A Dissipative Connector for CLT Buildings: Concept, Design and Testing

Abstract

:1. Introduction

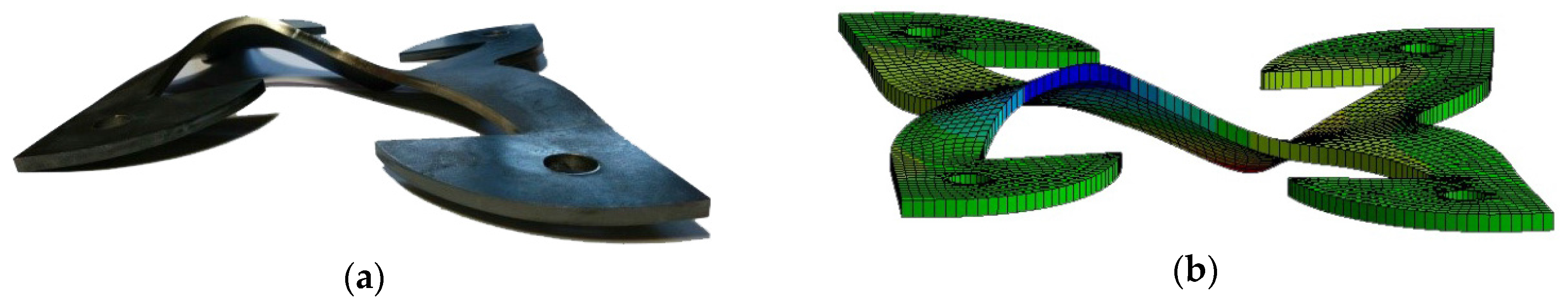

2. Designing Process

2.1. Design Criteria

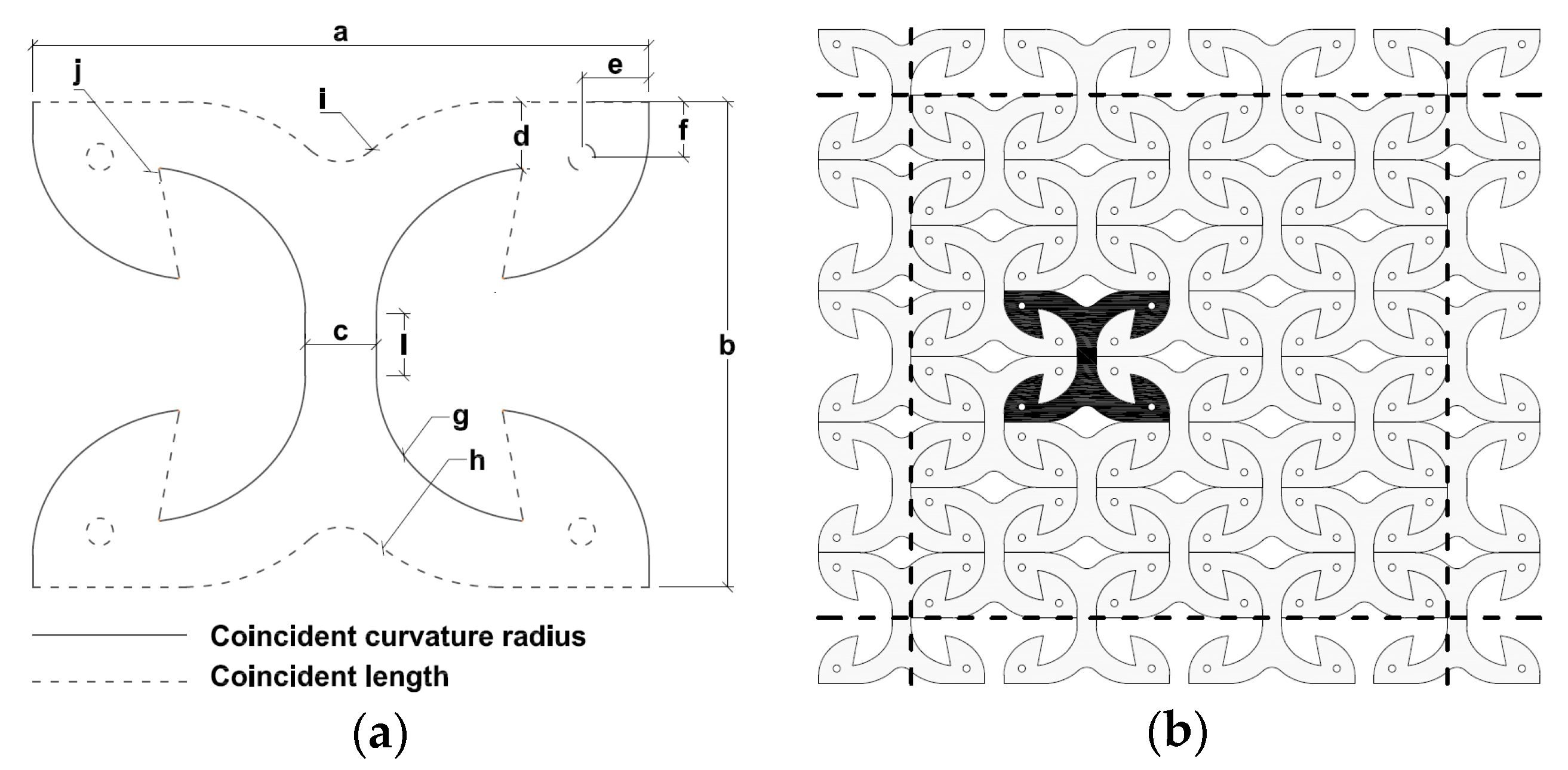

