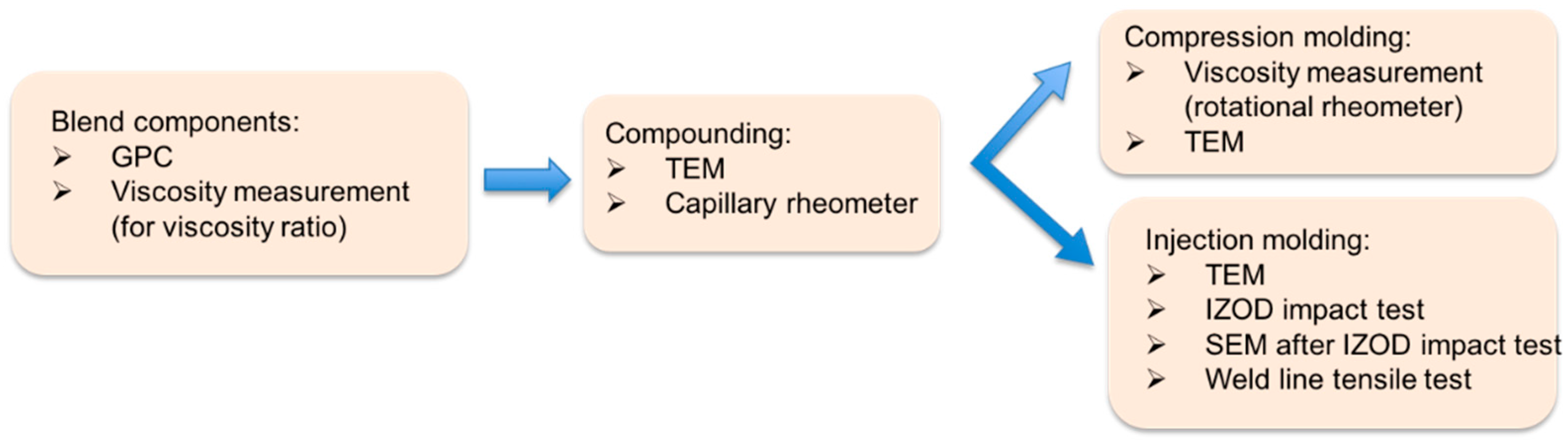

3.1. Rheological Properties of the Blend Components and the Blend Systems

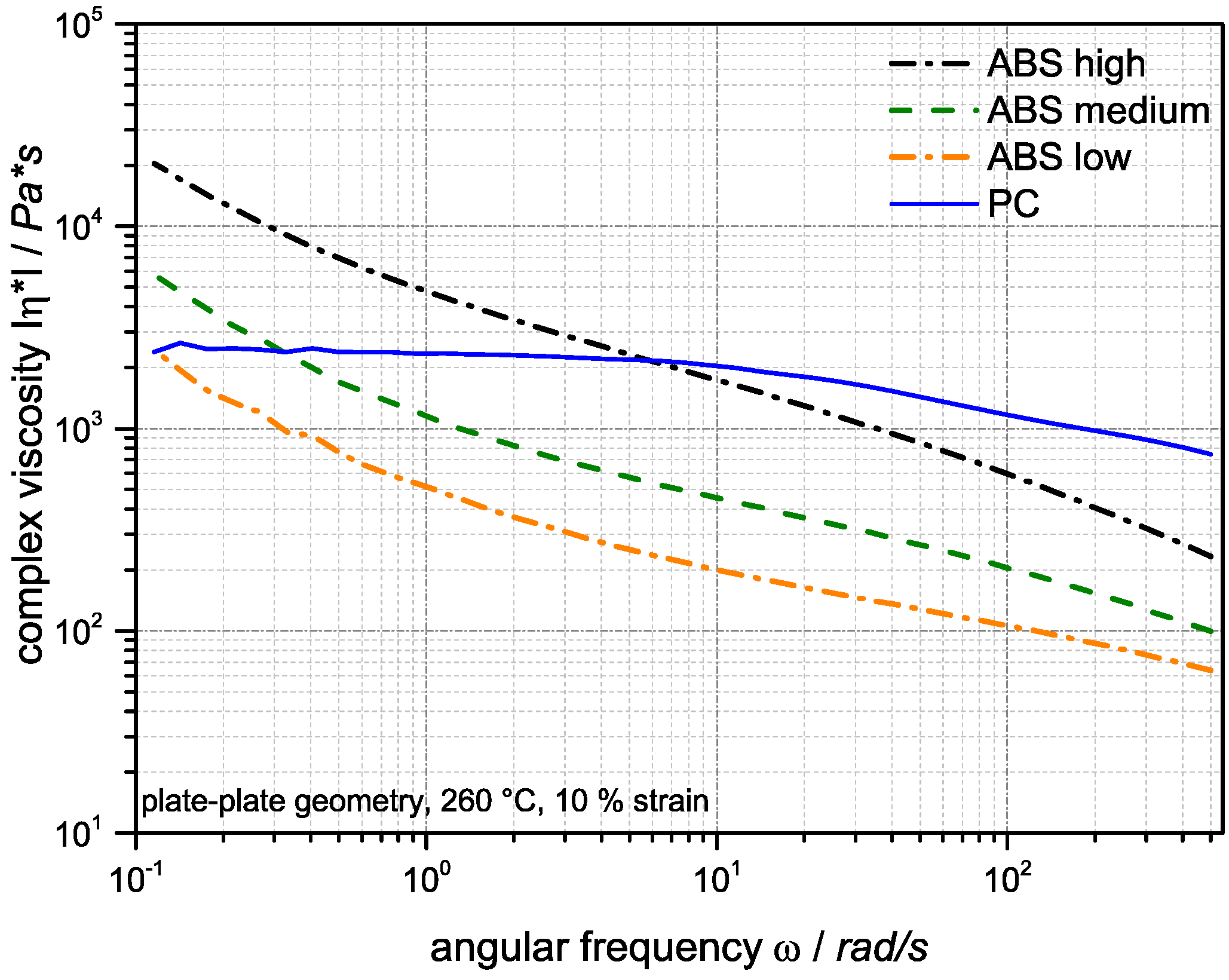

Figure 4 shows the complex viscosity of the neat polycarbonate and ABS components used in the built-up of the investigated PC/ABS blends as function of the oscillatory frequency (or shear rate) at a temperature of 260 °C, which is the processing temperature of the blend systems during its compounding, as well as injection molding.

The ABS components show a shear thinning behavior and, as expected, an increase of melt viscosity with the molecular weight of the SAN components. The increase of ABS viscosities at lower shear rates is a consequence of the network formation of the dispersed polybutadiene rubber particles [

35]. The viscosity of the PC shows a nearly Newtonian behavior over a wide frequency range. At the higher shear rates of >50 rad/s typically occurring during compounding in a twin-screw extruder and during injection molding, the viscosity of the PC component is higher compared to the viscosities of all three investigated ABS components. On the other hand, due to the network formation of the butadiene particles in the ABS and the mostly Newtonian behavior of the PC, at lower shear rates the melt viscosities of the ABS become higher compared to the PC. The frequency, at which the viscosities of the PC and ABS are equal, obviously increases with increasing molecular weight of the SAN in the ABS.

The effect of the ratio of viscosities of immiscible or partly miscible polymeric blend partners on the resulting phase morphology of polymer blend systems has been investigated in the literature [

14,

36,

37,

38,

39]. During compounding and injection molding different shear rates are known to occur. For further discussions of morphology formation, the ratios of the viscosities of the dispersed phase (ABS) and the matrix phase (PC) were calculated at the lower and higher shear rates approximating, to our best knowledge, the different shear conditions occurring during compounding and injection molding processing, respectively. For compounding in a twin-screw extruder, typically shear rates in the order of magnitude of 100 s

−1 are described in the literature [

40]. For injection molding, shear rates depend on injection speeds and other parameters, and generally are assumed to be in the order of magnitude of >1000 s

−1. The calculation of the viscosity ratios λ

d/m = λ

ABS/PC experienced by the blend during its compounding and injection molding was thus done on the basis of the viscosities of the ABS and the PC as measured by plate-plate rheometer (at 100 rad/s) and at the highest shear rate that was possible to measure with the available equipment for all blend components by a capillary rheometer (i.e., at 1500 s

−1), respectively (see

Table 2 and

Table 3). The values of the viscosity ratios at 100 rad/s (

Table 2) show an increasing viscosity ratio from 0.11 to 0.40 with increasing molecular weight of the SAN.

