1. Introduction

When researchers make mention of the causes of deforestation in Ghana much attention is placed on illegal loggers without taking into accounts the legal loggers, in other words, the timber production companies. Increasing in logging above the annual allowable cut (ACC) either by legal or illegal means has severe negative environmental, economic, and social implications and consequences. Logging to exceed the annual allowable cut leads to forest degradation or outright deforestation, thus reducing forest-related environmental services and biodiversity. The rate of logging in Ghana has increased, and this can be attributed to the fact that there has been an increase in the installation of milling companies and round wood utilization above the defined annual allowable cut [

1]. The annual allowable cut (AAC) for the forest in Ghana is an estimation of the amount of allowable timber to be harvested in the forest within a year, stated by the Ghana Forestry Commission. ACC is based on an estimation of the annual forest harvest, which is however, not accurate since the Forestry Commission does not have valid data of the forest growth in Ghana. The Forestry Commission, under the Forest Services Division in 1990, estimated that the annual allowable cut (AAC) for already exported species was 1.2 m

3/ha/year. This brought the annual allowable cut (AAC) to 1.2 million m

3. However, by 1995 it had become known that this production rate was not sustainable since most of the forests were progressively depleted in stocks of some major species [

1]. The current AAC is 2.0 million m

3, 0.5 million m

3 from forest reserves, and 1.5 million m

3 from the off-reserve areas. However, the current total timber harvest in Ghana is estimated at approximately 3.7 million m

3 to 6 million m

3, which is almost two to three times the AAC [

2]

Increases in the installation of timber production companies have resulted in the increase in logging of timber in Ghana. Increased milling volume with the high amount of wood waste generated by timber production companies can be attributed to the use of outmoded sawmilling machines, inexperienced operators and not using the waste for other beneficial products [

3]. The timber industry operates with obsolete equipment with installed capacities that exceed the annual allowable cut (AAC). [

4]. Ghana is considered one of the countries in West Africa having a large number of sawmilling industries with a high volume of lumber and the export of timber has been a key activity in the country [

4]. The Ghanaian timber industry is made up of many wood-processing units and other enterprises that focus on furniture production. There are over 41,000 small-scale carpenters registered with the Association of Small-Scale Carpenters in the country. The small-scale carpenters denote the largest group of end-users. They need about 219,000 m

3 of sawn timber annually. This represents about 72% of the total domestic timber requirement for the entire country [

5].

The recovery rate in the timber industry is about 60%. Due to the high amount of wood waste generated by the timber companies, their targets are not met for their production. In order to meet the target, more timber must be harvested by the timber production companies. This has led to unsustainable forest tree utilization in Ghana [

6]. The timber industry is characterized by an over-capacity of obsolete, outmoded and inefficient mills. It was reported that new factories were installed in the late 1990s and early 2000s to bring the processing capacity to about 5.2 million m

3, which is far from the ACC of 2 million m

3 [

7]. The increase in mill capacity is attributed largely to the availability of relatively cheap raw materials [

7]. Waning the situation is the fact that the timber industry is operating at a low recovery rate (20–40%) which is 60–80% of the total timber recovered, due to the inefficiency of the mills [

8] leading to inefficient material use. For timber companies to meet their production target within the year, they have to increase their annual harvest, exceeding the ACC which hence results in deforestation in the country.

The FAO has predicted that the global consumption of industrial wood products will increase by 45% in 2020, and experts are concerned about the additional pressure this will put on the world’s forests [

9,

10,

11]. This additional pressure on the world’s forests calls for sustainable utilization and efficient usage of wood in its production. Sustainable development is a key issue for governmental bodies, industries, and other stakeholders, particularly in the timber production sector, to come up with a wakeup call in improving the efficiency of primary wood utilization, which could help to reduce the rate of harvesting and hence a reduction in the ACC and to meet the increasing demand for wood without further impacting the world’s forests. Better recovery also provides a high volume of secondary resources (offcuts, broken timber, and slabs) for recycling into new advanced materials. This further enhances the environmental profile of wood. Reducing, recovering, and enhancing the utilization of wood waste from harvesting and processing of wood are recognized as one of the top strategic objectives and research areas in Africa.

Several works have been conducted regarding the causes of the high rate of deforestation in Ghana. Major attention has been placed on illegal logging, using forest lands for illegal farming and illegal mining activities. Less attention has been placed on timber production companies as a contributing factor to deforestation.

The main objectives of this research is;

To assess the wood waste generation, its management practices by timber production companies in Ghana and its effect on the forest.

To assess the knowledge and technical know-how of wood waste by timber production companies in Ghana.

Our Research questions;

What are the wood waste management practices employed by the timber production companies that increase the waste generation?

Do the timber production companies have the knowledge and technical know-how of wood waste?

2. Literature

The rapid rate of forest resource depletion and degradation, especially in the humid tropics, has been the focus of much environmental concern in recent years [

1]. Although the proximate causes of this high rate global forest loss are complex and quite poorly understood [

12,

13,

14,

15,

16,

17], it is generally acknowledged that formulating a good forest policy and implementing it effectively is essential for sustainable forest management [

1]. First, even though the actual extent of forest loss is contested, it is generally acknowledged that the country Ghana has lost at least 50% of its forest cover between 1900 and the 2000s [

18,

19,

20,

21]. It can be stated that the fastest rate of deforestation in Ghana can also be attributed to the way the wood industries mismanage wood in their operations in Ghana [

19].

