Pressure Control for a Hydraulic Cylinder Based on a Self-Tuning PID Controller Optimized by a Hybrid Optimization Algorithm

Abstract

:1. Introduction

2. Literature Review

2.1. Proportion Integration Differentiation Controller

2.2. Particle Swarm Optimization Algorithm

2.3. Discussion

3. Background

3.1. PID Controller

3.2. Particle Swarm Optimization

3.3. Genetic Algorithm

4. The Proposed Method

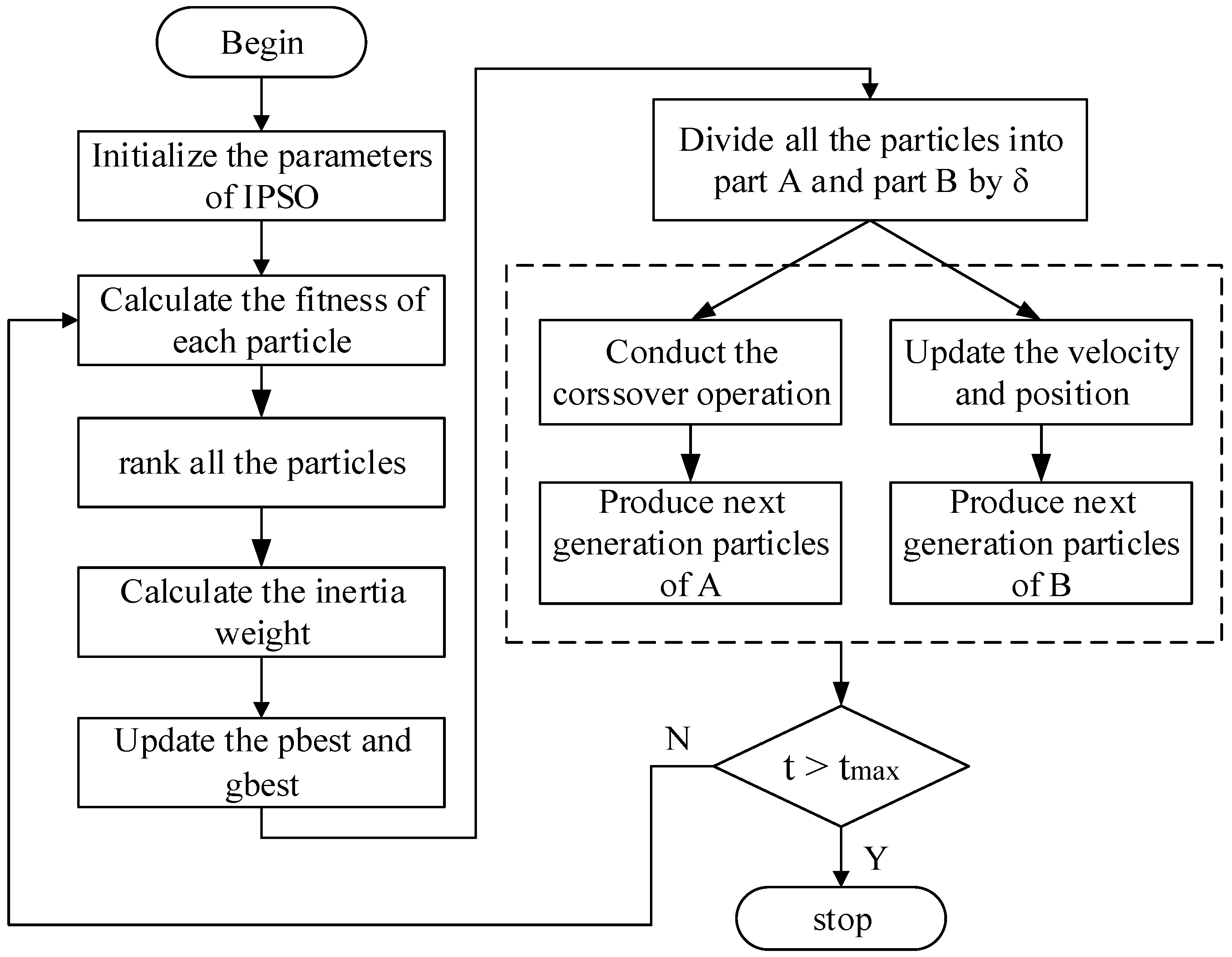

4.1. Hybrid Optimization Algorithm

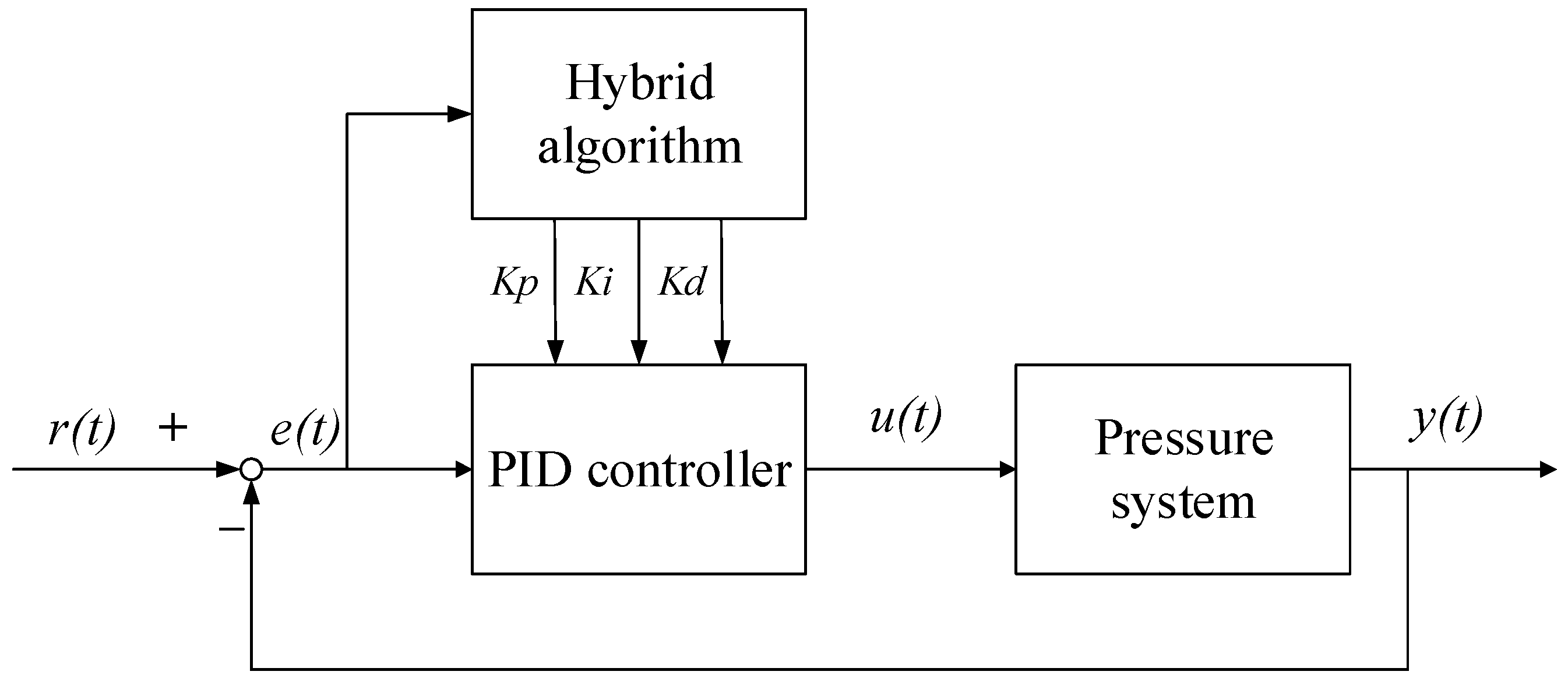

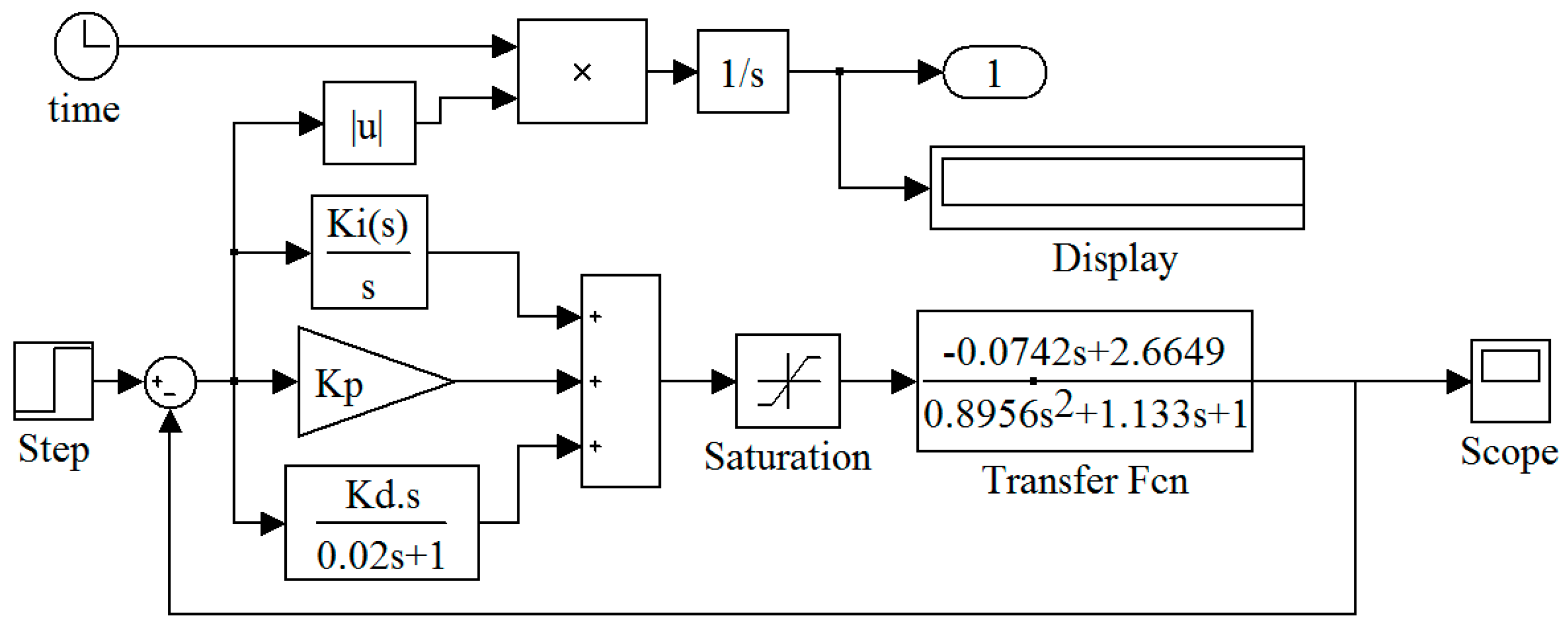

