Selective Photophysical Modification on Light-Emitting Polymer Films for Micro- and Nano-Patterning

Abstract

:1. Introduction

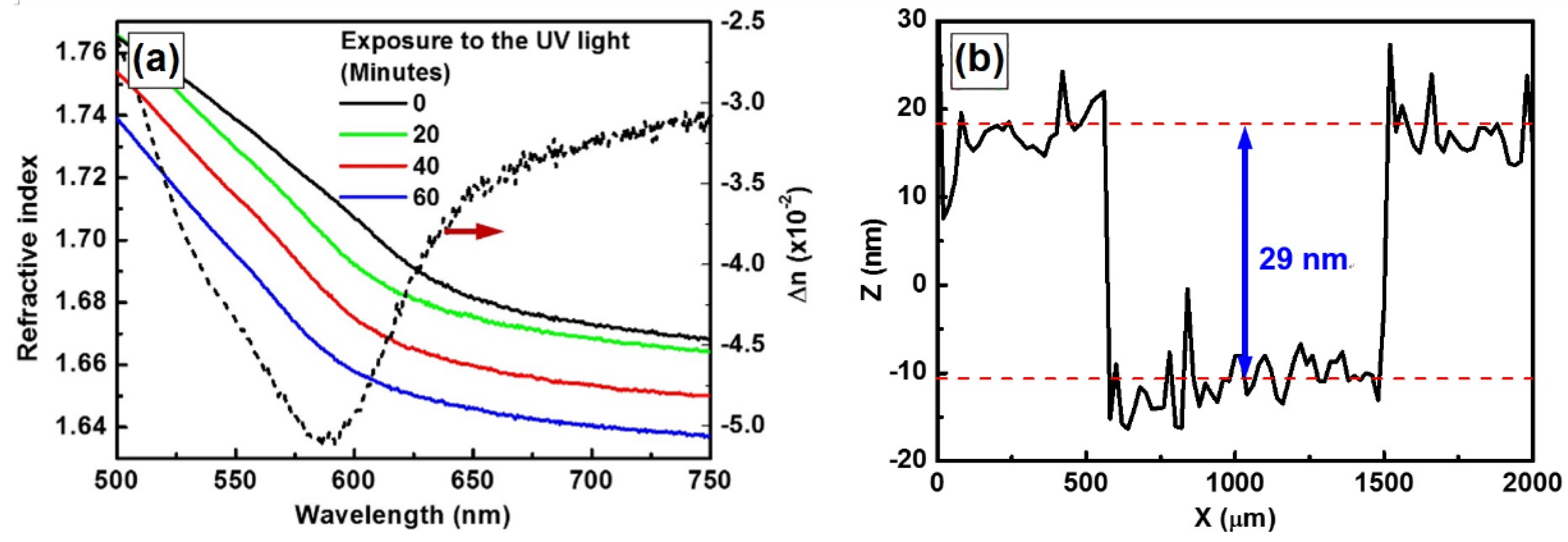

2. Laser-Induced Cross-Linking in Polymer Film

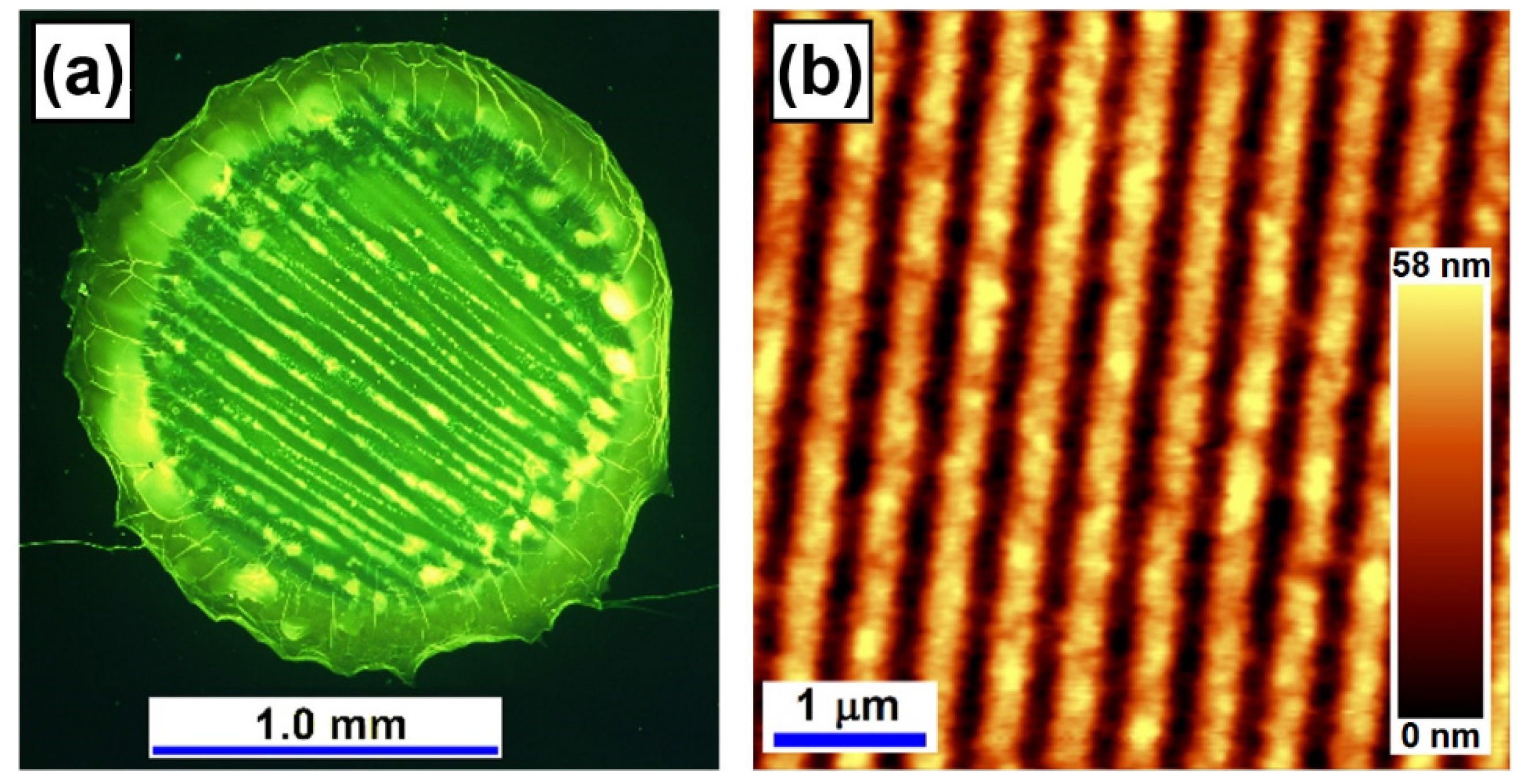

3. Spatial Selectivity in Laser-Induced Cross-Linking

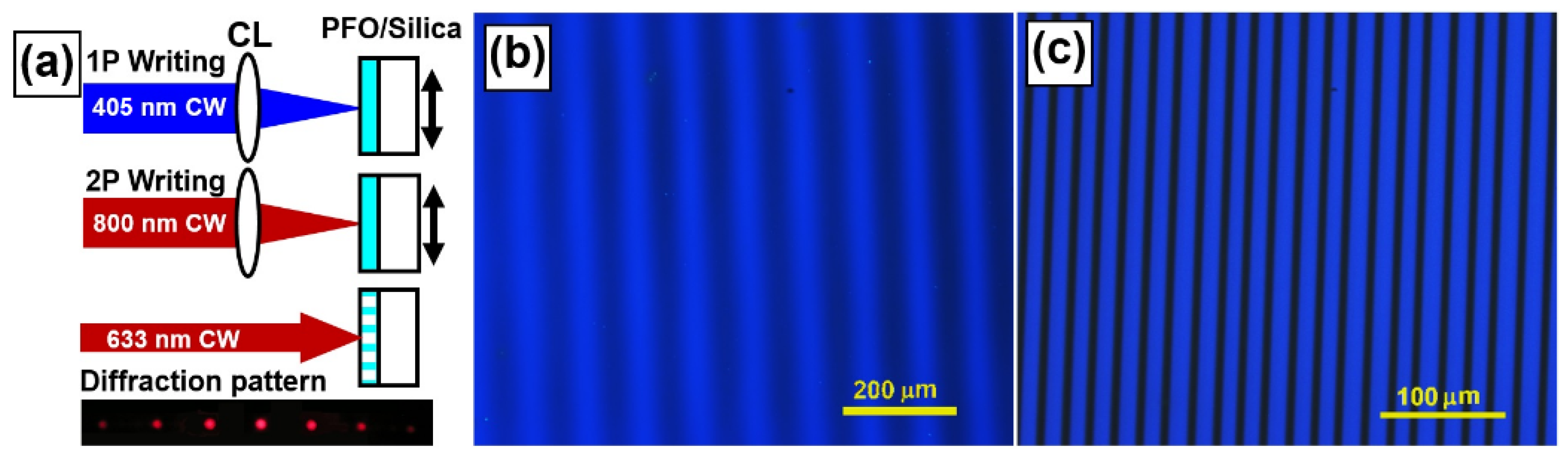

3.1. Single- and Two-Photon-Induced Cross-Linking Processes

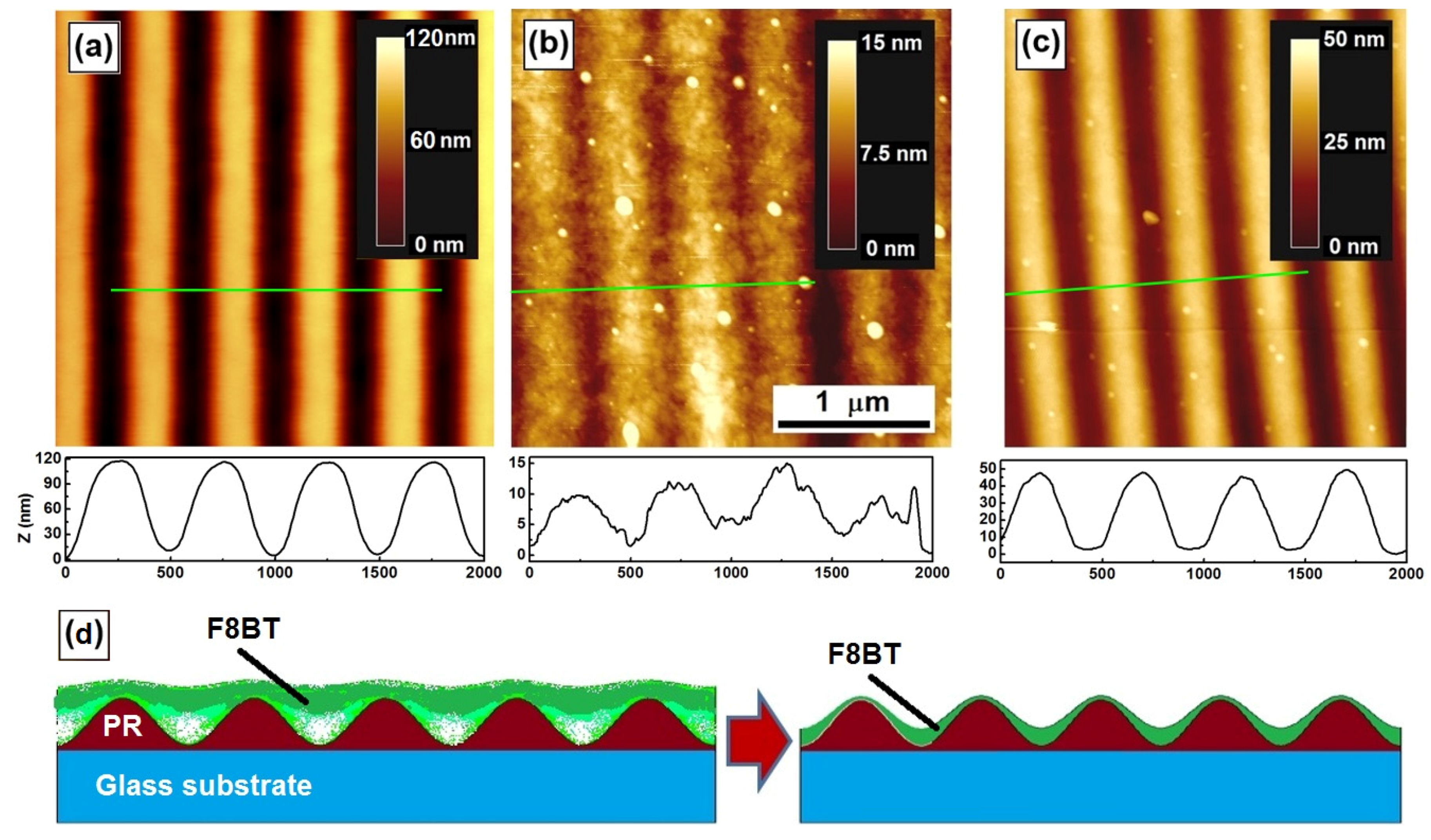