Ghana has one of the highest deforestation rates in Africa and the world, at 2% per annum [

22]. Between 1990 and 2000, Ghana lost an average of 135,000 hectares of forest per year; amounting to an average annual deforestation rate of 2% [

1,

23,

24,

25]. Between 2000 and 2005, Ghana’s forests decreased by a further 115,000 hectares, with a rate of forest change of 2% per annum. In total, between 1990 and 2005, Ghana lost 26% of its forest cover, or around 1,931,000 hectares [

23,

26,

27]. From an area of 1.64 million ha in 1990, the total timber production areas dwindled to 0.86 million ha by 2010 indicating an average annual decline of 29,030 ha. Significantly, the size of the social forests has also been declining by 1500 ha annually over the last two decades.

Deforestation in Ghana is primarily driven by slash and burn agriculture. Timber harvesting, wildfires, mining, and rising demand for fuelwood are also important contributors to deforestation in the country [

26]. In the cocoa-growing regions of Ghana, which also happen to be in the forest areas, large tracts of tropical forests have been cleared to support increasing cocoa cultivation. Ghana’s economy is agriculturally based with lots of income coming from cocoa exports. Currently, Ghana is the world’s second-largest producer of cocoa beans. When world cocoa prices are low, Ghana’s foreign exchange earnings are significantly affected; this is often compensated for, by increasing timber and mineral exports. Thus, cocoa farming is both a direct and indirect driver of deforestation (UNEP, Accra, Ghana, 2008) [

26].

Since more wood is wasted and not managed by the wood industries, more wood needs to be harvested to reach the desired level of production. Timber production companies in Ghana allow the wood shavings, offcuts, sawdust, and the branches of the harvested timber in the forest to go waste in the forest and the sawmills. The excessive harvesting of timber in both legal and illegal methods is far exceeding that of the AAC and is additionally an important single factor contributing to deforestation and forest degradation in Ghana [

23,

27,

28]. In recent times, logging activity has been intensified in Ghana due to greater densities of desirable timber species [

8,

29,

30].

Timber production companies and sawmilling has recorded a rising trend in production just as the export and domestic consumption of sawn timber, particularly during the post-economic recovery program era of 1983. The total sawn timber production has been increasing from 472,000 m

3 in 1990 to 740,000 m

3 in 1997. Local consumption of sawn timber has increased from a level of 270,000 m

3 in 1990 to 461,000 m

3 in 1997 [

23] and 930,270.48 m

3 in 2014.

Excessive logging has become a major issue in Ghana, harvesting of timber is one of the most important single factors contributing to deforestation in Ghana. However, in 1991, logging operations accounted for 14% of the deforested areas in Ghana Froest Service Division. (FSD) Annual Reports 1962–94) [

31,

32,

33]. Outside the forest, reserves logging has been on the increase mainly due to a lack of effective control. Illicit logging activities due to the poor supervisory role of the Forest Services Division are also having a serious toll on the timber resources in the country [

34,

35,

36,

37]. The division lacks the resources and logistics to adequately monitor timber operations and to ensure that timber contractors comply with the provisions in the logging manuals. A major problem associated with the logging procedure is the insufficient attention given to the yield allocation process. In the process of harvesting, seed trees, which influence regeneration, are supposed to be left behind. Unfortunately, due to lack of adequate information, such trees are not identified, and stock mapped leading to the harvesting of all trees, which has a strong influence on forest regeneration. This is a major contribution to deforestation in Ghana.

Wood waste has the potential for bioenergy production in the country to reduce the high pressure on the hydro energy systems in the country and to produce energy for households. Wood waste can also be used to make plywood and other wood types for household furniture and other furniture works that will reduce the amount of timber that needs to be harvested within a year. For fuelwood consumption in Ghana, it is well-grounded estimated that 14 million m3 of wood is consumed for energy production. It has also been estimated that the volume of fuelwood consumption in Ghana could rise from 15.9 million m3 to 20 million m3 by the year 2020. About 69% of all urban households in Ghana use charcoal for cooking and heating and the annual per capita consumption is around 180 kg. The total annual consumption is about 700,000 tons, 30% of which is consumed in the capital, Accra.

Study Area

The Republic of Ghana is a country situated on the Gulf of Guinea, within the subregion of the geographic area. Ghana features a landmass spanning 238,535 km2, equivalent to (92,099 km3), Ghana shares her borders with Cote d’Ivoire to the west (a part of Ghana), Burkina Faso to the north, Togo to the east and the Gulf of Guinea—part of the atlantic ocean—to the south.

The Closed Forest Zone is classed into evergreen forest, evergreen damp Forest, and the most abundant—semi-deciduous Forest. In 1992, it was made known that 1.5 million ha of “intact closed forest” were remaining in Ghana. The annual rate of deforestation within the country was said to have slowed within the 1980s to approximately 22,000 ha [

38].