The viscosity ratios at 1500 s

−1 (

Table 3) also increase with increasing molecular weight of the SAN from 0.11 to 0.18. Thus, the trend in the viscosity ratios for the investigated samples at the lower and higher shear rates experienced by the blend during compounding and injection molding, respectively, are, in principle, the same. However, while the viscosity ratio values calculated for higher and lower shear rates are practically the same for the PC/ABS blends based on the low and medium molecular weight SANs, for the blend based on the high molecular weight SAN the viscosity ratio turns out to be much lower in the case of the higher shear frequency. Hence, under the shear conditions typical of injection molding, the viscosity ratios of the investigated blend partners covers only a relatively small range, although the molecular weights of the SAN polymers covers the complete range that is commercially available.

The complex melt viscosities of the investigated PC/ABS 60/40 blends as a function of angular frequency are shown in

Figure 5. The shear viscosity of all PC/ABS blends is decreasing with increasing frequency, which is characteristic for a shear thinning behavior.

The PC/ABS curves of all three PC/ABS blend samples have nearly the same shape and, as expected, are just shifted towards lower melt viscosities with decreasing molecular weight of the SAN component in the blend. The rheological behavior of the blend systems is determined by both blend partners and shows a synergetic reduction of the viscosity vs. the calculated weight averaged viscosities of the blend partners PC and ABS in the majority of the assessed angular frequency range, in particular at higher shear rates typical of melt processes, such as compounding and injection molding. At very low shear rates below 0.1–1 rad/s the shear thinning behavior of the ABS however becomes dominant.

3.2. Morphology Formation during Compounding

During compounding of the PC/ABS blends, starting from the individual polymers PC, emulsion-ABS and SAN, the formation of blend morphology depends on the shear conditions, the viscosity ratio of the blend partners and, in principle, also their interfacial tension. In this study interfacial tension can be regarded as constant for all investigated PC/ABS samples as always the same PC and emulsion-ABS components are used and all SAN polymers have the same monomer composition.

