Effects of Microwave Treatment on Microstructure of Chinese Fir

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Microwave Treatment

2.3. Microstructure Analysis

2.4. Pore Structure Analysis

3. Results and Discussion

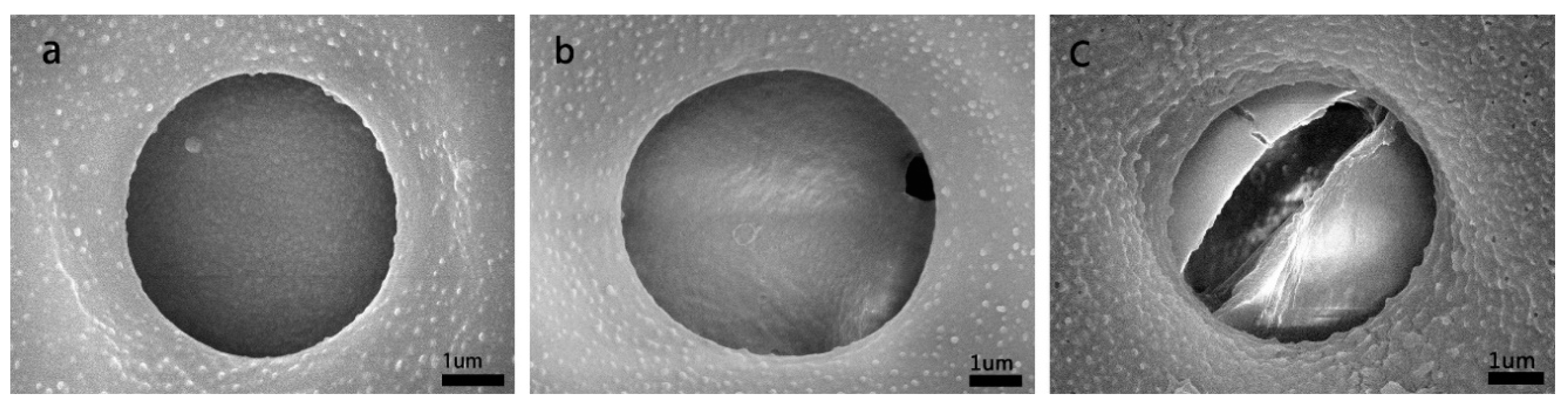

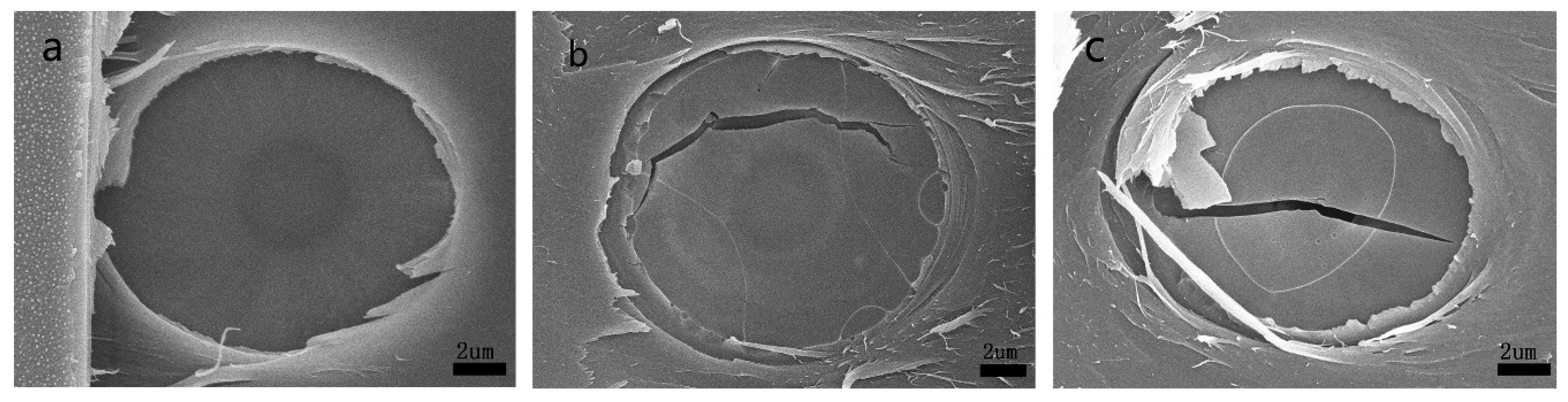

