Fatigue Failure Analyses on a Ti-45Al-8Nb-0.2W-0.2B-0.1Y Alloy at Different Temperatures

Abstract

:1. Introduction

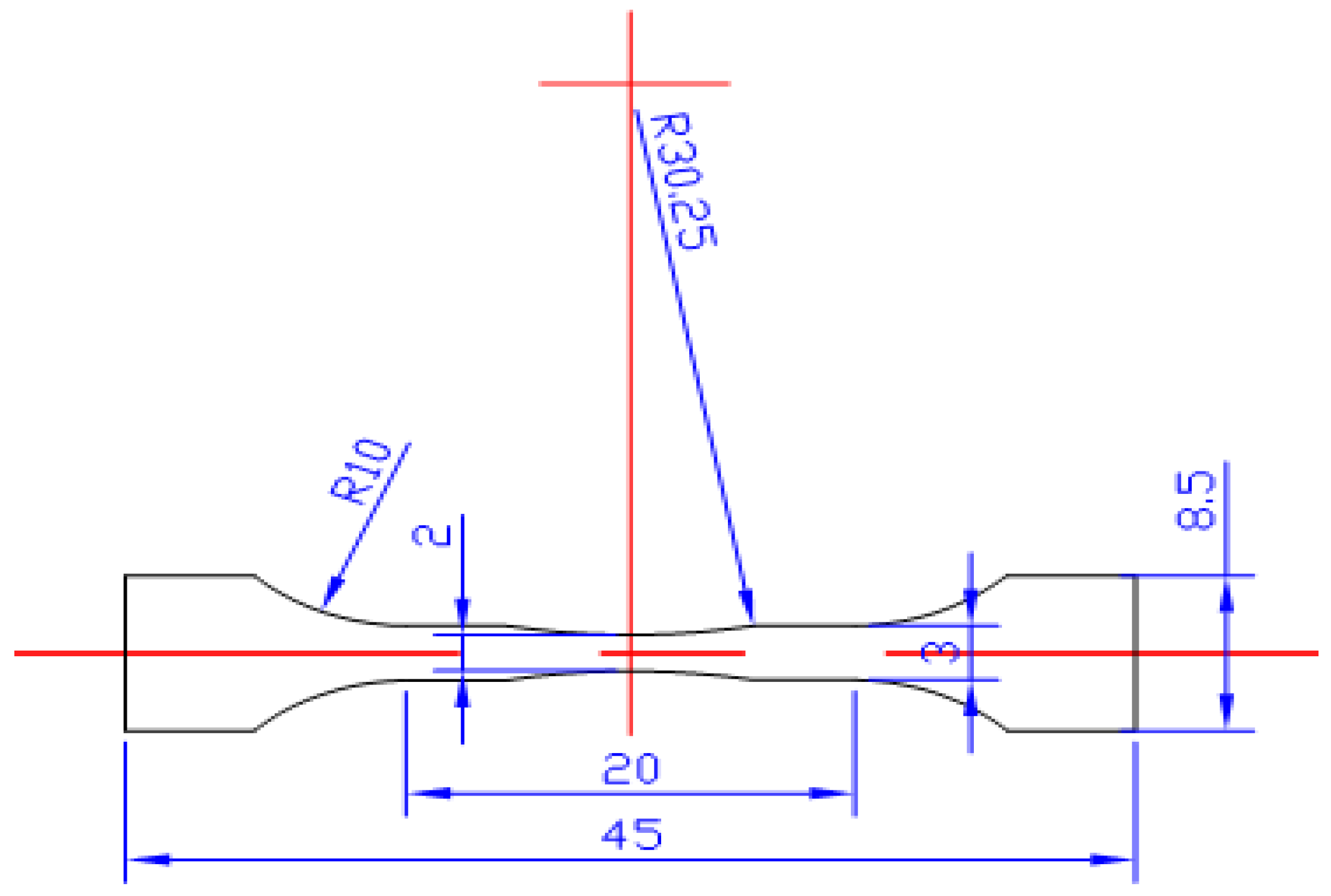

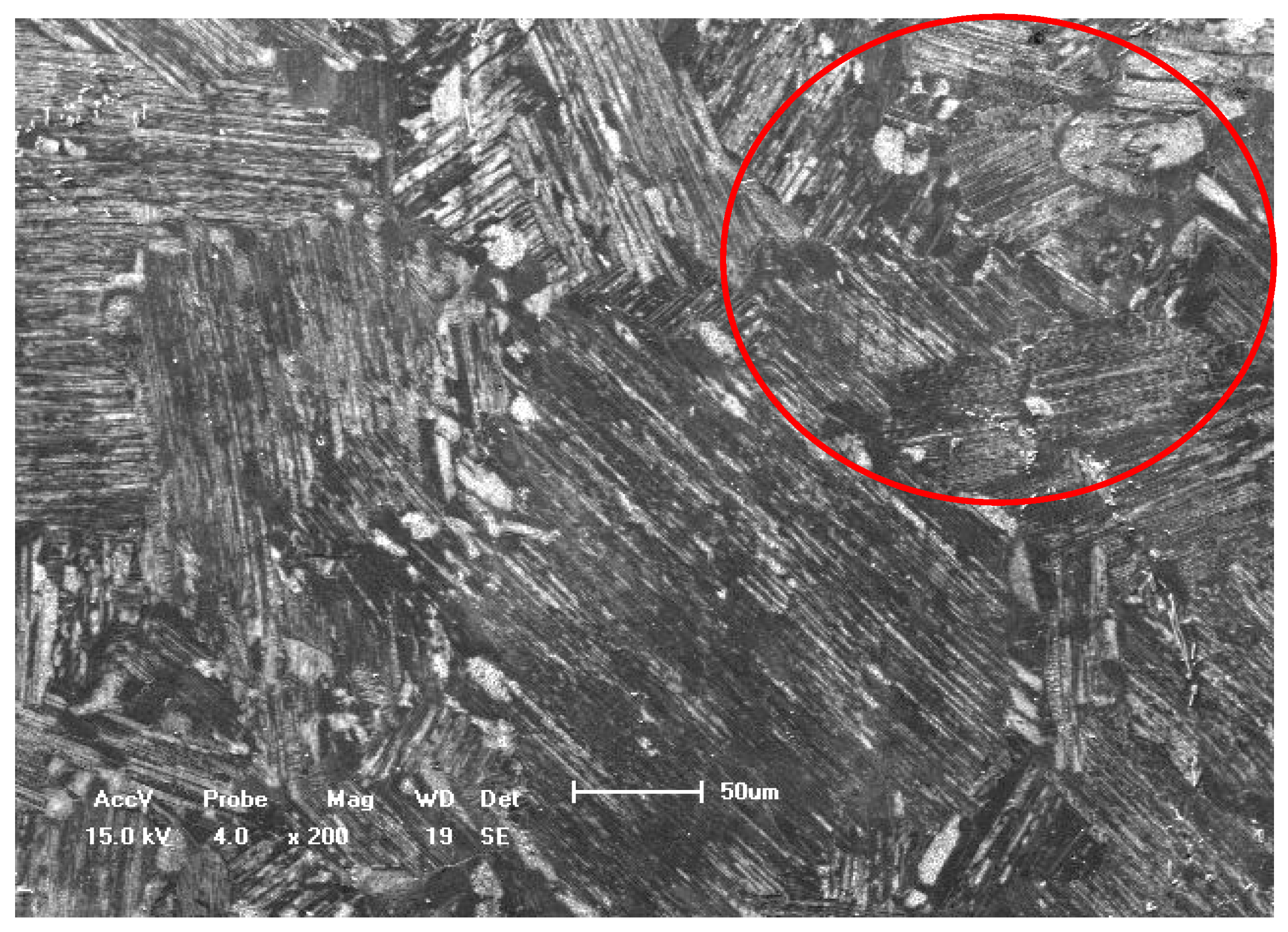

2. Experimental Method and Material

3. Results and Discussion

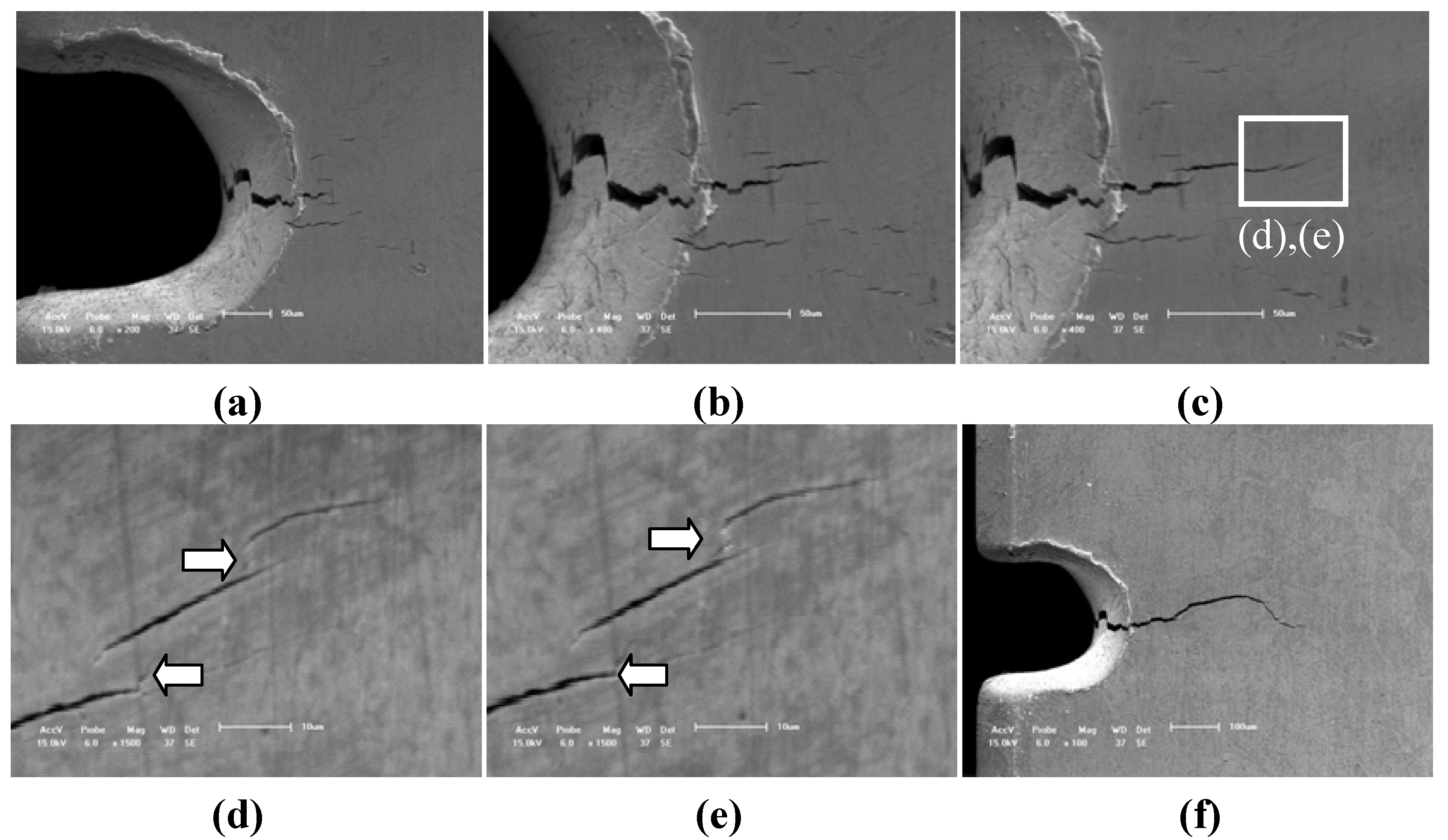

