Optimising Tree Plantation Land Use in Brazil by Analysing Trade-Offs between Economic and Environmental Factors Using Multi-Objective Programming

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Site

2.2. Production Systems

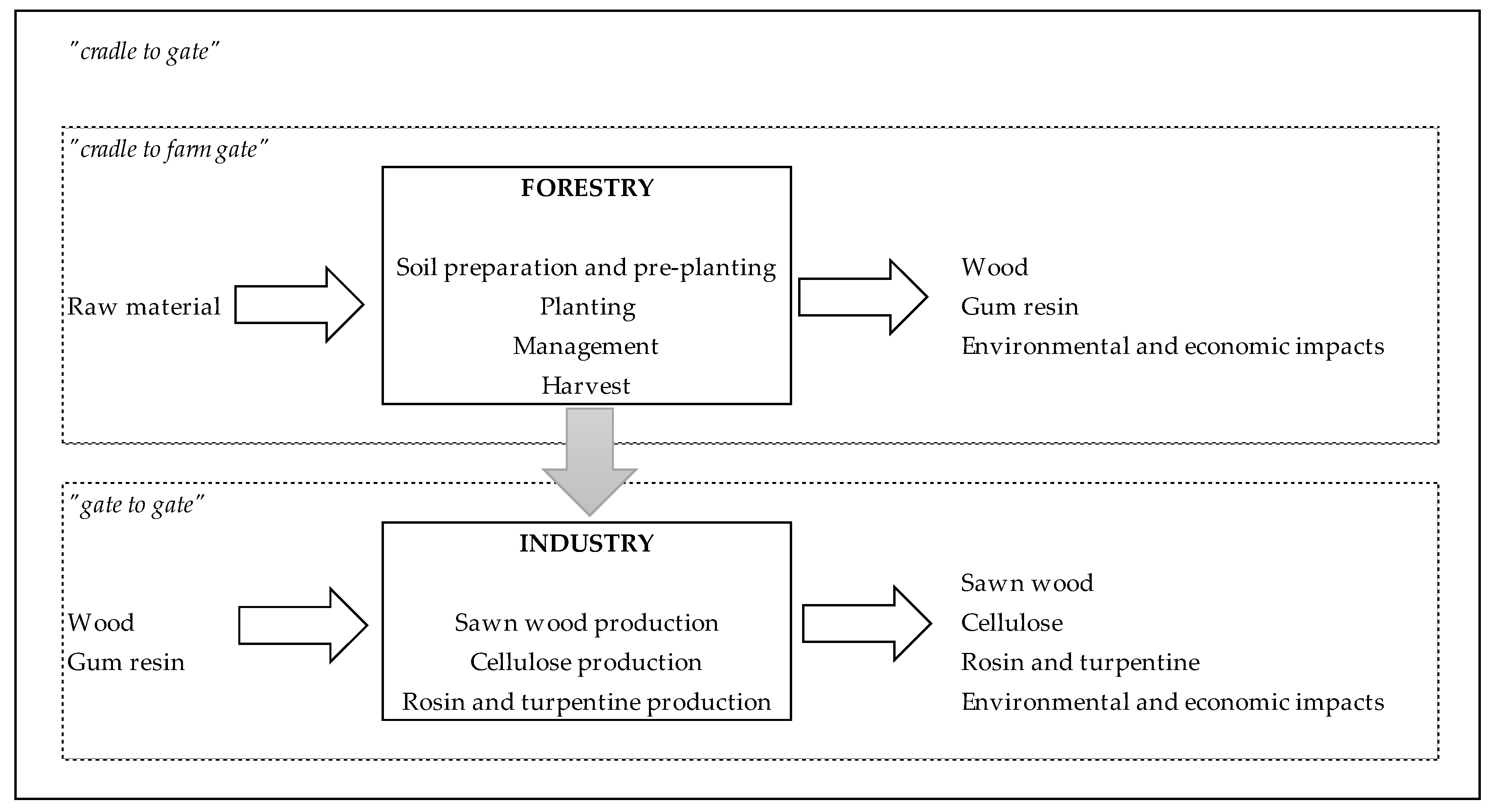

2.3. Scope and Functional Unit

2.4. Assessment of Potential Environmental Impacts

2.5. Assessment of Economic Impacts

2.6. Multicriteria Decision-Making Methods

2.6.1. Topsis

2.6.2. Multiobjective Optimization

3. Results

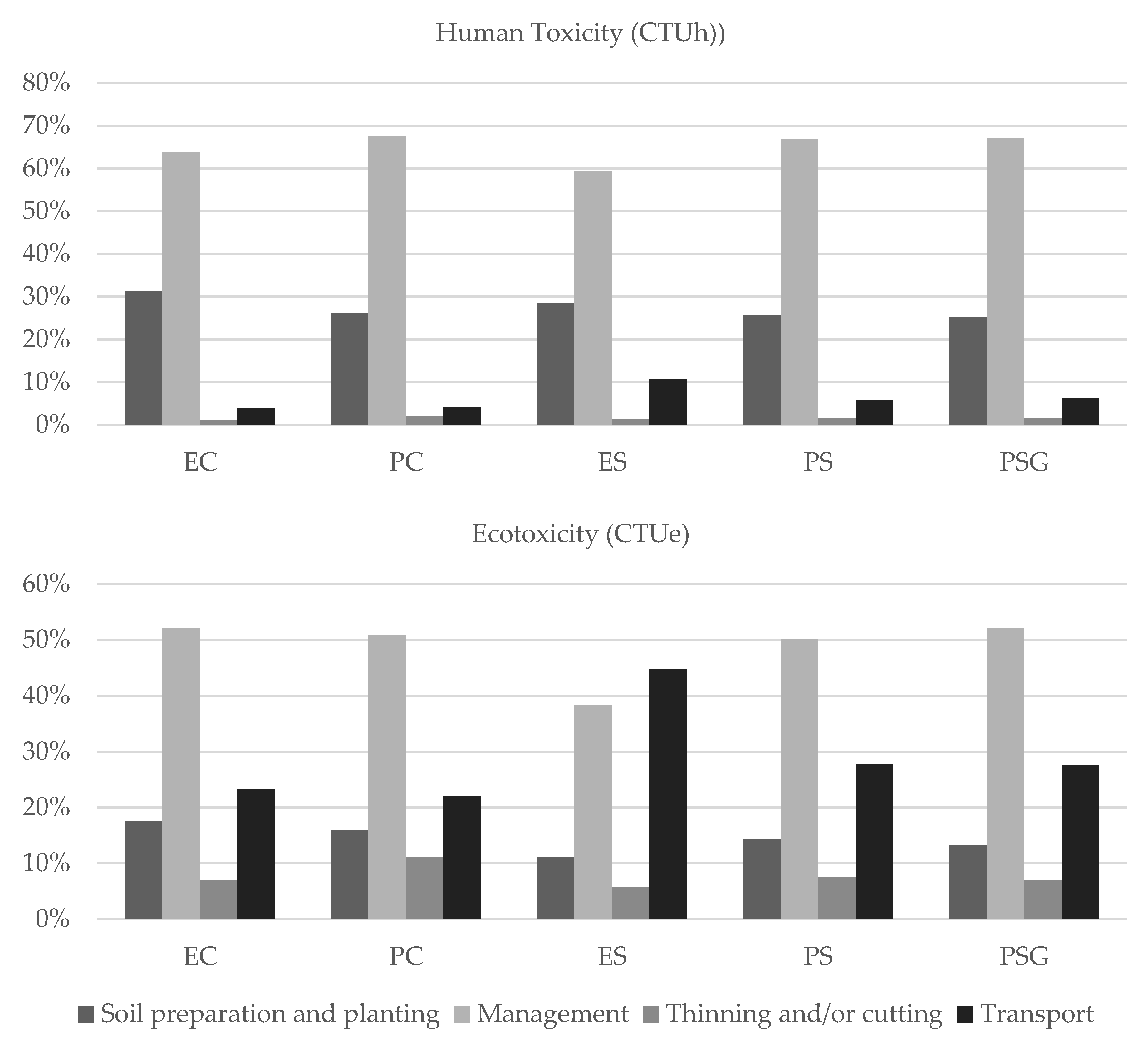

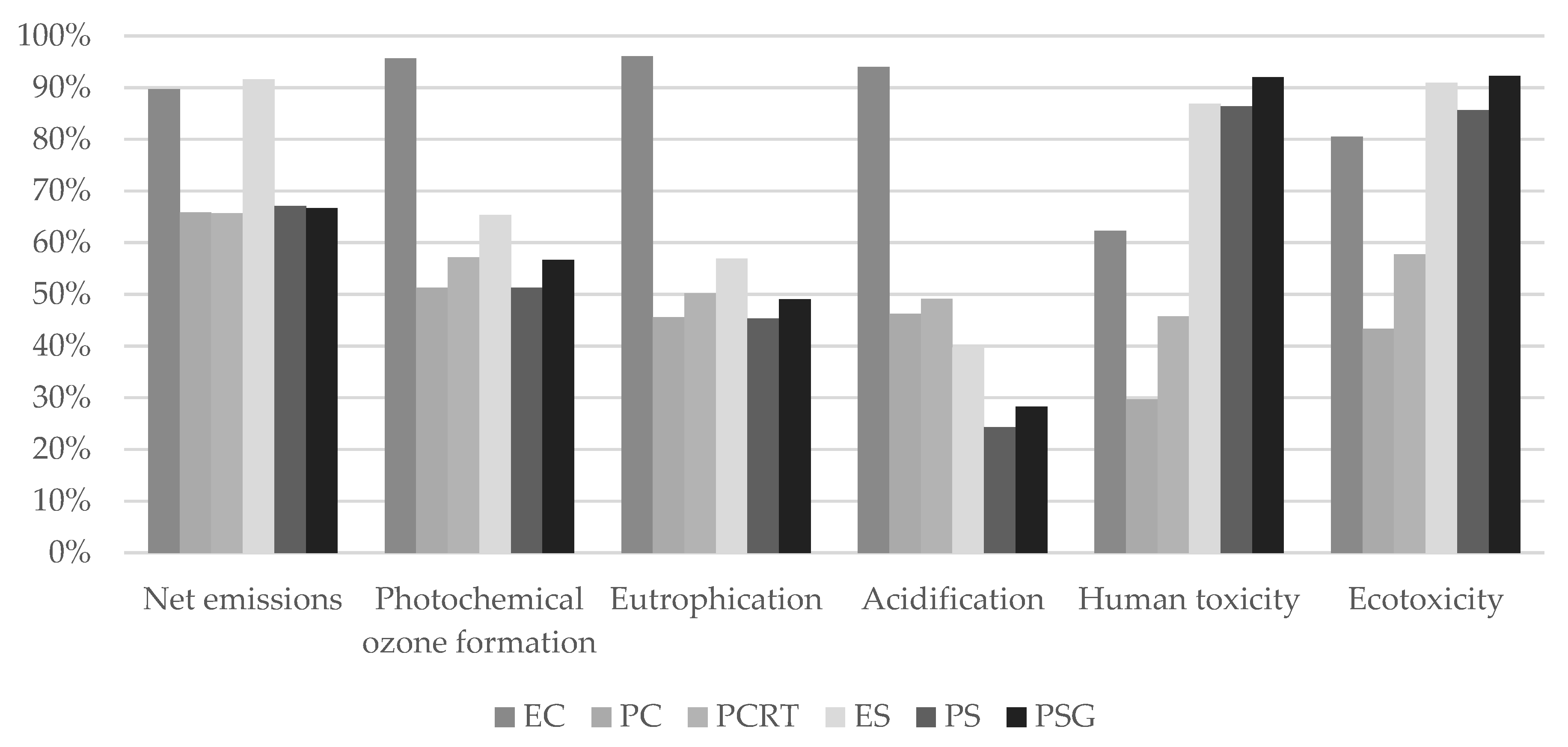

3.1. Environmental Impacts

3.1.1. Agricultural Process

3.1.2. Economic Impacts

3.2. Decision-Making Based on Multicriteria Methods

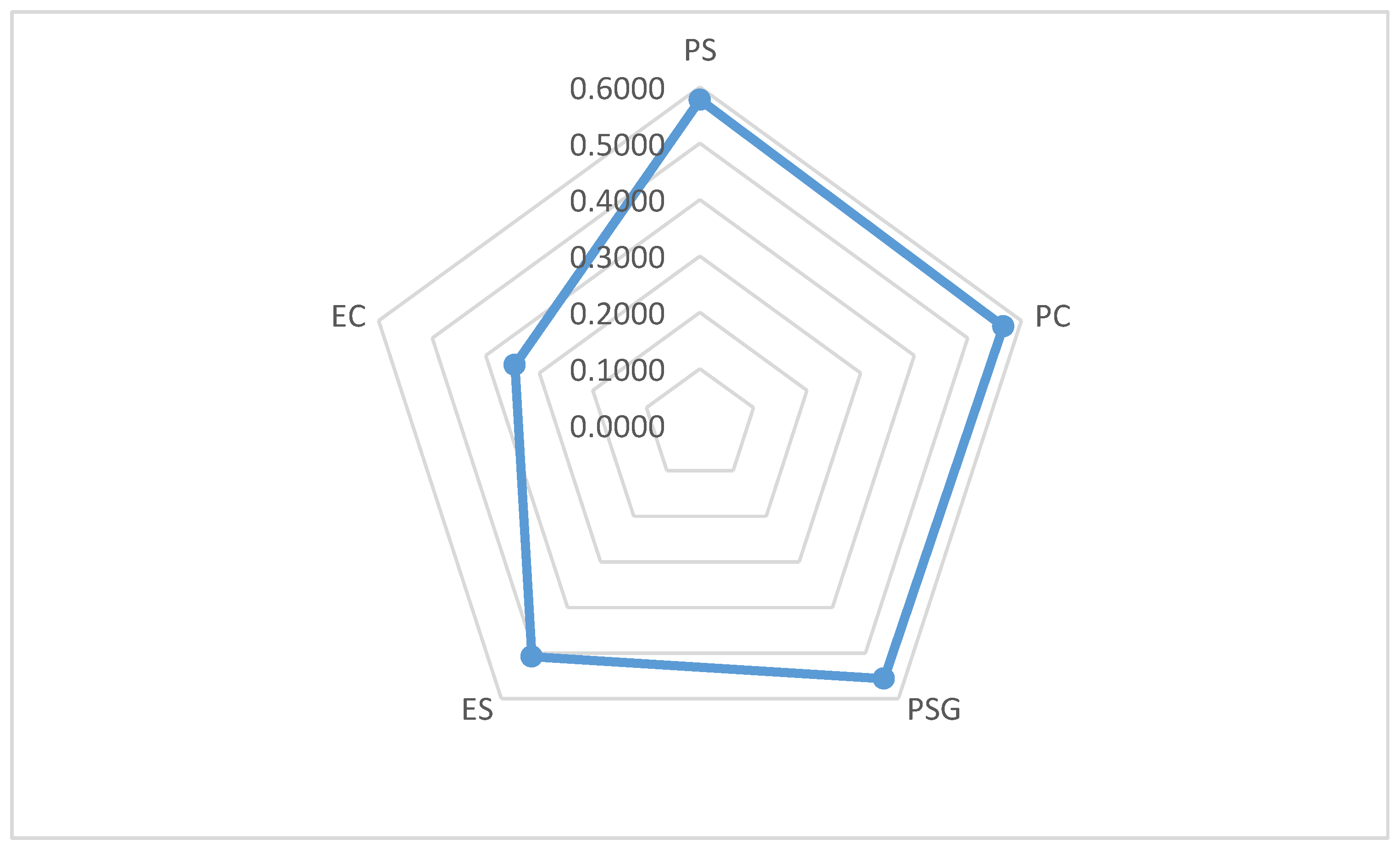

3.2.1. Ranking of Production Systems

3.2.2. Optimization of Land Use

4. Discussion

5. Conclusions

- Fossil fuels are the inputs that contribute the most to different categories of potential environmental impacts. The replacement by cleaner energy sources and the use of more efficient machines, equipment and vehicles is the main solution to improve the environmental and economic performance of the sector.

- The increase in transport efficiency also collaborates synergistically to increase the financial result, since this operation impacts the total cost of forestry activities in most evaluated systems the most.

