Investigation of the Self-Healing Behaviors of Microcapsules/Bitumen Composites by a Repetitive Direct Tension Test

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Microcapsule Fabrication Process

- SMA was added to 100 mL water at 50 °C and allowed to mix for 2 h. Then, a solution of NaOH (10%) was added dropwise, adjusting its pH value to 10. The above surfactant solution and rejuvenator were emulsified mechanically under a vigorous stirring rate for 10 min using a high-speed disperse machine.

- The encapsulation was carried out in a 500 mL three-neck round-bottomed flask equipped with a condensator and a tetrafluoroethylene mechanical stirrer. The above emulsion was transferred in the bottle, which was dipped in a steady temperature flume (room temperature). MMF prepolymer was added dropwise with a stirring speed of 500 r·min−1. The temperature was increased to 80 °C with a rate of 2 °C·min−1.

- After polymerization for 1 h, the temperature was decreased slowly to ambient temperature. At last, the resultant microcapsules were filtered and washed with pure water and dried in a vacuum oven.

2.3. Mixing of Bitumen and Microcapsules

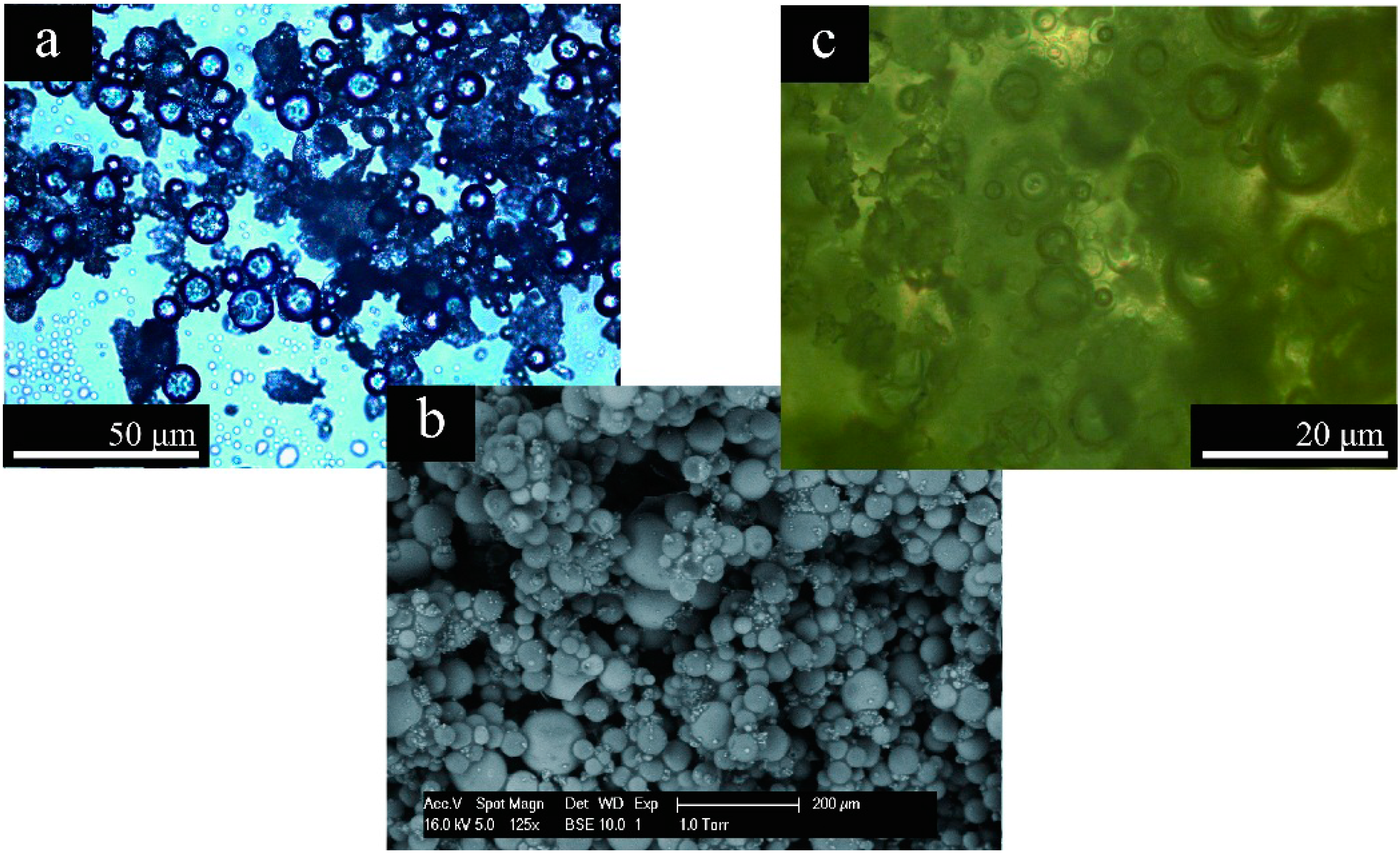

2.4. Morphology Observation

2.5. Mean Size of Microcapsules

2.6. Direct Tension Test

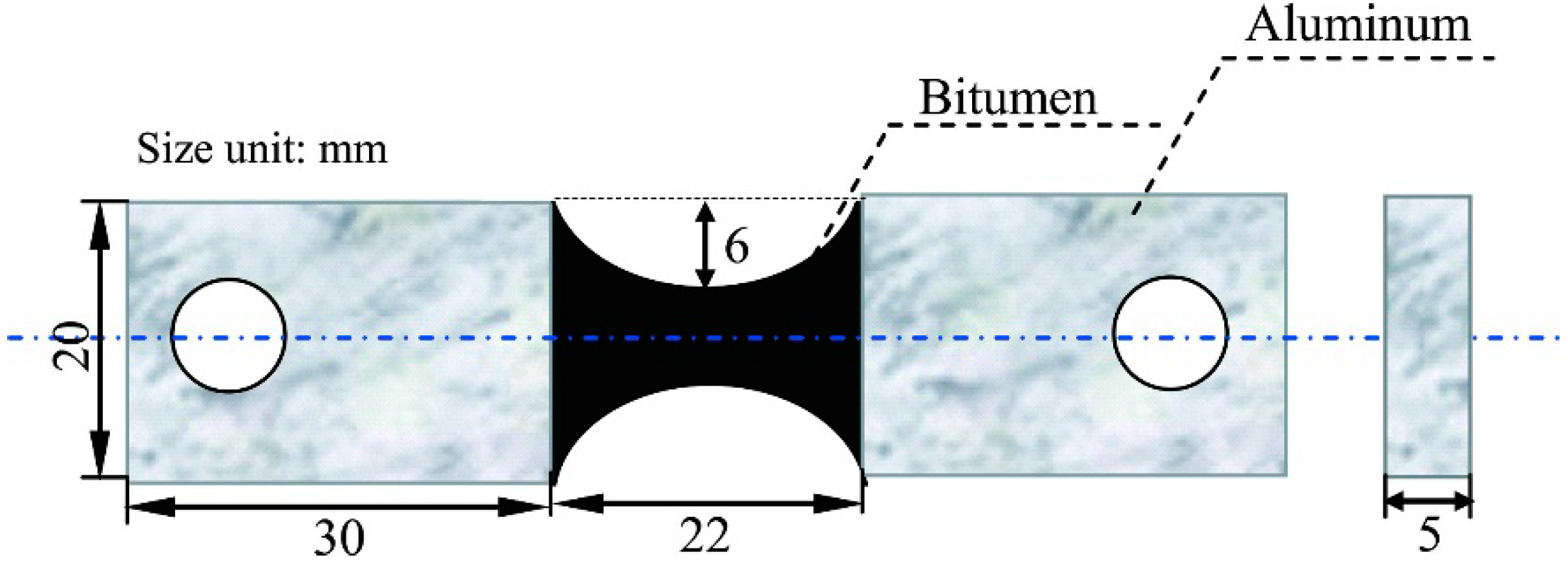

