Effect of Annealing Temperature on the Water Contact Angle of PVD Hard Coatings

Abstract

:1. Introduction

2. Experimental Details

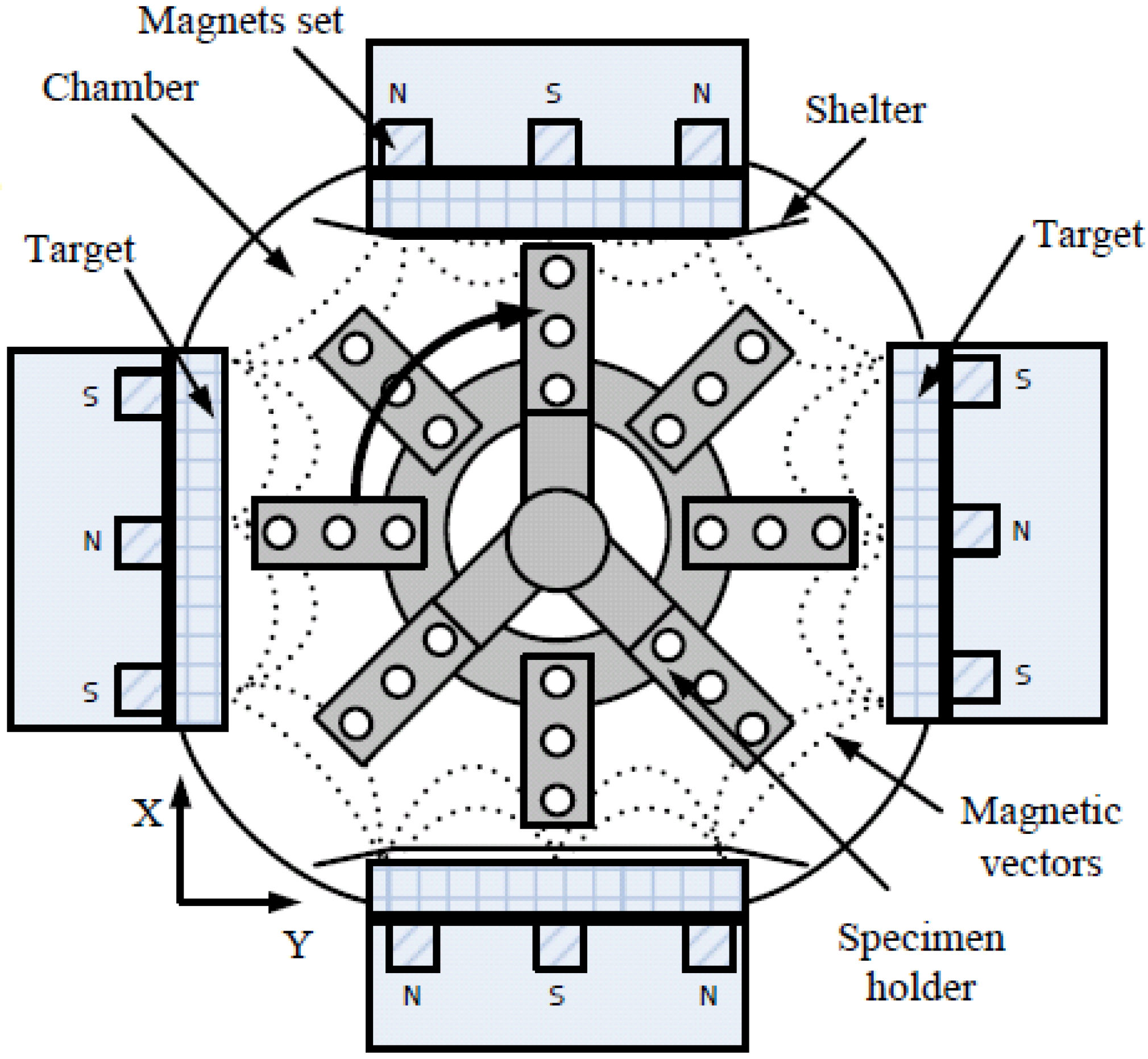

2.1. Coatings Preparation

| Coatings | AlN | Cr2N | (CrAl)2N | Si-DLC | Cr-DLC |

|---|---|---|---|---|---|

| Flow rate Ar/N2/C2H2 (sccm) | 30/12/0 | 34/16/0 | 30/20/0 | 35/0/0 | 25/5/20 |

| Working pressure (Pa) | 0.40 | 0.41 | 0.47 | 0.38 | 0.43 |

| Target materials | Al × 2 | Cr × 2 | Cr × 3 + Al × 1 | C × 3 + Si × 1 | Cr × 2 |

| Target current (A) | Al 6A | Cr 5A | Cr 4A + (Cr + Al) 1A | C 3A + (C + Si) 1.5A | Cr 5A |

| Substrate Bias Frequency (kHz) | 40 | 130 | 150 | 100 | 70 |

| Negative bias of substrate (−V) | 100 | 50 | 100 | 60 | 75 |

| Rotation speed of specimen (rpm) | 5 | 9 | 7 | 9 | 9 |

| Distance, target to specimen (cm) | 7 | 11 | 11 | 9 | 13 |

| Deposition time (min) | 420 | 25 | 60 | 150 | 80 |

| As-deposited roughness (nm) | 54 | 4 | 13 | 3 | 6 |

| Annealing temperature (°C) | 300, 600–800 | 300–800 | 300, 600–800 | 200–600 | 200, 300 |

