Forwarder Productivity in Salvage Logging Operations in Difficult Terrain

Abstract

:1. Introduction

2. Materials and Methods

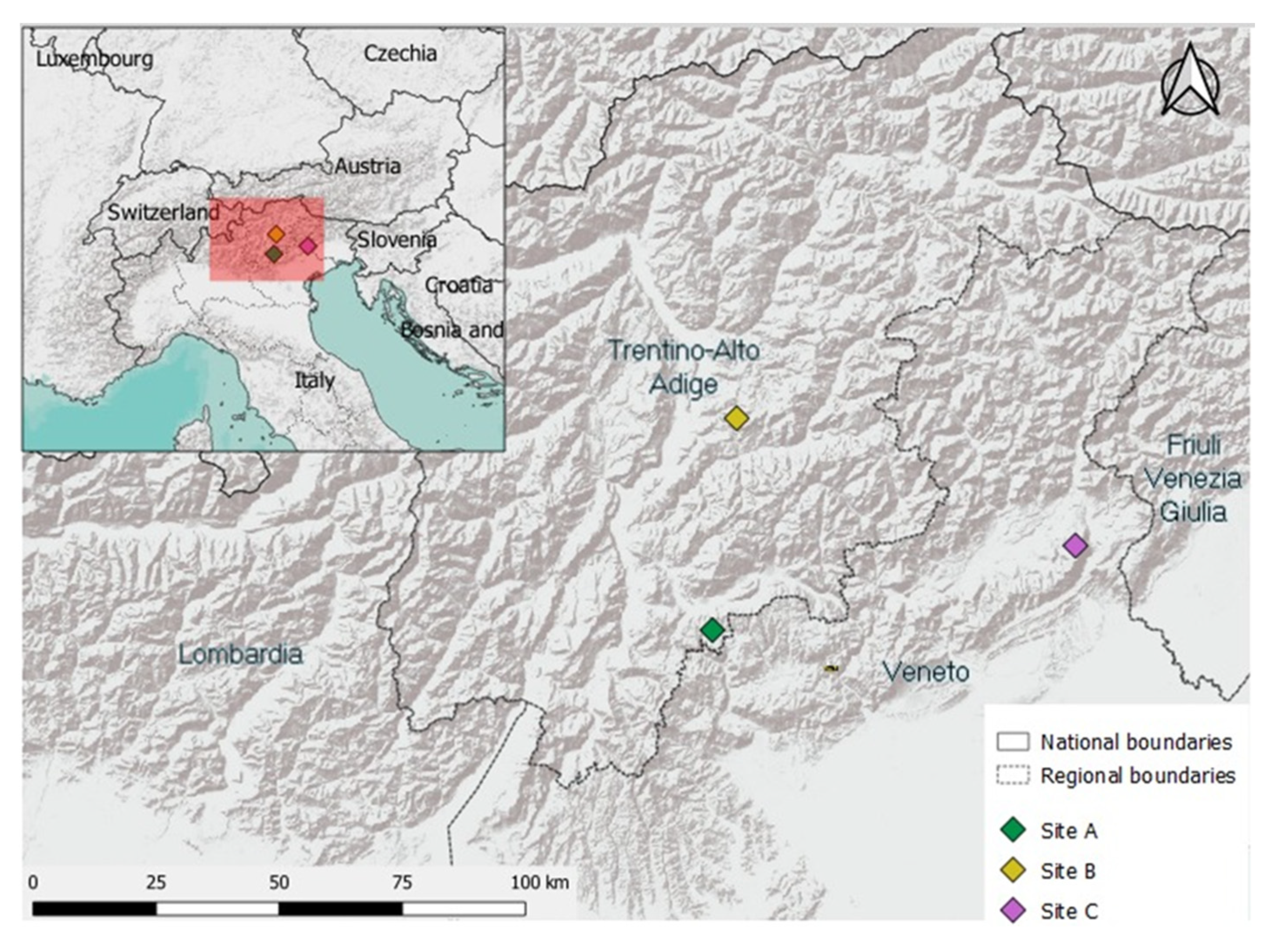

2.1. Case Studies

2.2. Machine Details

2.3. Data Collection

2.4. Time and Motion Study and Work Phase Classification

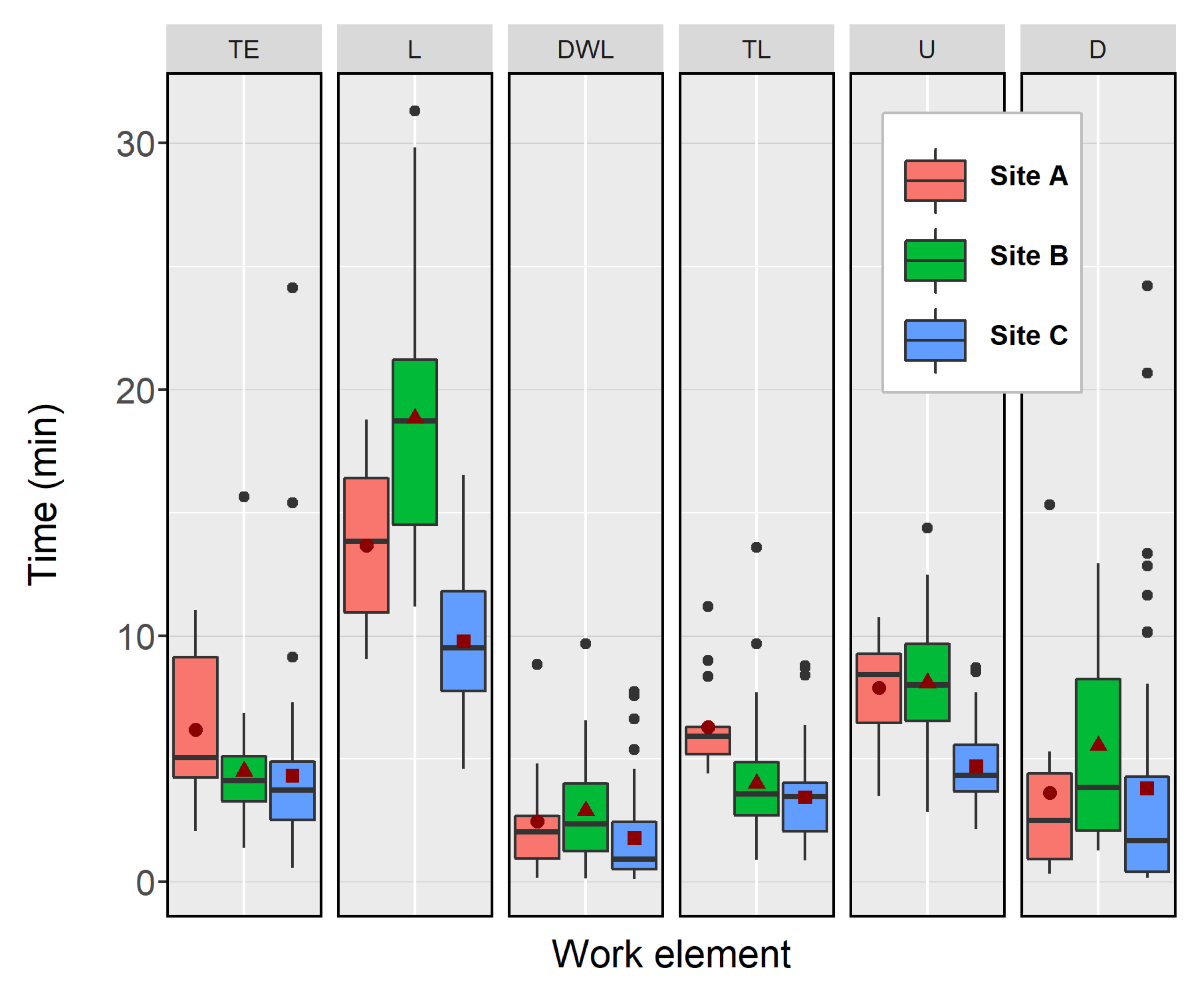

- travel empty: movement from the landing site (empty) to the loading site. Starts from the movement of the wheels, ends with the swing of the boom crane (priority 2);

- loading: starts with the swing of the boom crane at the loading site, ends when the boom crane stops to swing (priority 1);

- driving while loading: movement from different loading sites, starts from the movement of the wheels at loading site after a loading working element; ends when the boom crane starts to swing (priority 2);

- travel loaded: movement from the loading site to landing site; starts with the movement of the wheels, ends when the boom crane starts to swing (priority 2);

- unloading: when the boom crane unloads the logs at landing site; starts when the wheels stop and the boom crane starts to swing, end when the boom crane stops to swing and wheels start to move at the end of the unloading phase (priority 1);

- delay time: included delays up to 15 min.

2.5. Independent Variables

2.6. Productivity Model and Statistical Analysis

- Time moving (TM): the sum of travel empty, travel while loading, and travel loaded in minutes (Equation (1));

- Time loading (TL): loading time in minutes (Equation (2));

- Time unloading (TU): unloading time in minutes (Equation (3)).