The evolution of the forest cover in Ghana can compare with Côte d’Ivoire, with a parallel decline since the 1980’s due to the very same main drivers of conversion: cocoa area expansion and other perennial crops. The Forest Resources Assessment (FRA) (2015) states that the forest area of Ghana is 9.34 million ha, with an average deforestation rate of 28,400 ha/year for the 2000–2015 period. The Global Forest Watch (GFW) has reported that the forest area is 7 million ha (30% threshold) with an average tree loss of 40–60,000 ha/year, and with only 207,000 ha of dense forest. Approximately 1.6 million ha are gazetted as forest reserves. A 2014 map of canopy cover of forest reserves in Ghana showed the degradation and deforestation of many of them [

39].

The research work will be conducted in the areas (forested regions) where the timber production companies are established in Ghana.

3. Materials and Methods

The data for the research work was collected in Ghana

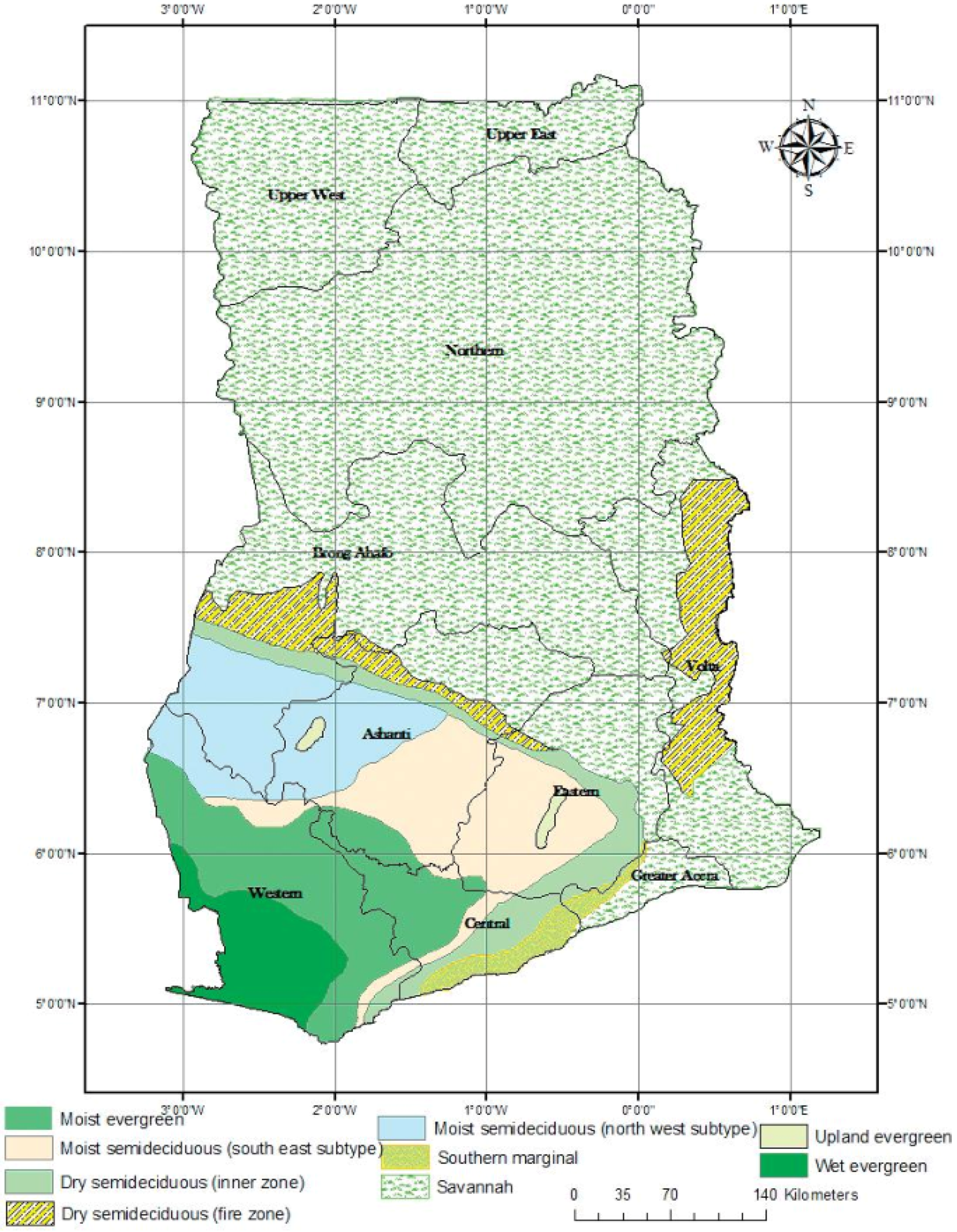

Figure 1, in 5 selected regions and 10 randomly selected districts where most of the timber companies are established. The data were collected from June–September 2019. The study population comprised of 50 randomly selected timber industries (Sawmills (27) and carpentry (23) enterprises) in 5 selected regions (Western North, Western Region, Ashanti region, Eastern Region and Bono Ahafo region) and 10 districts in Ghana.

A cluster sampling technique was used to select the respondents. Secondary data were used in this study. Secondary data on timber companies on the total number of waste used for other products like plywood produced from the wood waste they generate. Records on wood waste and the number of lumber produced per year were taken. The field survey used a structured questionnaire comprising both open- and closed-ended items. The questions were designed to gather data on the causes of the waste generated by timber companies, to find out if the timber companies use their wood waste generated in their operations into other products. The selected domestic interviewees were helped by a university student who interpreted the questions made in the English language to the operators who do not understand English.