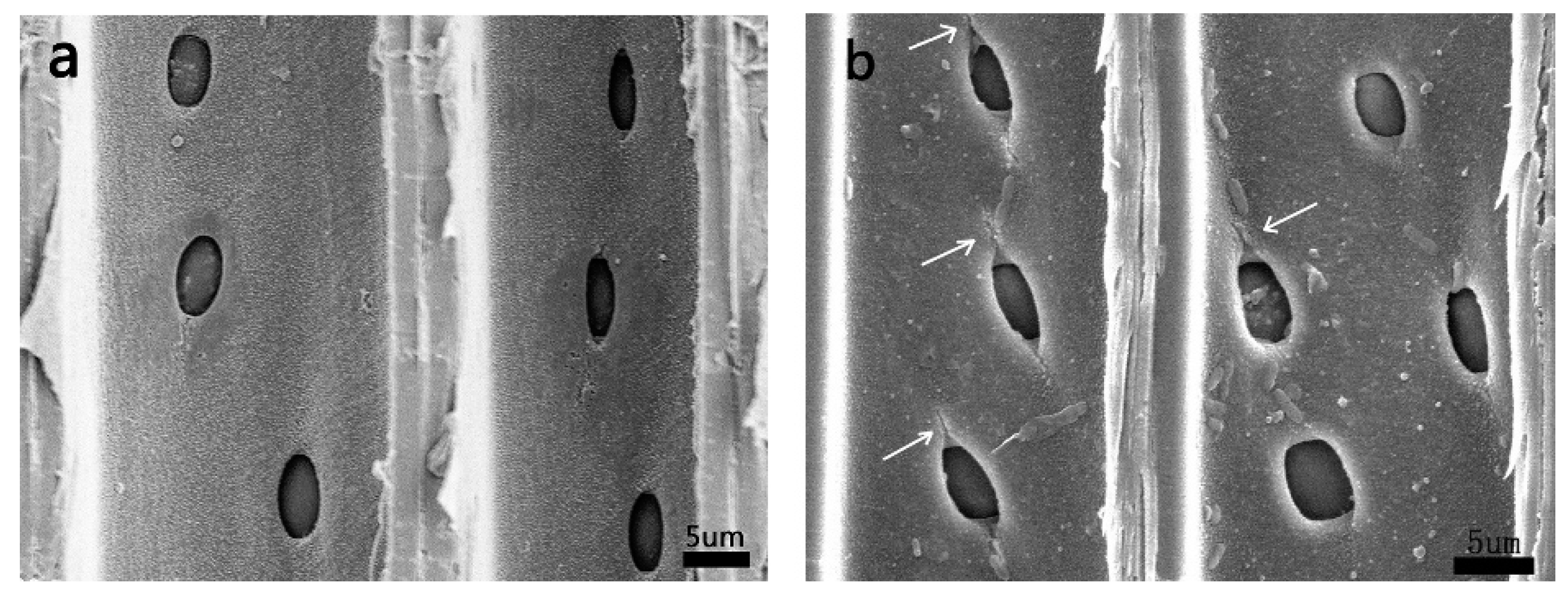

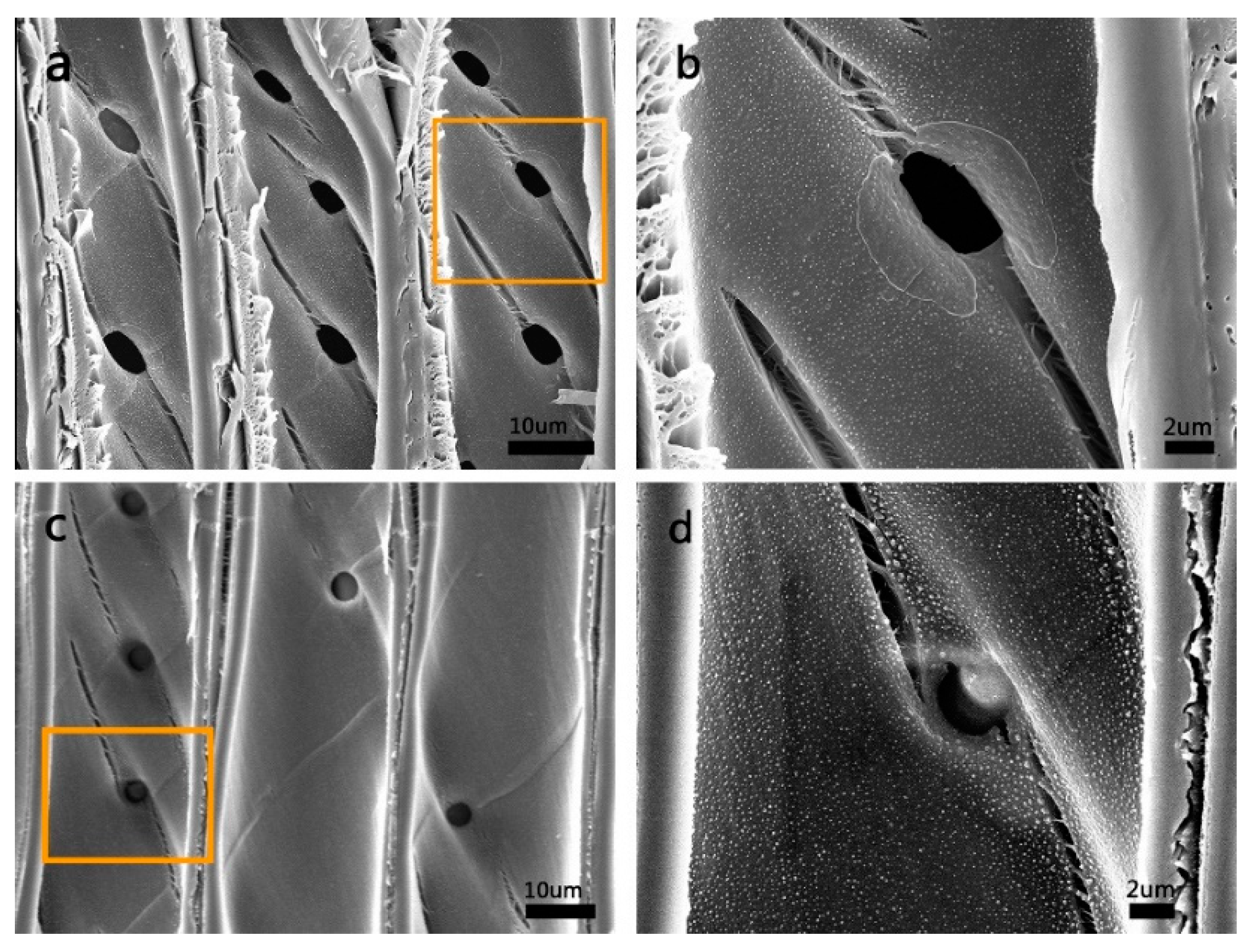

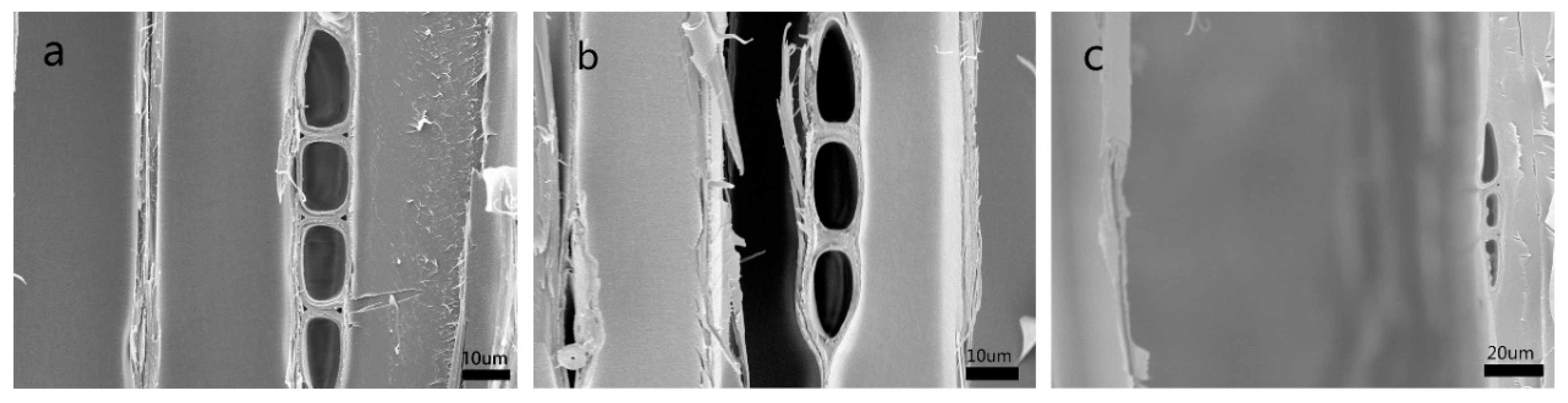

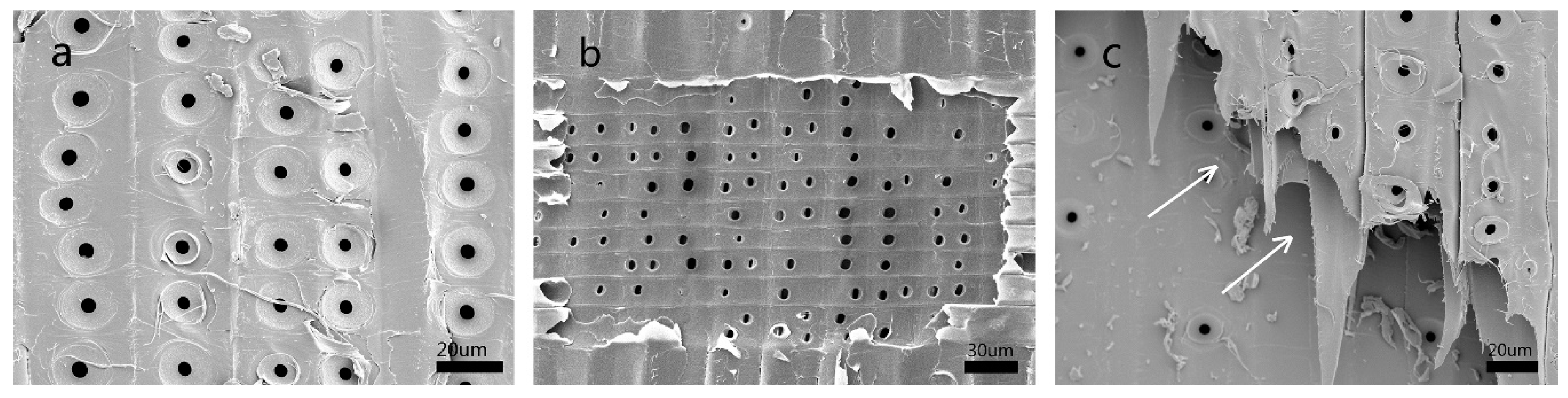

3.1. Microstructural Changes of MW-Treated Wood

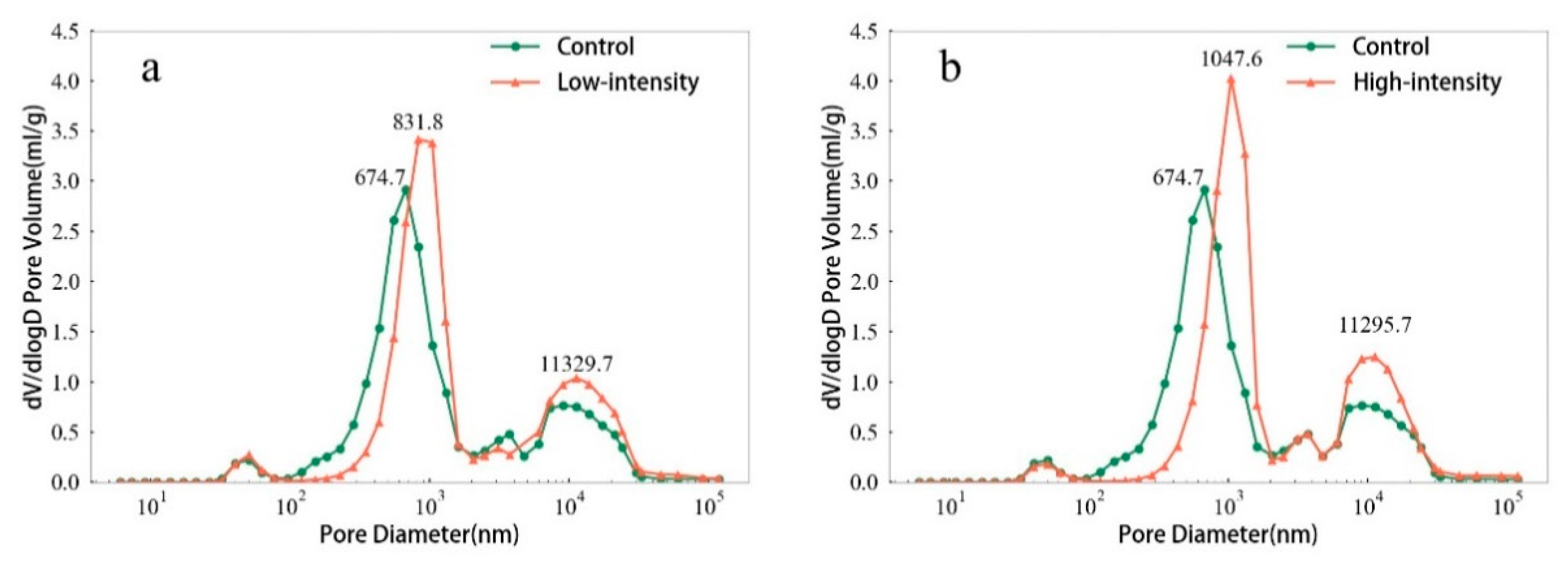

3.2. Pore Size Distribution Variation of MW-Treated Wood

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bao, F.; Lv, J. A study on fluid permeability of important Chinese woods. Sci. Silvae Sin. 1992, 28, 237–246. (In Chinese) [Google Scholar]

- Guo, J.; Guo, X.; Xiao, F.; Xiong, C.; Yin, Y. Influences of provenance and rotation age on heartwood ratio, stem diameter and radial variation in tracheid dimension of cunninghamia lanceolata. Eur. J. Wood Wood Prod. 2018, 76, 669–677. [Google Scholar] [CrossRef]

- Torgovnikov, G.; Vinden, P. High-Intensity microwave wood modification for increasing permeability. For. Prod. J. 2009, 59, 84–92. [Google Scholar]

- Torgovnikov, G.; Vinden, P. Microwave wood modification technology and its applications. For. Prod. J. 2010, 60, 173–182. [Google Scholar] [CrossRef]

- Vinden, P.; Torgovnikov, G.; Hann, J. Microwave Modification of radiata pine railway sleepers for preservative treatment. Eur. J. Wood Wood Prod. 2011, 69, 271–279. [Google Scholar] [CrossRef]

