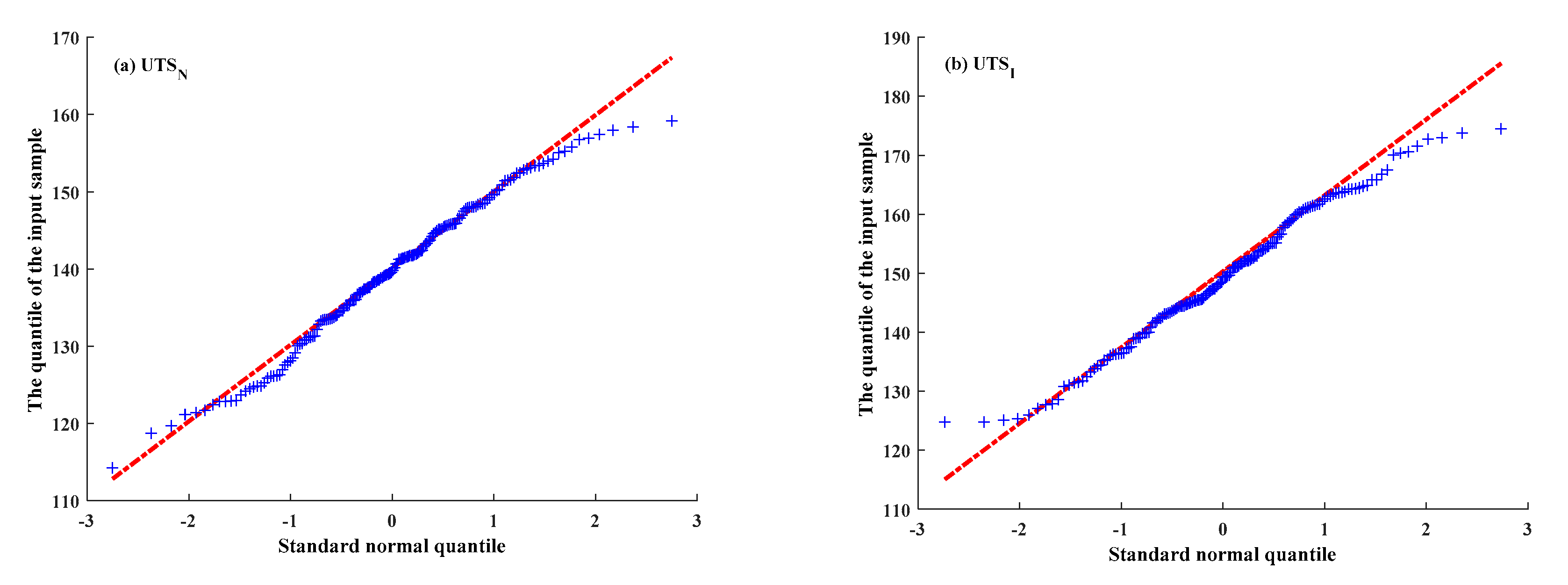

3.6. Classification of Bamboo Considering the Effect of Bamboo Nodes

4. Conclusions

- (1)

- The bamboo nodes have a significant effect on the moisture content, and their influences on the bearing capacity are as follows: the bearing capacity of the UC, CC and CT node specimens are higher than that of the internode specimen; the bearing capacity of the UT and B internode specimens are higher than that of the node specimens; and the bearing capacity of the US node and internode specimens are similar.

- (2)

- Bamboo joints have different effects on the mechanical properties. The UCS, UCE, UTE, CCS and CTS of the node specimens are higher than those of the internode specimens. The MOR, MOE and UTS of the internode specimens are higher than those of the node specimen. The USS of the node specimen and the internode specimen are similar. The relative difference in mechanical properties between nodes in the transverse striation direction is obvious.

- (3)

- The linear fitting relationship was obtained by fitting the mechanical properties of bamboo with the standardized parameter h/DB. The fitting results show that UCSN, UCSI, UCEN, UCEI, MORN, MORI, MOEN, MOEI, UTSN, UTSI, USSN, USSI and CCSI increase with increasing standardized parameter h/DB. CCSN, CTSN and CTSI decrease with increasing h/DB. The standardized parameter h/DB can be used to predict the mechanical properties of bamboo by fitting the relationship. Based on the relationship between the mechanical properties of bamboo and h/DB, the relationship between the performance values of the joints and the specimens with the same mechanical properties was deduced.

