Abstract

Although professional chainsaws have come a long way regarding technical and ergonomic development since first introduced into forestry, they still remain a high-risk tool that can cause serious health problems. In this research, three types of used professional chainsaws were observed regarding harmful vibrations they emit and possible connection to years in use, chainsaw type, characteristics and level of vibrations. Measurements were performed in accordance with the recommendations of ISO 5349:2001. For the measurements, a measuring chain consisting of a triaxial accelerometer manufactured by Bruel & Kjaer and a vibrometer of the same manufacturer Type 4447. To evaluate the emitted vibrations, a daily exposure value A(8) was used. Exposure durations to predefined working operations were identical for every used chainsaw to enable the possibility of equal comparability. Obtained results indicate that the daily vibration exposure A(8) is not affected by the years in use of the chainsaw. Results also show that the power and chainsaw type have an influence on daily vibration exposure. The recommendation for the praxis is to use even lighter and smaller chainsaw wherever is possible.

1. Introduction

Work in the forest brings significant pressures to forestry workers, and it is considered as one of the most dangerous industrial activities [1,2,3]. A more detailed analysis of accidents in the forestry sector has shown that the work on wood utilization is far more dangerous than other forestry operations [4].

Workers in the felling and processing of wood assortments are exposed to significant vibration levels because they use mechanized means of work from different manufacturers, with different mass and power of propulsion engines and that are expected to meet the defined working norm which is related to the operation method, stand conditions and work-related parameters.

The main causes that influence on vibration levels of chainsaw are mainly dynamic forces from the motor, sawing modes, unbalanced moving parts, shocks in gears, bearings and other mechanisms and also in the interaction between the operator, the machine and the wood being processed [5].

Workers whose hands are regularly exposed to higher-intensity vibrations transmitted through the palms and fingers can suffer damage with a number of consequences commonly referred to as the “hand-arm vibration syndrome” [6]. Exposure to excessive vibration levels is the cause of more than 13% of all occupational diseases in the Republic of Croatia [7].

Determining the actual vibration exposure of workers on the specific operations, in defined daily working time, is a lengthy process because of the need to sample a representative number of working tools. The process is even more complex if the daily work is composed of several activities of varying duration, during which vibrations of different levels occur [8]. Exposure to vibrations transmitted to the hand-arm system during handling with vibrating tools or vibrating work objects is expressed via energetic equivalent A(8). This is the average exposure over an eight-hour day and takes into account the magnitude of the vibration and how long the worker is exposed to it. The A(8) values are compared to the permissible exposure values defined by national rules, in accordance with Directive 2002/44/EC, after that a selection of safety measures is in order if proved necessary [6].

Directive 2002/44/EC unambiguously sets daily exposure action value of 2.5 m/s2 as a warning level above which protective measures must be applied and daily exposure limit value of 5 m/s2 above which work must be stopped.

When working with chainsaw in regeneration stands, loads on hands and arms caused by vibrations (HAV—hand-arm vibrations) exceeded the action value of daily exposures [6,9]. According to previous research [1,9], the vibration level of the chainsaw is affected by a large number of parameters (worker, chain tension, bar length, fuel quantity in the tank, method of holding the saw). The firmness of grip of the chainsaw handle, affecting the transfer of HA (hand-arm) vibrations, depends on worker’s experience, work operations and wood hardness. Thus, coupling forces exerted by fellers are higher with less experienced workers, higher in felling and cross-cutting than in limbing and higher with tree species of higher wood hardness [1,10,11,12]. The HAV exposures, when using Kasper safety bar, are not different compared to the use of conventional bar [2,13]. However, HAV differs between tree species and is higher with tree species of higher wood density [6,14]. One of the possible measures to reduce the harmful effect of HAV on workers is the use of anti-vibration gloves, which must comply with international standards [6,15]. The studies show that there are significant differences between the types of anti-vibration gloves in terms of their insulation effectiveness [16].

The chainsaw is a working tool, and as such, it needs to be inspected and maintained regularly for best performance and safety of workers. The worker should not start the working day without inspection of several key points of a chainsaw, such as handles, throttle controls, the sharpness of chain cutters, chain tension, lubrication system, chain brake, wear of the guide bar (turn if necessary), etc. [17]. Every chainsaw in professional forestry in Croatia must undergo an attestation process every three years. Maintenance and replacement of parts must be in accordance with manufacturers’ recommendations. A good example of a relation between the duration of consumable parts is 1 guide bar—2 sprockets—4 chains.

