Correlation between Mechanical Properties with Specific Wear Rate and the Coefficient of Friction of Graphite/Epoxy Composites

Abstract

:1. Introduction

2. Material Preparation and Experimental Procedure

2.1. Material Preparation

| Material | Matrix (E) wt % | Graphite (G) wt % | Date palm fiber (F) vol % |

|---|---|---|---|

| NE | 100 | 0 | 0 |

| GE1 | 99 | 1 | 0 |

| GE3 | 97 | 3 | 0 |

| GE5 | 95 | 5 | 0 |

| GE7 | 93 | 7 | 0 |

| FE | 100 | 0 | 35 |

| GFE | 97 | 3 | 35 |

2.2. Experimental Procedures

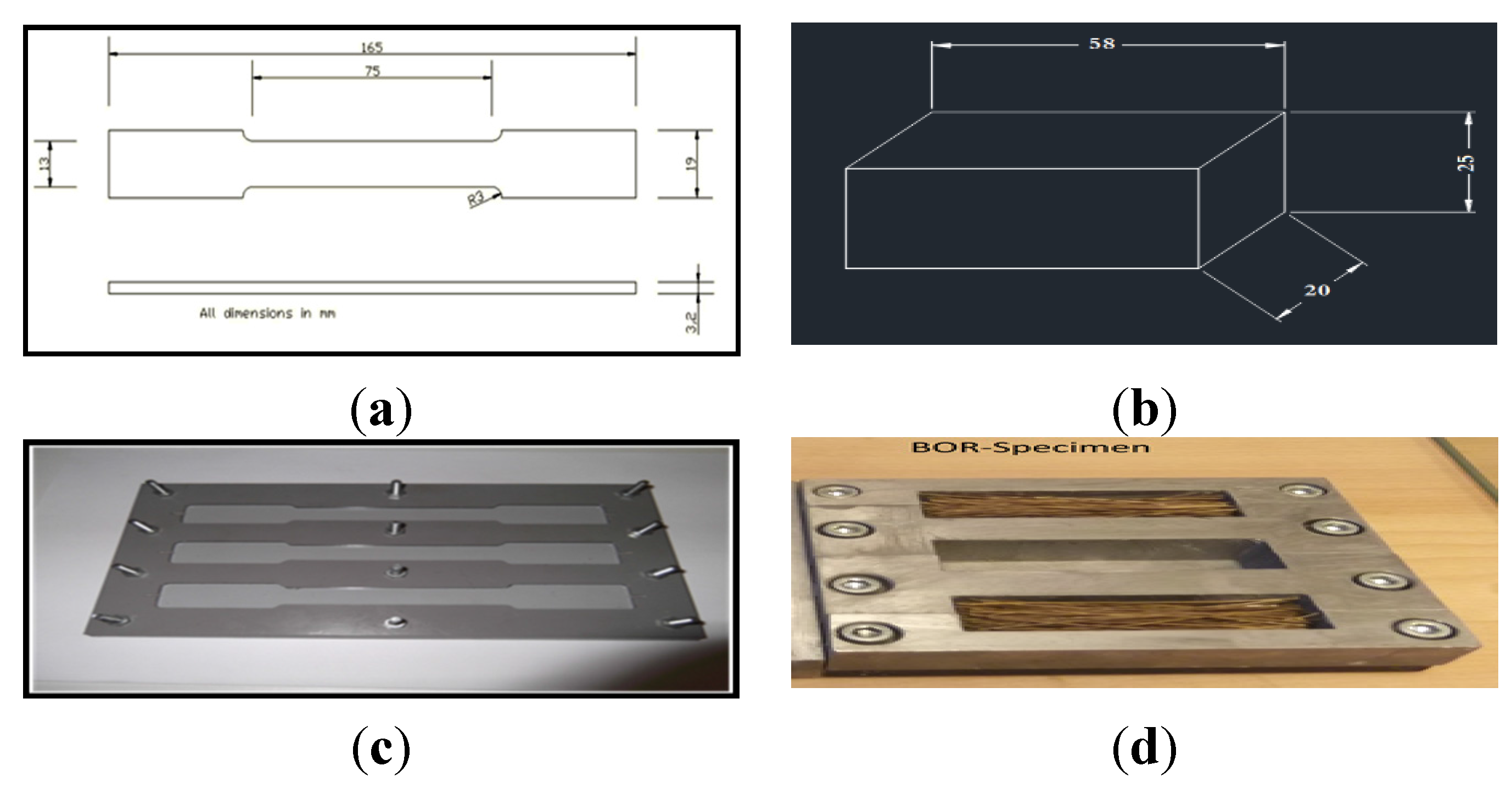

2.2.1. Mechanical Experiments of the Composites

| Material | Tensile, MPa (SD) | Modulus, GPa (SD) | Elongation, % (SD) | Shore Hardness (SD) |