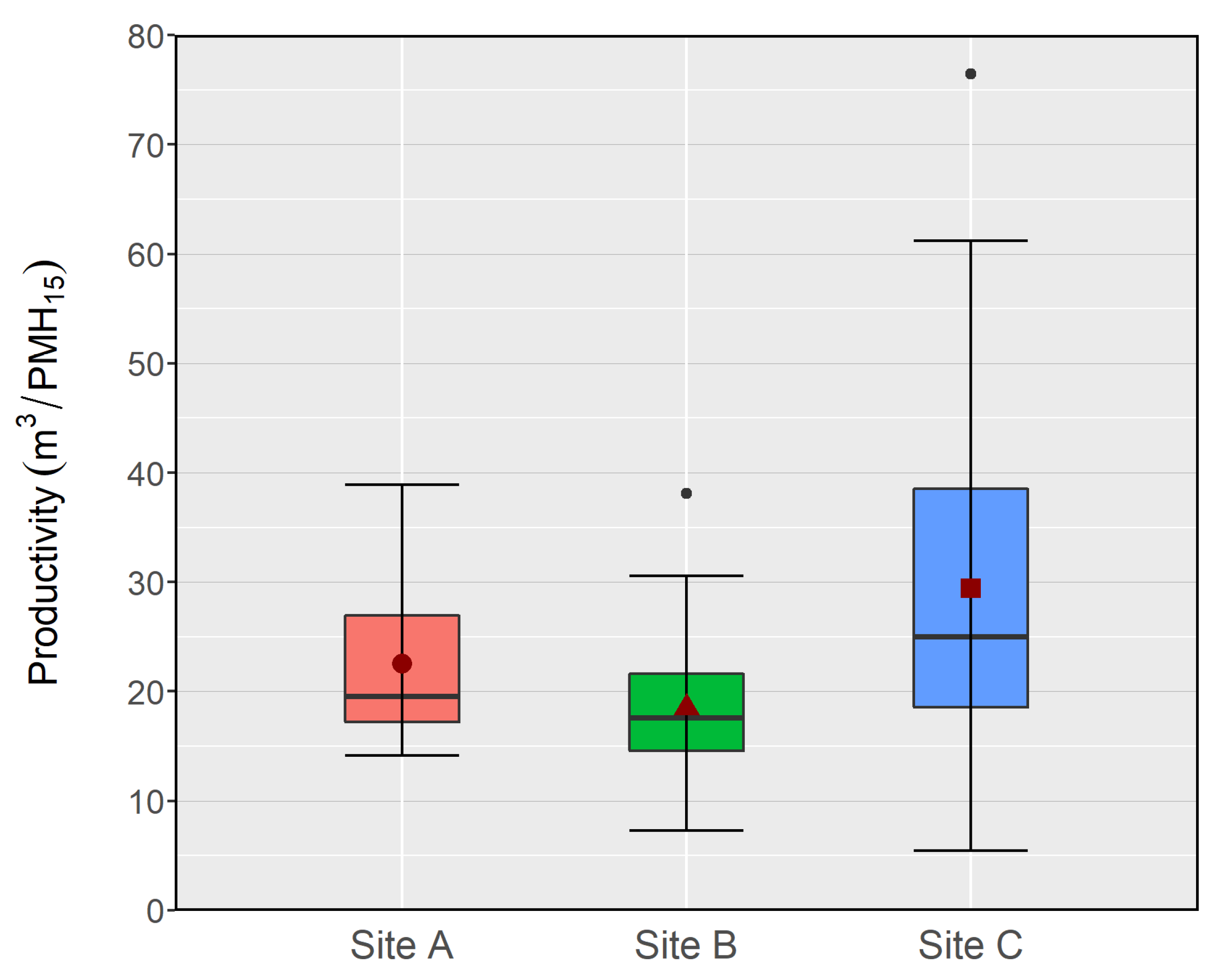

3. Results

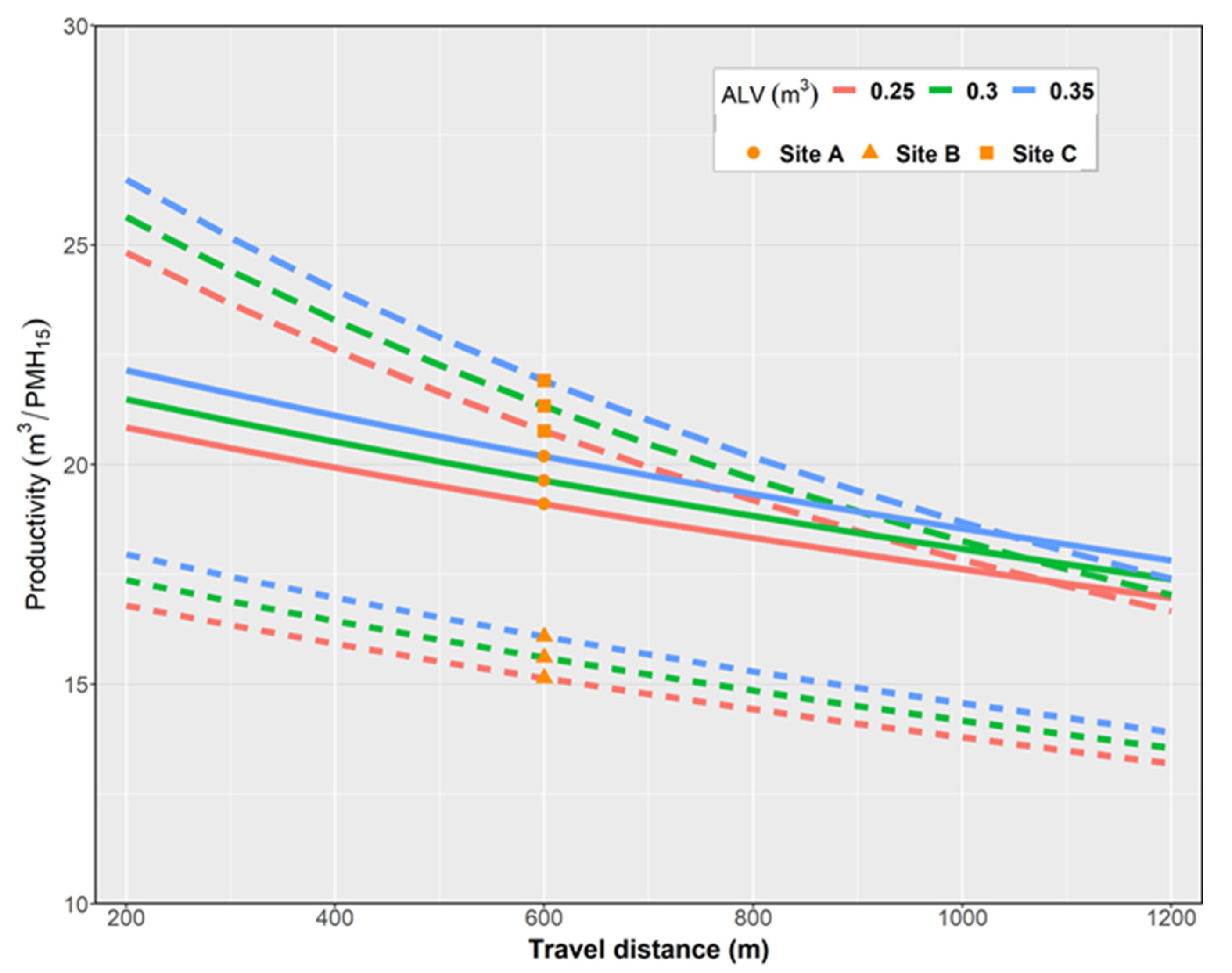

Productivity Equations

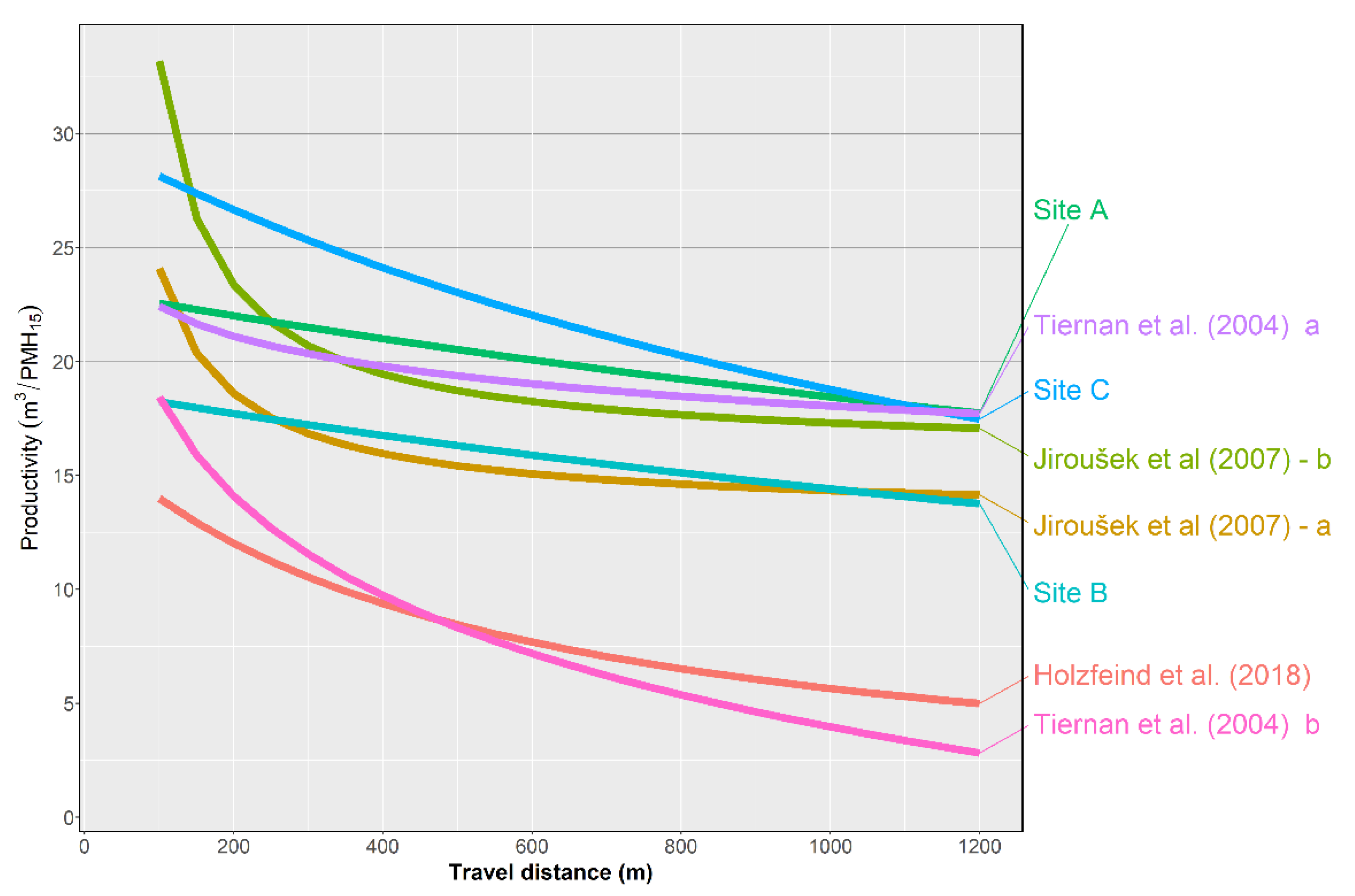

4. Discussions

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Coyette, H.; Schenk, C. Agriculture, Forestry and Fishery Statistics; Cook, E., Ed.; Eurostat: Luxemburg, 2019; pp. 83–99. ISBN 9789279330056. [Google Scholar]

- Seidl, R.; Schelhaas, M.-J.; Rammer, W.; Verkerk, P.J. Increasing forest disturbances in Europe and their impact on carbon storage. Nat. Clim. Chang. 2014, 4, 806–810. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lindner, M.; Maroschek, M.; Netherer, S.; Kremer, A.; Barbati, A.; Garcia-Gonzalo, J.; Seidl, R.; Delzon, S.; Corona, P.; Kolström, M.; et al. Climate change impacts, adaptive capacity, and vulnerability of European forest ecosystems. For. Ecol. Manage. 2010, 259, 698–709. [Google Scholar] [CrossRef]

- Gardiner, B.; Andreas, S.; Schelhaas, M.-J.; Orazio, C.; Blennow, K.; Nicoll, B. Living with Storm Damage to Forests; European Forestry Institute: Joensuu, Finland, 2013; Volume 3. [Google Scholar]