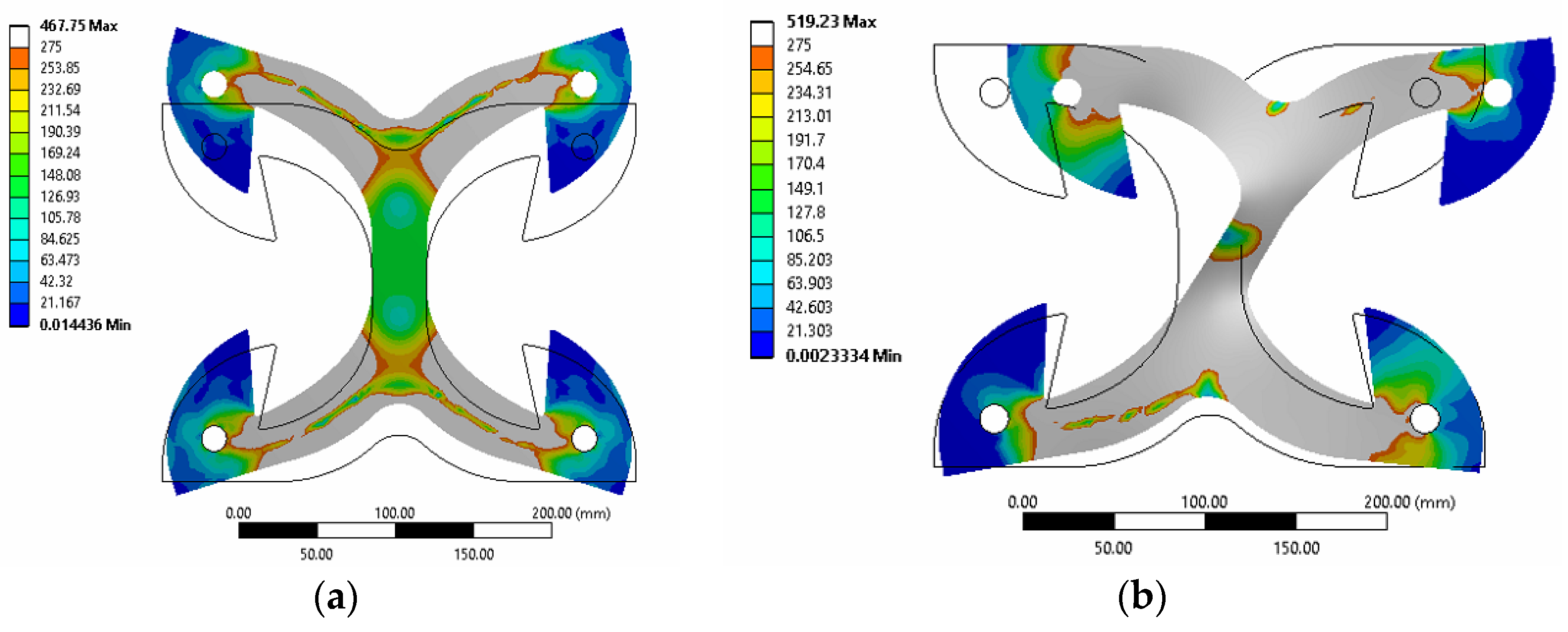

2.2. Parametric Design Assisted by Numerical Modelling

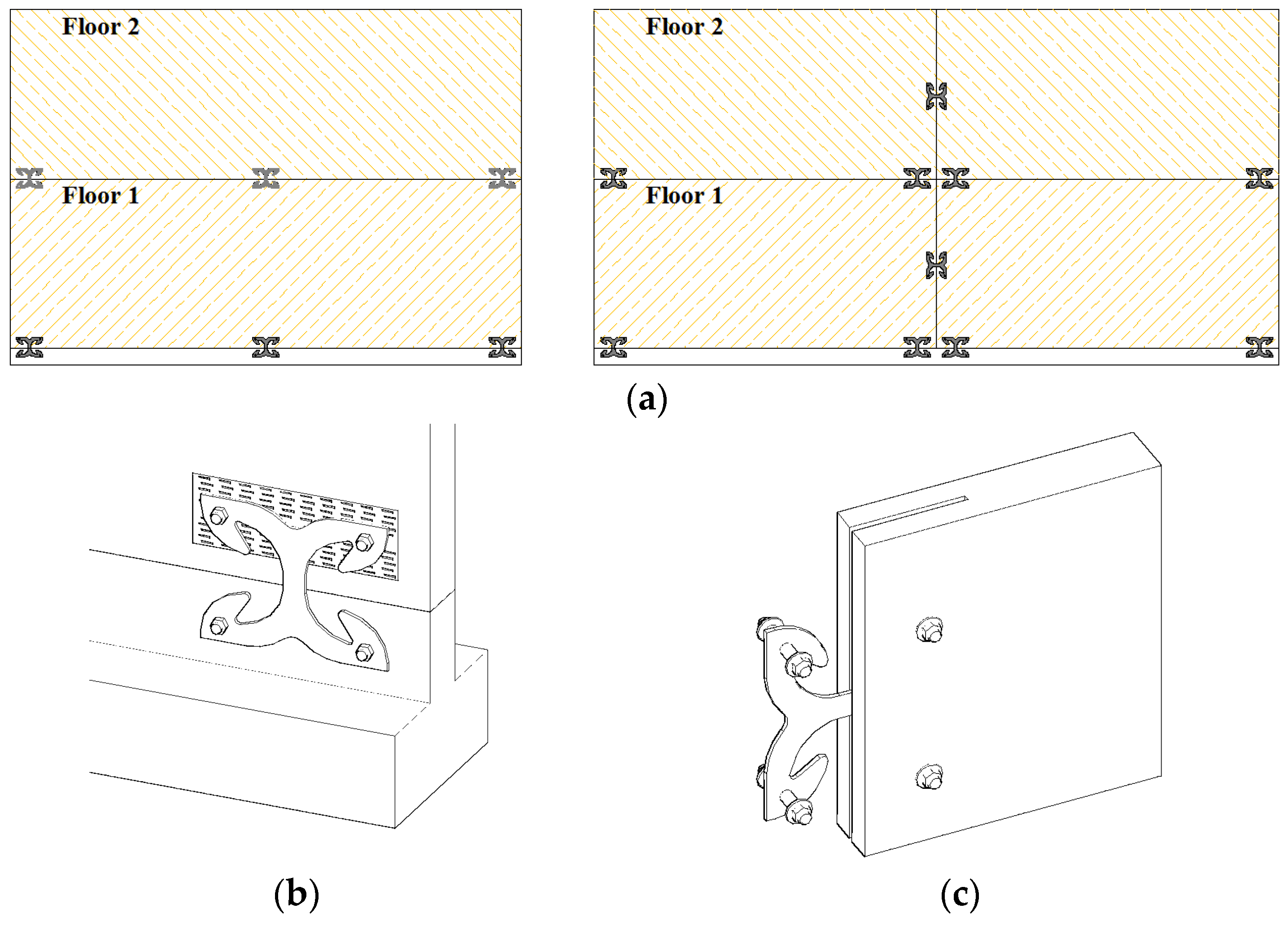

2.3. Anchoring to the Timber Panel

3. Experimental Tests

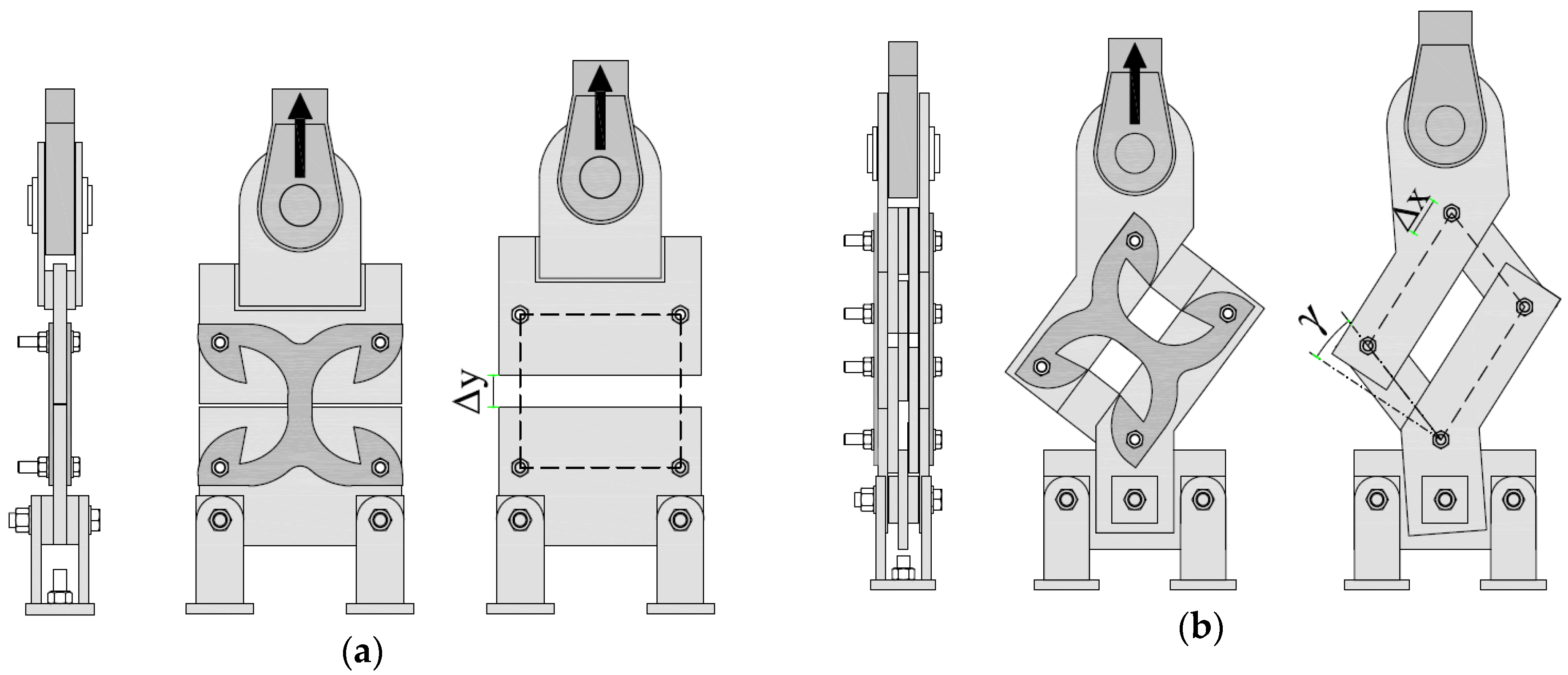