|---|---|---|---|---|

| NE | 55.5 (±3.57) | 0.62 (±0.84) | 9.1 (±5.91) | 82.2 (±3.38) |

| GE1 | 50 (±0.36) | 0.983 (±0.73) | 9.3 (±4.61) | 82.7 (±2.64) |

| GE3 | 39.1 (±2.81) | 1.01 (±2.08) | 10.8 (±5.94) | 83.4 (±4.05) |

| GE5 | 35.7 (±1.31) | 0.61 (±0.57) | 11.7 (±2.61) | 83.7 (±3.45) |

| GE7 | 30.86 (±4.22) | 0.4 (±3.46) | 12.8 (±4.05) | 84.5 (±4.12) |

| FE | 66.2 (±3.92) | 1.36 (±0.51) | 7.3 (±4.84) | 84.2 (±3.29) |

| GFE | 62.3 (±2.48) | 1.28 (±0.72) | 7.9 (±5.61) | 84.7 (±3.14) |

2.2.2. Tribological Experiments

2.2.3. Linear Regression for Mechanical and Tribological Data

3. Result and Discussion

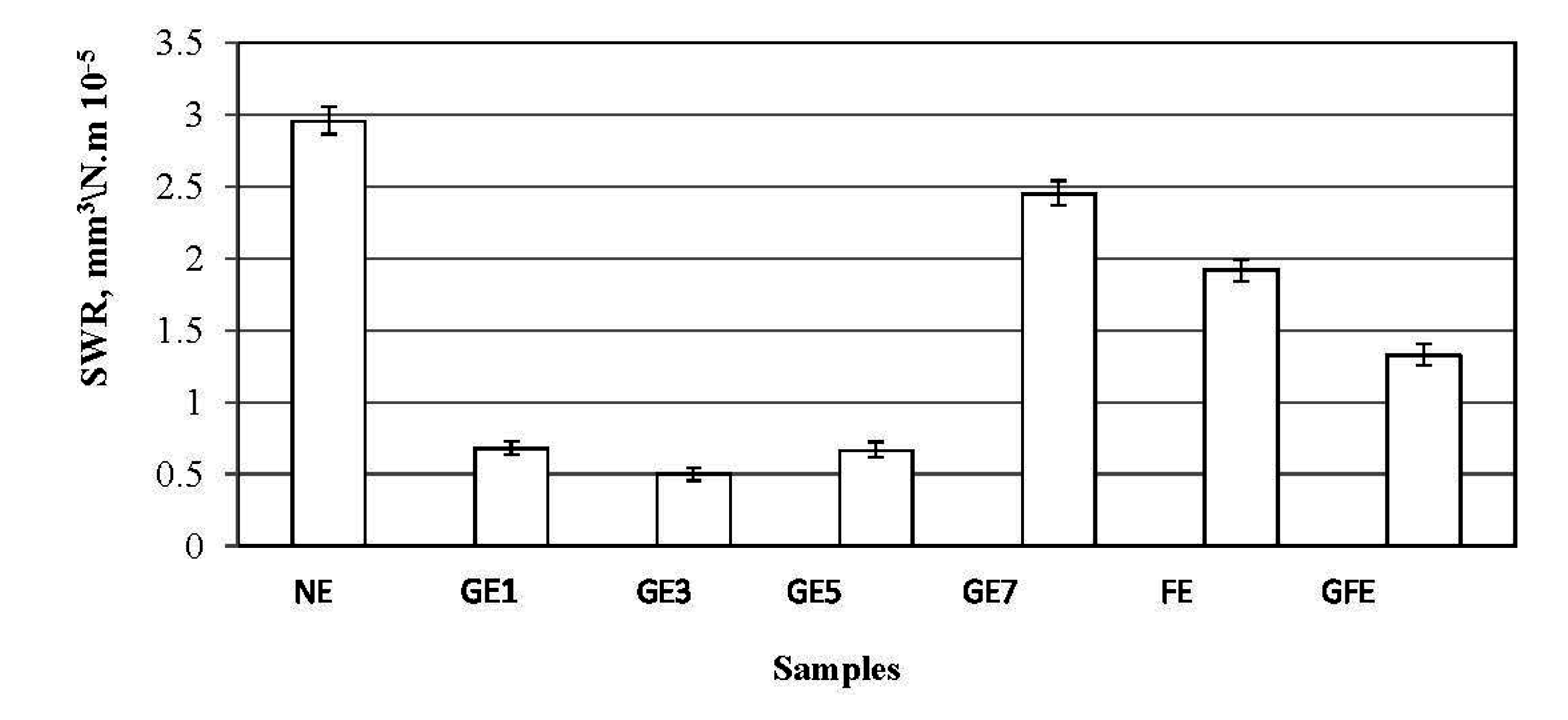

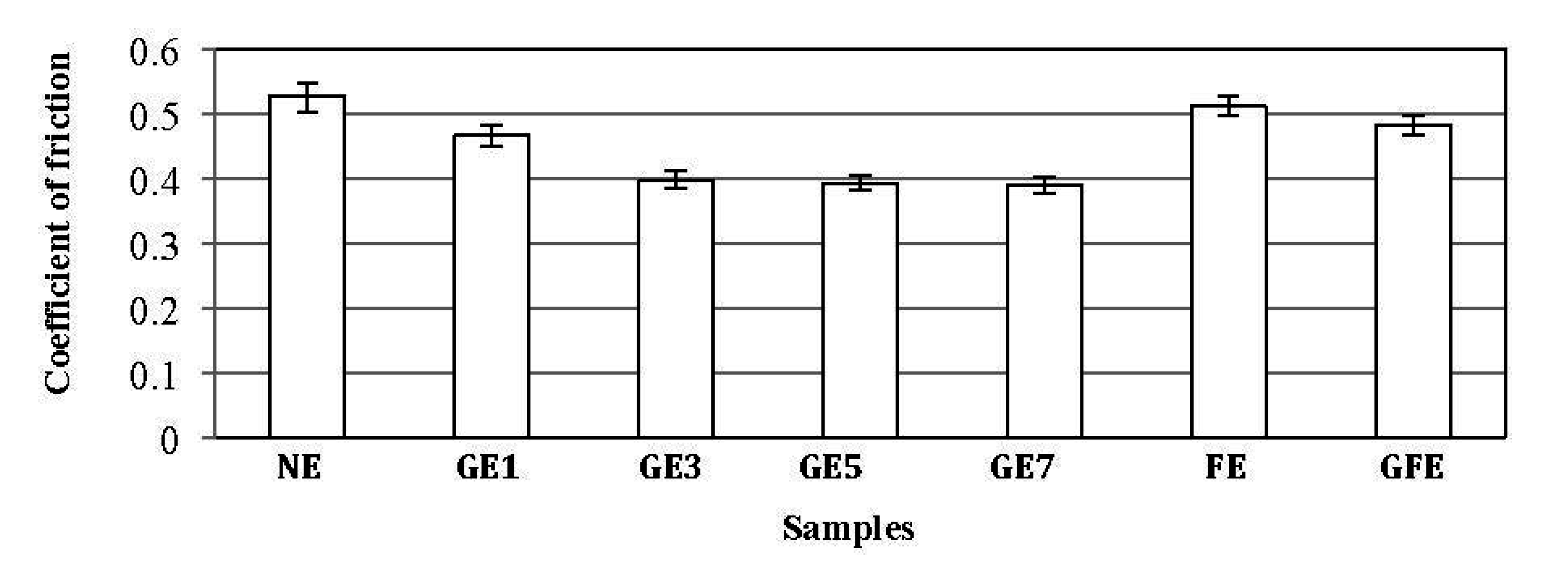

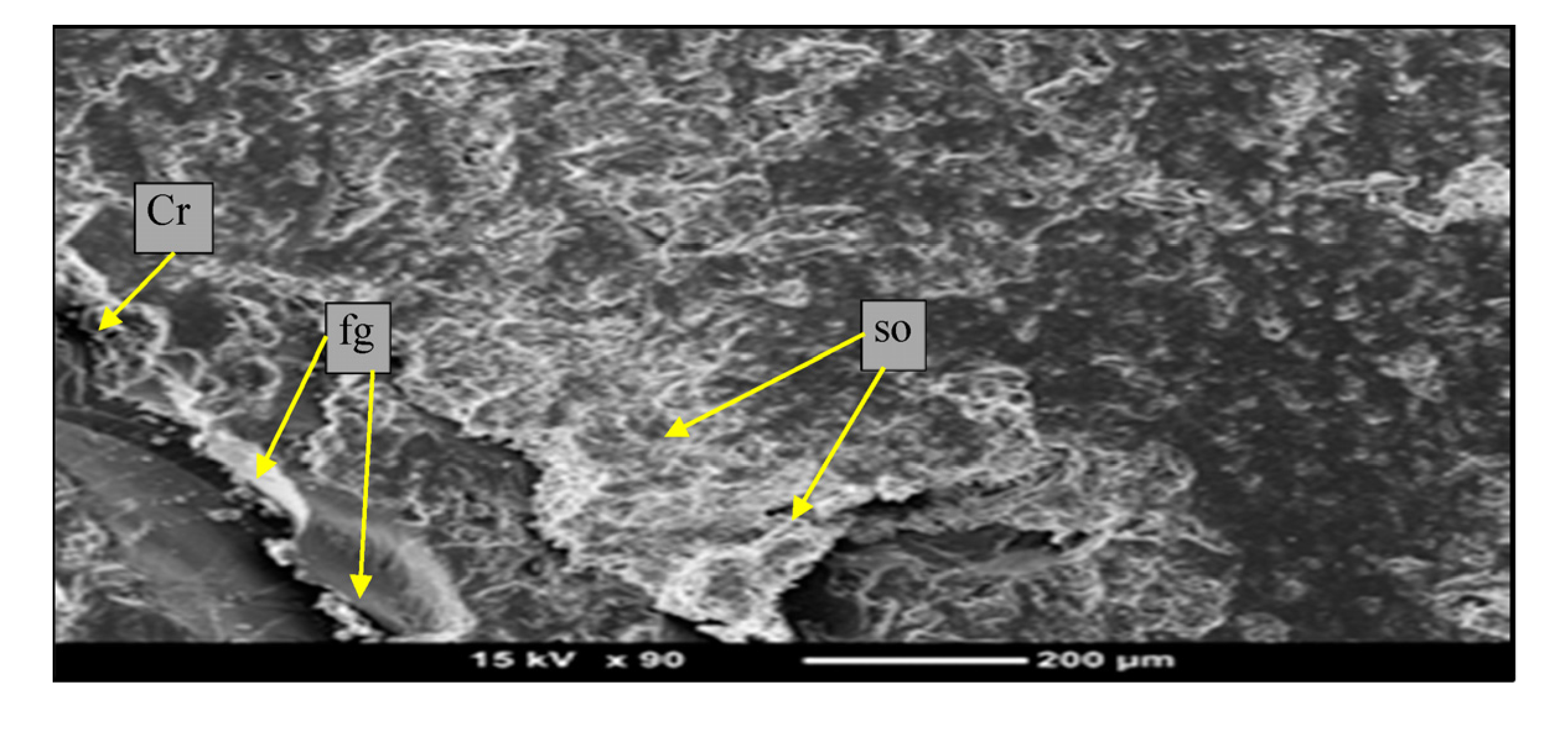

3.1. Specific Wear Rate and Friction Coefficient of Fillers/Epoxy Composites

3.2. Correlation of Tribological Behavior with Mechanical Behavior