- Johnstone, J.F.; Allen, C.D.; Franklin, J.F.; Frelich, L.E.; Harvey, B.J.; Higuera, P.E.; Mack, M.C.; Meentemeyer, R.K.; Metz, M.R.; Perry, G.L.; et al. Changing disturbance regimes, ecological memory, and forest resilience. Front. Ecol. Environ. 2016, 14, 369–378. [Google Scholar] [CrossRef]

- Crouzeilles, R.; Ferreira, M.S.; Chazdon, R.L.; Lindenmayer, D.B.; Sansevero, J.B.B.; Monteiro, L.; Iribarrem, A.; Latawiec, A.E.; Strassburg, B.B.N. Ecological restoration success is higher for natural regeneration than for active restoration in tropical forests. Sci. Adv. 2017, 3, e1701345. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Müller, J.; Noss, R.F.; Thorn, S.; Bässler, C.; Leverkus, A.B.; Lindenmayer, D. Increasing disturbance demands new policies to conserve intact forest. Conserv. Lett. 2019, 12, e12449. [Google Scholar] [CrossRef] [Green Version]

- Zimmermann, K.; Schuetz, T.; Weimar, H. Analysis and modeling of timber storage accumulation after severe storm events in Germany. Eur. J. For. Res. 2018, 137, 463–475. [Google Scholar] [CrossRef]

- Newton, M.; Fitzgerald, S.; Rose, R.R.; Adams, P.W.; Tesch, S.D.; Sessions, J.; Atzet, R.; Powers, R.F.; Skinner, C. Comment on «Post-Wildfire Logging Hinders Regeneration and Increases Fire Risk». Science 2006, 313, 615. [Google Scholar] [CrossRef] [Green Version]