3.2. Interference Cross-Linking with High Spatial Resolution

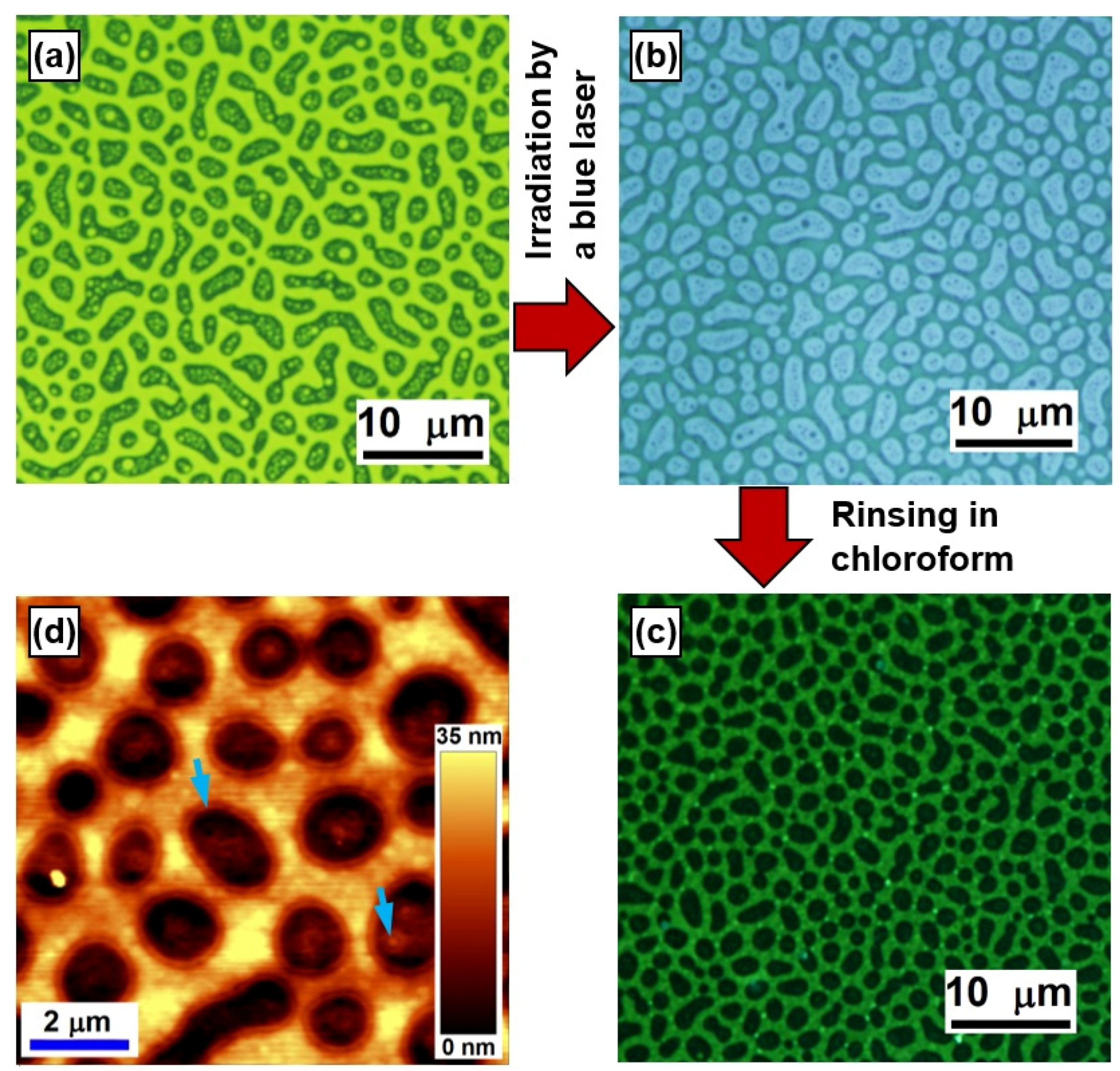

4. Phase-Selective Laser-Induced Cross-Linking in Polymer Blends for Plasmonic Patterning

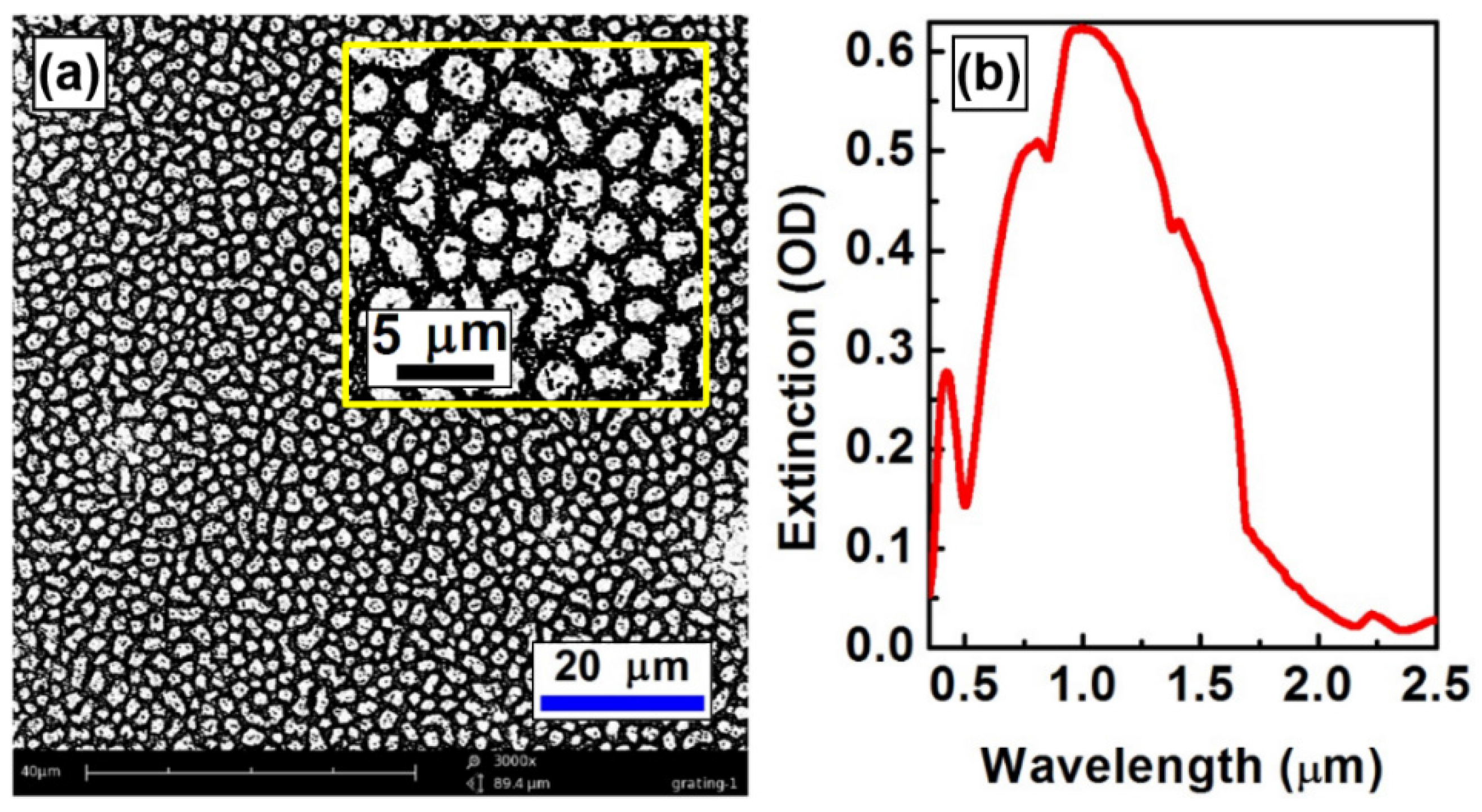

4.1. Selective Cross-Linking of the Phase-Separation Scheme of a Polymer-Blend Film

4.2. Metallization of the Selectively Cross-Linked Phase-Separation Pattern