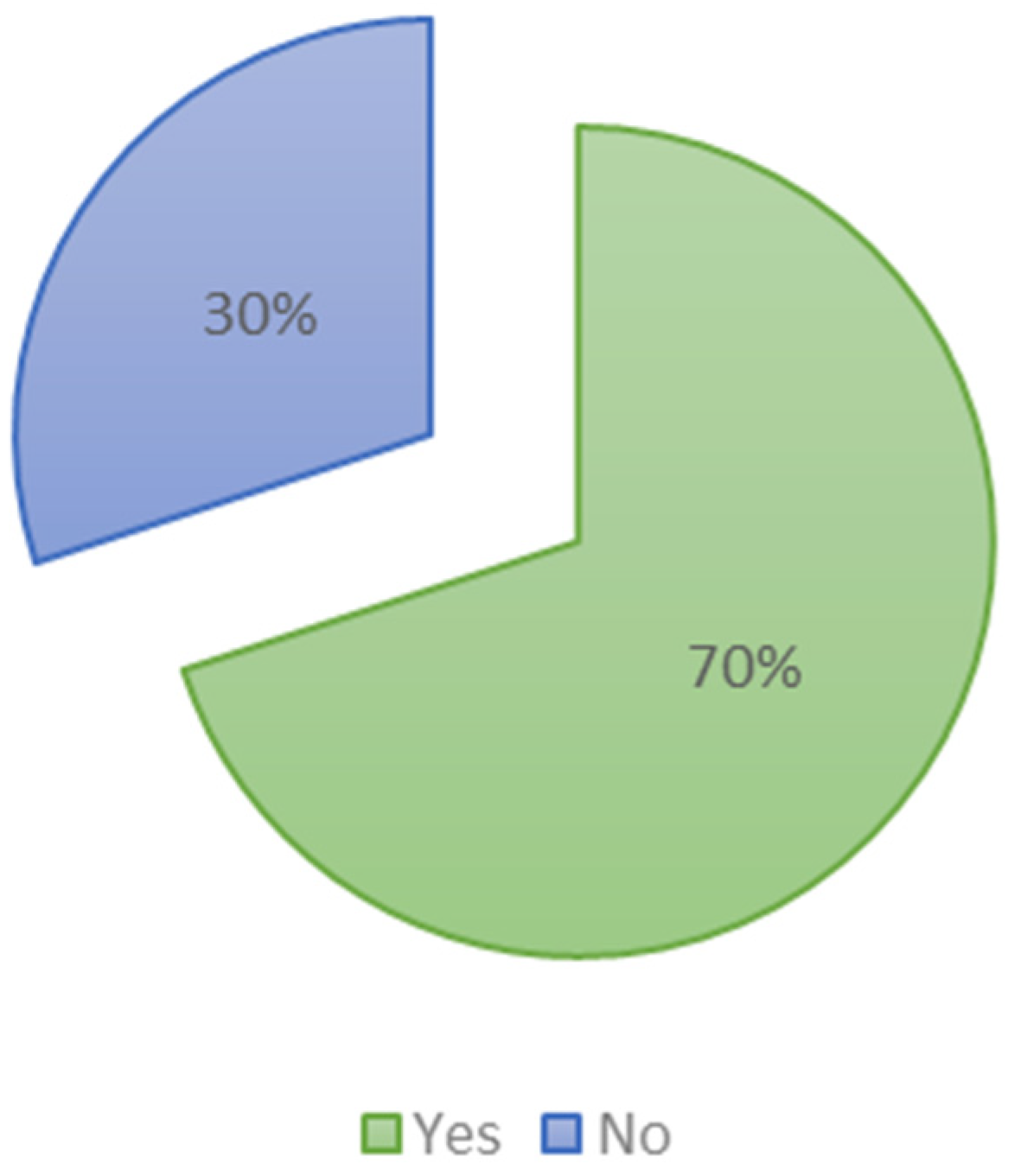

A copy of this questionnaire can be found in the electronic supplementary material. The questionnaire with 20 questions was administered to the 50 randomly selected timber production companies. Key informant interviews (KII) were engaged with the management of selected timber production industries as to how wood waste management practices in their industries are carried out, personal field observations were employed in the data collection, this helped us to come out with a structured questionnaire which was also the instrument for gathering primary data. Personal observations were also made where sawdust, wood shavings, and broken pieces of wood were placed at the site and how they were handled. The data obtained for different companies were compiled and analyzed with the statistical tool Microsoft office (excel). Simple descriptive statistics such as graphs, bar charts, and pie charts were used to compute the different modes of wood waste management practices by the timber production company contacted.