- Sample preparation: the testing samples were prepared in a pre-heated silicone rubber mould. Figure 2 shows the size of the tension test sample. The geometry of the bitumen can ensure the stress concentration in the middle of the bitumen sample [2]. Each sample was covered with another flat pre-heated silicone rubber in order to ensure the bitumen has the same shape on both sides. After being de-moulded, the samples were conditioned in a chamber for 24 h at 0 °C.

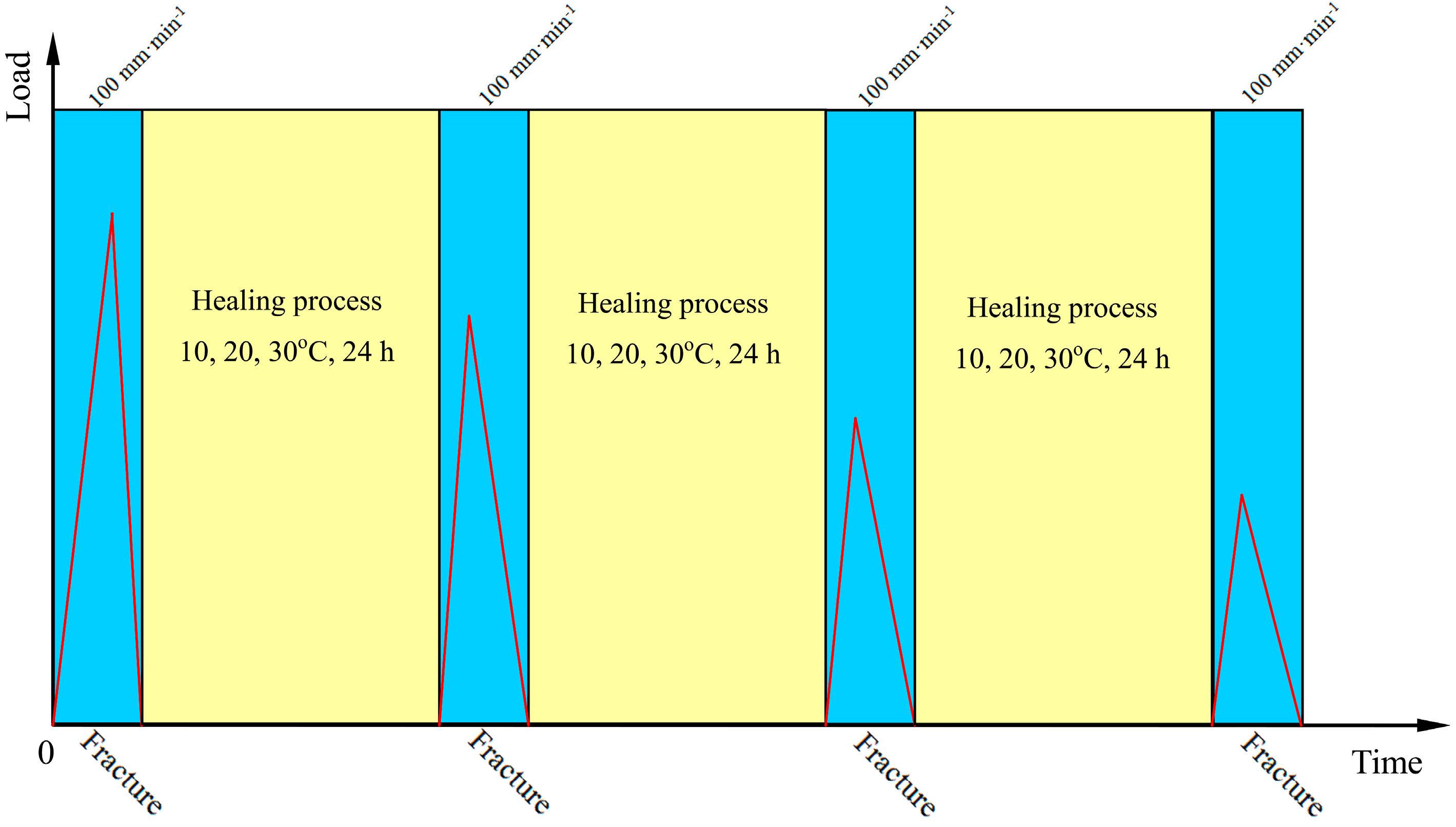

- Fracture and healing: samples were tested by a high–low temperature tension test machine (FR-103G, Farui Tech Co. Ltd., Shanghai, China; ±2.5% RH, ±1 °C) using a displacement speed of 100 mm·min−1 at 0 °C. The middle was fractured under the direct tension. The two parts of one broken sample were immediately put into the module again to ensure the two parts fit the crack very well. Each sample in the module was heated for 24 h under various temperatures of 10, 20 and 30 °C.

- Re-healing: After a healing process, the sample was re-conditioned in a chamber for 24 h at 0 °C. Then, the sample was de-moulded and the fracture process was repeated with the displacement speed of 100 mm·min−1 at 0 °C. The above re-fracture and re-healing rounds were repetitively tested, and the data were recorded automatically. Figure 3 illustrates the relationship between the time and fracture loads.