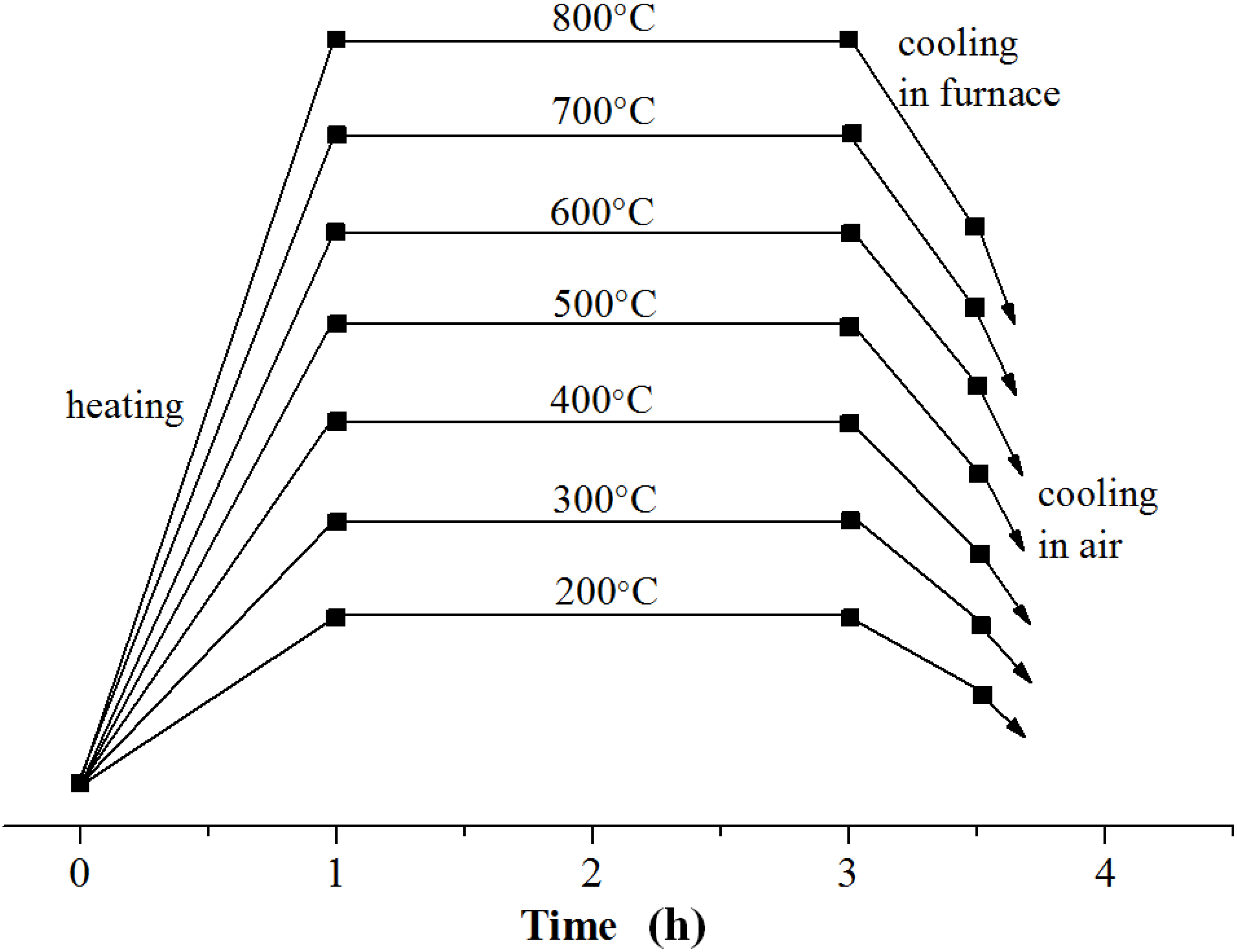

2.2. Post Annealing of Coatings

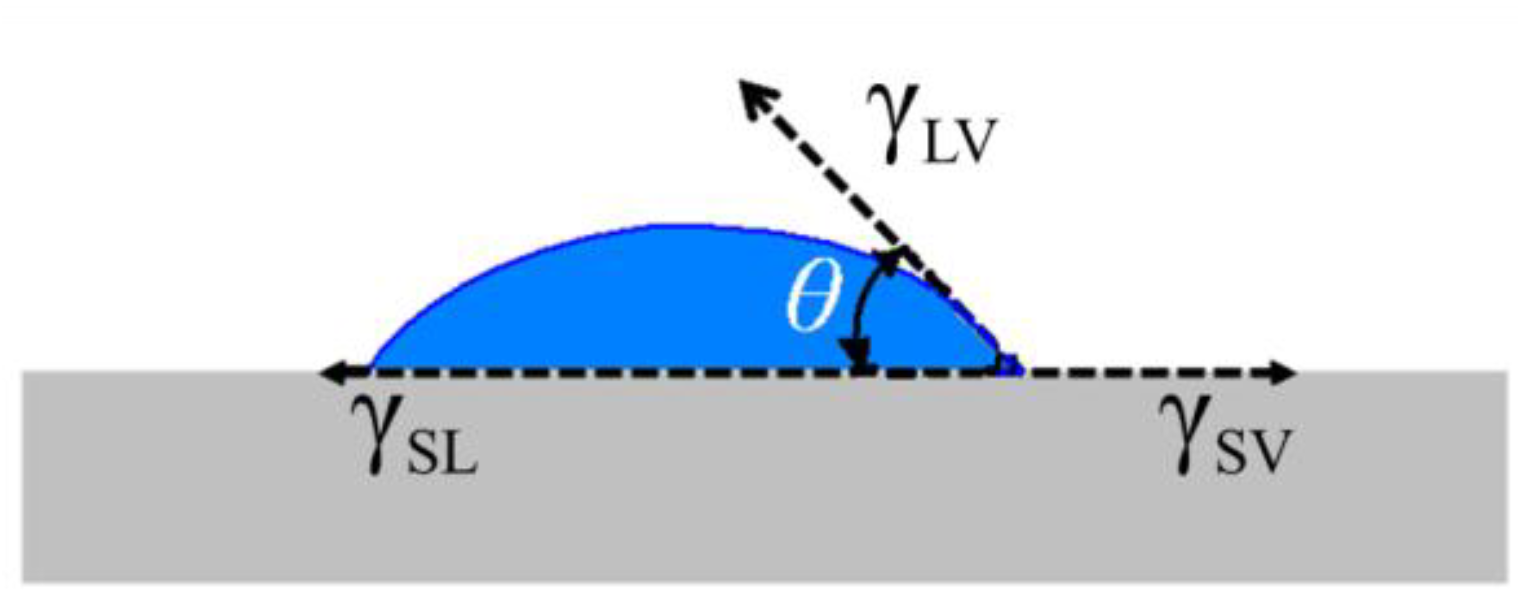

2.3. Characterization

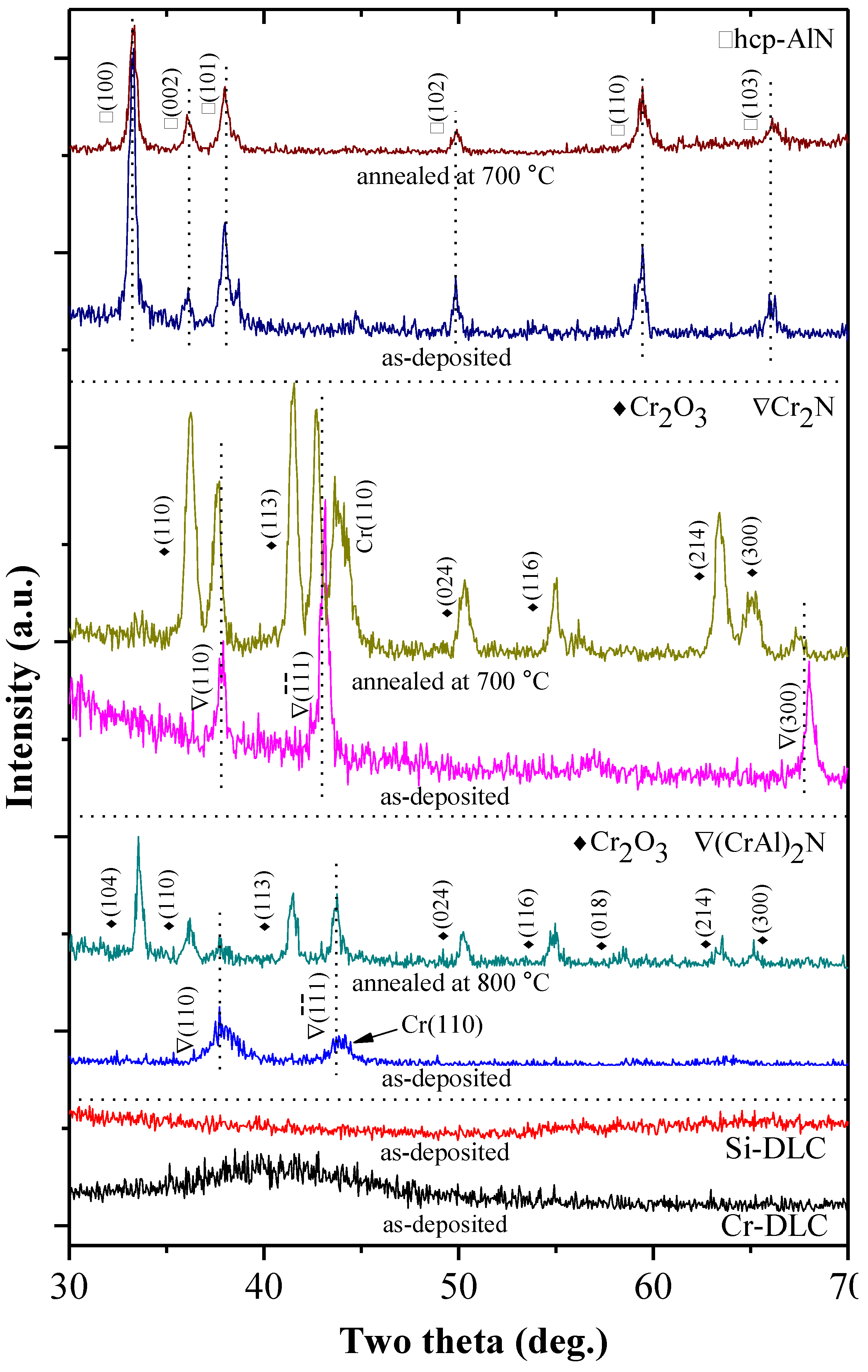