5. Discussion

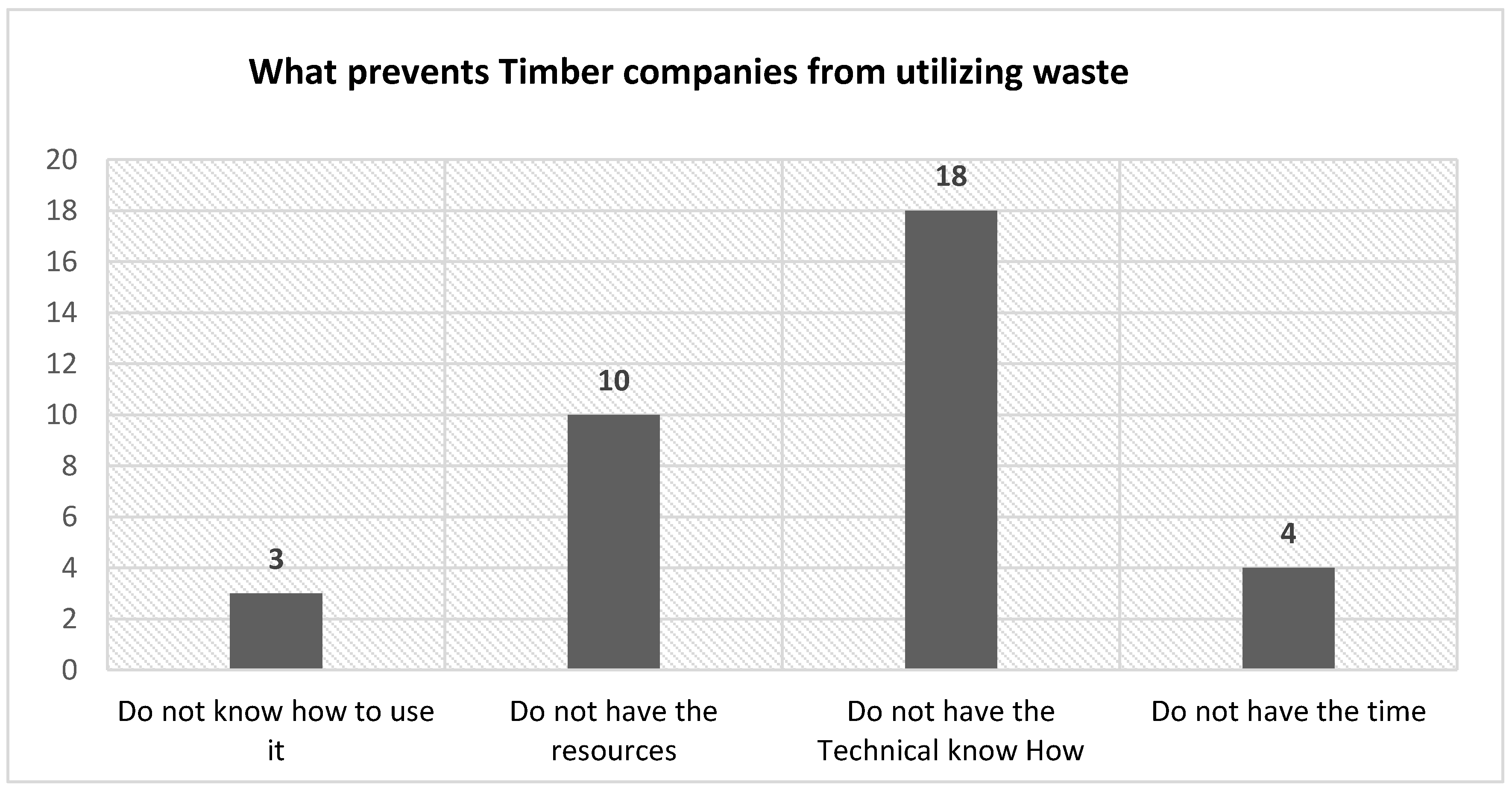

Timber is one of the major backbones of the Ghanaian economy. There has been an increase in the installation of new sawmills in the wood industry in the country. The study employed multi-disciplinary approaches to gathering data from the timber production companies on the wood waste generation and its management. The study found that timber companies in the country, have a fair idea about the waste they generate but confirmed they do not have the skills and the technology to utilize the waste into other products. Increased logging and sawmill production have resulted in an increase in wood waste generation by these companies. The management of wood waste generated by timber production companies in Ghana is below the standard of good wood waste management practices as compared to other wood industries in other countries, where such materials are considered as side streams and not waste. Wood waste generated at the harvesting, the milling, and the processing stages of lumber by the small-scale enterprises is not utilized in Ghana, as compared to some of the developed countries. Large chunks of wood harvested from the forest are wasted in the timber production process by timber production companies in Ghana.

Due to lack of knowledge, technology, time or management skills, a large number of wood wastes is burnt just to get rid of the waste without using to provide energy for steam or for energy that could have been used for their power plants to power some of the machines they use in the operations of the timber companies. This could reduce the demands of energy on the national grid. It was also found that the trunks, branches, and stumps of the timber are left in the forest to decay without utilizing them. These parts are often considered as logging residue. Logging residues consist of branches, leaves, lops, tops, damaged or unwanted stem wood. Such residues are often left in the forests for various reasons, of which the low demand for fuel is one [

38]. From the observations made in the study, it can be estimated that 40% of the round wood goes waste, from the logging stage through processing, the 60% recovery rate in each of these sawmills shows that a little over half the volume of logs converted to good lumber [

41]. The low product yield of logs processed in the region is the result of wood waste at various steps during log processing [

42].

