Abstract

A method for tuning PI controller parameters, a prescribed maximum time delay error or a relative time delay error is presented. The method is based on integrator plus time delay models. The integral time constant is linear in the relative time delay error, and the proportional constant is seen inversely proportional to the relative time delay error. The keystone in the method is the method product parameter, i.e., the product of the PI controller proportional constant, the integral time constant, and the integrator plus time delay model, velocity gain. The method product parameter is found to be constant for various PI controller tuning methods. Optimal suggestions are given for choosing the method product parameter, i.e., optimal such that the integrated absolute error or, more interestingly, the Pareto performance objective (i.e., integrated absolute error for combined step changes in output and input disturbances) is minimised. Variants of the presented tuning method are demonstrated for tuning PI controllers for motivated (possible) higher order process model examples, i.e., the presented method is combined with the model reduction step (process–reaction curve) in Ziegler–Nichols.

1. Introduction

This paper concerns tuning of PI controllers based on Integrator Plus Time Delay (IPTD) models/systems. Further details and developments regarding the -tuning algorithm are presented in the work [1,2]. IPTD processes and close-to IPTD systems are important/typical processes/systems found in the industry. Instances of IPTD processes are pulp and paper mills, oil water gas separators, communication networks, level systems and all lag-dominant processes, which may be approximated by IPTD models (see, e.g., [3,4,5]). Reported instances are high-purity distillation columns where there are relatively large time constants for minor differences in the reference, and where the time delay comes from an analyser (see, e.g., [6,7]). In Section 6.4 in [8], an example of reboiler control in connection with a distillation column was presented.

The majority of existing PI controller tuning rules for IPTD processes,

may be written as the following setting

where is the PI controller proportional gain, is the integral time constant, k is the gain velocity (slope) and is the time delay. and in Equation (2) are dimensionless parameters. For instance, using the classical Ziegler–Nichols (ZN) PI controller tuning rules, proposed in the works [9,10,11], gives , (i.e., the ZN closed loop method). Using the Internal Model Control (IMC) PI controller tuning rules in Table 1 of [7] with closed loop time constant , as proposed in [6], gives parameters and . Using the Simple/Skogestad IMC (SIMC) PI controller tuning rules, presented in the works of [8,12,13], with closed loop time constant (i.e., is the only tuning parameter in SIMC) gives and .

To find PI controller settings with good robustness properties (i.e., one could have uncertainties in the gain velocity and time delay) and simultaneously obtain reasonable fast reference and disturbance properties, for IPTD processes, the size and balanced relation between the parameters and are of importance.

Using the PI controller setting in Equation (2), we may define a Method Product (MP) parameter as,

The defined MP parameter in Equation (3) is constant for numerous PI controller tuning methods. The SIMC PI controller settings yield an MP parameter . The original ZN method gives an MP parameter (i.e., the ZN closed loop method).

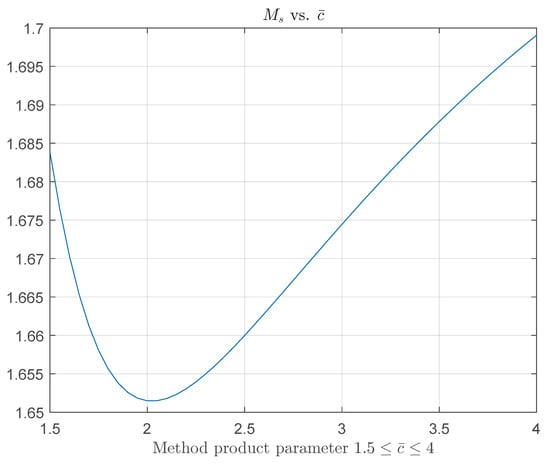

In this paper, we search for optimal MP parameters, i.e., choosing which ensures the closed loop system some optimal robustness or performance setting, e.g., minimisation of the Integrated Absolute Error (IAE) or sensitivity index given a prescribed robustness. Figure 1 shows that is approximately minimised for . However, it might be argued that the changes in is negligible, and that is optimal over the MP parameter interval .

Figure 1.

Consider PI control of the FOPTD process model, . The figure shows the robustness as a function of the MP parameter , given constant robustness, for the interval .

It has been pointed out that there is usually a high degree of trial-and-error in choosing the closed loop time constant tuning parameter in SIMC and IMC (e.g., [1] for SIMC and [6] for IMC). Note that one also may focus on the maximum sensitivity peak of the sensitivity function as described in [14], where some inequalities relating to the Gain Margin (GM) and the Phase Margin (PM) to the robustness are proposed on p. 126. Consider that the values of the minimum robustness are in the interval [14].