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zuniga, C.A.; Barlow, S.; Marder, S.R. Approaches to solution-processed multilayer organic light-emitting diodes based on cross-linking. Chem. Mater. 2011, 23, 658–681. [Google Scholar] [CrossRef]

- Inaoka, S.; Roitman, D.B.; Advincula, R.C. Cross-Linked Polyfluorene Polymer Precursors: Electrodeposition, PLED Device Characterization, and Two-Site Co-deposition with Poly(vinylcarbazole). Chem. Mater. 2005, 17, 6781–6789. [Google Scholar] [CrossRef]

- Berta, M.; Biver, É.; Maria, S.; Phan, T.N.T.; D’Aleo, A.; Delaporte, P.; Fages, F.; Gigmes, D. Nanosecond laser-induced periodic surface structuring of cross-linked azo-polymer films. Appl. Surf. Sci. 2013, 282, 880–886. [Google Scholar] [CrossRef]

- He, G.S.; Kim, K.S.; Yuan, L.; Cheng, N.; Prasad, P.N. Two-photon pumped partially cross-linked polymer laser. Appl. Phys. Lett. 1997, 71, 1619–1621. [Google Scholar] [CrossRef]

- Zhao, W.; Cao, T.; White, J.M. On the origin of green emission in polyfluorene polymers: The role of thermal oxidization degradation and cross-linking. Adv. Funct. Mater. 2004, 14, 783–790. [Google Scholar] [CrossRef]

- Agroui, K.; Collins, G.; Oreski, G.; Boehning, M.; Hadj Arab, A.; Ouadjaout, D. Effect of crosslinking on EVA-based encapsulant properties during photovoltaic module fabrication process. Revue Energies Renouv. 2015, 18, 303–314. [Google Scholar]

- Zhang, X.P.; Liu, H.M.; Li, H.W.; Zhai, T.R. Direct nanopatterning into conjugated polymers using interference crosslinking. Macromol. Chem. Phys. 2012, 213, 1285–1290. [Google Scholar] [CrossRef]

- Zhai, T.R.; Lin, Y.H.; Liu, H.M.; Feng, S.F.; Zhang, X.P. Nanoscale tensile stress approach for the direct writing of plasmonic nanostructures. Opt. Express 2013, 21, 24490–24496. [Google Scholar] [CrossRef] [PubMed]