2.7. Characterization of Virgin and Rejuvenated Bitumen

2.8. Evaluation of the Self-Healing Capability

3. Results and Discussion

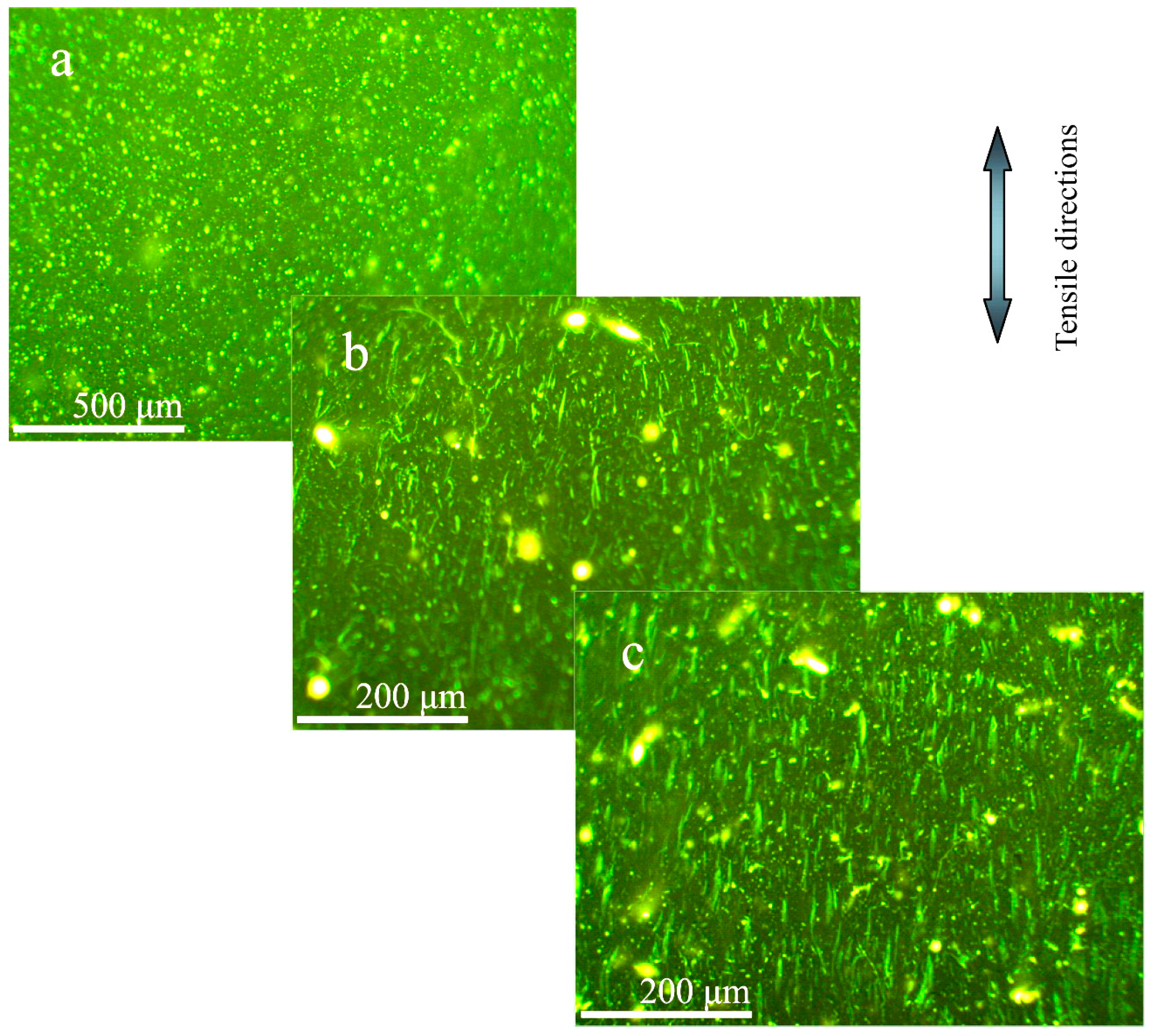

3.1. Microcapsule/Bitumen Sample Characterization

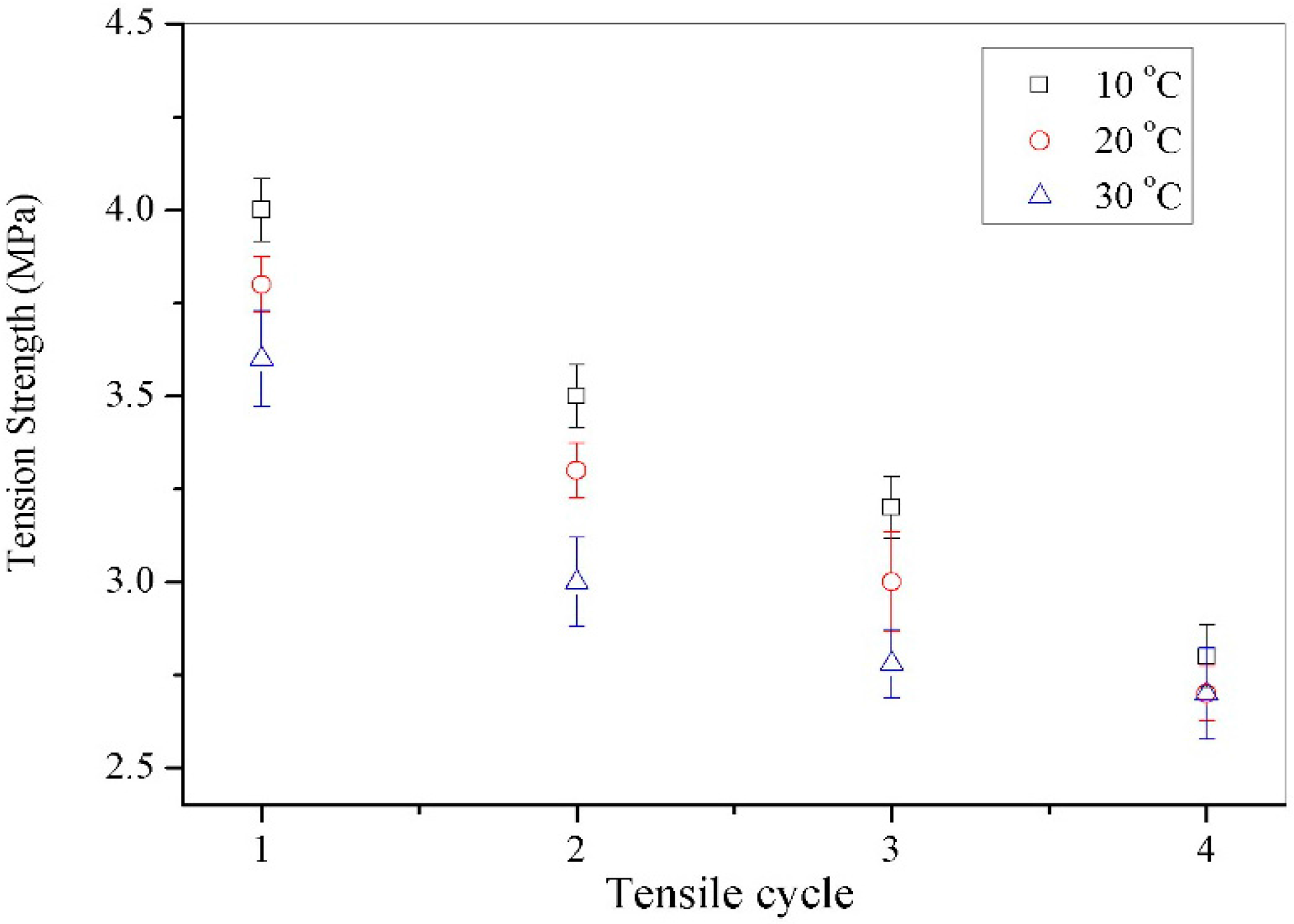

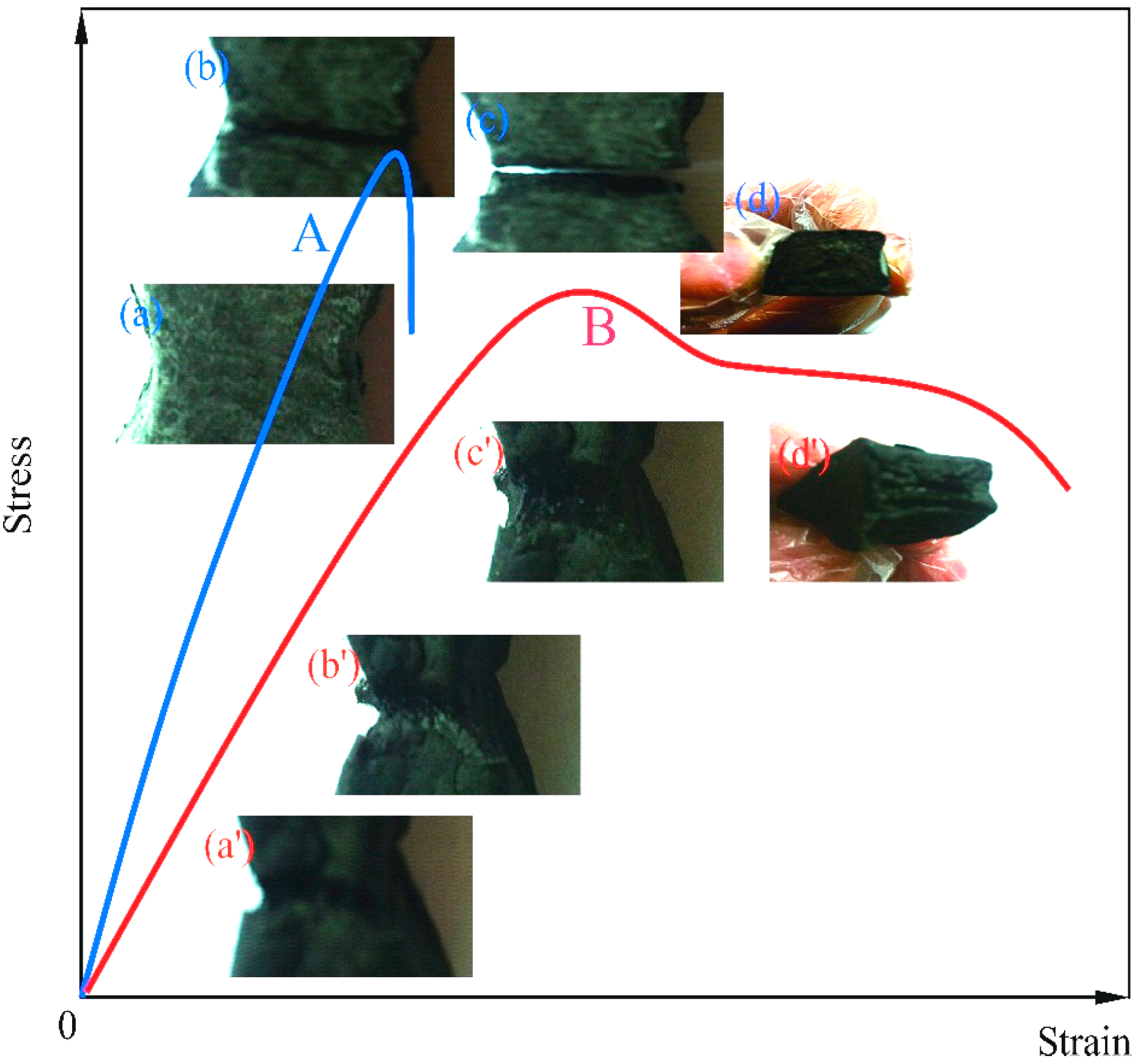

3.2. Tension Tests of the Self-Healing Microcapsule/Bitumen Samples

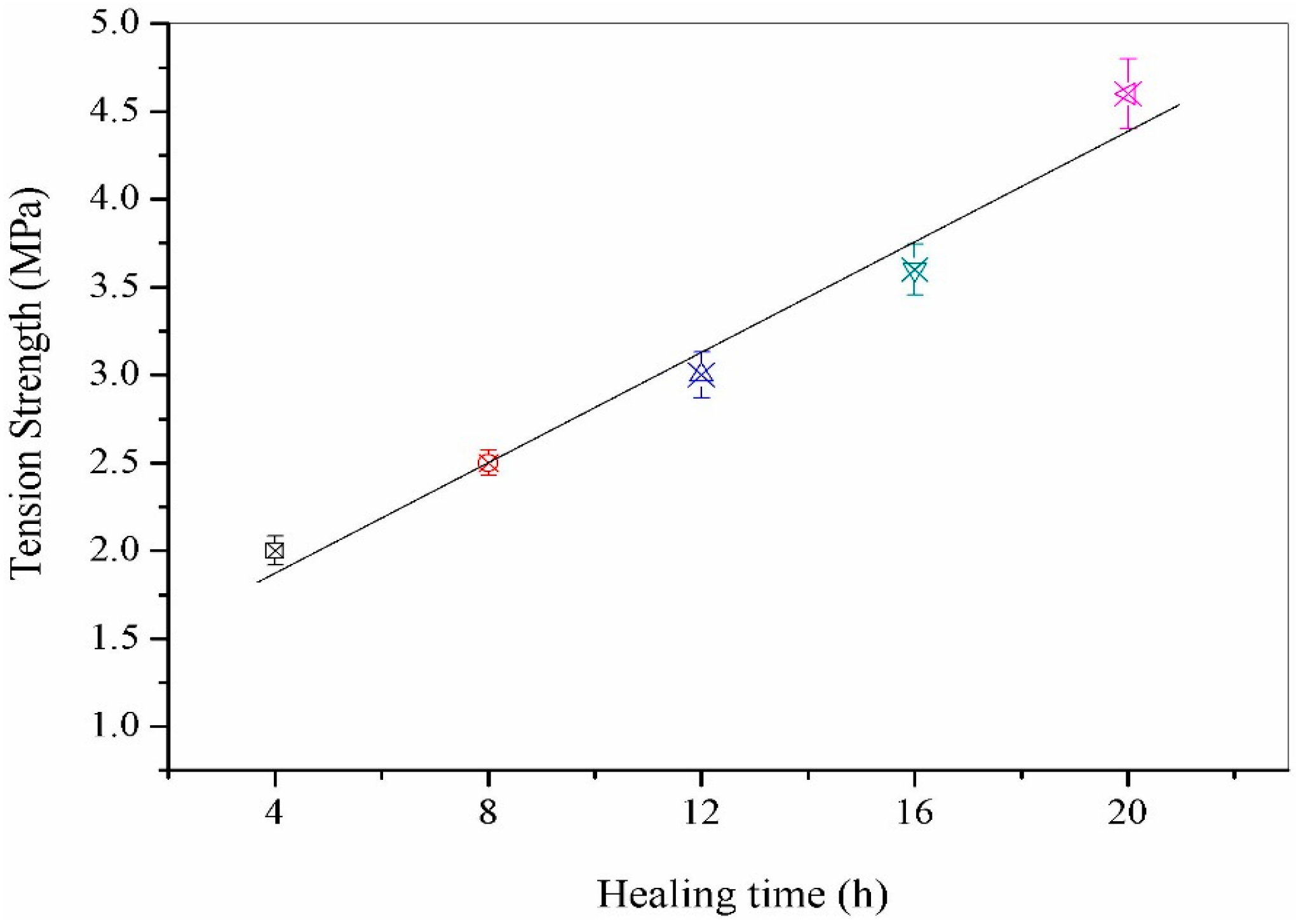

3.3. Effect of Temperature and Time on Self-Healing Capability

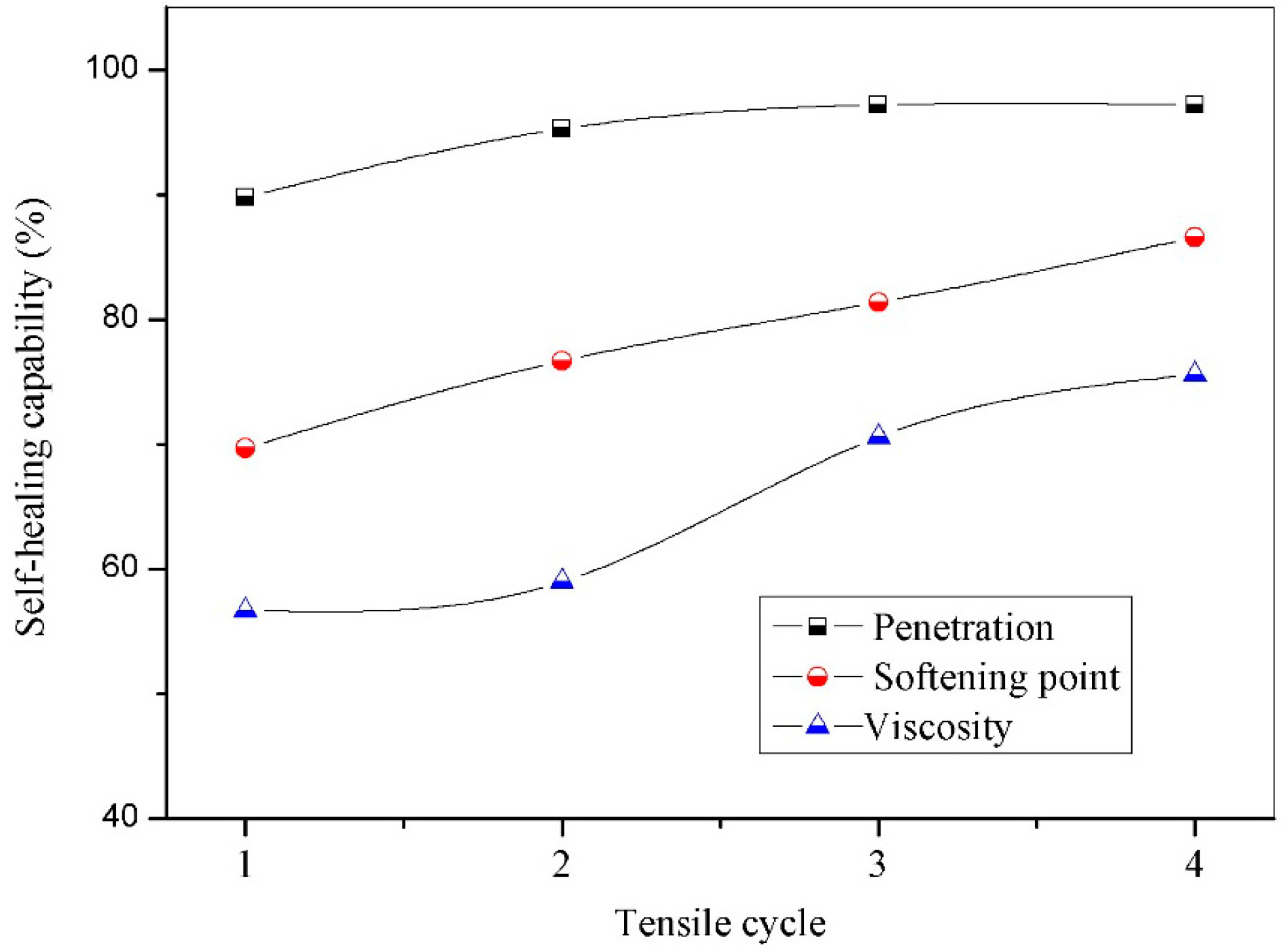

3.4. Properties of Virgin and Rejuvenated Bitumen

