Particleboards from Recycled Wood

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Wood Particles

2.1.2. Resin and Additives

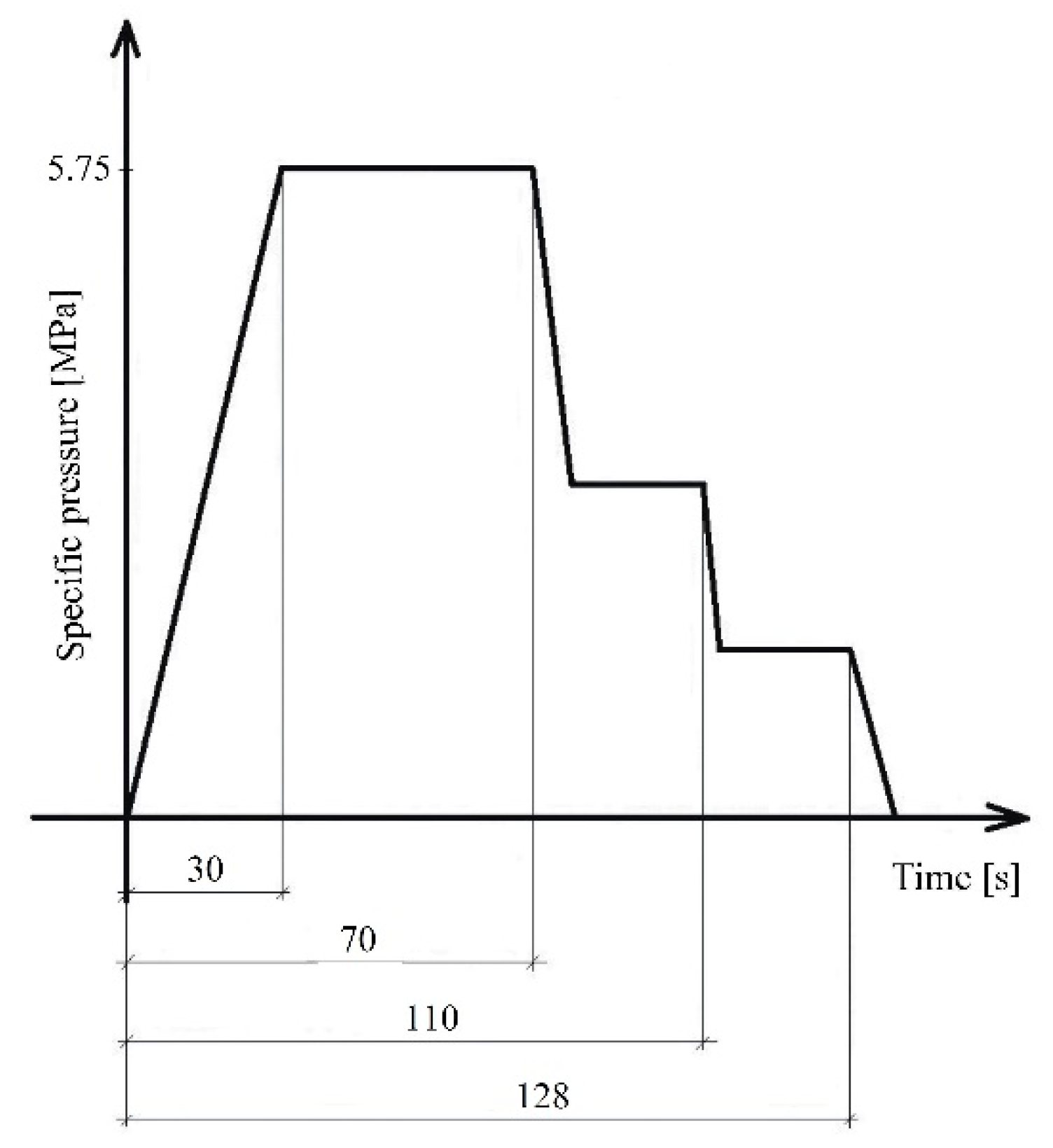

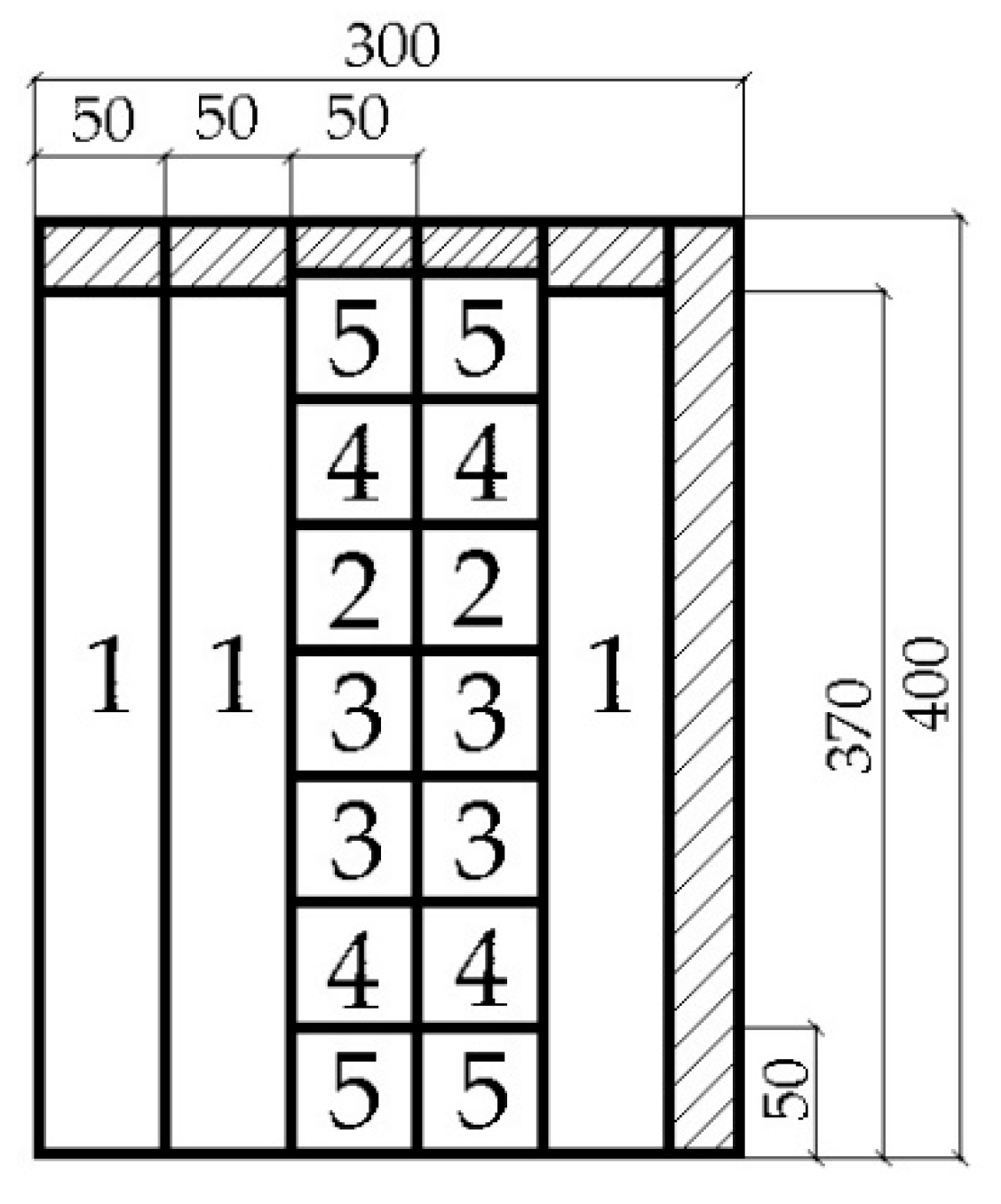

2.2. Particleboard Preparation

2.3. Physical and Mechanical Properties of PBs

2.4. Decay Resistance of PBs

2.5. Statistical Analyses

