A Self-Propagating Foaming Process of Porous Al-Ni Intermetallics Assisted by Combustion Reactions

Abstract

:1. Introduction

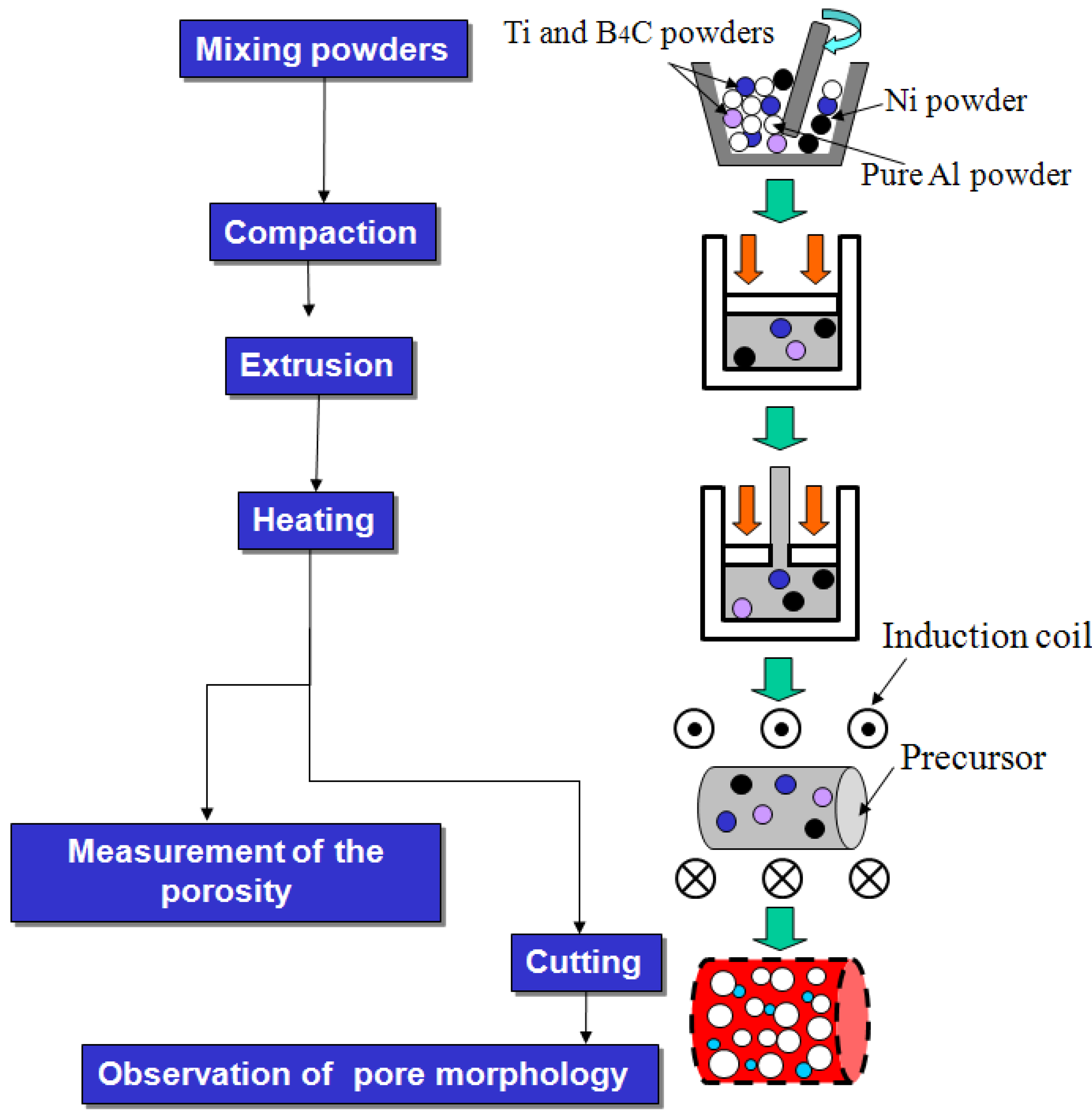

2. Experimental Procedure