- (4)

- The relationship between the mechanical properties was established by fitting 99 quartiles of each mechanical property value.

- (5)

- According to the standard deviation, UTSN and UTSI were divided into four grades, which could be predicted by the standardized parameter h/DB.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Asif, M.; Rahman, K.; Faisal, M.; Islam, M. Comparative Study on Mechanical Properties of Bamboo Strip and Bamboo Strip-glass Fiber Reinforced Hybrid Composites. J. Eng. Adv. 2020, 1, 6–10. [Google Scholar] [CrossRef]

- Lee, C.; Chung, M. Effects of bamboo species, steam-heating treatment, and adhesives on mechanical properties and dimensional stability of oriented bamboo scrimber boards. BioResources 2020, 15, 5342–5354. [Google Scholar] [CrossRef]

- Deore, H.; Minde, P. Study of Bamboo Reinforcement Concrete As a Sustainable Material In Construction. J. Adv. Sch. Res. Allied Educ. 2018, 15, 305–307. [Google Scholar] [CrossRef]

- Parashar, S.; Tomar, P. Synergy of Sustainable Bio-composite Bamboo Material in Green Technology—An Explicit Report. In Proceedings of the International Conference on Sustainable Computing in Science, Technology and Management (SUSCOM), Jaipur, India, 26–28 February 2019. [Google Scholar] [CrossRef]

- Chaowana, K.; Wisadsatorn, S.; Chaowana, P. Bamboo as a Sustainable Building Material—Culm Characteristics and Properties. Sustainability 2021, 13, 7376. [Google Scholar] [CrossRef]

- Jakovljević, S.; Lisjak, D. Investigation into the effects of humidity on the mechanical and physical properties of bamboo. Constr. Build. Mater. 2019, 194, 386–396. [Google Scholar] [CrossRef]

- Liu, P.; Xiang, P.; Zhou, Q.; Zhang, H.; Tian, J.; Demis Argaw, M. Prediction of Mechanical Properties of Structural Bamboo and Its Relationship with Growth Parameters. J. Renew. Mater. 2021, 9, 2223. [Google Scholar] [CrossRef]

- Kumar, A.; Vlach, T.; Laiblova, L.; Hrouda, M.; Kasal, B.; Tywoniak, J.; Hajek, P. Engineered bamboo scrimber: Influence of density on the mechanical and water absorption properties. Constr. Build. Mater. 2016, 127, 815–827. [Google Scholar] [CrossRef]

- Girma, Y.; Assefa, D. The Effect of Age and Height on Some Selected Physical Properties of Ethiopian Highland Bamboo (Yushania Alpina). Int. J. Sci. Res. Manag. 2018, 6. [Google Scholar] [CrossRef]

- Tan, T.; Rahbar, N.; Allameh, S.; Kwofie, S.; Dissmore, D.; Ghavami, K.; Soboyejo, W. Mechanical properties of functionally graded hierarchical bamboo structures. Acta Biomater. 2011, 7, 3796–3803. [Google Scholar] [CrossRef] [PubMed]

- Fu, Y.; Fang, H. Investigation of Chair Legs of Recombinant Bamboo through Finite Element Technology. DEStech Trans. Comput. Sci. Eng. 2017. [Google Scholar] [CrossRef][Green Version]

- Wei, Y.; Zhao, K.; Hang, C.; Chen, S.; Ding, M. Experimental Study on the Creep Behavior of Recombinant Bamboo. J. Renew. Mater. 2020, 8, 251–273. [Google Scholar] [CrossRef]

- Ngudiyono, N. Creep Shear Deformation Of Glued-Laminated Bamboo. Int. J. Geomate 2020, 19, 185–192. [Google Scholar] [CrossRef]

- Zhu, S.; Guo, Y.; Chen, Y.; Su, N.; Zhang, K.; Liu, S. Effects of the Incorporation of Nano-Bamboo Charcoal on the Mechanical Properties and Thermal Behavior of Bamboo-Plastic Composites. BioResources 2016, 11, 2684–2697. [Google Scholar] [CrossRef][Green Version]

