Wood Properties Characterisation of Thermo-Hydro Mechanical Treated Plantation and Native Tasmanian Timber Species

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Thermo-Hydro Mechanical (THM) Treatment and Preheating Treatment

2.3. Physical Tests

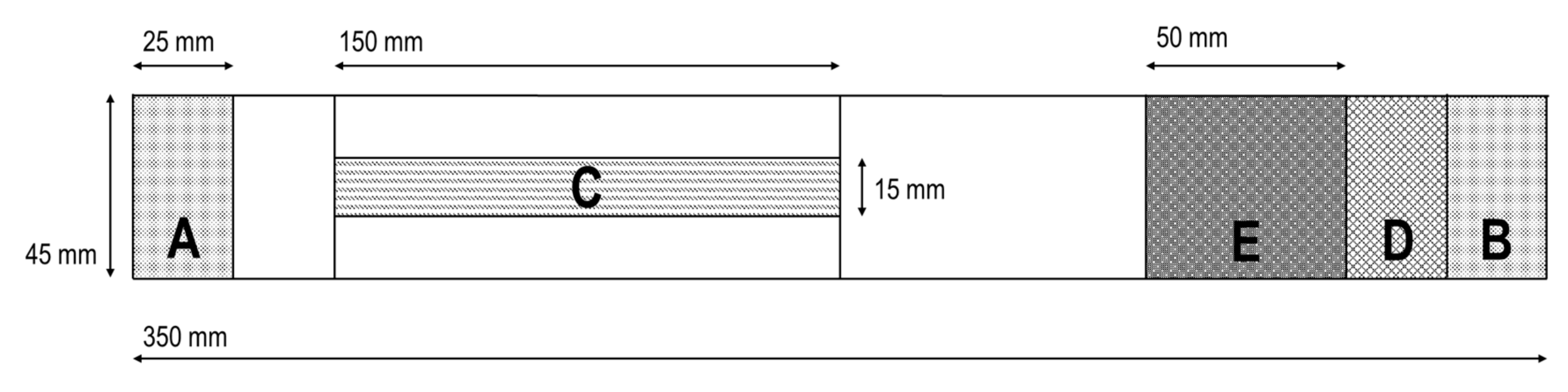

2.4. Mechanical Tests

2.5. Statistical Analysis

3. Results and Discussion

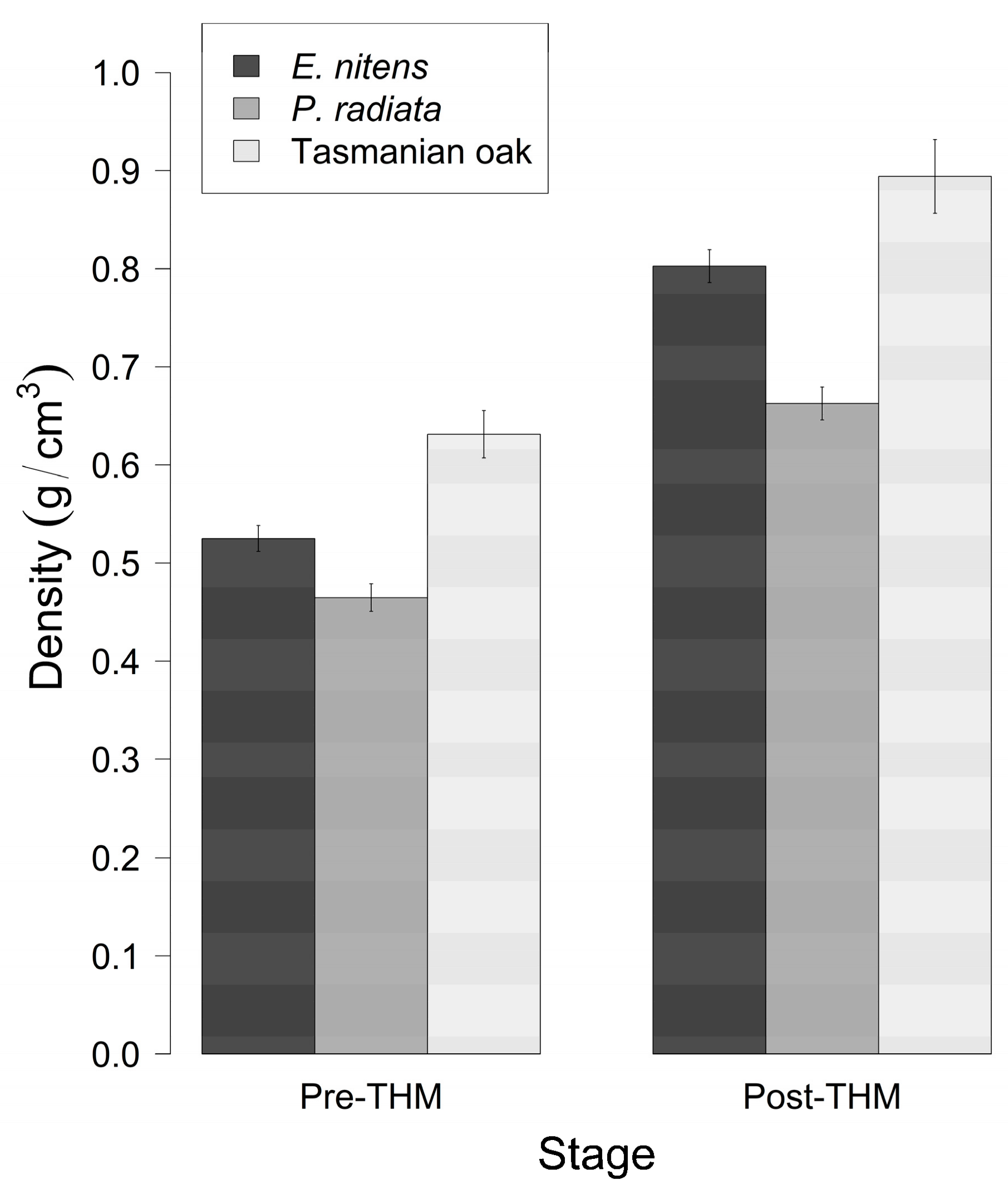

3.1. Densification of the Material

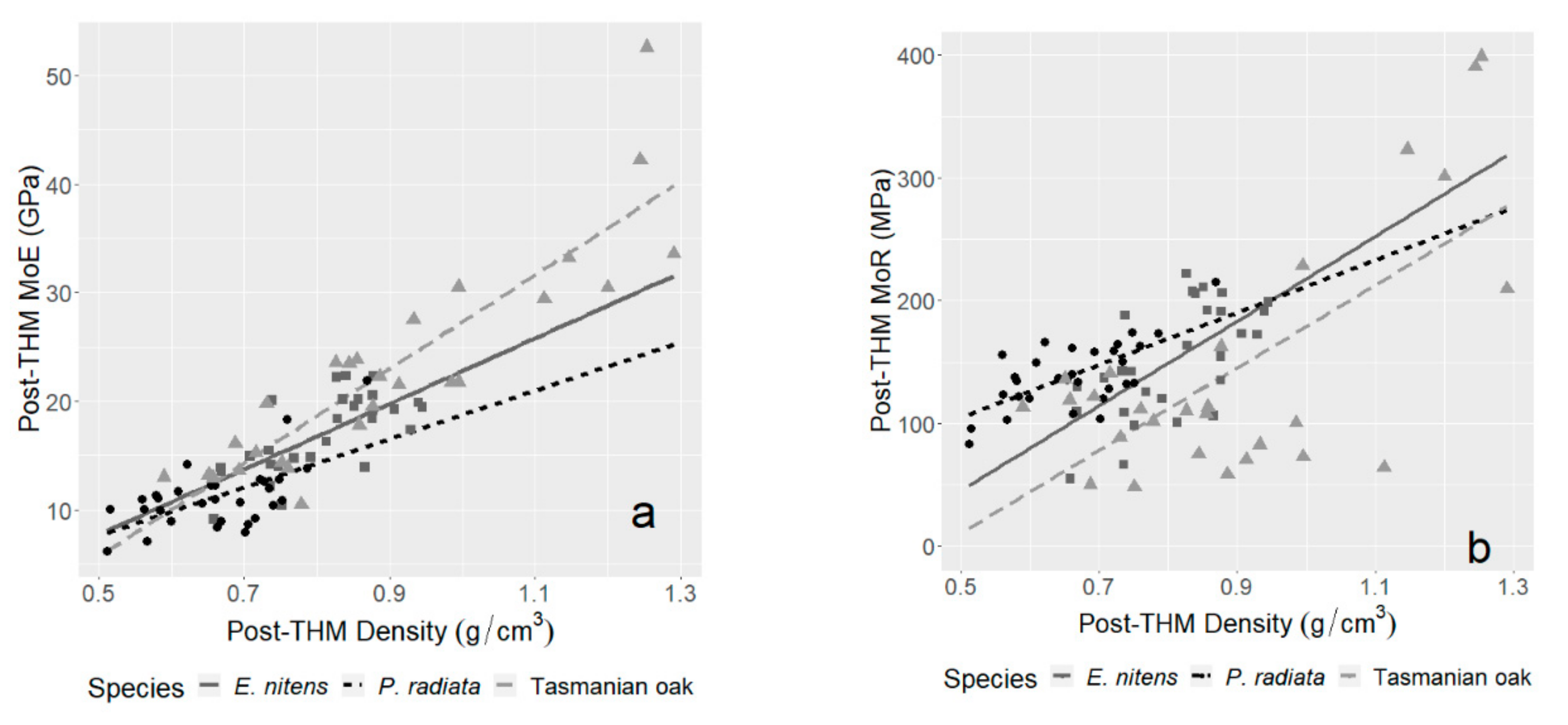

3.2. Mechanical Properties

3.3. Compression Degree, Springback, and Mass Loss

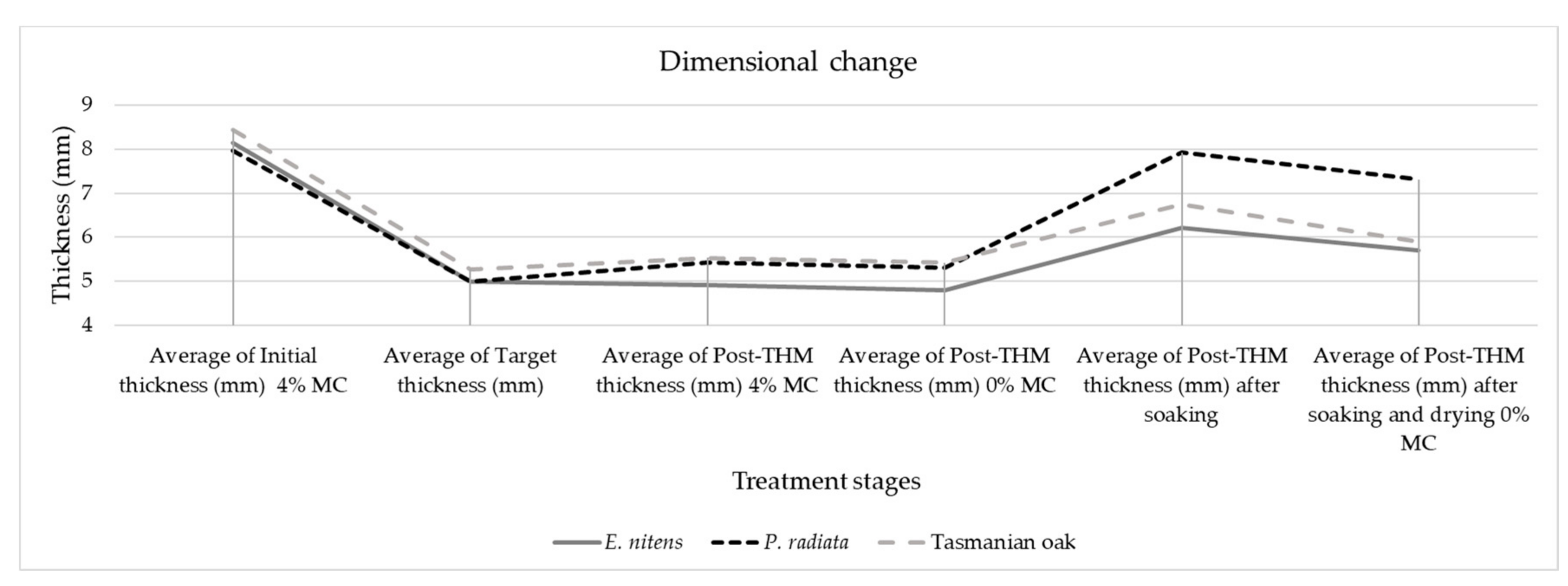

3.4. Dimensional Changes

