The Effect of Niobium Doping on the Electrical Properties of 0.4(Bi0.5K0.5)TiO3-0.6BiFeO3 Lead-Free Piezoelectric Ceramics

Abstract

:1. Introduction

2. Results and Discussion

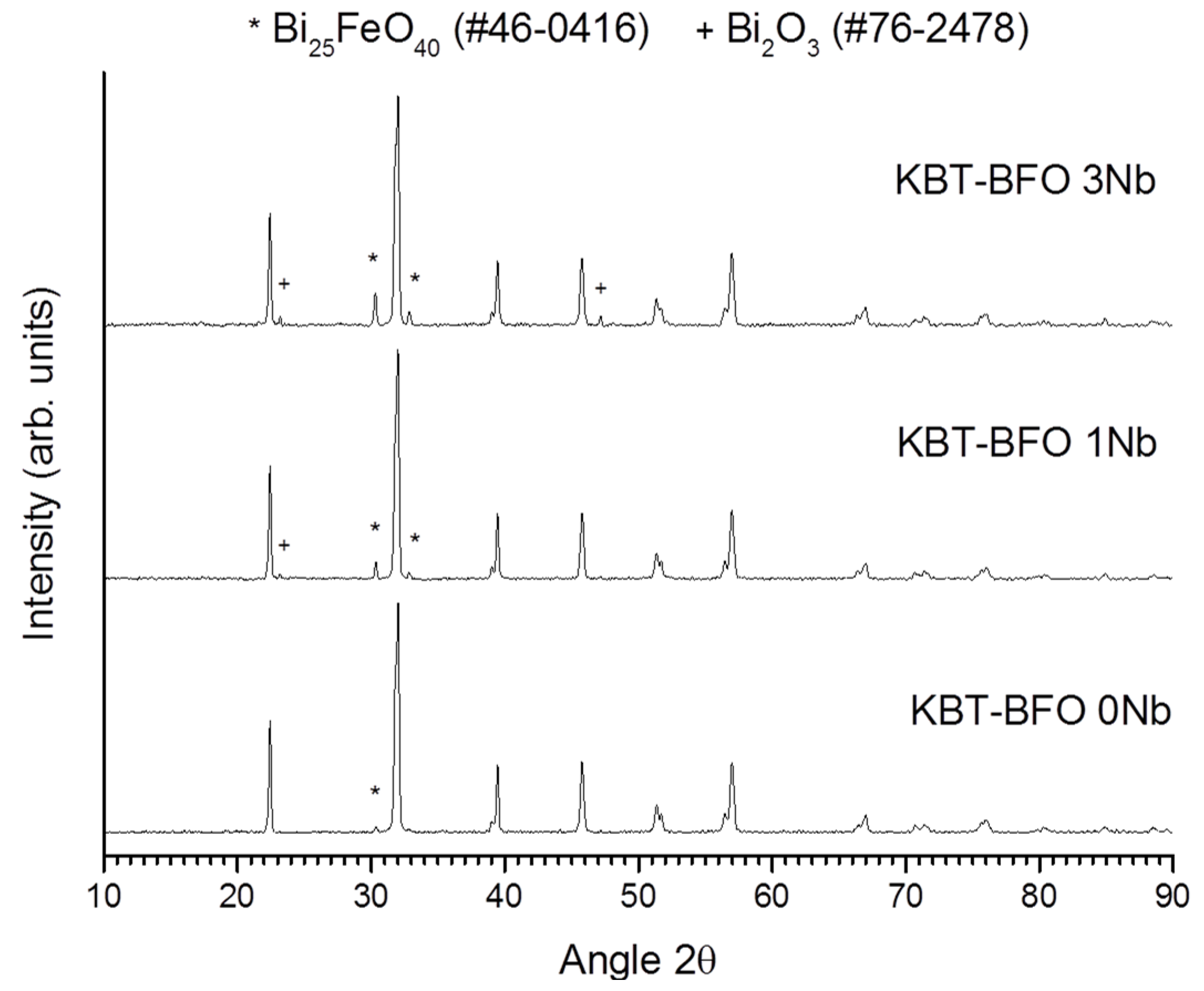

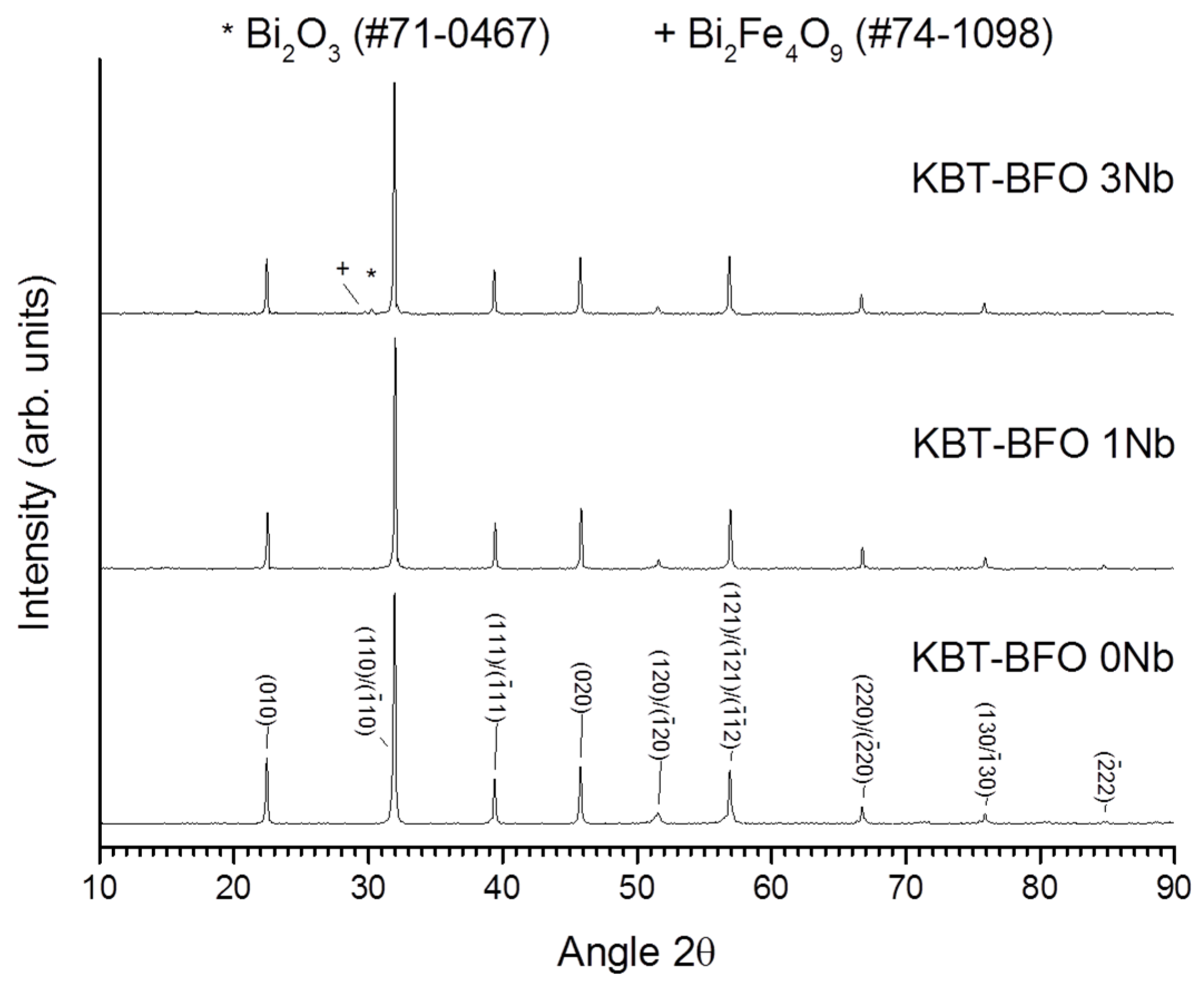