- Masood, S.; Khan, Z. Adoption of Green Building Technique: Replacement of Steel by Bamboo. Int. J. Trend Sci. Res. Dev. 2017, 1, 452–457. [Google Scholar] [CrossRef]

- Bashir, A.; Gupta, C.; Abubakr, M.A.; Abba, S.I. Analysis of Bamboo Fibre Reinforced Beam. J. Steel Struct. Constr. 2018, 4. [Google Scholar] [CrossRef]

- Giridhar, V. Flexural behavior of concrete with bamboo and steel reinforcement. Int. J. Emerg. Trends Eng. Dev. 2018, 6. [Google Scholar] [CrossRef]

- Shastry, A.; Unnikrishnan, S. Investigation on Elastic Properties of Bamboo and Behavior of Bamboo Reinforced Concrete Beams. Int. J. Earth Sci. Eng. 2017, 10, 304–312. [Google Scholar] [CrossRef]

- Chinese Standards Agency (CSA). Testing Methods for Physical and Mechanical Properties of Bamboo Used in Building. JG/T199-2007. 2007. Available online: https://www.chinesestandard.net/PDF/English.aspx/JGT199-2007 (accessed on 1 October 2007). (In Chinese).

- International Standards, Bamboo—Determination of Physical and Mechanical Properties—Part I: Requirements ISO 22157–1:2019 (E); International Organization for Standardization: Geneva, Switzerland, 2019; 25p, Available online: https://www.iso.org/standard/65950.html (accessed on 1 January 2019).

- Zhou, A.; Huang, D.; Che, S.; Zhang, P. Distribution of bamboo vascular bundles and their tensile mechanical properties. J. Build. Mater. 2012, 15, 730–734. (In Chinese) [Google Scholar]

- Zhao, X. Basic Research on Strength Properties of Xing’an Larch Gauge. Chin. Acad. For. 2010. Available online: http://libdb.csu.edu.cn/rwt/CNKI/https/NNYHGLUDN3WXTLUPMW4A/kcms/detail/detail.aspx?dbcode=CDFD&dbname=CDFD0911&filename=2010264558.nh&uniplatform=NZKPT&v=P3YFcP583RRQl%25mmd2FwOvRiYM1bcsxPvKHrXGN34ILGmYhV7AE55VJUHgg8AUQc%25mmd2FczHg (accessed on 1 June 2010). (In Chinese).

| Specimens Type | 0 < h < 1000 mm | 1000 ≤ h < 2000 mm | 2000 ≤ h < 3000 mm | 3000 ≤ h < 4000 mm | 4000 ≤ h < 5000 mm | 5000 ≤ h < 6000 mm | Average |

|---|---|---|---|---|---|---|---|

| UCN | 149.82 | 135.60 | 119.42 | 106.39 | 85.17 | 84.93 | 113.56 |

| UCI | 150.37 | 132.67 | 121.29 | 104.45 | 89.82 | 80.67 | 113.21 |

| BN | 0.05 | 0.06 | 0.06 | 0.05 | 0.04 | 0.04 | 0.05 |

| BI | 0.06 | 0.07 | 0.07 | 0.05 | 0.05 | 0.04 | 0.06 |

| UTN | 4.45 | 4.35 | 3.81 | 3.71 | 3.98 | 3.70 | 4.00 |

| UTI | 4.89 | 4.64 | 4.65 | 4.65 | 4.65 | 4.56 | 4.67 |

| USN | 53.89 | 56.53 | 43.71 | 39.83 | 40.70 | 33.49 | 44.69 |

| USI | 61.17 | 52.11 | 46.14 | 39.46 | 36.06 | 32.73 | 44.61 |

| CCN | 4.61 | 4.45 | 2.41 | 4.93 | 3.68 | 3.18 | 3.88 |

| CCI | 3.47 | 3.18 | 2.42 | 3.33 | 3.13 | 2.92 | 3.07 |

| CTN | 2.83 | 2.01 | 2.65 | 2.32 | 2.01 | 1.99 | 2.30 |

| CTI | 2.70 | 1.47 | 2.58 | 2.31 | 1.98 | 1.88 | 2.15 |

| Mechanical Performance Index | Quantity | Mean | Standard Deviation | Coefficient of Variation |