3.1. Surface Fatigue Crack Initiation and Propagation Behavior

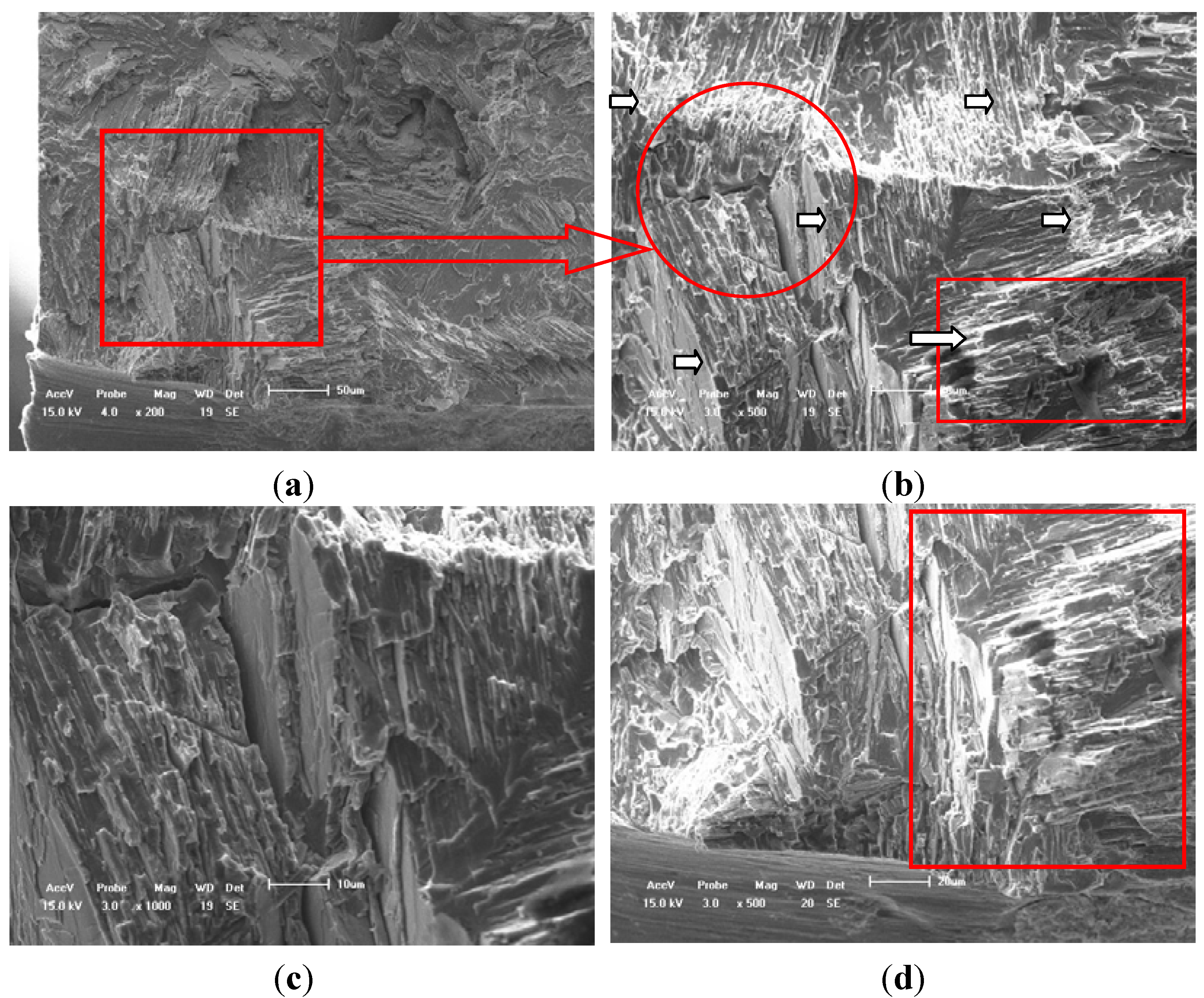

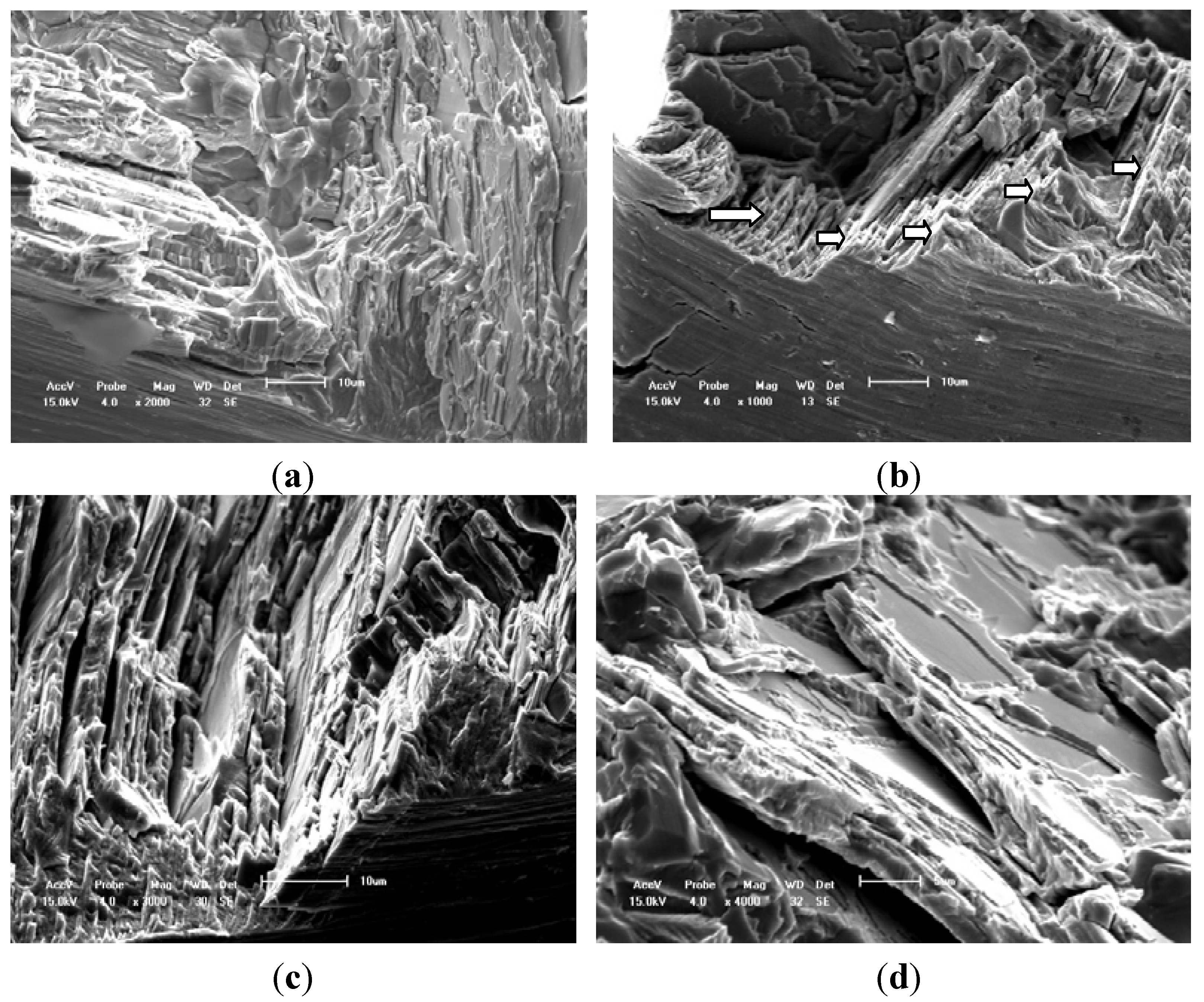

3.2. Fatigue Fracture Analysis at Different Temperatures Based on Cross-Sections

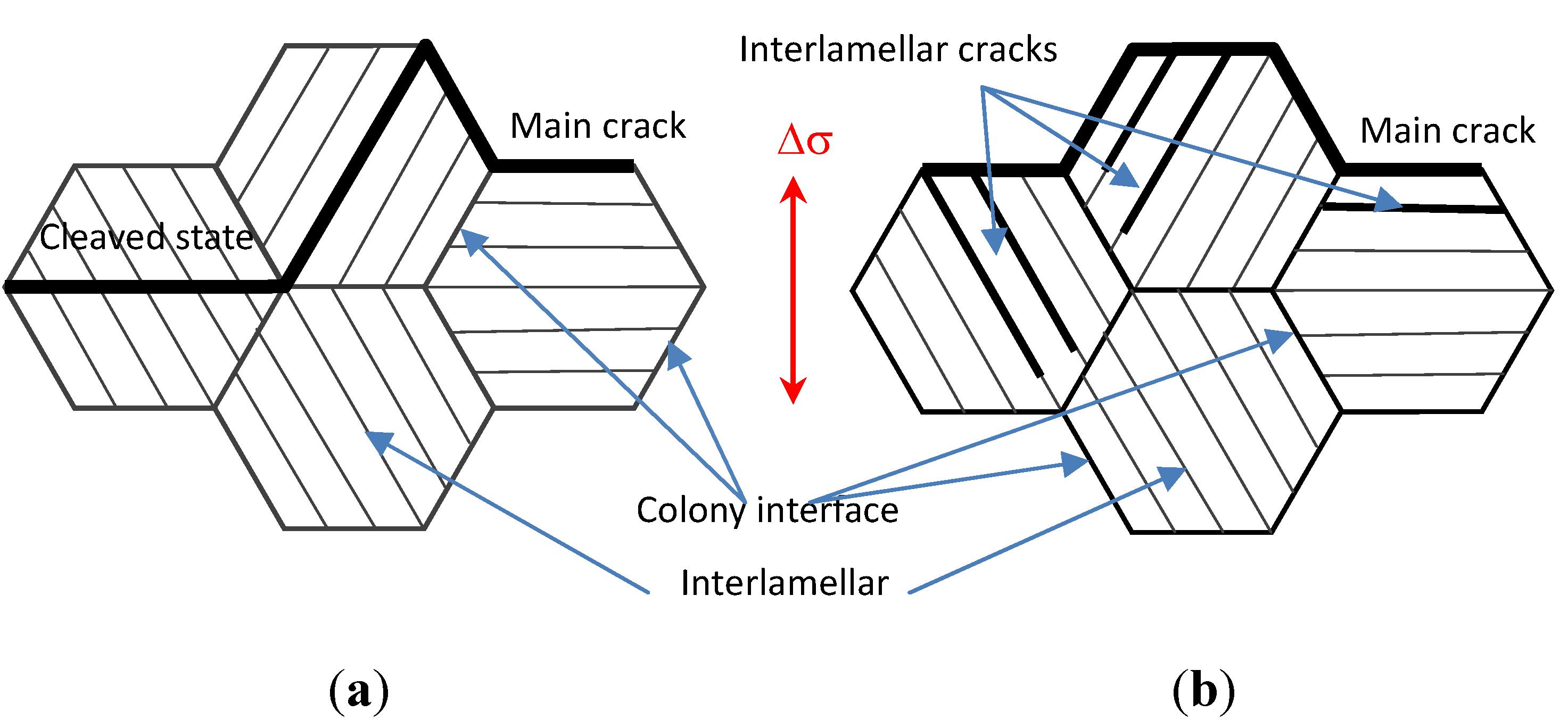

3.3. HCF Fracture Model of Tial Alloy With 8% Nb Content at Different Temperatures