3. Results and Discussion

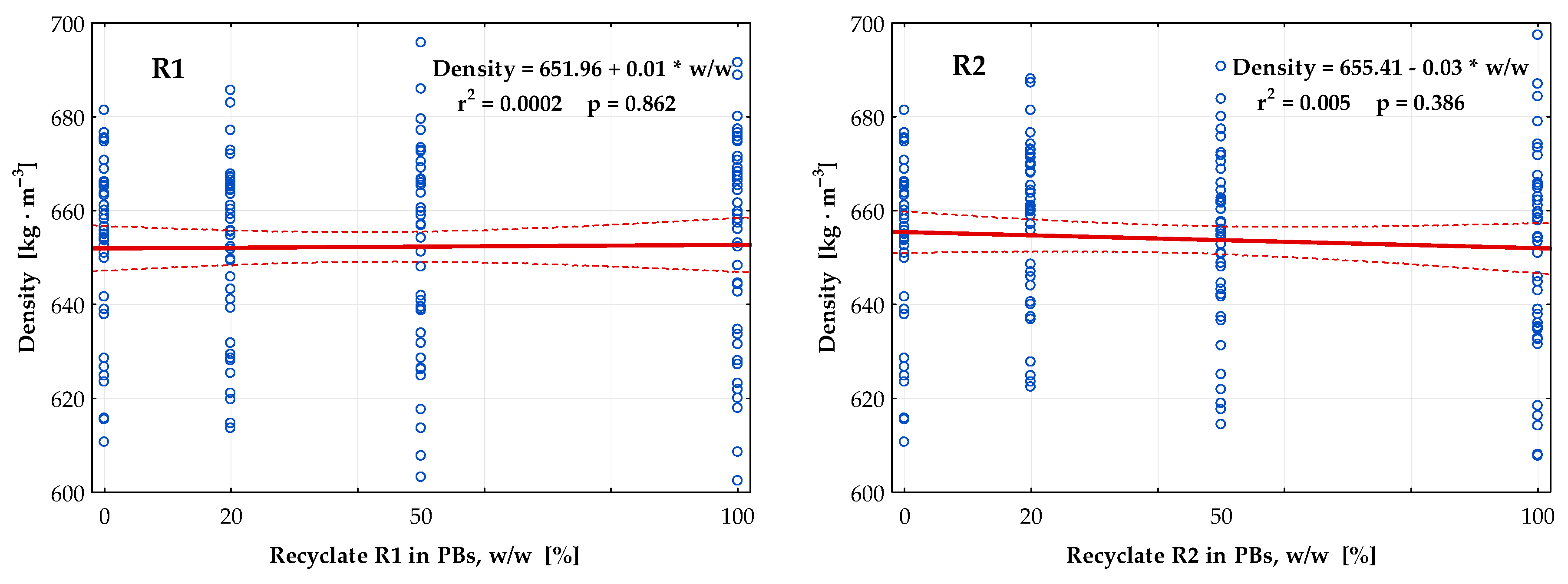

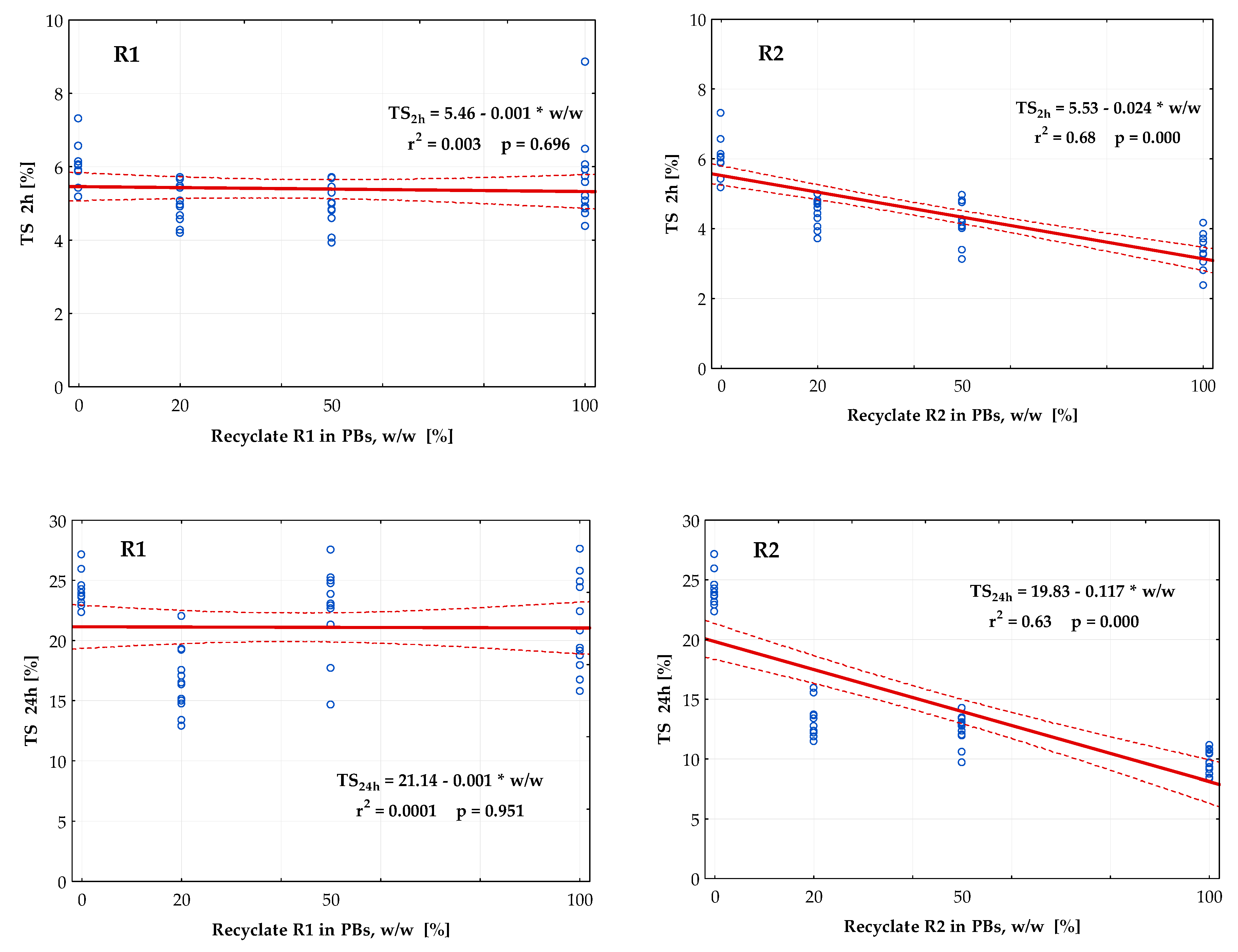

3.1. Physical and Mechanical Properties of PBs

3.2. Biological Resistance of PBs

4. Conclusions

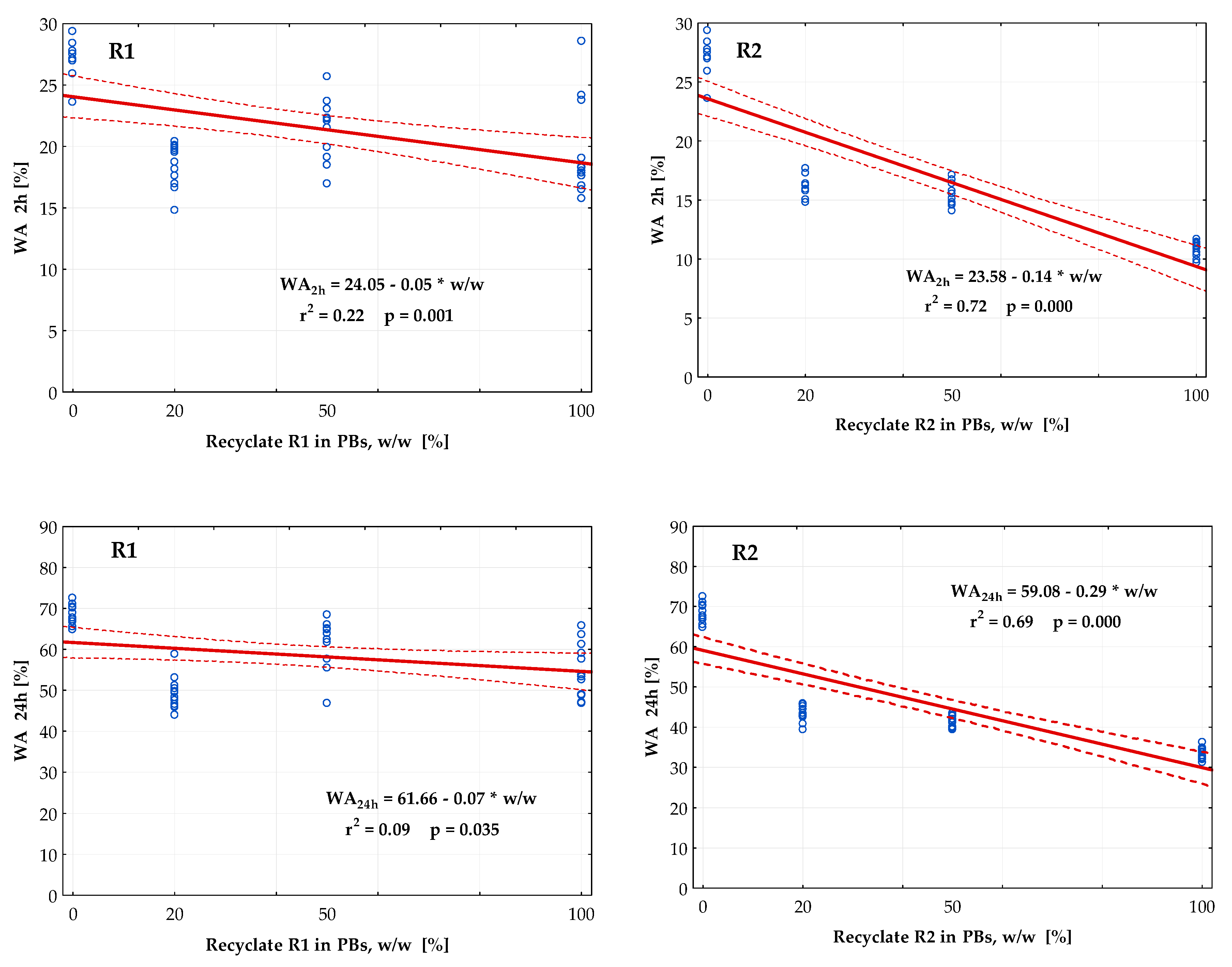

- The thickness swelling (TS) and the water absorption (WA) of PBs prepared from wood recyclates decreased more apparently when using R2 particles prepared from faulty UF-bonded PBs—with a decrease in TS after 24 h by 59% and in WA after 24 h by 51%. This was probably due to the presence of cured UF resin on the surfaces of such recycled wood particles. Adding the R1 particles from the old wood products did not apparently affect the moisture properties of the PBs.