The contributions of this work are itemised in the incoming:

- The PI controller tuning method in the work of [1,2] is further developed with more optimal settings for the MP parameter as well as tuning for some special instance integrating systems.

- In the instance of a small or zero time delay , we propose a variant in which the Maximum Time Delay Error (MTDE) is the tuning parameter (see Section 3.2).

- Two optimal settings for the MP parameter are presented in Section 4. These are optimal in the sense that they minimise a Pareto performance objective (i.e., integrated absolute error for combined step changes in output and input disturbances) on two different aspects. One additional MP parameter is deduced from approximating the time delay with a (2, 1) Pade approximation in Section 3.3.

- Additional MP parameter settings are suggested for minimising a variety of given indices.

- The presented method (including variants of this) is demonstrated and compared to the Pareto-Optimal (PO) and SIMC (when possible) tuned PI controllers on various motivated (possible) higher order process model examples in Section 5.

The rest of this paper is organised as follows. The preliminary theory containing the definitions and some basic theory are given in Section 2. In Section 3, we present analytical results about the MTDE and present PI controller tuning rules as a function of a prescribed MTDE. Numerical simulation examples for some (possible) higher order systems/models are presented in Section 5. The conclusion and discussion remarks are given in Section 7.

2. Preliminary Theory

2.1. Definitions

Given a PI controller

where is the proportional constant and is the integral time constant.

Consider the standard feedback system with disturbances as illustrated in Figure 2. To compare the different controllers, we consider indices such as defined in [12,14,15]. Performance is measured in a feedback system by

Figure 2.

Consider a control feedback system where the plant model is described by the process model, , PI controller, , and the disturbance model, , where disturbance v at the input when, , and at the output when, . Input u, output y and reference r.

Furthermore, the following is defined.

- evaluates the performance in case of a step input disturbance (), (default), with the reference, .

- evaluates the performance in case of a step output disturbance (), (default), with the reference, .

- evaluates the performance in case of a reference unit step, , with the disturbance, .

Similarly, we define the Integrated Time-weighted Absolute Error (ITAE), Integrated Square Error (ISE) and Integrated Time-weighted Square Error (ITSE) and Total input Value (TV) as the following i.e.,

where .

Robustness is quantified according to the maximum sensitivity peak

where, , and is the -norm.

2.2. Lag-Dominant Systems

Given a system approximated with a FOPTD model

where K is the process gain, is the time delay and T is the time constant. The system in Equation (11) may be defined as lag-dominant when which is the instance for numerous systems. It is known that, when then Equation (11) may be approximated with an IPTD model (see [6,7]). From Equation (11), we write,

Hence, when the system is lag-dominant and T “large”, we may approximate Equation (12) as an IPTD system (Equation (1)) where is the gain velocity (slope) and the time delay.

2.3. SIMC Tuning Rules

Given the FOPTD process in Equation (11). The standard SIMC PI controller settings [8,12,13] are as follows,

where is the prescribed time constant for the reference response chosen as .

Similarly, for an IPTD process as in Equation (1), we have the following PI controller settings,

3. Tuning for Maximum Time Delay Error

To get some understanding of the PM of the closed loop system and the MTDE, , we work out some analytic results in the following, which give a PI controller tuning method for IPTD processes.

3.1. Integrator Plus Time Delay Process

Consider an IPTD system where k is the gain velocity and is the time delay, and a PI controller. The loop transfer function, , is

The frequency response is given by , where the magnitude is and the phase angle is . We obtain the gain crossover frequency analytically as . From this, we obtain analytically that , and the MTDE , such that, .

A factor f is defined as

The gain crossover frequency is analytically given by

See previous paper [1] for proof of Equation (17).

The gain crossover frequency is then given by . We obtain the PM analytically as , and the MTDE as , where is defined as

Consider the instance in which the MP parameter is constant, then Equation (18) may be written as, , and, , where

is a function of and constant. Notice that the parameter f is defined by Equation (16).

We have the following Algorithm 1.

Algorithm 1

(Max time delay error tuning).

The MP parameter is defined as

We express β as a linear function of a prescribed Relative Time Delay Error (RTDE) , to ensure stability of the closed loop system. We have

where parameter a is given by Equation (19). Note that α can be expressed by

or with regard to the PI controller parameters

Note that Algorithm 1 is written as a MATLAB m-file function given in Appendix C in a previous paper [1].