4. Conclusions

Acknowledgments

References

- Cui, W.F.; Liu, C.M. Fracture characteristics of γ-TiAl alloy with high Nb content under cyclic loading. J. Alloy Compd. 2009, 477, 596–601. [Google Scholar] [CrossRef]

- Lu, X.; He, X.B.; Zhang, B.; Zhang, L.; Qu, X.H.; Guo, Z.X. Microstructure and mechanical properties of a spark plasma sintered Ti-45Al-8.5Nb-0.2W-0.2B-0.1Y alloy. Intermetallics 2009, 17, 840–846. [Google Scholar] [CrossRef]

- Xu, X.J.; Lin, J.P.; Wang, Y.L.; Gao, J.F.; Lin, Z.; Chen, G.L. Effects of forging on microstructure and tensile properties of Ti-45Al-(8-9)Nb-(W,B,Y) alloy. J. Alloy Compd. 2006, 414, 175–180. [Google Scholar] [CrossRef]

- Kumpfert, J.; Kim, Y.W.; Dimiduk, D.M. Effect of microstructure on fatigue and tensile properties of gamma TiAl Ti-46.5Al-3.0Nb-2.1Cr-0.2W. Mater. Sci. Eng. A 1995, 192–193, 465–473. [Google Scholar] [CrossRef]

- Inui, H.; Oh, M.H.; Nakamura, A.; Yamakuchi, M. Room-temperature tensile deformation of poysynthetically twinned crystals of TiAl. Acta Mater. 1992, 40, 3095–3104. [Google Scholar] [CrossRef]

- Cao, R.; Lin, Y.Z.; Hu, D.; Chen, J.H. Fracture behavior of a TiAl alloy under various loading modes. Eng. Fract. Mech. 2008, 75, 4343–4362. [Google Scholar] [CrossRef]

