Influence of Li2Sb Additions on Microstructure and Mechanical Properties of Al-20Mg2Si Alloy

Abstract

:1. Introduction

2. Experimental Section

2.1. Preparation of Al-20Mg2Si Alloy Modified with Various Contents of Li-Sb

2.2. Characterization

3. Results and Discussion

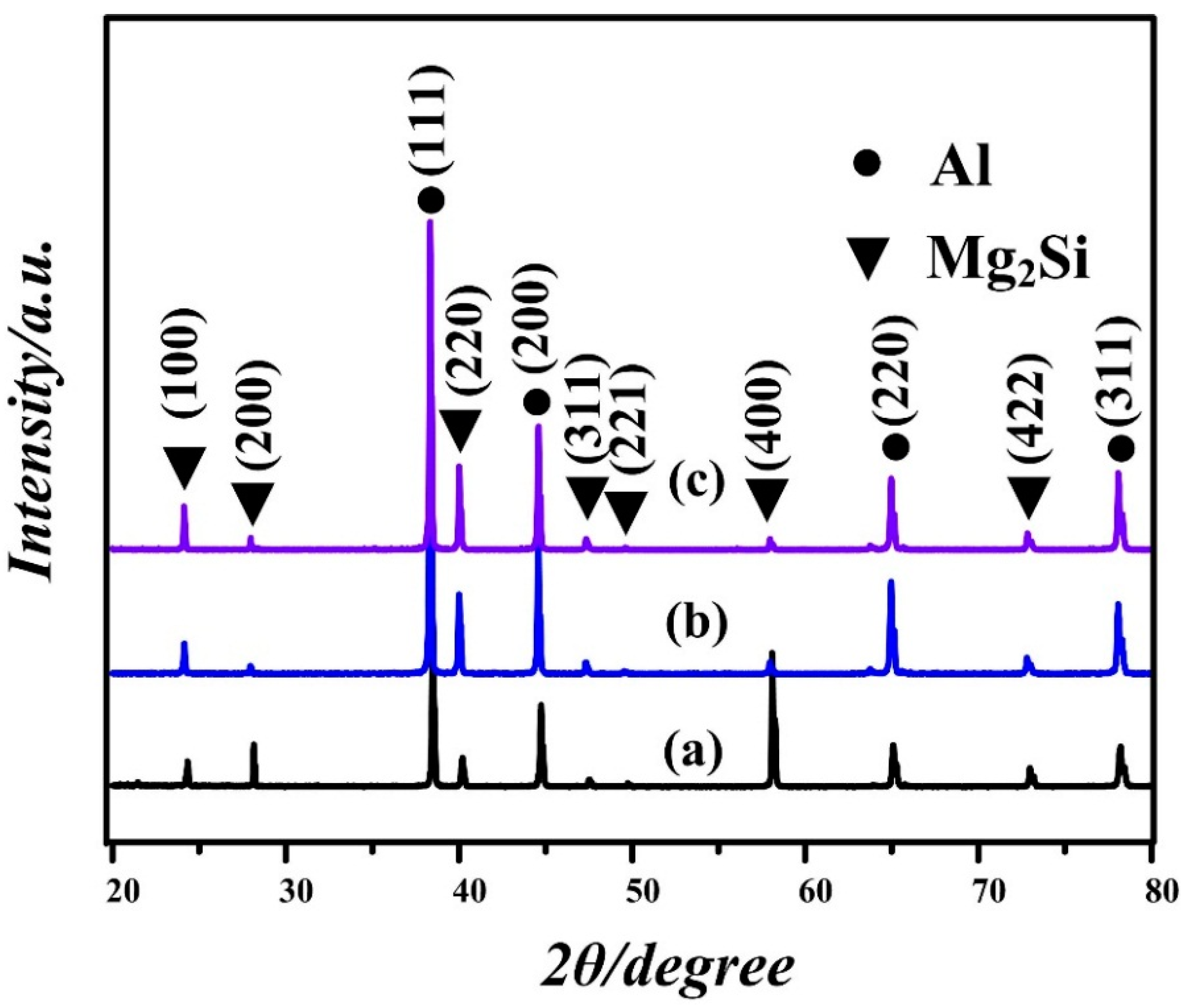

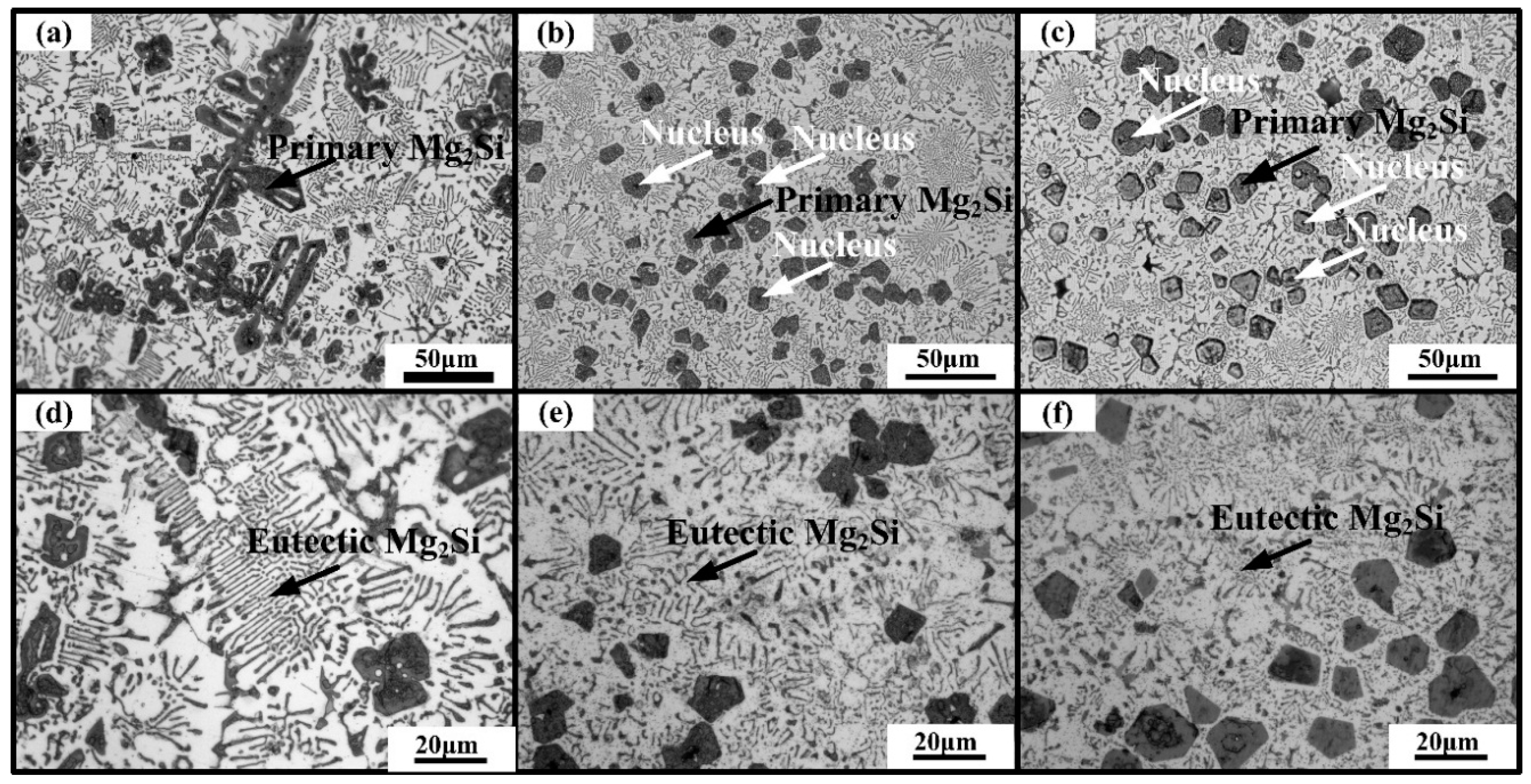

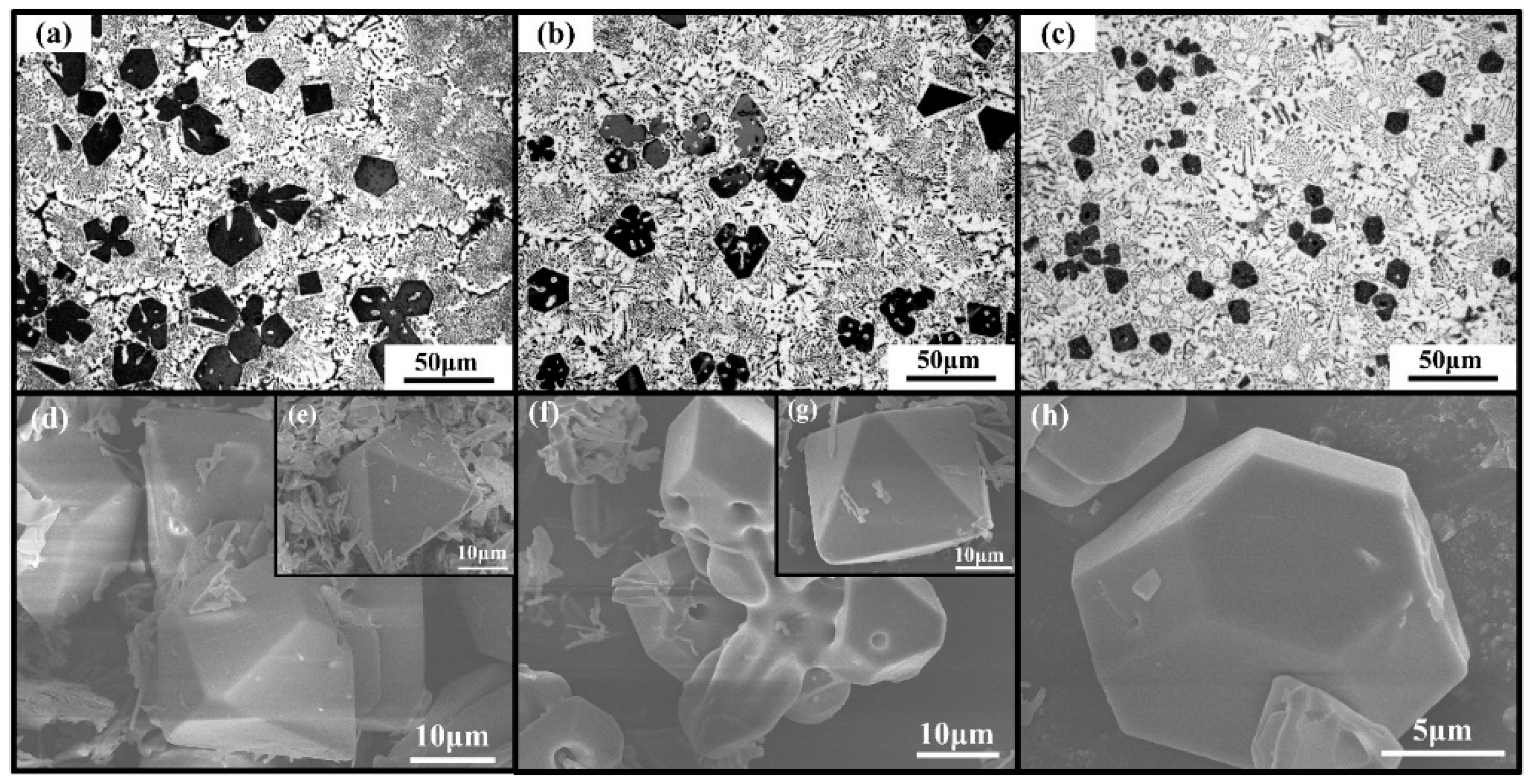

3.1. Microstructure of