- Nikolov, C.; Konôpka, B.; Kajba, M.; Galko, J.; Kunca, A.; Janský, L. Post-disaster Forest Management and Bark Beetle Outbreak in Tatra National Park, Slovakia. Mt. Res. Dev. 2014, 34, 326–335. [Google Scholar] [CrossRef]

- Leverkus, A.B.; Rey Benayas, J.M.; Castro, J.; Boucher, D.; Brewer, S.; Collins, B.M.; Donato, D.; Fraver, S.; Kishchuk, B.E.; Lee, E.J.; et al. Salvage logging effects on regulating and supporting ecosystem services—A systematic map. Canad. J. For. Res. 2018, 48, 983–1000. [Google Scholar] [CrossRef]

- Peterson, C.J.; Leach, A.D. Limited salvage logging effects on forest regeneration after moderate-severity windthrow. Ecol. Appl. 2008, 18, 407–420. [Google Scholar] [CrossRef]

- Kramer, K.; Brang, P.; Bachofen, H.; Bugmann, H.; Wohlgemuth, T. Site factors are more important than salvage logging for tree regeneration after wind disturbance in Central European forests. For. Ecol. Manag. 2014, 331, 116–128. [Google Scholar] [CrossRef]

- Pischeda, D. Technical Guide on Harvesting and Conservation of Storm Damaged Timber. 2004. Available online: https://videntjenesten.ku.dk/filer/Technical-Guide-on-harvesting-and-conservation-of-storm-damaged-timber.pdf (accessed on 30 January 2020).