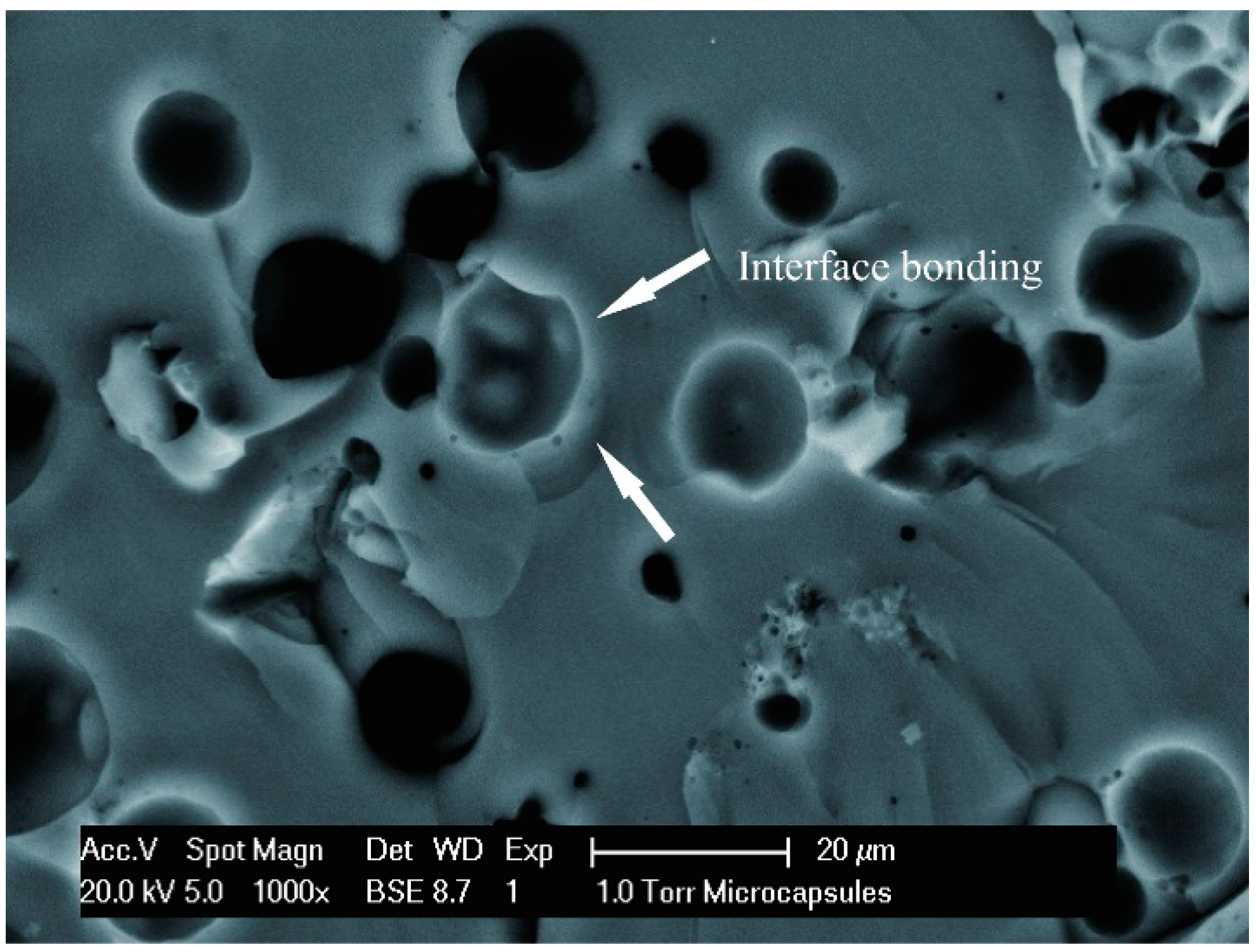

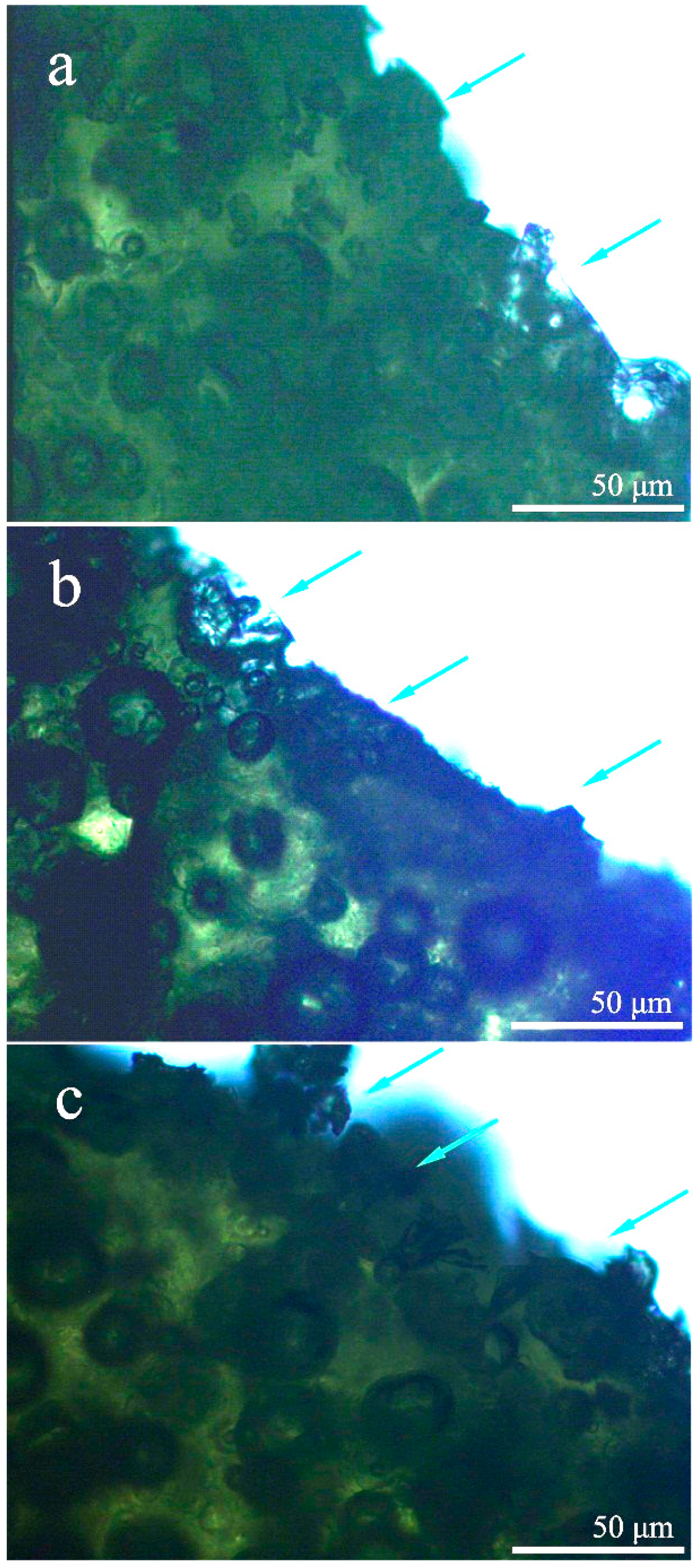

3.5. Morphology Analysis of a Tension Fracture

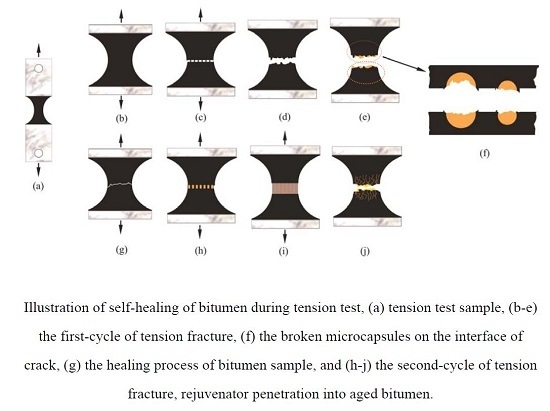

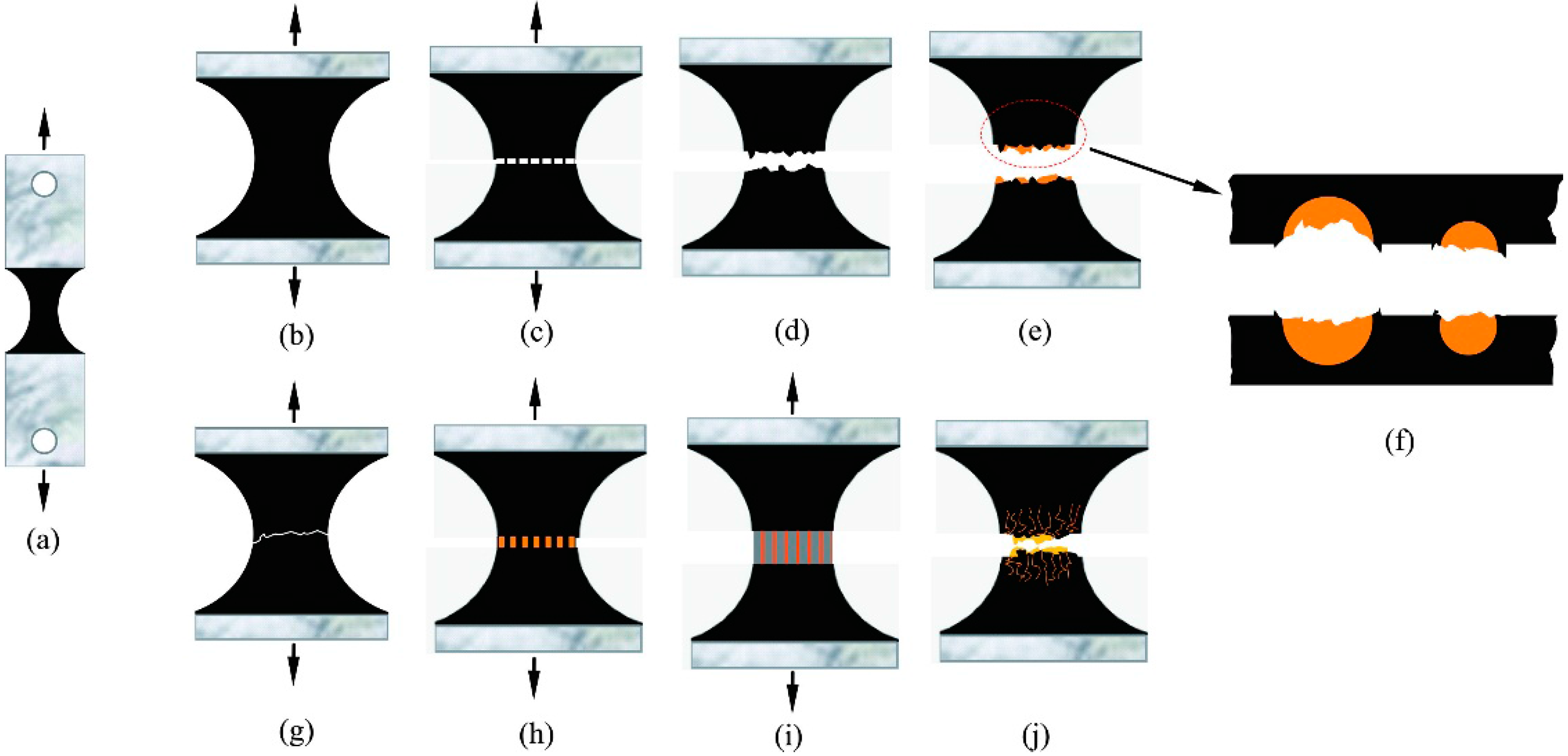

3.6. Mechanism Hypothesis of Self-Healing during Tension

4. Conclusions

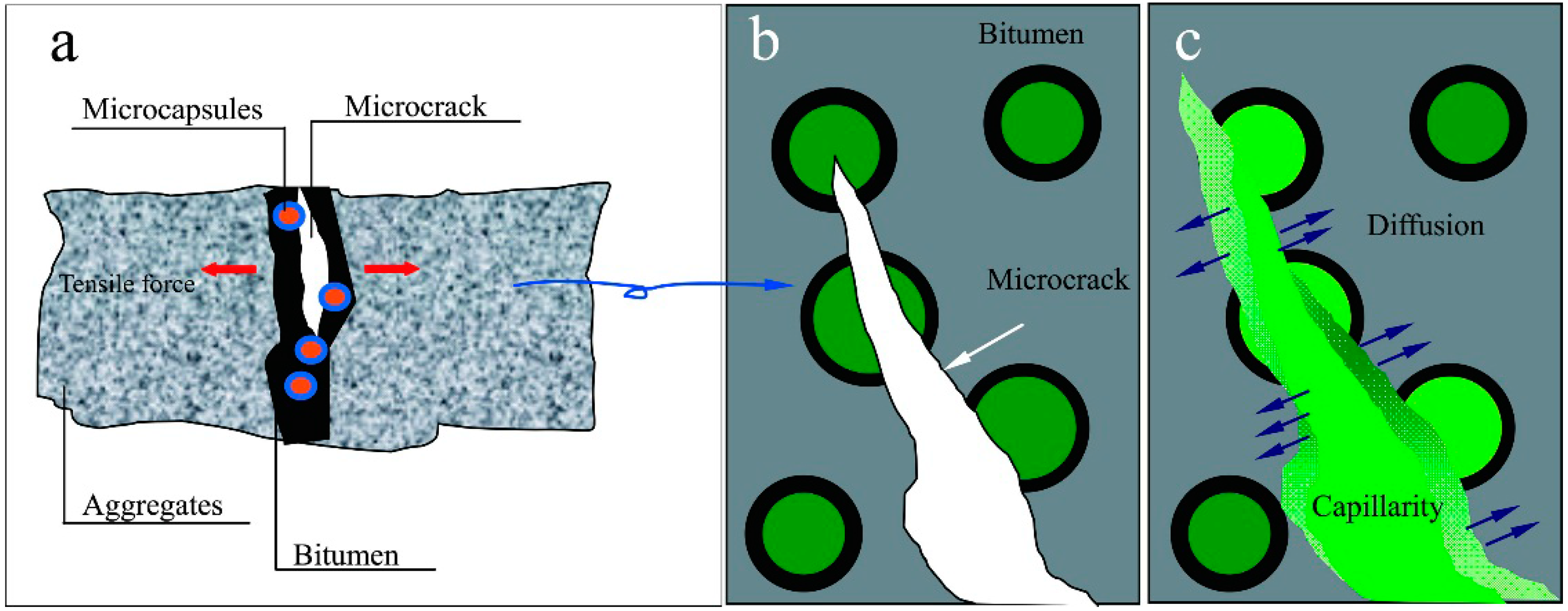

- The microcapsules can be broken by microcracks generating bitumen by a tensile strength; the oily rejuvenator can be easily penetrated and diffused into age bitumen.