International standards clearly define the measurement procedure and the expression of the result of measuring the vibration level on chainsaws in order to ensure the repeatability of measurements and thus the comparability of measurement results. This enables the evaluation of the ergonomic characteristics of chainsaws and the choice of chainsaws that best meet the statutory criteria. Daily exposure A(8) in this research is used as a reference point to test the effects of changing set of variables (years in use, power and mass) on it and does not represent a value that describes daily exposure under real working conditions.

The aim of the study was to measure vibration levels at chainsaw handles and to determine differences in simulated daily exposure A(8) value with respect to exploitation years, type of chainsaw, mass and power.

2. Materials and Methods

Measurements of vibrations transmitted to the hand-arm system of the operator were performed on the chainsaws described in Table 1. The chainsaws were properly prepared before the measurements (heated, chain tightened and sharpened according to manufacturer’s instructions).

Table 1.

Chainsaw characteristics.

The field measurement included 30 Stihl chainsaws, MS 260, MS 440 and MS 660. The first group consists of models MS 260, the second group MS 440 and the third group MS 660. The average years in the use of chainsaws is 5 years.

Measurements were performed in accordance with the recommendations of ISO 5349:2001 [18] all to meet the requirements set by the Ordinance on the Protection against Exposure to Vibration Risks (Official Gazette No. 155/2008) [19], and Directive 2002/44/EC [20].

All measurements were performed with instruments that meet the requirements of international standards, and all measuring transducers were calibrated in the manner required by international standards.

Measurements were taken for two measuring points in three characteristic modes, idle (I), medium throttle (MT) and full throttle (FT). Three vibration samples were taken for each mode with duration of 60 s per sample. The position of the operator in the measurements was in accordance with the recommendations of the mentioned standards.

For measurement purposes, a Brüel & Kjaer (Brüel & Kjær, Nærum, Denmark) triaxial accelerometer (type 4520-002) was mounted on a Brüel & Kjaer (Brüel & Kjær, Nærum, Denmark) Type UA3015 thin aluminum mount, and the accelerometer mount was pressed on the gripping handles of the saw to minimize the impact of measurement uncertainty due to changing accelerometer position and to ensure equal compressive force on the measuring place.

The accelerometer was fitted in a way that the axes are as close as possible to the axis direction given in the recommendation of ISO 5349:2001 [18], axis Z along with the hand, axis Y lateral to the hand and axis X vertical to the hand. For the measurements, a measuring chain consisting of a triaxial accelerometer manufactured by Brüel & Kjaer (Brüel & Kjær, Nærum, Denmark) and a triaxial vibrometer of the same manufacturer Type 4447, Ser. No.: 610435. Before the measurement, the entire measurement chain was calibrated using a Brüel & Kjaer calibrator, Calibrator Exciter Type 4294, Ser. No.: 2659181.

For the data obtained from measurements in three modes at all measuring points, the triaxial vibrometer calculated the weighted vibration values for time records in the direction of all three axes, in accordance with the recommendations of the standard ISO 5349:2001 [18].

Thus, the weighted acceleration levels in all three axes (ahwx, ahwy and ahwz) were obtained. From the weighted acceleration levels in all three axes, the vibration total value (ahv) for three modes according to the following relation was determined (Equation (1)):

ahwi – weighted effective acceleration levels (m/s2)

Based on the measured acceleration values on the chainsaws and the calculated vibration total values, a model for estimating the daily exposure value A(8) was calculated according to the relation (Equation (2)):

T0, daily working time of 8 h or 28,800 s; ahvi, vibration total value for i operation; Ti, duration of i operation; N, total number of operations.