|---|---|---|---|---|

| UCSN | 74 | 59.8 MPa | 4.13 MPa | 0.069 |

| UCSI | 231 | 57.2 MPa | 4.68 MPa | 0.082 |

| UCEN | 74 | 14.5 GPa | 1.17 GPa | 0.080 |

| UCEI | 231 | 13.6 GPa | 1.18 GPa | 0.087 |

| MORN | 75 | 130 MPa | 6.65 MPa | 0.046 |

| MORI | 80 | 133 MPa | 7.19 MPa | 0.054 |

| MOEN | 75 | 17.4 GPa | 0.804 GPa | 0.046 |

| MOEI | 80 | 17.7 GPa | 1.37 GPa | 0.077 |

| UTSN | 167 | 140 MPa | 12.3 MPa | 0.088 |

| UTSI | 147 | 149 MPa 9.40926 | 9.41 MPa | 0.063 |

| UTEN | 167 | 16.5 GPa | 1.15 GPa | 0.070 |

| UTEI | 158 | 16.3 GPa | 1.18 GPa | 0.072 |

| USSN | 61 | 15.9 MPa | 1.62 MPa | 0.109 |

| USSI | 144 | 15.9 MPa | 1.1 MPa | 0.069 |

| CCSN | 77 | 37.3 MPa | 4.65 MPa | 0.125 |

| CCSI | 100 | 27.9 MPa | 1.37 MPa | 0.049 |

| CTSN | 47 | 6.33 MPa | 0.489 MPa | 0.077 |

| CTSI | 73 | 3.77 MPa | 0.517 MPa | 0.137 |

| The Fitting Parameters | Relations | R2 |

|---|---|---|

| UCSN | UCSN = 0.203 h/DB + 54.331 | 0.678 |

| UCSI | UCSI = 0.186 h/DB + 50.665 | 0.661 |

| UCEN | UCEN = 0.058 h/DB + 12.796 | 0.546 |

| UCEI | UCEI = 0.062 h/DB+ 11.554 | 0.595 |

| MORN | MORN = 0.277 h/DB + 124.2 | 0.541 |

| MORI | MORI = 0.302 h/DB + 125.48 | 0.585 |

| MOEN | MOEN = 0.03 h/DB + 16.7 | 0.523 |

| MOEI | MOEI = 0.063 h/DB + 16.24 | 0.517 |

| UTSN | USSN = 0.451 h/DB + 123.7 | 0.574 |

| UTSI | USSI = 0.666 h/DB + 132.18 | 0.675 |

| UTEN | UTSN = 0.041 h/DB + 14.98 | 0.299 |

| UTEI | UTSI = 0.048 h/DB + 14.841 | 0.445 |

| USSN | UTEN = 0.061 h/DB + 13.86 | 0.694 |

| USSI | UTEI = 0.055 h/DB + 14.185 | 0.640 |

| CCSN | CCSN = −0.33 h/DB + 43.74 | 0.591 |

| CCSI | CCSI = 0.0335 h/DB + 26.423 | 0.353 |

| CTSN | CTSN = −0.04 h/DB + 7.62 | 0.228 |

| CTSI | CTSI = −0.017 h/DB + 4.236 | 0.107 |

| Mechanical Performance Index | Node-Internode | Internode-Node |

|---|---|---|

| UCS | UCSN = 1.09UCSI − 0.965 | UCSI = 0.916UCSN + 0.884 |

| UCE | UCEN = 0.945UCEI + 1.987 | UCEI = 1.07UCEN − 2.12 |

| MOR | MORN = 0.917UCEI + 9.11 | MORI = 1.09UCEN − 9.93 |

| MOE | MOEN = 0.476UCEI + 8.97 | MOEI = 2.1UCEN − 18.83 |

| UTS | UTSN = 0.677UTSI + 34.2 | UTSI = 1.47UTSN − 50.5 |

| UTE | UTEN = 0.854UTEI + 2.30 | UTEI = 1.17UTEN − 2.70 |

| USS | USSN = 1.11USSI − 1.87 | USSI = 0.9USSN + 1.69 |

| CCS | CCSN = −9.85CCSI + 304 | CCSI = −0.1CCSN + 30.86 |

| CTS | CTSN = 2.35CTSI − 2.35 | CTSI = 0.CTSN + 0.99 |

| Parameters | P2 | UCSN2 | UCEN2 | MORN2 | MOEN2 | UTSN2 | UTEN2 | USSN2 | CCSN2 | CTSN2 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| P1 | |||||||||||