4.2. The Process of Pressure Control on the Hydraulic Cylinder

5. Simulation and Analysis

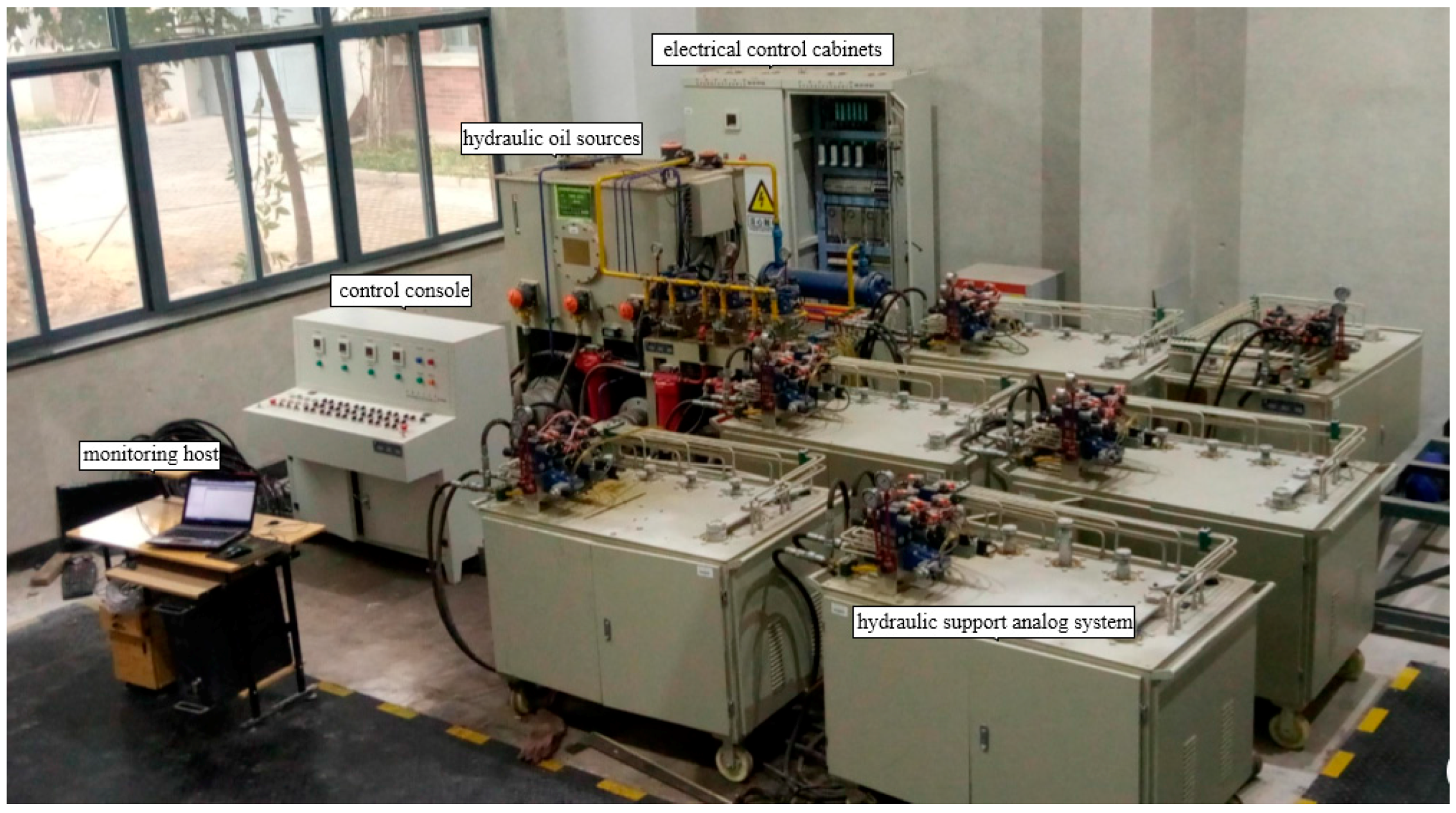

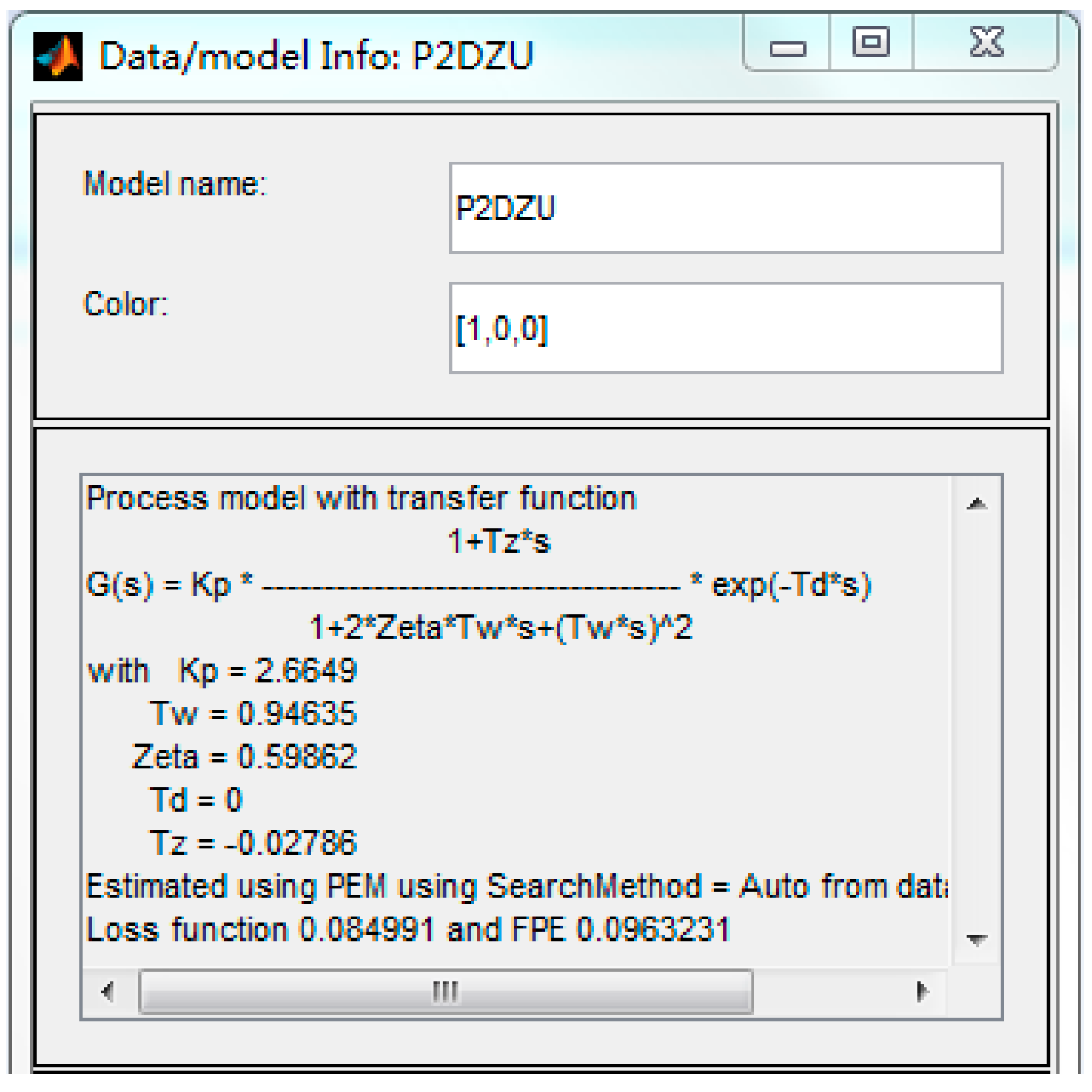

5.1. Acquiring the System Transfer Function

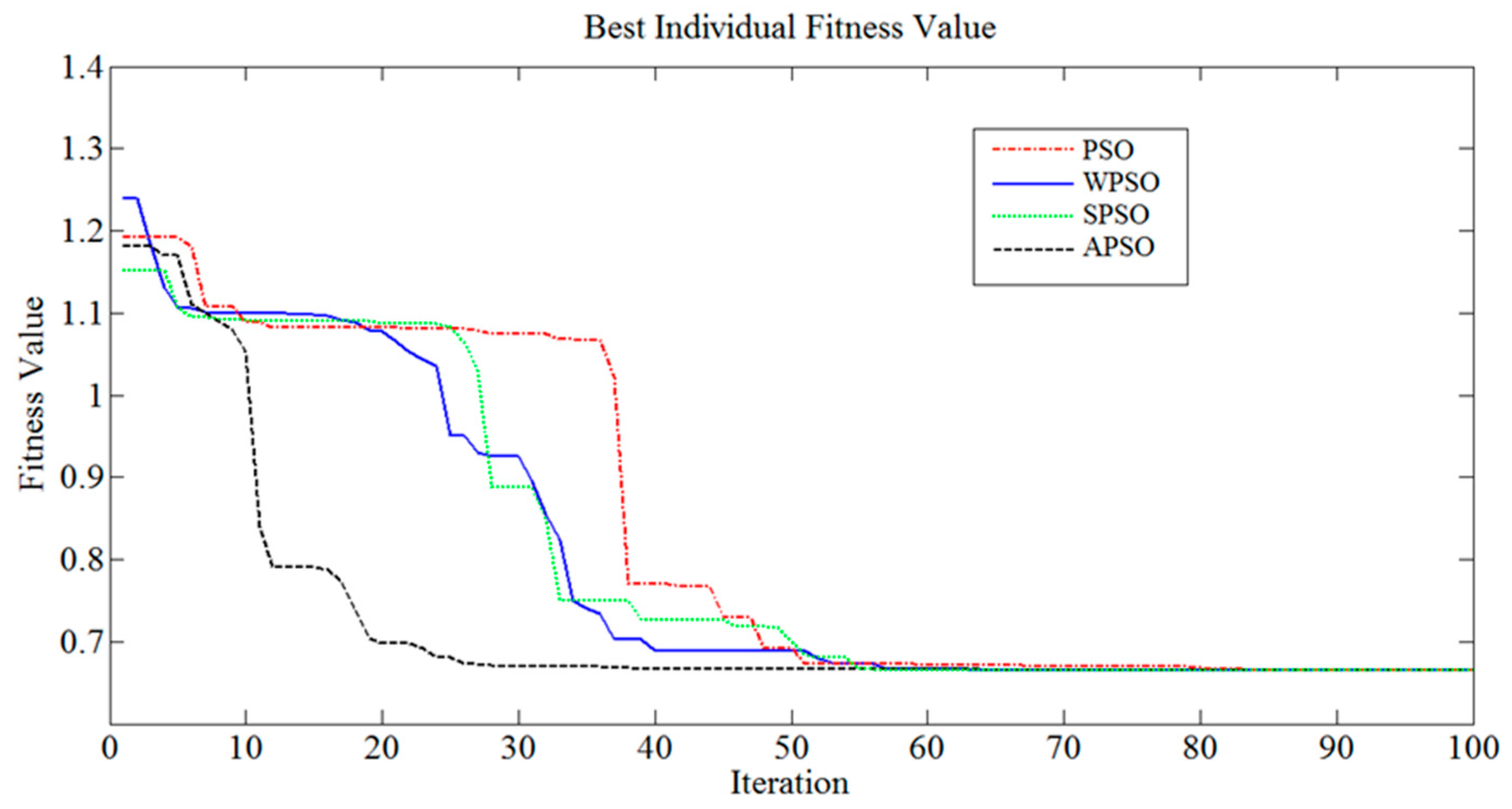

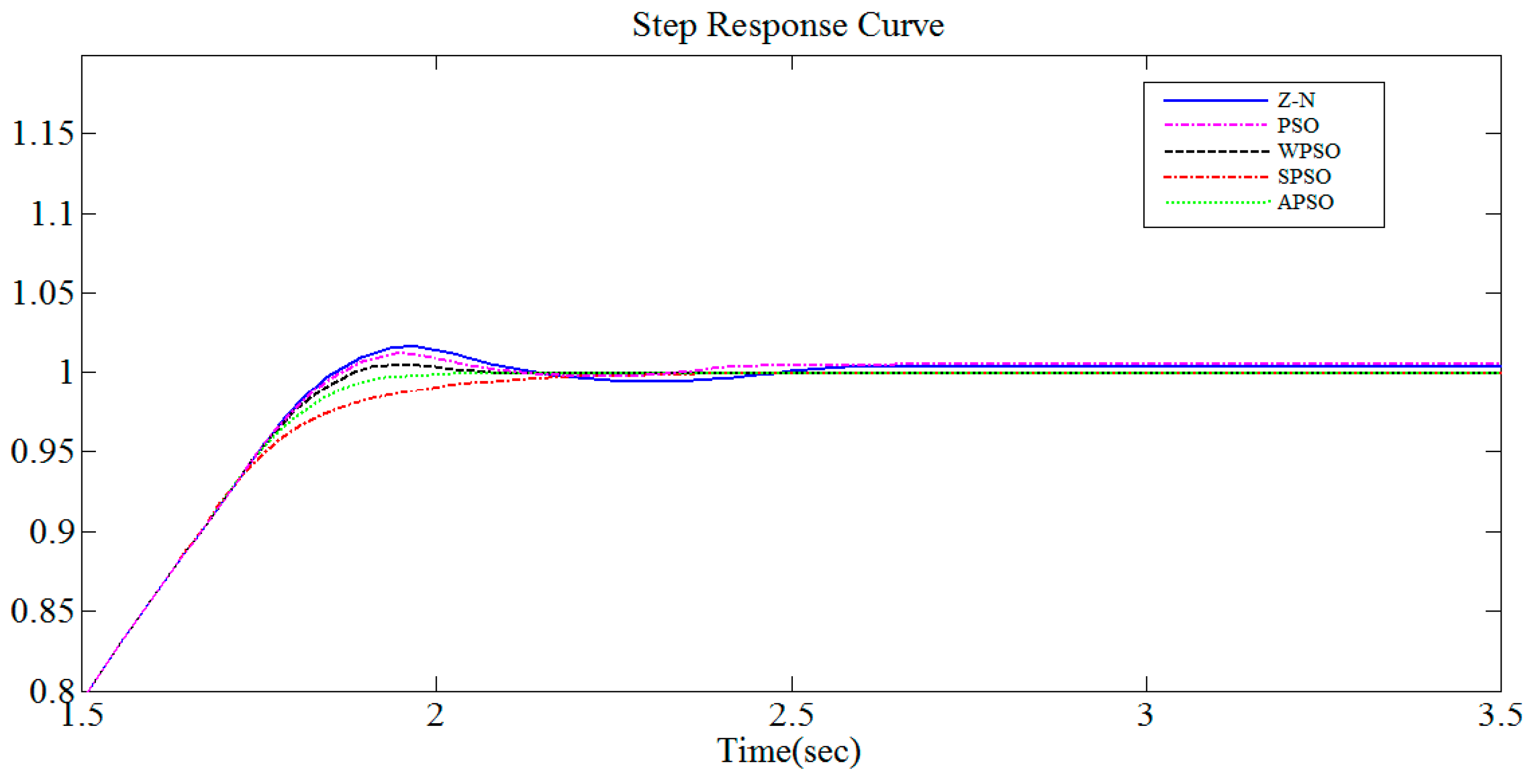

5.2. Parameters Setting and Simulation

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Visioli, A. Tuning of PID controllers with fuzzy logic. IEE Proc.-Control Theory Appl. 2001, 148, 1–8. [Google Scholar] [CrossRef]