3.1. Test Setup and Procedure

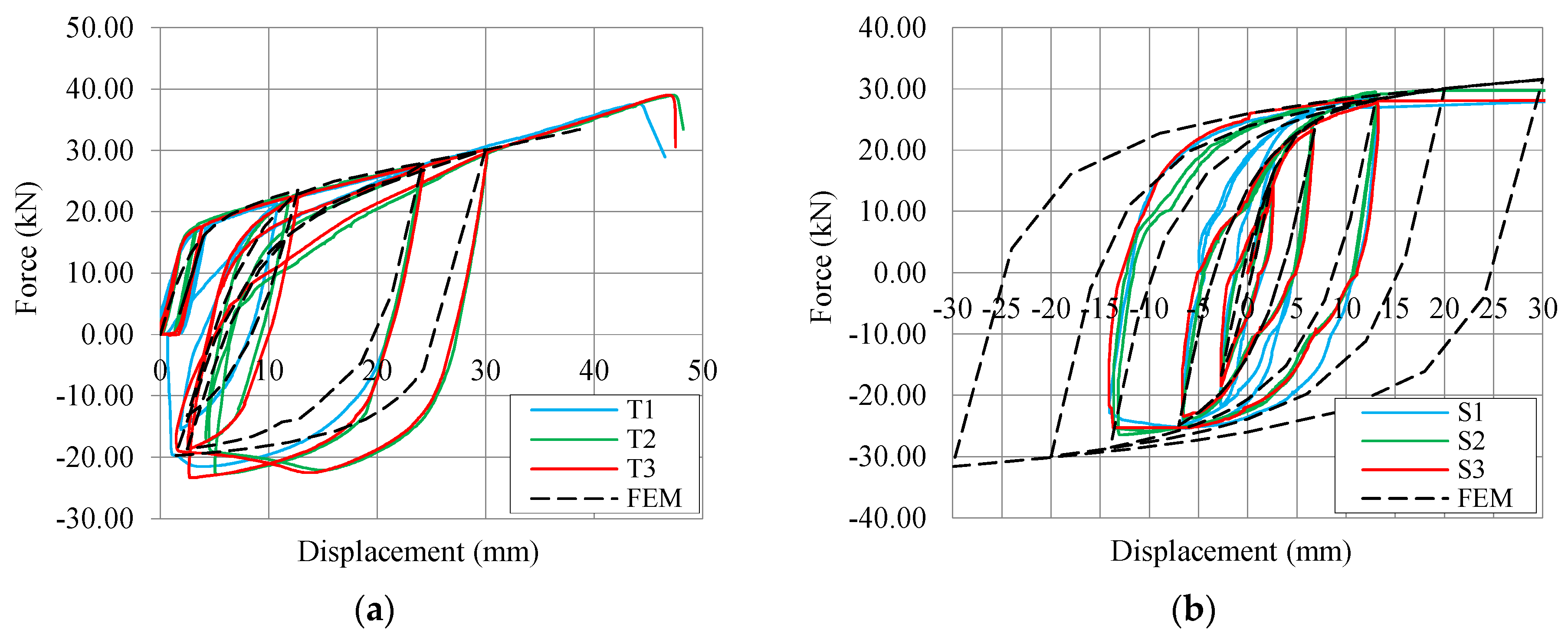

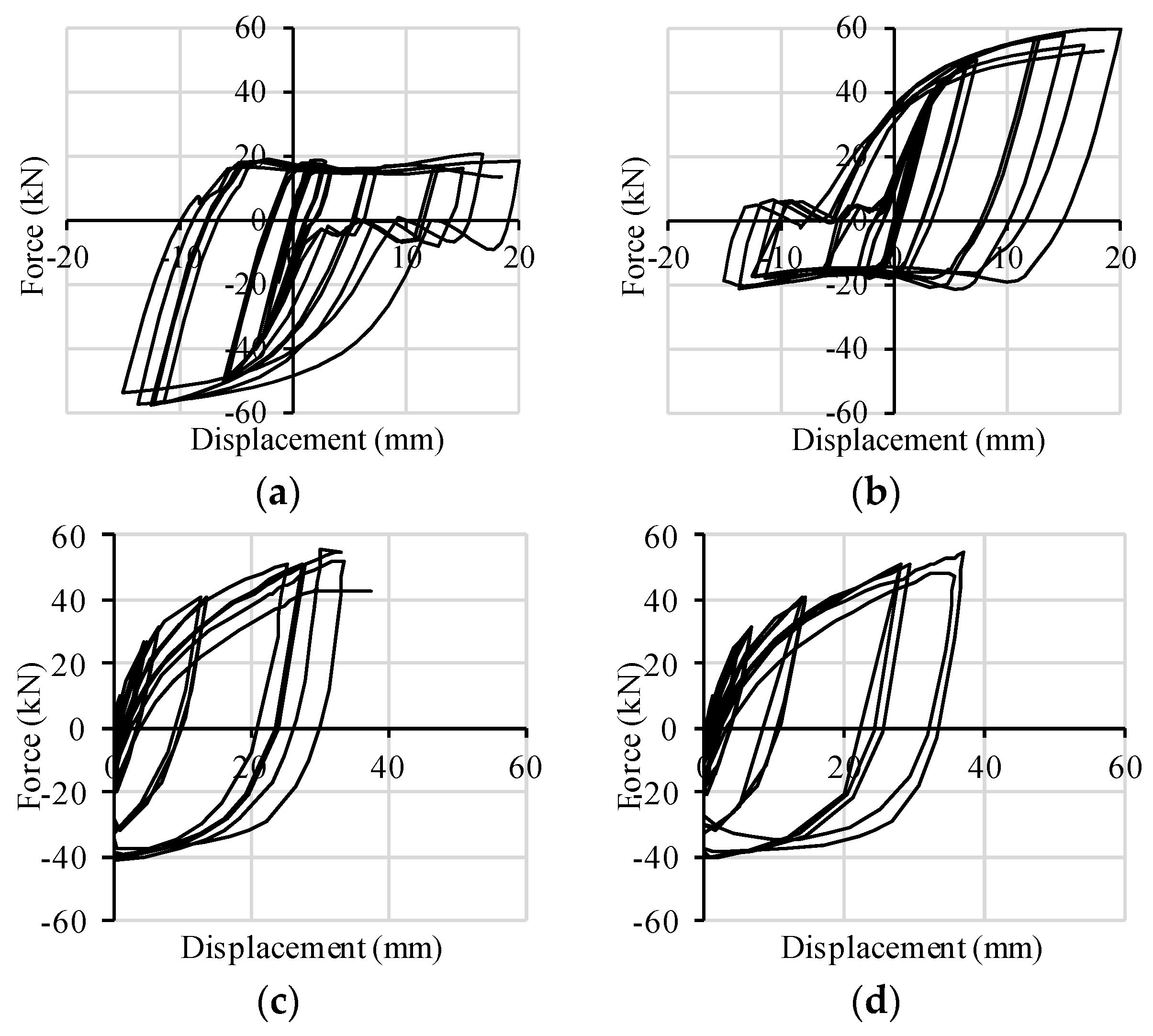

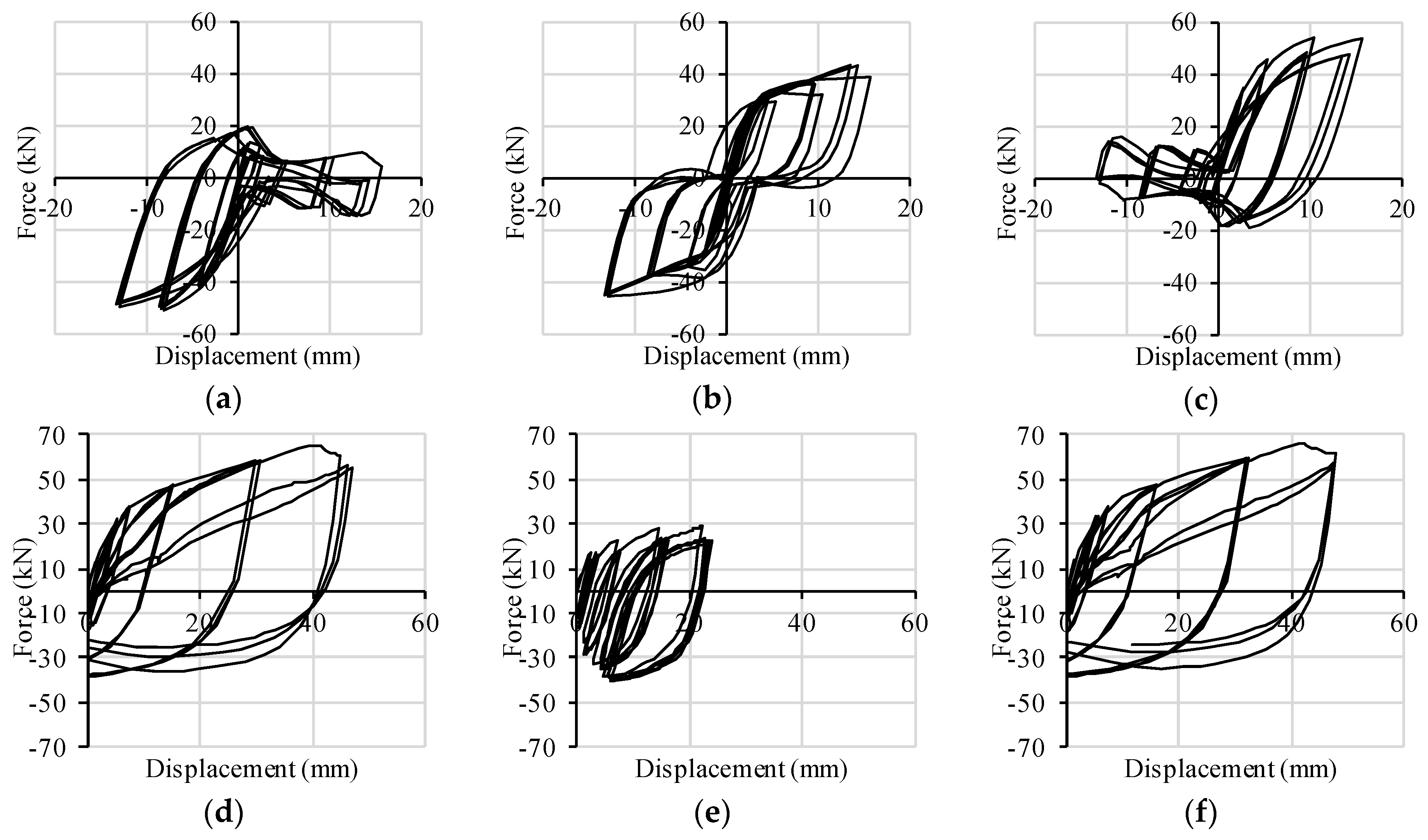

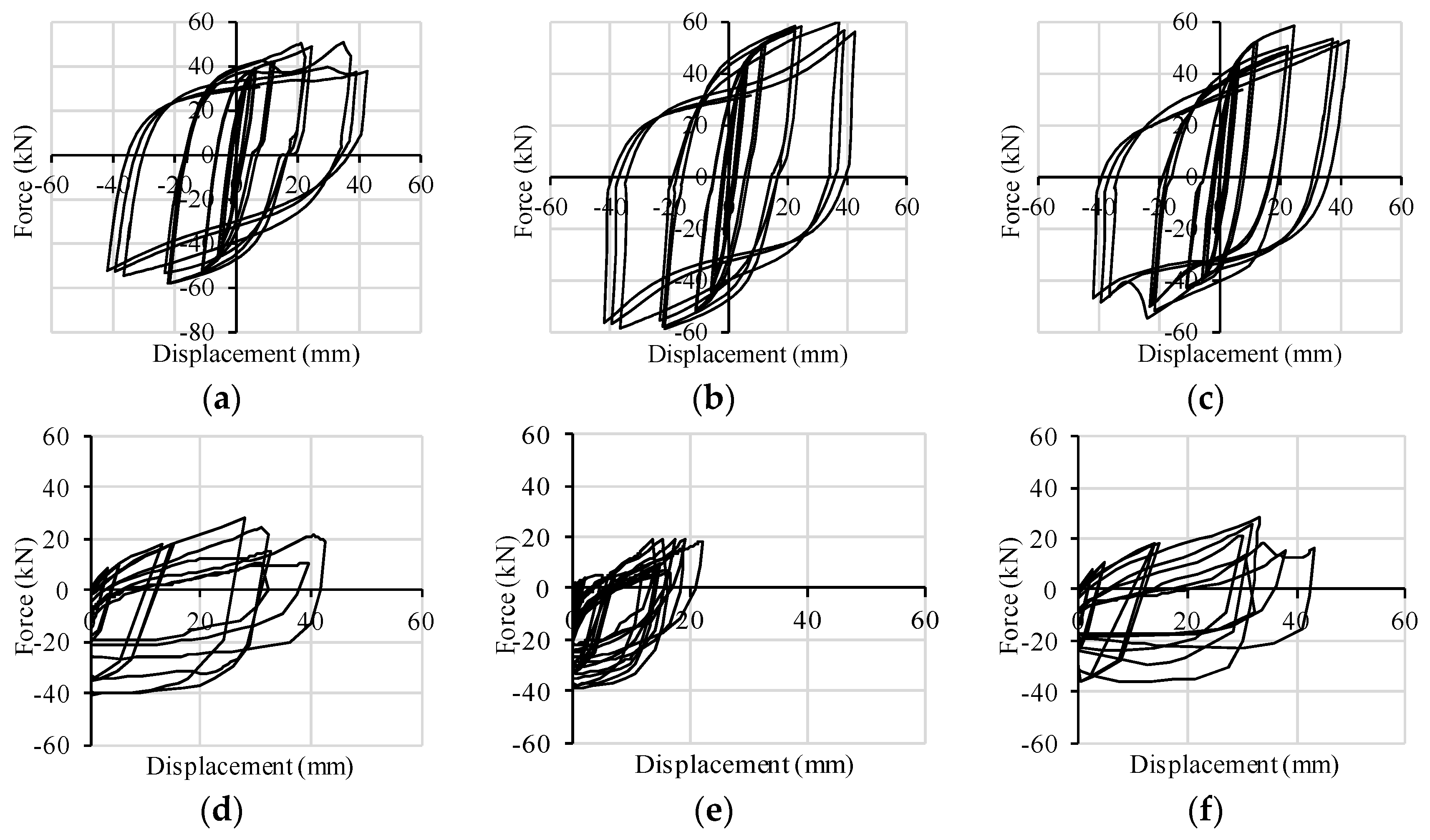

3.2. Test Results