The estimated recovery rate of the timber companies being 60% or lower highlights that the timber production companies have a very low recovery rate. It is estimated that the production targets of the timber companies are not met. In order to meet the production target, timber companies must increase the number of timbers they harvest or log from the forest. Logging has direct impacts on soil and hydrological cycles, as logging increased it results in a reduction in tree cover in the forest. This leads to increases in water runoff and soil erosion and hence forest degradation. Due to the high demand for round logs by the timber companies, less time is given for the forest to recover which also leads to forest degradation. At the macro level, deforestation by logging results in a reduction of carbon sequestration capacity, which in turn contributes to climate change. Deforestation from logging and timber conversion in the tropics accounts for approximately 15% of global greenhouse gas emissions annually [

43]. Increases in the installation of sawmills and the generation of Wood waste has direct detrimental effects on the forests in Ghana. Data from the forestry commission under the Forest Services Division of Ghana indicate that the level of harvesting over the last 10 years has been exceeding the AAC, indicating that the forest capacity has been surpassed for almost a decade. The official timber harvest data show that in the last decade, recorded forest reserve timber harvest has always been above the on-reserve AAC of 0.5 million m

3 except in 2009 when the harvest was equal to the AAC [

44]. It is still argued that the total timber harvest is approximately 6 million m

3 a year, representing three times the AAC, which is three times over the current ACC (2.0 m

3). On average, more than 46% capacity of the forest has been exceeded during the period [

23]. There are other factors like corruption on the side of officials and timber production companies who do not adhere to the rules and regulation that govern their logging activities in the forest, which makes it difficult to control and manage the ACC. Unethical and corrupt transactions normally occur in order to process and trade the logs once they have been harvested, in a form of “timber laundering” similar to money laundering. The law enforcement officials are bribed to turn a blind eye and deaf ears to trucks carrying harvested logs. Timber certifiers can be paid off to whitewash and paint illegally sourced logs [

45].