Safety precautions and safety rules for professional forestry work in Croatia are prescribed by the Ordinance on Occupational Safety and Health in Forestry (Official Gazette No. 10/86) [17]. This ordinance stipulates, in the legislative measures, that the effective working time with a chainsaw must not exceed 4 h in one working day. According to the above, the following parameters were selected for the input settings: total effective working time of 4 h with a chainsaw, whereby the worker is exposed to the vibrations in idle mode in one-third of the time, vibrations in medium throttle mode in one-third of the time and vibrations in full throttle mode in one-third of the time. The results indicate a reference A(8) value, that is, a higher one between the two measured handles on each chainsaw.

Data measured in the field were transformed into appropriate MS Excel® database. Further data analysis was performed using statistical software Statistica 13® (Dell Software, Round Rock, Texas, United States). Descriptive statistics was made for key variables. Statistical hypothesis testing was preformed to draw conclusions from the data collected. The following three null hypotheses (H0) have been put forward:

- (1)

- H0—There is no difference in simulated daily exposure A(8) value among chainsaw years in use.

- (2)

- H0—There is no difference in simulated daily exposure A(8) value among chainsaw types.

- (3)

- H0—There is no association between simulated daily exposure A(8) value and independent variables (years of use, power and mass).

The three null hypotheses are set to draw conclusions regarding the research goal. The Shapiro–Wilk test was used to determine whether a simulated daily exposure A(8) value is well-modelled by a normal distribution. Testing of differences, within formed database, was carried out between the simulated daily exposure A(8) value and two selected descriptive variables. Levene’s test was used to verify the homogeneity of variances. Used descriptive variables were: (a) chainsaw years in use and (b) chainsaw type in use.

Groups by chainsaw years in use:

- group 1: ≤4 years in use;

- group 2: 5–7 years in use;

- group 3: ≥8 years in use.

Groups by chainsaw type:

- group 1: MS 260;

- group 2: MS 440;

- group 3: MS 660.

Analysis of variance (ANOVA) was used to test the first and second null hypotheses. Tukey’s post hoc test was used to find out which specific group’s means (compared with each other) are different. For accepting or rejecting the third null hypothesis, a regression analysis was used to explore the impact of independent variables (years in use, power and mass of a chainsaw) on the dependent variable (simulated daily exposure A(8) value).

3. Research Results

The Table 2. shows the highest vibration values that appear on the front or rear handle in bold numbers. All the highest vibration values appear when idling.

Table 2.

Vibration measurements.

It should be emphasized that in the first group of chainsaws MS 260, as well as in the second group of chainsaws MS 440, the highest vibration values occur most often on the front handle, i.e., 6 out of a total of 10 chainsaws of the first group and 6 out of a total of 10 chainsaws of the second group. For the MS 660 chainsaws, the highest of the vibration values were measured on the rear handle (6 of a total of 10 chainsaws).

Shapiro–Wilk test of normality resulted with the p-value of 0.373, which confirms that simulated daily exposure A(8) value is well-modelled by a normal distribution.