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Payn, T.; Carnus, J.-M.; Freer-Smith, P.; Kimberley, M.; Kollert, W.; Liu, S.; Orazio, C.; Rodriguez, L.; Silva, L.N.; Wingfield, M.J. Changes in planted forests and future global implications. For. Ecol. Manag. 2015, 352, 57–67. [Google Scholar] [CrossRef]

- FAO. Global Forest Resources Assessment 2015—How Are the World’s Forests Changing? Food and Agriculture Organization of the United Nations: Rome, Italy, 2015. [Google Scholar]

- Binkley, D.; Campoe, O.C.; Alvares, C.; Carneiro, R.L.; Cegatta, Í.; Stape, J.L. The interactions of climate, spacing and genetics on clonal Eucalyptus plantations across Brazil and Uruguay. For. Ecol. Manag. 2017, 405, 271–283. [Google Scholar] [CrossRef]

- Derikvand, M.; Kotlarewski, N.; Lee, M.; Jiao, H.; Nolan, G. Characterisation of Physical and Mechanical Properties of Unthinned and Unpruned Plantation-Grown Eucalyptus nitens H. Deane & Maiden Lumber. Forests 2019, 10, 194. [Google Scholar] [CrossRef]

- Hill, C.A.S. Wood Modification: Chemical, Thermal and Other Processes; Wiley Series in Renewable Resources; Wiley: Chichester, UK, 2006; ISBN 978-0-470-02172-9. [Google Scholar]

- Lesar, B.; Humar, M.; Kamke, F.A.; Kutnar, A. Influence of the thermo-hydro-mechanical treatments of wood on the performance against wood-degrading fungi. Wood Sci Technol 2013, 47, 977–992. [Google Scholar] [CrossRef]

- Popescu, M.-C.; Lisa, G.; Froidevaux, J.; Navi, P.; Popescu, C.-M. Evaluation of the thermal stability and set recovery of thermo-hydro-mechanically treated lime (Tilia cordata) wood. Wood Sci. Technol. 2014, 48, 85–97. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A.; Mantanis, G. Wood modification technologies—A review. iForest Biogeosci. For. 2017, 10, 895–908. [Google Scholar] [CrossRef]

- Sandberg, D.; Haller, P.; Navi, P. Thermo-hydro and thermo-hydro-mechanical wood processing: An opportunity for future environmentally friendly wood products. Wood Mater. Sci. Eng. 2013, 8, 64–88. [Google Scholar] [CrossRef]

- Hajihassani, R.; Mohebby, B.; Najafi, S.K.; Navi, P.; Hajihassani, R.; Mohebby, B.; Najafi, S.K.; Navi, P. Influence of combined hygro-thermo-mechanical treatment on technical characteristics of poplar wood. Maderas-Cienc Tecnol. 2018, 20, 117–128. [Google Scholar] [CrossRef]