- Seng, T.L.; Khalid, M.B.; Yusof, R. Tuning of a neuro-fuzzy controller by genetic algorithm. IEEE Trans. Syst. Man Cybern. 1999, 29, 226–236. [Google Scholar] [CrossRef] [PubMed]

- Kawabe, T.; Tagami, T. A real coded genetic algorithm for matrix inequality design approach of robust PID controller with two degrees of freedom. In Proceedings of the 12th IEEE International Symposium on Intelligent Control, Istanbul, Turkey, 16–18 July 1997; pp. 119–124.

- Mukherjee, V.; Ghoshal, S.P. Intelligent particle swarm optimized fuzzy PID controller for AVR system. Electr. Power Syst. Res. 2007, 77, 1689–1698. [Google Scholar] [CrossRef]

- Savran, A.; Tasaltin, R.; Becerikli, Y. Intelligent adaptive nonlinear flight control for a high performance aircraft with neural networks. ISA Trans. 2006, 45, 225–247. [Google Scholar] [CrossRef]

- Hernandez-Guzman, V.M.; Carrillo-Serrano, R.V. Global PID position control of PM stepper motors and PM synchronous motors. Int. J. Control 2011, 11, 1807–1816. [Google Scholar] [CrossRef]

- Krohling, R.A.; Jaschek, H.; Rey, J.P. Designing PI/PID controller for a motion control system based on genetic algorithm. In Proceedings of the 12th IEEE International Symposium on Intelligent Control, Istanbul, Turkey, 16–18 July 1997; pp. 125–130.