- The sale of carbon credits is another market that, if explored, represents an opportunity to obtain important financial results for forestry, especially in eucalyptus systems, as well as an incentive to adopt more efficient environmental management practices.

- The cultivation of pine to obtain wood and gum-resin has a high demand for labor, making this component the costliest. Even though the higher demand for labor increases costs, the resin significantly increases the profitability of the property, which makes this system the one with the best economic performance among all evaluated. In addition to the financial results for the forest owner, resin contributes significantly more to the generation of jobs and the fixation of man in the countryside. For this reason, it is essential to have conditions that favor the employment relationship or even the provision of this service to enable this activity., Since employees are often hired individually by the rural producer or company that owns the forest, it would be interesting to create strategies that reduce hiring costs, favor the continuity of the provision of services, and provide greater legal certainty to employment relationships. The creation of companies specialized in the provision of this service or cooperatives organized by rural workers could be alternatives for the solution of labor problems in resin economic operations.

Author Contributions

Funding

Conflicts of Interest

References

- Ingrao, C.; Bacenetti, J.; Bezama, A.; Blok, V.; Geldermann, J.; Goglio, P.; Zabaniotou, A. Agricultural and forest biomass for food, materials and energy: Bio-economy as the cornerstone to cleaner production and more sustainable consumption patterns for accelerating the transition towards equitable, sustainable, post fossil-carbon societies. J. Clean. Prod. 2016, 117, 4–6. [Google Scholar] [CrossRef]

- Kleinschmit, D.; Arts, B.; Giurca, A.; Mustalahti, I.; Sergent, A.; Pülzl, H. Environmental concerns in political bioeconomy discourses. Int. For. Rev. 2017, 19, 41–55. [Google Scholar] [CrossRef]

- Mustalahti, I. The responsive bioeconomy: The need for inclusion of citizens and environmental capability in the forest based bioeconomy. J. Clean. Prod. 2018, 172, 3781–3790. [Google Scholar] [CrossRef]

- Pülzl, H.; Kleinschmit, D.; Arts, B. Bioeconomy–an emerging meta-discourse affecting forest discourses? Scand. J. For. Res. 2014, 29, 386–393. [Google Scholar] [CrossRef]

- Schmidt, O.; Padel, S.; Levidow, L. The bio-economy concept and knowledge base in a public goods and farmer perspective. Bio-Based Appl. Econ. 2012, 1, 47–63. [Google Scholar]

