Log Truck Value Analysis from Increased Rail Usage

Abstract

1. Introduction

2. Materials and Methods

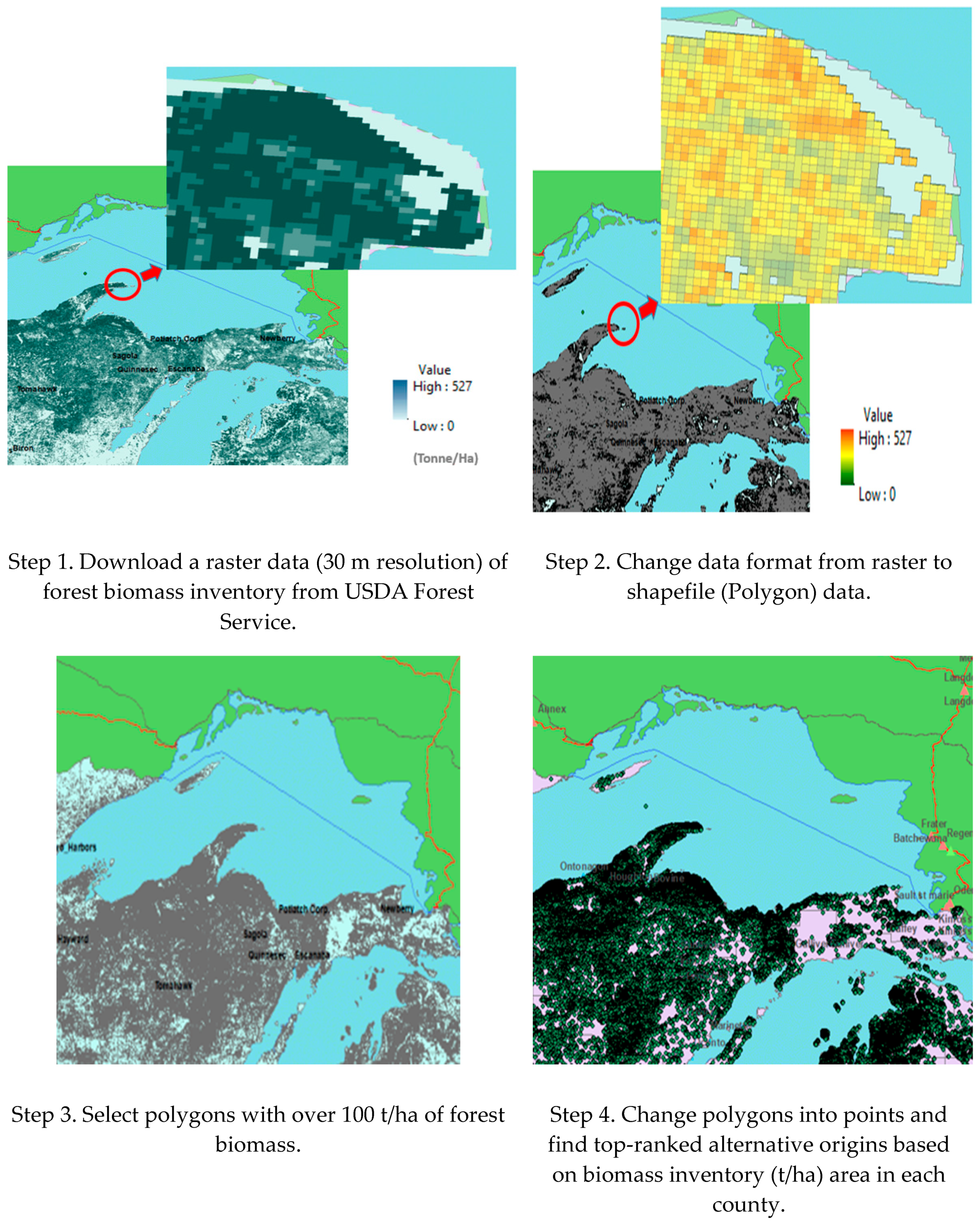

2.1. Data Collection and Preprocessing

- -Unique identifier for the trip;

- -Purchaser and seller company information;

- -Date/month/year of ticket issued;

- -Shipping location information such as origin/destination, distance, and transport mode;

- -Product type and rate information;

- -Weight information.

- (1)

- If 0 t < volume of logs in centroid < 1000 t;Number of New Origins in a county = 1 (the highest forest inventory location);

- (2)

- If 1000 t < volume of logs in centroid < 10,000 t;Number of New Origins in a county = 3 (three highest forest inventory locations);

- (3)

- If 10,000 t < volume of logs in centroid < 50,000 t;Number of New Origins in a county = 5 (five highest forest inventory locations);

- (4)

- If 50,000 t < volume of logs in centroid;Number of New Origins in a county = 10 (ten highest forest inventory locations).

