The Profitability of Cross-Cutting Practices in Butt-Rotten Picea abies Final-Felling Stands

Abstract

:1. Introduction

- (1)

- Cross cut a decayed pulpwood (or energy wood) pole of 3 m for pulping (or energy generation);

- (2)

- Sound short waste pieces (or offcuts or cull pieces).

2. Materials and Methods

2.1. Collection of Time and Motion Data

- (1)

- Automated cross cutting of healthy stem

- (2)

- Manual cross cutting of one pole of 3 m from a butt-rotten stem

- (3)

- Manual sounding of one offcut from a butt-rotten stem

- (4)

- Manual sounding of two offcuts from a butt-rotten stem

- (5)

- Manual sounding of three offcuts from a butt-rotten stem

- (6)

- Manual sounding of four offcuts from a butt-rotten stem

- (7)

- Manual sounding of five offcuts from a butt-rotten stem.

2.2. Detecting Relationship between the Diameter and Height of the Decayed Column

2.3. Data Analysis

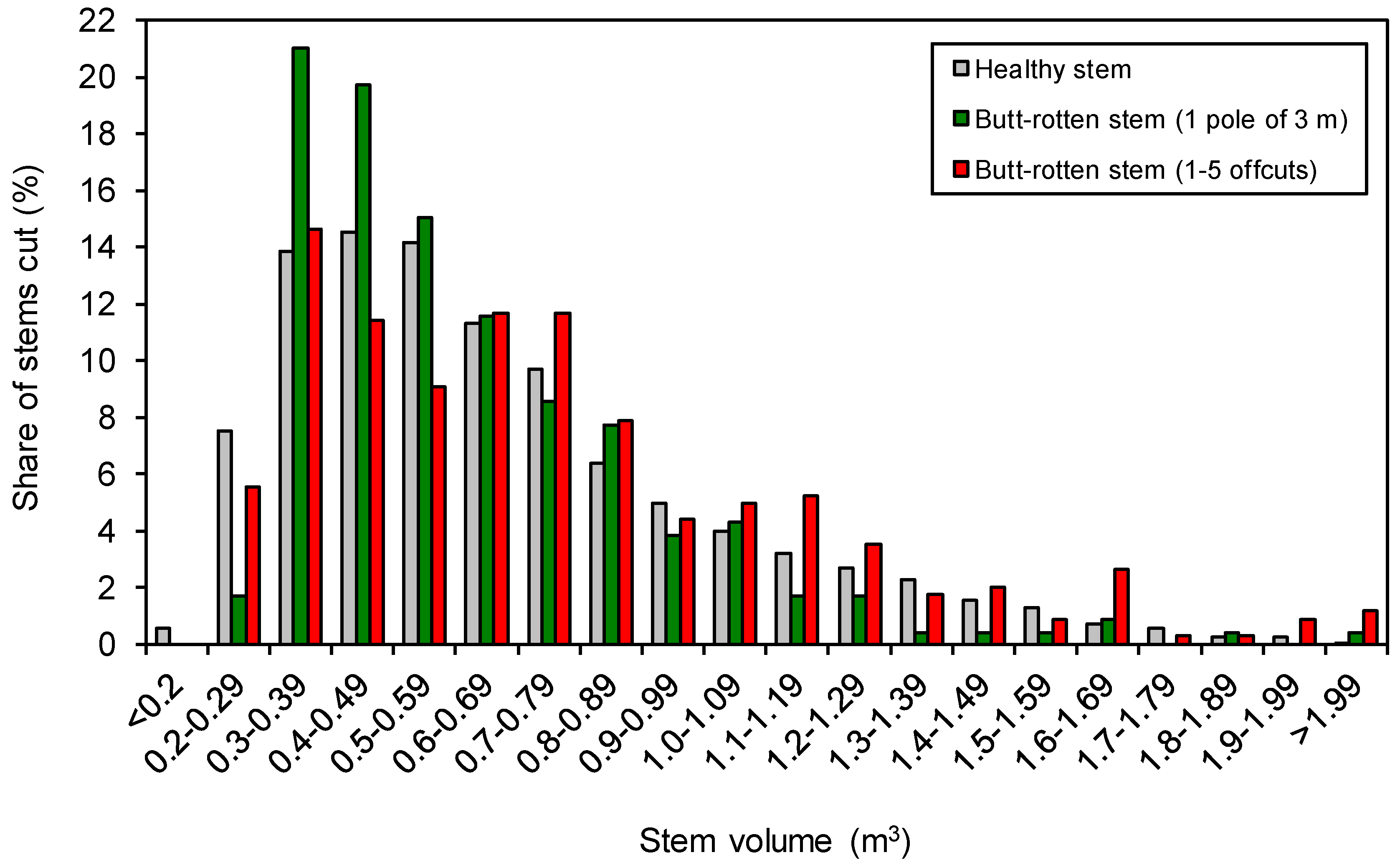

2.4. Description of Study Data

2.5. Modelling Stem Processing Time and Productivity

2.6. Calculating Harvesting Costs

2.7. Modelling of the Sawlog Removal and Value Recovery of the Stem

3. Results

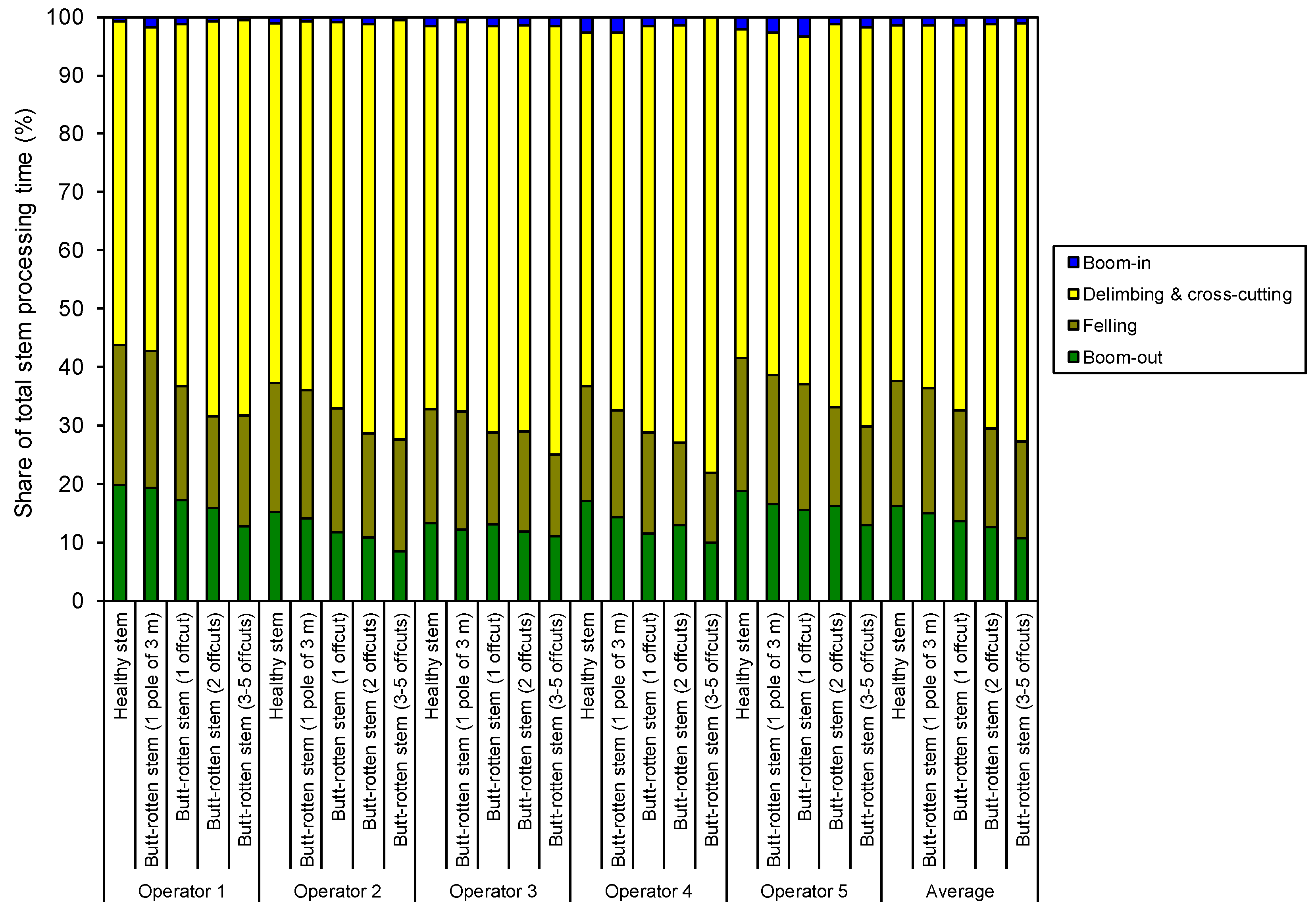

3.1. Time Consumption

3.1.1. Distribution of the Stem Processing Time

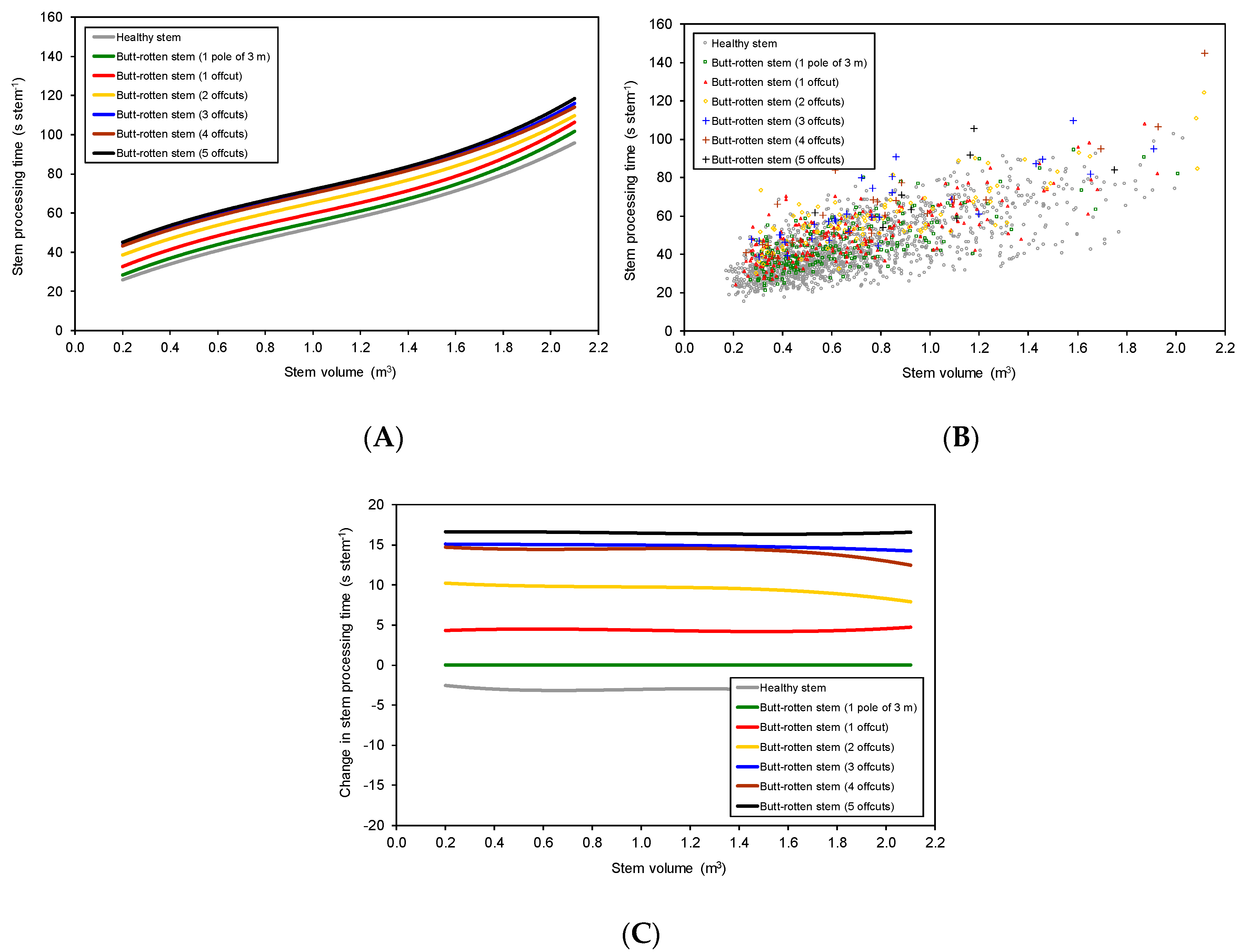

3.1.2. Modeling Stem Processing Time Consumption

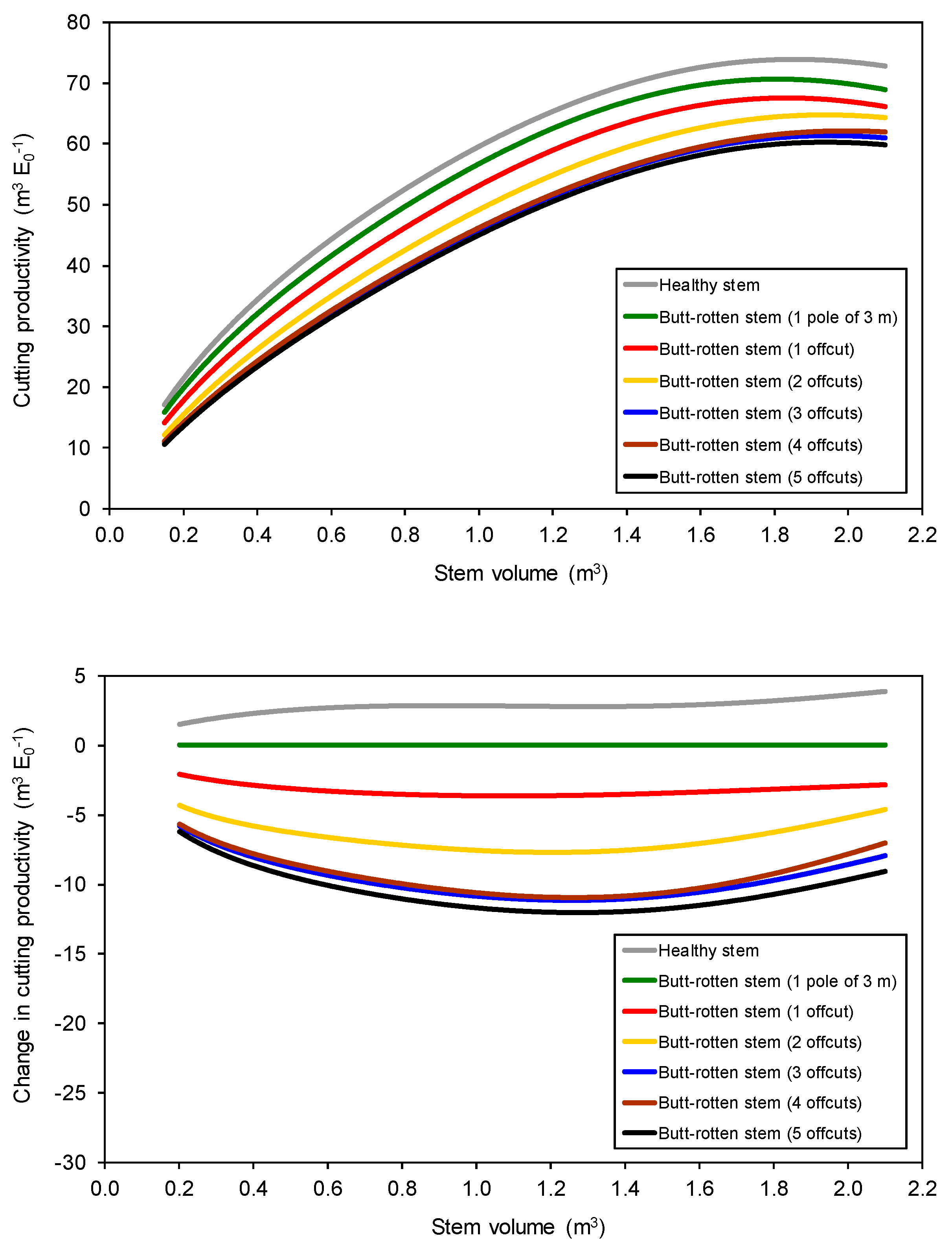