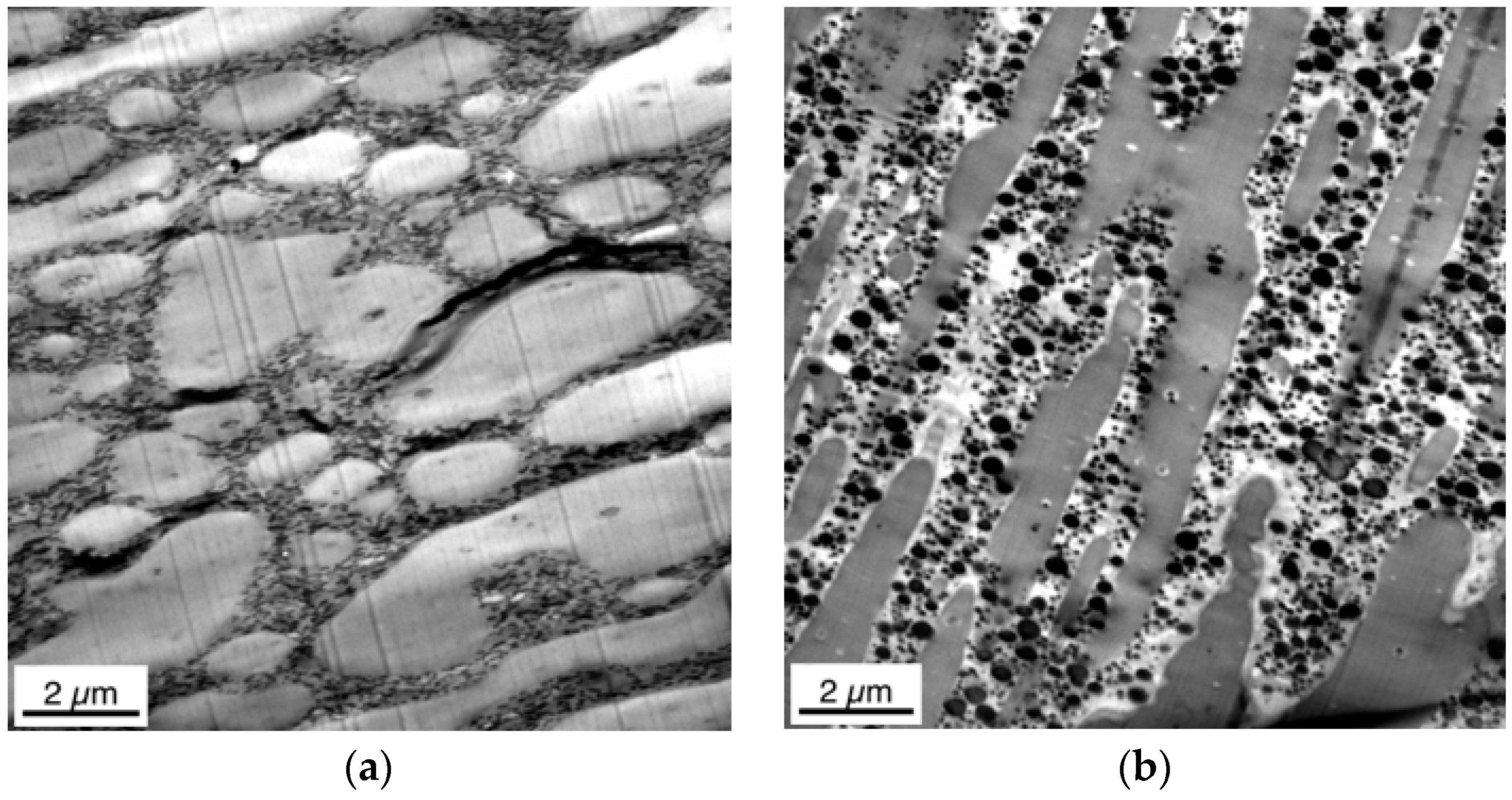

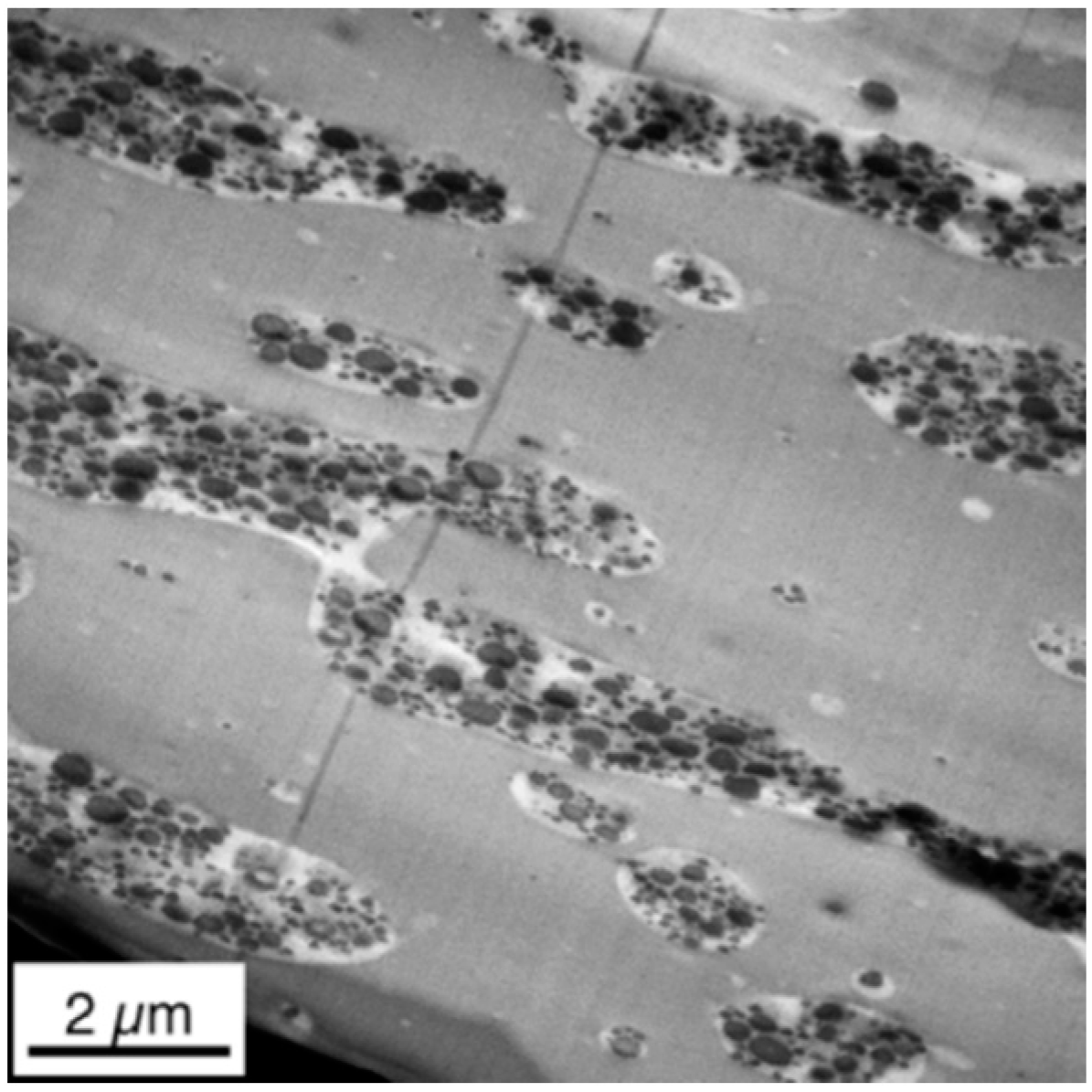

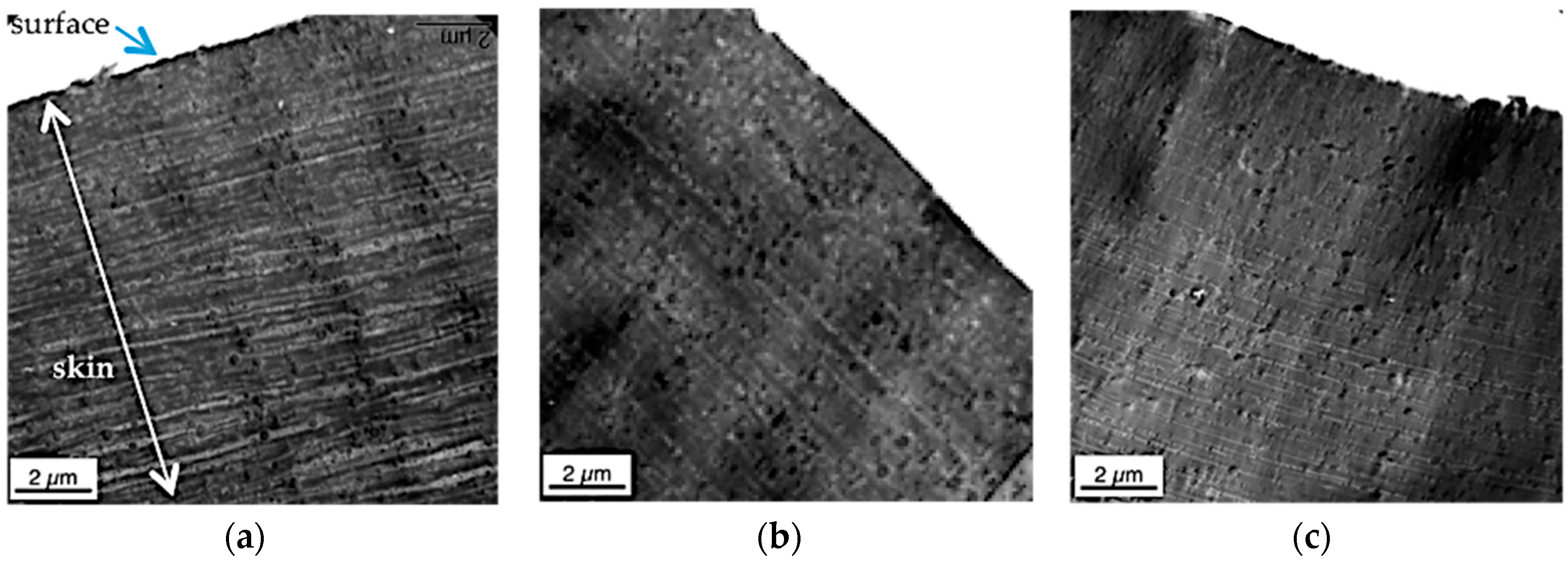

TEM micrographs taken on ultramicrotome cuts that had been collected from the compounded pellets in different orientations relative towards the strand extrusion direction, show a severely different morphology characterized by a different degree of deformation and orientation of the ABS phase (

Figure 6). Interestingly, depending on the cutting orientation, morphology in the compounded pellets is either phase-inverted versus the expectation for a PC/ABS 60/40 blend, i.e., ABS forms the matrix and PC forms the dispersed phase (

Figure 6a) or is co-continuous (

Figure 6b).

Obviously, for interpretation of TEM micrographs on pellets it is crucial to provide detailed information about the position and direction of the investigated microtome cut. In published TEM studies on pellets, where this information has not been explicitly provided, the interpretations and drawn conclusions have to be taken with high caution, in particular since it is very difficult to define and, thus, to keep constant the cutting orientation in compounded pellets of a series of samples.

The morphology of the compressed sample shows a similar morphology compared to that of the pellet. This is shown in

Figure 7. Due to no significant effect of compression molding on the morphology of PC/ABS, the micrograph will not be further discussed.

