Abstract

Over the last few decades, detecting surface defects has attracted significant attention as a challenging task. There are specific classes of problems that can be solved using traditional image processing techniques. However, these techniques struggle with complex textures in backgrounds, noise, and differences in lighting conditions. As a solution to this problem, deep learning has recently emerged, motivated by two main factors: accessibility to computing power and the rapid digitization of society, which enables the creation of large databases of labeled samples. This review paper aims to briefly summarize and analyze the current state of research on detecting defects using machine learning methods. First, deep learning-based detection of surface defects on industrial products is discussed from three perspectives: supervised, semi-supervised, and unsupervised. Secondly, the current research status of deep learning defect detection methods for X-ray images is discussed. Finally, we summarize the most common challenges and their potential solutions in surface defect detection, such as unbalanced sample identification, limited sample size, and real-time processing.

1. Terminology

- Support Vector Machine (SVM): an algorithm used in supervised learning for classifying and performing regression tasks.

- Region of Interest (ROI): an area within an image or video that is deemed particularly significant or relevant.

- Local Binary Patterns (LBP): a technique used in computer vision for extracting features and analyzing images.

- Reduced Coordinate Cluster Representation (RCCR): a method for representing and processing image data for object recognition that is efficient.

- Convolutional Neural Network (CNN): a neural network architecture commonly used for image and video processing tasks.

- Zero Defect Manufacturing (ZDM): a strategy to eliminate defects in the manufacturing process and improve quality.

- Deep Neural Network (DNN): a neural network architecture with multiple layers, commonly used for image recognition and natural language processing tasks.

- MobileNet Single Shot MultiBox Detector (MobileNet-SSD): a lightweight convolutional neural network that is designed for real-time object detection on mobile and embedded devices.

- Fully Convolutional Network (FCN): a neural network architecture used for semantic segmentation tasks.

- Region-based Convolutional Neural Network (RCNN): a neural network architecture used for object detection tasks.

- Autoencoders (AEs): a neural network architecture used for unsupervised learning tasks such as dimensionality reduction and anomaly detection.

- Generative Adversarial Networks (GANs): a neural network architecture used for generative tasks such as image synthesis and image-to-image translation.

- Self-Organizing Map based (SOM-based): an unsupervised learning algorithm that organizes data into a 2D grid of clusters.

- General-purpose Annotation of Photos and Replica (GAPR) datasets: created by the German Pattern Recognition Association, is a collection of images specifically designed for the detection of texture defects.

- German Association for Pattern Recognition (DAGM) datasets: a collection of images specifically designed for the detection of textured surfaces.

- Northeastern University (NEU) datasets: created by Northeastern University, a collection of images of surface defects that includes six different types of defects.

- Convolutional Denoising AutoEncoder (CDAE): a type of autoencoder designed to remove noise from images.

- Non-Destructive Testing (NDT): a method of evaluating the properties of a material, component, or system without causing damage.

- VGG: VGG is a pioneering object-recognition model that can have up to 19 layers. Created as a deep CNN, it surpasses other models on many tasks and datasets apart from ImageNet. VGG is still a widely used architecture for image recognition today.

- Mean Average Precision (mAP): a metric used to evaluate the performance of object detection models, that calculates the average precision across different classes and object instances.

2. Introduction

Several factors affect the quality of manufactured products during the manufacturing process, including poor working conditions, inadequate technology, and various other factors. Among product defects, poor product quality is most visible in surface defects. Therefore, detecting product surface defects [1] ensures a high qualification ratio and reliable quality.

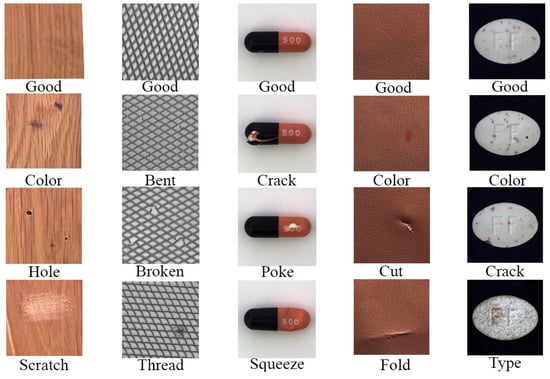

A defect is generally defined as an absence or area that differs from a normal sample. Figure 1 compares normal samples with defective samples of industrial products.

Figure 1.

Normal samples of industrial products are compared to defective samples. The first row contains good samples, and the second, third, and fourth rows contain defective samples. The first, second, third, fourth, and fifth columns display wood, grid, capsule, leather, and bill, respectively, and there are three types of defects listed below the image.

In the past, identifying defects was carried out by experts, but this process was not efficient. One major reason for this was that human subjectivity greatly affected the detection results. Additionally, human inspection alone cannot meet the need for real-time detection, and thus, it is not able to fulfill all the necessary requirements.

A significant amount of time has been dedicated to using traditional methods to detect surface defects. When differentiation exists between the defect color and the background, traditional image processing methods can perform well. Traditional methods in terms of the product’s features can be categorized into three types: texture-based features, color-based features, and shape-based features.

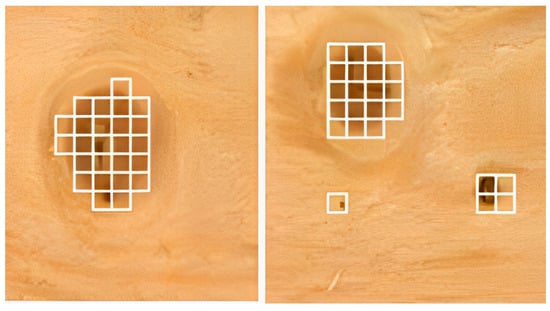

Several studies have used specialized techniques for detecting surface defects. In color-based feature, for instance, literature [2] proposed a technique involving the use of a percentage of the feature of color histogram and a vector texture feature to classify image blocks to detect surface defects on wood; this method has been proven effective by experiments, especially with defects involving junctions. In Figure 2, the method results are shown.

Figure 2.

An example of the result of wood defect detection using the presented technique in [2].

Research conducted in literature [3] employed cosine similarity to verify the validity of the periodic law in magneto-optical images by utilizing the color moment feature. This method was successful in identifying the appropriate magneto-optical image for detecting and locating welding defects. Literature [4] describes a two-step technological process for SVM-based and color histogram-based defect detection in particle boards, followed by localization of defects using smoothing and thresholding. According to literature [5], color moment features and FSIFT features were merged based on their magnitude of influence for the purpose of resolving the tile surface defect problem not being adequately described by a single feature.

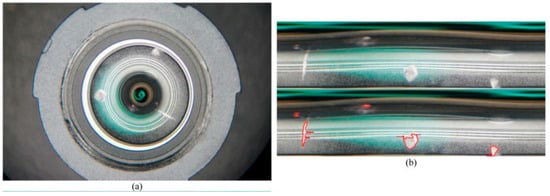

In terms of shape-based feature methods, literature [6] proposed a method of detecting cutting defects on magnetic surfaces. In this method, the image of the magnetic surface is reconstructed using the Fourier transform and Hough transform, and, in order to obtain defect information, the gray difference between the original image and the reconstructed image is compared. A method for identifying defects on bottle surfaces was presented in reference [7]. This method includes a step for extracting regions of interest, where the boundary line of the light source is determined using a fast Hough transform algorithm. In [8], global Fourier image reconstruction and template matching were proposed as a method for detecting and locating small defects in aperiodic images. Literature [9] described how to detect surface defects on small camera lenses using Hough transforms, polar coordinate transforms, weighted Sobel filters, and SVM algorithms. Different types of defects were detected in several test images. In Figure 3, red highlights are used to indicate defects such as stains, scratches, and dots.

Figure 3.

A camera lens with several defects: (a) original image and (b) converted result based on inspection result and polar coordinate transformation [9].