3.2. Cutting Productivity by Using Different Cross-Cutting Practices

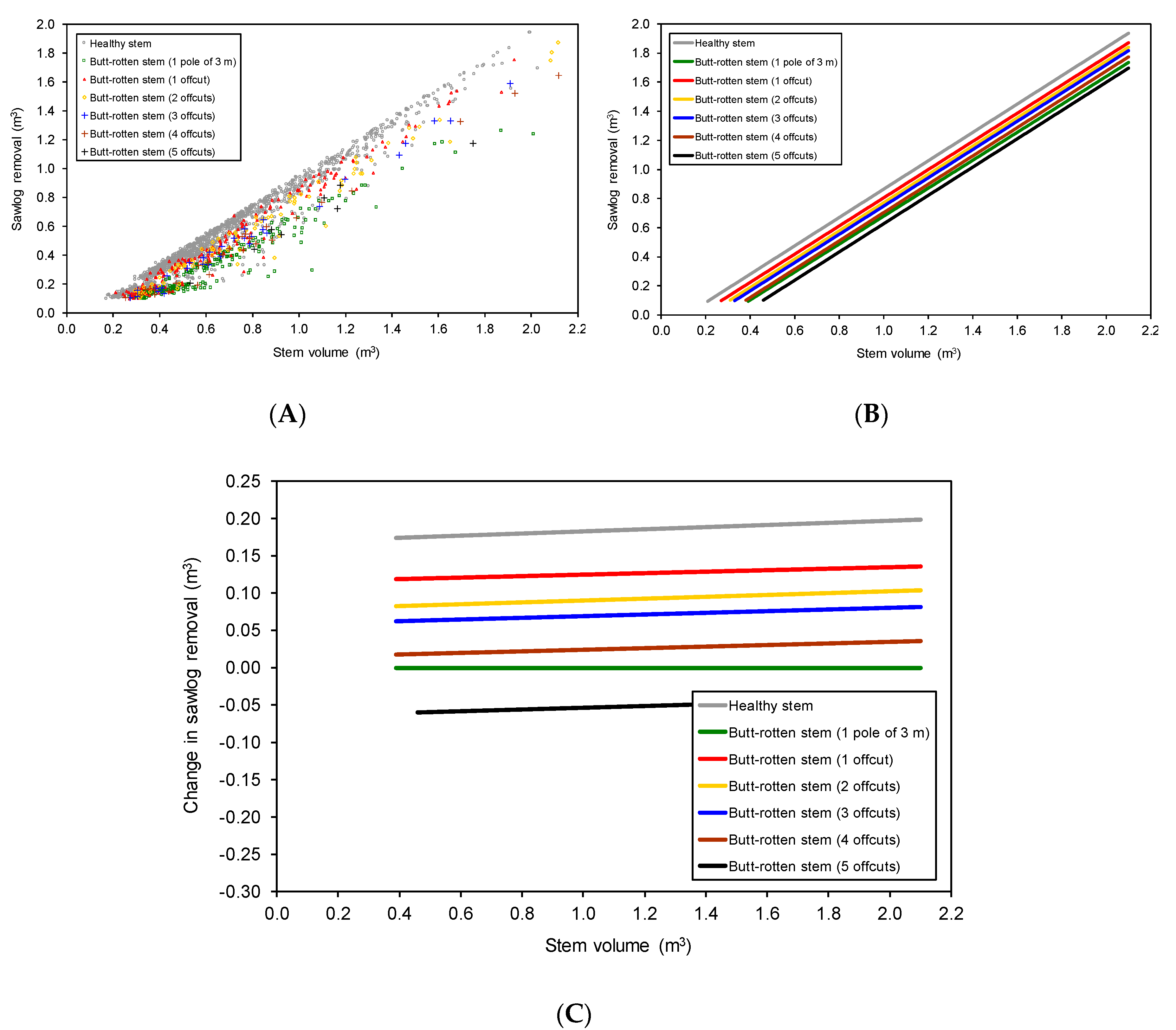

3.3. Sawlog Removal in Different Cross-Cutting Practices

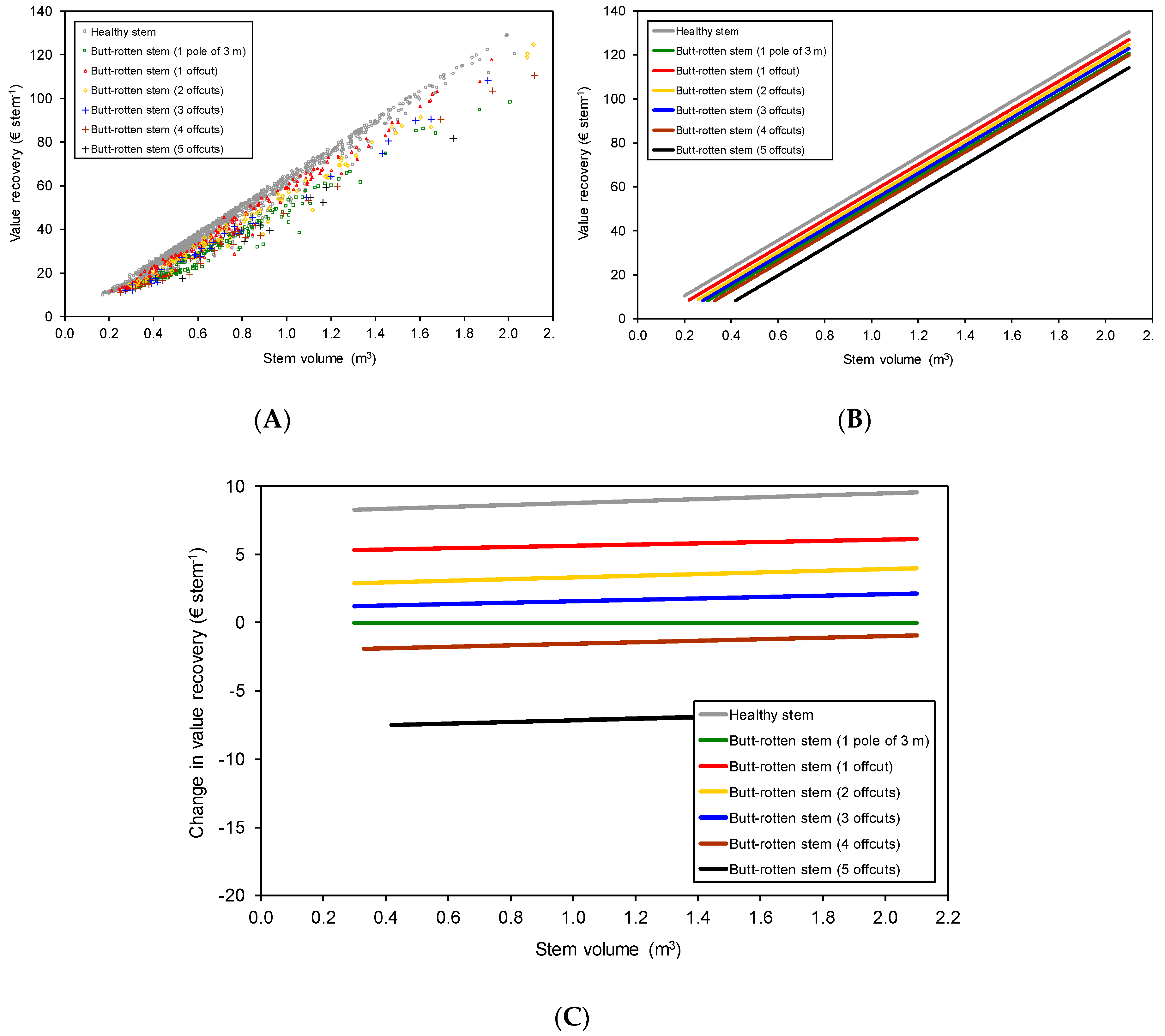

3.4. Value Recovery of Stem at Roadside Landing

3.5. Modelling Relationship between Diameter and Height of Decayed Column in Butt-Rotten Stems

4. Discussion

4.1. Assessing the Data

4.2. Evaluation of the Study Findings

- (1)

- When the diameter of the decayed column at the stump height is small (≤5 cm), try to sound one to three offcuts from the butt-rotten Norway spruce stem.

- (2)

- When the width of the decay is larger (>5 cm), first cross cut the 3 m decayed Norway spruce pole and then observe the advance of the decayed column in the stem.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Garbeletto, M.; Gonthier, P. Biology, Epidemiology, and Control of Heterobasidion Species Worldwide. Ann. Rev. Phytopathol. 2013, 51, 39–59. [Google Scholar] [CrossRef] [PubMed]

- Korhonen, K.; Capretti, P.; Karjalainen, R.; Stenlid, J. Distribution of Heterobasidion annosum intersterility groups in Europe. In Heterobasidion annosum: Biology, Ecology, Impact and Control; Woodward, S., Stenlid, J., Karjalainen, R., Hüttermann, A., Eds.; CAB International: Wallingford, UK, 1998; pp. 93–104. [Google Scholar]

- Woodward, S.; Stenlid, J.; Karjalainen, R.; Hüttermann, A. Heterobasidion annosum: Biology, Ecology, Impact and Control; CAB International: Wallingford, UK, 1998; p. 589. [Google Scholar]