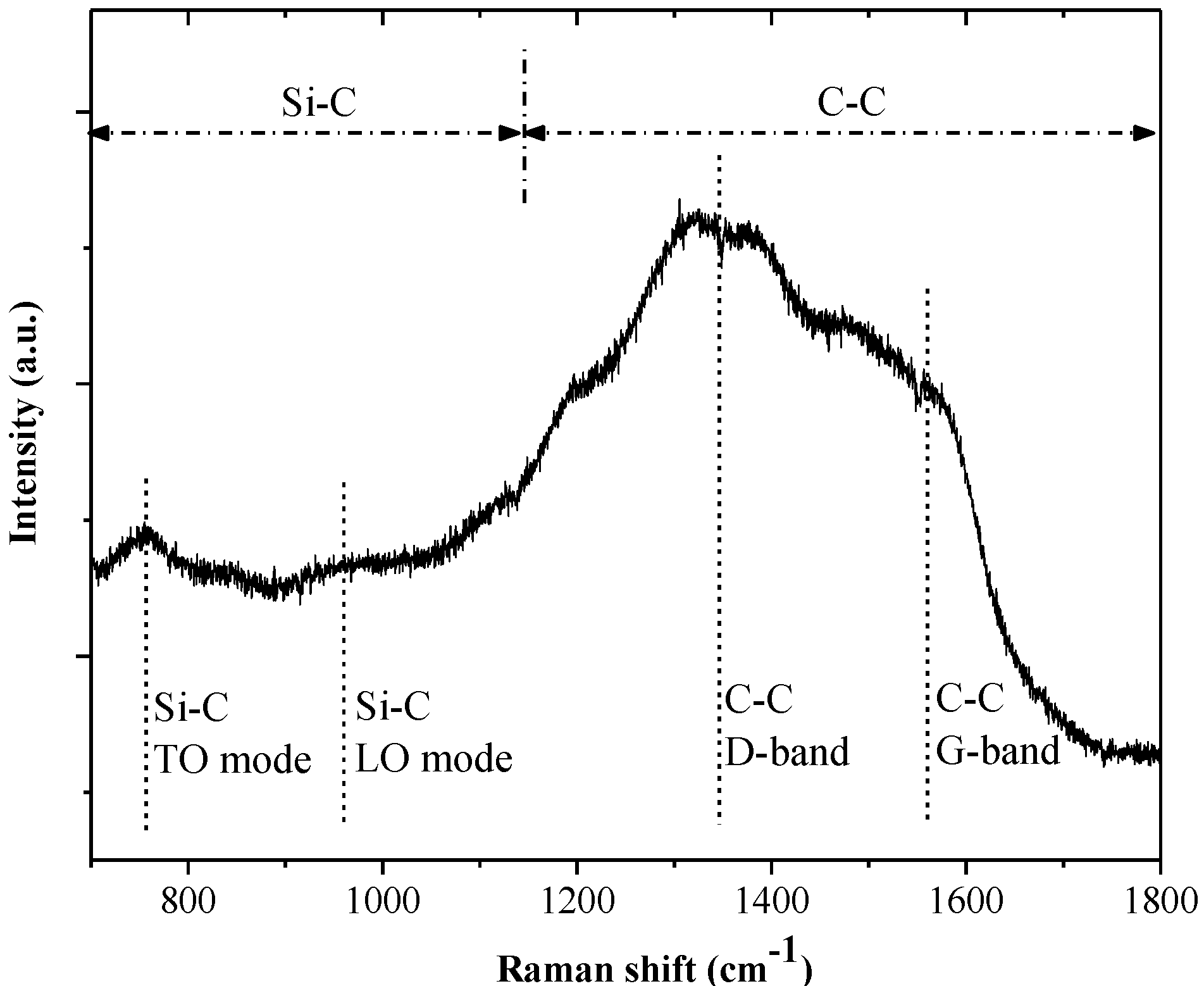

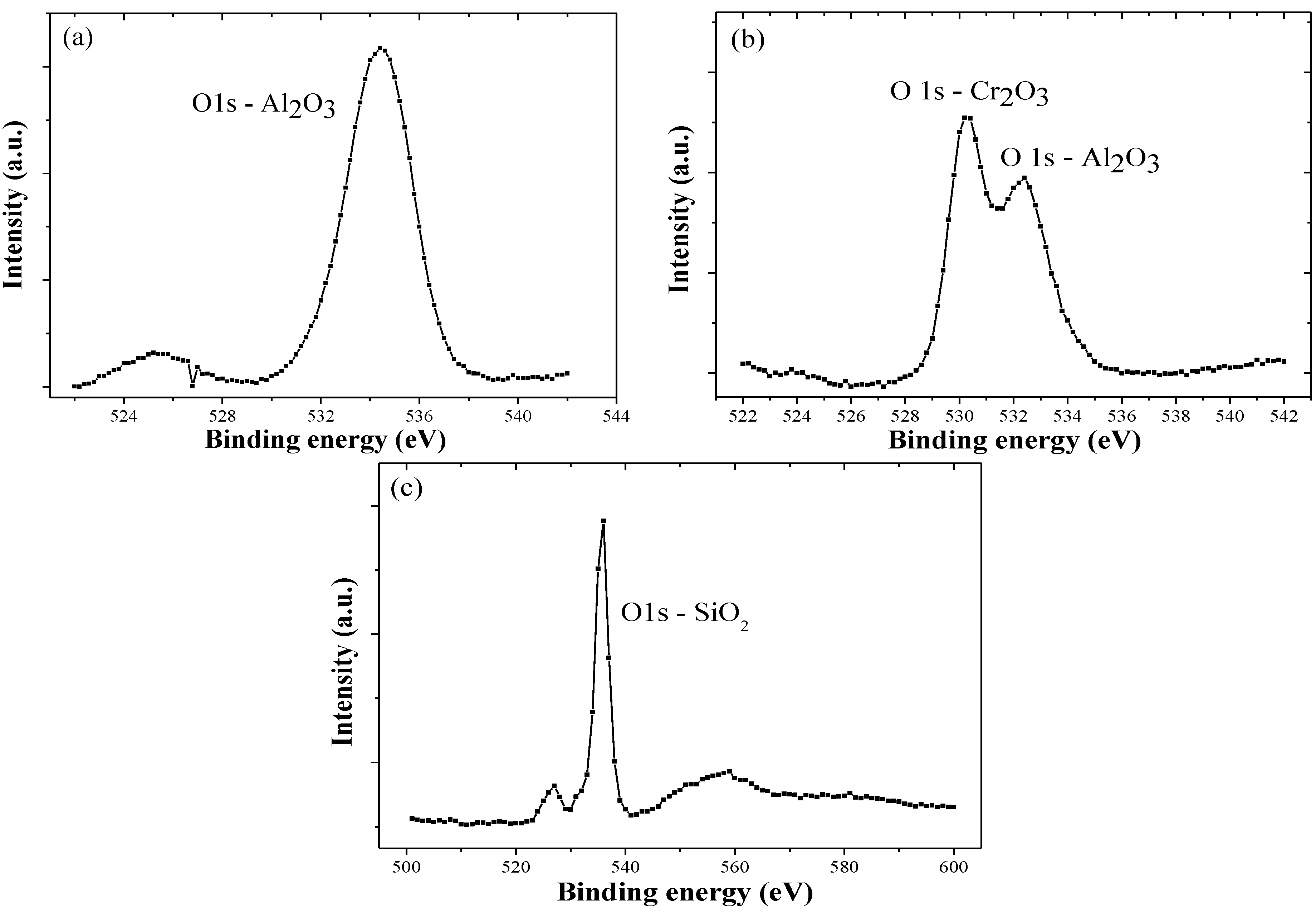

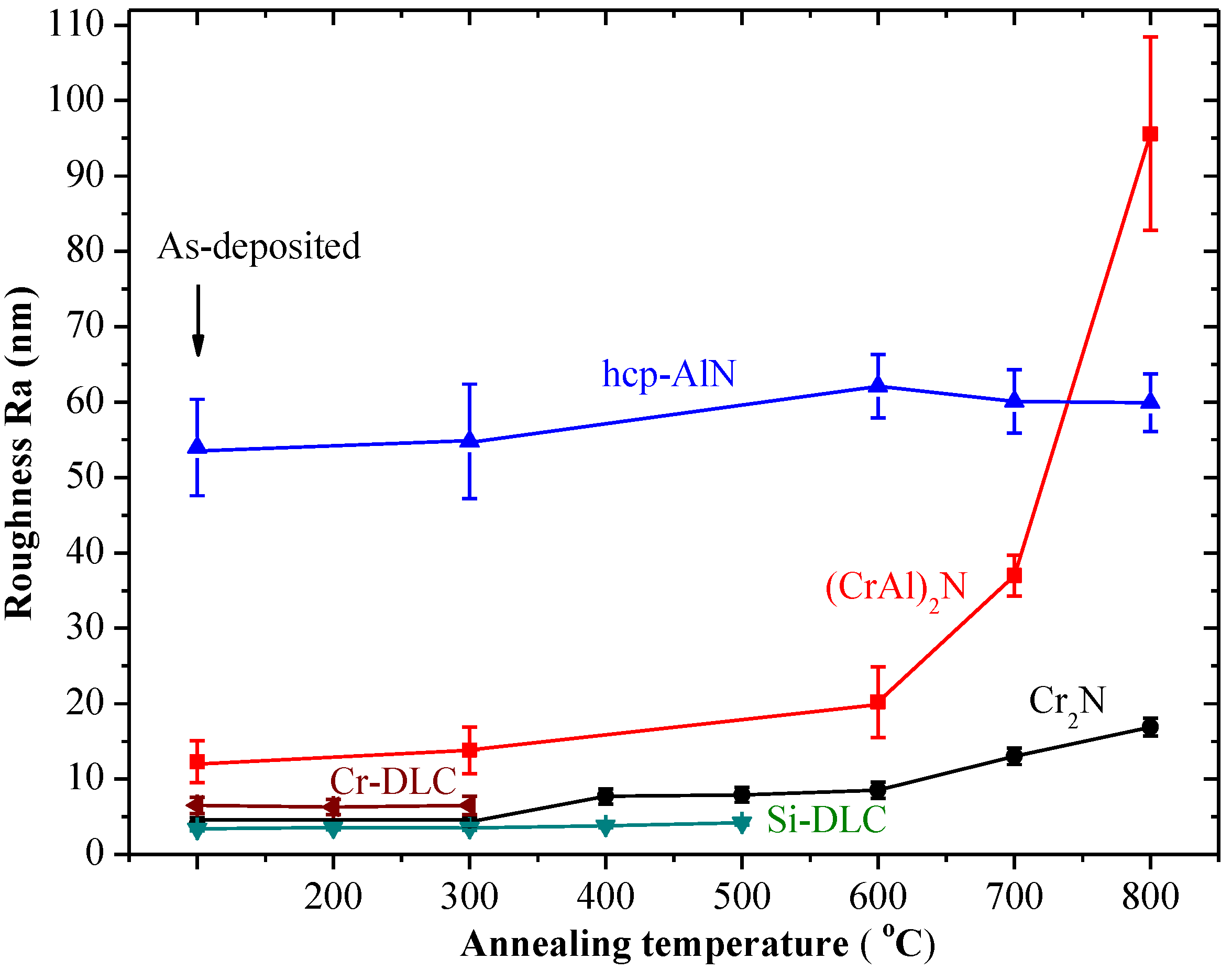

3. Results and Discussion

4. Conclusions

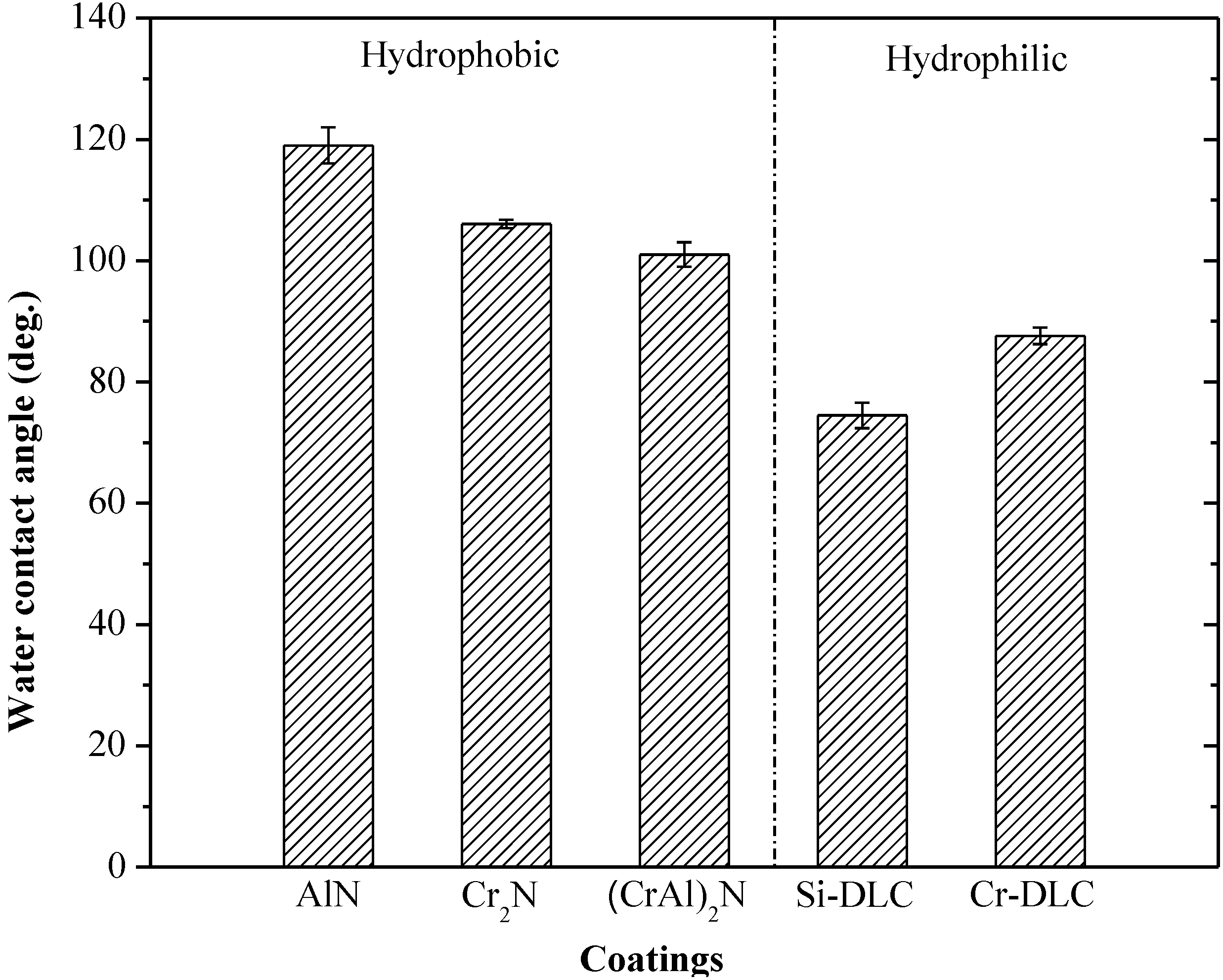

- The as-deposited hcp-AlN, Cr2N and (CrAl)2N coatings exhibit hydrophobic behavior and respectively possess WCAs of 119°, 106° and 101°. On the contrary, the as-deposited Si-DLC and Cr-DLC coatings exhibit hydrophilic behavior and respectively possess WCAs of 74° and 88°.

- The annealed Cr2N and (CrAl)2N coatings are characterized by hydrophobic behavior with higher degrees of WCA. The annealed hcp-AlN coating is characterized by hydrophilic behavior and differs from the as-deposited one. Both the annealed Si-DLC and Cr-DLC are hydrophilic.