- European Comission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: Innovating for Sustainable Growth: A Bioeconomy for Europe. Available online: http://ec.europa.eu/research/bioeconomy/pdf/official-strategy_en.pdf (accessed on 14 November 2017).

- Costanza, R.; D’Arge, R.; De Groot, R.; Farber, S.; Grasso, M.; Hannon, B.; Raskin, R.G. The value of the world’s ecosystem services and natural capital. Nature 1997, 387, 253–260. [Google Scholar] [CrossRef]

- The Economics of Ecosystems and Biodiversity (TEEB). Mainstreaming the Economics of Nature: A Synthesis of the Approach: Conclusions and Recommendations of TEEB. Available online: http://www.teebweb.org/publication/mainstreaming-the-economics-of-nature-a-synthesis-of-the-approach-conclusions-and-recommendations-of-teeb/ (accessed on 22 December 2017).

- Ellison, D.; Morris, C.E.; Locatelli, B.; Sheil, D.; Cohen, J.; Murdiyarso, D.; Gaveau, D. Trees, forests and water: Cool insights for a hot world. Glob. Environ. Chang. 2017, 43, 51–61. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO). Forestry for a Low-Carbon Future: Integrating Forests and Wood Products in Climate Change Strategies 2016. Available online: http://www.fao.org/3/a-i5857e.pdf (accessed on 19 October 2016).