Al-20Mg2Si Alloy Modified with Li and Sb Simultaneously

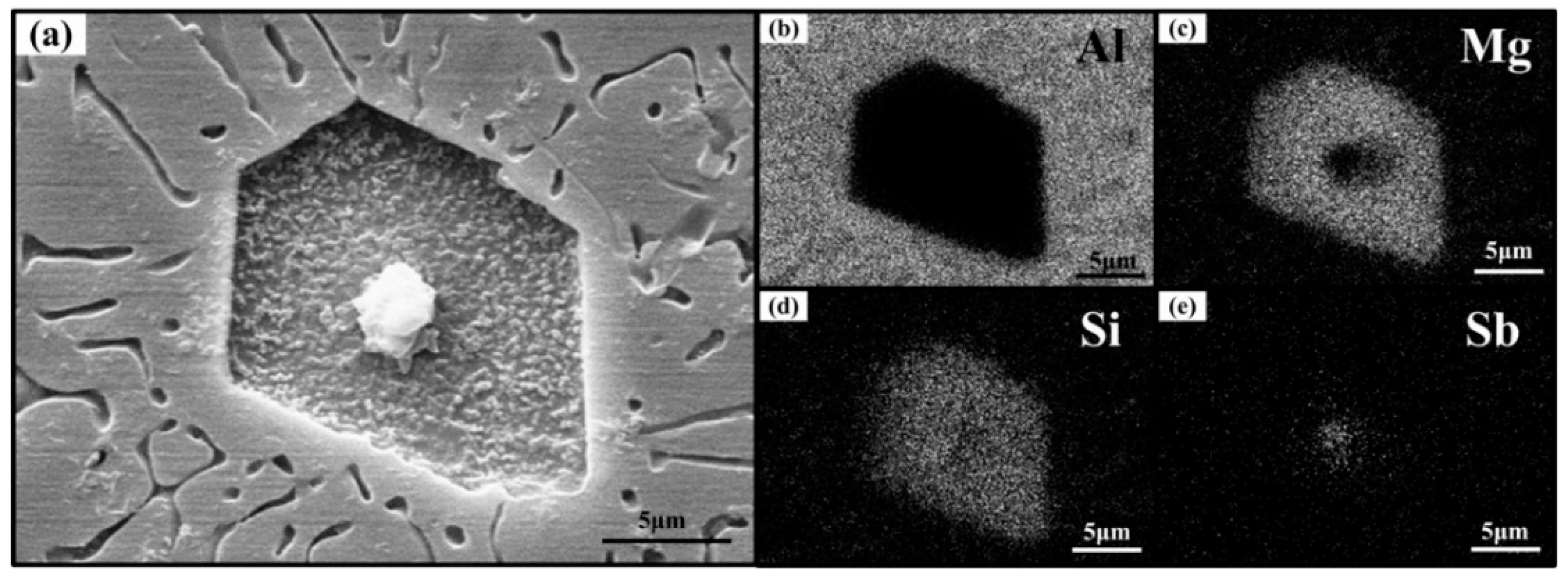

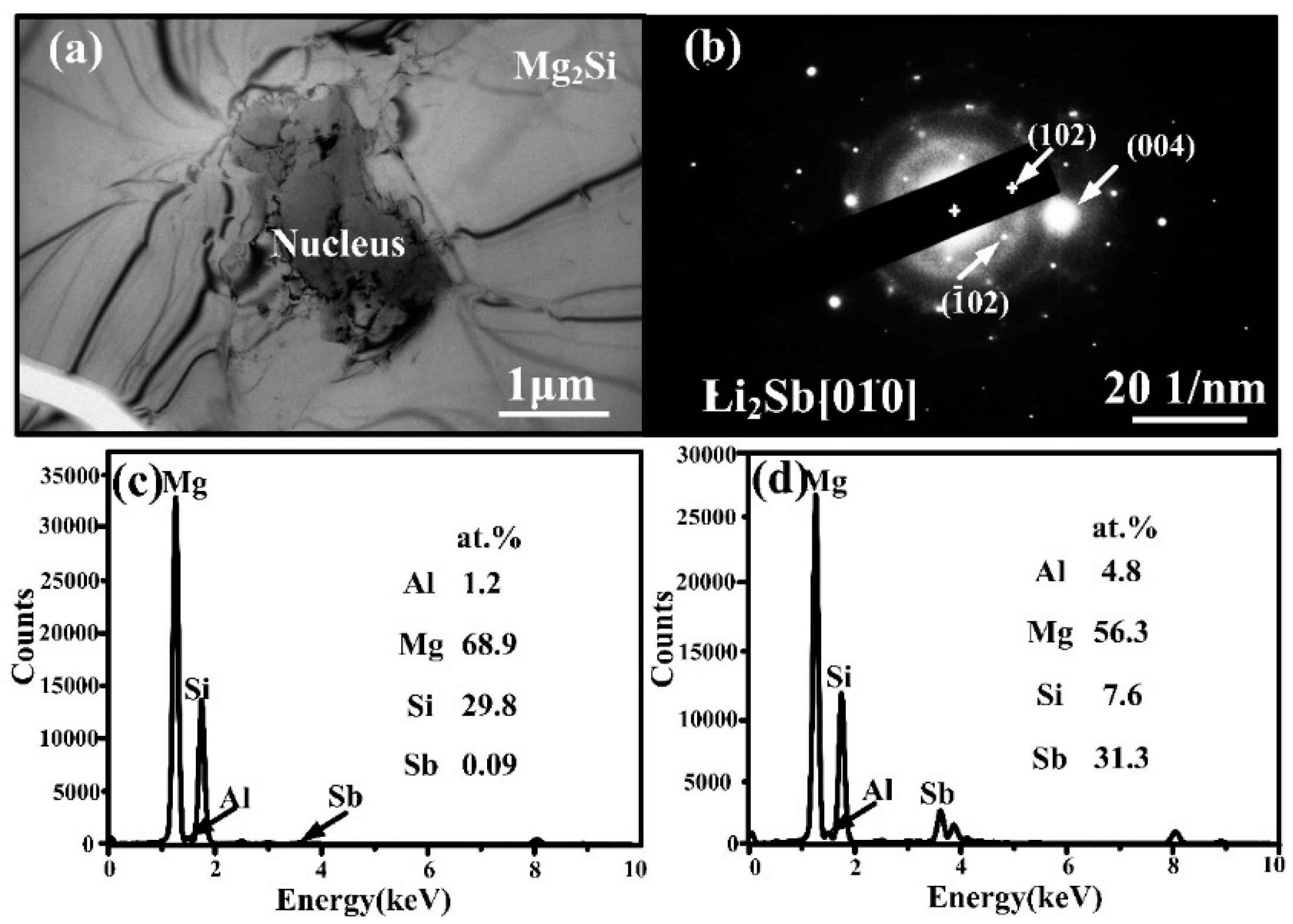

3.2. Characterization of Nucleus in Primary Mg2Si

3.3. Effect of Li2Sb Nucleus on Mechanical Properties of Al-20Mg2Si Alloy

4. Conclusions

- (1)