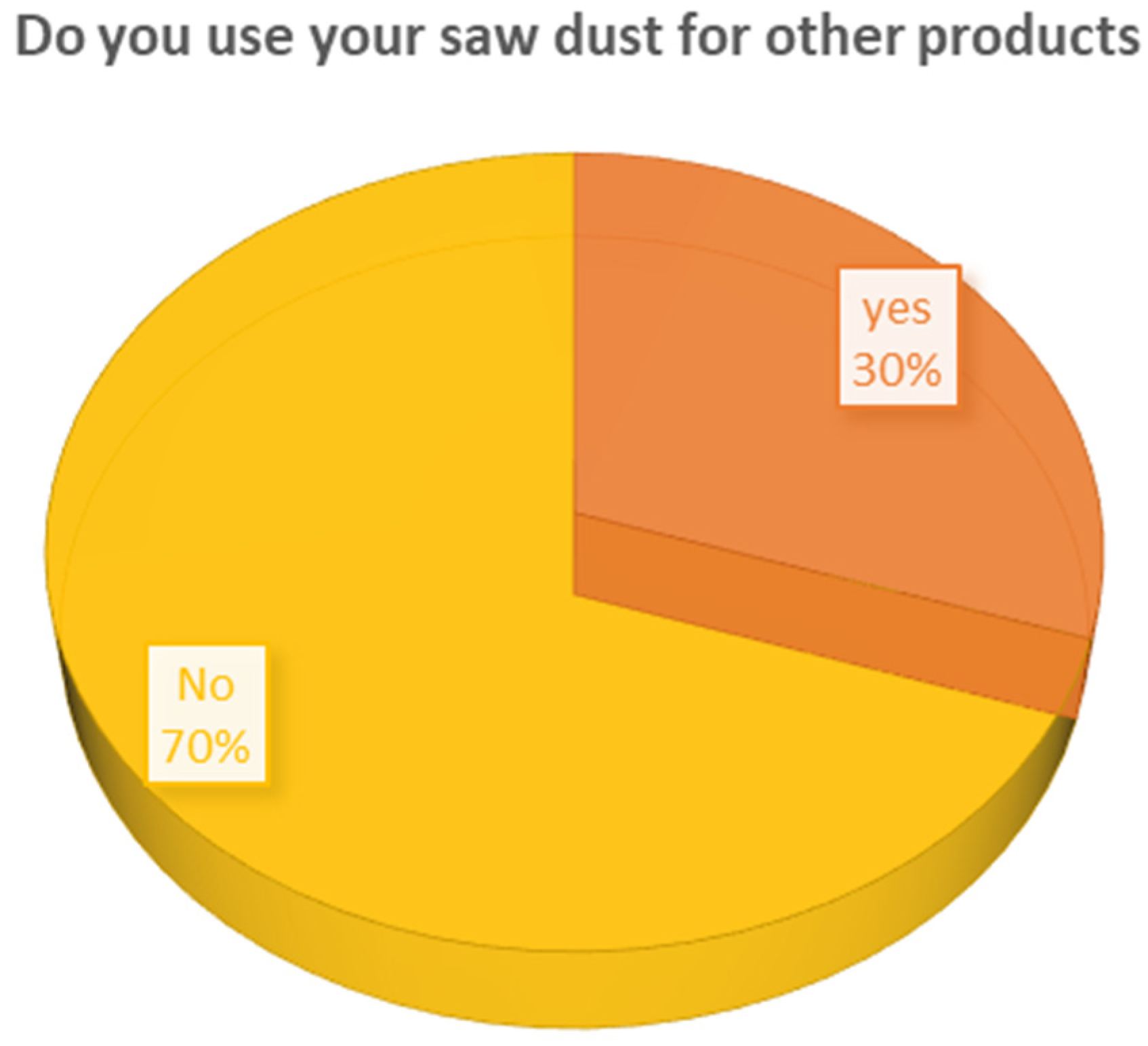

From the research conducted, it was observed that in Ghana, most of the timber production companies both the milling companies and the carpentry enterprises do not manage their waste, the side streams, and harvesting residue they produce during their operations. Wood shavings, sawdust, wood slabs, offcuts, branches, and others are not used. All the wood waste could be used for other products like particle boards, fiberboards, and chipboards that could serve the purpose of clean lumber and pay the same price as that of clean lumber. Wood or lumber needed to produce household artifacts; wood waste can be used in its production. For example, manufacturing of school desks in the lower cycle schools and in offices that need regular lumber for production, wood waste can be used or recycled to produce those artifacts in order to reduce the number of woods needed for their production. Sawdust actuality a product of all mechanical wood processing operations, mostly sawmilling, is generally not regarded as a prime pulping material due to its small size, although it proves to be acceptable for the manufacture of particleboard [

23]. Sawdust can also be used to produce energy in a form of heat, in other words fuel energy can reduce and prevent the rate at which local communities go into the forest to cut down trees for fuel. Nowadays most wood processing plants being built in developed countries incorporate hog fuel burners to safeguard against certain and costly fossil fuel supply [

23].

A large fraction of the total wood waste produced from harvesting and processing of trees can be recycled. The off-cuts, wood chips, and sawdust collected from these operations can be used to make particleboard and other products, woody biomass is getting increasing attention in current European discussions [

46]. For example, Finland has become an icon on the use of wood for the development of bio-economy and circular economy aiming to carbon-neutral society. Wood products are typically considered to have lower climate impacts than equivalent products made from fossil raw materials. This needs, however, sustainable forest management and high material efficiency. Woody biomass is presently used in many different value chains, e.g., as wood-based products and materials, bio-chemicals, and bioenergy, and many different industrial sectors. Targets for greenhouse gas emission reduction and more resource-efficient society are expected to further increase the demand for wood raw material in Europe during the next decades. Woody biomass is, when sustainably grown, a fully renewable resource and a largely recyclable and reusable material. Only a small fraction of wood products cannot be re-used or recovered directly (e.g., hygiene paper). However, as woody biomass is a limited resource, its use and the service life of wood fibers should be optimized. Wood waste has the tendency to be used for many valuable items instead of leaving it go waste. In many developed wood-industrialized countries, wood wastes are considered as a side stream. It is used for other products or allocates to other timber production companies for example pulp, paper, or energy production.

It can be an estimate that half on the annual allowable cut of wood in Ghana is lost, wasted from the harvest to the wood processing by timber production companies. It can be considered that roughly 45% to 55% of the log input to a sawmill or plywood plant is to become waste. [