3.3. Morphology Formation during Injection Molding

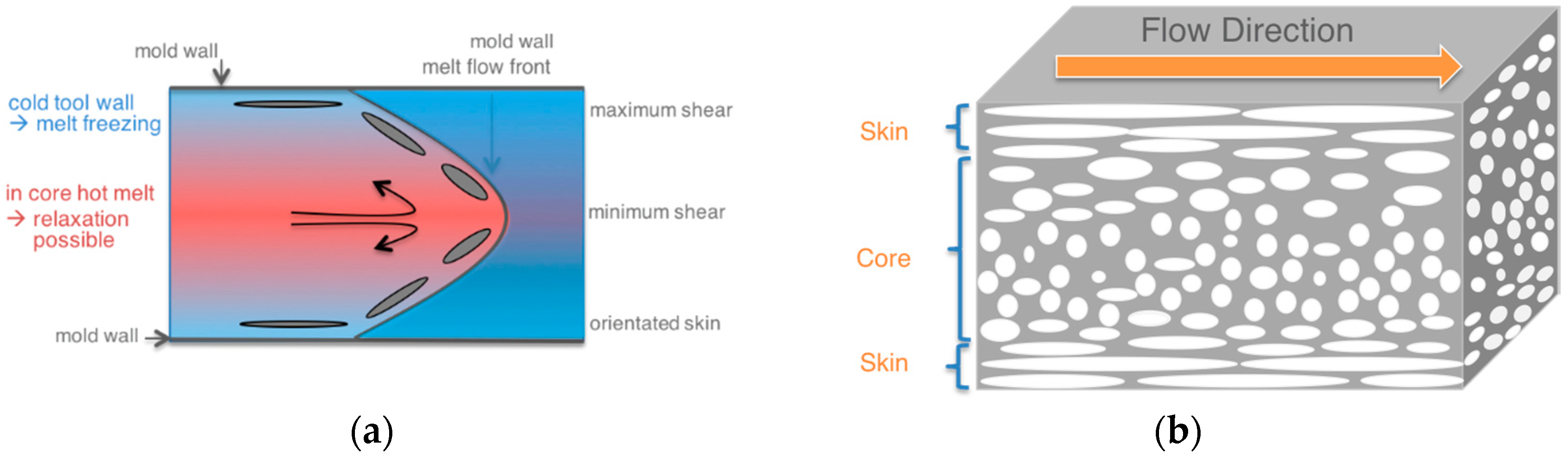

During injection molding of a thermoplastic material the melt is experiencing a combination of shear and elongational flow field gradients. In blends of immiscible or partly miscible polymers this results in different phase morphologies at different positions in the specimen. Another consequence are different morphology views depending on the orientation of the microtome cut relative to the orientation of the melt flow in the injection molding process at the position where the cut is taken.

In this study, the phase morphology of the injection-molded specimens was always investigated on microtome cuts generated in a direction parallel to the injection flow, as shown in

Figure 3.

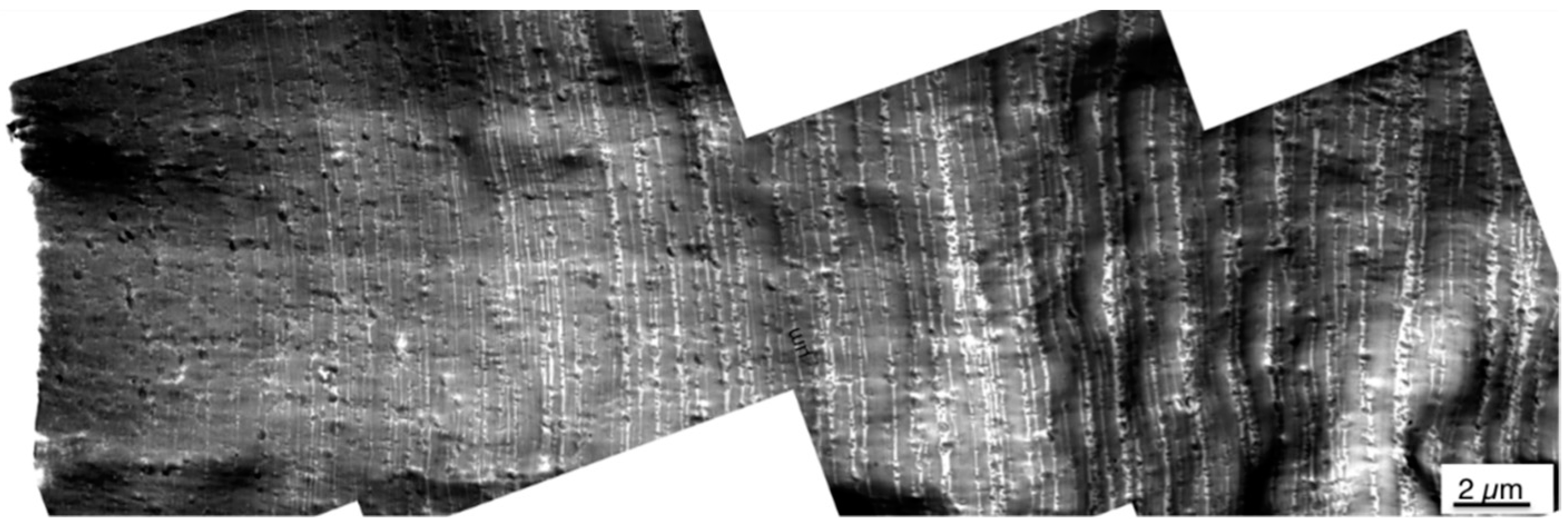

The morphology of polymer blends is preferentially investigated by TEM as it allows good visual contrast separation of the different polymer phases. A major disadvantage of TEM versus SEM images is that TEM can only visualize a very small section of the specimen. So far published TEM investigations of the skin section of injection-molded specimens have commonly studied a layer covering the first 150 µm from the surface of the specimens. Only a very small part of this large layer was actually visualized by the published TEM pictures and a more comprehensive view of the real surface was not shown. Hence, these previous studies left the question where, within the 150 µm layer, the particular picture had been taken, i.e., these studies were implicitly suggesting a homogeneous morphology within this 150 µm thick skin layer.

In contrast to the previous work, in the present study the microtome cuts have been prepared at the surface itself and the TEM pictures have been taken in such a way to explicitly show this surface. Thus, it is always well-defined at which depth below the surface a certain morphology is observed. Moreover, morphology profiles were recorded within the skin layers of the injection-molded specimens prepared from the PC/ABS blends.

Figure 8 and

Figure 9 show skin morphology profile examples for the PC/ABS blends based on low and high molecular weight SAN polymers, respectively. Panorama views of the first 50 µm surface layer are shown in the top row of

Figure 8 and

Figure 9. The middle row of

Figure 6 shows non-overlapping TEM micrographs taken at different distances from the surface up to a depth of about 120 µm, still within the skin layer of the injection-molded specimen. All of the micrographs shown in the top and middle row of

Figure 8 were taken on a single microtome cut generated in the skin of the specimen as shown in

Figure 3. In addition, pictures were taken on various microtome cuts generated in the core of the injection-molded specimens, i.e., at a distance of about 2000 µm below their surface (see bottom row in

Figure 6). Hence,

Figure 6 shows the full profile from the surface up to the core in the very center of the injection-molded specimen. Thus, for the first time, the true surface and the morphology changes appearing from skin to core of the specimen are visualized. On the left side of the upper row micrograph in

Figure 8 and

Figure 9, where the white backgrounds start, the real surfaces of the test specimens are visible. The morphology within the first 5 µm surface layer of the specimen made of the PC/ABS blend based on the low molecular weight SAN (image detail marked by the orange box in the upper row panorama view of