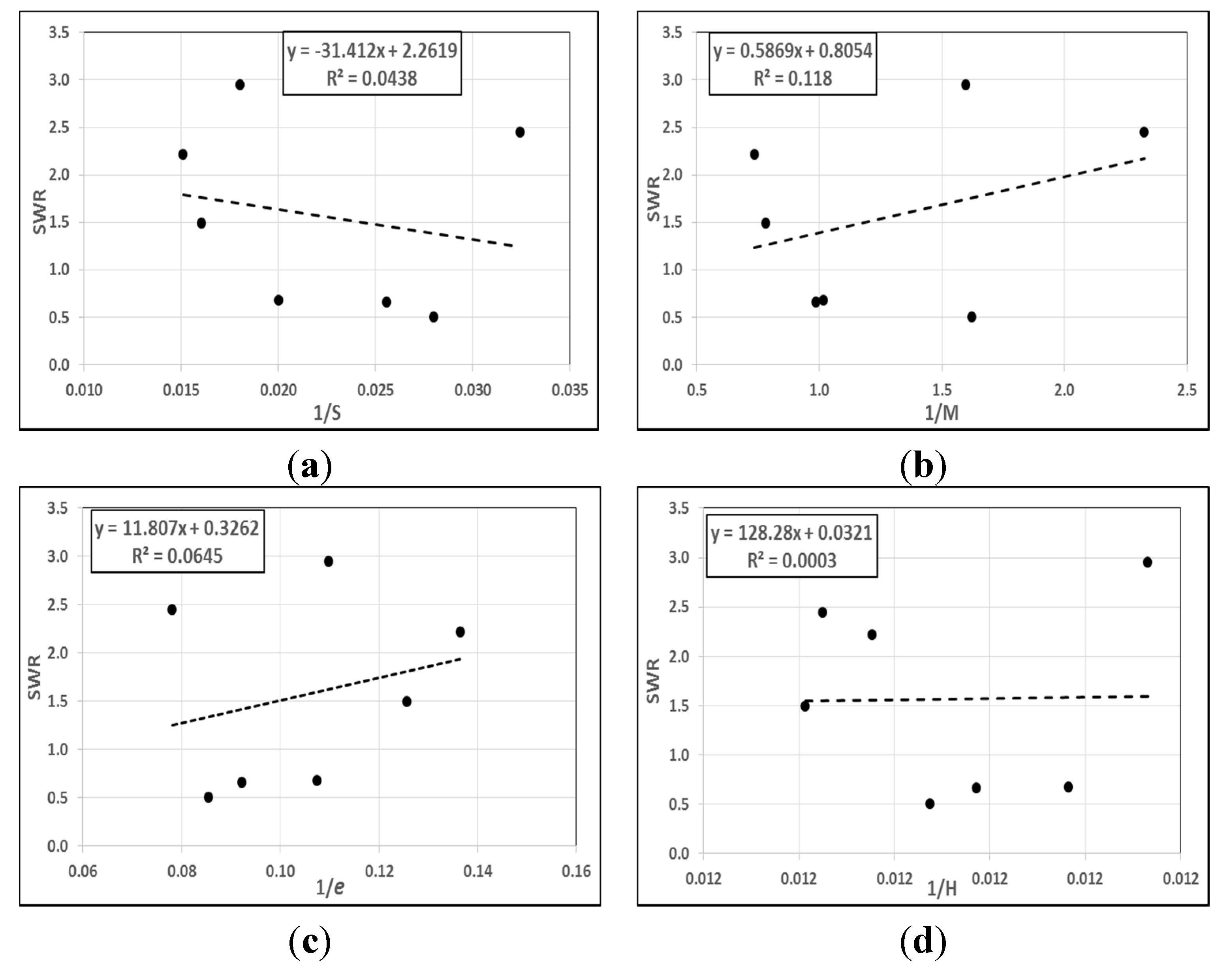

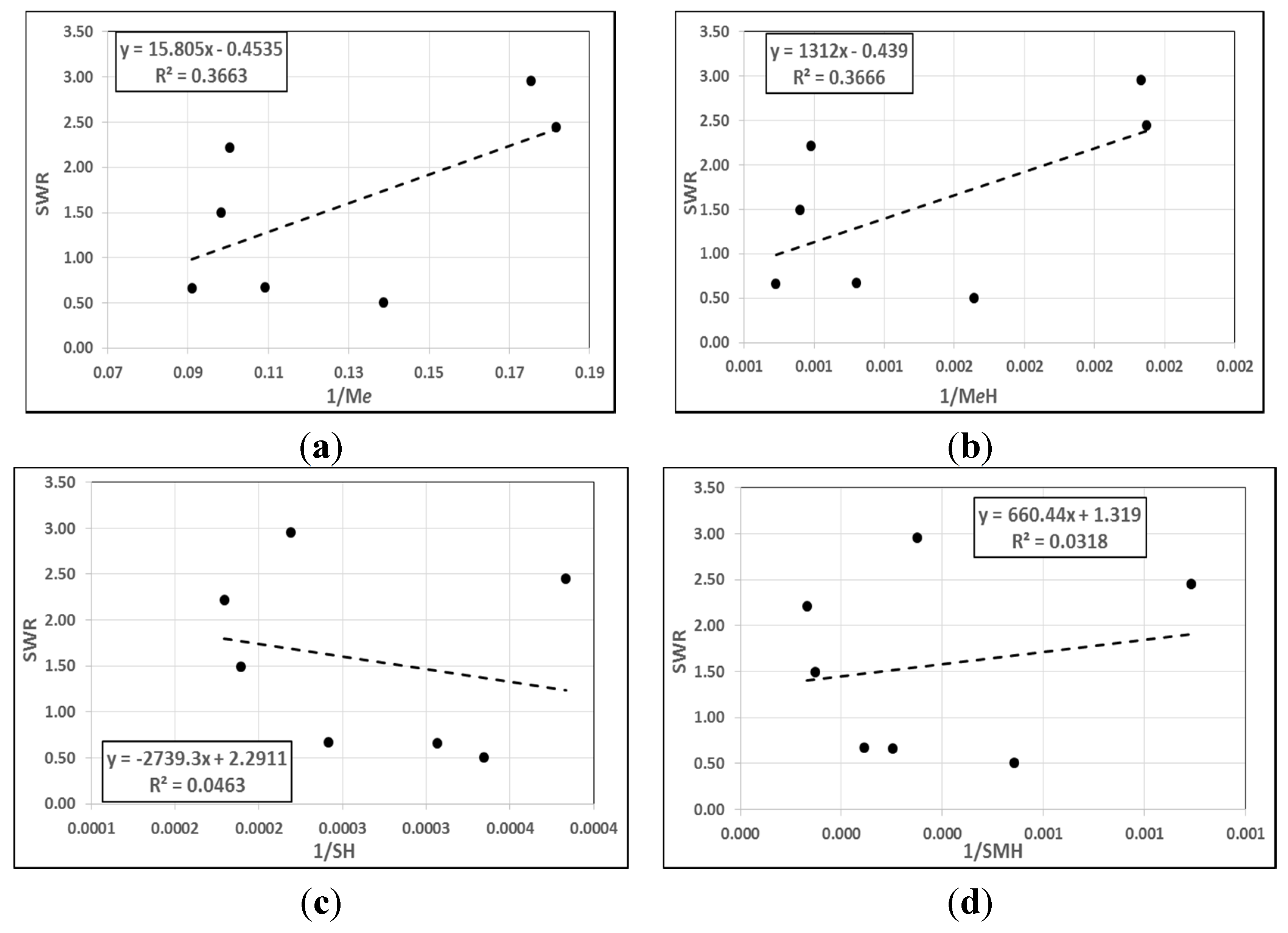

3.2.1. Specific Wear Rate and Mechanical Properties of Fillers/Epoxy Composites

| Factor | S−1 | M−1 | e−1 | H−1 | (SM)−1 | (Se)−1 | (SH)−1 | (Me)−1 |

|---|---|---|---|---|---|---|---|---|

| R2% | 4.38 | 11.8 | 6.45 | 0.03 | 3.17 | 9.36 | 4.63 | 36.63 |

| Factor | (MH)−1 | (eH)−1 | (SMe)−1 | (SMH)−1 | (SHe)−1 | (MeH)−1 | (SMeH)−1 | - |