Before advancing, we demonstrate the above algorithm in an instance to enhance the robustness of the classical closed loop ZN PI controller tuning.

Example 1

(ZN with increased margins).

Given the classical ZN PI controller tuning (closed loop method), in which , , where the RTDE and the robustness .

For the original ZN method, we have the MP parameter . Specifying an RTDE parameter, . Using Equations (21) and (22) gives the altered ZN PI controller parameters

The altered ZN PI controller tuning, and , for an IPTD process has margins , robustness and prescribed . The altered ZN PI controller tuning has relatively smooth closed loop responses with a relative damping slightly less than one. The ZN method parameter is not too far from one of the recommended optimal parameters (see below).

Arguably, the most important characteristic of a PI controller setting is the robustness vs. model uncertainty in connection with a reasonably smooth and fast closed loop reference and disturbance responses. An MTDE is reasonable. This is approximately equal to the MTDE for the SIMC setting, . One idea may be to find theoretical arguments for setting the MP parameter such that the closed loop system gets some optimal settings, e.g., minimise the robustness given prescribed robustness . Consider using the PI controller tuning rules deduced in [1] which gives the MP parameter .

The MP parameter may be seen as a tuning parameter. SIMC uses a MP parameter and the corresponding , which is below the recommended margin, but the MTDE is acceptable, i.e., . Based on the numerical simulations in this and previous works [1,2], we suggest a relatively broad interval for choosing the MP parameter , i.e., .

Furthermore, we propose choosing the RTDE to unsure stability, and choosing as for robustness and to make certain that (p. 125 in [14]) is reasonable.

3.2. Pure Integrating Process

Consider the limiting case of an integrating process, i.e., (no delay), or a time constant system with a large time constant such that , i.e., we consider a process model, . Using the definition for the RTDE tuning parameter, , and the PI controller tuning Equations (23) and (24), we find the PI controller tuning

Notice that Equations (26) and (27) are tuning variants in which the MTDE is the tuning parameter instead of the RTDE .

Consider the limiting case of an integrating process, i.e., (no delay). From Equations (26) and (27), we find the PI controller tuning

Notice that in this case.

3.3. Using a () Pade Approximation

Consider the disturbance response with PI control,

Consider a () Pade approximation, , i.e., with a second order numerator polynomial and a first order denominator polynomial, i.e., an approximation,

where , and .

Using the same procedure as in Section 5.2 in [1], and with unit relative damping, we find a third order polynomial for the closed loop response,

We prescribe a third order polynomial

When comparing Equations (32) and (33), we find that

By inserting Equations (34) and (36) into Equation (35), it can be shown that

We solve the third order polynomial in Equation (37) with respect to , and find a real positive solution, .

Furthermore, we find that the PI controller parameters

where may be seen as a tuning parameter.

When assuming that the response time constant , then we may express the PI controller parameters and with

where the product is a nonlinear function of the tuning parameter c. We find that it makes sense to choose c in the interval, .

From the PI controller setting in Equation (38) with , we find the MP parameter .

For reducing the complexity of the problem, the (1, 2) Pade approximation was used; e.g., a (2, 2) Pade would result in a fourth order polynomial. Notice that a (1, 1) Pade approximation was used in the earlier work of [1] in Section 5.2.

4. Optimal Performance Settings

Consider the following Pareto performance objective defined as

where is the servo-regulator parameter originally introduced in [2], and is chosen in the interval for the weighting between output disturbance (servo) weighting and input disturbance (regulator) weighting . In Equation (41), the function argument is . In this work, we set ([16]). Furthermore, we set , which was argued in [17] to be the equivalent of setting , which was used in the original work of [16] and also [2]. The reference/weight values are calculated as following, , and, , for a prescribed robustness . We set which is the robustness value corresponding to a SIMC-tuned PI controller with for a FOPTD process where ([16]).

We consider the reference example where we are given an IPTD process with . We find the same reference values as in [18], viz. where and , and where and .

The following main performance objective is defined in a mean square error sense,

where x is a tuning method and, (default) and M = length().

A couple of optimal suggestions for the choice of the MP parameter are worked out in the following. The first MP parameter setting may be found by solving the following optimization problem,

where Alg. 1 () and Alg. 1o () is pre-calculated as follows

Interestingly, the MP parameter setting in Equation (43) is approximately equal to the setting which is deduced in Section 3.3. Additional MP parameter settings are given in Table 1 based on solving Equation (43) for different servo-regulator parameters in the Pareto performance objective J (Equation (41)).