- Pelit, H.; Yalçın, M. Resistance of mechanically densified and thermally post-treated pine sapwood to wood decay fungi. J. Wood Sci. 2017, 63, 514–522. [Google Scholar] [CrossRef][Green Version]

- Candelier, K.; Thevenon, M.-F.; Petrissans, A.; Dumarcay, S.; Gerardin, P.; Petrissans, M. Control of wood thermal treatment and its effects on decay resistance: A review. Ann. For. Sci. 2016, 73, 571–583. [Google Scholar] [CrossRef]

- Kamperidou, V. The Biological Durability of Thermally- and Chemically-Modified Black Pine and Poplar Wood Against Basidiomycetes and Mold Action. Forests 2019, 10, 1111. [Google Scholar] [CrossRef]

- Bao, M.; Huang, X.; Jiang, M.; Li, N.; Yu, Y.; Yu, W. Study on the changes in surface characteristics of Populus tomentosa due to thermo-hydro-process. J. Wood Sci. 2018, 64, 264–278. [Google Scholar] [CrossRef]

- Pertuzzatti, A.; Missio, A.L.; Cademartori, P.H.G.; Santini, E.J.; Haselein, C.R.; Berger, C.; Gatto, D.A.; Tondi, G. Effect of Process Parameters in the Thermomechanical Densification of Pinus elliottii and Eucalyptus grandis Fast-growing Wood. BioResources 2018, 13, 1576–1590. [Google Scholar] [CrossRef]

- Guo, F.; Huang, R.; Lu, J.; Chen, Z.; Cao, Y. Evaluating the effect of heat treating temperature and duration on selected wood properties using comprehensive cluster analysis. J. Wood Sci. 2014, 60, 255–262. [Google Scholar] [CrossRef]

- Kutnar, A.; Sernek, M. Densification of wood. Zb. Gozdarstva Lesar. 2007, 82, 53–62. [Google Scholar]

- Kutnar, A.; Kamke, F.A. Influence of temperature and steam environment on set recovery of compressive deformation of wood. Wood Sci. Technol. 2012, 46, 953–964. [Google Scholar] [CrossRef]

- Bao, M.; Huang, X.; Jiang, M.; Yu, W.; Yu, Y. Effect of thermo-hydro-mechanical densification on microstructure and properties of poplar wood (Populus tomentosa). J. Wood Sci. 2017, 63, 591–605. [Google Scholar] [CrossRef]

- Zhou, Q.; Chen, C.; Tu, D.; Zhu, Z.; Li, K. Surface Densification of Poplar Solid Wood: Effects of the Process Parameters on the Density Profile and Hardness. BioResources 2019, 14, 4814–4831. [Google Scholar] [CrossRef]

- Sadatnezhad, S.; Khazaeian, A.; Sandberg, D.; Tabarsa, T. Continuous Surface Densification of Wood: A New Concept for Large-scale Industrial Processing. BioResources 2017, 12, 3122–3132. [Google Scholar] [CrossRef]

- Kutnar, A.; Sandberg, D. Next steps in developing thermally modified timber to meet requirements of European low carbon economy. Int. Wood Prod. J. 2015, 6, 8–13. [Google Scholar] [CrossRef]

- Kutnar, A.; Kamke, F.A.; Sernek, M. The mechanical properties of densified VTC wood relevant for structural composites. Holz Roh Werkst 2008, 66, 439–446. [Google Scholar] [CrossRef]

- Rautkari, L.; Kamke, F.A.; Hughes, M. Density profile relation to hardness of viscoelastic thermal compressed (VTC) wood composite. Wood Sci. Technol. 2011, 45, 693–705. [Google Scholar] [CrossRef]