3.2.1. Analysis of Test Results

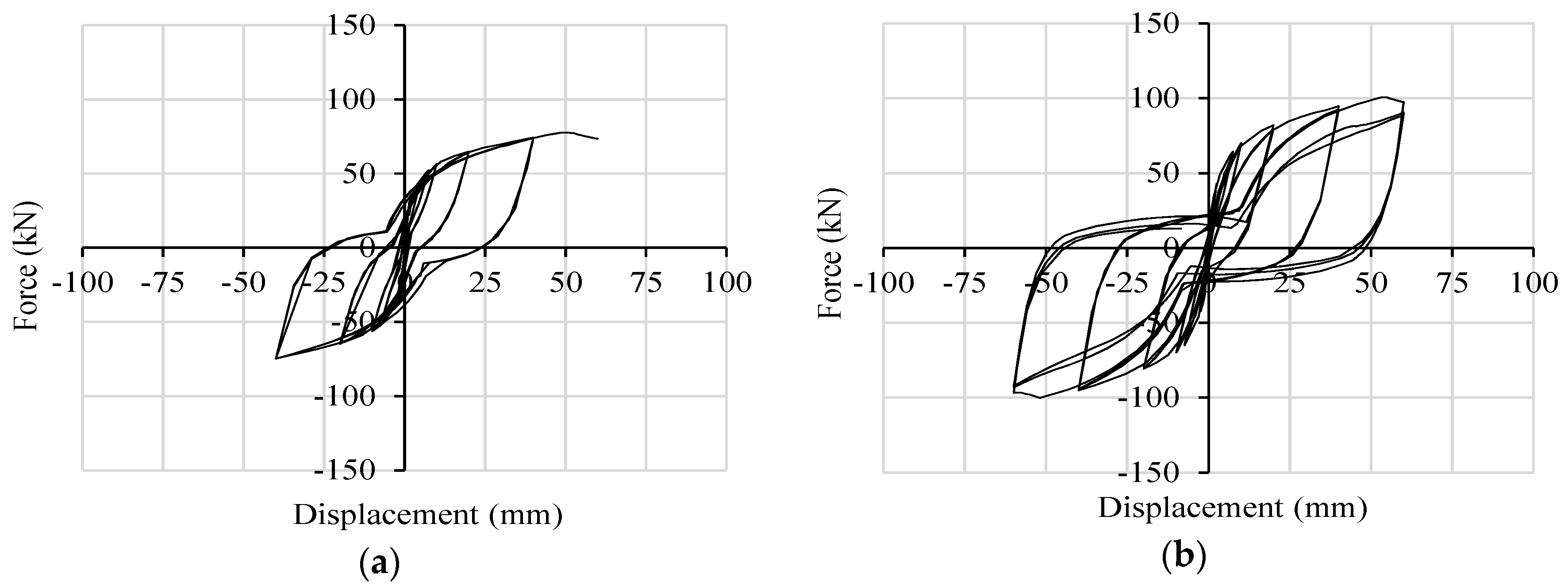

3.2.2. Comparison with Typical Connections for CLT Walls

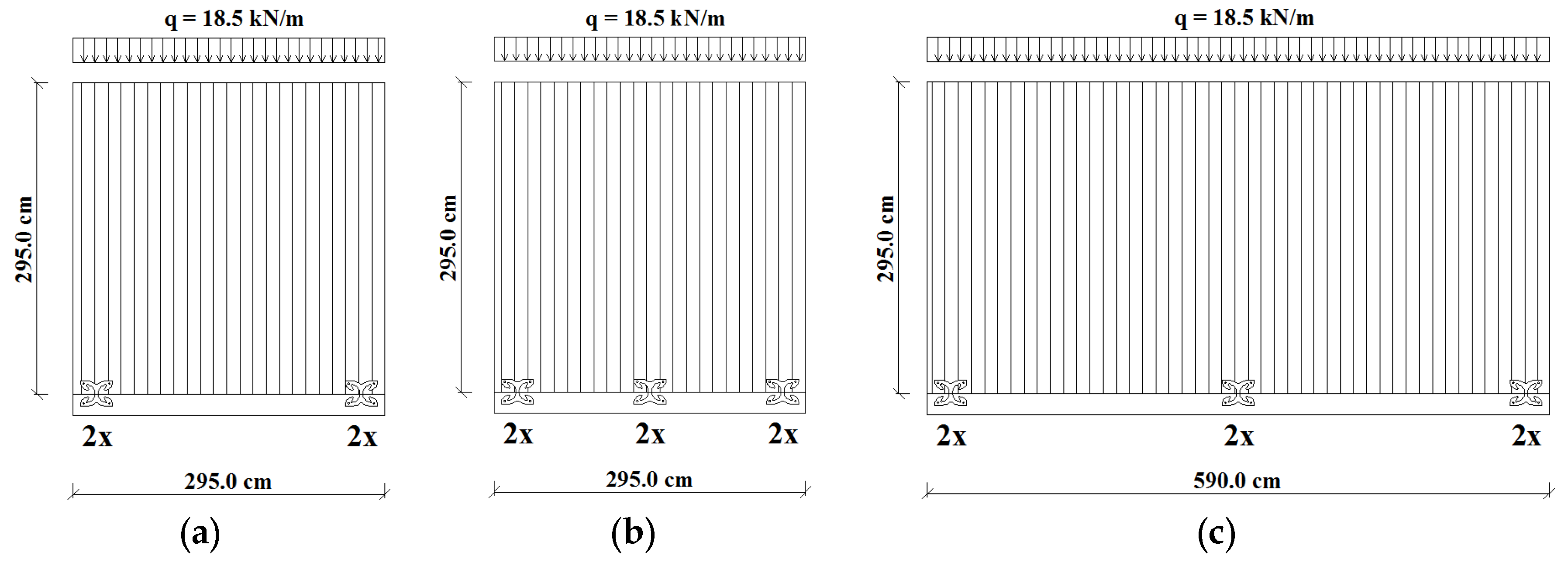

4. Numerical Modeling of CLT Shear Walls

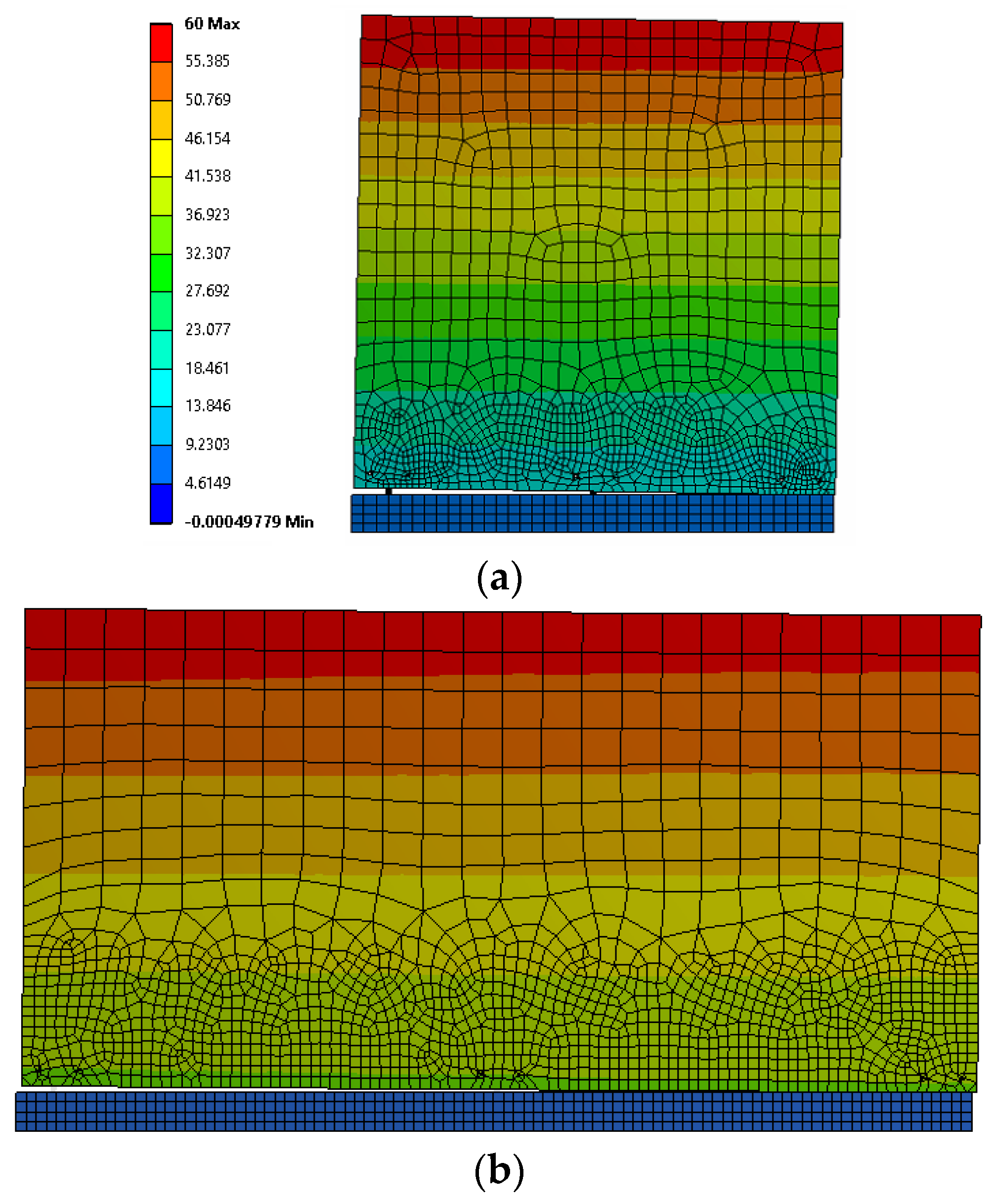