- Asiegbu, F.O.; Adomas, A.; Stenlid, J. Conifer root and butt rot caused by Heterobasidion annosum (Fr.) Bref. s.l. Mol. Plant Pathol. 2005, 6, 395–409. [Google Scholar] [CrossRef] [PubMed]

- Seifert, T. Simulating the extent of decay caused by Heterobasidion annosum s. l. in stems of Norway spruce. For. Ecol. Manag. 2007, 248, 95–106. [Google Scholar] [CrossRef]

- Müller, M.M.; Piri, T.; Hantula, J. Ilmaston lämpeneminen haastaa nykyistä tehokkaampaan juurikäävän torjuntaan (Global warming is challenging more effective control of Heterobasidion spp. root and butt rot). Metsätieteen Aikakauskirja 2012, 4, 312–315. [Google Scholar] [CrossRef]

- Piri, T.; Selander, A.; Hantula, J. Juurikääpätuhojen Tunnistaminen ja Torjunta (Identifying and Prevention of Root and Butt-Rot Damage); Finnish Forest Centre: Lahti, Finland, 2017; p. 50. Available online: https://www.metsakeskus.fi/sites/default/files/juurikaapa.pdf (accessed on 20 July 2019).

- La Porta, N.; Capretti, P.; Thomsen, I.M.; Kasanen, R.; Hietala, A.M.; Von Weissenberg, K. Forest pathogens with higher damage potential due to climate change in Europe. Can. J. Plant Pathol. 2008, 30, 177–195. [Google Scholar] [CrossRef]

- Müller, M.M.; Sievänen, R.; Beuker, E.; Meesenburg, H.; Kuuskeri, J.; Hamberg, L.; Korhonen, K. Predicting the activity of Heterobasidion parviporum on Norway spruce in warming climate from its respiration rate at different temperatures. For. Pathol. 2014, 44, 325–336. [Google Scholar] [CrossRef]