- Kärhä, K.; Anttonen, T.; Poikela, A.; Palander, T.; Laur, A. Evaluation of Salvage Logging Productivity and Costs in Windthrown Norway Spruce-Dominated Forests. Forests 2018, 9, 280. [Google Scholar] [CrossRef] [Green Version]

- Enache, A.; Kühmaier, M.; Visser, R.; Stampfer, K. Forestry operations in the European mountains: A study of current practices and efficiency gaps. Scand. J. For. Res. 2016, 31, 412–427. [Google Scholar] [CrossRef]

- Bodaghi, A.I.; Nikooy, M.; Naghdi, R.; Venanzi, R.; Latterini, F.; Tavankar, F.; Picchio, R. Ground-based extraction on salvage logging in two high forests: A productivity and cost analysis. Forests 2018, 9, 1–18. [Google Scholar]

- Visser, R.; Stampfer, K. Expanding ground-based harvesting onto steep terrain: A review. Croat. J. For. Eng. 2015, 36, 321–331. [Google Scholar]

- Mologni, O.; Grigolato, S.; Cavalli, R. Harvesting systems for steep terrain in the Italian Alps: State of the art and future prospects. Contemp. Eng. Sci. 2016, 9, 1229–1242. [Google Scholar] [CrossRef]

- Tiernan, D.; Zeleke, G.; Owende, P.M.; Kanali, C.; Lyons, J.; Ward, S. Effect of Working Conditions on Forwarder Productivity in Cut-to-length Timber Harvesting on Sensitive Forest Sites in Ireland. Biosyst. Eng. 2004, 87, 167–177. [Google Scholar] [CrossRef]

- Cambi, M.; Grigolato, S.; Neri, F.; Picchio, R.; Marchi, E. Effects of Forwarder Operation on Soil Physical Characteristics: A Case Study in the Italian Alps. Croat. J. For. Eng. 2017, 37, 233–239. [Google Scholar]

- Proto, A.R.; Macrì, G.; Visser, R.; Harrill, H.; Russo, D.; Zimbalatti, G. Factors affecting forwarder productivity. Eur. J. For. Res. 2018, 137, 143–151. [Google Scholar] [CrossRef]

- Proto, A.R.; Macrì, G.; Visser, R.; Harrill, H.; Russo, D.; Zimbalatti, G. A case study on the productivity of forwarder extraction in small-scale Southern Italian forests. Small-scale For. 2018, 17, 71–87. [Google Scholar] [CrossRef]

- Holzfeind, T.; Stampfer, K.; Holzleitner, F. Productivity, setup time and costs of a winch-assisted forwarder. J. For. Res. 2018, 23, 196–203. [Google Scholar] [CrossRef]

- Nurminen, T.; Korpunen, H.; Uusitalo, J. Time Consumption Analysis of the Mechanized Cut-to lenght Harvesting System. Silva. Fenn. 2006, 40, 335–363. [Google Scholar] [CrossRef] [Green Version]

- Stankić, I.; Poršinsky, T.; Tomašić, Ž. Productivity models for operational planning of timber forwarding in croatia. Croat. J. 2012, 33, 61–78. [Google Scholar]

- Ghaffarian, M.R.; Stampfer, K.; Sessions, J. Forwarding productivity in Southern Austria. Croat. J. For. Eng. 2007, 28, 169–175. [Google Scholar]

- Eriksson, M.; Lindroos, O. Productivity of harvesters and forwarders in CTL operations in northern Sweden based on large follow-up datasets. Int. J. For. Eng. 2014, 25, 179–200. [Google Scholar] [CrossRef]

- Jiroušek, R.; Klvač, R.; Skoupý, A. Productivity and costs of the mechanised cut-to-length wood harvesting system in clear-felling operations. J. For. Sci. 2007, 53, 476–482. [Google Scholar] [CrossRef] [Green Version]

- Bergkvist, I. Beskrivning och Analys av de Dominerande Maskinsystemen (Salvaging Windfalls)—Description and Analysis of Dominant Machine Systems; Skogforsk: Uppsala, Sweden, 2005; p. 15. [Google Scholar]

- Chirici, G.; Giannetti, F.; Travaglini, D.; Nocentini, S.; Francini, S.; D’Amico, G.; Calvo, E.; Fasolini, D.; Broll, M.; Maistrelli, F.; et al. Forest damage inventory after the “Vaia” storm in Italy. Forest@-Rivista Selvic. Ecol. For. 2019, 16, 3–9. [Google Scholar] [CrossRef] [Green Version]

- Motta, R.; Ascoli, D.; Corona, P.; Marchetti, M.; Vacchiano, G. Silviculture and wind damages. The storm “Vaia.”. Forest@-Rivista Selvic. Ecol. For. 2018, 15, 94–98. [Google Scholar] [CrossRef] [Green Version]