- Zhou, W.D.; Gao, X.; Liu, G.H. Randomization in particle swarm optimization for global search ability. Expert Syst. Appl. 2011, 38, 15356–15364. [Google Scholar] [CrossRef]

- Lu, Y.Z.; Yan, D.P.; Zhang, J.Y.; Levy, D. A variant with a time varying PID controller of particle swarm optimizers. Inf. Sci. 2015, 297, 21–49. [Google Scholar] [CrossRef]

- Zhang, S.W.; Chau, K.W. Dimension Reduction Using Semi-Supervised Locally Linear Embedding for Plant Leaf Classification. Lect. Notes Comput. Sci. 2009, 5754, 948–955. [Google Scholar]

- Alfi, A.; Modares, H. System identification and control using adaptive particle swarm optimization. Appl. Math. Model. 2011, 35, 1210–1221. [Google Scholar] [CrossRef]

- Wu, C.L.; Chau, K.W.; L, Y.S. Methods to improve neural network performance in daily flows prediction. J. Hydrol. 2009, 372, 80–93. [Google Scholar] [CrossRef]

- Mitsukura, Y.; Yamamoto, T.; Kaneda, M. A design of self-tuning PID controllers using a genetic algorithm. In Proceedings of the American Control Conference, San Diego, CA, USA, 2–4 June 1999; pp. 1361–1365.