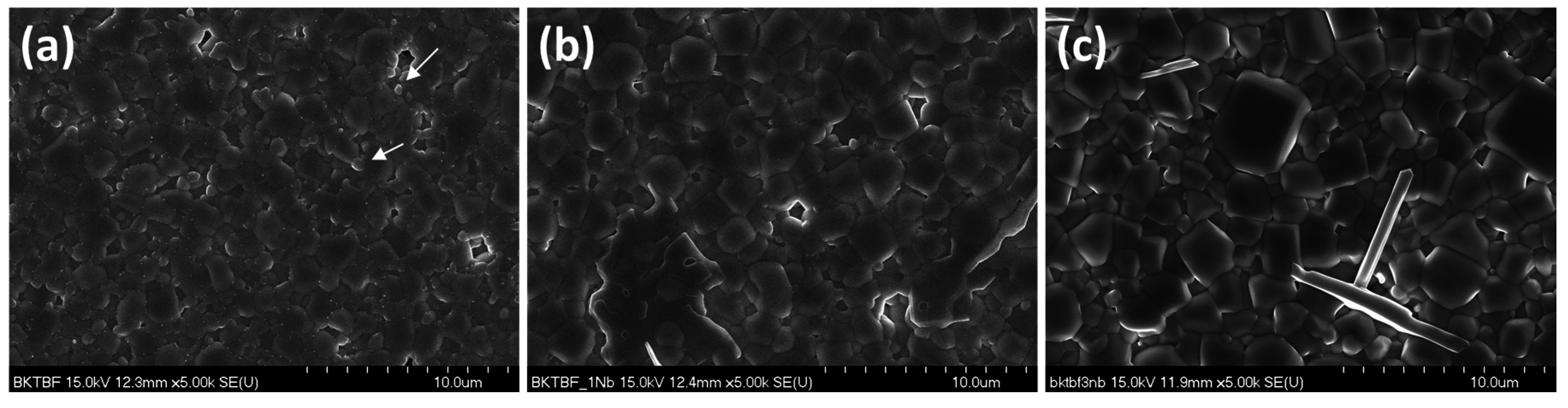

| Sample | Density (% Relative Density) | a Unit Cell Parameter (nm) | β (°) | Mean Grain Diameter (μm) |

|---|---|---|---|---|

| 0.4(K0.5Bi0.5)TiO3-0.6BiFeO3 | 98.9 ± 0.2 | 0.396218 (0.0000031) | 90.0195 (0.00082) | 0.9 ± 0.5 |

| 0.4(K0.5Bi0.5)Ti0.99Nb0.01O3-0.6BiFe0.99Nb0.01O3 | 98.5 ± 1.0 | 0.396243 (0.0000066) | 89.9882 (0.00276) | 1.3 ± 0.5 |

| 0.4(K0.5Bi0.5)Ti0.97Nb0.03O3-0.6BiFe0.97Nb0.03O3 | 98.4 ± 0.4 | 0.396437 (0.0000077) | 89.99 (0.00207) | 1.4 ± 0.6 |