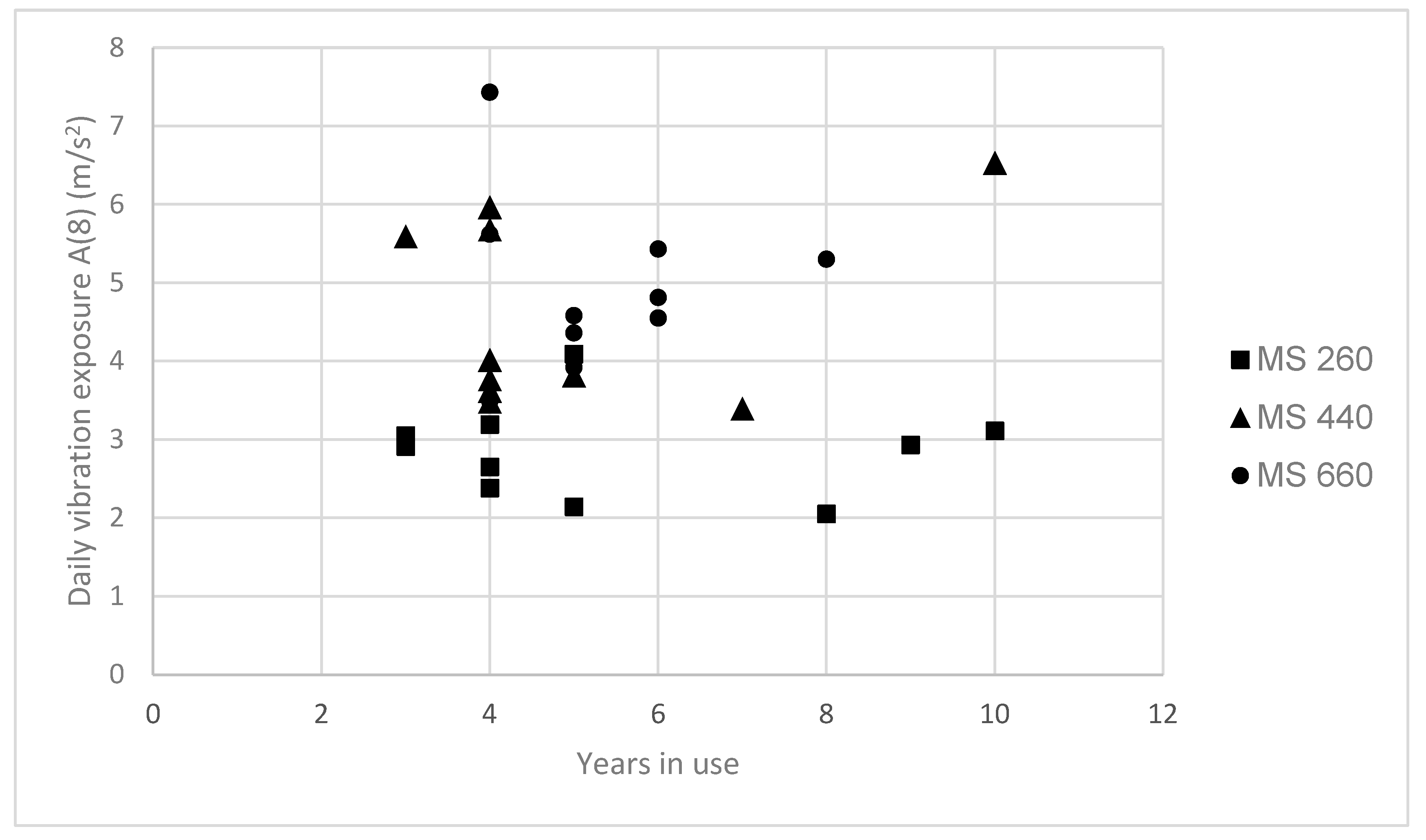

According to Figure 1, the daily vibration exposure A(8) is not affected by the years in the use of the chainsaw. Levene’s test proved the assumption of homogeneity of variance between data groups by chainsaw years in use (F = 3.179; p = 0.08) within the daily vibration exposure A (8) value. Statistically significant difference was not determined for A(8) value among the groups by chainsaw years in use F(2, 27) = 0.0424, p = 0.9586. In accordance with the result obtained, the first null hypothesis is accepted.

Figure 1.

Daily vibration exposure A(8) in regard to years in use.

According to the model, no chainsaw in the first group (MS 260) exceeds the limit value of 5 m/s2. Four chainsaws in the second group (MS 440) exceed the limit A(8) value (Table 3). Like four chainsaws from the third group (MS 660).

Table 3.

Average vibration total values.