- A direct tensile test was applied to analyze the mechanical properties of bitumen/microcapsule materials. The results show that microcapsules of this sample can be broken by microcracks in different conditions with a good normal distribution. The bitumen has a multi-recovery ability. The size and content of microcapsules affects the tensile strength values of bitumen samples. The healing temperature and time greatly affect the healing process.

- A reparative fracture-healing process of tensile tests confirms that the aged bitumen can have recovery properties with the help of rejuvenator.

- The mechanism analysis indicates that the penetration and capillary behaviors of rejuvenator are the main reasons for self-healing of bitumen. The aged bitumen can be softened and have partial recovery properties with enough time under certain temperatures.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Qiu, J.; Molenaar, A.A.A.; van de Ven, M.F.C.; Wu, S.; Yu, J. Investigation of self healing behaviors of asphalt mixes using beam on elastic foundation setup. Mater. Struct. 2012, 45, 777–791. [Google Scholar] [CrossRef]

- Qiu, J.; van de Ven, M.F.C.; Wu, S.; Yu, J.; Molenaar, A.A.A. Evaluating self healing capability of bituminous mastics. Exp. Mech. 2012, 52, 1163–1171. [Google Scholar] [CrossRef]

- Corbett, L.W. Composition of asphalt based on generic fractionation using solvent deasphaltening, elution-adsorption chromatography and densimetric characterization. Anal. Chem. 1969, 41, 576–579. [Google Scholar] [CrossRef]

- Durrieu, F.; Farcas, F.; Mouillet, V. The influence of UV aging of a Styrene/Butadiene/Styrene modified bitumen: Comparison between laboratory and on site aging. Fuel 2007, 86, 1446–1451. [Google Scholar] [CrossRef]