- Diaz-Balteiro, L.; Alfranca, O.; González-Pachón, J.; Romero, C. Ranking of industrial forest plantations in terms of sustainability: A multicriteria approach. J. Environ. Manag. 2016, 180, 123–132. [Google Scholar] [CrossRef]

- Turner, J.A.; Dhakal, B.; Yao, R.; Barnard, T.; Maunder, C. Non-timber values from planted forests: Recreation in Whakarewarewa forest. N. Z. J. For. 2011, 55, 24–31. [Google Scholar]

- Boxall, P.C.; Adamowicz, W.L.; Swait, J.; Williams, M.; Louviere, J. A comparison of stated preference methods for environmental valuation. Ecol. Econ. 1996, 18, 243–253. [Google Scholar] [CrossRef]

- Winjobi, O.; Shonnard, D.R.; Bar-Ziv, E.; Zhou, W. Techno-economic assessment of the effect of torrefaction on fast pyrolysis of pine. Biofuels Bioprod. Biorefin. 2016, 10, 117–128. [Google Scholar] [CrossRef]

- Daystar, J.; Treasure, T.; Reeb, C.; Venditti, R.; Gonzalez, R.; Kelley, S. Environmental impacts of bioethanol using the NREL biochemical conversion route: Multivariate analysis and single score results. Biofuels Bioprod. Biorefin. 2015, 9, 484–500. [Google Scholar] [CrossRef]

- Tran, N.; Illukpitiya, P.; Yanagida, J.F.; Ogoshi, R. Optimizing biofuel production: An economic analysis for selected biofuel feedstock production in Hawaii. Biomass Bioenergy 2011, 35, 1756–1764. [Google Scholar] [CrossRef]

- Grison, K.; Pistor, V.; Scienza, L.C.; Zattera, A.J. The physical perspective on the solid and molten states associated with the mechanical properties of eco-friendly HDPE/P inus taeda wood-plastic composites. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Victor, A.; Pulidindi, I.N.; Gedanken, A. Levulinic acid production from Cicer arietinum, cotton, Pinus radiata and sugarcane bagasse. RSC Adv. 2014, 4, 44706–44711. [Google Scholar] [CrossRef]

- Rodrigues-Corrêa, K.C.D.S.; de Lima, J.C.; Fett-Neto, A.G. Pine oleoresin: Tapping green chemicals, biofuels, food protection, and carbon sequestration from multipurpose trees. Food Energy Secur. 2012, 1, 81–93. [Google Scholar] [CrossRef]

- Ohlström, M.; Mäkinen, T.; Laurikko, J.; Pipatti, R. New Concepts for Biofuels in Transportation: Biomass-Based Methanol Production and Reduced Emissions in Advanced Vehicles. Available online: https://cris.vtt.fi/en/publications/new-concepts-for-biofuels-in-transportation-biomass-based-methano (accessed on 12 November 2018).

- Pirard, R.; Petit, H.; Baral, H. Local impacts of industrial tree plantations: An empirical analysis in Indonesia across plantation types. Land Use Policy 2017, 60, 242–253. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO). Global Forest Resources Assessment 2005. Available online: http://www.fao.org/docrep/008/a0400e/a0400e00.htm (accessed on 28 November 2016).

- Food and Agriculture Organization of the United Nations (FAO). Global Forest Resources Assessment 2015. Available online: http://www.fao.org/3/a-i4808e.pdf (accessed on 15 October 2016).

- Food and Agriculture Organization of the United Nations (FAO). Global Forest Resources Assessment 2010. Available online: http://www.fao.org/docrep/013/i1757e/i1757e.pdf (accessed on 7 November 2016).

- Baral, S.; Chhetri, B.B.K.; Baral, H.; Vacik, H. Investments in different taxonomies of goods: What should Nepal’s community forest user groups prioritize? For. Policy Econ. 2019, 100, 24–32. [Google Scholar] [CrossRef]

- Indufor. Strategic Review on the Future of Forest Plantations in the World 2012. Available online: http://www.fao.org/forestry/42701-090e8a9fd4969cb334b2ae7957d7b1505.pdf (accessed on 26 March 2017).

- Dodet, M.; Collet, C. When should exotic forest plantation tree species be considered as an invasive threat and how should we treat them? Biol. Invasions 2012, 14, 1765–1778. [Google Scholar] [CrossRef]

- Lorentz, K.A.; Minogue, P.J. Exotic Eucalyptus plantations in the southeastern US: Risk assessment, management and policy approaches. Biol. Invasions 2015, 17, 1581–1593. [Google Scholar] [CrossRef]

- Cademus, R.; Escobedo, F.J.; McLaughlin, D.; Abd-Elrahman, A. Analyzing trade-offs, synergies, and drivers among timber production, carbon sequestration, and water yield in Pinus elliotii forests in southeastern USA. Forests 2014, 5, 1409–1431. [Google Scholar] [CrossRef]

- Vance, E.D.; Loehle, C.; Wigley, T.B.; Weatherford, P. Scientific basis for sustainable management of Eucalyptus and Populus as short-rotation woody crops in the US. Forests 2014, 5, 901–918. [Google Scholar] [CrossRef]

- Kröger, M. The expansion of industrial tree plantations and dispossession in Brazil. Dev. Chang. 2012, 43, 947–973. [Google Scholar] [CrossRef]

- Moreira, J.M.M.Á.P.; Simioni, F.J.; de Oliveira, E.B. Importância e desempenho das florestas plantadas no contexto do agronegócio brasileiro. Floresta 2017, 47, 85–94. [Google Scholar] [CrossRef]

- Oliveira, Y.M.M.; Oliveira, E.B. Plantações Florestais: Geração de Benefícios com Baixo Impacto Ambiental. Available online: http://www.alice.cnptia.embrapa.br/alice/handle/doc/1076130 (accessed on 31 October 2019).