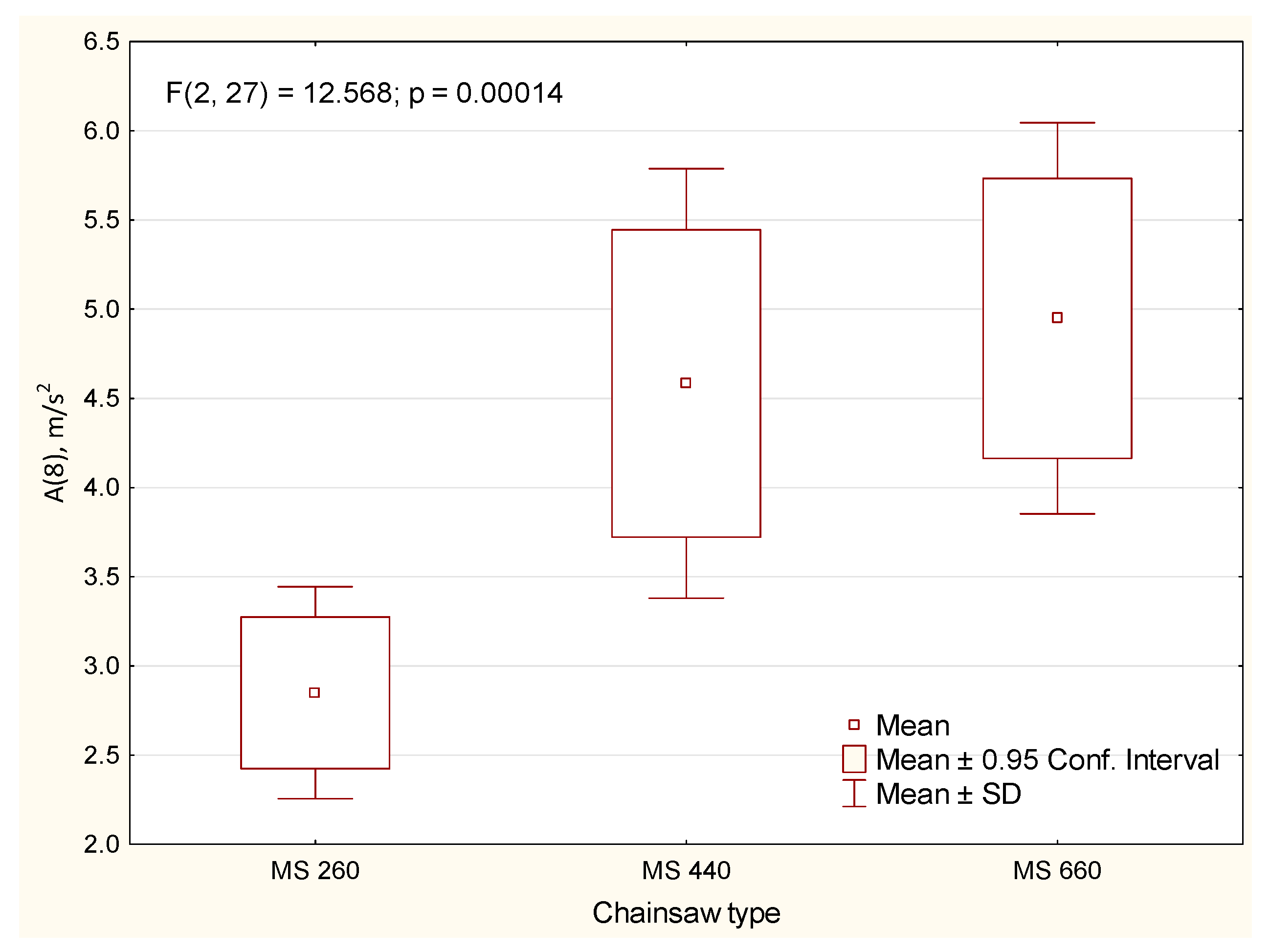

ANOVA test was also used to test the difference of simulated daily exposure A(8) value among three groups of chainsaw type. Levene’s test proved the assumption of homogeneity of variance between data groups by chainsaw type (F = 1.615; p = 0.12) within the daily vibration exposure A(8) value. Statistically significant difference was determined among the groups F (2, 27) = 12.568, p = 0.001 (Figure 2). The second null hypothesis is rejected. Using the Tukey’s post hoc test, conducted testing of the differences showed that the mean A(8) value in group 1 (MS 260; M = 2.85; SD = 0,59; N = 10) is significantly different from group 2 (MS 440; M = 4.58; SD = 1,20; N = 10) and group 3 (MS 660; M = 4.95; SD = 1,10; N = 10). Statistically significant difference was not determined between group 2 and 3 (Figure 2).

Figure 2.

Mean value of A(8) among three groups of chainsaw type.