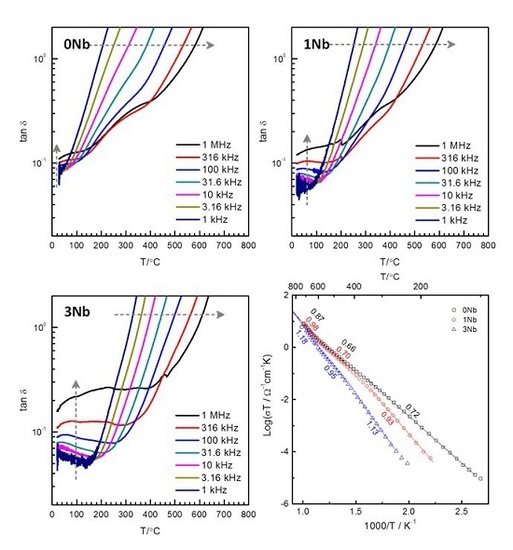

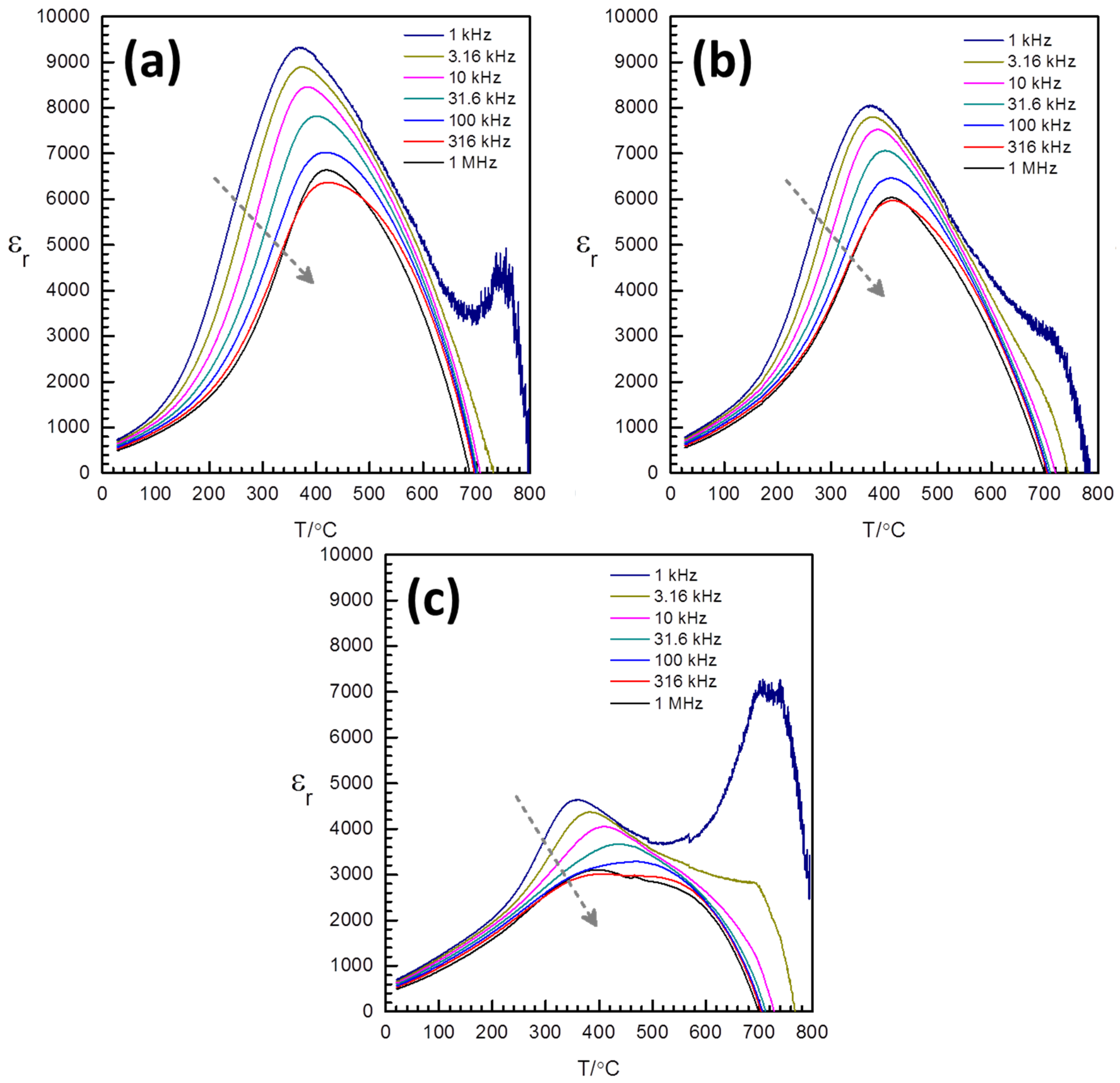

| Sample | εrmax (10 kHz/1 MHz) | Tmax (10 kHz/1 MHz) | tanδ (10 kHz/1 MHz, 40 °C) | σ (Ω−1·cm−1/300 °C) | σ (Ω−1·cm−1/30 °C) | d33 (pC/N) | Smax/Emax (pm/V) |