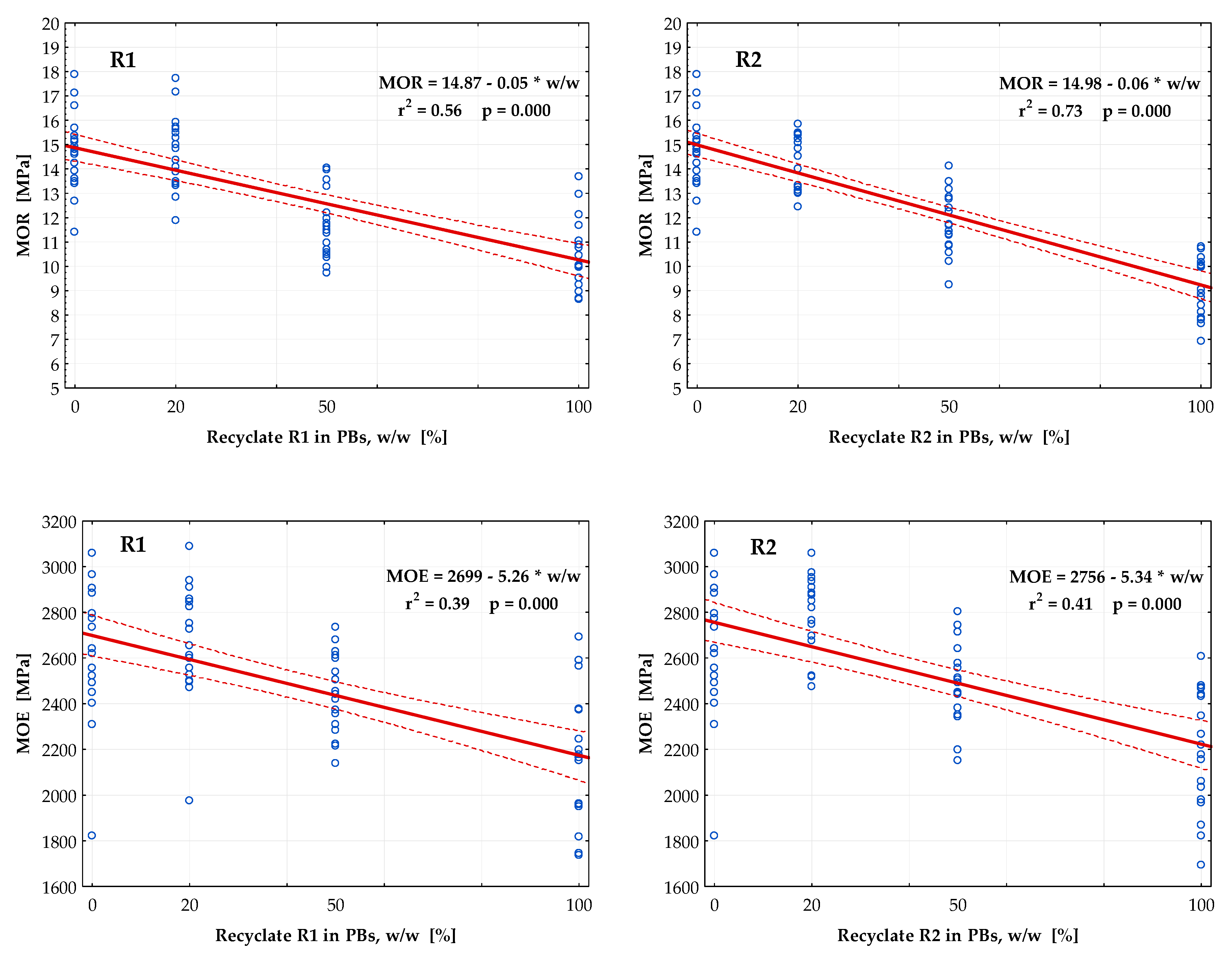

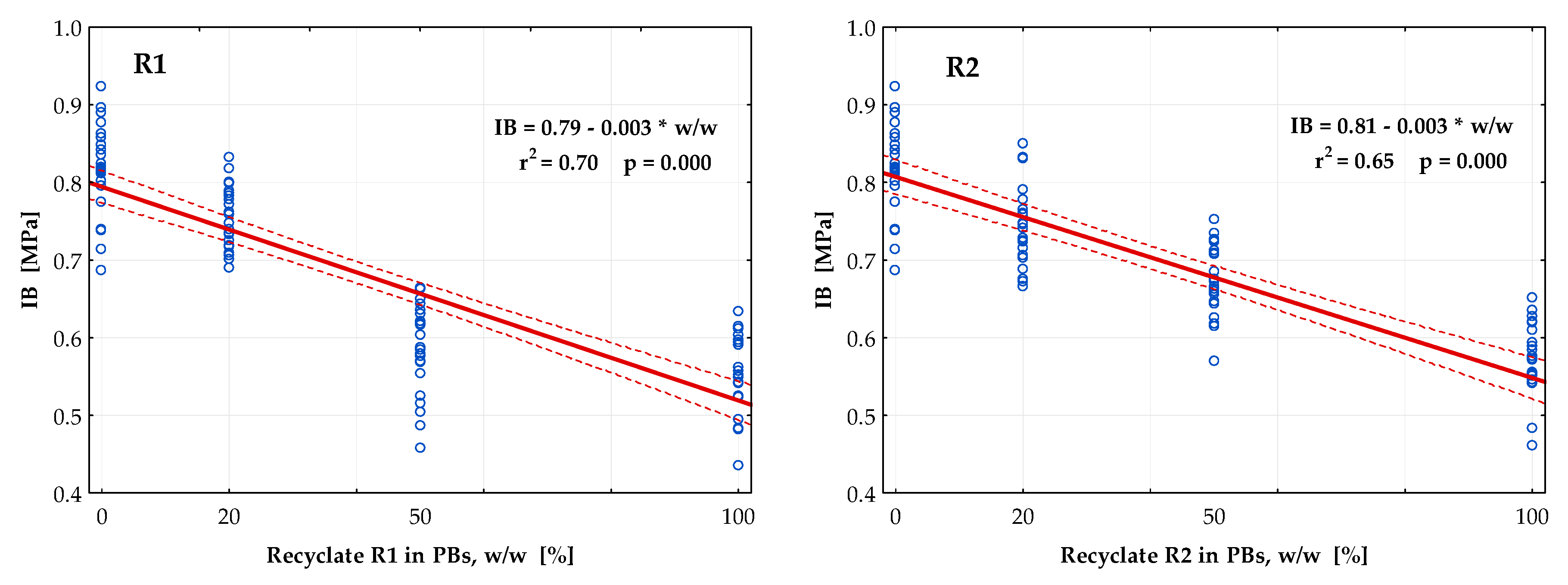

- The modulus of rupture (MOR) in bending, the modulus of elasticity (MOE) in bending, and the internal bond (IB) of the PBs were negatively affected by a larger amount of R1 and R2 recyclates in them. The most apparent decrease in all the tested mechanical properties was shown for the PBs prepared only from recyclates—containing 100% R1 or R2—i.e., there was a decrease in the MOR from 14.7 to 10.6 or 9.30 MPa, a decrease in the MOE from 2637 to 2155 or 2194 MPa, and a decrease in the IB from 0.82 to 0.55 MPa.

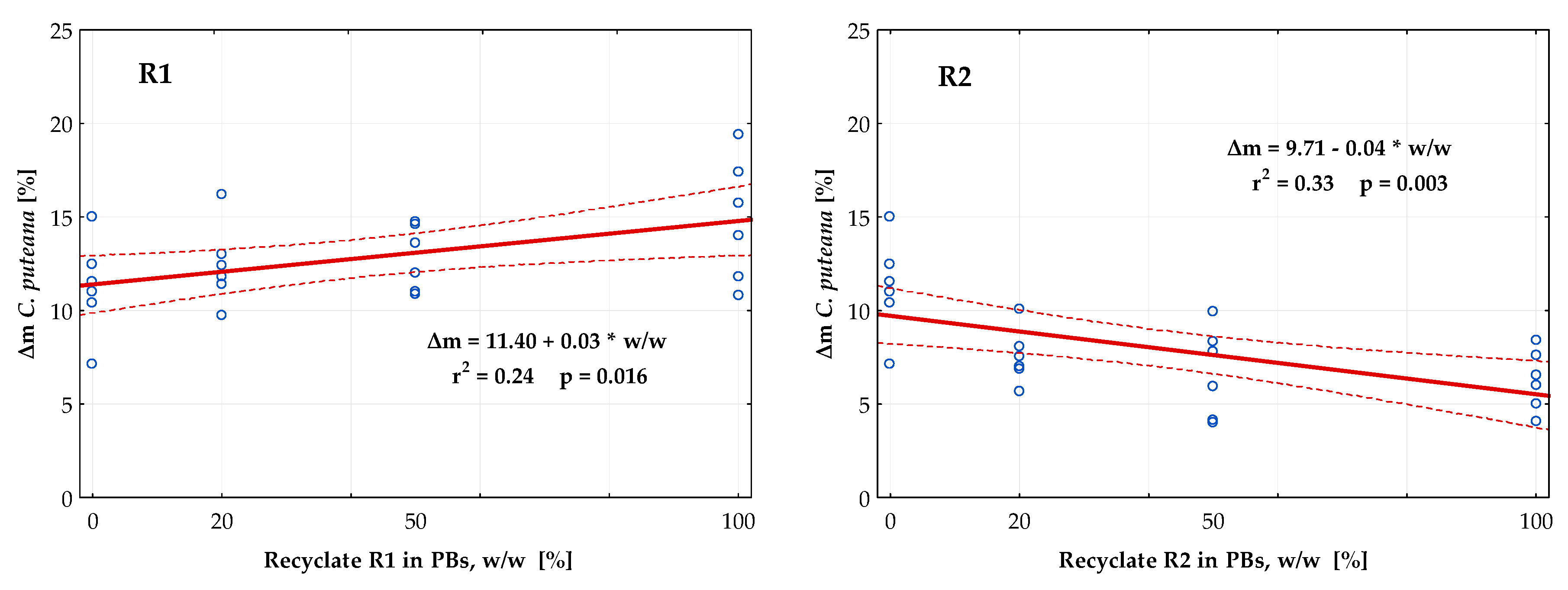

- The biological resistance of PBs to the brown-rot fungus Coniophora puteana decreased in the presence of the R1 recyclate, from the old wood products. On the contrary, the R2 recyclate, from the faulty PBs, evidently suppressed the decay activity of C. puteana in newly prepared PBs. The R2 recyclate had, in this situation, a similar effect as was determined in the case of the moisture properties of the PBs—probably due to the presence of some portion of cured UF resin on its surfaces.