Standard multiple regression analysis was used to study the effects of changing set of variables (years in use, power and mass) on the dependent variable, which is represented by the simulated daily exposure A(8) value. Conducted analysis resulted in a coefficient of determination R2 = 0.426, which means that the analyzed model, with integrated independent variables, explained 42.6% of variance (Table 4) within the weighted daily exposure A(8) value. Only independent variable, power, showed statistically significant unique contribution (β = 1.6325) that best explains the value of the dependent variable A(8). The remaining two independent variables did not show statistically significant unique contribution, although the variance inflation factor (VIF) for mass and years in use is extremely high. Despite the obtained values, there is no statistical justification that daily vibration exposure A(8) value is related to mass and years in use because, within the model in question, the greatest contribution is from independent variable power (partial R2 = 0.4479) In accordance with the result obtained, the third null hypothesis is rejected.

Table 4.

Regression analysis for dependent variable, daily exposure value A(8).

4. Discussion

Today, many industries still rely on motor-manual or manual work, either as a consequence of a low technological level or because of the unavailability of modern technologies in underdeveloped countries [21]. The Croatian forestry sector, i.e., the harvesting operations, are also characterized by a large share of motor-manual work where more than 85% of prescribed yield in state forests is cut by a chainsaw every year. Accordingly, 14 workers on average per year in Croatian Forests Ltd. are banned from operating a chainsaw due to the development of an occupational disease related to vibration and/or noise exposure [22]. Vibration exposure is an important indicator in defining occupational safety measures in harvesting operations [23].

Every chainsaw in professional forestry in Croatia must undergo an attestation process every three years. Maintenance and replacement of parts must be in accordance with manufacturers’ recommendations.

The results of the research showed that first and the second group of chainsaws (MS 260 and MS 440) have the highest measured vibration values most often on the front handle, while MS 660 chainsaws the highest vibration measured values had on the rear handle (Table 2). A previous study [24] conducted in a similar way to this study on Stihl MS 230 concluded that the greatest vibration values occurred on the rear handle during idling. The sampled MS 260 chainsaws did not exceed the simulated daily exposure A(8) value over the four hours period of effective work. Four MS 440 and four MS 660 sampled chainsaws exceeded the simulated daily exposure A(8) value over the same period in effective work (Table 2).

Statistically significant difference was not determined for simulated A(8) value among the groups by chainsaw years in use. The reason for this is these chainsaws were used in Croatian Forests Ltd. where they are subjected to regular services. However, a statistically significant difference was determined among the groups of chainsaw type, which can be explained with differences in engines and anti-vibration systems (Figure 2). Independent variables (years in use, power and mass), within standard multiple regression analysis (Table 4), explained only 42.6% of variance regarding dependent variable (simulated daily exposure A(8) value). Only power, as independent variable, showed statistically significant unique contribution that best explains the value of the dependent variable. The reason for the foregoing is association between simulated daily exposure A(8) value and power. Chainsaw vibrations come from two main sources, its engine, and interaction of the chain and wood. Furthermore, presented chainsaws were powered by single cylinder two stroke engines, which are poorly balanced in comparison to multi-cylinder four stroke engines. Single-cylinder engines rely on counterweights on the crankshaft to balance the forces from the up-down movement of the piston. It is logical to conclude that in the more powerful engines with higher forces produced, it is harder to sustain engine balance and thus lower vibration emission. Although independent variable, mass, did not show a statistically significant unique contribution to explaining the value of the dependent variable A(8), the inter-correlation coefficient between mass and power is high and positively related due to the simple fact that more powerful engines require more material for the engine itself and the crankcase supporting it.

Given the fact that this paper deals with used chainsaws, a comparison with declared data is not valid. According to Directive 2006/42/EC [25] manufacturers are required to provide the following vibration data transmitted by a portable handheld or manually operated machine: vibration total value to which the hands are exposed, if it exceeds 2.5 m/s2, and measurement uncertainty. According to the data obtained from manufacturers’ catalog, a measurement uncertainty of 2 m/s2 is indicated. Stihl MS 260 has declared vibration total value of 3.1 m/s2 on the front handle and 3.6 m/s2 on the rear handle, which does not coincide with the obtained average vibration total values. The same was observed with the MS 440, which has declared a vibration total value of 4.2 m/s2 on the front handle and 4.5 m/s2 on the rear handle. Average vibration total values are in line with declared vibration total values for MS 660, where vibration magnitude is 6.3 m/s2 on the front handle and 7.3 m/s2 on the rear handle. The difference between obtained results and declared data is almost certainly in different measurement methods and the fact that over the years some chainsaw models had their anti-vibration system upgraded and thus their vibration levels changed. A good example is MS 661 chainsaw, which has superseded MS 660 in Croatian forestry. This chainsaw has higher vibration total values declared on the front handle. Calcante et al. [26] confirms that the reduction in the amount of emissions can be remarkably improved not only with the technological progress of the engine design but above all by adopting advanced fuels that lead to a more efficient combustion process.