- Brunberg, T. Underlag Till Produktionsnormer För Skotare (Productivity-Norm Data for Forwarders); Skogforsk: Uppsala, Sweden, 2004. [Google Scholar]

- Mologni, O.; Dyson, P.; Amishev, D.; Proto, A.R.; Zimbalatti, G.; Cavalli, R.; Grigolato, S. Tensile force monitoring on large winch-assist forwarders operating in British Columbia. Croat. J. For. Eng. 2018, 39, 193–204. [Google Scholar]

- Holzleitner, F.; Kastner, M.; Stampfer, K.; Höller, N.; Kanzian, C. Monitoring Cable Tensile Forces of Winch-Assist Harvester and Forwarder Operations in Steep Terrain. Forests 2018, 9, 53. [Google Scholar] [CrossRef] [Green Version]

- Grigolato, S.; Panizza, S.; Pellegrini, M.; Ackerman, P.; Cavalli, R. Light-lift helicopter logging operations in the Italian Alps: A preliminary study based on GNSS and a video camera system. For. Sci. Technol. 2016, 12, 88–97. [Google Scholar] [CrossRef] [Green Version]

- Björheden, R. Basic Time Concepts for International Comparisons of Time Study Reports. J. For. Eng. 1991, 2, 33–39. [Google Scholar] [CrossRef]

- Spinelli, R.; Visser, R.J.M. Analyzing and estimating delays in harvester operations. Int. J. For. Eng. 2008, 19, 36–41. [Google Scholar] [CrossRef]

- Manner, J.; Nordfjell, T.; Lindroos, O. Effects of the number of assortments and log concentration on time consumption for forwarding. Silva. Fenn. 2013, 47. [Google Scholar] [CrossRef] [Green Version]

- Stampfer, K. Influence of terrain conditions and thinning regimes on productivity of a track-based steep slope harvester. In Proceedings of the International Mountain Logging and 10th Pacific Northwest Skyline Symposium, Corvallis, OR, USA, 28 March–1 April 1999; pp. 78–87. [Google Scholar]

- Bates, D.; Mächler, M.; Bolker, B.M.; Walker, S.C. Fitting linear mixed-effects models using lme4. J. Stat. Softw. 2015, 67. [Google Scholar] [CrossRef]

- Hiesl, P.; Benjamin, J.G. A multi-stem feller-buncher cycle-time model for partial harvest of small-diameter wood stands. Int. J. For. Eng. 2013, 24, 101–108. [Google Scholar] [CrossRef]

- Magee, L. R2 measures based on Wald and Likelihood Ratio Joint significance tests. Am. Stat. 1990, 44, 250–253. [Google Scholar]

- Malinen, J.; Taskinen, J.; Tolppa, T. Productivity of Cut-to-Length Harvesting by Operators’ Age and Experience. J. Theory Appl. For. Eng. 2018, 39, 15–22. [Google Scholar]

- Brewer, J.; Talbot, B.; Belbo, H.; Ackerman, P.; Ackerman, S. A comparison of two methods of data collection for modelling productivity of harvesters: Manual time study and follow-up study using on-board-computer stem records. Ann. For. Res. 2018, 61, 109–124. [Google Scholar] [CrossRef] [Green Version]

| Site A | Site B | Site C | |

|---|---|---|---|

| Location | Passo Vezzena | Redagno di sopra | Nevegal |

| Province | Trento | Bolzano | Belluno |

| Elevation (m a.s.l.) | 1460 | 1600 | 1300 |

| Total area (ha) | 20 | 30.5 | 60.48 |

| Damaged area (%) | 65 | 100 | 40 |

| Estimated damaged wood (m3) | 3500 | 10,000 | 25,000 |

| Average slope (%) | 17 | 24 | 33 |

| Species (% of volume) | |||

| Abies alba | 35 | 30 | - |

| Picea abies | 65 | 60 | 73 |

| Larix decidua | - | 10 | 21 |

| Broad leaved | - | - | 6 |

| Case Studies | Site A | Site B | Site C | |

|---|---|---|---|---|

| Model | John Deere 1210 E | Ecolog 574 B | Ponsse Buffalo | |

| Engine | - | John Deere 6068 | CAT 3065 E | Mercedes-Benz MTU OM936 |

| Power | kW (hp) | 136 (183) | 129 (173) | 210 (286) |

| Ground clearance | mm | 605 | 650 | 680 |

| Cylinders | n° | 6 | 6 | 6 |

| Wheel number | n° | 8 | 8 | 8 |

| Steering angle | ° | 44 | 40 | 44 |

| Weight empty | t | 18.1 | 17.0 | 19.8 |

| Load capacity | t | 13 | 14 | 15 |

| Tire size | - | 710/45-26,5 | 710/45-26,5 | 710/45-26,5 |

| Boom crane model | - | CF7 | Loglift 83 | Ponsse K 90+ M |

| Gross lifting torque | kNm | 125 | 76 | 140 |

| Maximum boom reach | m | 10.0 | 8.4 | 10.0 |

| Definitions | Variable |

|---|---|

| Average ground slope during moving time | |

| Average ground slope during loading time | |

| Average log volume | |

| Average machine inclination during moving time | |

| Average machine inclination during loading time | |

| Load volume | |

| Maximum ground slope during moving time | |

| Maximum ground slope during loading time | |

| Maximum machine inclination during moving time | |

| Maximum machine inclination during loading time | |

| Number of logs | |

| Speed | |

| Travel distance |

| Site A | Site B | Site C | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Variables | Unit | Min | Average | Max | Min | Average | Max | Min | Average | Max |