The second MP parameter is found by

where Alg. 1 () and PO () are pre-calculated as follows

Notice that is equal to the recommended MP parameter in [2]. However, the MP parameter in this paper results from an optimization problem, while the one proposed in [2] originated from an ad hoc approach.

Figure 3 illustrates the two MP parameters described above. In terms of the main performance objective (Equation (42)), Table 2 shows that is times better than SIMC (arguably ), and times better than .

Figure 3.

Reference example (Example 2). Consider PI control of the IPTD model, . The figure illustrates the trade-off between the Pareto performance objective J (Equation (41)) and robustness (Equation (10)). It illustrates the MP parameters and for Algorithm 1 proposed in Section 4. SIMC is added for comparison.

Table 2.

Reference example (Example 2), i.e., an IPTD model, . Comparing the different settings for the MP parameters for Algorithm 1 and SIMC using the main performance objective (Equation (42)).

Based on numerical simulations, we present the recommended settings for choosing the MP parameter as proposed in Table 3.

Table 3.

Summary: The table shows the recommended settings for the MP parameter for minimizing the objectives in the first row.

Consider PI controller settings for an IPTD system, , with varying gain velocity, k, and time delay . Table 4 and Table 5 illustrate the , i.e., the minimum of , , , and , , , , , respectively, as a function of .

Table 4.

Consider PI controller settings for an IPTD system, , with varying gain velocity, k, and time delay . The table illustrates the , i.e., the minimum of the , , and indices as a function of , with PI controller settings from Algorithm 1.

Table 5.

Consider PI controller settings for an IPTD system, , with varying gain velocity, k, and time delay . The table illustrates , i.e., the minimum of , , , and indices as a function of , with PI controller settings from Algorithm 1.

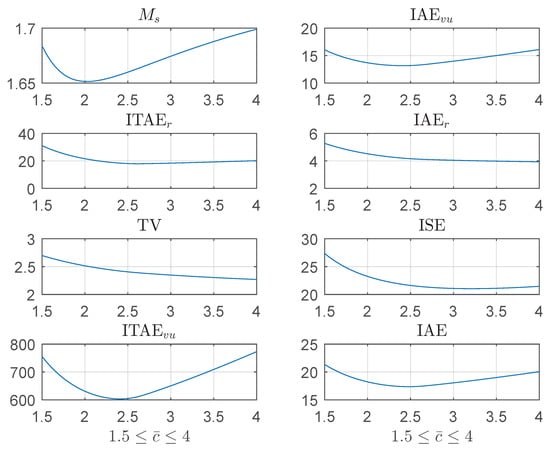

Consider PI controller settings for an IPTD system, , where and time delay . Figure 4 shows the indices , , , , , , , and as a function of varying the MP parameter and with prescribed RTDE .

Figure 4.

Consider PI control of an IPTD process, with process parameters and . PI controller with settings as in Algorithm 1. The figure shows the indices , , , , , , , and as a function of varying the MP parameter and with prescribed RTDE .

5. Simulation Examples

In the following simulations (if possible), we compare Algorithm 1, with the recommended MP parameter settings, vs. the SIMC tuning rule [12].

We continue with studying the reference example considered in Section 4. See also [1] for additional details on this example.

Example 2

(Reference Example).

The same IPTD example as in [1] is used, i.e., a process model, , with gain velocity and time delay is considered.

The time-domain responses given a prescribed robustness, , are illustrated in Figure 5. The corresponding PI controller parameters, indices and margins are given in Table 6. The margins for the controllers are all acceptable, i.e., and as in [14].

Figure 5.

Example 2 (Reference example). Consider PI control of an IPTD process model, . The figure illustrates the time-domain responses, given a prescribed robustness , of the following methods: the PO PI, SIMC with prescribed closed loop time constant and Algorithm 1 where the MP parameter (proposed in Section 4) and RTDE . An output disturbance unit step is presented at time and an input disturbance unit step at time .

Table 6.

Example 2. Consider PI control of the IPTD process model, . The table shows the controller parameter, indices and margins are given for prescribed robustness for the following methods: Alg. 1 (), SIMC () and PO PI ().

Example 3

(Lag-dominant system).