- Adding the suitable types of wood recyclates to PBs is important in terms of economy and the environment as well. Generally, PBs containing wood recyclates could be used for less or more stressed exposures, considering the used type and amount of recyclate content.

- The three-layered UF resin-bonded PBs based on wood recyclates showed sufficient mechanical properties, complying with EN 312 [40], and fulfilled the requirements for particleboard type P2, except in the MOR for PB variants with 100% recyclates.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kollmann, F.F.P.; Kuenzi, E.W.; Stamm, A.J. Principles of Wood Science and Technology, II Wood Based Materials, 1st ed.; Springler: Berlin/Heidelberg, Germany, 1975; p. 703. [Google Scholar]

- Barbu, M.C.; Réh, R.; Çavdar, A.D. Non-wood lignocellulosic composites. In Research Developments in Wood Engineering and Technology, 1st ed.; Aguilera, A., Davim, J.P., Eds.; IGI Global: Hershey PA, USA, 2014; Volume 8, pp. 281–319. [Google Scholar] [CrossRef] [Green Version]

- Nunes, L.; Réh, R.; Barbu, M.C.; Walker, P.; Thomson, A.; Maskell, D.; Knapic, S.; Bajraktari, A.; Greef, J.M.; Brischke, C.; et al. Nonwood bio-based materials. In Performance of Bio-Based Building Materials, 1st ed.; Jones, D., Brischke, C., Eds.; Woodhead Publishing: Duxford, UK, 2017; Volume 3, pp. 97–186. ISBN 978-0-08-100982-6. [Google Scholar]