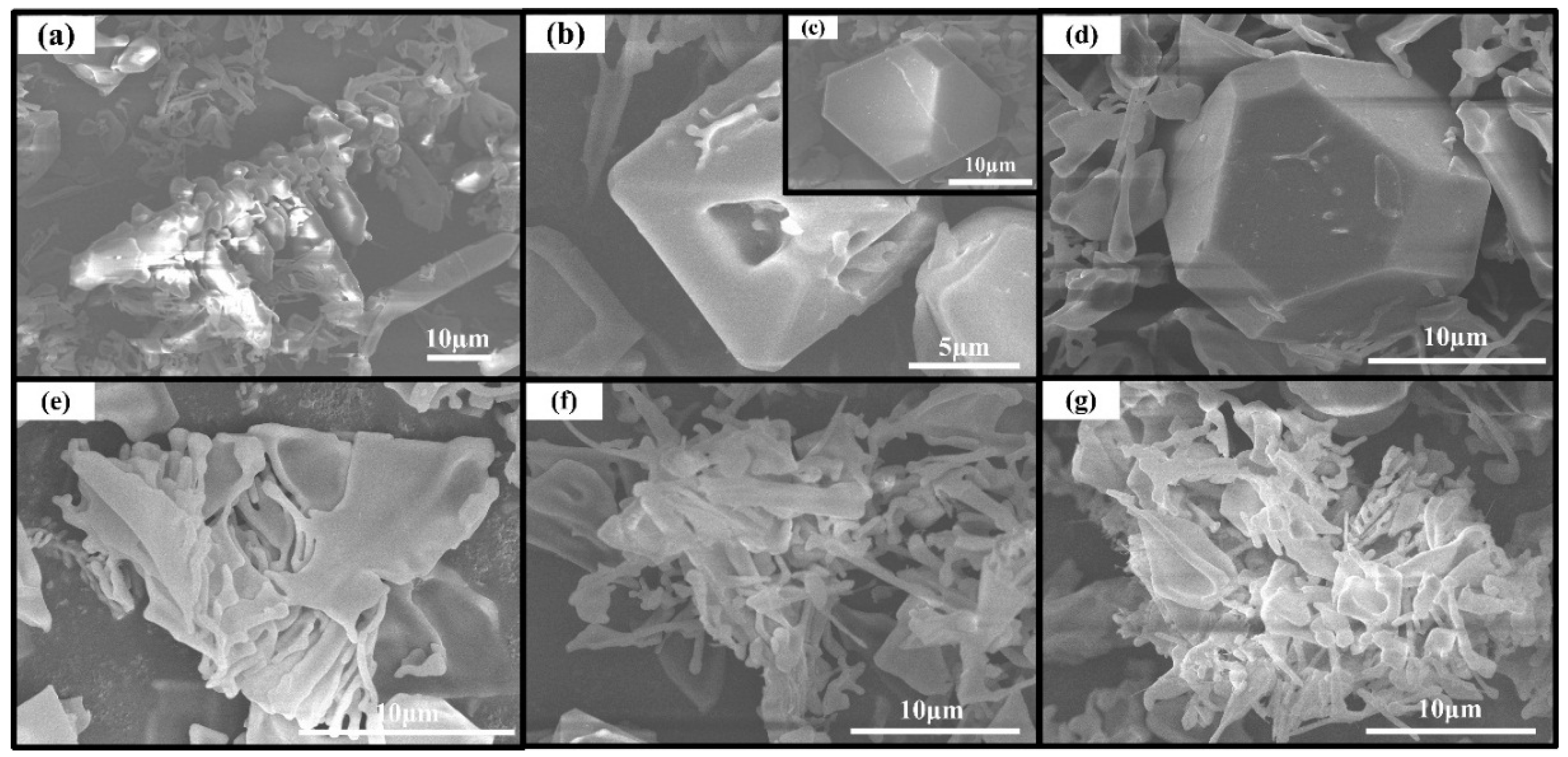

- The 3-D morphology of primary Mg2Si was observed by extracting the Mg2Si crystals from Al–20Mg2Si alloys. With the addition of Li-Sb, the size of primary Mg2Si decreased from ~300 to ~15–25 μm and the morphology changed from coarse dendrite to defective truncated octahedron and finally to perfect truncated octahedral shape.

- (2)

- The modification mechanism of Li-Sb can be concluded as follows: Li2Sb can act as better substrates to enhance the heterogeneous nucleation rate of primary Mg2Si; meanwhile, excess Li atoms were absorbed on and restricted the growth of {100} facets. The modification effect of Li-Sb was better than that of either Li or Sb, respectively.

- (3)

- Influence of Li2Sb on mechanical properties of Al–20Mg2Si alloys was also investigated. With the addition of Li and Sb, ultimate compression strength (UCS) of Al-20Mg2Si alloys increased from ~283 to ~341 MPa and the yield strength (YS) at 0.2% offset increased from ~112 to ~179 MPa, while almost no change was seen in the uniform elongation. The addition of Li and Sb also led to the increase in microhardness of α-Al matrix from ~91 to ~104 Hv.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Du, Q.; Li, Y.J. An extension of the Kampmann-Wagner numerical model towards as-cast grain size prediction of multicomponent aluminum alloys. Acta Mater. 2014, 71, 380–389. [Google Scholar] [CrossRef]

- Kim, Y.M.; Wang, L.; You, B.S. Grain refinement of Mg-Al cast alloy by the addition of manganese carbonate. J. Alloys Compd. 2010, 490, 695–699. [Google Scholar] [CrossRef]

- Li, C.; Liu, X.F.; Wu, Y.Y. Refinement and modification performance of Al-P master alloy on primary Mg2Si in Al–Mg–Si alloys. J. Alloys. Compd. 2008, 465, 145–150. [Google Scholar] [CrossRef]

- VaziriYeganeh, S.E.; Razaghian, A.; Emamy, M. The influence of Cu-15P master alloy on the microstructure and tensile properties of Al-25 wt% Mg2Si composite before and after hot-extrusion. Mater. Sci. Eng. A 2013, 566, 1–7. [Google Scholar]