In the texture-based feature method, for example in [10], a multi-block local binary pattern (LBP) algorithm has been improved. In addition to having the simplicity and efficiency of LBP, this algorithm ensures high recognition accuracy by varying the block size to describe defect features. According to the experiment, the method has the speed to meet online real-time detection requirements (63 milliseconds/image), outperform the widely used scale-invariant feature transform (SIFT), speed up robust features (SURF), and gray-level co-occurrence matrix (GLCM) algorithms for recognition accuracy (94.30%), demonstrating that MB-LBP can be used to detect images in real time online. Literature [11] used a fuzzy model that was based on extracting GLCM features and processed it using MATLAB. The model took in three variables as inputs: autocorrelation, square root of variance, and the number of objects. Using fuzzy logic on ceramic defects, the accuracy of the ceramic inspection process with a light intensity of 300 lx, camera distance of 50 cm, and a 1.3 MP or 640 × 480 pixel image size was determined using the training data of 96.87%, and the accuracy of the real-time system was 92.31%. According to literature [12], features such as Reduced Coordinated Cluster Representation (RCCR) are used to form a one-class classifier. An algorithm based on texture periodicity estimates the primitive unit size of defect-free fabrics during the training phase. After splitting the fabrics into samples of one unit, RCCR features are used in a one-class classifier to learn their local structure. In [13], morphological filters are used to detect defects on billet surfaces in order to distinguish them from scales. With the help of morphological erosion and dilation techniques with repetition, the image is converted into a binary image by using morphological top-hat filtering and thresholding. The detection efficiency of the proposed algorithm is evaluated using real billet images to evaluate its performance. The proposed algorithm is found to be effective and suitable for analyzing billet images with scales in experiments. According to literature [14], the GLCM is defined as the fabric image’s characteristic matrix. To distinguish defect-free from defective images, Euclidean distance is used and, in order to determine the pattern period, the autocorrelation function is used. In this paper, the authors discussed two GLCM parameters in relation to Euclidean distances. Furthermore, in addition to being concise and objective, Euclidean distances have the advantage of being reliable and objective for defect detection. According to the algorithm’s tests, it is not only accurate, but also more adaptable to yarn-dyed fabrics with short organization cycles. Table 1 summarizes recent applications of machine learning algorithms for surface defect detection in industrial products, categorized by texture, color, and shape features. Table 2 compares the strengths and weaknesses of feature-based methods for detecting surface defects, including accuracy, computational efficiency, and robustness. These tables provide an overview of the diversity of approaches and key factors affecting performance in the field of surface defect detection.

Table 1.

Recent applications using machine-learning-based vision algorithms for detecting surface defects in industrial products, categorized into three categories based on texture, color, and shape features.

Table 2.

An overview of the strengths and weaknesses of various feature-based methods for detecting surface defects in industrial products.

Using only one feature or one class of features on industrial products is rarely sufficient because their surfaces typically contain a variety of information. Consequently, many features are used in combination in practical applications, making it difficult to detect defects. Additionally, feature-based approaches are highly effective when they detect defects in images with little or no variation, and when defects appear on surfaces in a consistent pattern. Considering the wide range of uncertainties in industrial settings, it is important to develop methods that are adaptable to such wide ranges of variations in defect intensity, shape, and size.

Deep learning models based on convolutional neural networks (CNN) have had a lot of success in various computer vision fields, such as recognizing faces, identifying pedestrians, detecting text in images, and tracking targets. Additionally, these models are used in a wide range of industrial settings for defect detection. This includes both commercial and industrial applications, such as in the automotive industry for detecting defects in cars. The deep-learning-based surface defect detection software is employed in these settings to improve the efficiency and accuracy of the defect detection process.

Recently, several papers covering the latest techniques, applications, and other aspects have been published on deep learning in defect detection [19]. Literature [12] describes the different types of defects and compares mainstream and deep learning methods for defect detection. Various defect detection techniques are discussed in literature [20], including ultrasonic inspection, machine vision, and deep learning. Literature [21] focuses on the use of AI-enhanced metrology, computer vision, and quality assessment in the Zero Defect Manufacturing (ZDM) process. The study also highlights the use of IoT/IIoT technology as a means of supporting these tools and implementing AI algorithms for data processing and sharing. Literature [22] discusses deep learning methods for detecting surface defects, then discusses three critical issues related to small samples and real-time defects detection. In [23,24], the authors analyze and compare the benefits and drawbacks of the above methods. There are also defect detection surveys in several application domains, including fabric defects [25], corrosion detection [26], pavement defects [27], metal defect detection [28], and industrial applications [29]. The investigation shows that, in the field of surface defect detection of industrial products, there is currently a limited literature review on machine learning methods, and while some papers summarize the challenges and problems, the mentioned solutions are not systematic. The first section of this paper addresses the above issues by summarizing the research status on the detection of surface defects on industrial products using deep learning algorithms and then discusses the issues in the process of industrial surface defect detection, such as unbalanced sample identification problems, small sample problems, and real-time problems.

This paper is organized as follows. Section 3 provides an overview of deep learning methods for surface defect detection in industrial products from three perspectives, along with a common dataset for surface defect detection. In Section 4, we summarize the recent research status of deep learning methods for X-ray image defect detection. A discussion of the main problems and their solutions is provided in Section 5. In Section 6, a brief description of future research directions is provided and Section 7 concludes the paper with a conclusion.

3. Deep Learning Surface Defect Detection Methods for Industrial Products

Deep learning has become increasingly popular in the field of defect detection due to its rapid development. This section summarizes the state of research on inspection of industrial products for detecting surface defects. Learning-based approaches are classified as supervised, semi-supervised, and unsupervised. The performance of learning-based methods is best optimized when large datasets are provided. In particular, supervised techniques perform well when there are sufficient examples of each class in the dataset.

3.1. Supervised

Supervised detection requires large datasets of defect-free and defective samples labeled in a training set. Since all the training data is labeled, detection rates can be very high. It must be noted, however, that supervised detection may not always the most effective approach due to the imbalance of classes in the datasets. There are a number of datasets that supervised learning methods use, including the fabric dataset [30], rail defect dataset [31], and railroad dataset [32].

Deep neural networks and feature extraction and classification methods used in supervised methods differ in their structures. For example, detecting cross-category defects without retraining was proposed using a two-layer neural network in the literature [33]. Based on structural similarities between image pairs, the method learns differential features, which may result in some structural similarities among different classification objects. This method has been shown to be able to detect defects in different types of factories based on experiments in real factory datasets. Literature [34] suggests that the composition of kernels is more important than the number of layers when it comes to detection results. To detect small defects and textures in surface images, it is necessary to use a sample image that is large enough for computational accuracy and reducing the cost of the network. ShuffleNet uses convolution of pointwise groups and channel shuffle as two new techniques to achieve this goal. Literature [35] proposes a novel in-line inspection system for plastic containers based on ShuffleNet V2. The system can be used to inspect images on complex backgrounds as well. In [36], they proposed ShuffleDefectNet, a deep-learning-based defect detection system that achieved 99.75% accuracy on the NEU dataset.

Reference [37] suggested that shallow CNN networks can be used to identify anomalies. To train the model, only negative images are used and the research employs full-size images. The argument is that it is not necessary to have full-size examples of both defective and defect-free samples, as the negative samples already have pixels that correspond to the defect-free regions. Based on the Fast R-CNN model, Faster R-CNN introduces a region proposal network (RPN), which enables an end-to-end learning algorithm. This leads to a near-costless regional recommendation algorithm that significantly improves the speed of target detection. Faster R-CNN was used in [38] to detect PCB surface defects, a new network was proposed combining ResNet50, GRAPN residual units, and ShuffleNetV2. Using a cascaded RCNN structure, as described in literature [39], the defect detection problem of power line insulators can be changed into a two-level target detection problem; the results are shown in Figure 4.

Figure 4.

The results of insulator defect detection. The green box represents the non-defective insulator, and the red box represents the defective insulator [39].

In limited hardware configurations, MobileNet-SSD [9] improves real-time object detection performance. There is no need to sacrifice accuracy for the reduction of parameters in this network. An SSD network classifies regression and boundary box regression using various convolution layers. Translation invariance and variability are resolved in this model, resulting in good detection precision and speed. Object detection is effective when defects have regular or predictable shapes [40]. Additional preprocessing steps can be applied to more complex defect types. Fully Convolutional Networks (FCNs) use all convolutional layers as network layers; label maps can be directly derived using pixel-level prediction. To achieve accurate results, a deconvolution layer with larger data sizes is used. In literature [41], FCN and Faster R-CNN were combined to develop a deep learning model that could detect stains, leaks, and pipeline blockages in tunnels. A method for segmenting defects in solar cell electroluminescence pictures was presented in [42]. A defect segmentation map was obtained in one step by combining FCN with a specific U-net architecture.

3.2. Unsupervised

Research has begun to explore unsupervised methods to overcome the disadvantages of supervised methods. By learning the inherent characteristics of the input training data, the machine can learn some of its own characteristics and connections when there is no label information and automatically classifies the input training data based on the pattern of these unlabeled data [43]. It automatically classifies these unlabeled data based on inherent characteristics and connections between the data. Methods based on reconstruction and embedding similarity are the most commonly used to detect surface defects among unsupervised learning methods. Reconstruction-based methods such as autoencoders (AEs) and Generative Adversarial Networks (GANs) are most commonly used. Popular algorithms include PaDIM [44], SPADE [45] PatchCore [46], etc. In [47], an algorithm based on DBN was proposed for detecting defects in solar cells. Both training and reconstructed images were used as supervision data by the fine-tuning network of the BP algorithm. Literature [48] proposed a multi-scale convolutional denoising autoencoder with high accuracy and robustness that synthesizes the results of multiple pyramid levels.

A SOM-based detection method was proposed in [49] for determining the difference between normal and defective wood. The first stage involves detecting suspected defect areas, and the second stage involves separately inspecting each defect area. A detection method that uses GANs was proposed in reference [50]. The method is divided into two stages: first, a generative network and a learning mechanism based on statistical representation are used to detect new areas. In the second stage, defects and normal samples are directly distinguished using the Frechet distance. The solar panel dataset was used to test the method, and it achieved 93.75% accuracy.