- Alma, M.H.; Temiz, A.; Kalaycioglu, H. Wood-based panels from alternative raw material. In Performance in Use and New Products of Wood Based Composites, 1st ed.; Fan, M., Ohlmeyer, M., Irle, M., Haelvoet, W., Athanassiadou, E., Rochester, I., Eds.; Brunel University Press: London, UK, 2009; Volume 13, pp. 267–283. ISBN 978-1-902316-75-8. [Google Scholar]

- Maloney, T.M. Modern Particleboard and Dry-Process Fiberboard Manufacturing, 2nd ed.; Miller Freeman: San Francisco, CA, USA, 1993; pp. 626–669. [Google Scholar]

- Deppe, H.J.; Ernst, K. Taschenbuch der Spanplattentechnik, 4th ed.; DRW: Leinfelden-Echterdingen, Germany, 2000; p. 552. ISBN 3-87181-349-4. [Google Scholar]

- Laskowska, A.; Mamiński, M. The properties of particles produced from waste plywood by shredding in a single-shaft shredder. Maderas Cienc. Technol. 2020, 22, 197–204. [Google Scholar] [CrossRef]

- The European Parliament and the Council. Directive 2008/98/EC of the European Parliament and the Council of 19 November 2008 on waste and repealing certain Directives. Off. J. Eur. Union 2008, 51, 3–30. [Google Scholar]

- Réh, R. Wood-Based Particle and Fiber Panel Products, 1st ed.; TU Zvolen: Zvolen, Slovak Republic, 2013; p. 136. ISBN 978-80-228-2498-9. [Google Scholar]

- FAOSTAT. Food and Agriculture Organization of the United Nations. Forestry Production and Trade. Available online: http://www.fao.org/faostat/en/#data/FO (accessed on 18 September 2020).

- Varis, R. (Ed.) Particleboard. In Wood-Based Panels Industry, 1st ed.; Finnish Woodworking Engineers Association: Bookwell Oy, Porvoo, Finland, 2018; Volume 4, pp. 197–223. ISBN 978-952-68627-8-1. [Google Scholar]

- Kharazipour, A.; Kües, U. Recycling of wood composites and solid wood products. In Wood Production, Wood Technology, and Biotechnological Impacts, 1st ed.; Kües, U., Ed.; Universitätsverlag: Göttingen, Germany, 2007; Volume 20, pp. 509–533. ISBN 13: 978-3-940344-11-3. [Google Scholar]

- Wan, H.; Wang, X.M.; Barry, A.; Shen, J. Recycling wood composite panels: Characterizing recycled materials. BioResources 2014, 9, 7554–7565. [Google Scholar] [CrossRef] [Green Version]

- Michanickl, A.; Boehme, C. Process for Recovering Chips and Fibers from Residues of Timber-Derivated Materials, Old Pieces of Furniture, Production Residues, Waste and Other Timber Containing Materials. U.S. Patent 5804035, 8 September 1998. [Google Scholar]

- Roffael, E.; Dix, B.; Behn, C.; Bär, G. Use of UF-bonded recycling particle- and fibreboards in MDF-production. Eur. J. Wood Prod. 2010, 68, 121–128. [Google Scholar] [CrossRef] [Green Version]

- Franke, R.; Roffael, E. Zum recycling von span- und MDF-platten. Teil 1: Über die Hydrolyseresistenz von ausgehärteten Harnstoff-Formaldehydharzen (UF-Harzen) in Span- und mitteldichten Faserplatten (MDF). Holz als Roh-und Werkstoff 1998, 56, 79–82. [Google Scholar] [CrossRef]

- Lykidis, C.; Grigoriou, A. Hydrothermal recycling of waste and performance of the recycled wooden particleboards. Waste Manag. 2008, 28, 57–63. [Google Scholar] [CrossRef]

- Lykidis, C.; Grigoriou, A. Quality characteristics of hydrothermally recycled particleboards using various wood recovery parameters. Int. Wood Prod. J. 2011, 2, 38–43. [Google Scholar] [CrossRef]

- Michanickl, A. Recycling of Laminated Boards. Asian International Laminates Symposium, Hong Kong, China; TAPPI Press: Atlanta, Georgia, USA, 1997; pp. 269–274. [Google Scholar]

- Ye, K.; Yu, W.; Qu, Y. Influence of water thermal treatment on particle form and recyclability of waste particleboard. China Wood Ind. 1998, 6, 7–9. [Google Scholar]

- Roffael, E. Method for Use of Recycled Lignocellulosic Composite Materials. U.S. Patent Application Publication US 2002/0153107 A1, 24 October 2002. [Google Scholar]

- Roffael, E.; Athanassiadou, E.; Mantanis, G. Recycling of particle- and fibreboards using the extruder technique. In Proceedings of the 2nd Conference on Environmental Protection in the Wood Industry (Umweltschutz in der Holzwerkstoffindustrie), Goettingen, Germany, 21–22 March 2002; Georg-August-Universität Göttingen: Goettingen, Germany; pp. 56–65. [Google Scholar]

- Mantanis, G.; Athanassiadou, E.; Nakos, P.; Coutinho, A. A new process for recycling waste fiberboards. In Proceedings of the 38th International Wood Composites Symposium, Washington, DC, USA, 5–8 April 2004; Pullman, Wash.: Washington, DC, USA, 2004; pp. 119–122. [Google Scholar]

- Czarnecki, R.; Dziurka, D.; Łęcka, J. The use of recycled boards as the substitute for particles in the centre layer of particleboards. Electron. J. Pol. Agric. Univ. 2003, 6. Available online: http://www.ejpau.media.pl/volume6/issue2/wood/art-01.html (accessed on 16 September 2020).