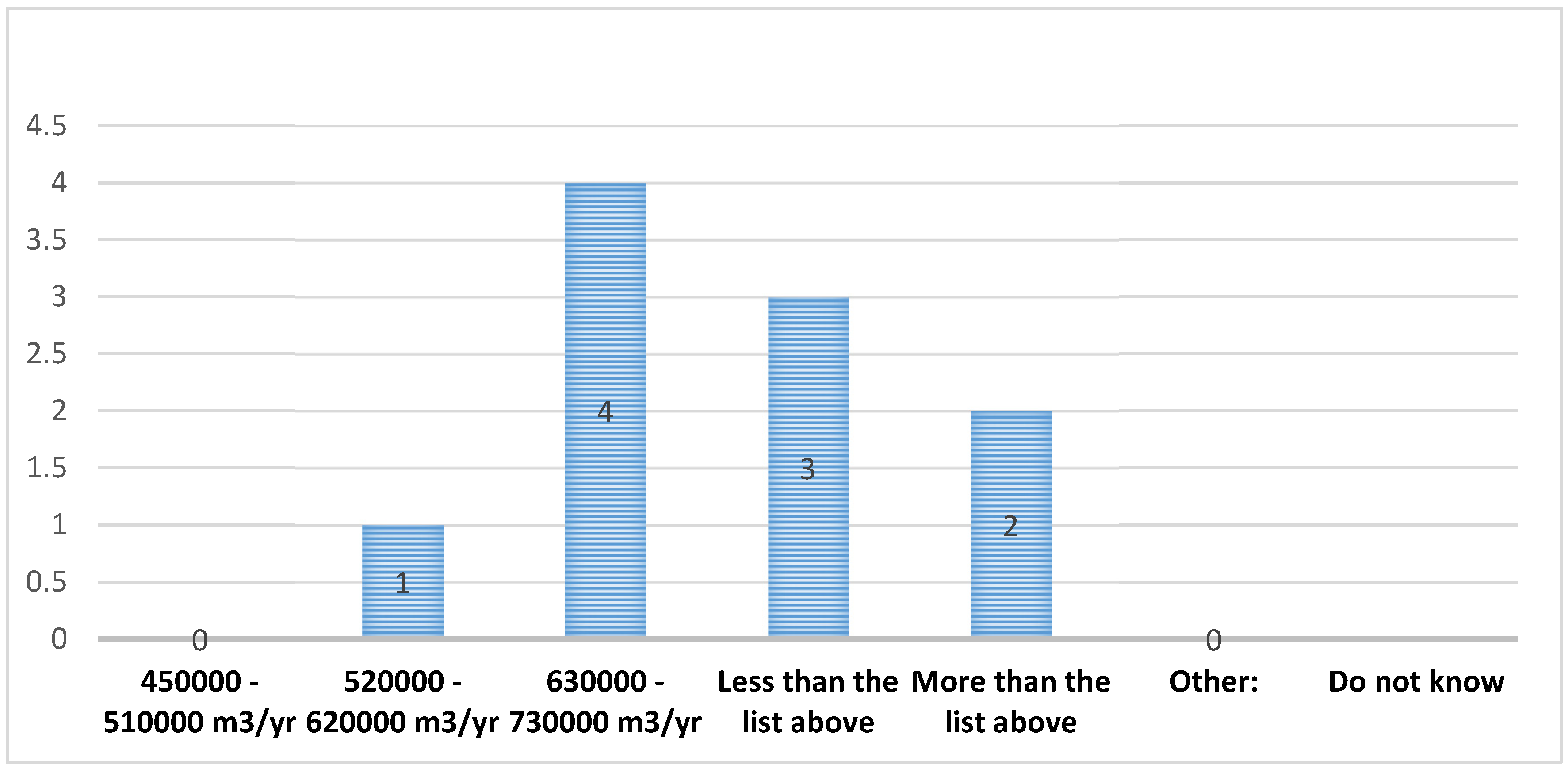

23]. When total wood needed for a timber company is 620,000 m

3/a, it can be estimated that 310,000 m

3/a, which is half of the total production, goes into waste. Before the total 620,000, m

3/a can be reached another half of the total round wood is needed to be harvested. This is pushing timber production companies to harvest more round wood to reach their target of production or economic. A high rate of logging can consequently lead to deforestation.

From the study, it is observed 40 out of the 50 respondents do not know the capacity of their production. Timber companies do not keep records for their operations. Institutions create records to support the activities they carry out. However, if these records are not managed properly, they will not provide the necessary support, and information might be lost causing problems for the institution. [

47,

48,

49] According to [

48,

50], organizations use records to support accountability, when they need to prove that they have met their obligations or complied with the best practice or established policies.

6. Conclusions

When researchers make mention of the causes of deforestation in Ghana much attention is placed on illegal loggers without taking into accounts the legal loggers in other words the timber production companies. The rate of logging in Ghana has increased and this can be attributed to the fact that there has been increasing installed milling capacity and round wood utilization above the sustainable annual allowable cut (ACC) due to the low recovery rate of the timber production companies. The high amount of wood waste generated by timber production companies can be attributed to the use of outmoded sawmilling machines, inefficient machines, and unskilled operators. The Ghanaian timber industry is made up of many wood-processing units and enterprises that focus on furniture production and other artifacts. Due to the high amount of wood waste generated by the timber companies, their targets are not met for their production, in order to meet the target, they increase the timber they harvested, which leads to the increase in the ACC, hence contributing to deforestation in Ghana. The main objective of this research was to assess the wood waste management practices of timber production companies in Ghana and to assess the knowledge and technical know-how of the management of wood waste by timber production companies in Ghana and relate it to the deforestation in the country.

Wood waste generated by timber production companies can be considered as one of the leading factors causing deforestation in Ghana. A high amount of wood is wasted during the processing of the wood and these are not used for alternative products. Wood waste that is generated by timber companies can be used for other products that normal lumber can also be used for. From the observation of the study, it was made known that, most of the timber production companies do not know the amount of lumber they produce and the waste they generate. Timber production companies not knowing the total wood they produce within a year let alone waste they generate in their operation is suicidal and this is not helping them to track the level of waste they generate and what they can do to curb the situation. It was also made known in the study that timber production companies lack the technical know-how, equipment, and resources for utilizing the waste they generate. Timber production companies should find ways of utilizing their wood waste.

It will be vital for all timber production companies to find the modern techniques and the ways to utilize the wood waste they produce during their operations. Using the waste they generate judiciously can equally serve the same purpose and generate the same income as that of clean lumber which can help them to meet their production target, hence reducing the high rate of logging in the forest which will help reduce the ACC, which leads to the managment of deforestation in the country.

It will be recommended to the Government of Ghana and the Ghana Forestry Commission to open doors for investors from developed countries like Finland, Canada, and Norway who have the technical know-how in the use of wood waste, to come and establish companies that can utilize the tonnes of wood waste generated by timber companies in the country. The Government of Ghana can reduce the amount of timber harvested by timber production companies by insisting the timber production companies utilize their waste to meet their production target. The government of Ghana, in collaboration with the Ghana Forestry Commission and other Non-governmental Organizations, need to invest in the wood industry, most especially in wood waste management. The Ghana Forestry Commission and the timber production companies should organize workshops and seminars for their operators with the modern ways of milling the timber. The forestry commission, from time to time inspect the state of the machines of the timber production companies to see to it that their machines are in order.