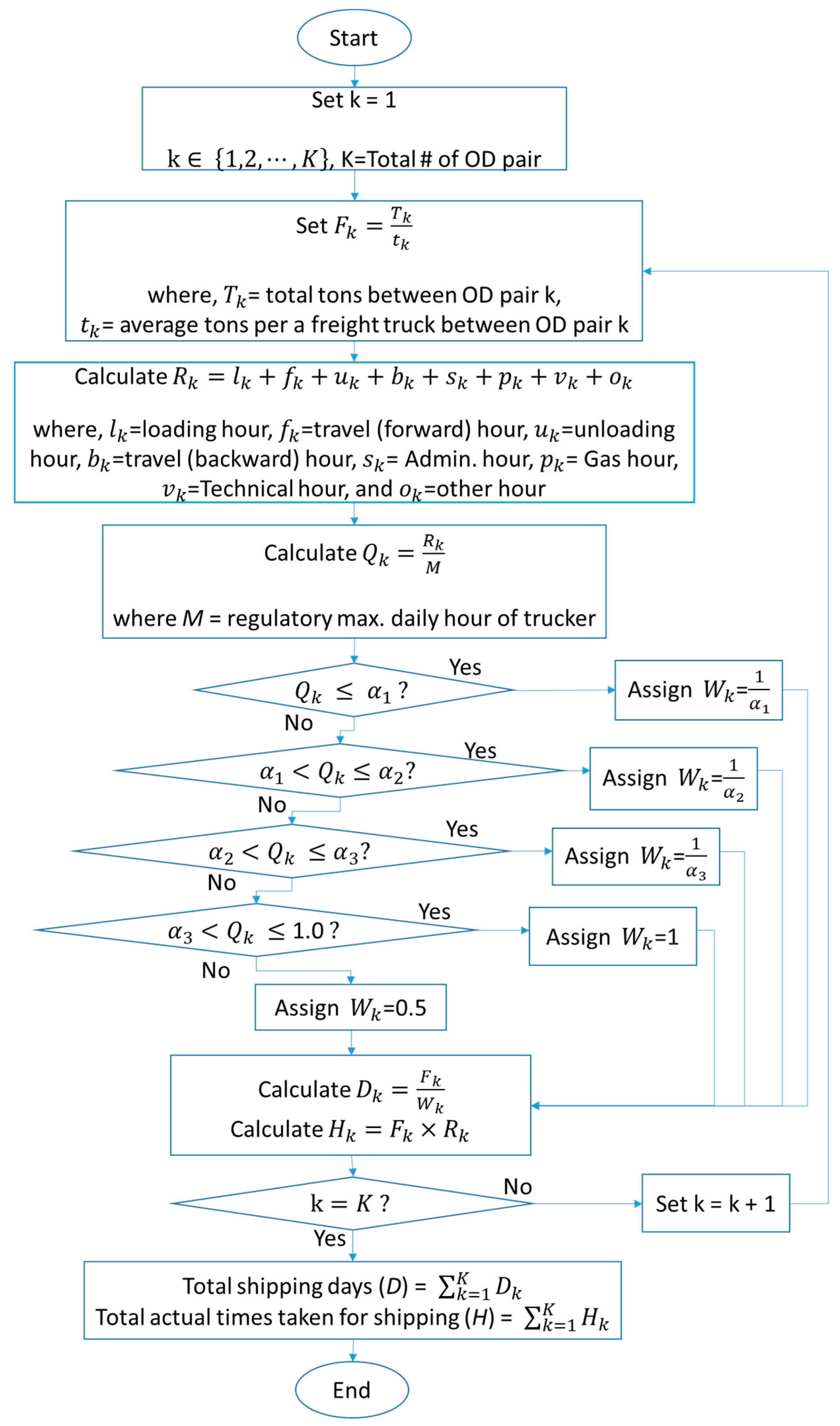

2.2. Methodology

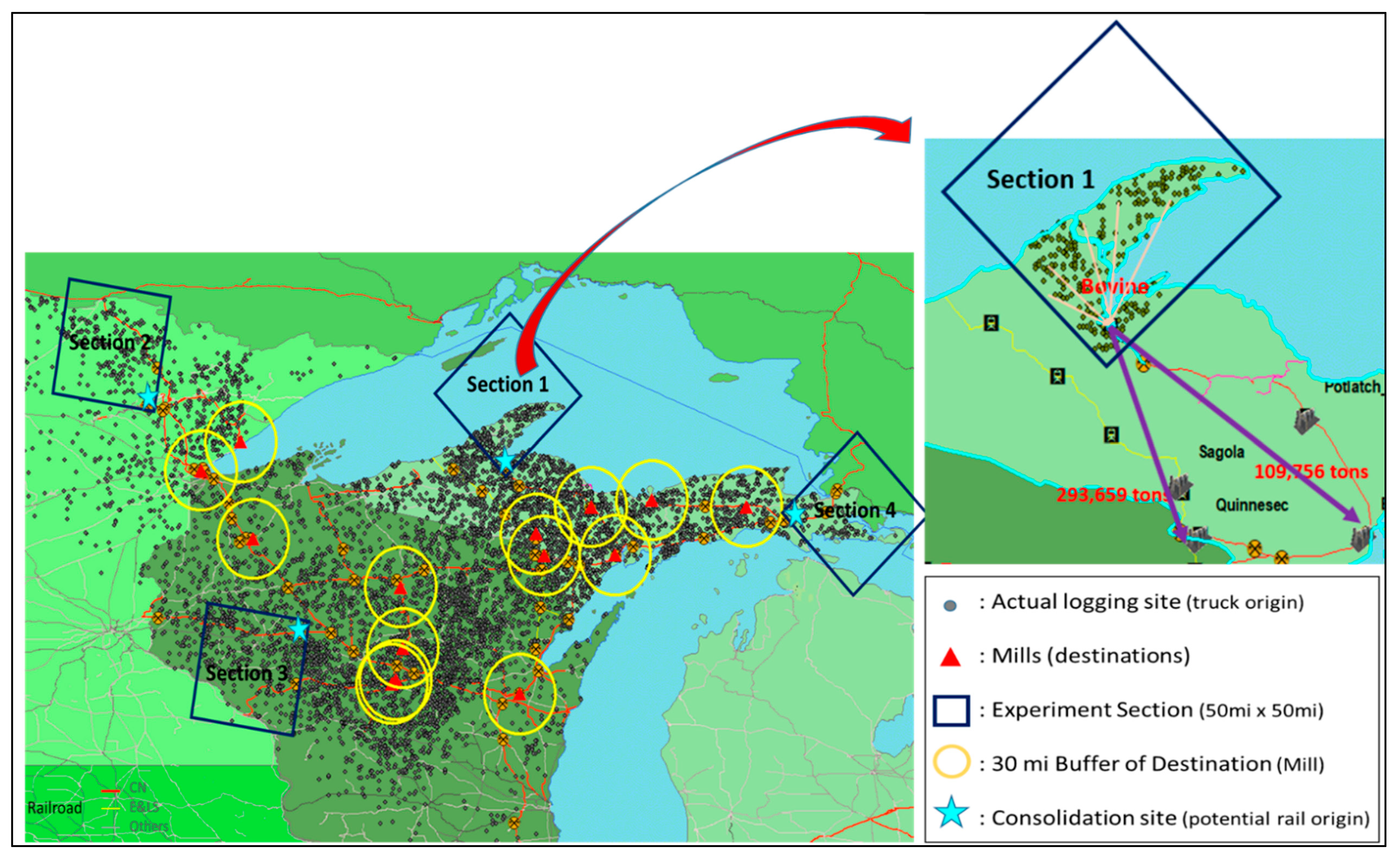

2.3. Rail Siding Case Studies

3. Results

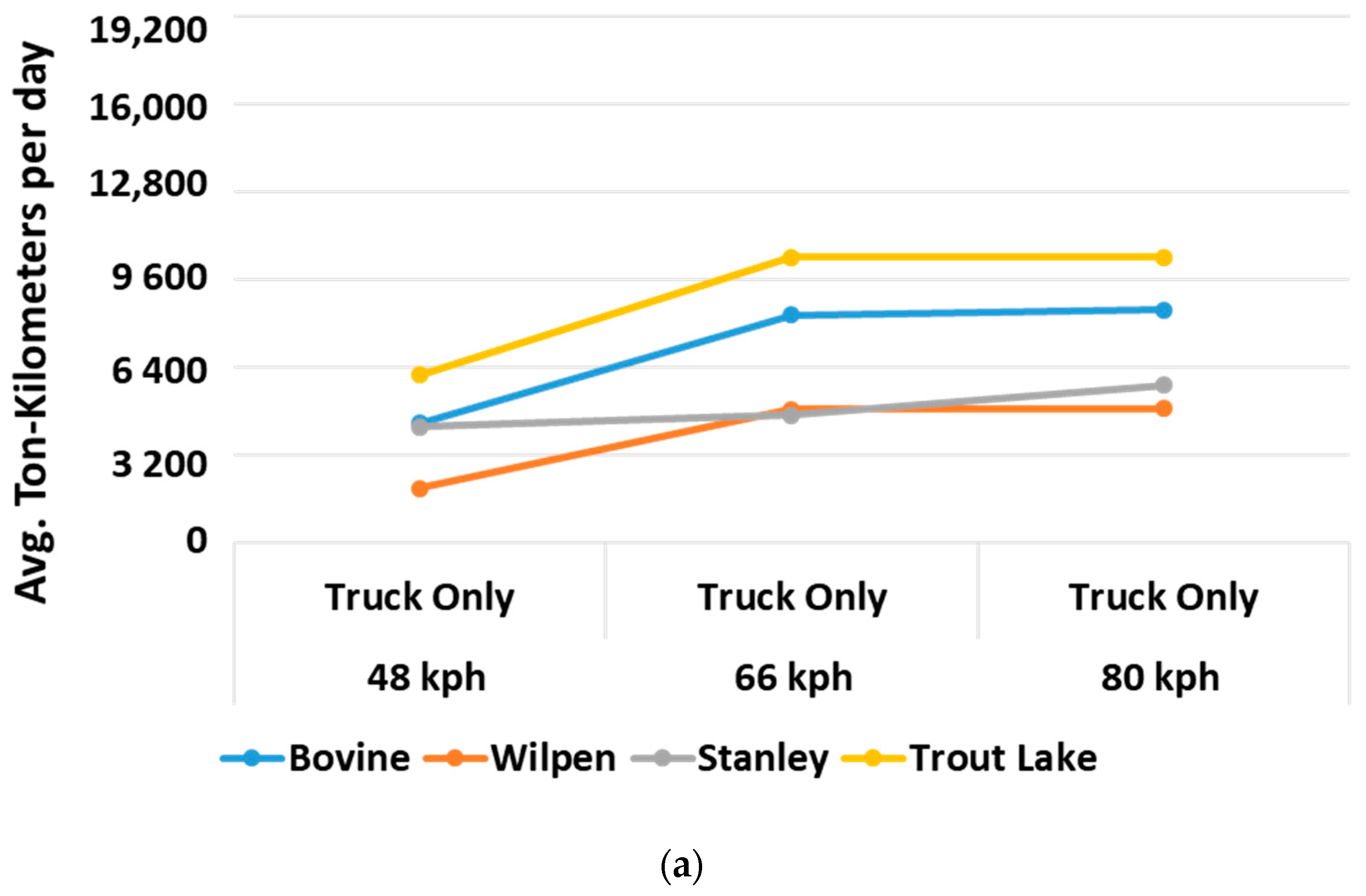

3.1. Results of Log Truck Value Analysis

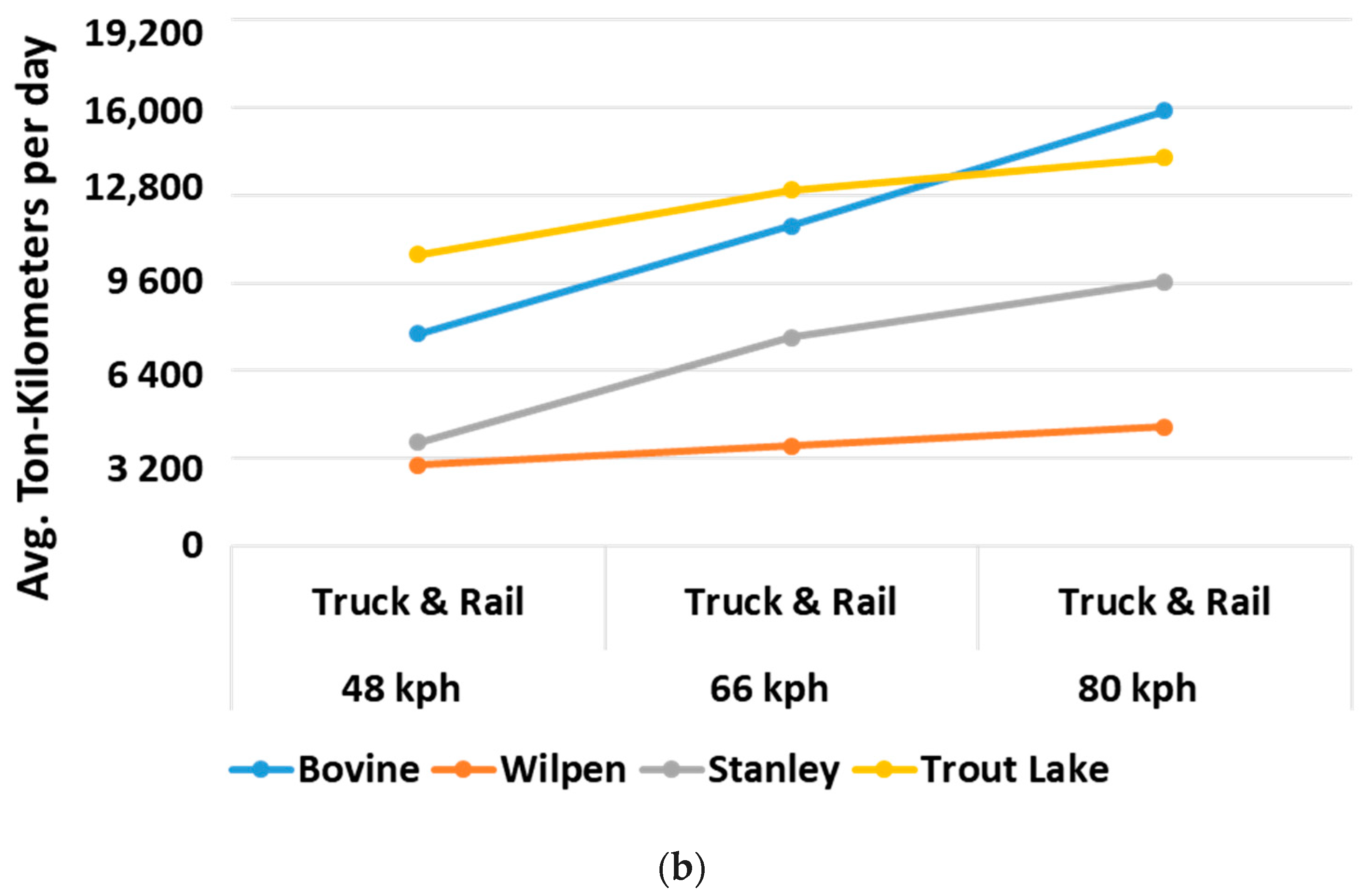

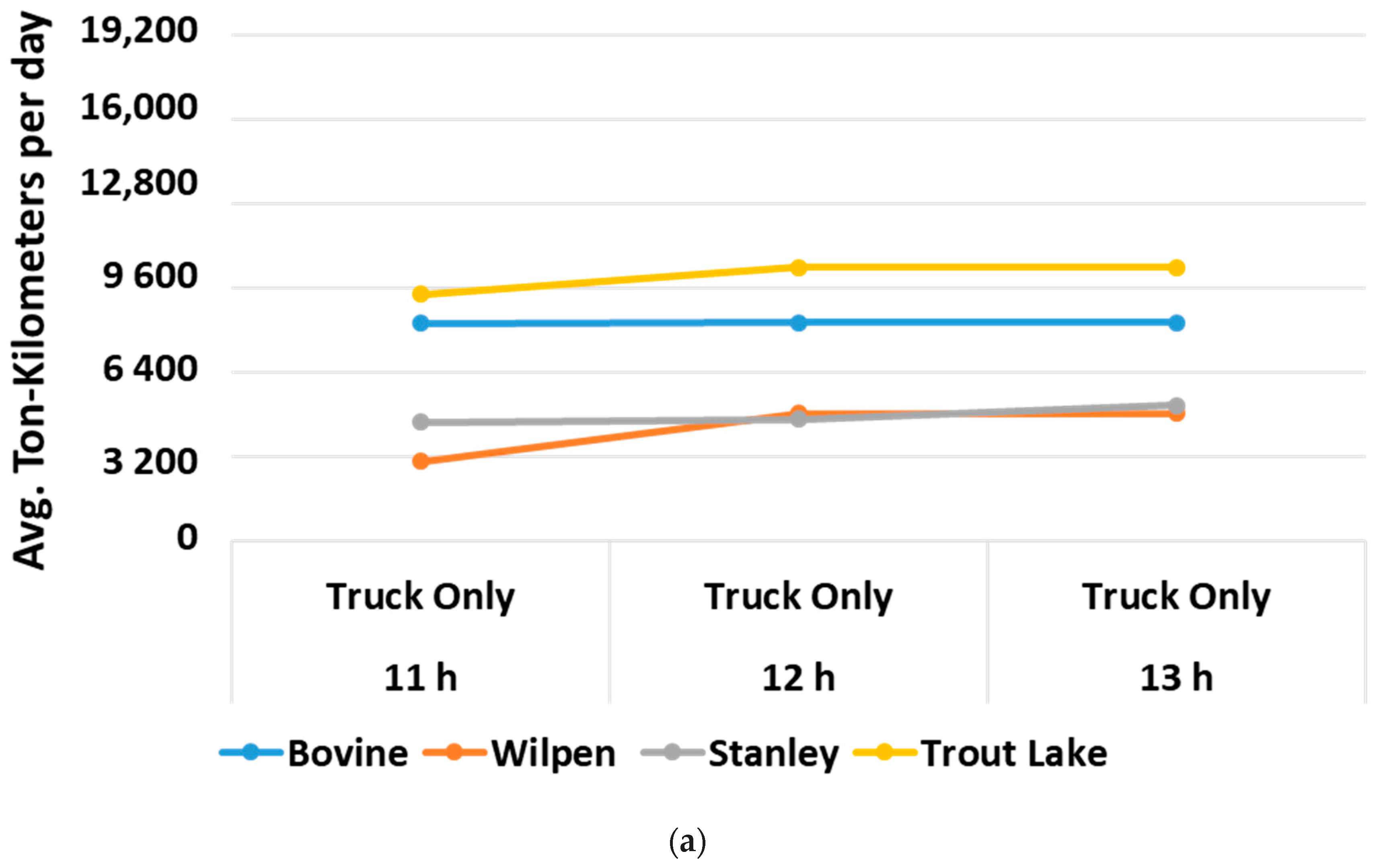

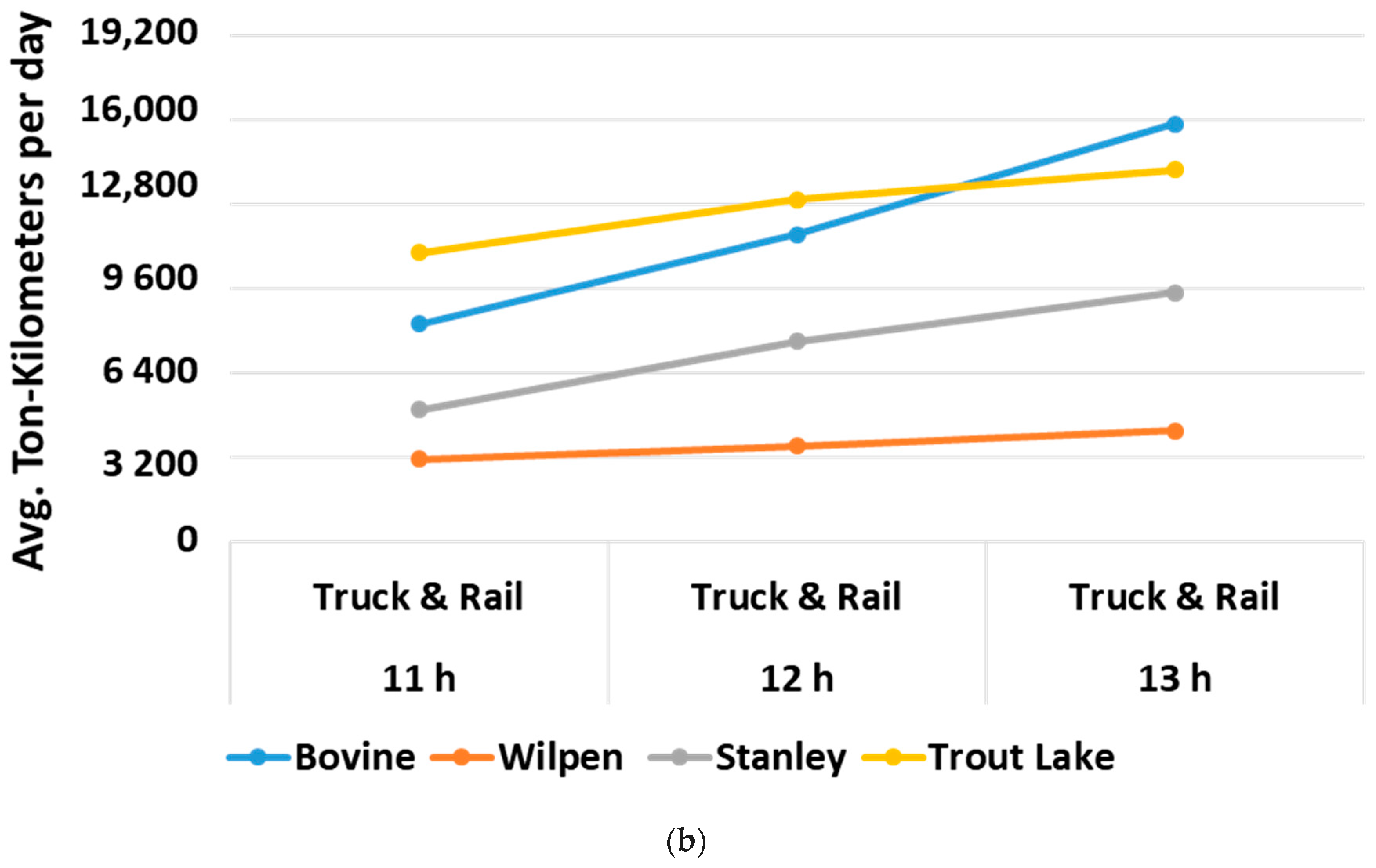

3.2. Sensitivity Analysis

4. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Youngs, R.L. Meeting the challenge of change. For. Prod. J. 2007, 57, 6. [Google Scholar]