- Harris, G.A.; Torgovnikov, G.; Vinden, P.; Brodie, G.I.; Shaginov, A. Microwave pretreatment of backsawn messmate boards to improve drying quality: Part 1. Dry. Technol. 2008, 26, 579–584. [Google Scholar] [CrossRef]

- Dömény, J.; Koiš, V.; Dejmal, A. Microwave radiation effect on axial fluid permeability in false heartwood of beech (Fagus Sylvatica L.). BioResources 2014, 9, 372–380. [Google Scholar] [CrossRef][Green Version]

- He, X.; Xiong, X.; Xie, J.; Li, Y.; Wei, Y.; Quan, P.; Mou, Q.; Li, X. Effect of microwave pretreatment on permeability and drying properties of wood. BioResources 2017, 12, 3850–3863. [Google Scholar] [CrossRef]

- Balboni, B.M.; Ozarska, B.; Garcia, J.N.; Torgovnikov, G. Microwave treatment of eucalyptus macrorhyncha timber for reducing drying defects and its impact on physical and mechanical wood properties. Eur. J. Wood Wood Prod. 2018, 76, 861–870. [Google Scholar] [CrossRef]

- Zhang, Y.; Jia, K.; Cai, L.; Shi, S.Q. Acceleration of moisture migration in larch wood through microwave pre-treatments. Dry. Technol. 2013, 31, 666–671. [Google Scholar] [CrossRef]

- Dashti, H.; Shahverdi, M.; Taghiyari, H.R.; Salehpur, S.; Heshmati, S. Effects of steaming and microwave pretreatments on mass transfer characteristics of aleppe oak (quercus infectoria). BioResources 2012, 7, 3262–3273. [Google Scholar]

- Liu, H.; Wang, Q.; Yang, L.; Jiang, T.; Cai, Y. Modification of larch wood by intensive microwave irradiation. J. For. Res. 2005, 16, 237–240. [Google Scholar]

- Li, X.; Zhang, B.; Li, W.; Li, Y. Research on the effect of microwave pretreatment on moisture diffusion coefficient of wood. Wood Sci. Technol. 2005, 39, 521–528. [Google Scholar] [CrossRef]

- Plötze, M.; Niemz, P. Porosity and pore size distribution of different wood types as determined by mercury intrusion porosimetry. Eur. J. Wood Wood Prod. 2011, 69, 649–657. [Google Scholar] [CrossRef]

- Ding, W.D.; Koubaa, A.; Chaala, A.; Belem, T.; Krause, C. Relationship between wood porosity, wood density and methyl methacrylate impregnation rate. Wood Mater. Sci. Eng. 2008, 3, 62–70. [Google Scholar] [CrossRef]

- Martin-Sampedro, R.; Martin, J.A.; Eugenio, M.E.; Revilla, E.; Villar, J.C. Steam explosion treatment of Eucalyptus globulus wood: Influence of operational conditions on chemical and structural modifications. BioResources 2011, 6, 4922–4935. [Google Scholar]

- Schneider, A. Investigations on the suitability of mercury porosimetry for the evaluation of wood impregnability. Eur. J. Wood Wood Prod. 1983, 41, 101–107. [Google Scholar] [CrossRef]

- He, S.; Lin, L.; Fu, F.; Zhou, Y.; Fan, M. Microwave treatment for enhancing the liquid permeability of Chinese fir. BioResources 2014, 9, 1924–1938. [Google Scholar] [CrossRef]

- Wang, D.; Peng, L.; Zhu, G.; Fu, F.; Zhou, Y.; Song, B. Improving the sound absorption capacity of wood by microwave treatment. BioResources 2014, 9, 7504–7518. [Google Scholar] [CrossRef]

- Tong, Y.; Zhao, G. Structure of bordered pit membrane of Cunninghamia lanceolata tracheid. Sci. Silvae Sin. 2007, 43, 151–153. [Google Scholar]