- Rowell, R.M.; Spelter, H.; Arola, R.A.; Davis, P.; Friberg, T.; Hemingway, R.W.; Rials, T.; Luneke, D.; Narayan, R.; Simonsen, J.; et al. Opportunities for composites from recycled wastewood-based resources: A problem analysis and research plan. For. Prod. J. 1993, 43, 55–63. [Google Scholar]

- Grigoriou, A. The ecological importance of wood products. Sci. Ann. Dep. For. Nat. Environ. 1996, 39, 703–714. [Google Scholar]

- Ihnát, V.; Lübke, H.; Russ, A.; Borůvka, V. Waste agglomerated wood materials as a secondary raw material for chipboards and fibreboards Part I. Preparation and characterization of wood chips in terms of their reuse. Wood Res. 2017, 62, 45–56. [Google Scholar]

- Ihnát, V.; Lübke, H.; Balberčák, J.; Kuňa, V. Size reduction downcycling of waste wood. Review. Wood Res. 2020, 65, 205–220. [Google Scholar] [CrossRef]

- Werner, F.; Althaus, H.J.; Richter, K. Post-consumer wood in environmental decision-support tools. Schweiz. Z. Forstwes. 2002, 153, 97–106. [Google Scholar] [CrossRef] [Green Version]

- Wilson, J.B. Life-cycle inventory of particleboard in terms of resources, emissions, energy and carbon. Wood Fiber Sci. 2010, 42, 90–106. [Google Scholar]

- Parobek, J.; Paluš, H.; Kaputa, V.; Šupín, M. Analysis of wood flows in Slovakia. BioResoureces 2014, 9, 6453–6462. [Google Scholar] [CrossRef]

- Kutnar, A. Environmental Use of Wood Resources. In Environmental Impacts of Traditional and Innovative Forest-Based Bioproducts. Environmental Footprints and Eco-design of Products and Processes; Kutnar, A., Muthu, S.S., Eds.; Springer: Singapore, 2016; pp. 1–18. ISBN 978-981-10-0653-1. [Google Scholar]

- Ormondroyd, G.A.; Spear, M.J.; Skinner, C. The opportunities and challenges for re-use and recycling of timber and wood products within the construction sector. In Environmental Impacts of Traditional and Innovative Forest-Based Bioproducts. Environmental Footprints and Eco-design of Products and Processes; Kutnar, A., Muthu, S.S., Eds.; Springer: Singapore, 2016; pp. 45–104. ISBN 978-981-10-0653-1. [Google Scholar]

- Gaff, M.; Trgala, K.; Adamová, T. Environmental Benefits of Using Recycled Wood in the Production of Wood-Based Panels, 1st ed.; CZU: Prag, Czech Republic, 2018; pp. 1–51. ISBN 978-80-213-2852-5.

- Irle, M.; Barbu, M.C. Wood-based panel technology. In Wood-Based Panels—An Introduction for Specialists, 1st ed.; Thoemen, H., Irle, M., Sernek, M., Eds.; Brunel University Press: London, UK, 2010; Volume 1, pp. 1–90. ISBN 978-1-902316-82-6. [Google Scholar]

- Laskowska, A.; Mamiński, M. Properties of particleboard produced from post-industrial UF- and PF-bonded plywood. Eur. J. Wood Prod. 2018, 76, 427–435. [Google Scholar] [CrossRef] [Green Version]

- Azambuja, R.R.; Castro, V.G.; Trianoski, R.; Iwakiri, S. Recycling wood waste from construction and demolition to produce particleboards. Maderas Cienc. Technol. 2018, 20, 681–690. [Google Scholar] [CrossRef]

- Weber, C.; Iwakiri, S. Utilization of waste of plywood, MDF, and MDP for the production of particleboards. Ciência Florest. 2015, 25, 405–413. [Google Scholar] [CrossRef] [Green Version]

- Hameed, M.; Rönnols, E.; Bramryd, T. Particleboard based on wood waste material bonded by leftover cakes of rape oil. Part 1: The mechanical and physical properties of particleboard. Holztechnologie 2019, 6, 31–39. [Google Scholar]

- EN 312. Particleboards—Specifications; European Committee for Standardization: Brussels, Belgium, 2010. [Google Scholar]

- EN 827. Adhesives—Determination of Conventional Solids Content and Constant Mass Solids Content; European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- EN ISO 2431. Paints and Varnishes—Determination of Flow Time by Use of Flow Cups (ISO 2431:2019); European Committee for Standardization: Brussels, Belgium, 2019. [Google Scholar]

- EN 1245. Adhesives—Determination of pH; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

- EN 323. Wood-Based Panels—Determination of Density; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- EN 322. Wood-Based Panels—Determination of Moisture Content; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- EN 317. Particleboards and Fibreboards—Determination of Swelling in Thickness after Immersion in Water; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- STN 490164. Particle Boards—Determination of Water Absorption; Slovak Office of Standards, Metrology and Testing: Bratislava, Slovak Republic, 1980. [Google Scholar]

- EN 310. Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- EN 319. Particleboards and Fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board; European Committee for Standardization: Brussels, Belgium, 1993. [Google Scholar]

- ENV 12038. Durability of Wood and Wood-Based Products—Wood-Based Panels—Method of Test for Determining the Resistance against Wood-Destroying Basidiomycetes; European Committee for Standardization: Brussels, Belgium, 2002. [Google Scholar]

- Nourbakhsh, A.; Ashori, A. Particleboard made from waste paper treated with maleic anhydride. Waste Manag. Res. 2010, 28, 51–55. [Google Scholar] [CrossRef] [PubMed]

- Reinprecht, L. Wood Deterioration, Protection and Maintenance, 1st ed.; John Wiley & Sons Ltd.: Chichester, UK, 2016; p. 357. ISBN 978-1-119-10653-1. [Google Scholar]

- EN 350. Durability of Wood and Wood-Based Products—Testing and Classification of the Durability to Biological Agents of Wood and Wood-Based Materials; European Committee for Standardization: Brussels, Belgium, 2016. [Google Scholar]

- Karimi, A.N.; Tajvidi, M.; Pourabbasi, S. Effect of compatibilizer on the natural durability of wood flour/high density polyethylene composites against rainbow fungus (Coriolus versicolor). Polym. Compos. 2007, 28, 273–277. [Google Scholar] [CrossRef]

- Shalbafan, A.; Benthien, J.T.; Lerche, H. Biological characterization of panels manufactured from recycled particleboards using different adhesives. BioResources 2016, 11, 4935–4946. [Google Scholar] [CrossRef]

- Cavdar, A.D.; Tomak, E.D.; Mengeloglu, F. Long-term leaching effect on decay resistance of wood-plastic composites treated with boron compounds. J. Polym. Environ. 2018, 26, 756–764. [Google Scholar] [CrossRef]