4.1. Numerical Modelling

4.2. Analysis of Results

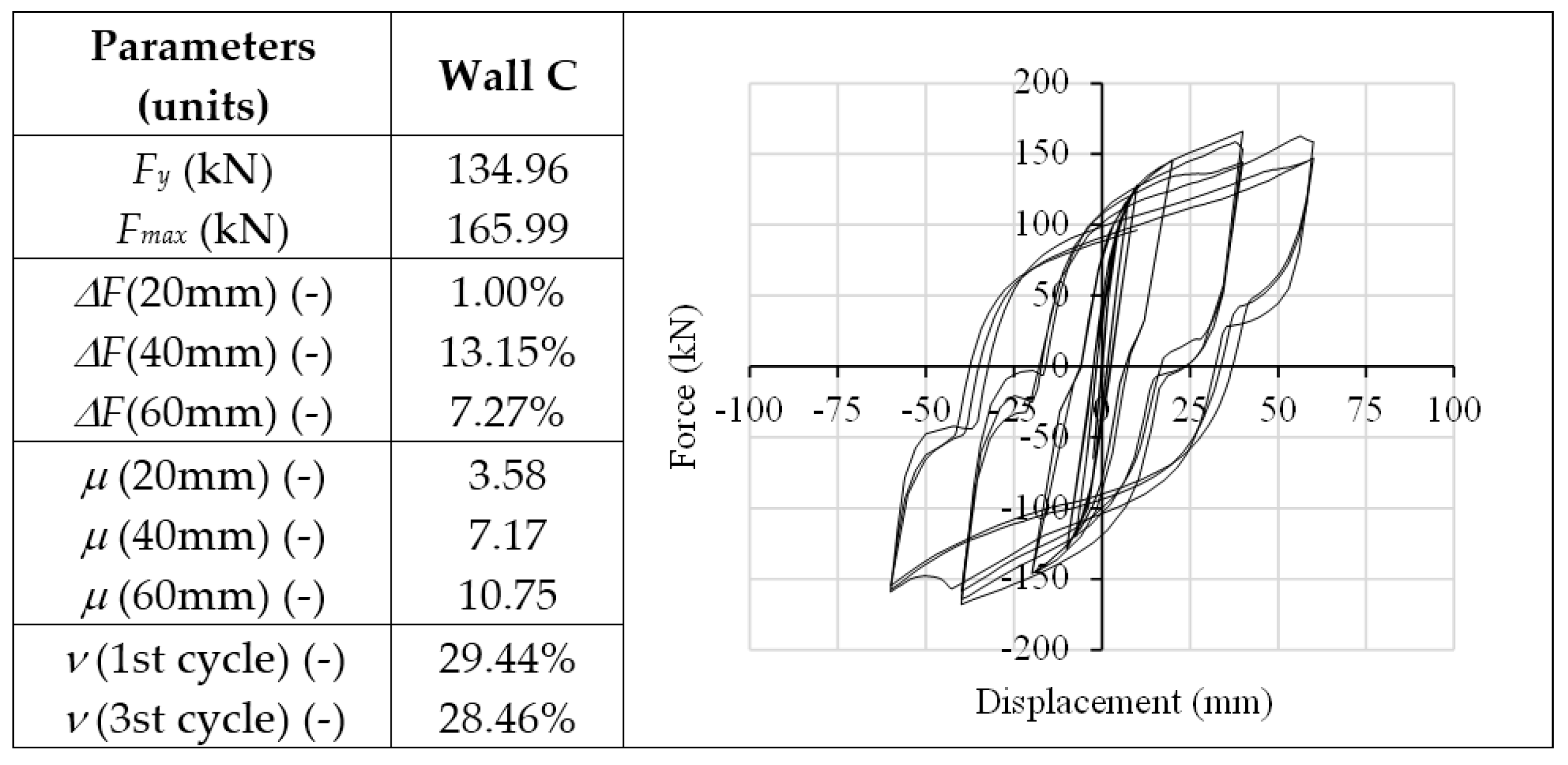

4.2.1. Comparison with CLT Walls Anchored with Traditional Connections

4.2.2. Evaluation of the Response of a Squat CLT Shear Wall

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ceccotti, A. New technologies for construction of medium-rise buildings in seismic regions: The XLAM case. Struct. Eng. Int. 2008, 18, 156–165. [Google Scholar] [CrossRef]