- Chang, W.D.; Shih, S.P. PID controller design of nonlinear systems using an improved particle swarm optimization approach. Commun. Nonlinear Sci. Numer. Simul. 2010, 15, 3632–3639. [Google Scholar] [CrossRef]

- Taormina, R.; Chau, K.W. Data-driven input variable selection for rainfall-runoff modeling using binary-coded particle swarm optimization and Extreme Learning Machines. J. Hydrol. 2015, 529, 1617–1632. [Google Scholar] [CrossRef]

- Mercieca, J.; Simon, G.F. A Metaheuristic Particle Swarm Optimization Approach to Nonlinear Model Predictive Control. Int. J. Adv. Intell. Syst. 2012, 5, 357–369. [Google Scholar]

- Zhang, J.; Chau, K.W. Multilayer Ensemble Pruning via Novel Multi-sub-swarm Particle Swarm Optimization. J. Univ. Comput. Sci. 2009, 15, 840–858. [Google Scholar]

- Abido, M.A. Optimal Design of Power–System Stabilizers Using Particle Swarm Optimization. IEEE Trans. Energy Convers. 2002, 3, 406–413. [Google Scholar] [CrossRef]

- Porwikn, P.; Doroz, R.; Orczyk, T. Signatures verification based on PNN classifier optimized by PSO algorithm. Pattern Recognit. 2016, 60, 998–1014. [Google Scholar] [CrossRef]

- Chatterjee, A.; Chatterjee, R.; Matsuno, F.; Endo, T. Neuro-fuzzy state modeling of flexible robotic arm employing dynamically varying cognitive and social component based PSO. Measurement 2007, 40, 628–643. [Google Scholar] [CrossRef]

- Wang, W.C.; Chau, K.W.; Xu, D.M.; Chen, X.Y. Improving Forecasting Accuracy of Annual Runoff Time Series Using ARIMA Based on EEMD Decomposition. Water Resour. Manag. 2015, 29, 2655–2675. [Google Scholar] [CrossRef]

- Chau, K.W.; Wu, C.L. A hybrid model coupled with singular spectrum analysis for daily rainfall prediction. J. Hydroinform 2010, 12, 458–473. [Google Scholar] [CrossRef]

- Xu, J.; Wang, Z.B.; Wang, J.B.; Tan, C.; Zhang, L.; Liu, X.H. Acoustic-Based Cutting Pattern Recognition for Shearer through Fuzzy C-Means and a Hybrid Optimization Algorithm. Appl. Sci. 2016, 6, 294. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, C.M.; Huang, C.C. Improved particle swarm algorithm for hydrological parameter optimization. Appl. Math. Comput. 2010, 217, 3207–3215. [Google Scholar] [CrossRef]

- Liu, X.Y. Optimization design on fractional order PID controller based on adaptive particle swarm optimization algorithm. Nonlinear Dyn. 2016, 84, 379–386. [Google Scholar] [CrossRef]

- Padhy, P.K.; Majhi, S. Improved automatic tuning of PID controller for stable processes. ISA Trans. 2009, 48, 423–427. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.P.; Daley, S. Optimal-tuning nonlinear PID control of hydraulic systems. Control Eng. Pract. 2000, 8, 1045–1053. [Google Scholar] [CrossRef]

- Panda, R.C.; Yu, C.C.; Huang, H.P. PID tuning rules for SOPDT systems: Review and some new results. ISA Trans. 2004, 43, 283–295. [Google Scholar] [CrossRef]

- Okochi, G.S.; Yao, Y. A review of recent developments and technological advancements of variable-air-volume (VAV) air-conditioning systems. Renew. Sustain. Energy Rev. 2016, 59, 784–817. [Google Scholar] [CrossRef]

- Ang, K.H.; Chong, G. PID Control System Analysis, Design and Technology. IEEE Trans. Control Syst. Technol. 2005, 13, 559–576. [Google Scholar]

- Liu, G.P.; Daley, S. Optimal-tuning PID control for industrial systems. Control Eng. Pract. 2001, 9, 1185–1194. [Google Scholar] [CrossRef]

- Astrom, K.J.A.; Hagglund, T. The future of PID control. Control Eng. Pract. 2001, 9, 1163–1175. [Google Scholar] [CrossRef]

- Dey, C.; Mudi, R.K. An improved auto-tuning scheme for PID controllers. ISA Trans. 2009, 48, 396–409. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.C. New tuning method for PID controller. ISA Trans. 2002, 41, 473–484. [Google Scholar] [CrossRef]