| R2% | 12.06 | 6.7 | 6.27 | 3.18 | 10.33 | 36.66 | 6.39 | - |

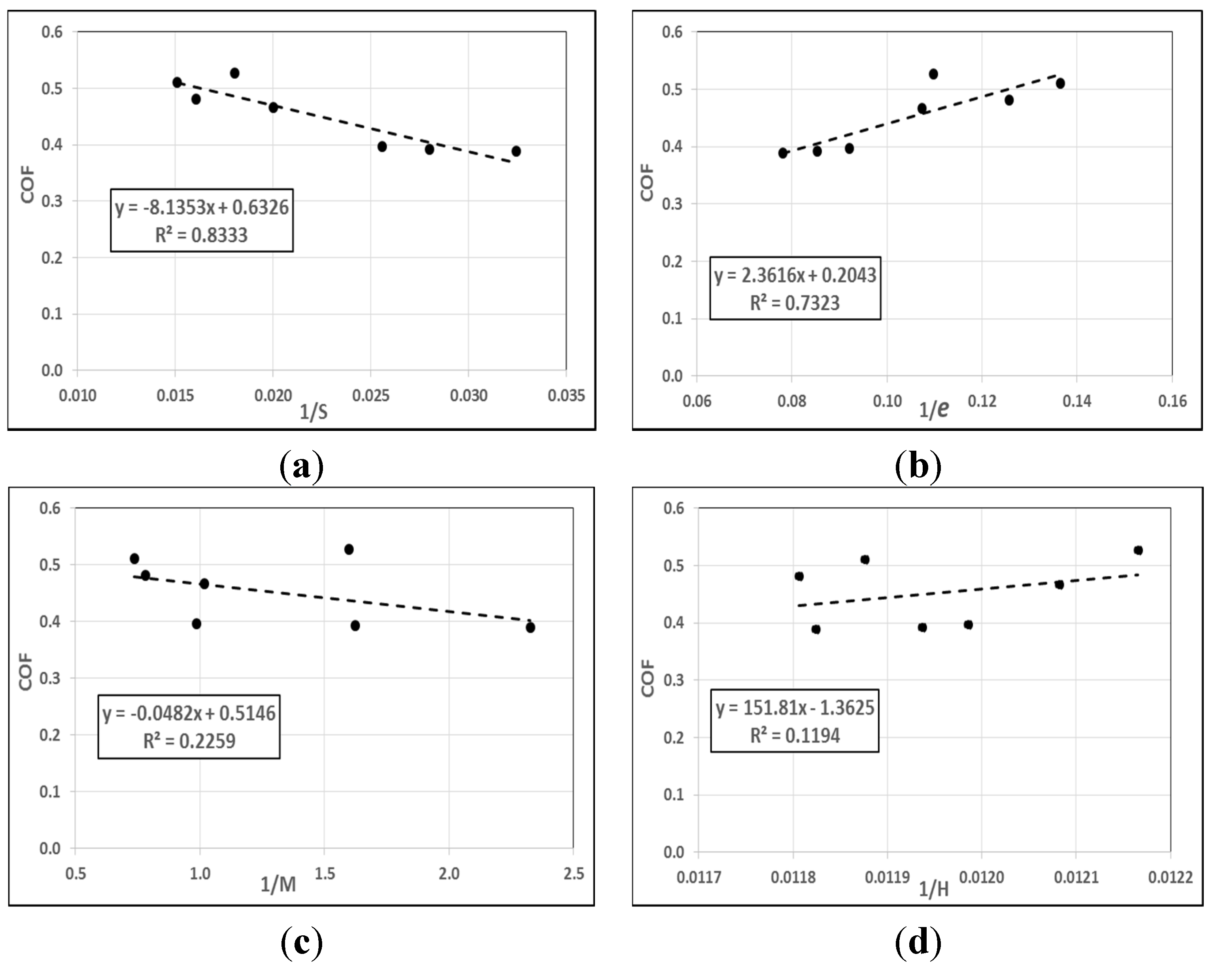

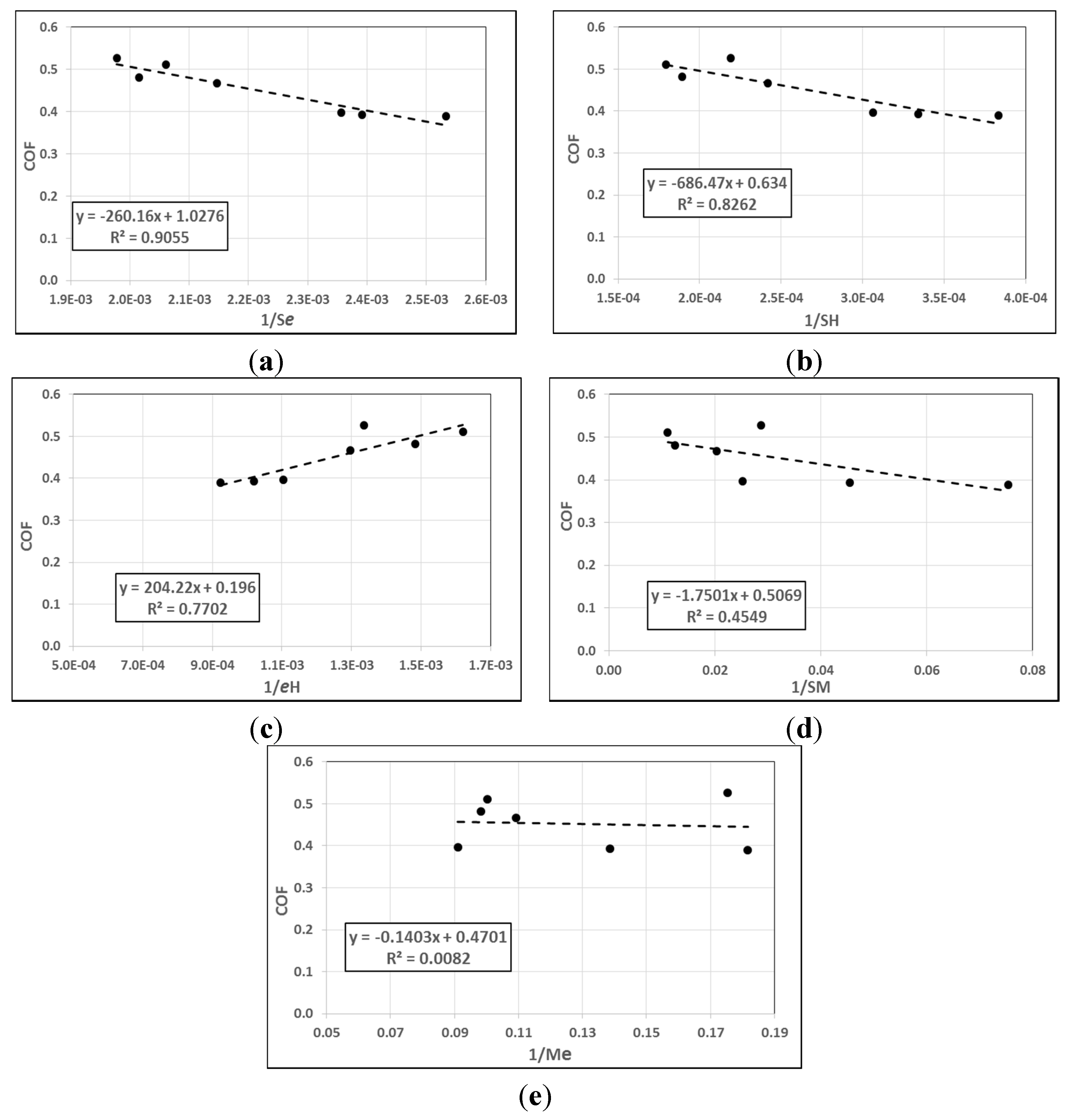

3.2.2. Coefficient of Friction and Mechanical Properties of Fillers/Epoxy Composites

| Factor | S−1 | M−1 | e−1 | H−1 | (SM)−1 | (Se)−1 | (SH)−1 | (Me)−1 |

|---|---|---|---|---|---|---|---|---|

| R2% | 83.3 | 22.6 | 73.2 | 11.9 | 45.5 | 90.55 | 82.62 | 0.82 |

| Factor | (MH)−1 | (eH)−1 | (SMe)−1 | (SMH)−1 | (SHe)−1 | (MeH)−1 | (SMeH)−1 | - |

| R2% | 21.37 | 77.02 | 35.61 | 45.14 | 89.29 | 0.46 | 34.78 | - |

4. Conclusions

- Graphite, as an additive to polymer composites, has led to eclectic effects on mechanical properties of graphite/epoxy composites, at the same time as affirmative effects on tribological properties of graphite/epoxy composites.

- Date palm fiber reinforced epoxy composites with or without graphite have shown an amended mechanical performance and slight improvement of the tribological performance.