- Ceccotti, A.; Sandhaas, C.; Okabe, M.; Yasumura, M.; Minowa, C.; Kawai, N. SOFIE project—3D shaking table test on a seven-storey full-scale cross-laminated timber building. Earthq. Eng. Struct. Dyn. 2013, 42, 2003–2021. [Google Scholar] [CrossRef]

- Gavric, I.; Fragiacomo, M.; Ceccotti, A. Cyclic behavior of CLT wall systems: Experimental tests and analytical prediction models. J. Struct. Eng. 2015. [Google Scholar] [CrossRef]

- Popovski, M.; Gavric, I. Performance of a 2-story CLT house subjected to lateral loads. J. Struct. Eng. 2015. [Google Scholar] [CrossRef]

- Flatscher, G.; Schickhofer, G. Shaking-table test of a cross-laminated timber structure. P. I. Civil Eng. Str. B 2015, 168, 878–888. [Google Scholar]

- Eurocode 8—Design of Structures for Earthquake Resistance, Part 1: General Rules, Seismic Actions and Rules for Buildings; EN 1998-1; CEN: Brussels, Belgium, 2004.

- Pozza, L.; Scotta, R.; Trutalli, D.; Ceccotti, A.; Polastri, A. Analytical formulation based on extensive numerical simulations of behavior factor q for CLT buildings. In Proceedings of the Meeting 46 of the Working Commission W18-Timber Structures, CIB, Vancouver, BC, Canada, 26–29 August 2013.

- Pozza, L.; Scotta, R. Influence of wall assembly on behaviour of cross-laminated timber buildings. P. I. Civil Eng. Str. B 2014. [Google Scholar] [CrossRef]

- Pozza, L.; Scotta, R.; Trutalli, D.; Polastri, A.; Smith, I. Experimentally based q-factor estimation of cross-laminated timber walls. P. I. Civil Eng. Str. B 2016. [Google Scholar] [CrossRef]

- Smith, I.; Landis, E.; Gong, M. Fracture and Fatigue in Wood; John Wiley and Sons: Chichester, UK, 2003. [Google Scholar]

- Piazza, M.; Polastri, A.; Tomasi, R. Ductility of timber joints under static and cyclic loads. P.I. Civil Eng. Str. B 2011, 164, 79–90. [Google Scholar] [CrossRef]

- Germano, F.; Metelli, G.; Giuriani, E. Experimental results on the role of sheathing-to-frame and base connections of a European timber framed shear wall. Constr. Build. Mater. 2015, 80, 315–328. [Google Scholar] [CrossRef]

- Gattesco, N.; Dudine, A.; Franceschinis, R. Experimental investigation on the seismic behavior of timber shear walls with particle boards. In Proceedings of the World Conference on Timber Engineering WCTE, Auckland, New Zealand, 15–19 July 2012.

- Gattesco, N.; Boem, I. Seismic performances and behavior factor of post-and-beam timber buildings braced with nailed shear walls. Eng. Struct. 2015, 100, 674–685. [Google Scholar] [CrossRef]

- Sartori, T.; Piazza, M.; Tomasi, R.; Grossi, P. Characterization of the mechanical behavior of light-frame shear walls through full-scale tests. In Proceedings of the World Conference on Timber Engineering WCTE, Auckland, New Zealand, 15–19 July 2012.

- Sartori, T.; Tomasi, R. Experimental investigation on sheathing-to-framing connections in wood shear walls. Constr. Build. Mater. 2013, 56, 2197–2205. [Google Scholar] [CrossRef]

- Tomasi, R.; Sartori, T. Mechanical behavior of connections between wood framed shear walls and foundations under monotonic and cyclic load. Constr. Build. Mater. 2013, 44, 682–690. [Google Scholar] [CrossRef]

- Pozza, L.; Scotta, R.; Trutalli, D.; Polastri, A. Behaviour factor for innovative massive timber shear walls. B. Earthq. Eng. 2015, 13, 3449–3469. [Google Scholar] [CrossRef]

- Gavric, I.; Fragiacomo, M.; Ceccotti, A. Capacity seismic design of X-LAM wall system based on connection mechanical properties. In Proceedings of the Meeting 46 of the Working Commission W18-Timber Structures, CIB, Vancouver, BC, Canada, 26–29 August 2013.

- Fragiacomo, M.; Dujic, B.; Sustersic, I. Elastic and ductile design of multi-storey crosslam massive wooden buildings under seismic actions. Eng. Struct. 2011, 33, 3043–3053. [Google Scholar] [CrossRef]

- Johansen, K.W. Theory of Timber Connections; International Association of bridge and structural Engineering: Bern, Switzerland, 1949; pp. 249–262. [Google Scholar]

- Eurocode 5—Design of Timber Structures, Part 1: General—Common Rules and Rules for Buildings; EN 1995-1-1; CEN: Brussels, Belgium, 2009.

- Polastri, A.; Angeli, A.; Dal Ri, G. A new construction system for CLT structures. In Proceedings of the World Conference on Timber Engineering WCTE, Quebec City, QC, Canada, 10–14 August 2014.

- Loo, W.Y.; Kun, C.; Quenneville, P.; Chouw, N. Experimental testing of a rocking timber shear wall with slip-friction connectors. Earthq. Eng. Struc. 2014, 43, 1621–1639. [Google Scholar] [CrossRef]

- Latour, M.; Rizzano, G. Cyclic behavior and modeling of a dissipative connector for cross-laminated timber panel buildings. J. Earthq. Eng. 2015, 19, 137–171. [Google Scholar] [CrossRef]

- Sarti, F.; Palermo, A.; Pampanin, S. Quasi-static cyclic testing of two-thirds scale unbonded posttensioned rocking dissipative timber walls. J. Struct. Eng. 2015. [Google Scholar] [CrossRef]

- Gavric, I.; Ceccotti, A.; Fragiacomo, M. Experimental cyclic tests on cross-laminated timber panels and typical connections. In Proceedings of the ANIDIS, Bari, Italy, 18–22 September 2011.

- ANSYS Mechanical Workbench; R14; ANSYS, Inc.: Canonsburg, PA, USA, 2012.

- Priestley, M.J.N.; Seible, F.; Calvi, G.M. Seismic Design and Retrofit of Bridges; Wiley: New York, NY, USA, 1996. [Google Scholar]

- Blass, H.J.; Schmid, M.; Litze, H.; Wagner, B. Nail plate reinforced joints with dowel-type fasteners. In Proceedings of the 6th World Conference on Timber Engineering, Whistler, BC, Canada, 31 July–3 August 2000.