- Abdel Badie Sharkawy. Genetic fuzzy self-tuning PID controllers for antilock braking systems. Eng. Appl. Artif. Intell. 2010, 23, 1041–1052. [Google Scholar]

- Gaing, Z.L. A particle swarm optimization approach for optimum design of PID controller in AVR system. IEEE Trans. Energy Convers. 2004, 19, 324–391. [Google Scholar] [CrossRef]

- Chopra, V.; Singla, S.K.; Dewan, L. Comparative Analysis of Tuning a PID Controller using Intelligent Methods. Acta Polytech. Hung. 2014, 11, 235–249. [Google Scholar]

- Liu, B.; Wang, L.; Jin, Y.H.; Tang, F. Improved particle swarm optimization combined with chaos. Chaos Solitons Fractals 2005, 25, 1261–1271. [Google Scholar] [CrossRef]

- He, S.; Prempain, E.; Wu, Q.H. An improved particle swarm optimizer for mechanical design optimization problems. Eng. Optim. 2004, 36, 585–605. [Google Scholar] [CrossRef]

- Das, S.; Abraham, A.; Konar, A. Automatic Clustering Using an Improved Differential Evolution Algorithm. IEEE Trans. Syst. Man Cybern. 2008, 38, 218–237. [Google Scholar] [CrossRef]

- Bouallegue, S.; Haggege, J.; Ayadi, M.; Benrejeb, M. PID-type fuzzy logic controller tuning based on particle swarm optimization. Eng. Appl. Artif. Intell. 2012, 25, 484–493. [Google Scholar] [CrossRef]

- Zhu, M.; Yang, C.L.; Li, W.L. Auto-tuning algorithm of particle swarm PID parameter based on D-Tent chaotic model. J. Syst. Eng. Electron. 2013, 24, 828–837. [Google Scholar] [CrossRef]

- Par, J.B.; Jeong, Y.W.; Shin, J.R. An Improved Particle Swarm Optimization for Nonconvex Economic Dispatch Problems. IEEE Trans. Power Syst. 2010, 25, 156–166. [Google Scholar]

- Lu, Y.Z.; Yan, D.P.; Levy, D. Chaotic particle swarm optimization for optimal design of PID controllers in industrial systems. J. Intell. Fuzzy Syst. 2016, 30, 3007–3016. [Google Scholar] [CrossRef]

- Fang, H.Q.; Chen, L.; Shen, Z.Y. Application of an improved PSO algorithm to optimal tuning of PID gains for water turbine governor. Energy Convers. Manag. 2011, 52, 1763–1770. [Google Scholar] [CrossRef]

- Chang, W.D.; Chen, C.Y. PID Controller Design for MIMO Processes Using Improved Particle Swarm Optimization. Circuits Syst Signal Process. 2014, 33, 1473–1490. [Google Scholar] [CrossRef]

| Tuning Method | Convergence Iteration | Overshoot (%) | Steady State Time (sec) | Running Time (sec) | |||

|---|---|---|---|---|---|---|---|

| Z–N | 40 | 0.5 | 4.5 | —— | 1.64 | 3.0294 | —— |

| PSO | 31.3072 | 0.3540 | 3.5556 | 82 | 1.12 | 2.6472 | 12.16 |

| WPSO | 29.4390 | 0.3540 | 4.2422 | 60 | 0.52 | 2.4286 | 12.57 |

| SPSO | 25.7658 | 0.3540 | 4.2677 | 56 | 0 | 2.8785 | 13.83 |

| APSO | 22.3045 | 0.3523 | 3.4870 | 40 | 0 | 2.3192 | 16.78 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, R.; Tan, C.; Xu, J.; Wang, Z.; Jin, J.; Man, Y. Pressure Control for a Hydraulic Cylinder Based on a Self-Tuning PID Controller Optimized by a Hybrid Optimization Algorithm. Algorithms 2017, 10, 19. https://doi.org/10.3390/a10010019

Wang R, Tan C, Xu J, Wang Z, Jin J, Man Y. Pressure Control for a Hydraulic Cylinder Based on a Self-Tuning PID Controller Optimized by a Hybrid Optimization Algorithm. Algorithms. 2017; 10(1):19. https://doi.org/10.3390/a10010019

Chicago/Turabian StyleWang, Ru, Chao Tan, Jing Xu, Zhongbin Wang, Jingfei Jin, and Yiqiao Man. 2017. "Pressure Control for a Hydraulic Cylinder Based on a Self-Tuning PID Controller Optimized by a Hybrid Optimization Algorithm" Algorithms 10, no. 1: 19. https://doi.org/10.3390/a10010019

APA StyleWang, R., Tan, C., Xu, J., Wang, Z., Jin, J., & Man, Y. (2017). Pressure Control for a Hydraulic Cylinder Based on a Self-Tuning PID Controller Optimized by a Hybrid Optimization Algorithm. Algorithms, 10(1), 19. https://doi.org/10.3390/a10010019