- Correlation studies did not reveal any correlation between the mechanical properties and the specific wear rate.

- Tensile strength and elongation at the break play a significant role in the friction behavior of fillers/epoxy composite materials.

- The correlation results between the combination of mechanical properties with the COF are revealed:

- ○

- The modulus of elasticity had more influence on the COB compared to the hardness.

- ○

- Hardness has a wobbling correlation with COF.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Vishwanath, B.; Verma, A.P.; Rao, C.V.S.K. Effect of reinforcement on friction and wear of fabric reinforced polymer composites. Wear 1993, 167, 93–99. [Google Scholar] [CrossRef]

- Aldousiri, B.; Shalwan, A.; Chin, C.W. A review on tribological behaviour of polymeric composites and future reinforcements. Adv. Mater. Sci. Eng. 2013, 2013, 645923. [Google Scholar] [CrossRef]

- Hashmi, S.A.R.; Dwivedi, U.K.; Chand, N. Friction and sliding wear of UHMWPE modified cotton fibre reinforced polyester composites. Tribol. Lett. 2006, 21, 79–87. [Google Scholar] [CrossRef]

- Mylsamy, K.; Rajendran, I. Influence of fibre length on the wear behaviour of chopped agave americana fibre reinforced epoxy composites. Tribol. Lett. 2011, 44, 75–80. [Google Scholar] [CrossRef]

- Cenna, A.A.; Doyle, J.; Page, N.W.; Beehag, A.; Dastoor, P. Wear mechanisms in polymer matrix composites abraded by bulk solids. Wear 2000, 240, 207–214. [Google Scholar] [CrossRef]

- Shao, L.; Low, B.T.; Chung, T.S.; Greenberg, A.R. Polymeric membranes for the hydrogen economy: Contemporary approaches and prospects for the future. J. Membr. Sci. 2009, 327, 18–31. [Google Scholar] [CrossRef]

- Yousif, B.F. Effect of oil palm fibres volume fraction on mechanical properties of polyester composites. Int. J. Mod. Phys. B 2010, 24, 4459–4470. [Google Scholar] [CrossRef]

- Aldousiri, B.; Alajmi, M.; Shalwan, A. Mechanical properties of palm fibre reinforced recycled HDPE. Adv. Mater. Sci. Eng. 2013, 2013. [Google Scholar] [CrossRef]

- Cheung, H.Y.; Ho, M.P.; Lau, K.T.; Cardona, F.; Hui, D. Natural fibre-reinforced composites for bioengineering and environmental engineering applications. Compos. Part B Eng. 2009, 40, 655–663. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibres: Can they replace glass in fibre reinforced plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Thomas, S.; Pothan, L.A. Natural Fibre Reinforced Polymer Composites: From Macro to Nanoscale; Old City Publishing: Philadelphia, PA, USA, 2008; pp. 3–12. [Google Scholar]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Albdiry, M.T.; Yousif, B.F. Morphological structures and tribological performance of unsaturated polyester based untreated/silane-treated halloysite. Mater. Des. 2013, 48, 68–76. [Google Scholar]

- Yousif, B.F.; Nirmal, U. Wear and frictional performance of polymeric composites aged in various solutions. Wear 2011, 272, 97–104. [Google Scholar] [CrossRef]

- Pavlidou, S.; Papaspyrides, C.D. A review on polymer–layered silicate nanocomposites. Prog. Polym. Sci. 2008, 33, 1119–1198. [Google Scholar] [CrossRef]

- Alexandre, M.; Dubois, P. Polymer-layered silicate nanocomposites: Preparation, properties and uses of a new class of materials. Mater. Sci. Eng. R Rep. 2000, 28, 1–63. [Google Scholar] [CrossRef]

- Kiliaris, P.; Papaspyrides, C.D. Polymer/layered silicate (clay) nanocomposites: An overview of flame retardancy. Prog. Polym. Sci. 2010, 35, 902–958. [Google Scholar] [CrossRef]

- Yousif, B.F.; Shalwan, A.; Chin, C.W.; Ming, K.C. Flexural properties of treated and untreated kenaf/epoxy composites. Mater. Des. 2012, 40, 378–385. [Google Scholar] [CrossRef]

- Gopinath, A.; Kumar, M.S.; Elayaperumal, A. Experimental investigations on mechanical properties of jute fiber reinforced composites with polyester and epoxy resin matrices. Procedia Eng. 2014, 97, 2052–2063. [Google Scholar] [CrossRef]

- Li, J.; Wu, Z.; Huang, C.; Li, L. Multiscale carbon nanotube-woven glass fiber reinforced cyanate ester/epoxy composites for enhanced mechanical and thermal properties. Compos. Sci. Technol. 2014, 104, 81–88. [Google Scholar] [CrossRef]

- Withers, G.J.; Yu, Y.; Khabashesku, V.N.; Cercone, L.; Hadjiev, V.G.; Souza, J.M.; Davis, D.C. Improved mechanical properties of an epoxy glass–fiber composite reinforced with surface organomodified nanoclays. Compos. Part B Eng. 2015, 72, 175–182. [Google Scholar] [CrossRef]

- Kaymakci, A.; Ayrilmis, N. Investigation of correlation between Brinell hardness and tensile strength of wood plastic composites. Compos. Part B Eng. 2014, 58, 582–585. [Google Scholar] [CrossRef]

- Yousif, B.F.; El-Tayeb, N.S.M. Wear characteristics of thermoset composite under high stress three-body abrasive. Tribol. Int. 2010, 43, 2365–2371. [Google Scholar] [CrossRef]