- Boonstra, M.J.; Blomberg, J. Semi-isostatic densification of heat-treated radiata pine. Wood Sci. Technol. 2007, 41, 607. [Google Scholar] [CrossRef]

- Li, L.; Gong, M.; Yuan, N.; Li, D. An Optimal Thermo-Hydro-Mechanical Densification (THM) Process for Densifying Balsam Fir Wood. BioResources 2013, 8, 3967–3981. [Google Scholar] [CrossRef][Green Version]

- Unsal, O.; Candan, Z.; Buyuksari, U.; Korkut, S.; Chang, Y.-S.; Yeo, H.-M. Effect of Thermal Compression Treatment on the Surface Hardness, Vertical Density Propile and Thickness Swelling of Eucalyptus Wood Boards by Hot-pressing. J. Korean Wood Sci. Technol. 2011, 39, 148–155. [Google Scholar] [CrossRef]

- Wentzel, M.; González-Prieto, Ó.; Brischke, C.; Militz, H. Physico-mechanical properties of thermally modified Eucalyptus nitens wood for decking applications. Drvna Ind. 2019, 70, 235–245. [Google Scholar] [CrossRef]

- Standards Australia. AS/NZS 1080.3:2000|Timber-Methods of Test-Density; Standards Australia/Standards New Zealand: Strathfield, Australia, 2000. [Google Scholar]

- Standards Australia. AS/NZS 1080.1:2012|Timber-Methods of Test Moisture Content; Standards Australia/Standards New Zealand: Sydney, Australia, 2012. [Google Scholar]

- Laine, K.; Rautkari, L.; Hughes, M.; Kutnar, A. Reducing the set-recovery of surface densified solid Scots pine wood by hydrothermal post-treatment. Eur. J. Wood Prod. 2013, 71, 17–23. [Google Scholar] [CrossRef]

- DIN-Deutsches Institut für Normung. DIN 52192:1979-05 Prüfung von Holz. Druckversuch quer zur Faserrichtung (Testing of Wood; Compression Test Perpendicular to Grain); Deutsches Institut für Normung: Berlin, Germany, 1979. [Google Scholar]

- CEN-European Committee for Standardization. EN 1534 Wood and Parquet Flooring-Determination of Resistance to Indentation (Brinell)-Test Method; European Committee for Standardization: Brussels, Belgium, 2000. [Google Scholar]

- Tukey, J.W. Exploratory Data Analysis; Addison-Wesley Publishing Company: Reading, MA, USA, 1977; ISBN 978-0-201-07616-5. [Google Scholar]

- Wentzel, M.; Fleckenstein, M.; Hofmann, T.; Militz, H. Relation of chemical and mechanical properties of Eucalyptus nitens wood thermally modified in open and closed systems. Wood Mater. Sci. Eng. 2019, 14, 165–173. [Google Scholar] [CrossRef]

- de Cademartori, P.H.G.; Missio, A.L.; Mattos, B.D.; Gatto, D.A.; de Cademartori, P.H.G.; Missio, A.L.; Mattos, B.D.; Gatto, D.A. Effect of thermal treatments on technological properties of wood from two Eucalyptus species. Anais Acad. Bras. Ciências 2015, 87, 471–481. [Google Scholar] [CrossRef]

- Knapic, S.; Santos, J.; Santos, J.A.D.; Pereira, H. Natural durability assessment of thermo-modified young wood of eucalyptus. Maderas-Cienc. Tecnol. 2018, 20, 489–498. [Google Scholar] [CrossRef]

- Esteves, B.M.; Pereira, H.M. Wood modification by heat treatment: A review. BioResources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Ulker, O.; Imirzi, O.; Burdurlu, E. The effect of densification temperature on some physical and mechanical properties of Scots Pine ( Pinus sylvestries L.). BioResources 2012, 7, 5581–5592. [Google Scholar] [CrossRef]