An air-heater was studied in [19] and it was found that a FOPTD model with process gain , time delay and time constant , gives a sufficient model approximation. We approximate the FOPTD model as an IPTD process where the gain velocity (slope) and time delay, .

The Pareto performance objective J vs. trade-off curves are shown in Figure 6. In terms of the main performance objective it can be seen in Table 7 that is times better than and times better than SIMC.

Figure 6.

Example 3. Consider PI control of the FOPTD process model, , where , and . The figure shows the trade-off curves with the Pareto performance objective J (Equation (41)) and robustness (Equation (10)). It illustrates the MP parameters and for Algorithm 1 (proposed in Section 4). SIMC with set-point time constant is added for comparison.

Table 7.

Example 3. The table shows the comparison of the settings for Algorithm 1 and SIMC using the main performance objective (Equation (42)).

The time-domain responses, given a prescribed robustness, , are illustrated in Figure 7. The corresponding PI controller parameters, indices and margins are given in Table 8. The margins for the controllers are all acceptable, i.e., and as in [14]. Notice, that the prescribed MTDE, is almost equal the exact .

Figure 7.

Example 3. Consider PI control of the FOPTD process model, , where , and . The figure illustrates the time-domain responses, given a prescribed robustness , of the following methods: the PO PI, SIMC with prescribed closed loop time constant , and Algorithm 1 where the MP parameter (proposed in Section 4) and RTDE . An output disturbance unit step is presented at time and an input disturbance unit step at time .

Table 8.

Example 3. The table shows the PI controller parameter, indices and margins are given for prescribed robustness .

Some results regarding a couple of motivated higher order processes are presented in the following examples. Notice that SIMC offers the half-rule model reduction technique. However, for our case, we approximate the higher order systems by identifying two parameters, the unit reaction rate and the lag L from a step response, i.e., the Process–Reaction Curve (PRC) as presented in the work of ZN [9,10,11]. We denote the variant as follows: PRC + Algorithm 1.

Example 4

(Higher order process).

A distillation column studied in [20] (p. 591) is partly described by the following process model,

By identifying the lag L and the maximum slope (unit reaction rate) from the PRC method we may approximate the process model as an IPTD model with gain velocity and time delay .

Using the half-rule technique in SIMC, we approximate a FOPTD model where the gain , time constant , and time delay .

The Pareto Performance objective J vs. robustness trade-off curves are illustrated in Figure 8. Notice, that is the closest to optimal on the most robust part of the -interval. SIMC is crossing around and is the closest to optimal on the less robust part. In terms of the main performance objective , we show in Table 9 that is times better than , and times better than SIMC.

Figure 8.

Example 4. Consider PI control of the higher order process model (Equation (47)). The figure illustrates the trade-off curves with the Pareto performance objective J (Equation (41)) and robustness (Equation (10)). It shows the MP parameter settings and for Algorithm 1 proposed in Section 4. SIMC is added for comparison.

Table 9.

Example 4. The table shows the comparison of the different settings for Algorithm 1 and SIMC using the main performance (Equation (42)).

The time-domain responses, for a prescribed robustness , are illustrated in Figure 9. The corresponding PI controller parameters, indices and margins are given in Table 10. The margins for the controllers are all acceptable, i.e., and , as in [14]. Notice, that the prescribed MTDE, is almost equal to the exact .

Figure 9.

Example 4. Consider PI control of the higher order process model (Equation (47)). The figure illustrates the time-domain responses, given a prescribed robustness , of the following methods: the PO PI controller vs. SIMC with closed loop time constant , and PRC + Algorithm 1 where the MP parameter setting (proposed in Section 4) and RTDE . An output disturbance unit step is presented at time and an input disturbance unit step at time .

Table 10.

Example 4. The table shows the PI controller parameters, indices and margins are given for prescribed robustness .

Note that the half-rule technique in SIMC is not compatible with process models containing complex poles/underdamped dynamics, hence, in such cases, we consider arguably the same algorithm as SIMC, i.e., Algorithm 1, where the MP parameter, . An example of this is given in the following.

Example 5

(Underdamped system).

An unmanned submersible vehicle studied in [21] is described partly by

i.e., from commanded elevator deflection u to the pitch angle of the vehicle y. We approximate Equation (48) by an IPTD model with gain velocity and time delay .

The Pareto performance objective J vs. trade-off curves are illustrated in Figure 10. In terms of the main performance objective , we show in Table 11 that is times better than and times better than . Notice that is closest to optimal on the most robust part of the -interval. Furthermore, is seen crossing both and around and is closest to optimal on the less robust part.