- Kim, S.W.; Kumar, K.S.; Oh, M.H.; Wee, D.M. Crack propagation behavior in TiAl single and Bi-PST crystals. Intermetallics 2007, 15, 976–984. [Google Scholar] [CrossRef]

- Mine, Y.J.; Fujisaki, H.; Matsuda, M.; Takeyama, M.; Takashima, K. Micro tension behavior of TiAl polysynthetically twinned crystals with 0°- and 90°-oriented lamellae. Scripta Mater. 2011, 65, 707–710. [Google Scholar] [CrossRef]

- Henaff, G.; Gloanec, A.L. Fatigue properties of TiAl alloys. Intermetallics 2005, 13, 543–558. [Google Scholar] [CrossRef]

- Mine, Y.J.; Takashima, K.; Bowen, P. Effect of lamellar spacing on fatigue crack growth behavior of a TiAl-based alumined with lamellar microstructure. Mater. Sci. Eng. A 2012, 532, 13–20. [Google Scholar] [CrossRef]

- Liu, Y.; Shazly, M.; Lewandowski, J.J. Microstructural effects on crack path selection in bending and fatigue in a Nb-19Si-5Cr-3.5Hf-24Ti-0.75Sn-1W alloy. Mater. Sci. Eng. A 2010, 527, 1489–1500. [Google Scholar] [CrossRef]

- Zhu, S.J.; Peng, L.M.; Moriya, T.; Mutoh, Y. Effect of stress ratio on fatigue crack growth in TiAl intermetallaics at room and elevated temperatures. Mater. Sci. Eng. A 2000, 290, 198–206. [Google Scholar] [CrossRef]

- Loria, E.A. Fatigue crack growth behavior and plane-strain fracture toughness of a multi component Nb-Ti-Al alloy. Mater. Sci. Eng. A 1998, 254, 63–66. [Google Scholar] [CrossRef]

- Bache, M.R.; Morgans, C.C. Domestic object damage and fatigue behavior of an advanced gamma TiAl alloy. Intermetallics 2011, 19, 782–786. [Google Scholar] [CrossRef]

- Burke, J.J. Fatigue, Environment and Temperature Effects; Plenum Press: New York, NY, USA, 1983; pp. 265–300. [Google Scholar]

- Mendez, J.; Mailly, S.; Villechaise, P. Temperature and environmental effects on low cycle fatigue resistance of titanium alloys. In Temperature-Fatigue Interaction, Proceedings of International Conference on Temperature-Fatigue Interaction, 9th International Springs Meeting, Paris, France, 29–31 May 2001; Elsevier: Amsterdam, The Netherland, 2002; pp. 95–102. [Google Scholar]

- Bridier, F.; Villechaise, P.; Mendes, J. Slip and fatigue crack formation processes in a α/β titanium alloy in relation to crystallographyic texture on different scales. Acta Mater. 2008, 56, 3951–3962. [Google Scholar] [CrossRef]

- Phichak, A.L.; Williams, R.E.A.; Williams, J.C. Crystallography of fatigue crack initiation and growth in fully lamellar Ti6Al4V. Metall. Mater. Trans. Phys. Metal. Mater. Sci. 2010, 41, 106–124. [Google Scholar] [CrossRef]

- Li, X.D.; Wang, X.S.; Ren, H.H.; Chen, Y.L.; Mu, Z.T. Effect of prior corrosion state on the fatigue small cracking behavior of 6151-T6 aluminum alloy. Corros. Sci. 2012, 55, 26–33. [Google Scholar] [CrossRef]

- Wang, X.S.; Li, X.D.; Ren, H.H.; Zhao, H.Y.; Murai, R. SEM in-situ study on high cycle fatigue of SnPb-solder joint in electronic packaging. Microelectron. Reliab. 2011, 51, 1377–1384. [Google Scholar] [CrossRef]

- Wang, X.S.; Yan, C.K.; Li, Y.; Xue, Y.B.; Meng, X.K.; Wu, B.S. SEM in-situ study on failure of nanocrystal metallic thin films and substrate structure under three point bending. Int. J. Fract. 2008, 151, 269–279. [Google Scholar] [CrossRef]