| AGSM | % | 11.2 | 15.7 | 22.8 | 9.5 | 24.7 | 32.7 | 17.6 | 31.2 | 43.9 |

| AGSL | % | 11.5 | 23.1 | 36.1 | 9.5 | 25.1 | 34.7 | 19.3 | 34.1 | 72.6 |

| ALV | m3 | 0.1 | 0.34 | 0.67 | 0.15 | 0.33 | 0.81 | 0.11 | 0.36 | 0.81 |

| AMIM | % | 18.0 | 22.6 | 26.5 | 21.6 | 30.7 | 38.4 | 19.9 | 39.6 | 57.6 |

| AMIL | % | 15.0 | 21.5 | 39.7 | 7.5 | 33.4 | 60.1 | 17.0 | 41.7 | 65.0 |

| LV | 10.1 | 13.9 | 19.6 | 6.3 | 12.7 | 18.7 | 1.9 | 12.2 | 24.9 | |

| MGSM | % | 26.9 | 47.4 | 85.9 | 20.9 | 43.3 | 68.9 | 26.2 | 45.3 | 85.5 |

| MGSL | % | 24.3 | 43.9 | 85.9 | 19.2 | 31.9 | 56.7 | 24.8 | 40.4 | 94.8 |

| MMIM | % | 20.2 | 43.6 | 57.3 | 43.0 | 66.4 | 88.6 | 38.8 | 70.0 | 96.2 |

| MMIL | % | 20.3 | 38.0 | 58.8 | 20.5 | 56.9 | 90.4 | 31.6 | 65.6 | 95.6 |

| NL | n° | 26 | 55.0 | 104 | 23 | 42 | 65 | 11 | 38 | 86 |

| S | m s−1 | 1 | 1.3 | 1.6 | 0.4 | 0.8 | 1.3 | 0.3 | 0.8 | 1.7 |

| TD | m | 606 | 1181 | 1834 | 217 | 557 | 1457 | 41 | 434 | 2221 |

| Equation | Response Variable | Coefficient | Estim. | SE | t Value | p Value |

|---|---|---|---|---|---|---|

| 1 (TM) | Time moving (min) | ALV (m3) | −4.151 | 1.28 | −3.240 | 0.010 |

| MGSM (%) | 0.075 | 0.02 | 3.764 | <0.001 | ||

| 2 (TL) | Log Time loading (min) | ALV (m3) | −1.004 | 0.134 | −7.516 | <0.001 |

| MMIL (%) | −0.006 | 0.001 | −4.344 | <0.001 | ||

| MGSL (%) | 0.005 | 0.002 | 3.192 | 0.002 | ||

| 3 (TU) | Log Time unloading (min) | LV (m3) | 0.041 | 0.007 | 5.965 | <0.001 |

| NL (n°) | −0.004 | 0.002 | −2.324 | 0.020 |

| Equation | Coefficient | SD | Variance | p Value |

|---|---|---|---|---|

| 1 (TM) | TD | 0.002 | −228.5 | <0.001 |

| Equation | N | Variance | SD | LM | L0 | R2LR |

|---|---|---|---|---|---|---|

| 1 (TM) | 101 | 4.118 | 2.029 | −228.49 | −295.50 | 0.735 |

| 2 (TL) | 101 | 0.07 | 0.268 | 6.389 | −19.56 | 0.402 |

| 3 (TU) | 101 | 0.06 | 0.249 | −13.12 | −32.64 | 0.321 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cadei, A.; Mologni, O.; Röser, D.; Cavalli, R.; Grigolato, S. Forwarder Productivity in Salvage Logging Operations in Difficult Terrain. Forests 2020, 11, 341. https://doi.org/10.3390/f11030341

Cadei A, Mologni O, Röser D, Cavalli R, Grigolato S. Forwarder Productivity in Salvage Logging Operations in Difficult Terrain. Forests. 2020; 11(3):341. https://doi.org/10.3390/f11030341

Chicago/Turabian StyleCadei, Alberto, Omar Mologni, Dominik Röser, Raffaele Cavalli, and Stefano Grigolato. 2020. "Forwarder Productivity in Salvage Logging Operations in Difficult Terrain" Forests 11, no. 3: 341. https://doi.org/10.3390/f11030341

APA StyleCadei, A., Mologni, O., Röser, D., Cavalli, R., & Grigolato, S. (2020). Forwarder Productivity in Salvage Logging Operations in Difficult Terrain. Forests, 11(3), 341. https://doi.org/10.3390/f11030341