- Sen, S.; Ayrilmis, N.; Candan, Z. Fungicide and insecticide properties of cardboard panels made from used beverage carton with veneer overlay. Afr. J. Agric. Res. 2010, 5, 159–165. [Google Scholar]

- Reinprecht, L.; Vidholdová, Z.; Iždinský, J. Particleboards prepared with addition of copper sulphate. Part 1: Biological resistance. Acta Fac. Xylologiae Zvolen 2017, 59, 53–60. [Google Scholar] [CrossRef]

- Reinprecht, L.; Iždinský, J.; Vidholdová, Z. Biological resistance and application properties of particleboards containing nano-zinc oxide. Adv. Mater. Sci. Eng. 2018, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Pizzi, A. Wood products and green chemistry. Ann. For. Sci. 2016, 73, 185–203. [Google Scholar] [CrossRef] [Green Version]

| Quality Parameters | Unit | Method | KRONORES CB 4005 D | KRONORES CB 1637 D |

|---|---|---|---|---|

| Solid content | % | EN 827 [41] | 65.87 | 67.35 |

| Ford cup viscosity, 4 mm/20 °C | s | EN ISO 2431 [42] | 76 | 86 |

| pH value | EN 1245 [43] | 9.08 | 8.62 | |

| Gel time at 100 °C | s | Kronospan chloride test | 81 | 36 |

| Variant | Amount of Recycled Wood in PB, w/w (%) | Number of Produced Boards | Board Type |

|---|---|---|---|

| PB-C: | |||

| 100% particles of spruce wood | 0 | 6 | C |

| PB-R1: | |||

| 20%, 50% or 100% particles from | 20 | 6 | 20 R1 |

| mixture of recycled wood products, | 50 | 6 | 50 R1 |

| combined with 80, 50 or 0% | 100 | 6 | 100 R1 |

| particles of spruce wood | |||

| PB-R2: | |||

| 20%, 50% or 100% particles from | 20 | 6 | 20 R2 |

| faulty PBs, combined with 80, 50 | 50 | 6 | 50 R2 |

| or 0% particles of spruce wood | 100 | 6 | 100 R2 |

| Property of PB | Recyclate R1 in PB w/w (%) | ||||

|---|---|---|---|---|---|

| 0 | 20 | 50 | 100 | ||

| Density | (kg·m−3) | 653 (18.22) | 652 (18.42) | 649 (23.81) | 654 (22.26) |

| Thickness swelling (TS) after 2 h | (%) | 6.05 (0.53) | 4.98 (0.51) | 4.93 (0.56) | 5.65 (1.18) |

| Thickness swelling (TS) after 24 h | (%) | 23.95 (1.39) | 16.57 (2.64) | 22.76 (3.52) | 21.12 (3.83) |

| Water absorption (WA) after 2 h | (%) | 27.59 (2.05) | 18.54 (1.74) | 21.38 (2.42) | 19.55 (3.87) |

| Water absorption (WA) after 24 h | (%) | 68.52 (2.33) | 49.23 (3.95) | 62.02 (6.05) | 54.86 (6.52) |

| Internal bond (IB) | (MPa) | 0.82 (0.06) | 0.75 (0.04) | 0.58 (0.06) | 0.55 (0.06) |

| Modulus of rupture (MOR) | (MPa) | 14.7 (1.57) | 14.7 (1.48) | 11.6 (1.33) | 10.6 (1.40) |

| Modulus of elasticity (MOE) | (MPa) | 2637 (288) | 2666 (246) | 2442 (170) | 2155 (284) |

| Property of PB | Recyclate R2 in PB w/w (%) | ||||

|---|---|---|---|---|---|

| 0 | 20 | 50 | 100 | ||

| Density | (kg·m−3) | 653 (18.22) | 658 (16.53) | 652 (20.10) | 652 (21.63) |

| Thickness swelling (TS) after 2 h | (%) | 6.05 (0.53) | 4.48 (0.40) | 4.19 (0.56) | 3.32 (0.48) |

| Thickness swelling (TS) after 24 h | (%) | 23.95 (1.39) | 13.29 (1.35) | 12.43 (1.26) | 9.72 (0.98) |

| Water absorption (WA) after 2 h | (%) | 27.59 (2.05) | 16.41 (0.95) | 15.35 (0.95) | 10.80 (0.63) |

| Water absorption (WA) after 24 h | (%) | 68.52 (2.33) | 43.43 (1.91) | 41.30 (1.51) | 33.46 (1.44) |

| Internal bond (IB) strength | (MPa) | 0.82 (0.06) | 0.74 (0.05) | 0.68 (0.05) | 0.55 (0.12) |

| Modulus of rupture (MOR) | (MPa) | 14.7 (1.57) | 14.4 (1.18) | 11.8 (1.24) | 9.3 (1.27) |

| Modulus of elasticity (MOE) | (MPa) | 2637 (288) | 2800 (166) | 2486 (173) | 2194 (264) |

| Recyclate Type in PB | Mass Loss of PB Caused by C. puteana (%) Recyclates R1 or R2 in PB w/w (%) | |||

|---|---|---|---|---|

| 0 | 20 | 50 | 100 | |

| R1 | 11.26 (2.57) | 12.43 (2.14) | 12.81 (1.76) | 14.86 (3.30) |

| R2 | 11.26 (2.57) | 7.52 (1.47) | 6.69 (2.40) | 6.26 (1.61) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iždinský, J.; Vidholdová, Z.; Reinprecht, L. Particleboards from Recycled Wood. Forests 2020, 11, 1166. https://doi.org/10.3390/f11111166

Iždinský J, Vidholdová Z, Reinprecht L. Particleboards from Recycled Wood. Forests. 2020; 11(11):1166. https://doi.org/10.3390/f11111166

Chicago/Turabian StyleIždinský, Ján, Zuzana Vidholdová, and Ladislav Reinprecht. 2020. "Particleboards from Recycled Wood" Forests 11, no. 11: 1166. https://doi.org/10.3390/f11111166

APA StyleIždinský, J., Vidholdová, Z., & Reinprecht, L. (2020). Particleboards from Recycled Wood. Forests, 11(11), 1166. https://doi.org/10.3390/f11111166