Figure 10.

Example 5. Consider PI control of the higher order underdamped process model (Equation (48)). The figure shows the trade-off curves with the Pareto performance objective J (Equation (41)) and robustness (Equation (10)). It illustrates the PO PI controllers and PRC + Algorithm 1 variants with MP parameter settings , and .

Table 11.

Example 5. The table shows the different MP parameter settings for the PRC + Algorithm 1 variant with corresponding main performance (Equation (42)).

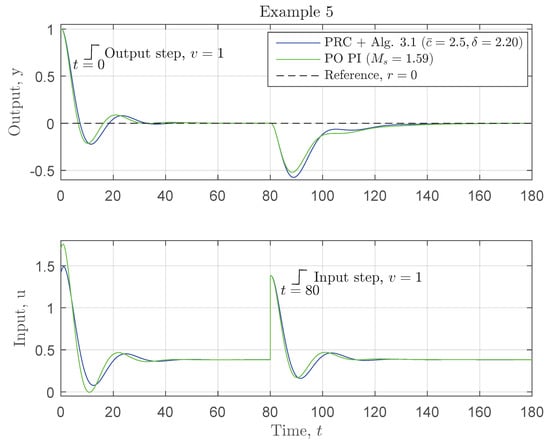

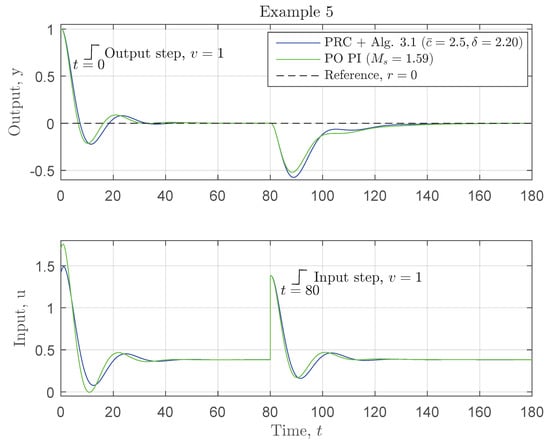

The time-domain responses, given a prescribed robustness , are illustrated in Figure 11. The corresponding PI controller parameters, indices and margins are given in Table 12. The margins for the controllers are all acceptable, i.e., and as in [14].

Figure 11.

Example 5. Consider PI control of the higher order underdamped process model (Equation (48)). The figure illustrates the time-domain responses, given a prescribed robustness , of following methods: the PO PI and the PRC + Algorithm 1 where the MP parameter setting (proposed in Section 4) and RTDE . An output disturbance unit step is presented at time and an input disturbance unit step at time .

Table 12.

Example 5. The corresponding controller parameter, indices and margins are given for prescribed robustness .

Last, we propose a tuning variant based on the PRC and Algorithm 1, as above. However, now, the gain velocity in the IPTD model is, instead, varying proportionally, i.e., , where is considered as a tuning parameter. TO simplify the tuning, we propose to set the RTDE equal constant (i.e., an ad hoc suggestion). This means that the only tuning parameter is . We denote this variant as follows: -PRC + Algorithm 1.

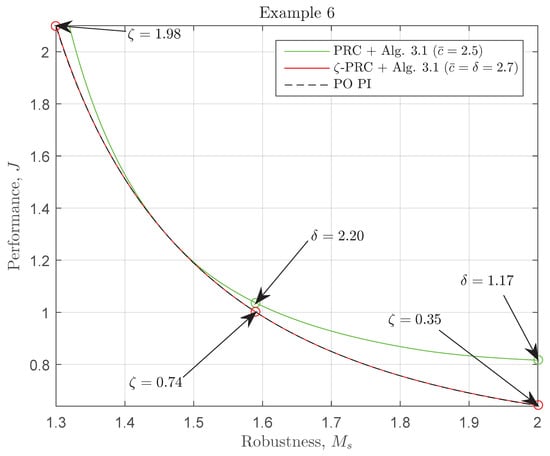

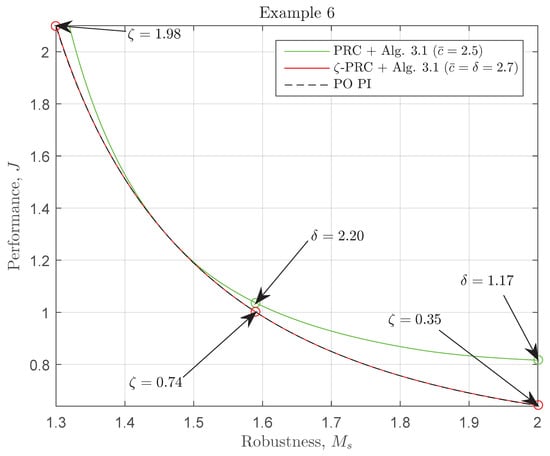

Example 6

ζ-PRC variant).