- Qiu, J. Self Healing of Asphalt Mixture. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2012. [Google Scholar]

- García, A.; Schlangen, E.; van de Ven, M. How to make capsules containing rejuvenators for their use in asphalt concrete. J. Wuhan Univ. Technol. 2010, 32, 18–21. [Google Scholar]

- Karlsson, R.; Isacsson, U. Material-related aspects of asphalt recycling-state of the art. J. Mater. Civ. Eng. 2006, 18, 81–92. [Google Scholar] [CrossRef]

- Su, J.F.; Schlangen, E. Synthesis and physicochemical properties of novel high compact microcapsules containing rejuvenator applied in asphalt. Chem. Eng. J. 2012, 198–199, 289–300. [Google Scholar] [CrossRef]

- Su, J.F.; Qiu, J.; Schlangen, E. Stability investigation of self-healing microcapsules containing rejuvenator for bitumen. Polym. Degrad. Stab. 2013, 98, 1205–1215. [Google Scholar] [CrossRef]

- Su, J.F.; Schlangen, E.; Qiu, J. Design and construction of methylation-melamine-formaldehyde microcapsules containing rejuvenator for asphalt. Powder Technol. 2013, 235, 563–571. [Google Scholar] [CrossRef]

- Su, J.F.; Qiu, J.; Schlangen, E.; Wang, Y.Y. Investigation the possibility of a new approach of using microcapsules containing waste cooking oil: In situ rejuvenation for aged bitumen. Constr. Build. Mater. 2015, 74, 83–92. [Google Scholar] [CrossRef]

- Su, J.F.; Schlangen, E.; Wang, Y.Y. Investigation the self-healing mechanism of aged bitumen using microcapsules containing rejuvenator. Constr. Build. Mater. 2015, 85, 49–56. [Google Scholar] [CrossRef]

- Poulikakos, L.D.; Tiwari, M.K.; Partl, M.N. Analysis of failre mechanism of bitumen films. Fule 2013, 106, 437–447. [Google Scholar] [CrossRef]

- Qiu, J.; van de Ven, M.F.C.; Wu, S.; Yu, J.; Molenaar, A.A.A. Investigating the self healing capability of bituminous binders. Road Mater. Pavement Des. 2009, 10, 81–94. [Google Scholar] [CrossRef]

- Su, J.F.; Qiu, J.; Schlangen, E. Experimental investigation of self-healing behavior of bitumen/microcapsule composites by a modified beam on elastic foundation method. Mater. Struct. 2015, 48, 4067–4076. [Google Scholar] [CrossRef]

- Hammoum, F.; Chailleux, E.; Nguyen, H.N.; Erhlacher, A.; Piau, J.M.; Bodin, D. Experimental and Numerical Analysis of Crack Initiation and Growth in Thin Film of Bitumen. Road Mater. Pavement Des. 2009, 10, 39–61. [Google Scholar] [CrossRef]

- Standard Test Method for Penetration of Bitumenus Materials; ASTM D5; ASTM International: West Conshohocken, PA, USA, 2013.

- Standard Test Method for Softening Point of Bitumen; ASTM D36; ASTM International: West Conshohocken, PA, USA, 2014.

- Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer; ASTM D4402; ASTM International: West Conshohocken, PA, USA, 2015.

- Su, J.F.; Dong, H.; Wang, X.Y. Influence of temperature on the deformation behaviors of melamine-formaldehyde microcapsules containing phase change material. Mater. Lett. 2012, 84, 158–161. [Google Scholar] [CrossRef]

- Su, J.F.; Wang, X.Y.; Dong, H. Interface stability of microencapsulated-paraffin filled epoxy composites: Effect of methylation reaction on melamine-formaldehyde shell material. Compos. Interface 2011, 18, 645–659. [Google Scholar] [CrossRef]

- Asli, H.; Ahmadinia, E.; Zargar, M.; Karim, M.R. Investigation on physical properties of waste cooking oil—Rejuvenated bitumen binder. Constr. Build. Mater. 2012, 37, 398–405. [Google Scholar] [CrossRef]

- Su, J.-F.; Zhao, Y.-H.; Wang, X.-Y.; Dong, H.; Wang, S.-B. Effect of interface debonding on the thermal conductivity of microencapsulated-paraffin filled epoxy-matrix composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 325–332. [Google Scholar] [CrossRef]

- Su, J.F.; Wang, Y.Y.; Han, N.X.; Yang, P.; Han, S. Experimental investigation and mechanism analysis of novel multi-self-healing behaviors of bitumen using microcapsules containing rejuvenator. Constr. Build. Mater. 2016, 106, 317–329. [Google Scholar] [CrossRef]

| Samples | Core/Shell Ratio | Content (wt. %) | Mean Size (μm) |

|---|---|---|---|

| 1 | 1:1 | 1.0 | 10 ± 0.2 |

| 2 | 20 ± 0.5 | ||

| 3 | 30 ± 0.4 | ||

| 4 | 1:1 | 3.0 | 10 ± 0.3 |

| 5 | 20 ± 0.5 | ||

| 6 | 30 ± 0.5 | ||

| 7 | 1:1 | 5.0 | 10 ± 0.6 |

| 8 | 20 ± 0.7 | ||

| 9 | 30 ± 0.5 |

| Bitumen | Original Bitumen (80/100) | Aged Bitumen (40/50) | Tension Test Cycles | ||||

|---|---|---|---|---|---|---|---|

| Properties | 1 | 2 | 3 | 4 | |||

| Penetration (mm/10, 25 °C) | 86 | 43 | 60 | 66 | 70 | 74 | |

| Softening point (°C) | 46.7 | 53.5 | 52 | 49 | 48 | 48 | |

| Viscosity (135 °C) (mPa·s) | 325 | 578 | 573 | 550 | 460 | 430 | |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, J.-F.; Yang, P.; Wang, Y.-Y.; Han, S.; Han, N.-X.; Li, W. Investigation of the Self-Healing Behaviors of Microcapsules/Bitumen Composites by a Repetitive Direct Tension Test. Materials 2016, 9, 600. https://doi.org/10.3390/ma9070600

Su J-F, Yang P, Wang Y-Y, Han S, Han N-X, Li W. Investigation of the Self-Healing Behaviors of Microcapsules/Bitumen Composites by a Repetitive Direct Tension Test. Materials. 2016; 9(7):600. https://doi.org/10.3390/ma9070600

Chicago/Turabian StyleSu, Jun-Feng, Peng Yang, Ying-Yuan Wang, Shan Han, Ning-Xu Han, and Wei Li. 2016. "Investigation of the Self-Healing Behaviors of Microcapsules/Bitumen Composites by a Repetitive Direct Tension Test" Materials 9, no. 7: 600. https://doi.org/10.3390/ma9070600

APA StyleSu, J.-F., Yang, P., Wang, Y.-Y., Han, S., Han, N.-X., & Li, W. (2016). Investigation of the Self-Healing Behaviors of Microcapsules/Bitumen Composites by a Repetitive Direct Tension Test. Materials, 9(7), 600. https://doi.org/10.3390/ma9070600