The most acceptable way of increasing the aspect of health and safety for chainsaw operators in the Croatian forestry is the application and implementation of technical, legislative and educational measures related to daily vibration exposure. Technical and educational preventive measures are related to operator’s regular maintenance (pre-operating, daily and weekly measures), training, personal safety equipment, etc. Legislative measures are related to safety precautions and safety rules for professional forestry work. Previously mentioned is prescribed by the Ordinance on Occupational Safety and Health in Forestry in each country.

5. Conclusions

All the highest vibration values of tested chainsaws appeared when idling, on the front handle for the group of chainsaws MS 260 and MS 440, while for the group of chainsaws MS 660, the highest values were measured on the rear handle.

The daily vibration exposure A(8) is not affected by the years in the use of the chainsaw.

In the first group (MS 260), there is no chainsaw that exceeds the limit value of 5 m/s2, while in the second (MS 440) and third (MS 660) groups, four chainsaws per group exceed the limit A(8) value. The conclusion is that in the more powerful engines with higher forces produced, it is harder to sustain engine balance and thus lower vibration emission.

Despite the results obtained, which say that daily vibration exposure A(8) is not affected by the years in use, it is necessary to perform vibration measurements of chainsaws after a certain period of use in order to protect the health of workers. This is mainly because most used chainsaws are not properly maintained.

During further research, it is necessary to conduct work and time study studies on the chainsaw in order to determine the time periods during which the worker is loaded with different vibration values. Based on the measurement of vibration on chainsaws after a certain time of use and determining the structure of the working time of workers under different operating conditions, it is necessary to propose models for estimating the daily vibration exposure A(8). With the development of the estimation model, it is possible to determine the need to remove a chainsaw with higher vibration values than permitted.

Author Contributions

Conceptualization, M.L. and M.B.; formal analysis, M.L. and Z.P.; investigation, M.L. and Z.P.; methodology, M.Š.; software, M.L.; supervision, M.Š.; validation, M.Š.; visualization, M.L.; writing—original draft, M.L. and M.B.; writing—review and editing, Z.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

Croatian Forests Ltd., Faculty of Forestry - University of Zagreb and Public Institution of Krka National Park.

Conflicts of Interest

The authors declare no conflict of interest.

References and Notes

- Yovi, E.Y.; Yamada, Y. Addressing Occupational Ergonomics Issues in Indonesian Forestry: Laborers, Operators, or Equivalent Workers. Croat. J. For. Eng. 2019, 40, 351–363. [Google Scholar] [CrossRef]

- EU-OSHA. Occupational Safety and Health in Europe’s Forestry Industry. European Agency for Safety and Health at Work. 2016. Available online: https://osha.europa.eu/en/publications/e-facts/efact29/view (accessed on 28 December 2016).

- Adams, G.; Armstrong, H.; Cosman, M. Independent Forestry Safety Review—An Agenda for Change in the Forestry Sector. 2014. Available online: https://www.nzfoa.org.nz/images/stories/pdfs/safety/20141031finalreportsummary_web_311014.pdf (accessed on 17 December 2019).

- International Labour Organization (ILO). Occupational Safety and Health in Forestry; Report II; Forestry and Wood Industries Committee, Second Session: Geneva, Switzerland, 1991. [Google Scholar]

- International Organization for Standardization UNI EN ISO 11681-1:2011 Machinery for Forestry—Portable Chain-saw Safety Requirements and Testing—Part 1: Chain-Saws for Forest Service; International Organization for Standardization: Geneva, Switzerland, 2011.