Figure 8) is shown in

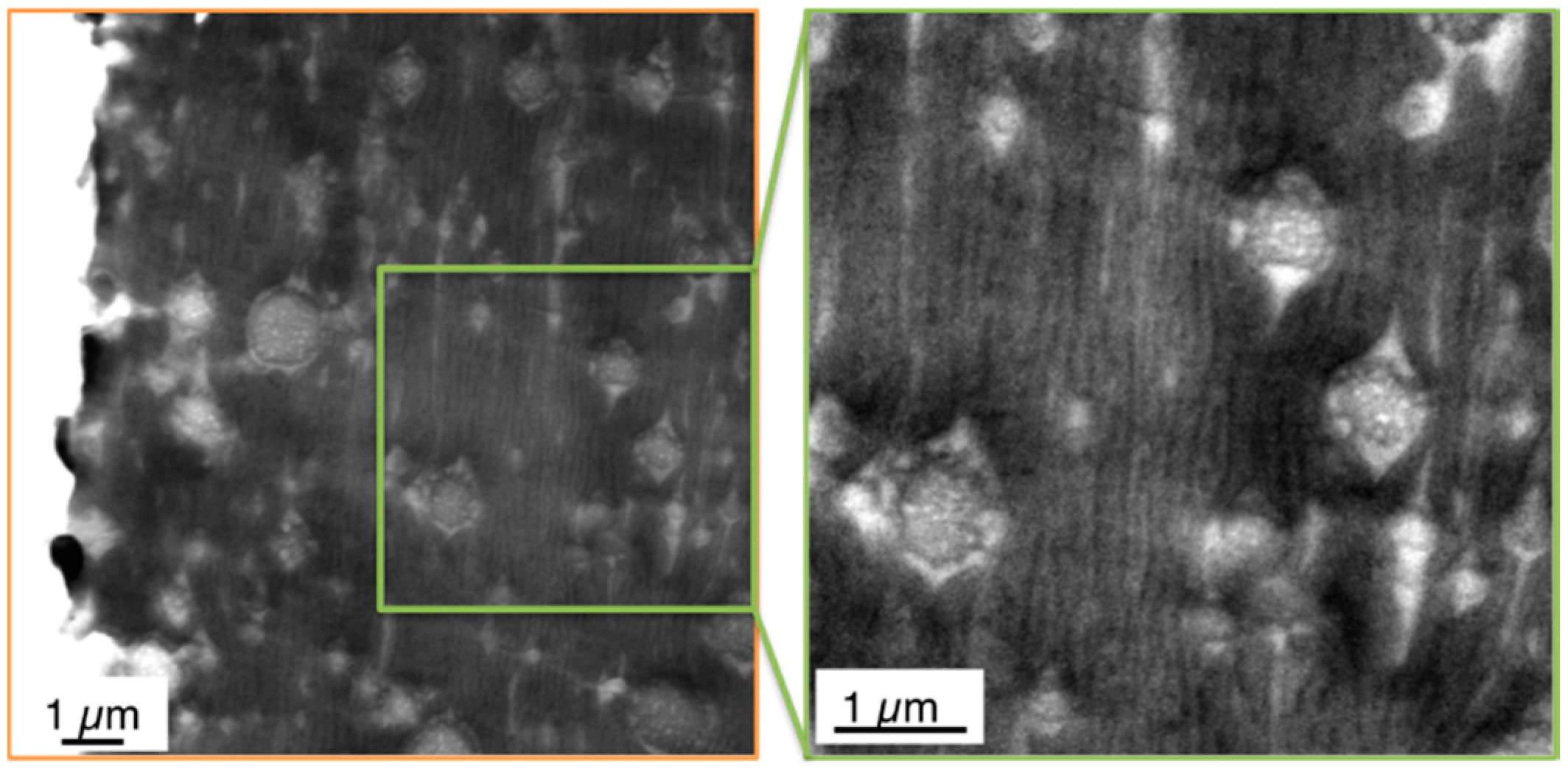

Figure 8 at higher magnifications to visualize the very special microscopic morphology here, which is described in the present investigation for the first time.

The panorama view in

Figure 9 for the PC/ABS blend based on the high molecular weight SAN shows the same specimen surface section that is visualized in the upper row of

Figure 8 for the respective material based on the low molecular weight SAN.

On the basis of this morphology profile, and the already published data [

17,

18,

19,

20], a more precise and distinguished model of the PC/ABS blend morphology formation during injection molding was developed and is displayed in

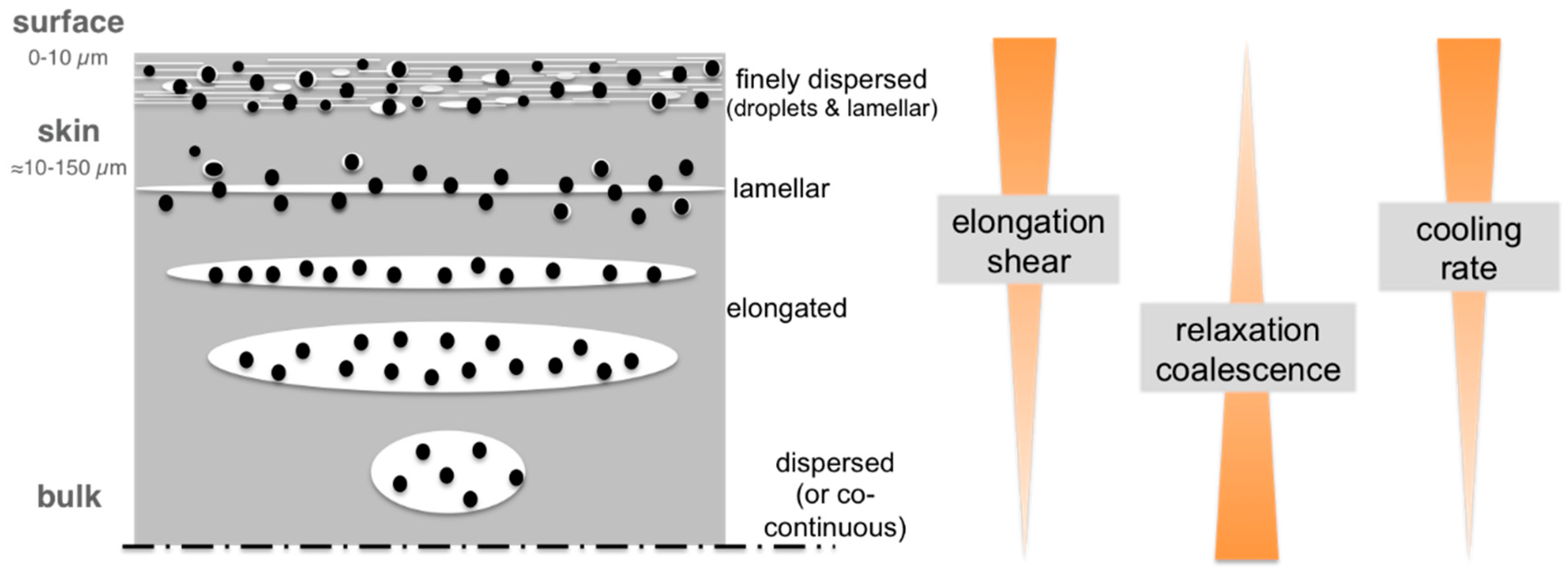

Figure 10.