- Fowler, G.; Pashby, I.R.; Shipway, P.H. The effect of particle hardness and shape when abrasive water jet milling titanium alloy Ti6Al4V. Wear 2009, 266, 613–620. [Google Scholar] [CrossRef]

- Harsha, A.P.; Tewari, U.S. Two-body and three-body abrasive wear behaviour of polyaryletherketone composites. Polym. Test. 2003, 22, 403–418. [Google Scholar] [CrossRef]

- Shipway, P.H.; Ngao, N.K. Microscale abrasive wear of polymeric materials. Wear 2003, 255, 742–750. [Google Scholar] [CrossRef]

- Arhaim, Y.H.; Shalwan, A.; Yousif, B.F. Correlation between frictional force, interface temperature and specific wear rate of fibre polymer composites. Adv. Mater. Res. 2013, 685, 45–49. [Google Scholar] [CrossRef]

- Yamaguchi, Y. Preface. In Tribology of Plastic Materials; Elsevier: Amsterdam, The Netherlands, 1990. [Google Scholar]

- Yamaguchi, Y. Their characteristics and applications to sliding components. In Tribology of Plastic Materials; Elsevier: Amsterdam, The Netherlands, 1990; pp. 93–141. [Google Scholar]

- Dwivedi, U.K.; Chand, N. Influence of MA-g-PP on abrasive wear behaviour of chopped sisal fibre reinforced polypropylene composites. J. Mater. Process. Technol. 2009, 209, 5371–5375. [Google Scholar] [CrossRef]

- Chand, N.; Dwivedi, U.K. Effect of coupling agent on abrasive wear behaviour of chopped jute fibre-reinforced polypropylene composites. Wear 2006, 261, 1057–1063. [Google Scholar] [CrossRef]

- Goriparthi, B.K.; Suman, K.N.S.; Rao, N.M. Effect of fiber surface treatments on mechanical and abrasive wear performance of polylactide/jute composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1800–1808. [Google Scholar] [CrossRef]

- Zhao, G.; Hussainova, I.; Antonov, M.; Wang, Q.; Wang, T. Friction and wear of fiber reinforced polyimide composites. Wear 2013, 301, 122–129. [Google Scholar] [CrossRef]

- Budinski, K.G. Resistance to particle abrasion of selected plastics. Wear 1997, 203–204, 302–309. [Google Scholar] [CrossRef]

- Harsha, A.P.; Tewari, U.S.; Venkatraman, B. Three-body abrasive wear behaviour of polyaryletherketone composites. Wear 2003, 254, 680–692. [Google Scholar] [CrossRef]

- Larsen-Basse, J.; Tadjvar, A. Slurry abrasion of polymers under simulated submarine conditions. Wear 1988, 122, 135–149. [Google Scholar] [CrossRef]

- American Society for Testing Materials. Standard Test Method for Tensile Properties of Plastics; ASTM D638-99; ASTM International: West Conshohocken, PA, USA, 2000. [Google Scholar]

- American Society for Testing Materials. Standard Test Method for Ranking Resistance of Materials to Sliding Wear Using Block-on-Ring Wear Test; ASTM G77-98; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- American Society for Testing Materials. Standard Test Method for Rubber Property—Durometer Hardness; ASTM International: West Conshohocken, PA, USA, 2005. [Google Scholar]

- Busick, D.N.; Spontak, R.J.; Balik, C.M. Effects of graphite content on the morphology and barrier properties of poly(vinylidene fluoride) composites. Polymer 1999, 40, 6023–6029. [Google Scholar] [CrossRef]

- Stachowiak, G.W. Wear: Materials, Mechanisms and Practice; Wiley: Hoboken, NJ, USA, 2005. [Google Scholar]

- Suresha, B.; Kumar, K.S.; Seetharamu, S.; Kumaran, P.S. Friction and dry sliding wear behavior of carbon and glass fabric reinforced vinyl ester composites. Tribol. Int. 2010, 43, 602–609. [Google Scholar] [CrossRef]

- Pihtili, H. An experimental investigation of wear of glass fibre–epoxy resin and glass fibre–polyester resin composite materials. Eur. Polym. J. 2009, 45, 149–154. [Google Scholar] [CrossRef]

- Bahadur, S.; Gong, D.; Anderegg, J. Investigation of the influence of CaS, CaO and CaF2 fillers on the transfer and wear of nylon by microscopy and XPS analysis. Wear 1996, 197, 271–279. [Google Scholar] [CrossRef]

- Friedrich, K.; Zhang, Z.; Schlarb, A.K. Effects of various fillers on the sliding wear of polymer composites. Compos. Sci. Technol. 2005, 65, 2329–2343. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alajmi, M.; Shalwan, A. Correlation between Mechanical Properties with Specific Wear Rate and the Coefficient of Friction of Graphite/Epoxy Composites. Materials 2015, 8, 4162-4175. https://doi.org/10.3390/ma8074162

Alajmi M, Shalwan A. Correlation between Mechanical Properties with Specific Wear Rate and the Coefficient of Friction of Graphite/Epoxy Composites. Materials. 2015; 8(7):4162-4175. https://doi.org/10.3390/ma8074162

Chicago/Turabian StyleAlajmi, Mahdi, and Abdullah Shalwan. 2015. "Correlation between Mechanical Properties with Specific Wear Rate and the Coefficient of Friction of Graphite/Epoxy Composites" Materials 8, no. 7: 4162-4175. https://doi.org/10.3390/ma8074162

APA StyleAlajmi, M., & Shalwan, A. (2015). Correlation between Mechanical Properties with Specific Wear Rate and the Coefficient of Friction of Graphite/Epoxy Composites. Materials, 8(7), 4162-4175. https://doi.org/10.3390/ma8074162