- Kärhä, K.; Koivusalo, V.; Palander, T.; Ronkanen, M. Treatment of Picea abies and Pinus sylvestris Stumps with Urea and Phlebiopsis gigantea for Control of Heterobasidion. Forests 2018, 9, 139. [Google Scholar] [CrossRef]

- Kallio, T.; Norokorpi, Y. Kuusikon tyvilahoisuus (Butt rot in a Norway spruce stand). Silv. Fenn. 1972, 6, 4861. [Google Scholar] [CrossRef]

- Hallaksela, A.-M. Causal agents of butt-rot in Norway spruce in southern Finland. Silv. Fenn. 1984, 18, 5216. [Google Scholar] [CrossRef]

- Stenlid, J.; Wästerlund, I. Estimating the frequency of stem rot in Picea abies using an increment borer. Scand. J. For. Res. 1986, 1, 303–308. [Google Scholar] [CrossRef]

- Piri, T.; Korhonen, K.; Sairanen, A. Occurrence of Heterobasidion annosum in Pure and Mixed Spruce Stands in Southern Finland. Scand. J. For. Res. 1990, 5, 113–125. [Google Scholar] [CrossRef]

- Huse, K.J.; Solheim, H.; Venn, K. Råte i Gran Registrert på Stubber Etter Hogst Vinteren 1992 (Stump Inventory of Root and Butt Rots in Norway Spruce Cut in 1992); Research Paper 23; Norwegian Forest Research Institute: Ås, Norway, 1994; p. 26. [Google Scholar]

- Vasiliauskas, R.; Stenlid, J.; Johansson, M. Fungi in bark peeling wounds of Picea abies in central Sweden. Eur. J. For. Pathol. 1996, 26, 285–296. [Google Scholar] [CrossRef]