- Emamy, M.; Khorshidi, R.; Raouf, A.H. The influence of pure Na on the microstructure and tensile properties of Al-Mg2Si metal matrix composite. Mater. Sci. Eng. A 2011, 528, 4337–4342. [Google Scholar] [CrossRef]

- Li, C.; Wu, Y.Y.; Li, H.; Liu, X.F. Morphological evolution and growth mechanism of primary Mg2Si phase in Al–Mg2Si alloys. Acta Mater. 2011, 59, 1058–1067. [Google Scholar] [CrossRef]

- Mabuchi, M.; Higashj, K. Strengthening mechanisms of Mg-Si alloys. Acta Mater. 1996, 44, 4611–4618. [Google Scholar] [CrossRef]

- Wang, L.; Qin, X.Y. The effect of mechanical milling on the formation of nanocrystalline Mg2Si through solid-state reaction. Scr. Mater. 2003, 49, 243–248. [Google Scholar] [CrossRef]

- Ardakan, A.H.; Ajersch, F. Thermodynamic evaluation of hypereutectic Al-Si (A390) alloy with addition of Mg. Acta Mater. 2010, 58, 3422–3428. [Google Scholar] [CrossRef]

- Qin, Q.D.; Li, W.X.; Zhao, K.W.; Qiu, S.L.; Zhao, Y.G. Effect of modification and aging treatment on mechanical properties of Mg2Si/Al composite. Mater. Sci. Eng. A 2010, 527, 2253–2257. [Google Scholar] [CrossRef]

- Nasiri, N.; Emamy, M.; Malekan, A.; Norouzi, M.H. Microstructure and tensile properties of cast Al-15%Mg2Si composite: Effects of phosphorous addition and heat treatment. Mater. Sci. Eng. A 2012, 556, 446–453. [Google Scholar] [CrossRef]

- Khorshidi, R.; Hassani, A.; Rauof, A.H.; Emamy, M. Selection of an optimal refinement condition to achieve maximum tensile properties of Al-15%Mg2Si composite based on TOPSIS method. Mater. Des. 2013, 46, 442–450. [Google Scholar] [CrossRef]

- Soltani, N.; Jafari Nodooshan, H.R.; Bahrami, A.; Pech Canul, M.I.; Liu, W.C.; Wu, G.H. Effect of hot extrusion on wear properties of Al-15 wt.% Mg2Si in situ metal matrix composites. Mater. Des. 2014, 53, 774–781. [Google Scholar] [CrossRef]

- Zhang, J.; Fan, Z.; Wang, Y.Q.; Zhou, B.L. Equilibrium pseudobinary Al-Mg2Si phase diagram. Mater. Sci. Technol. 2001, 17, 494–496. [Google Scholar] [CrossRef]

- Jiang, Q.C.; Wang, H.Y.; Wang, Y.; Ma, B.X.; Wang, J.G. Modification of Mg2Si in Mg-Si alloys with yttrium. Mater. Sci. Eng. A 2005, 392, 130–135. [Google Scholar] [CrossRef]

- Emamy, M.; Emami, A.R.; Tavighi, K. The effect of Cu addition and solution heat treatment on the microstructure, hardness and tensile properties of Al-15%Mg2Si-0.15%Li composite. Mater. Sci. Eng. A 2013, 576, 36–44. [Google Scholar] [CrossRef]

- Chen, L.; Wang, H.Y.; Li, Y.J.; Zha, M.; Jiang, Q.C. Morphology and size control of octahedral and cubic primary Mg2Si in an Mg-Si system by regulating Sr contents. Cryst. Eng. Comm. 2014, 16, 448–454. [Google Scholar] [CrossRef]

- Hou, J.; Li, C.; Liu, X.F. Nucleating role of an effective in situ Mg3P2 on Mg2Si in Mg-Al-Si alloys. J. Alloys Compd. 2011, 509, 735–739. [Google Scholar] [CrossRef]

- Yuan, G.Y.; Liu, Z.L.; Wang, Q.D.; Ding, W.J. Microstructure refinement of Mg-Al-Zn-Si alloys. Mater. Lett. 2002, 56, 53–58. [Google Scholar] [CrossRef]