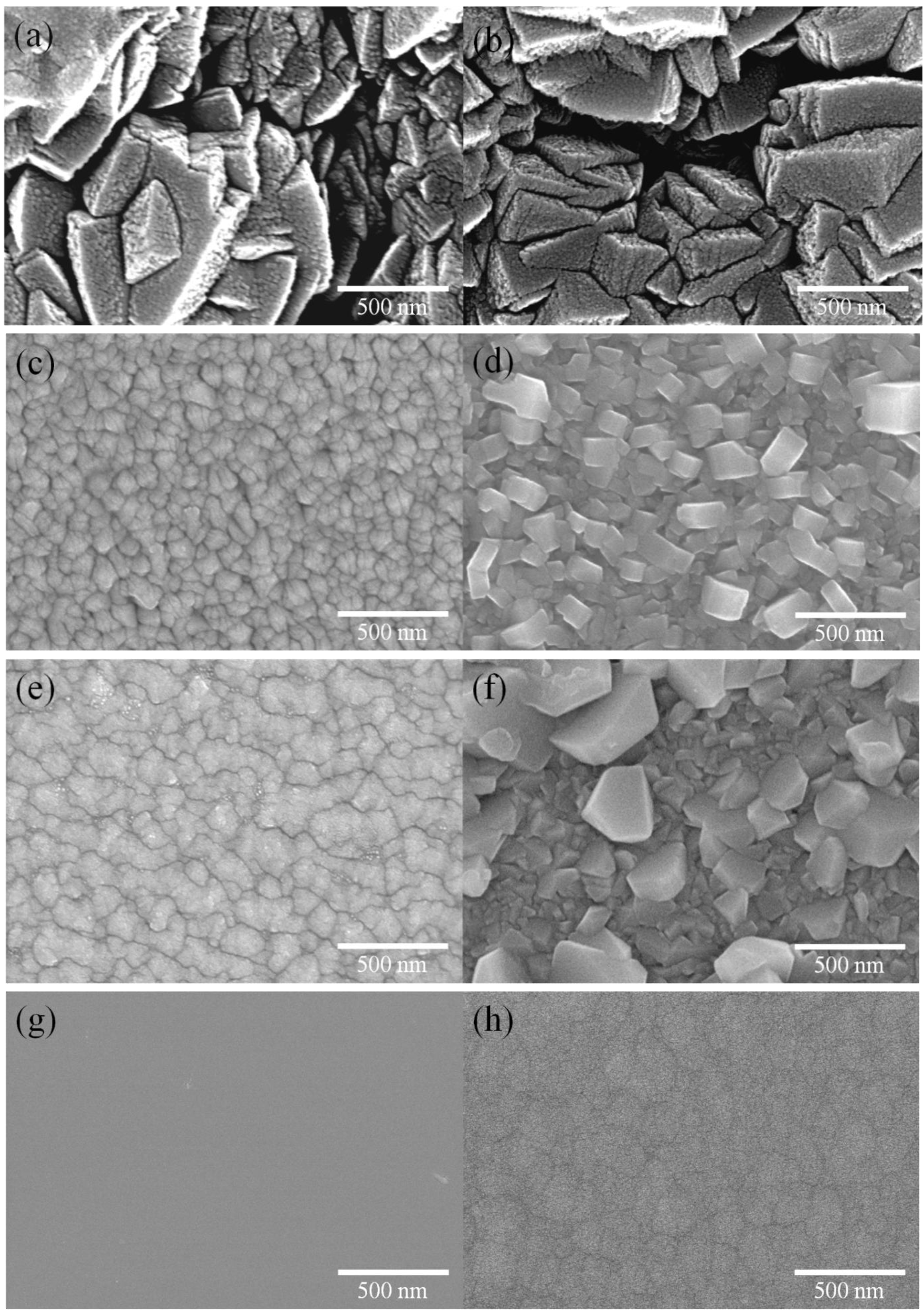

- The annealed Cr2N coating exhibits the best anti-sticking property with the highest WCA. As the annealing temperature rises to 700 °C, the WCA increases to 115°. The increase of WCA is the result of the retained Cr2N and the increased roughness. According to the roughness results as shown by SEM and XRD, the rougher surface of the annealed Cr2N and (CrAl)2N is due to the formation and growth of Cr2O3 crystals on the coating’s surface.

- For the 600 °C annealed (CrAl)2N coating, the WCA decreases to 90° and the roughness only slightly increases to 20 nm. The decrease of the WCA is caused by the formation of the Cr2O3 and Al2O3 on the coating surface. The WCA of the 800 °C annealed (CrAl)2N coating has a WCA of 101° with retained (CrAl)2N and a rougher surface. The increase in WCA is caused by the retained (CrAl)2N and increased roughness.

- There is no obvious difference of roughness between the as-deposited and the annealed hcp-AlN coatings. The lower WCA of the annealed hcp-AlN coatings is related to the Al2O3 thin film on the coating, meaning that the WCA of the annealed hcp-AlN is related to the crystal structure and has little correlation with roughness.

- The roughness of both the as-deposited and annealed Si-DLC and Cr-DLC coatings is stable. This indicates that the WCAs of the annealed Si-DLC and Cr-DLC coatings are related to the crystal structure and has little correlation with roughness.

Acknowledgments

Conflict of Interest

References

- Pradhan, S.K.; Nouveau, C.; Vasin, A.; Djouadi, M.-A. Deposition of CrN coatings by PVD methods for mechanical application. Surf. Coat. Technol. 2005, 200, 141–145. [Google Scholar] [CrossRef]

- Martínez, E.; Romero, J.; Lousa, A.; Esteve, J. Wear behavior of nanometric CrN/Cr multilayers. Surf. Coat. Technol. 2003, 163–164, 571–577. [Google Scholar] [CrossRef]

- Kamiya, M.; Tanoue, H.; Takikawa, H.; Taki, M.; Hasegawa, Y.; Kumagai, M. Preparation of various DLC films by T-shaped filtered arc deposition and the effect of heat treatment on film properties. Vacuum 2009, 83, 510–514. [Google Scholar] [CrossRef]

- Esteve, J.; Romero, J.; Gómez, M.; Lousa, A. Cathodic chromium carbide coatings for molding die applications. Surf. Coat. Technol. 2004, 188–189, 506–510. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Kuklinski, Z.; Myslinski, P. Hard CrCN/CrN multilayer coatings for tribological applications. Surf. Coat. Technol. 2010, 204, 2289–2293. [Google Scholar] [CrossRef]

- Van Stappen, M.; Vandierendonck, K.; Mol, C.; Beeckman, E.; de Clercq, E. Practice vs. laboratory tests for plastic injection moulding. Surf. Coat. Technol. 2001, 142–144, 143–145. [Google Scholar]

- Chiu, S.M.; Hwang, S.J.; Chu, C.W.; Gan, D. The influence of Cr-based coating on the adhesion force between epoxy molding compounds and IC encapsulation mold. Thin Solid Films 2006, 515, 285–292. [Google Scholar] [CrossRef]

- Zheng, L.J.; Wu, X.D.; Lou, Z.; Wu, D. Superhydrophobicity from microstructured surface. Sci. Bull. 2004, 49, 1779–1787. [Google Scholar] [CrossRef]