- Vasiliauskas, R.; Stenlid, J. Fungi inhabiting stems of Picea abies in managed stand in Lithuania. For. Ecol. Manag. 1998, 109, 119–126. [Google Scholar] [CrossRef]

- Vasiliauskas, R. Spread of Amylostereum areolatum and A. chailletii decay in living stems of Picea abies. Forestry 1999, 72, 95–102. [Google Scholar] [CrossRef]

- Vasiliauskas, R. Damage to trees due to forestry operations and its pathological significance in temperate forests: A literature review. Forestry 2001, 74, 319–336. [Google Scholar] [CrossRef]

- Piri, T.; Korhonen, K. Infection of advance regeneration of Norway spruce by Heterobasidion parviporum. Can. J. For. Res. 2001, 31, 937–942. [Google Scholar] [CrossRef]

- Arhipova, N.; Gaitnieks, T.; Donis, J.; Stenlid, J.; Vasaitis, R. Butt rot incidence, causal fungi, and related yield loss in Picea abies stands of Latvia. Can. J. For. Res. 2011, 41, 2337–2345. [Google Scholar] [CrossRef]

- Tamminen, P. Butt-rot in Norway spruce in southern Finland. Comm. Inst. For. Fenn. 1985, 127, 1–52. [Google Scholar]

- Piri, T. The spreading of the S type of Heterobasidion annosum from Norway spruce stumps to the subsequent tree stand. Eur. J. For. Pathol. 1996, 26, 193–204. [Google Scholar] [CrossRef]

- Rönnberg, J.; Jørgensen, B.B. Incidence of Root and Butt Rot in Consecutive Rotations of Picea abies. Scand. J. For. Res. 2000, 15, 210–217. [Google Scholar] [CrossRef]

- Mattila, U.; Nuutinen, T. Assessing the Incidence of Butt Rot in Norway spruce in Southern Finland. Silv. Fenn. 2007, 41, 473. [Google Scholar] [CrossRef]

- Kallio, T. An example on the economic loss caused by decay in growing spruce timber in South Finland. Silv. Fenn. 1972, 6, 116–124. [Google Scholar]

- Swedjemark, G.; Stenlid, J. Population Dynamics of the Root Rot Fungus Heterobasidion annosum Following Thinning of Picea abies. Oikos 1993, 66, 247–254. [Google Scholar] [CrossRef]

- Mäkelä, M.; Lipponen, K.; Sainio, M. Tyvilahoa Sisältävän Kuusen Määrä, Laatu ja Käyttömahdollisuudet Sellun Raaka-aineena (Quantity, Quality and Use of Butt-rotten Norway Spruce Timber as a Raw Material of Pulping); Metsätehon Raportti 50; Metsäteho Ltd.: Helsinki, Finland, 1998; p. 30. [Google Scholar]

- Natural Resources Institute Finland. Teollisuuspuun Kauppa, Kantohinnat 01–05/2019 (Industrial Roundwood Trade, Stumpage Prices, January–May 2019); Natural Resources Institute Finland, Statistics: Vantaa, Finland, 2019; Available online: http://statdb.luke.fi/PXWeb/pxweb/fi/LUKE/LUKE__04%20Metsa__04%20Talous__02%20Teollisuuspuun%20kauppa__02%20Kuukausitilastot/01a_Kantohinnat_kk.px/table/tableViewLayout1/?rxid=7baece36-3f68-4290-a707-3f0cb45404b9 (accessed on 20 July 2019).

- Kadunc, A. The Incidence of Rot in Norway Spruce and its Influence on the Value of Trees in Slovenia. Croat. J. For. Eng. 2013, 34, 137–149. [Google Scholar]

- Kallio, T.; Tamminen, P. Decay of spruce (Picea abies (L.) Karst.) in the Åland Islands. Acta For. Fenn. 1974, 138, 1–42. [Google Scholar] [CrossRef]

- Warren, G.; Baines, P.; Plamondon, J.; Pitt, D.G. Effects of precommercial thinning on the forest value chain in northwestern New Brunswick: Part 3—Incidence of root and butt decay. For. Chron. 2013, 89, 464–473. [Google Scholar] [CrossRef]

- Labelle, E.R.; Soucy, M.; Cyr, A.; Pelletier, G. Effect of Tree Form on the Productivity of a Cut-to-Length Harvester in a Hardwood Dominated Stand. Croat. J. For. Eng. 2016, 37, 175–183. [Google Scholar]

- Labelle, E.R.; Bergen, M.; Windisch, J. The effect of quality bucking and automatic bucking on harvesting productivity and product recovery in a pine-dominated stand. Eur. J. For. Res. 2017, 136, 639–652. [Google Scholar] [CrossRef]

- Kärhä, K.; Änäkkälä, J.; Hakonen, O.; Palander, T.; Sorsa, J.-A.; Räsänen, T.; Moilanen, T. Analyzing the Antecedents and Consequences of Manual Log Bucking in Mechanized Wood Harvesting. Mech. Mater. Sci. Eng. 2017, 12, 1–15. [Google Scholar] [CrossRef]

- Labelle, E.R.; Huß, L. Creation of value through a harvester on-board bucking optimization system operated in a spruce stand. Silv. Fenn. 2018, 52, 9947. [Google Scholar] [CrossRef]

- Skogforsk. StanForD: Standard for Forest Data and Communications; Skogforsk: Uppsala, Sweden, 2007; p. 97. Available online: http://www.skogforsk.se/contentassets/b063db555a664ff8b515ce121f4a42d1/stanford_main-doc_070327.pdf (accessed on 20 July 2019).

- Arlinger, J.; Möller, J.J.; Sorsa, J.-A.; Räsänen, T. Introduction to StanForD 2010. Structural Descriptions and Implementation Recommendations; Skogforsk: Uppsala, Sweden, 2019; p. 102. Available online: https://www.skogforsk.se/cd_490398/contentassets/1a68cdce4af1462ead048b7a5ef1cc06/stanford-2010-introduction-190106.pdf (accessed on 20 July 2019).

- Groover, M.P. Work Systems and Methods, Measurement, and Management of Work; Pearson Education International: Upper Saddle River, NJ, USA, 2007; p. 778. [Google Scholar]

- Nuutinen, Y.; Väätäinen, K.; Heinonen, J.; Asikainen, A.; Röser, D. The Accuracy of Manually Recorded Time Study Data for Harvester Operation Shown via Simulator Screen. Silv. Fenn. 2008, 42, 63–72. [Google Scholar] [CrossRef]

- Palander, T.; Nuutinen, Y.; Kariniemi, A.; Väätäinen, K. Automatic Time Study Method for Recording Work Phase Times of Timber Harvesting. For. Sci. 2013, 59, 472–483. [Google Scholar] [CrossRef]

- Kärhä, K.; Anttonen, T.; Poikela, A.; Palander, T.; Laurén, A.; Peltola, H.; Nuutinen, Y. Evaluation of Salvage Logging Productivity and Costs in Windthrown Norway Spruce-Dominated Forests. Forests 2018, 9, 280. [Google Scholar] [CrossRef]

- Eriksson, M.; Lindroos, O. Productivity of harvesters and forwarders in CTL operations in northern Sweden based on large follow-up datasets. Int. J. For. Eng. 2014, 25, 179–200. [Google Scholar] [CrossRef]

- Strandström, M. Average Wood Harvesting Conditions in Finland, 2010–2017; Metsäteho Ltd., Statistics: Vantaa, Finland, 2018. [Google Scholar]