|---|---|---|---|---|---|---|---|

| 0.4(K0.5Bi0.5)TiO3-0.6BiFeO3 | 8460 | 384 °C | 0.08 | 3.38 × 10−5 | 1.57 × 10−10 | 20 | 90 |

| 6637 | 419 °C | 0.11 | |||||

| 0.4(K0.5Bi0.5)Ti0.99Nb0.01O3-0.6BiFe0.99Nb0.01O3 | 7527 | 387 °C | 0.07 | 1.36 × 10−5 | 1.25 × 10−12 | 13 | 65 |

| 6034 | 413 °C | 0.13 | |||||

| 0.4(K0.5Bi0.5)Ti0.97Nb0.03O3-0.6BiFe0.97Nb0.03O3 | 4050 | 412 °C | 0.07 | 1.09 × 10−6 | 2.69 × 10−15 | 11 | 56 |

| 3104 | 398 °C | 0.18 |

3. Experimental Section

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Teague, J.R.; Gerson, R.; James, W.J. Dielectric hysteresis in single crystal BiFeO3. Solid State Commun. 1970, 8, 1073–1074. [Google Scholar] [CrossRef]

- Kaczmarek, W.; Paja̧k, Z.; Połomska, M. Differential thermal analysis of phase transitions in (Bi1−xLax)FeO3 solid solution. Solid State Commun. 1975, 17, 807–810. [Google Scholar] [CrossRef]

- Lebeugle, D.; Colson, D.; Forget, A.; Viret, M. Very large spontaneous electric polarization in BiFeO3 single crystals at room temperature and its evolution under cycling fields. Appl. Phys. Lett. 2007, 91. [Google Scholar] [CrossRef]

- Yun, K.Y.; Ricinschi, D.; Kanashima, T.; Noda, M.; Okuyama, M. Giant ferroelectric polarization beyond 150 μC/cm2 in BiFeO3 thin film. Jpn. J. Appl. Phys. 2004, 43, L647–L648. [Google Scholar] [CrossRef]

- Rojac, T.; Bencan, A.; Drazic, G.; Kosec, M.; Damjanovic, D. Piezoelectric nonlinearity and frequency dispersion of the direct piezoelectric response of BiFeO3 ceramics. J. Appl. Phys. 2012, 112. [Google Scholar] [CrossRef]

- Rojac, T.; Kosec, M.; Damjanovic, D. Large electric-field induced strain in BiFeO3 Ceramics. J. Am. Ceram. Soc. 2011, 94, 4108–4111. [Google Scholar] [CrossRef]

- Rojac, T.; Kosec, M.; Budic, B.; Setter, N.; Damjanovic, D. Strong ferroelectric domain-wall pinning in BiFeO3 ceramics. J. Appl. Phys. 2010, 108. [Google Scholar] [CrossRef]

- Rojac, T.; Bencan, A.; Malic, B.; Tutuncu, G.; Jones, J.L.; Daniels, J.E.; Damjanovic, D. BiFeO3 ceramics: Processing, electrical, and electromechanical properties. J. Am. Ceram. Soc. 2014, 97, 1993–2011. [Google Scholar] [CrossRef]

- Valant, M.; Axelsson, A.-K.; Alford, N. Peculiarities of a solid-state synthesis of multiferroic polycrystalline BiFeO3. Chem. Mater. 2007, 19, 5431–5436. [Google Scholar] [CrossRef]

- Cen, Z.; Zhou, C.; Yang, H.; Zhou, Q.; Li, W.; Yuan, C. Structural, ferroelectric and piezoelectric properties of Mn-modified BiFeO3–BaTiO3 high-temperature ceramics. J. Mater. Sci. Mater. Electron. 2013, 24, 3952–3957. [Google Scholar] [CrossRef]

- Ning, H.X.; Lin, Y.; Hou, X.B.; Zhang, L.L. High thermally stable BiFeO3-PbTiO3-BaTiO3 ceramics with improved ferroelectric properties. J. Mater. Sci. Mater. Electron. 2014, 25, 1162–1166. [Google Scholar] [CrossRef]