- Kariz, M.; Kuzman, M.K.; Sernek, M.; Hughes, M.; Rautkari, L.; Kamke, F.A.; Kutnar, A. Influence of temperature of thermal treatment on surface densification of spruce. Eur. J. Wood Prod. 2017, 75, 113–123. [Google Scholar] [CrossRef]

- Rautkari, L.; Laine, K.; Kutnar, A.; Medved, S.; Hughes, M. Hardness and density profile of surface densified and thermally modified Scots pine in relation to degree of densification. J. Mater. Sci. 2013, 48, 2370–2375. [Google Scholar] [CrossRef]

- Gong, M.; Lamason, C. Improvement of Surface Properties of Low Density Wood: Mechanical Modification with Heat Treatment (Project No. UNB57); University of New Brunswick: Fredericton, NB, Canada, 2007. [Google Scholar]

- Gong, M.; Nakatani, M.; Yang, Y.; Afzal, M.T. Maximum Compression Ratios of Softwoods Produced in Eastern Canada. In Proceedings of the 9th World Conference on Timber Engineering, Portland, OR, USA, 6–10 August 2006; p. 7. [Google Scholar]

- Laine, K.; Segerholm, K.; Wålinder, M.; Rautkari, L.; Hughes, M. Wood densification and thermal modification: Hardness, set-recovery and micromorphology. Wood Sci. Technol. 2016, 50, 883–894. [Google Scholar] [CrossRef]

- Fries, A.; Ericsson, T. Genetic parameters for early wood and latewood densities and development with increasing age in Scots pine. Ann. For. Sci. 2009, 66, 404. [Google Scholar] [CrossRef]

- Esteves, B.; Marques, A.V.; Domingos, I.; Pereira, H. Influence of steam heating on the properties of pine (Pinus pinaster) and eucalypt (Eucalyptus globulus) wood. Wood Sci. Technol. 2006, 41, 193. [Google Scholar] [CrossRef]

- Zaman, A.; Alén, R.; Kotilainen, R. Thermal Behavior of Scots Pine (Pinus Sylvestris) and Silver Birch (Betula Pendula) at 200–230°. Wood Fiber. Sci. 2007, 32, 138–143. [Google Scholar] [CrossRef]

- Lovaglio, T.; Gindl-Altmutter, W.; Meints, T.; Moretti, N.; Todaro, L. Wetting Behavior of Alder (Alnus cordata (Loisel) Duby) Wood Surface: Effect of Thermo-Treatment and Alkyl Ketene Dimer (AKD). Forests 2019, 10, 770. [Google Scholar] [CrossRef]

- Alén, R.; Kotilainen, R.A.; Zaman, A.U. Thermochemical behaviour of Norway spruce (Picea abies) at 180–225 °C. Wood Sci. Technol. 2002, 36, 163–171. [Google Scholar] [CrossRef]

- Hillis, W.E. Chemical aspects of heartwood formation. Wood Sci. Technol. 1968, 2, 241–259. [Google Scholar] [CrossRef]

- Morais, M.C.; Pereira, H. Variation of extractives content in heartwood and sapwood of Eucalyptus globulus trees. Wood Sci. Technol. 2012, 46, 709–719. [Google Scholar] [CrossRef]

| Species | Initial Thickness (mm) | Compressed Thickness (mm) | Densification Ratio (%) | Density (g/cm3) | ||||

|---|---|---|---|---|---|---|---|---|

| Target | Actual | Target | Actual | Target | Actual | Before Treatment | After Treatment | |

| E. nitens | 8.0 | 8.17 (0.14) | 5.0 | 4.86 (0.03) | 38.8 | 40.5 (1.19) | 0.52 (0.07) a | 0.80 (0.09) d * |

| P. radiata | 8.0 | 7.99 (0.25) | 5.0 | 5.29 (0.44) | 37.3 | 33.8 (5.84) | 0.46 (0.07) b | 0.66 (0.09) e * |

| Tasmanian oak | 8.0 | 8.44 (0.65) | 5.0 | 5.37 (0.53) | 37.3 | 36.2 (6.81) | 0.63 (0.12) c | 0.89 (0.19) d * |