- Kärhä, K.; Poikela, A.; Palander, T. Productivity and Costs of Harwarder Systems in Industrial Roundwood Thinnings. Croat. J. For. Eng. 2018, 39, 23–33. [Google Scholar]

- Hakkila, P.; Saranpää, P.; Kalaja, H.; Repola, J. Suomalainen Havukuitupuu—Laadun Hallinta ja Vaihtelu (Finnish Softwood Pulpwood—Quality Management and Variation); Finnish Forest Research Institute: Vantaa, Finland, 2002; p. 92. [Google Scholar]

- Malinen, J.; Laitila, J.; Väätäinen, K.; Viitamäki, K. Variation in age, annual usage and resale price of cut-to-length machinery in different regions of Europe. Int. J. For. Eng. 2016, 27, 95–102. [Google Scholar] [CrossRef]

- Finlex. Metsäkonealan Työsopimus 1.2.2018–31.1.2020 (Terms of Employment in Forest Machine Business, 1.2.2018–31.1.2020); The Trade Association of Finnish Forestry and Earth Moving Contractors & Industrial Union: Helsinki, Finland, 2018; p. 38. Available online: https://www.finlex.fi/data/tes/3722/MU23Metskon1802.pdf (accessed on 20 July 2019).

- Brunberg, T. Fuel Consumption in Forest Machines 2012; Arbetsrapport Från Skogforsk 789; Skogforsk: Uppsala, Sweden, 2013; p. 12. [Google Scholar]

- Statistics Finland. Metsäalan Kone- ja Autokustannusindeksi 2015 = 100 (Machine and Truck Cost Index in Forestry, 2015 = 100); Handbook; Statistics Finland: Helsinki, Finland, 2018; p. 29. [Google Scholar]

- Sirén, M. One-Grip Harvester Operation, It’s Silvicultural Result and Possibilities to Predict Tree Damage; Research Papers 694; Finnish Forest Research Institute: Vantaa, Finland, 1998; p. 179. [Google Scholar]

- Kärhä, K.; Rönkkö, E.; Gumse, S.-I. Productivity and Cutting Costs of Thinning Harvesters. Int. J. For. Eng. 2004, 15, 43–56. [Google Scholar] [CrossRef]

- Ovaskainen, H. Timber Harvester Operators’ Working Technique in First Thinning and the Importance of Cognitive Abilities on Work Productivity; Dissertationes Forestales 79; The Finnish Society of Forest Science: Vantaa, Finland, 2009; p. 62. [Google Scholar]

- Dvořák, J.; Malkovský, Z.; Macků, J. Influence of human factor on the time of work stages of harvesters and crane-equipped forwarders. J. For. Sci. 2008, 54, 24–30. [Google Scholar] [CrossRef] [Green Version]

- Ovaskainen, H.; Uusitalo, J.; Väätäinen, K. Characteristics and Significance of Harvester Operators’ Working Technique in Thinnings. Int. J. For. Eng. 2004, 15, 67–77. [Google Scholar] [CrossRef]

- Purfürst, F.T. Learning Curves of Harvester Operators. Croat. J. For. Eng. 2010, 31, 89–97. [Google Scholar]

- Purfürst, F.T.; Erler, J. The Human Influence on Productivity in Harvester Operations. Int. J. For. Eng. 2011, 22, 15–22. [Google Scholar] [CrossRef]

- Palander, T.; Ovaskainen, H.; Tikkanen, L. An Adaptive Work Study Method for Identifying the Human Factors that Influence the Performance of a Human-Machine System. For. Sci. 2012, 58, 377–389. [Google Scholar] [CrossRef]

- Nurminen, T.; Korpunen, H.; Uusitalo, J. Time Consumption Analysis of the Mechanized Cut-to-length Harvesting System. Silva Fenn. 2006, 40, 346. [Google Scholar] [CrossRef]

- Brunberg, T. Basic Data for Productivity Norms for Extra Large Single-Grip Harvesters in Final Felling; Redogörelse Från Skogforsk 2; Gälve Offset AB: Gälve, Sweden, 2007; p. 8. [Google Scholar]

- Jiroušek, R.; Klvač, R.; Skoupý, A. Productivity and costs of the mechanized cut-to-length wood harvesting system in clear-felling operations. J. For. Sci. 2007, 53, 476–482. [Google Scholar] [CrossRef]

- Brzózko, J.; Szereszewiec, B.; Szereszewiec, E. Productivity of machine timber harvesting at the wind-damaged site. Ann. Warsaw Univ. Life Sci. SGGW Agric. 2009, 54, 41–49. [Google Scholar]

- Spinelli, R.; Hartsough, B.R.; Magagnotti, N. Productivity Standards for Harvesters and Processors in Italy. For. Prod. J. 2010, 60, 226–235. [Google Scholar] [CrossRef]

- Visser, R.; Spinelli, R. Determining the shape of the productivity function for mechanized felling and felling-processing. J. For. Res. 2012, 17, 397–402. [Google Scholar] [CrossRef]

- Jylhä, P.; Jounela, P.; Koistinen, M.; Korpunen, H. Koneellinen Hakkuu: Seurantatutkimus (Mechanized Cutting: Follow-Up Study); Natural Resources and Bioeconomy Studies 11; Natural Resources Institute Finland: Helsinki, Finland, 2019; p. 53. [Google Scholar]

- Möykkynen, T.; Miina, J.; Pukkala, T.; von Weissenberg, K. Modelling the spread of butt rot in a Picea abies stand in Finland to evaluate the profitability of stump protection against Heterobasidion annosum. For. Ecol. Manag. 1998, 106, 247–257. [Google Scholar] [CrossRef]

- Möykkynen, T.; Miina, J.; Pukkala, T. Optimizing the management of a Picea abies stand under risk of butt rot. For. Pathol. 2000, 30, 65–76. [Google Scholar] [CrossRef]

- Pukkala, T.; Möykkynen, T.; Thor, M.; Rönnberg, J.; Stenlid, J. Modeling infection and spread of Heterobasidion annosum in even-aged Fennoscandian conifer stands. Can. J. For. Res. 2005, 35, 74–85. [Google Scholar] [CrossRef]

- Palander, T.; Eronen, J.; Kärhä, K.; Ovaskainen, H. Development of a wood damage monitoring system for mechanized harvesting. Ann. For. Res. 2018, 61, 1–16. [Google Scholar] [CrossRef]

- Palander, T.S.; Eronen, J.P.; Peltoniemi, N.P.; Aarnio, A.I.; Kärhä, K.; Ovaskainen, H.K. Improving a stem-damage monitoring system for a single-grip harvester using a logistic regression model in image processing. Biosyst. Eng. 2019, 180, 36–49. [Google Scholar] [CrossRef]

- Murphy, G. Determining Stand Value and Log Product Yields Using Terrestrial Lidar and Optimal Bucking: A Case Study. J. For. 2008, 106, 317–324. [Google Scholar] [CrossRef]

- Aruga, K.; Liu, C.; Uemura, R.; Furusawa, T. Economic Balance of a Clearcutting Operation Using Terrestrial LiDAR. Eur. J. For. Eng. 2016, 2, 1–10. [Google Scholar]

- Qin, R.; Qiu, Q.; Lam, J.H.M.; Tang, A.M.C.; Leung, M.W.K.; Lau, D. Health assessment of tree trunk by using acoustic-laser technique and sonic tomography. Wood Sci. Technol. 2018, 52, 1113–1132. [Google Scholar] [CrossRef]