| α | UCSN1 | 1 | 0.313 | 1.388 | 0.16 | 2.337 | 0.280 | 0.258 | 1.137 | −0.339 | |

| UCEN1 | 3.128 | 1 | 4.4 | 05 | 7.421 | 0.889 | 0.817 | 3.604 | −1.084 | ||

| MORN1 | 0.709 | 0.225 | 1 | 0.114 | 1.673 | 0.201 | 0.186 | 0.813 | −0.245 | ||

| MOEN1 | 6.116 | 1.913 | 8.538 | 1 | 14.296 | 1.717 | 1.587 | 6.957 | −2.056 | ||

| UTSN1 | 0.42 | 0.134 | 0.589 | 0.067 | 1 | 0.12 | 0.109 | 0.485 | −0.147 | ||

| UTEN1 | 3.516 | 1.115 | 4.93 | 0.562 | 8.329 | 1 | 0.917 | 4.041 | −1.223 | ||

| USSN1 | 3.787 | 1.198 | 5.324 | 0.608 | 8.921 | 1.073 | 1 | 4.316 | −1.303 | ||

| CCSN1 | 0.861 | 0.273 | 1.205 | 0.138 | 2.04 | 0.244 | 0.223 | 1 | −0.298 | ||

| CTSN1 | −2.879 | −0.889 | −4203 | −0.471 | −6.954 | −0.797 | −0.752 | −3.227 | 1 | ||

| β | UCSN1 | 0 | −3.615 | 48.665 | 7.962 | 0.155 | −0.439 | 0.377 | −30.961 | 26.627 | |

| UCEN1 | 12.601 | 0 | 65.281 | 9.975 | 27.964 | 2.909 | 3.489 | −17.363 | 22.712 | ||

| MORN1 | −33.614 | −14.519 | 0 | 2.505 | −80.342 | −10.135 | −8.611 | −70.082 | 38.551 | ||

| MOEN1 | −47.358 | −18.427 | −17.913 | 0 | −110.53 | −13.744 | −11.986 | −84.857 | 42.386 | ||

| UTSN1 | 0.967 | −3.588 | 49.289 | 8.117 | 0 | −0.39 | 0.508 | −30.819 | 26.872 | ||

| UTEN1 | 2.39 | −3.12 | 51.162 | 8.336 | 3.938 | 0 | 0.834 | −28.96 | 26.156 | ||

| USSN1 | −0.094 | −3.862 | 47.467 | 7.899 | −1.16 | −0.647 | 0 | −31.264 | 26.967 | ||

| CCSN1 | 27.936 | 4.988 | 87.063 | 12.424 | 64.394 | 7.3 | 7.567 | 0 | 17.406 | ||

| CTSN1 | 78.111 | 20.733 | 157.22 | 20.516 | 181.86 | 21.39 | 20.594 | 57.533 | 0 | ||

| Parameters | P2 | UCSN2 | UCEN2 | MORN2 | MOEN2 | UTSN2 | UTEN2 | USSN2 | CCSN2 | CTSN2 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| P1 | |||||||||||

| α | UCSN1 | 1 | 0.334 | 18.526 | 0.328 | 3.057 | 0.301 | 0.296 | 0.326 | −0.200 | |