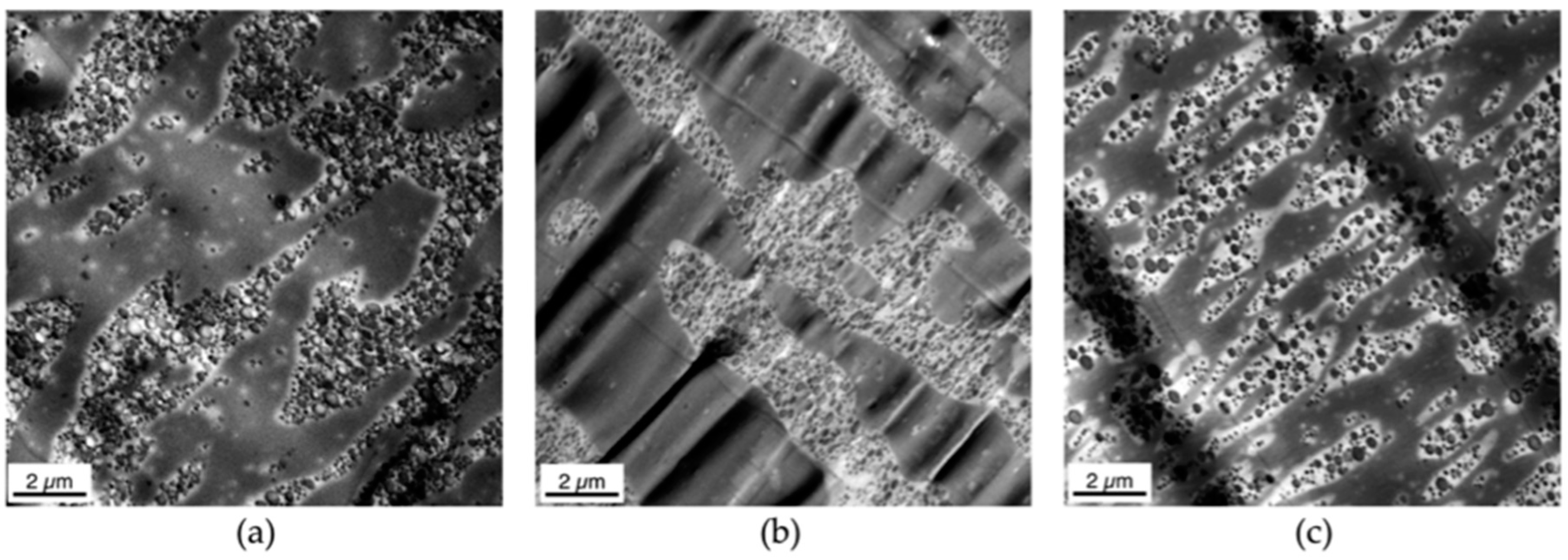

Within the specimens injection-molded from the currently investigated PC/ABS 60/40 compositions, in the core the ABS domains are relatively coarsely dispersed, only slightly deformed, or form a co-continuous network with the polycarbonate. Due to the reduced cooling rate in the core compared to the skin layer, thermodynamically unstable phase deformations resulting from the shear and elongational flow fields had obviously sufficient possibility to relax and provided ABS domains time for some coalescence. The morphology observed in the core, thus, can be assumed to be closer to the thermodynamic equilibrium state compared to the morphology observed nearer to the surface. With decreasing distance from the surface the dispersed ABS phases experience higher shear and elongational forces upon melt injection and, thus, are more strongly stretched. At the same time the cooling rate increases with decreasing distance from the cold mold surface and, thus, time for relaxation of the stretched domains is restricted, i.e., the non-equilibrium, strongly oriented phase morphology is partly frozen. With further decreasing distance from the surface these deformation processes become more pronounced and eventually result in lamellar ABS morphologies. In the core morphologies described so far, the SAN-grafted polybutadiene rubber particles are exclusively found in the SAN domains. The thickness of the ABS lamellae decreases with decreasing distance from the surface of the specimen. While due to their SAN grafting shell the rubber particles preferred to be dispersed in the SAN phase in the core, this is not any more possible when deformation of the SAN domains eventually result in a decrease of the thickness of these lamellae below the diameter of the rubber particles (100–400 nm). This happens very near to the surface (within a 5–50 µm layer). In the PC/ABS blend based on low molecular weight SAN the thickness of the lamellae in the first 15 µm from the surface e.g., ranges from 50 and 300 nm. Here the SAN-grafted rubber particles increasingly become dispersed in the polycarbonate phase leaving pure SAN lamellae, which are now free of rubber particles. These rubber-free, very low-viscosity SAN lamellae are even more susceptible to deformation. Thus, under the effect of the very high shear and elongational forces related to the friction close to the mold surface, and due to the missing elasticity originally provoked by the rubber phase, they cannot withstand any more break up into finely-dispersed and strongly-elongated streak-like SAN nano-phases, with a thickness in the range of only 10–20 nm. These can only be visualized at the highest TEM magnifications (see

Figure 11b).

Isolated polybutadiene rubber particles surrounded by a thin SAN grafting shell are left behind in the PC phase. This special surface morphology is observed only within the first few microns from the real surface of the specimens, because practically instantaneous freezing does not allow any coalescence of this energetically unfavorable, non-equilibrium state there. In principle, the same hierarchical morphology profile was observed in the injection-molded specimens of all three PC/ABS blends independent on the molecular weight of the SAN polymer (compare upper row of

Figure 8 with

Figure 9 and see

Figure 12 comparing the surface morphology of all three investigated PC/ABS specimens).

The thickness of the surface layer, which is characterized by the strongly dispersed and elongated (streak like) SAN nano-phases, is increasing with increasing molecular weight of the SAN from 2 to 3 µm in case of the blend based on the SAN with low molecular weight to 5–6 µm for the blend based on the SAN with high molecular weight. The thickness of the ABS lamellae, which are characteristic of the skin layer following the direct surface layer, decreases with increasing molecular weight of the SAN. In the specimen made of the PC/ABS blend based on low molecular weight SAN these lamellae are up to 300 nm thick at a depth of 12 µm below the specimen’s surface, whereas in the specimen made of the blend based on the high molecular weight SAN maximum lamellar thickness at this depth is only 50 nm. Moreover, the thickness of the skin layer in which the ABS/SAN phases exhibit a lamellar morphology increases with the viscosity of the SAN in the PC/ABS blend. While in the specimen made of the PC/ABS containing low molecular weight SAN the transition from lamellar to elongated dispersed phase morphology starts already within a distance of about 25 µm from the surface (see upper row in

Figure 8), in the specimen of the PC/ABS based on the high molecular weight SAN the thickness of the lamellar skin layer is >40 µm (see

Figure 8). The reason for all three observations is believed to be the higher shear forces resulting during injection molding from the viscosity increase of the melt due to the molecular weight increase of the SAN polymer component (see also

Figure 4 and

Table 3).

Figure 13 shows the TEM micrographs recorded on microtome cuts generated from the core of the different injection-molded specimens, i.e., at a distance of about 2000 µm below the surface. The core phase morphologies of all three investigated PC/ABS blend specimens differing in molecular weight of the SAN polymer constituent are very similar to each other, but they are strongly different from those previously described morphologies observed for the same materials at the surface and in the skin layers of the injection-molded specimens (compare

Figure 12 with

Figure 13).

The ABS domains in the core of injection-molded PC/ABS specimens in all different specimens are only slightly oriented by injection molding compared to the morphology observed in the skin. The morphologies of the PC/ABS blends with SAN low and SAN medium look practically identical. This observation correlates with the similar viscosity ratio λ

ABS/PC within the two blend systems (0.11 for the blend based on SAN low and 0.13 for the blend based on SAN medium, measured at the high shear rates typical of injection molding). Slightly larger ABS domains are visible in the bulk of these two blends compared to the PC/ABS blend with high molecular weight SAN and, thus, with a significantly, but not drastically, higher viscosity ratio λ

d/m of 0.18, measured at a shear rate of 1500 s

−1 (see also

Table 3). In the PC/ABS blend based on the high molecular weight SAN, the ABS domains show increased deformation, smaller domain sizes, and are obviously in a transition to break up. We believe that this is caused by the higher viscosity ratio of λ

d/m favoring improved dispersion and, consequently, smaller phase domain sizes as was already concluded in the previously published literature [

11,

12,

14]. Additionally, due to the higher melt viscosity of the blend based on the high molecular weight SAN (see

Table 2 and

Figure 4), the shear forces experienced by the melt upon injection molding are increased, so phase deformation as a necessary precursor of drop break up can be assumed to be more pronounced. Furthermore, the higher molecular weight of the SAN also prevents phase coalescence of the dispersed ABS phase as it increases its viscosity.