- Visalga, G.; Petrauskas, E.; Rupšys, P. Method for increasing and accuracy of detecting decay by the Arbotom® 3-D tree tomograph on Picea abies (L.) Karst. tree damaged by Heterobasidion annosum (Fr.) Bref. In Proceedings of the 7th International Scientific Conference Rural Development 2015, Aleksandras Stulginskis University, Kaunas, Lithuania, 19–20 November 2015; Raupelienė, A., Ed.; pp. 1–5. [Google Scholar] [CrossRef]

- Gilbert, G.S.; Ballesteros, J.O.; Barrios-Rodriguez, C.A.; Bonadies, E.F.; Cedeño-Sánchez, M.L.; Fossatti-Caballero, N.J.; Trejos-Rodríguez, M.M.; Pérez-Suñiga, J.M.; Holub-Young, K.S.; Henn, L.A.W.; et al. Use of Sonic Tomography to Detect and Quantify Wood Decay in Living Trees. Appl. Plant Sci. 2016, 4, 1–13. [Google Scholar] [CrossRef]

- Akay, A.E.; Serin, H.; Pak, M. How stem defects affect the capability of optimum bucking method? J. Fac. For. Istanb. Univ. 2015, 65, 38–45. [Google Scholar] [CrossRef]

| Property | John Deere 1270G | Komatsu 911.5 | Komatsu 931.1 | Ponsse Ergo |

|---|---|---|---|---|

| Weight (kg) 1 | 22,600 | 19,700 | 21,300 | 20,900 |

| Engine | JD 6090 PowerTech Plus | Agco Sisu Power 74 AWI | Agco Sisu Power 74 AWI | Mercedes-Benz OM 936 LA |

| Power (kW) | 200 | 170 | 193 | 210 |

| Boom | John Deere CH7 | Valmet CRH18 | Komatsu CRH22 | Ponsse C5 |

| Maximum reach (m) | 11.7 | 10.0 | 9.8 | 10.0 |

| Lifting capacity gross (kNm) | 197 | 186 | 217 | 248 |

| Harvester head | John Deere H414 | Komatsu 365 | Komatsu 365 | Ponsse H7 |

| Weight (kg) | 1100 | 1200 | 1200 | 1150 |

| Felling diameter (cm) | 62 | 65 | 65 | 64 |

| Delimbing diameter (cm) | 43 | 47 | 47 | 75 |

| Work Element | Description |

|---|---|

| Moving | Moving forward and reversing started when the harvester started to move and ended when the harvester stopped to perform another task. |

| Boom-out | Steering out the boom and grabbing (i.e., Boom-out) started when the boom started to swing towards a tree and ended when the harvester’s head rested on a tree and the felling cut began. |

| Felling | Felling started when the felling cut began and ended when the feeding and delimbing of the stem started. |

| Processing | Processing consisted of delimbing and cross-cutting, as well as sounding. Processing started when the feeding rolls started to turn and ended when the last piece of the stem dropped from the harvester’s head. |

| Boom-in | Steering the boom front (i.e., Boom-in) occurred when the harvester operator steered the harvester’s head to the front of the harvester before moving forward or reversing. |

| Miscellaneous time | Miscellaneous times in cutting work included the planning of work, clearing of undergrowth, sorting of industrial roundwood poles, and removing of logging residues. |

| Cross-Cutting Practice | Harvesting Cost Function |

|---|---|

| Healthy stem | 3.878 + 1.485/x |

| Butt-rotten stem (1 pole of 3 m) | 3.906 + 1.588/x |

| Butt-rotten stem (1 offcut) | 3.925 + 1.784/x |

| Butt-rotten stem (2 offcuts) | 3.898 + 2.021/x |

| Butt-rotten stem (3 offcuts) | 3.915 + 2.218/x |

| Butt-rotten stem (4 offcuts) | 3.910 + 2.201/x |

| Butt-rotten stem (5 offcuts) | 3.918 + 2.278/x |

| Cross-Cutting Practice | Estimate of Coefficient | Standard Error of Estimate | t-Value |

|---|---|---|---|

| Healthy stem | |||

| a | 23.845 | 1.995 | 11.951 *** |

| b | 53.895 | 7.457 | 7.227 *** |

| c | –26.600 | 8.321 | –3.197 *** |

| d | 9.054 | 2.745 | 3.298 *** |

| e | –7.758 | 0.519 | –14.954 *** |

| Adjusted R2 = 0.561; F value = 634.5 ***; Standard error of the estimate of the model = 10.455 | |||

| Butt-Rotten Stem (1 pole of 3 m) | |||

| a | 16.847 | 2.046 | 8.234 *** |

| b | 59.369 | 7.864 | 7.550 *** |

| c | –32.974 | 8.776 | –3.757 *** |

| d | 11.300 | 2.894 | 3.904 *** |

| e | 0.946 | 0.772 | 1.226 |

| Adjusted R2 = 0.512; F value = 520.5 ***; Standard error of the estimate of the model = 11.027 | |||

| Butt-Rotten Stem (1 offcut) | |||

| a | 16.004 | 2.026 | 7.899 *** |

| b | 61.287 | 7.765 | 7.892 *** |

| c | –35.309 | 8.664 | –4.075 *** |

| d | 12.054 | 2.858 | 4.218 *** |

| e | 5.815 | 0.836 | 6.955 *** |

| Adjusted R2 = 0.524; F value = 544.6 ***; Standard error of the estimate of the model = 10.899 | |||

| Butt-Rotten Stem (2 offcuts) | |||

| a | 17.250 | 2.003 | 8.614 *** |

| b | 56.882 | 7.692 | 7.395 *** |

| c | –30.429 | 8.581 | –3.546 *** |

| d | 10.358 | 2.831 | 3.659 *** |

| e | 11.151 | 1.182 | 9.436 *** |

| Adjusted R2 = 0.533; F value = 565.4 ***; Standard error of the estimate of the model = 10.791 | |||

| Butt-Rotten Stem (3 offcuts) | |||

| a | 16.834 | 2.013 | 8.363 *** |

| b | 59.125 | 7.727 | 7.651 *** |

| c | –32.747 | 8.621 | –3.798 *** |

| d | 11.150 | 2.844 | 3.921 *** |

| e | 16.107 | 1.966 | 8.194 *** |

| Adjusted R2 = 0.528; F value = 554.2 ***; Standard error of the estimate of the model = 10.848 | |||

| Butt-Rotten Stem (4 offcuts) | |||

| a | 17.412 | 2.021 | 8.616 *** |

| b | 56.572 | 7.765 | 7.286 *** |

| c | –29.450 | 8.667 | –3.398 *** |

| d | 9.964 | 2.860 | 3.483 *** |

| e | 15.547 | 2.118 | 7.341 *** |

| Adjusted R2 = 0.525; F value = 547.4 ***; Standard error of the estimate of the model = 10.884 | |||

| Butt-Rotten Stem (5 offcuts) | |||

| a | 16.882 | 2.036 | 8.290 *** |

| b | 59.942 | 7.817 | 7.668 *** |

| c | –34.017 | 8.723 | –3.900 *** |

| d | 11.669 | 2.877 | 4.056 *** |

| e | 17.457 | 3.897 | 4.479 *** |

| Adjusted R2 = 0.517; F value = 530.0 ***; Standard error of the estimate of the model = 10.976 | |||