| UCEN1 | 2.971 | 1 | 5.504 | 0.98 | 9.11 | 0.895 | 0.881 | 0.97 | −0.598 | ||

| MORN1 | 0.531 | 0.177 | 1 | 0.175 | 1.624 | 0.16 | 0.157 | 0.175 | −0.105 | ||

| MOEN1 | 3.002 | 1.008 | 5.58 | 1 | 9.248 | 0.905 | 0.888 | 0.987 | −0.600 | ||

| UTSN1 | 0.325 | 0.109 | 0.602 | 0.108 | 1 | 0.098 | 0.096 | 0.106 | −0.065 | ||

| UTEN1 | 3.31 | 1.108 | 6.151 | 1.089 | 10.137 | 1 | 0.983 | 1.08 | −0.658 | ||

| USSN1 | 3.349 | 1.121 | 6.196 | 1.098 | 10.246 | 1.01 | 1 | 1.09 | −0.671 | ||

| CCSN1 | 3.026 | 1.013 | 5.653 | 1.002 | 9.284 | 0.911 | 0.895 | 1 | −0.605 | ||

| CTSN1 | −4.954 | −1.658 | −9.337 | −1.649 | −15.268 | −1.496 | −1.457 | −1.631 | 1 | ||

| β | UCSN1 | 0 | −5.688 | 26.965 | −1.175 | −27.072 | −1.09 | −1.276 | 8.906 | 15.297 | |

| UCEN1 | 17.28 | 0 | 58.987 | 4.441 | 25.368 | 4.095 | 3.835 | 14.529 | 11.892 | ||

| MORN1 | −13.334 | −10.143 | 0 | −5.636 | −68.108 | −5.17 | −5.2 | 4.362 | 17.853 | ||

| MOEN1 | 4.345 | −4.315 | 34.669 | 0 | −15.088 | 0.189 | 0.042 | 10.188 | 14.432 | ||

| UTSN1 | 9.224 | −2.654 | 43.938 | 1.728 | 0 | 1.652 | 1.444 | 11.856 | 13.449 | ||

| UTEN1 | 3.867 | −4.415 | 33.807 | 0.064 | −15.607 | 0 | −0.172 | 10.15 | 14.478 | ||

| USSN1 | 4.707 | −4.129 | 35.815 | 0.405 | −12.836 | 0.285 | 0 | 10.484 | 14.386 | ||

| CCSN1 | −26.196 | −14.475 | −22.879 | −9.993 | −108.09 | −8.995 | −8.978 | 0 | 20.549 | ||

| CTSN1 | 76.365 | 19.841 | 169.08 | 23.985 | 206.81 | 21.903 | 21.310 | 33.895 | 0 | ||

| IV | III | II | I | ||

|---|---|---|---|---|---|

| UTSN | Value (MPa) | UTSN ≤ 131 | 131 < UTSN ≤140 | 140 < UTSN ≤148 | UTSN < 148 |

| h/DB | h/DB ≤ 16 | 16 < h/DB ≤36 | 36 < h/DB ≤54 | h/DB < 54 | |

| UTSI | Value (MPa) | UTSI ≤ 137 | 137 < UTSI ≤149 | 149 < UTSI ≤159 | UTSI < 159 |

| h/DB | h/DB ≤ 7 | 7 < h/DB ≤25 | 25 < h/DB ≤40 | h/DB < 40 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Zhou, Q.; Fu, F.; Li, W. Effect of Bamboo Nodes on the Mechanical Properties of P. edulis (Phyllostachys edulis) Bamboo. Forests 2021, 12, 1309. https://doi.org/10.3390/f12101309

Liu P, Zhou Q, Fu F, Li W. Effect of Bamboo Nodes on the Mechanical Properties of P. edulis (Phyllostachys edulis) Bamboo. Forests. 2021; 12(10):1309. https://doi.org/10.3390/f12101309

Chicago/Turabian StyleLiu, Pengcheng, Qishi Zhou, Feiyang Fu, and Wei Li. 2021. "Effect of Bamboo Nodes on the Mechanical Properties of P. edulis (Phyllostachys edulis) Bamboo" Forests 12, no. 10: 1309. https://doi.org/10.3390/f12101309

APA StyleLiu, P., Zhou, Q., Fu, F., & Li, W. (2021). Effect of Bamboo Nodes on the Mechanical Properties of P. edulis (Phyllostachys edulis) Bamboo. Forests, 12(10), 1309. https://doi.org/10.3390/f12101309