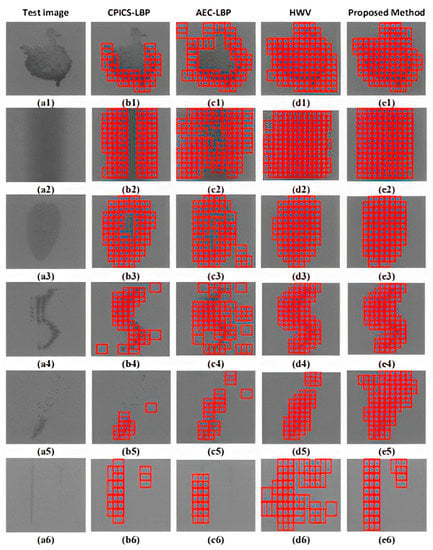

A multiscale AE with fully convolutional neural networks has been proposed [51], in which each FCAE sub-network directly obtains the original feature image from the input image and performs feature clustering. Utilizing a fully convolutional neural network, the residual images were combined to create the defect image. PatchCore, introduced in literature [46], is a technique for identifying and isolating abnormal data in scenarios where only normal examples are available. It balances the need to retain normal context through memory banks of patch-level features extracted from pre-trained ImageNet networks and minimize computational time via coreset subsampling to create a leading system for cold-start image anomaly detection and localization that is efficient on industrial benchmarks. On MVTec, the algorithm demonstrated an AUROC of over 99%, while also being highly efficient in small training set scenarios. Literature [52] presented a GAN-based surface vision detection framework that uses OTSU to segment fusion feature response maps and fuses the responses of the three layers of the GAN discriminator. The framework has been proven effective on datasets of wood cracks and road cracks. As shown in Figure 5, ref. [53] proposed a GAN-based method for detecting strip steel surface defects, in which the generator G uses encoding and the hidden space features in the penultimate layer are fed into a SVM to detect defects. The test results on images provided by the Handan Iron and Steel Plant indicated good accuracy. It is more effective at detecting texture images; however, its accuracy still needs to be improved.

Figure 5.

Presenting the results of experiments on six defect samples using four methods. The defect types are listed in the first column and include drops tar, shadow, floating, crush, pitted surface and scratch. The results from traditional manual feature extraction methods (CPICS-LBP, AEC-LBP, HWV and the proposed method in [53]) are shown in columns 2–5. The experiment compares the proposed method with current state-of-the-art methods in detecting strip steel surface defects.

3.3. Semi-Supervised

As a result of combining the properties of supervised and unsupervised methods, semi-supervised methods are developed. Only normal samples are used as training data for semi-supervised defect detection and a defect-free boundary is learned and set, and any samples outside the boundary are considered anomalous. Since there are few defective samples to be obtained, the method is extremely useful. Nevertheless, this method has lower accuracy in defect detection compared to supervised methods. Unlabeled sample data can be automatically generated by semi-supervised methods without manual intervention.

A framework for identifying defects in PCB solder joints was proposed in literature [54], which utilizes a combination of active learning and self-training through a sample query suggestion algorithm for classification. The framework has been demonstrated to improve classification accuracy while reducing the need for manual annotations. A semi-supervised model of convolutional autoencoder (CAE) and generative adversarial network is proposed in [55]. After training with unlabeled data, the stacked CAE’s encoder network is retained and input into the SoftMax layer as a GAN discriminator. Using GAN, false images of steel surface defects were generated to train the discriminator. For the detection of steel surface defects, literature [56] developed a WSL framework combining localization networks (LNets) and decision networks (DNets), with LNets trained by image level labels and outputs a heat map of potential defects as input to DNets. Through the use of the RSAM algorithm to weight the regions identified by LNet, the proposed framework has been demonstrated to be effective on real industrial datasets. The application prospects for weakly supervised methods are also wide because the methods simultaneously combine advantages of both supervised and unsupervised methods. There are few weakly supervised methods for detecting surface defects in industrial products. The literature [57] proposed a deep learning algorithm to learn defects from a variety of defect types with an unbalanced training sample pool for PCBA manufacturing products. In this method, an overall defect recognition accuracy of 98% is achieved in PBCA images using a novel batch sampling method and the sample weighted cost function.

A semi-supervised learning system that generates samples to detect surface defects was proposed according to the literature [58]. As part of the semi-supervised learning part, two CDCGAN and ResNet18 classifiers were used, and the NEU-CLS dataset was used to compare the two classifiers. In this way, supervised learning and transfer learning are both shown to be inferior to the method. A convolutional neural network structure based on residual network structures was proposed in [59] by stacking two layers of residual building modules together, resulting in a 43-layer convolutional neural network, while at the same time by appropriately increasing the network width; a more balanced network depth and network width can be obtained and accuracy can be improved. The network structure shows good performance on the DAGM, NEU steel, and copper clad plate datasets. Table 3 provides an overview of recent research in surface defect detection, including classifications of targets and Table 4 evaluates the strengths and weaknesses of deep learning techniques for detecting surface defects in industrial products, including accuracy, computational efficiency, and robustness. These tables give a comprehensive understanding of current research and the considerations for using deep learning in surface defect detection. Table 5 lists a selection of commonly used datasets for training and testing algorithms for detecting surface defects in industrial products. The datasets are classified based on the type of industrial products they are intended for. This information is useful for researchers and practitioners looking for suitable datasets for their work in the field of surface defect detection.

Table 3.

An overview of recent research publications as well as classifications based on targets.

Table 4.

Strengths and weaknesses of different techniques for detecting surface defects on industrial products using deep learning.

Table 5.

A list of common surface defect datasets with classifications for industrial products.

4. Deep Learning Defect Detection Methods for X-ray Images for Industrial Products

Non-destructive testing (NDT) is a method that uses radiography or ultrasound technologies to discover faults without causing damage to the detected objects. It is widely used in engineering industries to detect and evaluate defects in materials of all types.

An important technique in non-destructive testing is radiographic testing, which uses X-rays to identify and evaluate flaws or defects, such as cracks or porosities. Defects can appear in X-ray images in many shapes and sizes, making detection difficult. The images are often low contrast and noisy, making identification of defects difficult.

The traditional approach for identifying defects in industrial products is for human operators or experts to visually inspect radiographs. However, this method can be subjective and prone to errors. Additionally, the process of examining a large number of images can be time-consuming and may lead to misinterpretations. However, there have been significant advancements in the field of defect detection in recent years, thanks to the emergence of deep learning techniques. As a result, a number of methods for detecting defects have been proposed, which are more efficient and reliable than the conventional approach. This section aims to provide a summary of current research on industrial product defect detection methods using X-ray images. Specifically, it covers the use of deep learning techniques such as convolutional neural networks and generative adversarial networks to analyze radiographic images and identify defects with a high degree of accuracy. These methods have the potential to reduce the subjectivity and human errors associated with the traditional approach, as well as the time required for inspection. Additionally, they can be trained to improve over time with more data, making them more robust and reliable.