| Cross-Cutting Practice | Cutting Productivity Function |

|---|---|

| Healthy stem | 8.219 + 72.262x – 21.442x2 + 0.837x3 |

| Butt-rotten stem (1 pole of 3 m) | 7.778 + 65.628x – 15.578x2 – 0.841x3 |

| Butt-rotten stem (1 offcut) | 6.588 + 60.140x – 11.858x2 – 1.551x3 |

| Butt-rotten stem (2 offcuts) | 4.838 + 57.384x – 11.946x2 – 0.880x3 |

| Butt-rotten stem (3 offcuts) | 4.213 + 52.460x – 9.251x2 – 1.339x3 |

| Butt-rotten stem (4 offcuts) | 4.067 + 54.003x – 11.002x2 – 0.740x3 |

| Butt-rotten stem (5 offcuts) | 4.053 + 51.003x – 8.208x2 – 1.612x3 |

| Cross–Cutting Practice | Estimate of Coefficient | Standard Error of Estimate | t-Value |

|---|---|---|---|

| Healthy Stem | |||

| a | –0.230 | 0.005 | –49.845 *** |

| b | 0.973 | 0.005 | 202.280 *** |

| c | 0.121 | 0.004 | 32.277 *** |

| Adjusted R2 = 0.955; F value = 20,801 ***; Standard error of the estimate of the model = 0.075 | |||

| Butt–Rotten Stem (1 pole of 3 m) | |||

| a | –0.116 | 0.004 | –29.720 *** |

| b | 0.959 | 0.005 | 194.084 *** |

| c | –0.162 | 0.005 | –29.909 *** |

| Adjusted R2 = 0.952; F value = 19,738 ***; Standard error of the estimate of the model = 0.077 | |||

| Butt–Rotten Stem (1 offcut) | |||

| a | –0.140 | 0.005 | –30.255 *** |

| b | 0.969 | 0.006 | 163.428 *** |

| c | –0.023 | 0.007 | –3.177 *** |

| Adjusted R2 = 0.931; F value = 13,354 ***; Standard error of the estimate of the model = 0.093 | |||

| Butt–Rotten Stem (2 offcuts) | |||

| a | –0.141 | 0.005 | –30.936 *** |

| b | 0.971 | 0.006 | 164.315 *** |

| c | –0.059 | 0.010 | –5.814 *** |

| Adjusted R2 = 0.932; F value = 13,526 ***; Standard error of the estimate of the model = 0.092 | |||

| Butt–Rotten Stem (3 offcuts) | |||

| a | –0.141 | 0.005 | –30.981 *** |

| b | 0.970 | 0.006 | 163.950 *** |

| c | –0.079 | 0.017 | –4.693 *** |

| Adjusted R2 = 0.931; F value = 13,441 ***; Standard error of the estimate of the model = 0.093 | |||

| Butt–Rotten Stem (4 offcuts) | |||

| a | –0.141 | 0.005 | –31.055 *** |

| b | 0.970 | 0.006 | 165.088 *** |

| c | –0.124 | 0.018 | –6.925 *** |

| Adjusted R2 = 0.932; F value = 13,628 ***; Standard error of the estimate of the model = 0.092 | |||

| Butt–Rotten Stem (5 offcuts) | |||

| a | –0.142 | 0.005 | –31.306 *** |

| b | 0.971 | 0.006 | 164.596 *** |

| c | –0.202 | 0.033 | –6.165 *** |

| Adjusted R2 = 0.932; F value = 13,556 ***; Standard error of the estimate of the model = 0.092 | |||

| Cross-Cutting Practice | Estimate of Coefficient | Standard Error of Estimate | t-Value |

|---|---|---|---|

| Healthy Stem | |||

| a | –8.662 | 0.197 | –44.010 *** |

| b | 63.111 | 0.205 | 307.924 *** |

| c | 6.398 | 0.159 | 40.201 *** |

| Adjusted R2 = 0.980; F value = 47,886 ***; Standard error of the estimate of the model = 3.213 | |||

| Butt–Rotten Stem (1 pole of 3 m) | |||

| a | –2.746 | 0.180 | –15.244 *** |

| b | 62.413 | 0.228 | 273.532 *** |

| c | –7.618 | 0.250 | –30.523 *** |

| Adjusted R2 = 0.975; F value = 38,575 ***; Standard error of the estimate of the model = 3.571 | |||

| Butt–Rotten Stem (1 offcut) | |||

| a | –3.837 | 0.214 | –17.924 *** |

| b | 62.884 | 0.275 | 228.609 *** |

| c | –1.354 | 0.331 | –4.095 *** |

| Adjusted R2 = 0.964; F value = 26,131 ***; Standard error of the estimate of the model = 4.313 | |||

| Butt–Rotten Stem (2 offcuts) | |||

| a | –3.901 | 0.210 | –18.600 *** |

| b | 63.035 | 0.273 | 231.211 *** |

| c | –3.748 | 0.466 | –8.039 *** |

| Adjusted R2 = 0.964; F value = 26,782 ***; Standard error of the estimate of the model = 4.263 | |||

| Butt–Rotten Stem (3 offcuts) | |||

| a | –3.914 | 0.211 | –18.576 *** |

| b | 62.931 | 0.273 | 230.492 *** |

| c | –5.405 | 0.775 | –6.972 *** |

| Adjusted R2 = 0.964; F value = 26,564 ***; Standard error of the estimate of the model = 4.279 | |||

| Butt–Rotten Stem (4 offcuts) | |||

| a | –3.901 | 0.208 | –18.797 *** |

| b | 62.960 | 0.269 | 234.068 *** |

| c | –8.566 | 0.817 | –10.479 *** |

| Adjusted R2 = 0.965; F value = 27,397 ***; Standard error of the estimate of the model = 4.216 | |||

| Butt–Rotten Stem (5 offcuts) | |||

| a | –4.007 | 0.209 | –19.201 *** |

| b | 63.026 | 0.271 | 232.759 *** |

| c | –14.137 | 1.505 | –9.396 *** |

| Adjusted R2 = 0.965; F value = 27,104 ***; Standard error of the estimate of the model = 4.238 | |||

| Coefficient | Estimate of Coefficient | Standard Error of Estimate | t-Value |

|---|---|---|---|

| B | 7.362 | 0.294 | 25.026 *** |

| Adjusted R2 = 0.298; F value = 626.3 ***; Standard error of the estimate of the model = 52.578 | |||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kärhä, K.; Räsänen, M.; Palander, T. The Profitability of Cross-Cutting Practices in Butt-Rotten Picea abies Final-Felling Stands. Forests 2019, 10, 874. https://doi.org/10.3390/f10100874

Kärhä K, Räsänen M, Palander T. The Profitability of Cross-Cutting Practices in Butt-Rotten Picea abies Final-Felling Stands. Forests. 2019; 10(10):874. https://doi.org/10.3390/f10100874

Chicago/Turabian StyleKärhä, Kalle, Mikko Räsänen, and Teijo Palander. 2019. "The Profitability of Cross-Cutting Practices in Butt-Rotten Picea abies Final-Felling Stands" Forests 10, no. 10: 874. https://doi.org/10.3390/f10100874

APA StyleKärhä, K., Räsänen, M., & Palander, T. (2019). The Profitability of Cross-Cutting Practices in Butt-Rotten Picea abies Final-Felling Stands. Forests, 10(10), 874. https://doi.org/10.3390/f10100874