- Washburn, E.W. Note on a method of determining the distribution of pore sizes in a porous material. Proc. Natl. Acad. Sci. USA 1921, 7, 115–116. [Google Scholar] [CrossRef] [PubMed]

- Muzamal, M.; Jedvert, K.; Theliander, H.; Rasmuson, A. Structural changes in spruce wood during different steps of steam explosion pretreatment. Holzforschung 2015, 69, 61–66. [Google Scholar] [CrossRef]

- Erickson, H.D. Permeability of southern pine wood-a review. Wood Sci. 1970, 2, 149–158. [Google Scholar]

- Petty, J.A. Permeability and structure of the wood of sitka spruce. Proc. R. Soc. Lond. B 1970, 175, 149–166. [Google Scholar]

- Lu, J.; Lin, Z.; Jiang, J.; Zhao, Y.; Jiang, J.; Gao, R.; Yin, Y. Effect of diferent drying methods on the liquid impregnation of Chinese fir plantation wood. Sci. Silvae Sin. 2006, 42, 86–90. (In Chinese) [Google Scholar]

- Zhang, Y.; Cai, L. Effects of steam explosion on wood appearance and structure of sub-alpine fir. Wood Sci. Technol. 2006, 40, 427–436. [Google Scholar] [CrossRef]

- Xia, J.; Zhang, Y.; Cai, J. Opening cell pathways of larch wood by steam explosion. J. Fujian Agric. For. Univ. 2013, 42, 543–547. (In Chinese) [Google Scholar]

- Muzamal, M. Structural Modifications in Spruce Wood during Steam Explosion Pretreatment. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2016. [Google Scholar]

- Donaldson, L.; Xu, P. Microfibril orientation across the secondary cell wall of radiata pine tracheids. Trees 2005, 19, 644–653. [Google Scholar] [CrossRef]

- Deng, Q.; Li, S.; Chen, Y. Mechanical properties and failure mechanism of wood cell wall layers. Comput. Mater. Sci. 2012, 62, 221–226. [Google Scholar] [CrossRef]

- Muzamal, M.; Gamstedt, E.K.; Rasmuson, A. Modeling wood fiber deformation caused by vapor expansion during steam explosion of wood. Wood Sci. Technol. 2014, 48, 353–372. [Google Scholar] [CrossRef]

- Qing, H.; Mishnaevsky, L. 3D hierarchical computational model of wood as a cellular material with fibril reinforced, heterogeneous multiple layers. Mech. Mater. 2009, 41, 1034–1049. [Google Scholar] [CrossRef]

- Yamamoto, H. Role of the gelatinous layer on the origin of the physical properties of the tension wood. J. Wood Sci. 2004, 50, 197–208. [Google Scholar] [CrossRef]

- Schneider, A. Analysing the porosity of wood with the mercury porosimeter. Eur. J. Wood Wood Prod. 1979, 37, 295–302. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weng, X.; Zhou, Y.; Fu, Z.; Gao, X.; Zhou, F.; Fu, F. Effects of Microwave Treatment on Microstructure of Chinese Fir. Forests 2020, 11, 772. https://doi.org/10.3390/f11070772

Weng X, Zhou Y, Fu Z, Gao X, Zhou F, Fu F. Effects of Microwave Treatment on Microstructure of Chinese Fir. Forests. 2020; 11(7):772. https://doi.org/10.3390/f11070772

Chicago/Turabian StyleWeng, Xiang, Yongdong Zhou, Zongying Fu, Xin Gao, Fan Zhou, and Feng Fu. 2020. "Effects of Microwave Treatment on Microstructure of Chinese Fir" Forests 11, no. 7: 772. https://doi.org/10.3390/f11070772

APA StyleWeng, X., Zhou, Y., Fu, Z., Gao, X., Zhou, F., & Fu, F. (2020). Effects of Microwave Treatment on Microstructure of Chinese Fir. Forests, 11(7), 772. https://doi.org/10.3390/f11070772