A proposed system in literature [124] aimed to automate the process of inspecting and monitoring the condition of machines in the hard metal industry by analyzing defects in real production samples. Three models were created to analyze different types of data, a method called stacked generalization ensemble was applied and a random forest classifier was utilized to combine and analyze the results of the microprofilometer and ultrasound models. The fusion model was found to have improved performance and higher classification accuracy (88.24%) as compared to the individual models. Additionally, the shop floor model was able to effectively identify breakdowns during the manufacturing process and the ultrasound model was found to have better classification scores compared to the VGG-19 model. According to literature [125], a three-stage deep learning algorithm was proposed for detecting bubble patterns in engines. The algorithm consisted of training an autoencoder using normal images, fixing the coefficients of the encoder, and training a fully-connected network using both normal and defective images. To improve the performance of the network, the entire system was fine-tuned. According to [126], a CNN model was designed with ten layers that belong to six grades for detecting defects in X-ray welding images. It was possible to achieve 98.8% classification accuracy using CNN if the ReLU activation function was used for X-ray welding image recognition. A real-time X-ray image analysis method using Support Vector Machines (SVMs) was presented in [127]. Using a background subtraction algorithm, all potential defects were segmented, and three features were extracted, including the defect area, the grayscale average difference, and the grayscale standard deviation. In order to distinguish non-defects from defects, the extracted features were input into an SVM classifier. A real-time X-ray image defect detection method based on the proposed method reduced undetected defects and false alarms. Another SVM-based method for detecting weld defects was described in [128]. The training SVM is trained by extracting three feature vectors from potential weld defects using grey-level profile analysis. In the last step, the SVM is trained to differentiate between defects that are real and those that are potential. A high percentage of correct detections could be achieved using the proposed method. For detecting insert molding in automotive electronics, ref. [129] proposed a Yolov5-based DR image defect detection algorithm. Width and a window level are adjusted in the preprocessing stage of the acquired data, and fast guided filtering is used for edge retention. Using the overlap, tiny anomalies are detected, and a multi-task dataset is constructed. Using Ghost, which replaces the standard convolutional network with the backbone network with enhanced features, the number of parameters can be further reduced. Moreover, CSP-modules are embedded in the neck and backbone of the network to enhance feature extraction. As a result of adding the transformer attention module after spatial pyramid pooling, over-fitting can be avoided while computational effort can be reduced. DR data-based Yolo series target detection algorithms are used as a final step to conduct consistent experiments. For detecting bead toe errors, ref. [130] proposed a lightweight semantic segmentation network. An encoder extracts the texture features of different regions of the tire in the network first. Then, to fuse the encoder’s output feature, a decoder is introduced. A reduction in the dimension of the feature maps has allowed the positions of the bead toe to be recorded in the X-ray image. An index of local mIoU (L-mIoU) is proposed to evaluate the final segmentation effect. YOLOv3_EfficientNet is used as the backbone of the methodology instead of YOLOv3_darknet53. It results in a substantial improvement in YOLOv3 mean average precision, as well as a substantial reduction in inference time and storage space. DR image features are then used to enhance the data, thereby increasing the diversity of the clarity and shape of defects. With depth separable convolution, models can be deployed on embedded devices with acceptable accuracy loss ranges. A method was presented in [131] that utilizes deep learning with X-ray images to detect defects in aluminum casting parts used in automobiles, with the goal of improving the accuracy of both the algorithm and data augmentation. The study found that using Feature Pyramid Networks (FPNs) resulted in a 40.9% increase in Mean of Average Precision (mAP) value, making it the most effective modification. Additionally, using RoIAlign instead of RoI pooling in Faster R-CNN improved the accuracy of bounding box location. The study also proposed various data augmentation methods to compensate for the limited availability of X-ray image datasets for defect detection. The results showed that the mAP values for each data augmentation method reached an optimal value and did not continue to increase as the number of datasets increased. Overall, the proposed improvements to the Faster R-CNN algorithm resulted in better performance for X-ray image defect detection of automobile aluminum casting parts. Using the Faster R-CNN detection model with X-ray preprocessing was applied to the detection of tire defects in [132] to improve curve fitting performance. Faster R-CNN precision and recall of defects were improved by adjusting its feature extractor, proposal generator, and box classifier. According to literature [133], triplet deep neural networks can be used to detect weld defects. X-ray images are first preprocessed into relief images to make defects easier to identify. Following that, a deep network is constructed based on triplets, and a feature vector is obtained by mapping the triplets. The distance between similar defect feature vectors and the distance between different types of defect feature vectors must be closer. The SVM is also used for automatic detection and classification of weld defects. Based on the results of two experiments, the proposed method is capable of effectively detecting multiple defects. Table 6 and Table 7 together provide a comprehensive overview of the current state of research and practices in the field of deep learning for defect detection in X-ray images. Table 6 summarizes recent research publications, and Table 7 compares the strengths and weaknesses of different techniques. This information can be valuable for anyone interested in the advancement of this field.

Table 6.

Recent publications on deep learning defects detection in X-ray images.

Table 7.

Strengths and weaknesses of different deep-learning techniques for identifying defects in X-ray images.

5. Problems and Solutions

5.1. Unbalanced Sample Identification Problem

In industrial products, surface defects can also be detected with deep learning using unbalanced sample sets [137,138]. To train the deep learning model, it is usually necessary to have a balanced sample set of samples of different categories. This ideal situation, however, almost never occurs in the real world. More often than not, the majority of data in the dataset comes from “normal” samples, while “defective” or “abnormal” samples only make up a small portion. Supervised learning is one of the main tasks that suffers from unbalanced sample identification. The algorithm will therefore pay more attention to categories with larger data volumes and underestimate categories with smaller data volumes, affecting the model’s generalization and prediction abilities. The data-level process methods aim to maintain a consistent number of samples for all types within the training set. Resolving the unbalanced sample identification issue at the data level can be broken down into five categories: data resampling, data augmentation, class equalization sampling, data source, and synthetic sampling. It is necessary to collect more samples in fewer categories from the data source. By horizontally or vertically flipping, rotating, zooming, cropping, and other operations, we can purposefully increase the number of sample data in each category.

Regarding data resampling [139,140], it is good to resample a sample set to change the proportion of samples in each category, including oversampling and undersampling. Class equalization sampling groups samples by categories and generates sample lists for each category. To ensure that each category has an equal chance of participating in training, a random category is selected during training, and samples are randomly selected from the corresponding sample list. Synthetic samples [141] are generated by combining various characteristics of an existing sample to create a new sample. Using this method, you can create a new sample by randomly selecting a value from the feature.

5.2. Small Sample Problem

As a result of continuous optimization of industrial processes, the number of defective samples has decreased. This makes it difficult to use deep learning methods to detect surface defects in industrial products, since there are fewer and fewer defect images available for deep learning. Overfitting problems in training can easily occur with small samples [142]. Transfer learning applies knowledge gained from one task to a different but related task when there is insufficient data to complete the target task. Consequently, transfer learning is also a critical method for solving the small sample problem. For surface defect detection, literature [143,144] used VGG networks and transfer learning to detect emulsion pump bodies, printed circuit boards, transmission line components, steel plates, and wood surfaces. Fabric surface defect detection using DenseNet and transfer learning was described in [145]. The combination of transfer learning and AlexNet was used to detect surface defects on solar panels and fabrics in [146,147]. Solving the small sample problem can also be achieved by optimizing the network structure. For the first time, GAN was used for image anomaly detection with the AnoGAN model [148] in 2017. A continuous iterative optimization process is used to find an image that matches the test image closest in the latent space, and then DCGAN is used to detect anomalies in that image. The f-AnoGAN model was introduced in [149]. This model proposes a method of encoding an image so that latent points can be quickly mapped, and then using WGAN to detect anomalies. As a result of the introduction of an encoder, the AnoGAN’s iterative optimization process is much faster and less time-consuming. Additionally, the GANomaly model was proposed in [150] in 2018. It detects abnormal samples by comparing latent variables obtained by coding with latent variables obtained by reconstructing. There is no requirement for training with negative samples in any of the above models. It is also possible to obtain many sample images by enlarging the data. Using synthetic defects [151], the decorated plastic part dataset is expanded by adding synthetic defects to the defect-free image. Literature [152] described a technique for generating defect representations that combine hand-made and unsupervised learning features.

5.3. Real-Time Problem

It is essential to consider real-time problems when performing surface defect detection in real industrial environments. Real-time detection problems involve reducing detection time and improving detection efficiency to maintain roughly the same accuracy. Research has been conducted on real-time problems by some scholars. To detect surface defects on printed circuit boards, literature [153] suggested combining SSIM and MobileNet. Comparing the proposed algorithm with Faster R-CNN, it maintained high accuracy while being at least 12 times quicker than the existing algorithm. Literature [154] developed a novel 11-layer CNN model for detecting welding defects in robotic welding manufacturing. The proposed method was capable of detecting metal additive manufacturing in real time, which meets specific requirements for online detection.

6. Discussion

Deep learning technology has revolutionized the field of defect detection in industrial products. However, finding a suitable deep learning model for solving the defect detection problem is very difficult due to the particularities of industrial scenarios. In the coming years, deep learning will encounter challenges and trends as it becomes more widely used in industrial fields. A brief description of recent trends and future research directions is provided in this section.

- Integrating deep learning with other methods:

By incorporating other techniques such as traditional image processing, the robustness and performance of the defect detection system in challenging conditions can be enhanced. For instance, using traditional image processing techniques to preprocess the images before inputting them into a deep learning model can improve the quality of the data and make it easier for the model to effectively detect defects. Additionally, integrating deep learning with other techniques, such as physics-based simulations, can provide better understanding of the underlying physical causes of defects and lead to the development of more efficient and effective defect detection methods.

- Adjustment to various lighting scenarios:

Examining industrial products frequently occurs under diverse lighting conditions, which can make it hard to identify defects. Research in this field could concentrate on developing techniques for adapting to various lighting conditions and using them to enhance the precision of defect detection. This could include methods such as image enhancement techniques, color constancy techniques, and multiple exposure fusion techniques, to improve the visibility of defects in different lighting conditions. Additionally, research could also focus on developing deep learning models that are robust to changes in lighting conditions, such as using adversarial training methodologies, to improve the robustness of the model. This may lead to a more accurate and reliable defect detection system that can function in a wide range of lighting scenarios.

- Transparent AI:

To be implemented in industrial environments, defect detection systems need to be transparent and explainable. Research in this field could focus on developing techniques to make deep-learning-based defect detection systems more understandable, so that users can comprehend why a defect was missed or incorrectly identified.

- All aspects need to be taken into account:

In order for a defect detection system to perform well, it must take into account various factors. There are many factors that can influence the accurate detection of defects, such as defect size, shape, the technique for image acquisition, alignment and distortion of images, resolution of images, and algorithmic speed, among others. It is important to consider all of these factors when creating a mature and successful method.

- Limited number of defect samples:

In many industrial applications, deep learning methods require a large training dataset and have high computational costs, and the number of defect samples is often insufficient to detect defects. Additionally, as the product line is frequently updated, new defect types are introduced and the detection process becomes more challenging. When training on normal samples, a simple defect detection method does not have any issues dealing with a small defect dataset, but, when it comes to defect localization and classification, the size of the dataset containing defects can be a challenge.