- BTS, U. Average Length of Haul, Domestic Freight and Passenger Modes. 2019. Available online: https://www.bts.gov/content/average-length-haul-domestic-freight-and-passenger-modes-miles (accessed on 30 October 2019).

- Meyer, T.; Ernst, A.T.; Krishnamoorthy, M. A 2-phase algorithm for solving the single allocation p-hub center problem. Comput. Oper. Res. 2009, 36, 3143–3151. [Google Scholar] [CrossRef]

- Yaman, H. Allocation strategies in hub networks. Eur. J. Oper. Res. 2011, 211, 442–451. [Google Scholar] [CrossRef]

- Ishfaq, R.; Sox, C.R. Design of intermodal logistics networks with hub delays. Eur. J. Oper. Res. 2012, 220, 629–641. [Google Scholar] [CrossRef]

- Andersen, J.; Christiansen, M. Designing new European rail freight services. J. Oper. Res. Soc. 2009, 60, 348–360. [Google Scholar] [CrossRef]

- Pazour, J.A.; Meller, R.D.; Pohl, L.M. A model to design a national high-speed rail network for freight distribution. Transp. Res. Part A 2010, 44, 119–135. [Google Scholar] [CrossRef]

- Verma, M.; Verter, V.; Zufferey, N. A bi-objective model for planning and managing rail-truck intermodal transportation of hazardous materials. Transp. Res. Part E 2012, 48, 132–149. [Google Scholar] [CrossRef]

- Chang, H.; Jula, H.; Chassiakos, A.; Ioannou, P. A heuristic solution for the empty container substitution problem. Transp. Res. Part E 2008, 44, 203–216. [Google Scholar] [CrossRef]

- Bock, S. Real-time control of freight forwarder transportation networks by integrating multimodal transport chains. Eur. J. Oper. Res. 2010, 200, 733–746. [Google Scholar] [CrossRef]

- Di Francesco, M.; Lai, M.; Zuddas, P. Maritime repositioning of empty containers under uncertain port disruptions. Comput. Ind. Eng. 2013, 64, 827–837. [Google Scholar] [CrossRef]

- DOT, U. Transportation Networks. In Bureau of Transportation Statistics: National Transportation Atlas Database; US Department of Transportation: Washington, DC, USA, 2016. [Google Scholar]

- National Renewable Energy Laboratory. Biopower Atlas; National Renewable Energy Laboratory: Golden, CO, USA, 2015.

- Sun, G.; Mason, R.; Disney, S. MOVE: Modified Overall Vehicle Effectiveness. In Proceedings of the 8th International Symposium of Logistics, Seville, Spain, 14 July 2003. [Google Scholar]

- DOT, U. Hours of Service of Drivers: Final Rule; US Department of Transportation: Washington, DC, USA, 2011.