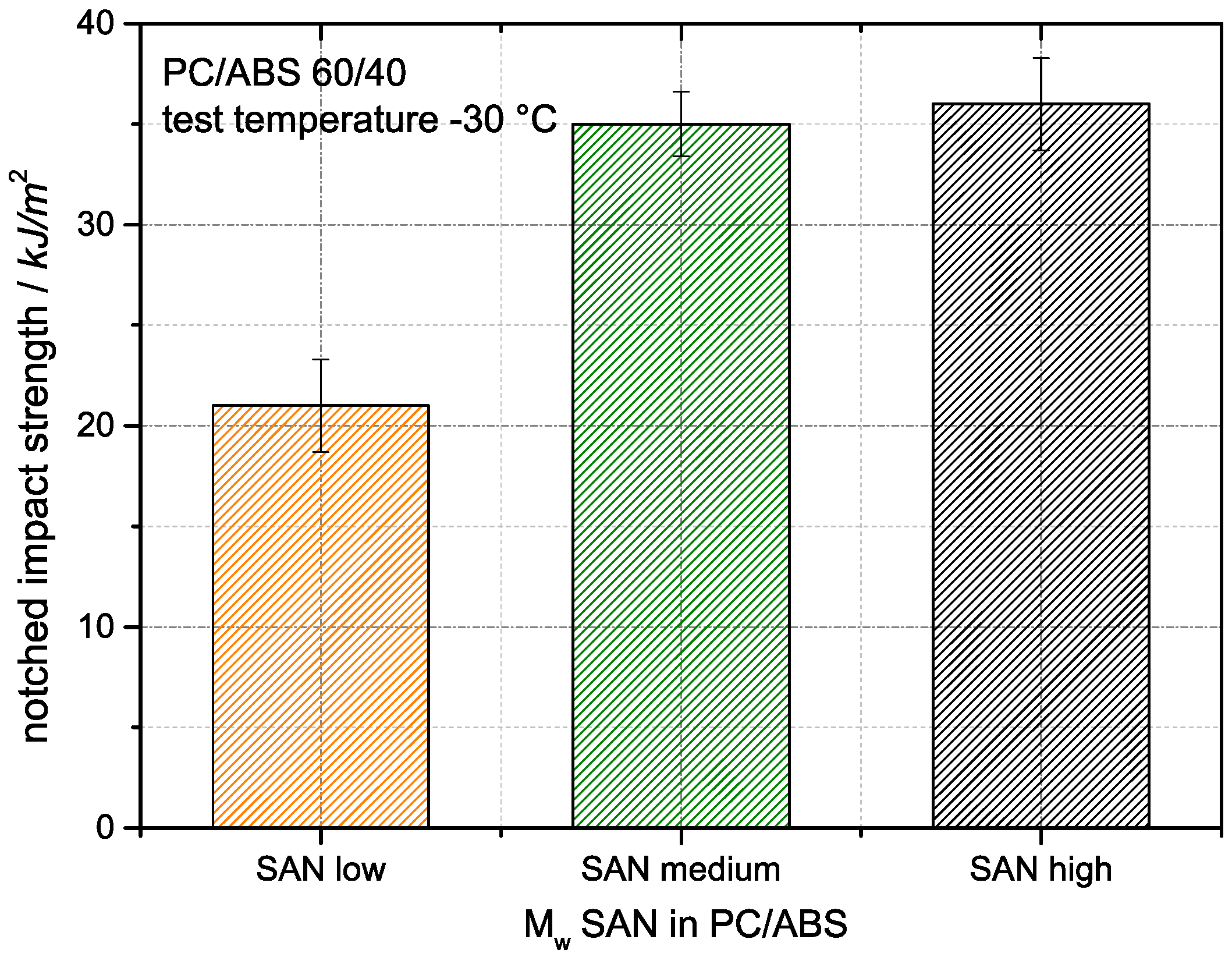

3.4. Correlations of Core Morpholgy with Mechanical Properties

Figure 14 shows the Izod notched impact strengths of the three PC/ABS blends differing in molecular weight of the SAN polymers that have been measured at −30 °C. The blends based on the medium and high molecular weight SAN show the same impact strength levels within the accuracy of the measurement. Obviously, beyond a certain threshold limit of SAN molecular weight (above 50,000 but below 100,000 g/mol) the impact strength of PC/ABS blend materials of this particular composition is not sensitive any more towards variations of the SAN molecular weight. On the other hand, the PC/ABS blend based on the lowest molecular weight SAN polymer shows a significantly lower Izod notched impact strength even though SAN low has a much lower polydispersity of molecular weight compared to SAN medium and high. Typically the mechanical properties of polymers improve with decreasing polydispersity due to the lower fraction of lowest molecular weight contributors [

41]. Therefore, for a SAN with the same Mw as SAN low but with the same D as for SAN medium and SAN high, an even lower Izod notched impact strength would be expected. According to general experience, Izod notched impact strength levels >>30 kJ/m

2 are known to typically correspond to a ductile failure while values significantly below this value are indicative of a rather brittle performance. Hence, the PC/ABS blends based on the medium and high molecular weight SAN were expected to show an essentially ductile failure, while the blend based on the SAN with the lowest molecular weight obviously was expected to show a clearly brittle behavior at low temperature. The decreasing Izod notched impact strength observed with the PC/ABS blend with the lowest molecular weight SAN is believed to be a consequence of the lower inherent fracture toughness of the low molecular weight SAN blend constituent. Morphology can be excluded as a major root cause for the ductility differences since the observed core morphologies were identical for the blends based on the low and medium molecular weight SANs (see

Figure 13a,b), which are different in low-temperature impact strength, while the materials based on the medium and high molecular weight SANs show different core morphologies (see

Figure 13b,c) but exhibit practically the same low-temperature impact strength.

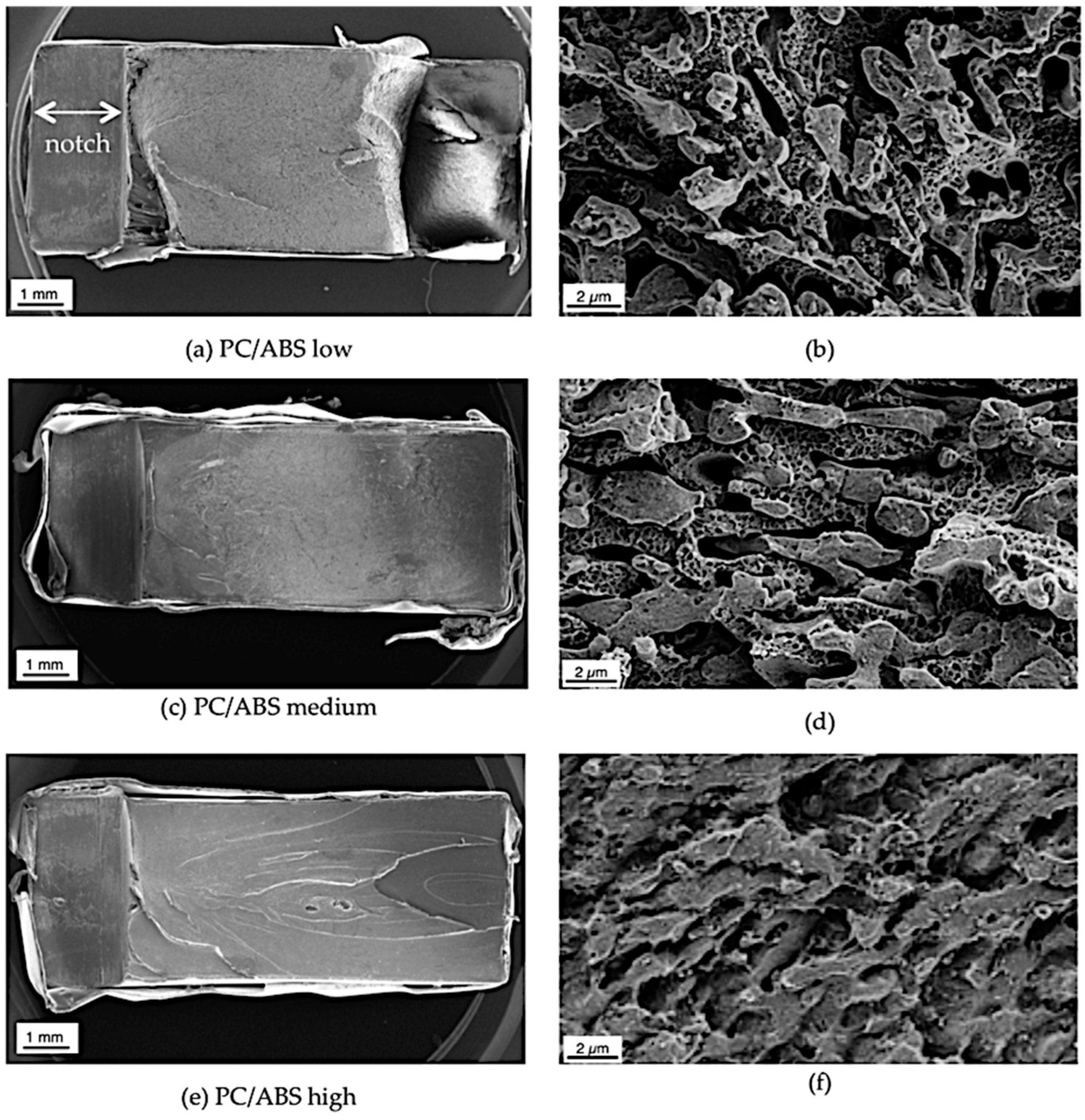

The fracture surfaces of the Izod impact strength specimens after testing at −30 °C were investigated via SEM to confirm the mode of impact failure. SEM micrographs are shown in

Figure 15 at a low magnification visualizing overviews of the complete fracture surface and thus the crack propagation path and at a higher magnification at a position in the middle of the crack path to visualize the phase adhesion during impact failure.