Consider the same process model as studied in Example 5. The model is approximated by an IPTD model, where the gain velocity is varied, , and time delay, . In this example, we set the RTDE .

It can be seen in Figure 12 that the PO PI curve and the ζ-PRC curve are indistinguishable. This is quite a surprising result. In terms of the main performance objective , we show in Table 13 that ζ-PRC is times better than variant.

Figure 12.

Example 6. PI control of the higher order underdamped process model (Equation (48)). The figure illustrates the trade-off curves with the Pareto performance objective J (Equation (41)) and robustness (Equation (10)). It shows the PO PI controllers with robustness and the ζ-PRC + Algorithm 1 variant where the RTDE is fixed and the main tuning parameter is ζ.

Table 13.

Example 6. Comparing the following variants, ζ-PRC + Algorithm 1 with MP parameter and MTDE settings and , and the PRC + Algorithm 1 with MP parameter setting , using the main performance defined in Equation (42).

The time-domain responses, for a prescribed robustness , are illustrated in Figure 13. As a consequence of the above, these responses are also indistinguishable. The corresponding PI controller parameters, indices and margins are given in Table 14.

Figure 13.

Example 6. PI control of the higher order underdamped process model (Equation (48)). The figure illustrates the time-domain responses, given a prescribed robustness , for the following methods: the PO PI and the ζ-PRC + Algorithm 1 variant with MP parameter and MTDE settings , and tuning parameter . An output disturbance unit step is presented at time and an input disturbance unit step at time .

Table 14.

Example 6. The corresponding controller parameter, indices and margins are given for prescribed robustness . ζ-PRC + Algorithm 1.

6. Discussion

Remarks to Section 3

It can be shown that the PM can be given as follows

for the PM in radians (see also [1,2]).

7. Concluding Remarks

The discussion and concluding remarks are itemised as follows.

- The method in [1,2] is further developed with more optimal MP tuning parameters as well as tuning for some special case integrating systems.

- Two optimal settings for the MP parameter are presented in Section 4. These are optimal in the sense that they minimise the main performance objective on two different aspects. Interestingly, one of the MP parameters may (arguably) be deduced from approximating the time delay with a (2, 1) Pade approximation in Section 3.3.

- In the case of a small or zero time delay , we propose a variant in which the MTDE is the tuning parameter.

- Note that for an IPTD model, the SIMC tuned PI controllers are seen far from optimal, i.e., PO (or (almost) equivalently, Algorithm 1 with the MP parameter setting as ). See Section 4.

- The presented method (and variants of this) is successfully demonstrated and compared to the SIMC and PO PI controllers on numerous motivated process model examples in Section 5.

- Note that, for the higher order process models in Examples 4 and 5, we use the PRC model reduction technique, which is generally easier to apply than the half-rule technique proposed in [12]. The half-rule technique is not compatible with handling complex poles.

- Some surprisingly optimal results are documented for Example 6, where a tuning method based on varying the gain velocity, , (, is the ZN unit reaction rate), i.e., the tuning parameter is . Note that setting the RTDE (i.e., an ad hoc choice) equal a constant is advisable.

- Note that the results in Section 5 are based on the original (possible) higher order models. The approximated IPTD models are only used for the PI controller design.

Author Contributions

David Di Ruscio contributed to the conception of the research, formulated the theory and helped revise the paper. Christer Dalen wrote the paper and did the numerical simulations.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| PI | Proportional Integrating |

| IPTD | Integrator Plus Time Delay |

| FOPTD | First Order Plus Time Delay |

| ZN | Ziegler–Nichols |

| IAE | Integrated Absolute Error |

| ITAE | Integrated Time-weighted Absolute Error |

| ISE | Integrated Square Error |

| ITSE | Integrated Time-weighted Square Error |

| TV | Total input Value |

| MP | Method Product |

| IMC | Internal Model Control |

| SIMC | Simple/Skogestad Internal Model Control |

| GM | Gain Margin |

| PM | Phase Margin |

| DM | Delay Margin |

| MTDE | Maximum Time Delay Error |

| PO | Pareto-Optimal |

| RTDE | Relative Time Delay Error |

References

- Di Ruscio, D. On Tuning PI Controllers for Integrating Plus Time Delay Systems. Model. Identif. Control 2010, 31, 145–164. [Google Scholar] [CrossRef]