- Utilizing transfer learning:

Defect patterns may be shared between two different application domains. There may be similarities in the morphology of cracks in two different materials, but they may be different in their sizes and colors. It is currently necessary to train two different networks in order to use current approaches. A well-trained, tested network can transfer its knowledge to a new network to speed up the training process. Currently, transfer learning is not effectively utilized in most approaches.

- Multi-modal sensor integration:

Defect detection in industrial products often relies on visual inspections using cameras or other imaging devices. However, incorporating other types of sensors, such as thermal, acoustic, or vibration sensors, can provide additional information that can aid in the detection of defects. Research in this area could focus on developing methods for integrating data from multiple sensors and using it to improve the accuracy of defect detection. This could include techniques such as sensor fusion, where data from multiple sensors is combined to provide a more comprehensive view of the product, or methods for combining deep learning with other types of sensor data, such as sensor data from IoT devices.

- Continuous learning:

In industrial environments, the product line is frequently updated, and new defect types are introduced. Research in this area could focus on developing methods for continuous online learning, which can be used to adapt the defect detection system as new data is acquired and new defects are introduced. This could include online learning techniques, where the system can continuously update its knowledge as new data is acquired, or active learning methods, where the system can actively select the most informative images for annotation. This would allow the system to adapt to changes in the product line and improve its performance over time.

- Real-time detection:

There are only a few existing defect detection methods that are implemented in real time. In order to apply these methods to real-time inspection scenarios in the future, computationally efficient methods must be developed among these methods in order to achieve detection success rates in real time.

- Reducing the complexity:

Users of defect detection methods are interested in understanding why a defect has been missed or incorrectly identified in an acceptable part when such a method fails to find the defect. The majority of deep learning methods follow a complex architecture, so humans have difficulty understanding the decision-making process and providing a rationale for failure. When it comes to deploying and improving the performance of a system, this can be a challenge. Moreover, in industrial applications, lightweight deep learning networks will be easier to deploy. Often, the processing resources used to support artificial intelligence computations are valuable in quality inspections on production lines and industrial maintenance monitoring. By using lightweight networks, the prediction system’s workload can be effectively reduced, which is extremely beneficial for simple terminal deployments and can also reduce costs and performance.

- A common reference database:

Testing can be conducted on different databases, though several studies have failed to provide satisfactory results due to inconsistency in such databases and a lack of testing samples. Additionally, most of the studies presented in this review have their own databases with varying sizes and quality. To evaluate and compare performance in the future, a common reference database would be helpful.

7. Conclusions

Deep learning is rapidly gaining momentum as a powerful tool in the field of defect detection on industrial products. In this paper, we conducted a comprehensive review of the current state-of-the-art in the use of machine learning methods for detecting defects in industrial products. We specifically focused on deep learning methods for detecting surface defects and defects from X-ray images, and provided a detailed overview of the different techniques and algorithms that have been proposed in these areas. We also discussed some of the key challenges and limitations of these methods, and highlighted potential solutions to these problems. The goal of this review was to provide researchers with a clear understanding of the current state-of-the-art in the field of surface defect detection for industrial products, and to serve as a reference for future research in this area.

Author Contributions

Authors contributed as follows: Conceptualization, A.S. and J.R.; methodology, J.R. and M.E.-G.; funding acquisition, J.R. and M.E.-G.; investigation, A.S., J.R. and M.E.-G.; writing original draft preparation, A.S. and J.R.; writing—review and editing, A.S., J.R. and M.E.-G.; supervision, J.R. and M.E.-G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Natural Sciences and Engineering Research Council of Canada (NSERC), grant number 210471.

Data Availability Statement

In the manuscript, you will find a list of the corresponding websites.

Conflicts of Interest

There are no conflicts of interest between the authors.

References

- Rasheed, A.; Zafar, B.; Rasheed, A.; Ail, N.; Sajid, M.; Dar, S.H.; Habib, U.; Shehryar, T.; Mahmood, M.T. Fabric Defect Detection Using Computer Vision Techniques: A Comprehensive Review. Math. Probl. Eng. 2020, 2020, 8189403. [Google Scholar] [CrossRef]

- Song, W.; Chen, T.; Gu, Z.; Gai, W.; Huang, W.; Wang, B. Wood Materials Defects Detection Using Image Block Percentile Color Histogram and Eigenvector Texture Feature. In Proceedings of the First International Conference on Information Sciences, Machinery, Materials and Energy, Chongqing China, 11–13 April 2015. [Google Scholar]

- Ma, N.; Gao, X.; Wang, C.; Zhang, Y.; You, D.; Zhang, N. Influence of Hysteresis Effect on Contrast of Welding Defects Profile in Magneto-Optical Image. IEEE Sens. J. 2020, 20, 15034–15042. [Google Scholar] [CrossRef]

- Prasitmeeboon, P.; Yau, H. Defect Detection of Particleboards by Visual Analysis and Machine Learning. In Proceedings of the 2019 5th International Conference on Engineering, Applied Sciences and Technology (ICEAST), Luang Prabang, Laos, 2–5 July 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Li, J.H.; Quan, X.X.; Wang, Y.L. Research on Defect Detection Algorithm of Ceramic Tile Surface with Multi-feature Fusion. Comput. Eng. Appl. 2020, 56, 191–198. [Google Scholar]

- Wang, F.l.; Zuo, B. Detection of surface cutting defect on magnet using Fourier image reconstruction. J. Cent. South Univ. 2016, 23, 1123–1131. [Google Scholar] [CrossRef]

- Wang, J.; Fu, P.; Gao, R.X. Machine vision intelligence for product defect inspection based on deep learning and Hough transform. J. Manuf. Syst. 2019, 51, 52–60. [Google Scholar] [CrossRef]

- Tsai, D.M.; Huang, C.K. Defect Detection in Electronic Surfaces Using Template-Based Fourier Image Reconstruction. IEEE Trans. Compon. Packag. Manuf. Technol. 2019, 9, 163–172. [Google Scholar] [CrossRef]

- Chang, C.-F.; Wu, J.-L.; Chen, K.-J.; Hsu, M.-C. A hybrid defect detection method for compact camera lens. Adv. Mech. Eng. 2017, 9, 1687814017722949. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, K.; Xu, J. An Improved MB-LBP Defect Recognition Approach for the Surface of Steel Plates. Appl. Sci. 2019, 9, 4222. [Google Scholar] [CrossRef]

- Putri, A.P.; Rachmat, H.; Atmaja, D.S.E. Design of Automation System for Ceramic Surface Quality Control Using Fuzzy Logic Method at Balai Besar Keramik (BBK). MATEC Web. Conf. 2017, 135, 53. [Google Scholar] [CrossRef]

- Yang, J.; Li, S.; Wang, Z.; Dong, H.; Wang, J.; Tang, S. Using Deep Learning to Detect Defects in Manufacturing: A Comprehensive Survey and Current Challenges. Materials 2020, 13, 5755. [Google Scholar] [CrossRef]

- Lee, D.; Kang, Y.; Park, C.; Won, S. Defect Detection Algorithm in Steel Billets Using Morphological Top-Hat filter. IFAC Proc. Vol. 2009, 42, 209–212. [Google Scholar] [CrossRef]

- Zhu, D.; Pan, R.; Gao, W.; Zhang, J. Yarn-Dyed Fabric Defect Detection Based On Autocorrelation Function And GLCM. Autex Res. J. 2015, 15, 226–232. [Google Scholar] [CrossRef]

- Gao, X.; Xie, Y.; Chen, Z.; You, D. Fractal feature detection of high-strength steel weld defects by magnetooptical imaging. Trans. China Weld. Inst. 2017, 38, 1–4. [Google Scholar] [CrossRef]

- Yun, J.P.; Choi, S.H.; Kim, J.W.; Kim, S.W. Automatic detection of cracks in raw steel block using Gabor filter optimized by univariate dynamic encoding algorithm for searches (uDEAS). NDT E. Int. 2009, 42, 389–397. [Google Scholar] [CrossRef]

- Li, Y.; Liu, M. Aerial Image Classification Using Color Coherence Vectors and Rotation & Uniform Invariant LBP Descriptors. In Proceedings of the 2018 IEEE 3rd Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chongqing China, 12–14 October 2018; pp. 653–656. [Google Scholar] [CrossRef]

- Ren, H.; Tian, K.; Hong, S.; Dong, B.; Xing, F.; Qin, L. Visualized investigation of defect in cementitious materials with electrical resistance tomography. Constr. Build. Mater. 2019, 196, 428–436. [Google Scholar] [CrossRef]

- Ma, Y.; Li, Q.; He, F.; Liu, Y.; Xi, S. Adaptive segmentation algorithm for metal surface defects. Chin. J. Sci. Instrum. 2017, 38, 245–251. [Google Scholar]

- Li, S.; Yang, J.; Wang, Z.; Zhu, S.; Yang, G. Review of Development and Application of Defect Detection Technology. Acta Autom. Sin. 2020, 46, 2319–2336. [Google Scholar]