- Timber Structures. Test Methods. Cyclic Testing of Joints Made with Mechanical Fasteners; EN 12512; CEN: Brussels, Belgium, 2001.

- Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature; EN ISO 6892-1; CEN: Brussels, Belgium, 2009.

- Muñoz, W.; Mohammad, M.; Salenikovich, A.; Quenneville, P. Need for a harmonized approach for calculations of ductility of timber assemblies. In Proceedings of the Meeting 41 of the Working Commission W18-Timber Structures, St. Andrews, NB, Canada, 25–28 August 2008.

- Foschi, R.O.; Bonac, T. Load slip characteristic for connections with common nails. Wood Sci. Technol. 1977, 9, 118–123. [Google Scholar]

- Foliente, G.C. Issues in seismic performance testing and evaluation of timber structural systems. In Proceedings of the International Wood Engineering Conference, New Orleans, LA, USA, 28–31 October 1996; pp. 29–36.

- Eurocode—Basis of Structural Design; EN 1990; CEN: Brussels, Belgium, 2001.

| Parameters (Units) | Dimensions | Parameters (Units) | Dimensions |

|---|---|---|---|

| a (mm) | 303.0 | d (mm) | 32.0 |

| b (mm) | 233.0 | e (mm) | 33.0 |

| c (mm) | 35.0 | f (mm) | 26.5 |

| Parameters (units) | Test T1 | Test T2 | Test T3 | Average | SD | 5% Characteristic |

|---|---|---|---|---|---|---|

| Fy (kN) | 17.55 | 18.37 | 17.99 | 17.97 | 0.36 | 17.18 |

| Vy (mm) | 1.89 | 2.01 | 1.98 | 1.96 | 0.06 | 1.83 |

| Fu (kN) | 37.18 | 37.84 | 38.25 | 37.76 | 0.48 | 36.70 |

| Vu (mm) | 44.30 | 47.30 | 47.00 | 46.20 | 1.48 | 42.98 |

| kel (kN/mm) | 9.31 | 9.12 | 9.08 | 9.17 | 0.11 | 8.94 |

| kpl (kN/mm) | 0.46 | 0.43 | 0.45 | 0.45 | 0.01 | 0.42 |

| μ(Vu) (-) | 23.49 | 23.49 | 23.72 | 23.57 | 0.12 | 23.30 |

| Ductility Class | H | H | H | H | - | - |

| Parameters | Test S1 | Test S2 | Test S3 | Average | SD | 5% Characteristic | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (units) | EN | EEEP | EN | EEEP | EN | EEEP | EN | EEEP | EN | EEEP | EN | EEEP |

| Fy (kN) | 26.71 | 27.41 | 29.41 | 28.88 | 28.14 | 27.83 | 28.09 | 28.04 | 1.21 | 0.68 | 25.46 | 26.56 |

| Vy (mm) | 2.38 | 2.60 | 4.00 | 4.45 | 4.02 | 4.53 | 3.46 | 3.86 | 0.84 | 0.98 | 1.63 | 1.73 |

| Fu (kN) | 29.00 | 27.41 | 29.70 | 28.88 | 28.40 | 27.83 | 29.03 | 28.04 | 0.58 | 0.68 | 27.76 | 26.56 |

| Vu (mm) | 50.00* | 50.00* | 58.00* | 58.00* | 80.00 | 80.00 | - | - | - | - | - | - |

| kel (kN/mm) | 11.24 | 10.55 | 7.36 | 6.49 | 7.00 | 6.14 | 8.53 | 7.73 | 2.10 | 2.19 | 3.95 | 2.95 |

| kpl (kN/mm) | 0.05 | 0.00 | 0.01 | 0.00 | 0.00 | 0.00 | 0.02 | 0.00 | 0.02 | 0.00 | 0.00 | 0.00 |

| μ (Vu=50mm) | 21.04 | 19.24 | 12.51 | 11.24 | 12.44 | 11.03 | 15.33 | 13.84 | 4.42 | 4.19 | 5.69 | 4.71 |

| Ductility Class | H | H | H | H | H | H | H | H | - | - | - | - |

| Parameters | Tension Test (EN Method) | Shear Test (EN Method) | Shear Test (EEEP Method) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Notations (Units) | F0.05 | F0.95 | γov | F0.05 | F0.95 | γov | F0.05 | F0.95 | γov |

| Fy (kN) | 17.18 | 18.76 | 1.09 | 25.46 | 30.71 | 1.21 | 26.56 | 29.52 | 1.11 |

| Fu (kN) | 36.70 | 38.81 | 1.06 | 27.76 | 30.30 | 1.09 | 26.56 | 29.52 | 1.11 |

| Steel Connectors (Mean Values from Tensile Test According to EN ISO 6892-1:2009) | Timber Panel (Typical Mean Values for CLT Panels) | ||

|---|---|---|---|

| Parameter | Value | Parameter | Value |

| Modulus E (MPa) | 210,000.0 | Modulus E (MPa) | 12,500.0 |

| Plastic Modulus E (MPa) | 957.0 | - | - |

| Thickness (mm) | 6.0 | Wall thickness (mm) | 85.0 |

| Mesh size (mm) | 5.0 | Mesh size (mm) | 20.0/200.0 |

| σy (MPa) | 310.0 | - | - |

| σu (MPa) | 500.0 | - | - |

| Parameters (units) | Wall I.1 | Wall A | Wall I.2 | Wall B |

|---|---|---|---|---|

| Fy (kN) | 50.00 | 56.30 | 87.40 | 72.98 |

| Fmax (kN) | 70.70 | 77.63 | 104.20 | 100.65 |

| ΔF (20mm) (-) | 10.00% | 0.34% | 9.00% | 3.10% |

| ΔF (40mm) (-) | 28.50% | 0.31% | 14.80% | 2.48% |

| ΔF (60mm) (-) | - | - | - | 8.12% |

| μ (20mm) (-) | 2.00 | 4.35 | 1.18 | 4.01 |

| μ (40mm) (-) | 4.00 | 8.70 | 2.35 | 8.02 |

| μ (60mm) (-) | - | 13.05 | 3.53 | 12.03 |

| Ed (1st cycle) (J) | 1728 | 2331 | 3016 | 4748 |

| Ed (3rd cycle) (J) | 1178 | 2174 | - | 3440 |

| ν (1st cycle) (-) | 19.60% | 24.80% | 16.20% | 24.57% |

| ν (3st cycle) (-) | 18.00% | 23.90% | 11.50% | 20.08% |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scotta, R.; Marchi, L.; Trutalli, D.; Pozza, L. A Dissipative Connector for CLT Buildings: Concept, Design and Testing. Materials 2016, 9, 139. https://doi.org/10.3390/ma9030139

Scotta R, Marchi L, Trutalli D, Pozza L. A Dissipative Connector for CLT Buildings: Concept, Design and Testing. Materials. 2016; 9(3):139. https://doi.org/10.3390/ma9030139

Chicago/Turabian StyleScotta, Roberto, Luca Marchi, Davide Trutalli, and Luca Pozza. 2016. "A Dissipative Connector for CLT Buildings: Concept, Design and Testing" Materials 9, no. 3: 139. https://doi.org/10.3390/ma9030139

APA StyleScotta, R., Marchi, L., Trutalli, D., & Pozza, L. (2016). A Dissipative Connector for CLT Buildings: Concept, Design and Testing. Materials, 9(3), 139. https://doi.org/10.3390/ma9030139