- Di Ruscio, D. PI Controller Tuning Based on Integrating Plus Time Delay Models: Performance Optimal Tuning. In Proceedings of the IASTED Control and Applications Conference (CA2012), Crete, Greece, 18–21 June 2012. [Google Scholar]

- Arbogast, J.E.; Cooper, D.J. Extension of IMC tuning correlations for non-self regulating (integrating) processes. ISA Trans. 2007, 46, 303–311. [Google Scholar] [CrossRef] [PubMed]

- Alfaro, V.; Vilanova, R. Model Reference Robust Tuning of 2Dof PI Controllers for Integrating Controlled Processes. In Proceedings of the 2012 20th Mediterranean Conference on Control & Automation (MED), Barcelona, Spain, 3–6 July 2012. [Google Scholar]

- Antonio Visioli, Q.Z. Control of Integral Processes with Dead Time; Springer-Verlag: London, UK, 2011. [Google Scholar]

- Tyreus, B.D.; Luyben, W.L. Tuning PI Controllers for Integrator/Dead Time Processes. Ind. Eng. Chem. Res. 1992, 31, 2625–2628. [Google Scholar] [CrossRef]

- Chien, I.L.; Fruehauf, P.S. Consider IMC Tuning to Improve Controller Performance. Chem. Eng. Prog. 1990, 86, 33–41. [Google Scholar]

- Skogestad, S. Probably the best simple PID tuning rules in the world. In Proceedings of the AIChE Annual Meeting, Reno, Nevada, 6 November 2001. [Google Scholar]

- Ziegler, J. “On-the-job” adjustments of air operated recorder-controllers. Instruments 1941, 16, 394–397. [Google Scholar]

- Ziegler, J.; Nichols, N.B. Optimum Settings for Automatic Controllers. Trans. Am. Soc. Mech. Eng. 1942, 64, 759–768. [Google Scholar] [CrossRef]

- Ziegler, J.; Nichols, N.B. Process lags in automatic control circuits. Trans. Am. Soc. Mech. Eng. 1943, 65, 433–444. [Google Scholar]

- Skogestad, S. Simple analytic rules for model reduction and PID controller tuning. J. Process Control 2003, 13, 291–309. [Google Scholar] [CrossRef]

- Skogestad, S. Simple analytic rules for model reduction and PID controller tuning. Model. Identif. Control 2004, 25, 85–120. [Google Scholar] [CrossRef]

- Åström, K.; Hägglund, T. PID Controllers: Theory, Design, and Tuning; Instrument Society of America: Research Triangle Park, NC, USA, 1995. [Google Scholar]

- Seborg, D.; Edgar, T.F.; Mellichamp, D.A. Process Dynamics and Ciontrol; John Wiley and Sons: Hoboken, NJ, USA, 1989. [Google Scholar]

- Grimholt, C.; Skogestad, S. Optimal PI-Control and Verification of the SIMC Tuning Rule. IFAC Proc. Vol. 2012, 45, 11–22. [Google Scholar] [CrossRef]

- Grimholt, C.; Skogestad, S. Optimal PID-Control on First Order Plus Time Delay Systems & Verification of the SIMC Rules. IFAC Proc. Vol. 2013, 46, 265–270. [Google Scholar] [CrossRef]

- Skogestad, S.; Grimholt, C. The SIMC Method for Smooth PID Controller Tuning; Springer: London, UK, 2012. [Google Scholar]

- Haugen, F. Comparing PI Tuning Methods in a Real Benchmark Temperature Control System. Model. Identif. Control 2010, 31, 79–91. [Google Scholar] [CrossRef]

- Luyben, W. Process Modeling, Simulation, and Control for Chemical Engineers; Chemical engineering series; McGraw-Hill: New York, NY, USA, 1990. [Google Scholar]

- Abbasi, I.; Ali, S.; Ovinis, M.; Naeem, W. U-Model Based Controller Design for an Unmanned Free Swimming Submersible (UFSS) Vehicle Under Hydrodynamic Disturbances; NISCAIR-CSIR: New Delhi, Delhi, India, 2017; Volume 46, pp. 742–748. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).