- Papageorgiou, E.I.; Theodosiou, T.; Margetis, G.; Dimitriou, N.; Charalampous, P.; Tzovaras, D.; Samakovlis, I. Short Survey of Artificial Intelligent Technologies for Defect Detection in Manufacturing. In Proceedings of the 2021 12th International Conference on Information, Intelligence, Systems & Applications (IISA), Chania Crete, Greece, 12–14 July 2021; pp. 1–7. [Google Scholar] [CrossRef]

- Tao, X.; Hou, W.; Xu, D. A Survey of Surface Defect Detection Methods Based on Deep Learning. Acta Autom. Sin. 2020, 47, 1017–1034. [Google Scholar]

- Zhang, Z.; Pang, W.; Xie, W.; Lv, M.; Wang, Y. Deep Learning for Real-time Applications: A Survey. J. Softw. 2020, 31, 2654–2677. [Google Scholar]

- Ma, S.; Wu, N.; Li, X. Deep learning with big data: State of the art and development. CAAI Trans. Intell. Syst. 2016, 11, 728–742. [Google Scholar]

- Kumar, A. Computer-Vision-Based Fabric Defect Detection: A Survey. IEEE Trans. Ind. Electron. 2008, 55, 348–363. [Google Scholar] [CrossRef]

- Ahuja, S.K.; Shukla, M.K. A survey of computer vision based corrosion detection approaches. In International Conference on Information and Communication Technology for Intelligent Systems; Springer: Berlin/Heidelberg, Germany, 2017; pp. 55–63. [Google Scholar]

- Cao, W.; Liu, Q.; He, Z. Review of Pavement Defect Detection Methods. IEEE Access 2020, 8, 14531–14544. [Google Scholar] [CrossRef]

- Fouzia, M.T.; Nirmala, K. A literature survey on various methods used for metal defects detection using image segmentation. Evaluation 2010, 5, 8. [Google Scholar]

- Czimmermann, T.; Ciuti, G.; Milazzo, M.; Chiurazzi, M.; Roccella, S.; Oddo, C.M.; Dario, P. Visual-Based Defect Detection and Classification Approaches for Industrial Applications—A SURVEY. Sensors 2020, 20, 1459. [Google Scholar] [CrossRef] [PubMed]

- Silvestre-Blanes, J.; Albero-Albero, T.; Miralles, I.; Pérez-Llorens, R.; Moreno, J. A Public Fabric Database for Defect Detection Methods and Results. Autex Res. J. 2019, 19, 363–374. [Google Scholar] [CrossRef]

- Faghih-Roohi, S.; Hajizadeh, S.; Núñez, A.; Babuska, R.; De Schutter, B. Deep convolutional neural networks for detection of rail surface defects. In Proceedings of the 2016 International Joint Conference on Neural Networks (IJCNN), Vancouver, BC, Canada, 24–29 July 2016; pp. 2584–2589. [Google Scholar] [CrossRef]

- Gan, J.; Li, Q.; Wang, J.; Yu, H. A Hierarchical Extractor-Based Visual Rail Surface Inspection System. IEEE Sens. J. 2017, 17, 7935–7944. [Google Scholar] [CrossRef]

- Luan, C.; Cui, R.; Sun, L.; Lin, Z. A Siamese Network Utilizing Image Structural Differences For Cross-Category Defect Detection. In Proceedings of the 2020 IEEE International Conference on Image Processing (ICIP), Abu Dhabi, United Arab Emirates, 25–28 October 2020; pp. 778–782. [Google Scholar] [CrossRef]

- Park, J.-K.; Kwon, B.-K.; Park, J.-H.; Kang, D.-J. Machine learning-based imaging system for surface defect inspection. Int. J. Precis. Eng. Manuf.-Green Technol. 2006, 3, 303–310. [Google Scholar] [CrossRef]

- Liang, Q.; Zhu, W.; Sun, W.; Yu, Z.; Wang, Y.; Zhang, D. In-line inspection solution for codes on complex backgrounds for the plastic container industry. Measurement 2019, 148, 106965. [Google Scholar] [CrossRef]

- Anvar, A.; Cho, Y.I. Automatic Metallic Surface Defect Detection using ShuffleDefectNet. J. Korea Soc. Comput. Inf. 2020, 25, 19–26. [Google Scholar]

- Racki, D.; Tomazevic, D.; Skocaj, D. Towards surface anomaly detection with deep learning. Procedia CIRP 2019, 79, 484–489. [Google Scholar]

- Hu, B.; Wang, J. Detection of PCB Surface Defects With Improved Faster-RCNN and Feature Pyramid Network. IEEE Access 2020, 8, 108335–108345. [Google Scholar] [CrossRef]

- Tao, X.; Zhang, D.; Wang, Z.; Liu, X.; Zhang, H.; Xu, D. Detection of Power Line Insulator Defects Using Aerial Images Analyzed With Convolutional Neural Networks. IEEE Trans. Syst. Man Cybern. Syst. 2020, 50, 1486–1498. [Google Scholar] [CrossRef]

- Song, L.; Li, X.; Yang, Y.; Zhu, X.; Guo, Q.; Yang, H. Detection of Micro-Defects on Metal Screw Surfaces Based on Deep Convolutional Neural Networks. Sensors 2018, 18, 3709. [Google Scholar] [CrossRef]

- Gao, X.; Jian, M.; Hu, M.; Tanniru, M.; Li, S. Faster multi-defect detection system in shield tunnel using combination of FCN and faster RCNN. Adv. Struct. Eng. 2019, 22, 2907–2921. [Google Scholar] [CrossRef]

- Balzategui, J.; Eciolaza, L.; Arana-Arexolaleiba, N. Defect detection on Polycrystalline solar cells using Electroluminescence and Fully Convolutional Neural Networks. In Proceedings of the 2020 IEEE/SICE International Symposium on System Integration (SII), Honolulu, HI, USA, 12–15 January 2020; pp. 949–953. [Google Scholar] [CrossRef]

- Dike, H.U.; Zhou, Y.; Deveerasetty, K.K.; Wu, Q. Unsupervised Learning Based On Artificial Neural Network: A Review. In Proceedings of the 2018 IEEE International Conference on Cyborg and Bionic Systems (CBS), Shenzhen, China, 25–27 October 2018; pp. 322–327. [Google Scholar] [CrossRef]

- Defard, T.; Setkov, A.; Loesch, A.; Audigier, R. PaDiM: A Patch Distribution Modeling Framework for Anomaly Detection and Localization. arXiv 2020, arXiv:2011.08785. [Google Scholar]

- Cohen, N.; Hoshen, Y. Sub-Image Anomaly Detection with Deep Pyramid Correspondences. arXiv 2020, arXiv:2005.02357. [Google Scholar]

- Roth, K.; Pemula, L.; Zepeda, J.; Schölkopf, B.; Brox, T.; Gehler, P. Towards Total Recall in Industrial Anomaly Detection. arXiv 2021, arXiv:2106.08265. [Google Scholar]

- Wang, X.; Li, J.; Yao, M.; He, W.; Qian, Y. Solar Cells Surface Defects Detection Based on Deep Learning. Pattern Recognit. Artif. Intell. 2014, 27, 517–523. [Google Scholar]

- Mei, S.; Yang, H.; Yin, Z. An Unsupervised-Learning-Based Approach for Automated Defect Inspection on Textured Surfaces. IEEE Trans. Instrum. Meas. 2018, 67, 1266–1277. [Google Scholar] [CrossRef]

- Silvén, O.; Niskanen, M.; Kauppine, H. Wood inspection with non-supervised clustering. Mach. Vis. Appl. 2003, 13, 275–285. [Google Scholar] [CrossRef]

- Lai, Y.T.K.; Hu, J.S. A Texture Generation Approach for Detection of Novel Surface Defects. In Proceedings of the 2018 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Miyazaki, Japan, 7–10 October 2018; pp. 4357–4362. [Google Scholar] [CrossRef]

- Yang, H.; Chen, Y.; Song, K.; Yin, Z. Multiscale Feature-Clustering-Based Fully Convolutional Autoencoder for Fast Accurate Visual Inspection of Texture Surface Defects. IEEE Trans. Autom. Sci. Eng. 2019, 16, 1450–1467. [Google Scholar] [CrossRef]

- Zhai, W.; Zhu, J.; Cao, Y.; Wang, Z. A Generative Adversarial Network Based Framework for Unsupervised Visual Surface Inspection. In Proceedings of the 2018 IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), Calgary, AB, Canada, 15–20 April 2018; pp. 1283–1287. [Google Scholar] [CrossRef]

- Liu, K.; Li, A.; Wen, X.; Chen, H.; Yang, P. Steel Surface Defect Detection Using GAN and One-Class Classifier. In Proceedings of the 2019 25th International Conference on Automation and Computing (ICAC), Lancaster, UK, 5–7 September 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Dai, W.; Mujeeb, A.; Erdt, M.; Sourin, A. Soldering defect detection in automatic optical inspection. Adv. Eng. Inform. 2020, 43, 101004. [Google Scholar] [CrossRef]