- Charas, A.; Alcacer, L.; Pimentel, A. Observation of field-effect in a cross-linked polyfluorene semiconductor. Chem. Phys. Lett. 2008, 455, 189–191. [Google Scholar] [CrossRef]

- Bernardo, G.; Charas, A.; Alcacer, L.; Morgado, J. Spin cast thin polymer interlayers in polymer light-emitting diodes: Thickness control through use of cross-linkable polymers. J. Appl. Phys. 2008, 103, 084510. [Google Scholar] [CrossRef]

- Charas, A.; Alves, H.; Alcacer, L.; Morgado, J. Use of cross-linkable polyfluorene in the fabrication of multilayer polyfluorene-based light-emitting diodes with improved efficiency. Appl. Phys. Lett. 2006, 89, 143519. [Google Scholar]

- Morteani, A.C.; Sreearunothai, P.; Herz, L.M.; Friend, R.H.; Silva, C. Exciton regeneration at polymeric semiconductor heterojunctions. Phys. Rev. Lett. 2004, 92, 247402. [Google Scholar] [CrossRef] [PubMed]

- Mcneill, C.R.; Watts, B.; Thomsen, L.; Belcher, W.J.; Greenham, N.C.; Dastoor, P.C.; Ade, H. Evolution of laterally phase-separated polyfluorene blend morphology studied by X-ray spectromicroscopy. Macromolecules 2009, 42, 3347–3352. [Google Scholar] [CrossRef]

- Coffey, D.C.; Reid, O.G.; Rodovsky, D.B.; Bartholomew, G.P.; Ginger, D.S. Mapping local photocurrents in polymer/fullerene solar cells with photoconductive atomic force microscopy. Nano Lett. 2007, 7, 738–744. [Google Scholar] [CrossRef] [PubMed]

- Abdullah, M.; Kim, J.S.; Renero-Lecuna, C.; Friend, R.H. Morphological Study of F8BT:PFB Thin Film Blends. Organ. Electron. 2015, 23, 87–98. [Google Scholar] [CrossRef]

- Zhai, T.R.; Zhang, X.P.; Dou, F. Microscopic Excavation into the Optically Pumped Polymer Lasers Based on Distributed Feedback. Chin. Phys. Lett. 2012, 29, 104204. [Google Scholar] [CrossRef]

- Zhang, X.P.; Sun, B.Q.; Guo, H.C.; Nau, D.; Giessen, H.; Friend, R.H. Metallic photonic crystals based on solution-processible gold nanoparticles. Nano Lett. 2006, 6, 651–655. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.M.; Zhang, X.P.; Zhai, T.R. Plasmonic nano-ring arrays through patterning gold nanoparticles into interferograms. Opt. Express 2013, 21, 15314–15322. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.P.; Li, H.W. Laser-induced selective crosslinking for scaling the heterointerfacial domain in polymer blends. Opt. Express 2013, 21, 24620–24629. [Google Scholar] [CrossRef] [PubMed]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Liu, F.; Li, H. Selective Photophysical Modification on Light-Emitting Polymer Films for Micro- and Nano-Patterning. Materials 2016, 9, 121. https://doi.org/10.3390/ma9030121

Zhang X, Liu F, Li H. Selective Photophysical Modification on Light-Emitting Polymer Films for Micro- and Nano-Patterning. Materials. 2016; 9(3):121. https://doi.org/10.3390/ma9030121

Chicago/Turabian StyleZhang, Xinping, Feifei Liu, and Hongwei Li. 2016. "Selective Photophysical Modification on Light-Emitting Polymer Films for Micro- and Nano-Patterning" Materials 9, no. 3: 121. https://doi.org/10.3390/ma9030121

APA StyleZhang, X., Liu, F., & Li, H. (2016). Selective Photophysical Modification on Light-Emitting Polymer Films for Micro- and Nano-Patterning. Materials, 9(3), 121. https://doi.org/10.3390/ma9030121