| Species | MoE (GPa) | MoR (MPa) | HB (N/mm2) | |||

|---|---|---|---|---|---|---|

| Before Treatment | After Treatment | Before Treatment | After Treatment | Before Treatment | After Treatment | |

| E. nitens | 13.41 (1.46) | 17.03 (3.56) * | 135.36 (25.86) | 151.9 (45.3) | 11.98 (3.03) | 23.22 (9.51) * |

| P. radiata | 11.67 (1.15) | 11.24 (3.04) | 115.86 (13.56) | 139.51 (27.1) * | 12.27 (3.54) | 18.39 (6.56) * |

| Tasmanian oak | 17.08 (1.05) | 22.87 (9.62) | 165.94 (5.17) | 144.07 (97.22) | 12.92 (1.75) | 21.18 (7.75) * |

| Dependent Variable | Species | Linear Regression Model | Coefficient of Determination (R2) | p Value |

|---|---|---|---|---|

| MoE (GPa) | E. nitens | 0.47 | *** | |

| P. radiata | 0.36 | *** | ||

| Tasmanian oak | 0.78 | *** | ||

| MoR (MPa) | E. nitens | 0.37 | *** | |

| P. radiata | 0.42 | *** | ||

| Tasmanian oak | 0.44 | *** |

| Species | Compression Degree (%) | Average Springback (%) | Mass Loss (%) |

|---|---|---|---|

| E. nitens | 68.2 a | −4.52 c | 2.42 (1.18) e |

| P. radiata | 52.1 b | 9.57 d | 3.60 (0.31) f |

| Tasmanian oak | 58.3 b | 2.49 cd | 4.13 (1.72) gf |

| Species | Thickness Swelling (%) | Water Absorption (%) | Set-Recovery (%) |

|---|---|---|---|

| E. nitens | 30.0 (17.7) a | 53.4 (10.9) a | 27.5 (7.75) a |

| P. radiata | 50.1 (6.55) b | 99.2 (16.5) b | 75.5 (9.74) b |

| Tasmanian oak | 24.1 (14.8) a | 45.2 (15.5) a | 17.4 (5.83) a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Balasso, M.; Kutnar, A.; Niemelä, E.P.; Mikuljan, M.; Nolan, G.; Kotlarewski, N.; Hunt, M.; Jacobs, A.; O’Reilly-Wapstra, J. Wood Properties Characterisation of Thermo-Hydro Mechanical Treated Plantation and Native Tasmanian Timber Species. Forests 2020, 11, 1189. https://doi.org/10.3390/f11111189

Balasso M, Kutnar A, Niemelä EP, Mikuljan M, Nolan G, Kotlarewski N, Hunt M, Jacobs A, O’Reilly-Wapstra J. Wood Properties Characterisation of Thermo-Hydro Mechanical Treated Plantation and Native Tasmanian Timber Species. Forests. 2020; 11(11):1189. https://doi.org/10.3390/f11111189

Chicago/Turabian StyleBalasso, Michelle, Andreja Kutnar, Eva Prelovšek Niemelä, Marica Mikuljan, Gregory Nolan, Nathan Kotlarewski, Mark Hunt, Andrew Jacobs, and Julianne O’Reilly-Wapstra. 2020. "Wood Properties Characterisation of Thermo-Hydro Mechanical Treated Plantation and Native Tasmanian Timber Species" Forests 11, no. 11: 1189. https://doi.org/10.3390/f11111189

APA StyleBalasso, M., Kutnar, A., Niemelä, E. P., Mikuljan, M., Nolan, G., Kotlarewski, N., Hunt, M., Jacobs, A., & O’Reilly-Wapstra, J. (2020). Wood Properties Characterisation of Thermo-Hydro Mechanical Treated Plantation and Native Tasmanian Timber Species. Forests, 11(11), 1189. https://doi.org/10.3390/f11111189