- Di, H.; Ke, X.; Peng, Z.; Dongdong, Z. Surface defect classification of steels with a new semi-supervised learning method. Opt. Lasers Eng. 2019, 117, 40–48. [Google Scholar] [CrossRef]

- Xu, L.; Lv, S.; Deng, Y.; Li, X. A Weakly Supervised Surface Defect Detection Based on Convolutional Neural Network. IEEE Access 2020, 8, 42285–42296. [Google Scholar] [CrossRef]

- Ren, J.; Gabbar, H.A.; Huang, X.; Saberironaghi, A. Defect Detection for Printed Circuit Board Assembly Using Deep Learning. In Proceedings of the International Conference Control Science and System Engineering (ICCSSE), Guangzhou, China, 14–16 July 2022. [Google Scholar]

- He, Y.; Song, K.; Dong, H.; Yan, Y. Semi-supervised defect classification of steel surface based on multi-training and generative adversarial network. Opt. Lasers Eng. 2019, 122, 294–302. [Google Scholar] [CrossRef]

- Zheng, X.; Wang, H.; Chen, J.; Kong, Y.; Zheng, S. A Generic Semi-Supervised Deep Learning-Based Approach for Automated Surface Inspection. IEEE Access 2020, 8, 114088–114099. [Google Scholar] [CrossRef]

- Fu, G.; Sun, P.; Zhu, W.; Yang, J.; Cao, Y.; Yang, M.Y.; Cao, Y. A deep-learning-based approach for fast and robust steel surface defects classification. Opt. Lasers Eng. 2019, 121, 397–405. [Google Scholar] [CrossRef]

- Akhyar, F.; Lin, C.Y.; Muchtar, K.; Wu, T.Y.; Ng, H.F. High Efficient Single-stage Steel Surface Defect Detection. In Proceedings of the 2019 16th IEEE International Conference on Advanced Video and Signal Based Surveillance (AVSS), Taipei, Taiwan, 18–21 September 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Li, K.; Wang, X.; Ji, L. Application of Multi-Scale Feature Fusion and Deep Learning in Detection of Steel Strip Surface Defect. In Proceedings of the 2019 International Conference on Artificial Intelligence and Advanced Manufacturing (AIAM), Dublin, Ireland, 17–19 October 2019; pp. 656–661. [Google Scholar] [CrossRef]

- Wang, T.; Chen, Y.; Qiao, M.; Snoussi, H. A fast and robust convolutional neural network-based defect detection model in product quality control. Int. J. Adv. Manuf. Technol. 2018, 94, 3465–3471. [Google Scholar] [CrossRef]

- Weimer, D.; Scholz-Reiter, B.; Shpitalni, M. Design of deep convolutional neural network architectures for automated feature extraction in industrial inspection. CIRP Ann. 2016, 65, 417–420. [Google Scholar] [CrossRef]

- Qiu, L.; Wu, X.; Yu, Z. A High-Efficiency Fully Convolutional Networks for Pixel-Wise Surface Defect Detection. IEEE Access 2019, 7, 15884–15893. [Google Scholar] [CrossRef]

- Yu, Z.; Wu, X.; Gu, X. Fully convolutional networks for surface defect inspection in industrial environment. In International Conference on Computer Vision Systems; Springer: Berlin/Heidelberg, Germany, 2017; pp. 417–426. [Google Scholar]

- Mujeeb, A.; Dai, W.; Erdt, M.; Sourin, A. Unsupervised Surface Defect Detection Using Deep Autoencoders and Data Augmentation. In Proceedings of the 2018 International Conference on Cyberworlds (CW), Singapore, 3–5 October 2018; pp. 391–398. [Google Scholar] [CrossRef]

- Deng, Z.; Yan, X.; Liu, X. Extremal Region Analysis based Deep Learning Framework for Defects Detection. In Proceedings of the 2020 IEEE International Conference on Information Technology, Big Data and Artificial Intelligence (ICIBA), Chongqing, China, 6–8 November 2020; pp. 142–145. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, X.; Zhou, N. Improved YOLOv5 with BiFPN on PCB Defect Detection. In Proceedings of the 2021 2nd International Conference on Artificial Intelligence and Computer Engineering (ICAICE), Hangzhou, China, 5–7 November 2021; pp. 196–199. [Google Scholar] [CrossRef]

- Lan, Z.; Hong, Y.; Li, Y. An improved YOLOv3 method for PCB surface defect detection. In Proceedings of the 2021 IEEE International Conference on Power Electronics, Computer Applications (ICPECA), Shenyang, China, 22–24 January 2021; pp. 1009–1015. [Google Scholar] [CrossRef]

- Luo, J.; Yang, Z.; Li, S.; Wu, Y. FPCB Surface Defect Detection: A Decoupled Two-Stage Object Detection Framework. IEEE Trans. Instrum. Meas. 2021, 70, 1–11. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, B.; Shao, Y.; Ye, Z. Surface Defect Detection of Rails Based on Convolutional Neural Network Multi-Scale-Cross FastFlow. In Proceedings of the 2022 5th International Conference on Pattern Recognition and Artificial Intelligence (PRAI), Chengdu, China, 19–21 August 2022; pp. 405–411. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, M.; Wang, Z.; Zhou, P. Surface Defect Detection of Hight-speed Railway Hub Based on Improved YOLOv3 Algorithm. In Proceedings of the 2021 IEEE 4th Advanced Information Management, Communicates, Electronic and Automation Control Conference (IMCEC), Xi’an, China, 25–27 May 2021; pp. 1386–1390. [Google Scholar] [CrossRef]

- Kang, G.; Gao, S.; Yu, L.; Zhang, D. Deep Architecture for High-Speed Railway Insulator Surface Defect Detection: Denoising Autoencoder With Multitask Learning. IEEE Trans. Instrum. Meas. 2019, 68, 2679–2690. [Google Scholar] [CrossRef]

- Natarajan, V.; Hung, T.Y.; Vaikundam, S.; Chia, L.T. Convolutional networks for voting-based anomaly classification in metal surface inspection. In Proceedings of the 2017 IEEE International Conference on Industrial Technology (ICIT), Toronto, ON, Canada, 22–25 March 2017; pp. 986–991. [Google Scholar] [CrossRef]

- He, H.; Yuan, M.; Liu, X. Research on Surface Defect Detection Method of Metal Workpiece Based on Machine Learning. In Proceedings of the 2021 6th International Conference on Intelligent Computing and Signal Processing (ICSP), Xi’an, China, 9–11 April 2021; pp. 881–884. [Google Scholar] [CrossRef]

- Feng, Z.; Guo, L.; Huang, D.; Li, R. Electrical Insulator Defects Detection Method Based on YOLOv5. In Proceedings of the 2021 IEEE 10th Data Driven Control and Learning Systems Conference (DDCLS), Suzhou, China, 14–16 May 2021; pp. 979–984. [Google Scholar] [CrossRef]

- Hu, M.; Ju, X. Two-stage insulator self-explosion defect detection method based on Mask R-CNN. In Proceedings of the 2021 2nd International Conference on Intelligent Computing and Human-Computer Interaction (ICHCI), Shenyang, China, 17–19 December 2021; pp. 13–18. [Google Scholar] [CrossRef]

- Zheng, L.; Wang, X.; Wang, Q.; Wang, S.; Liu, X. A Fabric Defect Detection Method Based on Improved YOLOv5. In Proceedings of the 2021 7th International Conference on Computer and Communications (ICCC), Chengdu, China, 10–13 December 2021; pp. 620–624. [Google Scholar] [CrossRef]

- Liu, Q.; Wang, C.; Li, Y.; Gao, M.; Li, J. A Fabric Defect Detection Method Based on Deep Learning. IEEE Access 2022, 10, 4284–4296. [Google Scholar] [CrossRef]

- Liu, K.H.; Chen, S.J.; Liu, T.J. Unsupervised UNet for Fabric Defect Detection. In Proceedings of the 2022 IEEE International Conference on Consumer Electronics—Taiwan, Taipei, Taiwan, 6–8 July 2022; pp. 205–206. [Google Scholar] [CrossRef]

- Huang, Y.; Yi, M.; Yang, W.; Yang, M. Research on surface defect intelligent detection technology of non-woven fabric based on support vector machine. In Proceedings of the 2022 IEEE International Conference on Electrical Engineering, Big Data and Algorithms (EEBDA), Changchun, China, 24–26 February 2022; pp. 895–898. [Google Scholar] [CrossRef]

- Li, L.; Jiang, Z.; Li, Y. Surface Defect Detection Algorithm of Aluminum Based on Improved Faster RCNN. In Proceedings of the 2021 IEEE 9th International Conference on Information, Communication and Networks (ICICN), Xi’an, China, 19–21 August 2021; pp. 527–531. [Google Scholar] [CrossRef]