- Leontsev, S.O.; Eitel, R.E. Dielectric and piezoelectric properties in Mn-modified (1−x)BiFeO3-xBaTiO3 ceramics. J. Am. Ceram. Soc. 2009, 92, 2957–2961. [Google Scholar] [CrossRef]

- Rödel, J.; Jo, W.; Seifert, K.T.P.; Anton, E.-M.; Granzow, T.; Damjanovic, D. Perspective on the development of lead-free piezoceramics. J. Am. Ceram. Soc. 2009, 92, 1153–1177. [Google Scholar] [CrossRef]

- Zhang, H.; Jo, W.; Wang, K.; Webber, K.G. Compositional dependence of dielectric and ferroelectric properties in BiFeO3-BaTiO3 solid solutions. Ceram. Int. 2014, 40, 4759–4765. [Google Scholar] [CrossRef]

- Yang, H.; Zhou, C.; Liu, X.; Zhou, Q.; Chen, G.; Wang, H.; Li, W. Structural, microstructural and electrical properties of BiFeO3-BaTiO3 ceramics with high thermal stability. Mater. Res. Bull. 2012, 47, 4233–4239. [Google Scholar] [CrossRef]

- Matsuo, H.; Noguchi, Y.; Miyayama, M.; Suzuki, M.; Watanabe, A.; Sasabe, S.; Ozaki, T.; Mori, S.; Torii, S.; Kamiyama, T. Structural and piezoelectric properties of high-density (Bi0.5K0.5)TiO3-BiFeO3 ceramics. J. Appl. Phys. 2010, 108. [Google Scholar] [CrossRef]

- Morozov, M.I.; Einarsrud, M.A.; Grande, T.; Damjanovic, D. Lead-free Relaxor-like 0.75Bi0.5K0.5TiO3-0.25BiFeO3 ceramics with large electric field-induced strain. Ferroelectrics 2012, 439, 88–94. [Google Scholar] [CrossRef] [Green Version]

- Morozov, M.I.; Einarsrud, M.-A.; Grande, T. Polarization and strain response in Bi0.5K0.5TiO3-BiFeO3 ceramics. Appl. Phys. Lett. 2012, 101. [Google Scholar] [CrossRef]

- Wu, J.G.; Wang, J.; Xiao, D.Q.; Zhu, J.G. Migration kinetics of oxygen vacancies in Mn-modified BiFeO3 thin films. ACS Appl. Mater. Interfaces 2011, 3, 2504–2511. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.J.; Lee, M.H.; Park, J.S.; Kim, M.H.; Song, T.K.; Kim, S.W.; Kim, W.J.; Jang, K.W.; Kim, S.S.; Do, D. Ferroelectric and piezoelectric properties of Mn-modified BiFeO3-BaTiO3 ceramics. J. Electroceram. 2014, 33, 37–41. [Google Scholar] [CrossRef]

- Fisher, J.; Kim, M.-G.; Kim, D.; Cha, S.-J.; Vu, H.; Nguyen, D.; Kim, Y.-H.; Moon, S.-H.; Lee, J.-S.; Hussain, A.; et al. Reactive sintering of (K0.5Bi0.5)TiO3-BiFeO3 lead-free piezoelectric ceramics. J. Korean Phys. Soc. 2015, 66, 1426–1438. [Google Scholar] [CrossRef]

- Kamiya, T.; Suzuki, T.; Tsurumi, T.; Daimon, M. Effects of manganese addition on piezoelectric properties of Pb(Zr0.5Ti0.5)O3. Jpn. J. Appl. Phys. 1992, 31, 3058–3060. [Google Scholar] [CrossRef]

- Yao, Z.; Liu, H.; Cao, M.; Hao, H.; Yu, Z. Effects of Mn doping on the structure and electrical properties of high-temperature BiScO3-PbTiO3-Pb(Zn1/3Nb2/3)O3 piezoelectric ceramics. Mater. Res. Bull. 2011, 46, 1257–1261. [Google Scholar] [CrossRef]

- Jun, Y.-K.; Moon, W.-T.; Chang, C.-M.; Kim, H.-S.; Ryu, H.S.; Kim, J.W.; Kim, K.H.; Hong, S.-H. Effects of Nb-doping on electric and magnetic properties in multi-ferroic BiFeO3 ceramics. Solid State Commun. 2005, 135, 133–137. [Google Scholar] [CrossRef]