- Chen, L.; Wang, H.Y.; Luo, D.; Zhang, H.Y.; Liu, B.; Jiang, Q.C. Synthesis of octahedron and truncated octahedron primary Mg2Si by controlling the Sb contents. Cryst. Eng. Comm. 2013, 15, 1787–1793. [Google Scholar] [CrossRef]

- Alizadeh, R.; Mahmudi, R. Effects of Sb addition on the modification of Mg2Si particles and high-temperature mechanical properties of cast Mg-4Zn-2Si alloy. J. Alloys Compd. 2011, 509, 9195–9199. [Google Scholar] [CrossRef]

- Wang, H.Y.; Li, Q.; Liu, B.; Zhang, N.; Chen, L.; Wang, J.G.; Jiang, Q.C. Modification of primary Mg2Si in Mg-4Si alloys with antimony. Metall. Mater. Trans. A 2012, 43, 4926–4932. [Google Scholar] [CrossRef]

- Powder Diffraction File Card Nos. 26–0651 (Li2Sb) and Mg2Si (65–2988) (CD ROM); International Center for Diffraction Data (ICDD): Newtown Square, PA, USA.

- Khorshidia, R.; Raoufa, A.H.; Emamy, M.; Campbell, J. The study of Li effect on the microstructure and tensile properties of cast Al-Mg2-Si metal matrix composite. J. Alloys Compd. 2011, 509, 9026–9033. [Google Scholar] [CrossRef]

- Yu, H.C.; Wang, H.Y.; Chen, L.; Liu, F.; Wang, C.; Jiang, Q.C. Heterogeneous nucleation of Mg2Si on CaSb2 nucleus in Al–Mg–Si alloys. Cryst. Eng. Comm. 2015, 17, 7048–7055. [Google Scholar] [CrossRef]

- Nie, J.F.; Wu, Y.Y.; Li, P.T.; Li, H.; Liu, X.F. Morphological evolution of TiC from octahedron to cube induced by elemental nickel. Cryst. Eng. Comm. 2012, 14, 2213–2221. [Google Scholar] [CrossRef]

- Azarbarmas, M.; Emamy, M.; Rassizadehghani, J.; Alipour, M.; Karamouz, M. The influence of beryllium addition on the microstructure and mechanical properties of Al-15%Mg2Si in-situ metal matrix composite. Mater. Sci. Eng. A 2011, 528, 8205–8211. [Google Scholar] [CrossRef]

| Materials | YS/MPa | UCS/MPa | Uniform Elongation/% | Hardness/Hv |

|---|---|---|---|---|

| Al-20Mg2Si | ||||

| Al-20Mg2Si-0.2(Li-Sb) | ||||

| Al-20Mg2Si-0.5(Li-Sb) |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, H.-C.; Wang, H.-Y.; Chen, L.; Zha, M.; Wang, C.; Li, C.; Jiang, Q.-C. Influence of Li2Sb Additions on Microstructure and Mechanical Properties of Al-20Mg2Si Alloy. Materials 2016, 9, 243. https://doi.org/10.3390/ma9040243

Yu H-C, Wang H-Y, Chen L, Zha M, Wang C, Li C, Jiang Q-C. Influence of Li2Sb Additions on Microstructure and Mechanical Properties of Al-20Mg2Si Alloy. Materials. 2016; 9(4):243. https://doi.org/10.3390/ma9040243

Chicago/Turabian StyleYu, Hong-Chen, Hui-Yuan Wang, Lei Chen, Min Zha, Cheng Wang, Chao Li, and Qi-Chuan Jiang. 2016. "Influence of Li2Sb Additions on Microstructure and Mechanical Properties of Al-20Mg2Si Alloy" Materials 9, no. 4: 243. https://doi.org/10.3390/ma9040243

APA StyleYu, H.-C., Wang, H.-Y., Chen, L., Zha, M., Wang, C., Li, C., & Jiang, Q.-C. (2016). Influence of Li2Sb Additions on Microstructure and Mechanical Properties of Al-20Mg2Si Alloy. Materials, 9(4), 243. https://doi.org/10.3390/ma9040243