- Sison, H.; Konghuayrob, P.; Kaitwanidvilai, S. A Convolutional Neural Network for Segmentation of Background Texture and Defect on Copper Clad Lamination Surface. In Proceedings of the 2018 International Conference on Engineering, Applied Sciences, and Technology (ICEAST), Phuket, Thailand, 4–7 July 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Lin, Z.; Guo, Z.; Yang, J. Research on texture defect detection based on faster-rcnn and feature fusion. In Proceedings of the 2019 11th International Conference on Machine Learning and Computing, Zhuhai, China, 22–24 February 2019; pp. 429–433. [Google Scholar]

- Wang, D.; Yu, W.; Lian, P.; Zhang, M. Textile Defect Detection Algorithm Based on Unsupervised Learning. In Proceedings of the 2022 7th International Conference on Image, Vision and Computing (ICIVC), Xi’an, China, 26–28 July 2022; pp. 81–86. [Google Scholar] [CrossRef]

- Sun, X.; Gu, J.; Huang, R.; Zou, R.; Giron Palomares, B. Surface Defects Recognition of Wheel Hub Based on Improved Faster R-CNN. Electronics 2019, 8, 481. [Google Scholar] [CrossRef]

- Chen, L.; Zhou, Y.; Zhou, H.; Zu, J. Detection of Polarizer Surface Defects Based on an Improved Lightweight YOLOv3 Model. In Proceedings of the 2022 4th International Conference on Intelligent Control, Measurement and Signal Processing (ICMSP), Hangzhou, China, 8–10 July 2022; pp. 138–142. [Google Scholar] [CrossRef]

- Li, P.; Dong, Z.; Shi, J.; Pang, Z.; Li, J. Detection of Small Size Defects in Belt Layer of Radial Tire Based on Improved Faster R-CNN. In Proceedings of the 2021 11th International Conference on Information Science and Technology (ICIST), Chengdu, China, 21–23 May 2021; pp. 531–538. [Google Scholar] [CrossRef]

- Wang, X.; Hu, Z. Grid-based pavement crack analysis using deep learning. In Proceedings of the 2017 4th International Conference on Transportation Information and Safety (ICTIS), Banff, AB, Canada, 8–10 August 2017; pp. 917–924. [Google Scholar] [CrossRef]

- Zhang, M.; Yin, L. Solar Cell Surface Defect Detection Based on Improved YOLO v5. IEEE Access 2022, 10, 80804–80815. [Google Scholar] [CrossRef]

- Azizah, L.M.; Umayah, S.F.; Riyadi, S.; Damarjati, C.; Utama, N.A. Deep learning implementation using convolutional neural network in mangosteen surface defect detection. In Proceedings of the 2017 7th IEEE International Conference on Control System, Computing and Engineering (ICCSCE), Penang, Malaysia, 24–26 November 2017; pp. 242–246. [Google Scholar] [CrossRef]

- Zhang, A.; Wang, K.C.; Li, B.; Yang, E.; Dai, X.; Peng, Y.; Fei, Y.; Liu, Y.; Li, J.Q.; Chen, C. Automated pixel-level pavement crack detection on 3d asphalt surfaces using a deep-learning network. Comput.-Aided Civ. Infrastruct. Eng. 2017, 32, 805–819. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z. Research on Textile Defect Detection Based on Improved Cascade R-CNN. In Proceedings of the 2021 International Conference on Artificial Intelligence and Electromechanical Automation (AIEA), Guangzhou, China, 14–16 May 2021; pp. 43–46. [Google Scholar] [CrossRef]

- He, Z.; Liu, Q. Deep Regression Neural Network for Industrial Surface Defect Detection. IEEE Access 2020, 8, 35583–35591. [Google Scholar] [CrossRef]

- Wei, R.; Bi, Y. Research on Recognition Technology of Aluminum Profile Surface Defects Based on Deep Learning. Materials 2019, 12, 1681. [Google Scholar] [CrossRef] [PubMed Central]

- Hang, J.; Sun, H.; Yu, X.; Rodríguez-Andina, J.J.; Yang, X. Surface Defect Detection in Sanitary Ceramics Based on Lightweight Object Detection Network. IEEE Open J. Ind. Electron. Soc. 2022, 3, 473–483. [Google Scholar] [CrossRef]

- Khumaidi, A.; Yuniarno, E.M.; Purnomo, M.H. Welding defect classification based on convolution neural network (CNN) and Gaussian kernel. In Proceedings of the 2017 International Seminar on Intelligent Technology and Its Applications (ISITIA), Surabaya, Indonesia, 28–29 August 2017; pp. 261–265. [Google Scholar] [CrossRef]

- Cha, Y.-J.; Choi, W.; Buyukozturk, O. Deep learning-based crack damage detection using convolutional neural networks. Comput.-Aided Civ. Infrastruct. Eng. 2017, 32, 361–378. [Google Scholar] [CrossRef]

- Roslan, M.I.B.; Ibrahim, Z.; Aziz, Z.A. Real-Time Plastic Surface Defect Detection Using Deep Learning. In Proceedings of the 2022 IEEE 12th Symposium on Computer Applications & Industrial Electronics (ISCAIE), Penang, Malaysia, 21–22 May 2022; pp. 111–116. [Google Scholar] [CrossRef]

- Xu, X.; Zheng, H.; Guo, Z.; Wu, X.; Zheng, Z. SDD-CNN: Small Data-Driven Convolution Neural Networks for Subtle Roller Defect Inspection. Appl. Sci. 2019, 9, 1364. [Google Scholar] [CrossRef]

- Yuan, Z.-C.; Zhang, Z.-T.; Su, H.; Zhang, L.; Shen, F.; Zhang, F. Vision-based defect detection for mobile phone cover glass using deep neural networks. Int. J. Precis. Eng. Manuf.-Green Technol. 2018, 19, 801–810. [Google Scholar] [CrossRef]

- Guan, S.; Wang, X.; Wang, J.; Yu, Z.; Wang, X.; Zhang, C.; Liu, T.; Liu, D.; Wang, J.; Zhang, L. Ceramic ring defect detection based on improved YOLOv5. In Proceedings of the 2022 3rd International Conference on Computer Vision, Image and Deep Learning & International Conference on Computer Engineering and Applications (CVIDL & ICCEA), Changchun, China, 20–22 May 2022; pp. 115–118. [Google Scholar] [CrossRef]

- Chen, H.; Pang, Y.; Hu, Q.; Liu, K. Solar cell surface defect inspection based on multispectral convolutional neural network. J. Intell. Manuf. 2018, 31, 453–468. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, M.; Li, C.; Meng, Z.; Li, Y.; Chen, Y.; Liu, L. Image Classification for Automobile Pipe Joints Surface Defect Detection Using Wavelet Decomposition and Convolutional Neural Network. IEEE Access 2022, 10, 77191–77204. [Google Scholar] [CrossRef]

- Xu, C.; Li, L.; Li, J.; Wen, C. Surface Defects Detection and Identification of Lithium Battery Pole Piece Based on Multi-Feature Fusion and PSO-SVM. IEEE Access 2021, 9, 85232–85239. [Google Scholar] [CrossRef]

- Maestro-Watson, D.; Balzategui, J.; Eciolaza, L.; Arana-Arexolaleiba, N. Deep learning for deflectometric inspection of specular surfaces. In The 13th International Conference on Soft Computing Models in Industrial and Environmental Applications; Springer: Berlin/Heidelberg, Germany, 2018; pp. 280–289. [Google Scholar]

- Ren, R.; Hung, T.; Tan, K.C. A Generic Deep-Learning-Based Approach for Automated Surface Inspection. IEEE Trans. Cybern. 2018, 48, 929–940. [Google Scholar] [CrossRef]

- Li, Y.; Lin, S.; Liu, C.; Kong, Q. The Defects Detection in Steel Coil End Face Based on SCED-Net. In Proceedings of the 2022 International Joint Conference on Neural Networks (IJCNN), Padua, Italy, 18–23 July 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Xie, L.; Xiang, X.; Xu, H.; Wang, L.; Lin, L.; Yin, G. FFCNN: A Deep Neural Network for Surface Defect Detection of Magnetic Tile. IEEE Trans. Ind. Electron. 2021, 68, 3506–3516. [Google Scholar] [CrossRef]

- PLien, C.; Zhao, Q. Product Surface Defect Detection Based on Deep Learning. In Proceedings of the 2018 IEEE 16th Intl Conf on Dependable, Autonomic and Secure Computing, 16th Intl Conf on Pervasive Intelligence and Computing, 4th Intl Conf on Big Data Intelligence and Computing and Cyber Science and Technology Congress (DASC/PiCom/DataCom/CyberSciTech), Athens, Greece, 12–15 August 2018; pp. 250–255. [Google Scholar] [CrossRef]

- Yang, X.; Dong, F.; Liang, F.; Zhang, G. Chip defect detection based on deep learning method. In Proceedings of the 2021 IEEE International Conference on Power Electronics, Computer Applications (ICPECA), Shenyang, China, 22–24 January 2021; pp. 215–219. [Google Scholar] [CrossRef]

- Wu, X.; Cao, K.; Gu, X. A surface defect detection based on convolutional neural network. In International Conference on Computer Vision Systems; Springer: Berlin/Heidelberg, Germany, 2017; pp. 185–194. [Google Scholar]