- Goglia, V.; Suchomel, J.; Žgela, J.; Dukić, I. Forestry workers’ expossure to vibration in the context of Directive 2002/44/EC. Šum List 2012, 136, 283–289. [Google Scholar]

- Kacian, N. Occupational diseases in Croatia. Work Saf. 1999, 3, 83–89. [Google Scholar]

- McGeoch, K.L.; Lawson, I.J.; Burke, F.; Proud, G.; Miles, J. Diagnostic criteria and staging of hand-arm vibration syndrome in the United Kingdom. Ind. Health 2005, 43, 527–534. [Google Scholar] [CrossRef] [PubMed]

- Goglia, V.; Suchomel, J.; Žgela, J.; Dukić, I. The effectiveness of forest pre-commercial thinning in the context of Directive 2002/44/EC. Šum List 2012, 136, 471–478. [Google Scholar]

- Malinowska-Borowska, J.; Harazin, B.; Zieliński, G. The influence of wood hardness and logging operation on coupling forces exerted by lumberjacks during wood harvesting. Int. J. Ind. Ergon. 2011, 41, 546–550. [Google Scholar] [CrossRef]

- Malinowska-Borowska, J.; Harazin, B.; Zieliński, G. Measuring coupling forces woodcutters exert on saws in real working conditions. Int. J. Occup. Saf. Ergon. 2012, 18, 77–83. [Google Scholar] [CrossRef] [PubMed]

- Malinowska-Borowska, J.; Zieliński, G. Coupling forces exerted on chain saws by inexperienced tree fellers. Int. J. Ind. Ergon. 2013, 43, 283–287. [Google Scholar] [CrossRef]

- Rottensteiner, C.; Stampfer, K. Evaluation of operator vibration exposure to chainsaws equipped with a Kesper safety bar. Scand. J. For. Res. 2013, 28, 193–200. [Google Scholar] [CrossRef]

- Rottensteiner, C.; Tsioras, P.; Stampfer, K. Wood density impact on hand-arm vibration. Croat. J. For. Eng. 2012, 33, 303–312. [Google Scholar]

- Goglia, V.; Žgela, J.; Dukić, I. The effectiveness of anti-vibration gloves: Part I. Šum List 2008, 132, 115–119. [Google Scholar]

- Goglia, V.; Žgela, J.; Dukić, I. The effectiveness of anti-vibration gloves: Part II. Šum List 2008, 132, 239–244. [Google Scholar]

- Ordinance on Occupational Safety and Health in Forestry (Official Gazette No. 10/86).

- International Organization for Standardization UNI EN ISO 5349-1:2001 Mechanical Vibration—Measurement and Evaluation of Human Exposure to Hand- Transmitted Vibration—Part 1: General Requirements; International Organization for Standardization: Geneva, Switzerland, 2001.

- Ordinance on the Protection against Exposure to Vibration Risks (Official Gazette No. 155/2008).

- European Parliament, Council of the European Union: Directive 2002/44/EC—Vibration; Joint Statement by the European Parliament and the Council: Brussels, Belgium, 2002.

- Landekić, M.; Katuša, S.; Mijoč, D.; Šporčić, M. Assessment and Comparison of Machine Operators’ Working Posture in Forest Thinning. South-East Eur. For. 2019, 10, 29–37. [Google Scholar] [CrossRef]

- Annual Business Report, 2015–2018: Croatian Forest Ltd. Annual Business Report. Available online: https://www.hrsume.hr/index.php/hr/godisnja-poslovna-izvjesca (accessed on 17 December 2019).

- EU Good Practice Guide for Hand-Arm Vibration. 2006. Available online: Resource.isvr.soton.ac.uk/HRV/VIBGUIDE/HAV%20Good%20practice%20Guide%20V7.7%20English%20260506.pdf (accessed on 17 December 2019).

- Feyzi, M.; Jafari, A.; Ahmadi, H. Investigation and analysis the vibration of handles of chainsaw without cutting. J. Agric. Mach. 2016, 6, 90–101. [Google Scholar]

- European Parliament. Council of the European Union: Directive 2006/42/EC—New Machinery Directive; Joint Statement by the European Parliament and the Council: Brussels, Belgium, 2006.

- Calcante, A.; Facchinetti, D.; Pessina, D. Analysis of Hazardous Emissions of Hand-Operated Forestry Machines Fuelled with Standard Mix or Alkylate Gasoline. Croat. J. For. Eng. 2018, 39, 109–116. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).