- Wang, T.; Jin, L.; Tian, Y.; Shu, L.; Hu, Q.; Wei, X. Microstructure and ferroelectric properties of Nb2O5-modified BiFeO3-BaTiO3 lead-free ceramics for energy storage. Mater. Lett. 2014, 137, 79–81. [Google Scholar] [CrossRef]

- Fisher, J.G.; Park, H.A.; Song, Y.O.; Baek, S.J.; Vu, H.V.; Kim, J.H.; Lee, S.J. Sintering, microstructure and electrical properties of (Bi0.5K0.5)-BiFeO3 lead-free piezoelectric ceramics. J. Korean Phys. Soc. 2015; in press. [Google Scholar]

- Selbach, S.M.; Einarsrud, M.-A.; Grande, T. On the Thermodynamic Stability of BiFeO3. Chem. Mater. 2009, 21, 169–173. [Google Scholar] [CrossRef]

- Morozov, M.I.; Lomanova, N.A.; Gusarov, V.V. Specific features of BiFeO3 formation in a mixture of bismuth(III) and iron(III) oxides. Russ. J. Gen. Chem. 2003, 73, 1676–1680. [Google Scholar] [CrossRef]

- Maître, A.; François, M.; Gachon, J.C. Experimental study of the Bi2O3-Fe2O3 pseudo-binary system. J. Phase Equilibr. Diffus. 2004, 25, 59–67. [Google Scholar] [CrossRef]

- Mikhaĭlovich, F.V. Ferroelectric Semiconductors; Consultants Bureau: New York, NY, USA, 1980; p. 318. [Google Scholar]

- Pabst, G.W.; Martin, L.W.; Chu, Y.-H.; Ramesh, R. Leakage mechanisms in BiFeO3 thin films. Appl. Phys. Lett. 2007, 90, 072902. [Google Scholar] [CrossRef]

- Dong, G.H.; Tan, G.Q.; Luo, Y.Y.; Liu, W.L.; Xia, A.; Ren, H.J. Charge defects and highly enhanced multiferroic properties in Mn and Cu co-doped BiFeO3 thin films. Appl. Surf. Sci. 2014, 305, 55–61. [Google Scholar] [CrossRef]

- Dong, G.; Tan, G.; Luo, Y.; Liu, W.; Ren, H.; Xia, A. Structural transformation and multiferroic properties of single-phase Bi0.89Tb0.11Fe1−xMnxO3 thin films. Appl. Surf. Sci. 2014, 290, 280–286. [Google Scholar] [CrossRef]

- Yuan, G.L.; Or, S.W.; Wang, Y.P.; Liu, Z.G.; Liu, J.M. Preparation and multi-properties of insulated single-phase BiFeO3 ceramics. Solid State Commun. 2006, 138, 76–81. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, P.; Chen, L.; Wang, J. Density functional theory plus U study of vacancy formations in bismuth ferrite. Appl. Phys. Lett. 2010, 96, 232906. [Google Scholar] [CrossRef]

- Paudel, T.R.; Jaswal, S.S.; Tsymbal, E.Y. Intrinsic defects in multiferroic BiFeO3 and their effect on magnetism. Phys. Rev. B 2012, 85, 104409. [Google Scholar] [CrossRef]

- Vengalis, B.; Devenson, J.; Oginskis, A.K.; Butkutė, R.; Maneiks, A.; Steikūnienė, A.; Dapkus, L.; Banys, J.; Kinka, M. Growth and investigation of heterostructures based on multiferroic BiFeO3. Acta Phys. Pol. A 2008, 113, 1095–1098. [Google Scholar]

- Masó, N.; West, A.R. Electrical properties of Ca-doped BiFeO3 ceramics: From p-type semiconduction to oxide-ion conduction. Chem. Mater. 2012, 24, 2127–2132. [Google Scholar] [CrossRef]