- Smith, P.; Bustamante, M.; Ahammad, H.; Clark, H.; Dong, H.; Elsiddig, E.A.; Masera, O. Agriculture, forestry and other land use (AFOLU). In Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2014; pp. 811–922. [Google Scholar]

- Brandão, M.; Clift, R.; Basson, L. A life-cycle approach to characterising environmental and economic impacts of multifunctional land-use systems: An integrated assessment in the UK. Sustainability 2010, 2, 3747–3776. [Google Scholar] [CrossRef]

- Governo do Estado de Mato Grosso do Sul. Plano Estadual para o Desenvolvimento de Florestas Plantadas: Relatório Final. Available online: https://m.sebrae.com.br/Sebrae/Portal%20Sebrae/UFs/MS/Estudos%20e%20Pesquisas/Plano%20Estadual%20para%20Desenvolvimento%20Economico%20de%20Florestas%20Plantadas.pdf (accessed on 23 November 2019).

- González-García, S.; Dias, A.C.; Feijoo, G.; Moreira, M.T.; Arroja, L. Divergences on the environmental impact associated to the production of maritime pine wood in Europe: French and Portuguese case studies. Sci. Total Environ. 2014, 472, 324–337. [Google Scholar] [CrossRef] [PubMed]

- Governo do Estado de Mato Grosso do Sul. Caderno Geoambiental. Available online: http://www.semade.ms.gov.br/caderno-geoambiental/ (accessed on 3 May 2017).

- Climate-Data. Clima: Ribas do Rio Pardo. Available online: https://pt.climate-data.org/location/43544/ (accessed on 3 May 2017).

- Indústria Brasileira de Árvores (IBÁ). Relatório Anual 2017. Available online: http://iba.org/images/shared/Biblioteca/IBA_RelatorioAnual2017.pdf (accessed on 13 April 2017).

- Dias, A.C.; Arroja, L. Environmental impacts of eucalypt and maritime pine wood production in Portugal. J. Clean. Prod. 2012, 37, 368–376. [Google Scholar] [CrossRef]

- Rosenbaum, R.K.; Bachmann, T.M.; Gold, L.S.; Huijbregts, M.A.; Jolliet, O.; Juraske, R.; McKone, T.E. USEtox—the UNEP-SETAC toxicity model: Recommended characterisation factors for human toxicity and freshwater ecotoxicity in life cycle impact assessment. Int. J. Life Cycle Assess. 2008, 13, 532. [Google Scholar] [CrossRef]

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; de Koning, A.; de Bruijn, H. Life Cycle Assessment: An Operational Guide to the ISO Standards. 2001. Available online: http://www.leidenuniv.nl/interfac/cml/lca2/ (accessed on 15 August 2017).

- Intergovernmental Panel on Climate Change (IPCC). IPCC Guidelines for National Greenhouse Gas Inventories. Available online: http://www.ipcc-nggip.iges.or.jp/public/2006gl/vol4.html (accessed on 23 April 2017).

- Franco, A.L.; Galli, O.C. Método para Análise de Investimentos: Alternativa para Classificação de Projetos com Prazo e Volume de Recursos Diferentes. Available online: http://www.abepro.org.br/biblioteca/enegep2007_TR590447_9837.pdf (accessed on 14 April 2018).

- Ecosystem Marketplace. Raising Ambition State of the Voluntary Carbon Markets 2016. Available online: http://www.forest-trends.org/documents/files/doc_5242.pdf (accessed on 25 September 2017).

- Almeida, A.T. O Conhecimento e o uso de Métodos Multicritério de Apoio a Decisão, 2nd ed.; Recife, Ed.; Editora Universitária da UFPE: Recife, Brazil, 2011. [Google Scholar]

- Baral, S.; Khadka, C.; Vacik, H. Using MCA tools for evaluating community-managed forests from a green economy perspective: Lessons from Nepal. Int. J. Sustain. Dev. World Ecol. 2019, 26, 672–683. [Google Scholar] [CrossRef]

- Tzeng, G.H.; Huang, J.J. Multiple Attribute Decision Making: Methods and Applications; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Sampaio, P.R. Teoria, Métodos e Aplicações de Otimização Multiobjetivo. Ph.D. Thesis, Programa de mestrado em Ciência da Computação, Universidade de São Paulo, São Paulo, Brazil, 2011. [Google Scholar]

- Ragsdale, C.T. Modelagem e Análise de Decisão; Cengage Learning: São Paulo, Brazil, 2009. [Google Scholar]

- Antunes, C.; Alves, M. Programação linear multiobjetivo-métodos interativos e software. In Anais do Congreso Latino-Iberoamericano de Investigación Operativa; Pontificia Universidad Católica de Chile: Santiago, Chile, 2012; pp. 4725–4736. [Google Scholar]