- Cai, F.; Huang, X.; Yang, Q.; Wei, R.H.; Nagy, D. Microstructure and tribological properties of CrN and CrSiCN coatings. Surf. Coat. Technol. 2010, 205, 182–188. [Google Scholar] [CrossRef]

- Kong, Q.H.; Jia, L.; Li, H.X.; Liua, X.H.; Wang, Y.J.; Chen, J.M.; Zhou, H.D. Composition, microstructure, and properties of CrNx films deposited using medium frequency magnetron sputtering. Appl. Surf. Sci. 2011, 257, 2269–2274. [Google Scholar] [CrossRef]

- Cakan, A.; Ozkaner, V.; Yildirim, M.M. Quantifying cutting and wearing behaviors of TiN- and CrN-coated AISI 1070 steel. Sensors 2008, 8, 6984–6998. [Google Scholar] [CrossRef]

- Bewilogua, K.; Cooper, C.V.; Specht, C.; Schröder, J.; Wittorf, R. Effect of target material on deposition and properties of metal-containing DLC (Me-DLC) coatings. Surf. Coat. Technol. 2000, 127, 224–232. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Wang, L.P.; Zhang, G.G.; Wang, Y.X.; Wang, Y.F.; Sun, X.J.; Xue, Q.J. TiC/a-C:H nanocomposite coatings as substitute for MoS2-based solid lubrication in helium atmosphere. J. Non-Cryst. Solids 2012, 358, 65–71. [Google Scholar] [CrossRef]

- Qi, J.W.; Wang, L.P.; Yan, F.Y.; Xue, Q.J. The tribological performance of DLC-based coating under the solid–liquid lubrication system with sand-dust particles. Wear 2013, 297, 972–985. [Google Scholar] [CrossRef]

- Liu, X.F.; Wang, L.P.; Xue, Q.J. DLC-based solid–liquid synergetic lubricating coatings for improving tribological behavior of boundary lubricated surfaces under high vacuum condition. Wear 2011, 271, 889–898. [Google Scholar] [CrossRef]

- Huang, M.-S.; Yang, Y.-S.; Hsu, W.-S.; Nian, S.-C. Effect of mold surface antistiction treatment on microinjection replication quality using Cr-N/Zr-DLC thin-layer coating. J. Polym. Eng. 2012, 32, 389–399. [Google Scholar]

- Calvimontes, A.; Mauermann, M.; Bellmann, C. Topographical anisotropy and wetting of ground stainless steel surfaces. Materials 2012, 5, 2773–2787. [Google Scholar] [CrossRef]

- Hakovirta, M.; Verda, R.; He, X.M.; Nastasi, M. Heat resistance of fluorinated diamond-like carbon films. Diam. Relat. Mater. 2001, 10, 1486–1490. [Google Scholar] [CrossRef]

- Lin, J.; Mishra, B.; Moore, J.J.; Sproul, W.D. A study of the oxidation behavior of CrN and CrAlN thin films in air using DSC and TGA analyses. Surf. Coat. Technol. 2008, 202, 3272–3283. [Google Scholar] [CrossRef]

- Young, T. An essay on the cohesion of fluids. Philos. Trans. R. Soc. Lond. 1805, 95, 65–87. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Keghelian, P.; Melinon, P.; Perez, A. Properties of silicon and silicon-carbon cluster assembled films. Nanostruct. Mater. 1999, 12, 277–280. [Google Scholar] [CrossRef]

- Song, D.Y.; Cho, E.-C.; Cho, Y.-H.; Conibeer, G.; Huang, Y.D.; Huang, S.J.; Green, M.A. Evolution of Si (and SiC) nanocrystal precipitation in SiC matrix. Thin Solid Films 2008, 516, 3824–3830. [Google Scholar] [CrossRef]

- Yang, C.; Tartaglino, U.; Persson, B.N.J. Influence of surface roughness on superhydrophobicity. Phys. Rev. Lett. 2006, 97, 116103:1–116103:4. [Google Scholar]

- Kijlstra, J.; Reihs, K.; Klamt, A. Roughness and topology of ultra-hydrophobic surfaces. Colloids Surf. A Phys. Eng. Asp. 2002, 206, 521–529. [Google Scholar] [CrossRef]

- Kolasinski, K.W. Surface Science: Foundations of Catalysis and Nanoscience, 2nd ed.; Wiley: Chichester, UK, 2008; pp. 255–294. [Google Scholar]

- Nakamura, M.; Kobayashi, M.; Kuzuya, N.; Komatsu, T.; Mochizuka, T. Hydrophilic property of SiO2/TiO2 double layer films. Thin Solid Films 2006, 502, 121–124. [Google Scholar] [CrossRef]

© 2013 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Yang, Y.-S.; Cho, T.-P. Effect of Annealing Temperature on the Water Contact Angle of PVD Hard Coatings. Materials 2013, 6, 3373-3386. https://doi.org/10.3390/ma6083373

Yang Y-S, Cho T-P. Effect of Annealing Temperature on the Water Contact Angle of PVD Hard Coatings. Materials. 2013; 6(8):3373-3386. https://doi.org/10.3390/ma6083373

Chicago/Turabian StyleYang, Yu-Sen, and Ting-Pin Cho. 2013. "Effect of Annealing Temperature on the Water Contact Angle of PVD Hard Coatings" Materials 6, no. 8: 3373-3386. https://doi.org/10.3390/ma6083373

APA StyleYang, Y.-S., & Cho, T.-P. (2013). Effect of Annealing Temperature on the Water Contact Angle of PVD Hard Coatings. Materials, 6(8), 3373-3386. https://doi.org/10.3390/ma6083373