- Lautala, P.; Pouryousef, H.; Stewart, R.; Ogard, L.; Vartiainen, J. Analyzing Log and Chip Truck Performance in the Upper Peninsula of Michigan with GPS Tracking Devices; National Center for Freight and Infrastructure Research and Education (CFIRE): Medison, WI, USA, 2011. [Google Scholar]

| Category | Summary of Log Movement Data | |

|---|---|---|

| 1 | Number of companies and mills | 5 companies and their 14 mills |

| 2 | Total Tonnage: | Total log tons = 7,936,027 |

| 3 | Number of Shipments | In total 227,715 records of truck shipment data |

| 4 | Number of Origins/Destinations | Origins (log landings/yards): 8206/Destinations (mills): 14 |

| 5 | Time Period | 2017 (January–December) |

| 6 | Study Area | WI, MN, and UP of MI in the US |

| 7 | Infrastructure | Actual road network provided by US DOT |

| 8 | Geographic coordinates system | Latitude and Longitude(Preprocessing: Modification to Latitude/Longitude) |

| Activity | Administration | Technical | Gas | Other | Loading | Unloading |

|---|---|---|---|---|---|---|

| Avg. stop time (hours) | 0.07 | 0.36 | 0.12 | 0.26 | 1.35 | 0.65 |

| Rail Siding | # of Truck Origins | Avg. Distance between Truck Origins and Mills (Destinations) | Avg. Distance between Truck Origins and Rail Siding | Total Shipping Tons | |

|---|---|---|---|---|---|

| Section 1 | Bovine, MI, USA | 207 | 216 km | 60 km | 247,896 t |

| Section 2 | Wilpen, MN, USA | 212 | 208 km | 105 km | 83,685 t |

| Section 3 | Stanley, WI, USA | 320 | 164 km | 76 km | 114,402 t |

| Section 4 | Trout Lake, MI, USA | 121 | 227 km | 53 km | 93,509 t |

| Route | Shipped Tons | Days (a) | Available Time for Shipping ((b) = 12 h × (a)) | Actual Time Taken for Shipping ((c) = Used Hours × (a)) | Time Efficiency ((c)/(b)) | |

|---|---|---|---|---|---|---|

| (1) Truck + Rail Scenario | From Forest to Bovine | 247,896 t | 2580 days | 30,960 h | 23,866 h | 77.1% |

| vs. | ||||||

| (2) Truck only Scenario | From Forest to Mill | 247,896 t | 5130 days | 61,560 h | 45,847 h | 74.5% |

| Route | Shipped Tons per Day (a) | Loaded Kilometers | Loaded Kilometers per Day (b) | Total Kilometers per Day | Avg. Loaded Ton-Kilometers per Day ((a) × (b)) | Avg. Empty Kilometers per Shipped Ton (c) | |

|---|---|---|---|---|---|---|---|

| (1) Truck + Rail Scenario | From Forest to Bovine | 96.1 t | 314,986 km | 122.1 km | 244.1 km | 11,732 t-km | 1.27 km |

| vs. | |||||||

| (2) Truck Only Scenario | From Forest to Mill | 48.3 t | 885,472 km | 172.7 km | 345.2 km | 8340 t-km | 3.58 km |

| Time Efficiency | Value Efficiency (Avg. Ton-Kilometers Per Day) | ||||||

|---|---|---|---|---|---|---|---|

| Rail Siding | Before: Truck Only | After: Truck and Rail | Change (Before/After) | Before: Truck Only | After: Truck and Rail | Change (Before/After) | |

| 1 | Bovine, MI, USA | 74.5% | 77.1% | 2.6%p↑ | 8340 t-km | 11,732 t-km | 41%↑ |

| 2 | Wilpen, MN, USA | 82.1% | 65.7% | 16.4%p↓ | 4875 t-km | 3671 t-km | 25%↓ |

| 3 | Stanley, WI, USA | 64.8% | 81.3% | 16.5%p↑ | 4664 t-km | 7657 t-km | 64%↑ |

| 4 | Trout Lake, MI, USA | 78.4% | 87.5% | 9.1%p↑ | 10,454 t-km | 13,063 t-km | 25%↑ |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ko, S.; Lautala, P.; Zhang, K. Log Truck Value Analysis from Increased Rail Usage. Forests 2020, 11, 677. https://doi.org/10.3390/f11060677

Ko S, Lautala P, Zhang K. Log Truck Value Analysis from Increased Rail Usage. Forests. 2020; 11(6):677. https://doi.org/10.3390/f11060677

Chicago/Turabian StyleKo, Sangpil, Pasi Lautala, and Kuilin Zhang. 2020. "Log Truck Value Analysis from Increased Rail Usage" Forests 11, no. 6: 677. https://doi.org/10.3390/f11060677

APA StyleKo, S., Lautala, P., & Zhang, K. (2020). Log Truck Value Analysis from Increased Rail Usage. Forests, 11(6), 677. https://doi.org/10.3390/f11060677