- Álvarez, S.; Rubio, A. Carbon Baseline in a mixed pine-oak forest in the Juarez mountain range (Oaxaca, Mexico) using the CO2FIX v. 3.2 model. Rev. Chapingo. Ser. Cienc. For. Ambiente 2013, 19, 125–137. [Google Scholar]

- Chatterjee, A.; Mooney, S.; Vance, G.F. Comparisons of carbon pools and economic profitability for managed ponderosa pine stands in Wyoming, USA. J. For. Res. 2010, 21, 482–486. [Google Scholar] [CrossRef][Green Version]

- Pérez, S.; Renedo, C.J.; Ortiz, A.; Manana, M. Energy potential of waste from 10 forest species in the North of Spain (Cantabria). Bioresour. Technol. 2008, 99, 6339–6345. [Google Scholar] [CrossRef] [PubMed]

- Thomas, S.C.; Malczewski, G.; Saprunoff, M. Assessing the potential of native tree species for carbon sequestration forestry in Northeast China. J. Environ. Manag. 2007, 85, 663–671. [Google Scholar] [CrossRef] [PubMed]

- Morales, M.; Aroca, G.; Rubilar, R.; Acuna, E.; Mola-Yudego, B.; González-García, S. Cradle-to-gate life cycle assessment of Eucalyptus globulus short rotation plantations in Chile. J. Clean. Prod. 2015, 99, 239–249. [Google Scholar] [CrossRef]

- Gonzalez-Garcia, S.; Berg, S.; Moreira, M.T.; Feijoo, G. Evaluation of forest operations in Spanish eucalypt plantations under a life cycle assessment perspective. Scand. J. For. Res. 2009, 24, 160–172. [Google Scholar] [CrossRef]

- Barrantes, L.; Matsuura, M.D.S.; Moreira, J.; Ugaya, C. Avaliação do ciclo de vida da madeira de eucalipto para produção de energia no Brasil. In Embrapa Meio Ambiente-Artigo em anais de Congresso (ALICE), Congresso Brasileiro em Gestão do Ciclo de Vida; Associação Brasileira de Ciclo de Vida: Fortaleza, Brasil, 2016; Volume 5, pp. 384–390. [Google Scholar]

- Cowling, E.B.; Furiness, C.S. Potentials for win-win alliances among animal agriculture and forest products industries: Application of the principles of industrial ecology and sustainable development. Sci. China Ser. C Life Sci. 2005, 48, 697–709. [Google Scholar]

- Ferraz, S.F.B.; Lima, W.P.; Rodrigues, C.B. Managing forest plantation landscapes for water conservation. Forest ecology and management. Amsterdã 2013, 301, 58–66. [Google Scholar]

- Stewart, H.T.; Race, D.H.; Curtis, A.L.; Stewart, A.J. A case study of socio-economic returns from farm forestry and agriculture in south-east Australia during 1993–2007. For. Policy Econ. 2011, 13, 390–395. [Google Scholar] [CrossRef]

- Silva, D.A.L.; Pavan, A.L.R.; de Oliveira, J.A.; Ometto, A.R. Life cycle assessment of offset paper production in Brazil: Hotspots and cleaner production alternatives. J. Clean. Prod. 2015, 93, 222–233. [Google Scholar] [CrossRef]

- Silva, D.A.L. Avaliação do Ciclo de Vida da Produção do Painel de Madeira MDP no Brasil. Available online: www.teses.usp.br/teses/disponiveis/88/88131/tde-31072012-121351/pt-br.php (accessed on 2 August 2017).

- Neves, G.A. Análise Econômico-Financeira da Exploração de Pinus Resinífero em Pequenos Módulos Rurais. Available online: http://www.ipef.br/servicos/teses/arquivos/neves,ga.pdf (accessed on 16 October 2017).

- Bukenya, M.; Johnsen, F.H.; Gombya-Ssembajjwe, W.S. Environmental and exchange entitlements from Eucalyptus woodlots: The case of Mukono district in Uganda. For. Trees Livelihoods 2009, 19, 3–17. [Google Scholar] [CrossRef]

- Florindo, T.J.; Medeiros, G.I.B.; Talamini, E.; da Costa, J.S.; Ruviaro, C.F. Carbon footprint and Life Cycle Costing of beef cattle in the Brazilian midwest. J. Clean. Prod. 2017, 147, 119–129. [Google Scholar] [CrossRef]

- Oliveira Silva, R.; Barioni, L.G.; Hall, J.J.; Moretti, A.C.; Veloso, R.F.; Alexander, P.; Moran, D. Sustainable intensification of Brazilian livestock production through optimized pasture restoration. Agric. Syst. 2017, 153, 201–211. [Google Scholar] [CrossRef]

- Chen, Y.L.; Liu, R.J.; Bi, Y.L.; Feng, G. Use of mycorrhizal fungi for forest plantations and minesite rehabilitation. In Mycorrhizal Fungi: Use in Sustainable Agriculture and Land Restoration; Springer: Berlin/Heidelberg, Germany, 2014; pp. 325–355. [Google Scholar]