The overview SEM micrographs show that the fracture surface smoothness increases with decreasing molecular weight of the SAN. In the case of the blend based on the low molecular weight SAN, the material shows a failure with material delamination. These results confirm an increasing ductility of the PC/ABS blend with increasing molecular weight of the SAN in good correlation with the measured values of the Izod notched impact strengths (

Figure 14). The SEM pictures at higher magnification for the PC/ABS blends based on the low and medium molecular weight SANs (

Figure 15b,d) compared to the material based on the high molecular weight SAN (

Figure 15f) show a more pronounced detachment of the polybutadiene rubber particles from the SAN (little voids at the size of the rubber particles) and also a more pronounced detachment of the ABS from the PC phases (smoother phase surfaces) during impact failure. Interfacial tension between the ABS and the PC phases has to be assumed to be the same for each of the three PC/ABS samples differing only in molecular weight of the SAN but not in the chemical nature and composition of the polymeric blend partners. Nevertheless, SEM micrographs give a strong indication that interphase adhesion is increasing with the SAN molecular weight. The reason is believed to be a stronger intermolecular entanglement of SAN and PC molecules in the interphase with increasing SAN molecular weight. Such entanglement obviously requires a SAN molecular weight threshold above 100,000 g/mol to be exceeded in order to become effective in enabling stress transfer between polymer phases to such an extent that a ductile fracture pattern results. Although a good interphase adhesion between PC and ABS domains resulting from intermolecular entanglement obviously seems to be a requirement to achieve a fully ductile low-temperature notched impact failure pattern, the actually measured Izod notched impact strength values seem to be less affected by this interphase adhesion, but rather predominantly determined by the inherent mechanical strength of the individual polymeric blend partners. Sufficient hetero-molecular entanglement between SAN and PC molecules needed for good interphase adhesion and good homo-molecular entanglement of SAN molecules required for sufficient inherent SAN toughness are found to require exceedance of different SAN molecular weight thresholds. Ductile low-temperature notched impact failure in a PC/ABS blend of the investigated composition requires that SAN molecular weight exceeds a threshold in the range of 100,000–170,000 g/mol, whereas high low-temperature Izod notched impact strength values require that SAN molecular weight exceeds only a lower threshold in the range of 50,000–100,000 g/mol.

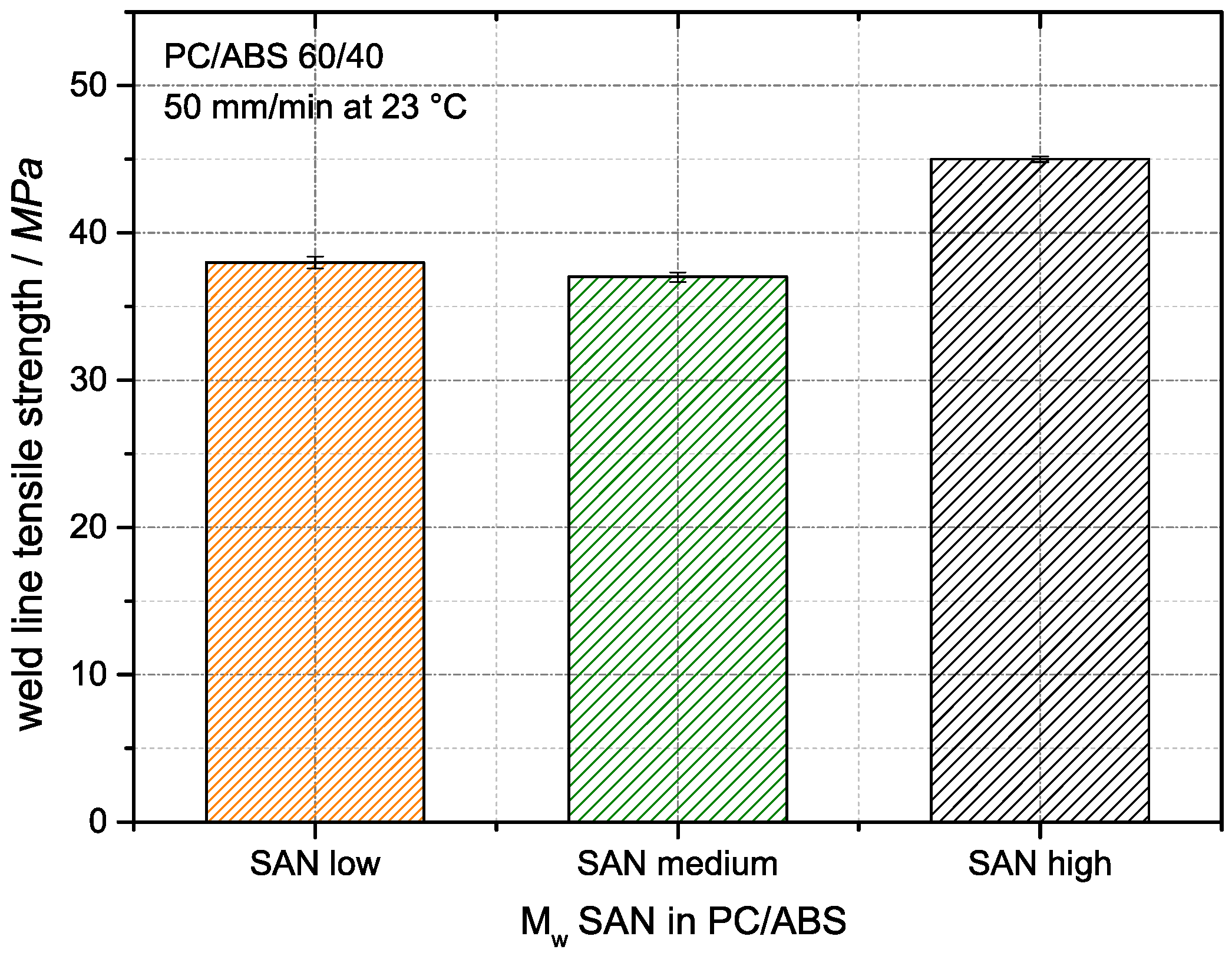

The conclusions from the SEM micrographs concerning the interphase adhesion between PC and ABS domains is independent of the molecular weight of the SAN are confirmed by the results of weld line tensile tests, which are displayed in

Figure 16. The weld line strength has been concluded in the literature to be a good indicator for changes of phase compatibility or phase adhesion, respectively, in heterogeneous polymer blends [

42,

43].

The weld line strength of the currently investigated PC/ABS blends based on low and medium molecular weight SANs are identical within the accuracy of measurement (37–38 MPa), whereas the weld line strength of the PC/ABS compound based on the high molecular weight SAN with a value of 45 MPa is 20% higher. These results correlate with the behavior seen in the SEM micrographs in

Figure 15, where the fracture surfaces of the PC/ABS blends with the low and medium molecular weight SAN showed the same morphology indicative of severe phase detachment upon impact testing, while the SEM micrograph of the material based on the high molecular weight SAN suggested a significantly different (improved) phase adhesion.