- Wang, X.S.; Liang, F.; Fan, J.H.; Zhang, F.H. Investigations on low-cycle fatigue small crack initiation and propagation mechanism of cast magnesium alloys based on in-situ observation with SEM. Philos. Mag. 2006, 86, 1581–1596. [Google Scholar] [CrossRef]

- Wang, X.S.; Fan, J.H. An evaluation the growth rate of fatigue small cracks in cast AM50 magnesium alloy at different temperature in vacuum environment. Int. J. Fatigue 2006, 28, 79–86. [Google Scholar] [CrossRef]

- Wang, X.S.; Xu, Y.; Xu, X.Q. Direct observations of microcracking in the fuel plate using the scanning electron microscope. Appl. Compos. Mater. 2004, 11, 145–154. [Google Scholar] [CrossRef]

- Wang, X.S.; Fan, J.H. SEM online investigation of fatigue crack initiation and propagation in notched cast magnesium specimens. J. Mater. Sci. 2004, 39, 2617–2620. [Google Scholar] [CrossRef]

- Wang, X.S.; Lu, X.; Wang, H.D. Investigation of surface fatigue microcrack growth behavior of cast Mg-Al alloy. Mater. Sci. Eng. A 2004, 364, 11–16. [Google Scholar] [CrossRef]

- Wang, X.S.; Li, Y.Q. Characterization of the fatigue surface microcrack growth in vicinal inclusion for powder metallurgy alloys. Acta Mech. Solida Sin. 2003, 16, 327–333. [Google Scholar]

- Thomason, P.F.; Rauchs, G.; Withers, P.J. Multi-scale finite-element modeling of fatigue-crack growth in TiAl intermetallic matrix TiNb and Nb platelet composites. Acta Mater. 2002, 50, 1453–1455. [Google Scholar] [CrossRef]

- Zou, J.P.; Xie, H.P.; Zhou, H.W.; Peng, S.P. SEM in situ investigation on thermal cracking behaviour of Pingdingshan sandstone at elevated temperatures. Geophys. J. Int. 2010, 181, 593–603. [Google Scholar]

- Standard Test Method for Measurement of Fatigue Crack Growth Rates; ASTM E647; ASTM International: West Conshohocken, PA, USA, 1998.

- Goto, M.; Han, S.Z.; Euh, K.; Kang, J.H.; Kim, S.S.; Kawagoishi, N. Formation of a high-cycle fatigue fracture surface and a crack growth mechanism of ultrafine-grained copper with different stages of microstructural evolution. Acta Mater. 2012, 58, 6294–6305. [Google Scholar] [CrossRef]

- Wang, Q.Y.; Kawagoishi, N.; Chen, Q. Effects of pitting corrosion on very high cycle fatigue behavior. Scripta Mater. 2003, 49, 711–716. [Google Scholar] [CrossRef]

© 2012 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license ( http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Wang, X.-S.; Zhang, M.; Song, X.-P.; Jia, S.; Chen, Q.; Kawagoishi, N. Fatigue Failure Analyses on a Ti-45Al-8Nb-0.2W-0.2B-0.1Y Alloy at Different Temperatures. Materials 2012, 5, 2280-2291. https://doi.org/10.3390/ma5112280

Wang X-S, Zhang M, Song X-P, Jia S, Chen Q, Kawagoishi N. Fatigue Failure Analyses on a Ti-45Al-8Nb-0.2W-0.2B-0.1Y Alloy at Different Temperatures. Materials. 2012; 5(11):2280-2291. https://doi.org/10.3390/ma5112280

Chicago/Turabian StyleWang, Xi-Shu, Min Zhang, Xi-Ping Song, Su Jia, Qiang Chen, and Norio Kawagoishi. 2012. "Fatigue Failure Analyses on a Ti-45Al-8Nb-0.2W-0.2B-0.1Y Alloy at Different Temperatures" Materials 5, no. 11: 2280-2291. https://doi.org/10.3390/ma5112280

APA StyleWang, X.-S., Zhang, M., Song, X.-P., Jia, S., Chen, Q., & Kawagoishi, N. (2012). Fatigue Failure Analyses on a Ti-45Al-8Nb-0.2W-0.2B-0.1Y Alloy at Different Temperatures. Materials, 5(11), 2280-2291. https://doi.org/10.3390/ma5112280