- Knoke, T.; Bendix, J.; Pohle, P.; Hamer, U.; Hildebrandt, P.; Roos, K.; Silva, B. Afforestation or intense pasturing improve the ecological and economic value of abandoned tropical farmlands. Nat. Commun. 2014, 5, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Toro, J.; Gessel, S.P. Radiata pine plantations in Chile. In Planted Forests: Contributions to the Quest for Sustainable Societies; Springer: Dodlek, The Netherlands, 1999; pp. 393–404. [Google Scholar]

| System | Production Purpose(s) | Spacing | Density (ha−1) |

|---|---|---|---|

| EC | Eucalyptus for cellulose | 3.4 m × 2.3 m | 1300 |

| PC | Pine for cellulose | 3 m × 1.5 m | 2222 |

| ES | Eucalyptus for sawn wood | 3 m × 2 m | 1667 |

| PS | Pine for sawn wood | 3 m × 2 m | 1667 |

| PSG | Pine for sawn wood and gum resin | 3 m × 2 m | 1667 |

| System | Wood Production by Thinning and Cutting (m3) | Total Production (m3) | MAI * (m3/ha/year) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 7 Years | 8 Years | 12 Years | 14 Years | 15 Years | 16 Years | 21 Years | ||||

| EC | MIN | 217.3 | 217.3 | 31 | ||||||

| MAX | 269.1 | 269.1 | 38.4 | |||||||

| AVG | 242.6 | 242.6 | 34.7 | |||||||

| PC | MIN | 398.2 | 398.2 | 26.5 | ||||||

| MAX | 508 | 508 | 33.9 | |||||||

| AVG | 453.3 | 453.3 | 30.2 | |||||||

| ES | MIN | 99.9 | 141 | 428.1 | 669 | 31.9 | ||||

| MAX | 119.1 | 172 | 512.3 | 803.4 | 38.3 | |||||

| AVG | 109.5 | 156.4 | 470.5 | 736.4 | 35.1 | |||||

| PS | MIN | 53.1 | 65 | 124.6 | 321 | 563.7 | 26.8 | |||

| MAX | 69.5 | 83 | 156.6 | 399.6 | 708.7 | 33.7 | ||||

| AVG | 61.2 | 73.9 | 140.4 | 360 | 635.5 | 30.3 | ||||

| PSG | MIN | 52.2 | 50.7 | 462.6 | 565.5 | 26.9 | ||||

| MAX | 71.6 | 62.6 | 569.1 | 703.3 | 33.5 | |||||

| AVG | 61.7 | 57 | 515.8 | 634.5 | 30.2 | |||||

| System | Revenue (US$) 1 | Costs (US$) 1 | API (%) 2 | Revenue C (US$ ) 1,3 | API C (%) 3 |

|---|---|---|---|---|---|

| EC | 6192.80 | 4058.65 | 6.90 | 6417.32 | 7.85 |

| PC | 10,035.28 | 4872.72 | 5.52 | 10,384.88 | 6.13 |

| ES | 18,091.24 | 10,417.43 | 2.70 | 18,772.77 | 3.19 |

| PS | 18,801.68 | 6271.11 | 8.23 | 19,301.28 | 8.77 |

| PSG | 30,918.41 | 11,451.55 | 9.53 | 31,416.09 | 9.85 |

| System | Gross Value Added (GVA) (US$) | Annual GVA (US$) |

|---|---|---|

| EC | 25,767.05 | 3681.11 |

| PC | 40,434.79 | 2695.62 |

| PCRT | 42,092.40 | 2806.22 |

| ES | 12,724.19 | 605.99 |

| PS | 7390.78 | 351.84 |

| PSG | 16,178.57 | 770.51 |

| Ranking | Criterium | ||

|---|---|---|---|

| Environmental | Economic | Environmental + Economic | |

| 1st | PC | PSG | PC |

| 2nd | PCRT | EC | PSG |

| 3rd | PS | PCRT | PCRT |

| 4th | ES | PC | EC |

| 5th | PSG | PS | PS |

| 6th | EC | ES | ES |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medeiros, G.; Florindo, T.; Talamini, E.; Fett Neto, A.; Ruviaro, C. Optimising Tree Plantation Land Use in Brazil by Analysing Trade-Offs between Economic and Environmental Factors Using Multi-Objective Programming. Forests 2020, 11, 723. https://doi.org/10.3390/f11070723

Medeiros G, Florindo T, Talamini E, Fett Neto A, Ruviaro C. Optimising Tree Plantation Land Use in Brazil by Analysing Trade-Offs between Economic and Environmental Factors Using Multi-Objective Programming. Forests. 2020; 11(7):723. https://doi.org/10.3390/f11070723

Chicago/Turabian StyleMedeiros, Giovanna, Thiago Florindo, Edson Talamini, Arthur Fett Neto, and Clandio Ruviaro. 2020. "Optimising Tree Plantation Land Use in Brazil by Analysing Trade-Offs between Economic and Environmental Factors Using Multi-Objective Programming" Forests 11, no. 7: 723. https://doi.org/10.3390/f11070723

APA StyleMedeiros, G., Florindo, T., Talamini, E., Fett Neto, A., & Ruviaro, C. (2020). Optimising Tree Plantation Land Use in Brazil by Analysing Trade-Offs between Economic and Environmental Factors Using Multi-Objective Programming. Forests, 11(7), 723. https://doi.org/10.3390/f11070723