- Makhdoom, A.R.; Akhtar, M.J.; Khan, R.T.A.; Rafiq, M.A.; Hasan, M.M.; Sher, F.; Fitch, A.N. Association of microstructure and electric heterogeneity in BiFeO3. Mat. Chem. Phys. 2013, 143, 256–262. [Google Scholar] [CrossRef]

- Morozov, M.I.; Einarsrud, M.A.; Grande, T. Control of conductivity and electric field induced strain in bulk Bi0.5K0.5TiO3-BiFeO3 ceramics. Appl. Phys. Lett. 2014, 104, 122905. [Google Scholar] [CrossRef]

- Shannon, R.D. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Crystall. A 1976, 32, 751–767. [Google Scholar] [CrossRef]

- Jin, L.; Li, F.; Zhang, S.J. Decoding the fingerprint of ferroelectric loops: Comprehension of the material properties and structures. J. Am. Ceram. Soc. 2014, 97, 1–27. [Google Scholar] [CrossRef]

- Jo, W.; Dittmer, R.; Acosta, M.; Zang, J.; Groh, C.; Sapper, E.; Wang, K.; Rödel, J. Giant electric-field-induced strains in lead-free ceramics for actuator applications—Status and perspective. J. Electroceram. 2012, 29, 71–93. [Google Scholar] [CrossRef]

- Bafandeh, M.; Gharahkhani, R.; Abbasi, M.; Saidi, A.; Lee, J.-S.; Han, H.-S. Improvement of piezoelectric and ferroelectric properties in (K,Na)NbO3-based ceramics via microwave sintering. J. Electroceram. 2014, 33, 128–133. [Google Scholar] [CrossRef]

- Bennett, J.; Shrout, T.R.; Shujun, Z.; Owston, H.E.; Stevenson, T.J.; Esat, F.; Bell, A.J.; Comyn, T.P. Variation of piezoelectric properties and mechanisms across the relaxor-like/ferroelectric continuum in BiFeO3-(K0.5Bi0.5)TiO3-PbTiO3 ceramics. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2015, 62, 33–45. [Google Scholar] [CrossRef] [PubMed]

- Bennett, J.; Bell, A.J.; Stevenson, T.J.; Smith, R.I.; Sterianou, I.; Reaney, I.M.; Comyn, T.P. Multiferroic properties of BiFeO3-(K0.5Bi0.5)TiO3 ceramics. Mater. Lett. 2013, 94, 172–175. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fisher, J.G.; Jang, S.-H.; Park, M.-S.; Sun, H.; Moon, S.-H.; Lee, J.-S.; Hussain, A. The Effect of Niobium Doping on the Electrical Properties of 0.4(Bi0.5K0.5)TiO3-0.6BiFeO3 Lead-Free Piezoelectric Ceramics. Materials 2015, 8, 8183-8194. https://doi.org/10.3390/ma8125457

Fisher JG, Jang S-H, Park M-S, Sun H, Moon S-H, Lee J-S, Hussain A. The Effect of Niobium Doping on the Electrical Properties of 0.4(Bi0.5K0.5)TiO3-0.6BiFeO3 Lead-Free Piezoelectric Ceramics. Materials. 2015; 8(12):8183-8194. https://doi.org/10.3390/ma8125457

Chicago/Turabian StyleFisher, John G., Seo-Hee Jang, Mi-So Park, Hengyang Sun, Su-Hyun Moon, Jong-Sook Lee, and Ali Hussain. 2015. "The Effect of Niobium Doping on the Electrical Properties of 0.4(Bi0.5K0.5)TiO3-0.6BiFeO3 Lead-Free Piezoelectric Ceramics" Materials 8, no. 12: 8183-8194. https://doi.org/10.3390/ma8125457

APA StyleFisher, J. G., Jang, S.-H., Park, M.-S., Sun, H., Moon, S.-H., Lee, J.-S., & Hussain, A. (2015). The Effect of Niobium Doping on the Electrical Properties of 0.4(Bi0.5K0.5)TiO3-0.6BiFeO3 Lead-Free Piezoelectric Ceramics. Materials, 8(12), 8183-8194. https://doi.org/10.3390/ma8125457