2.1. Preparation of Precursor

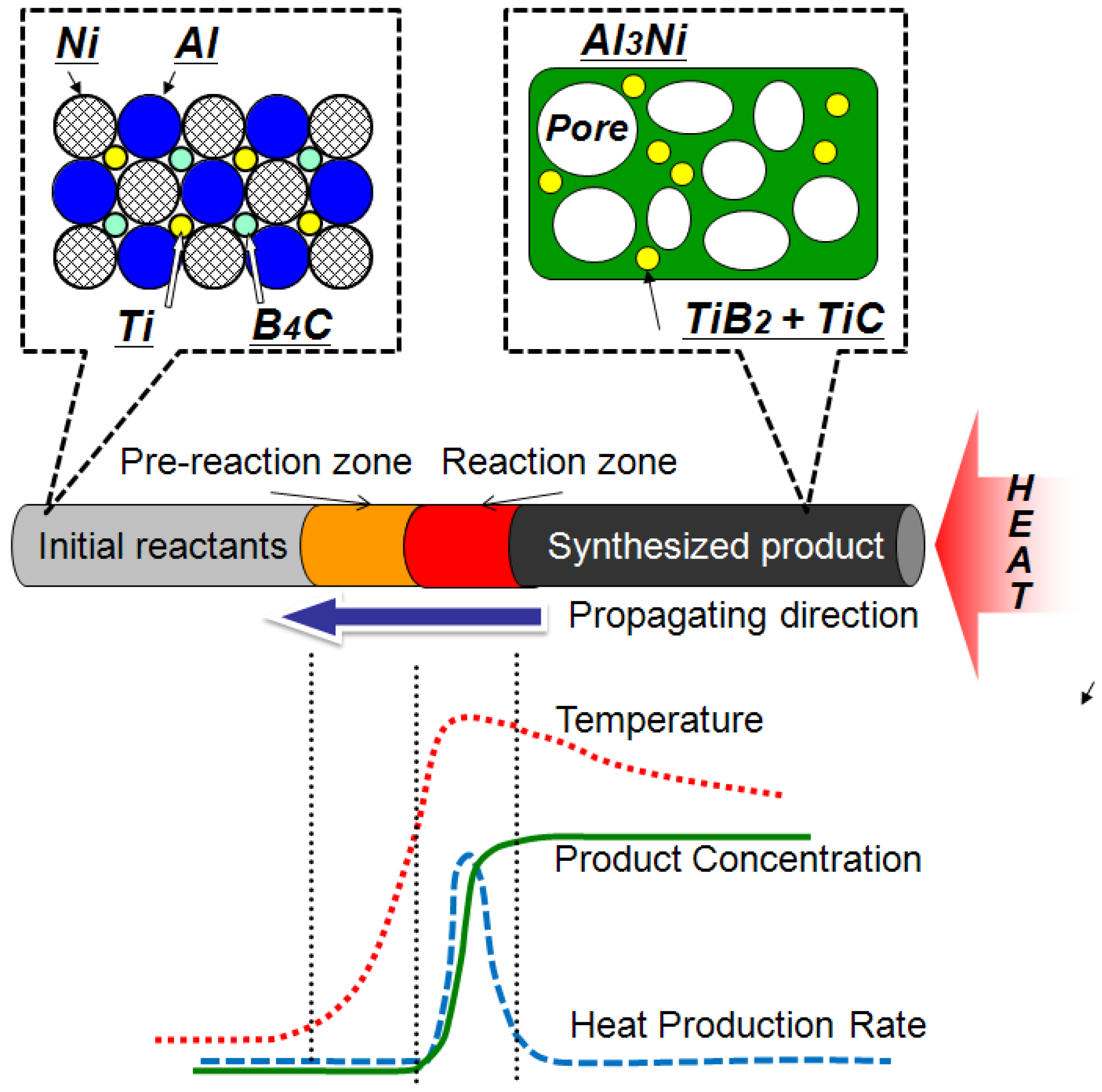

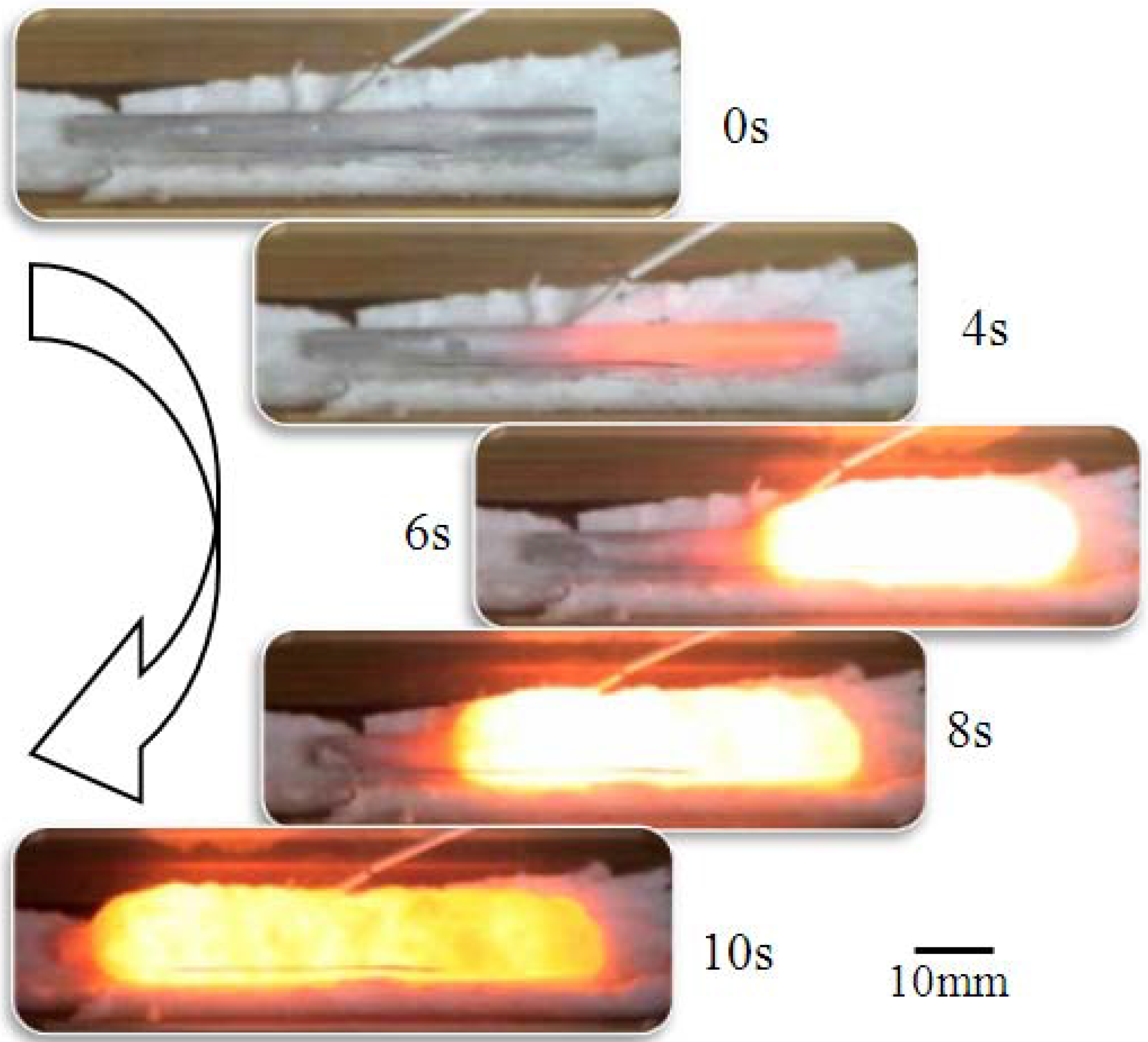

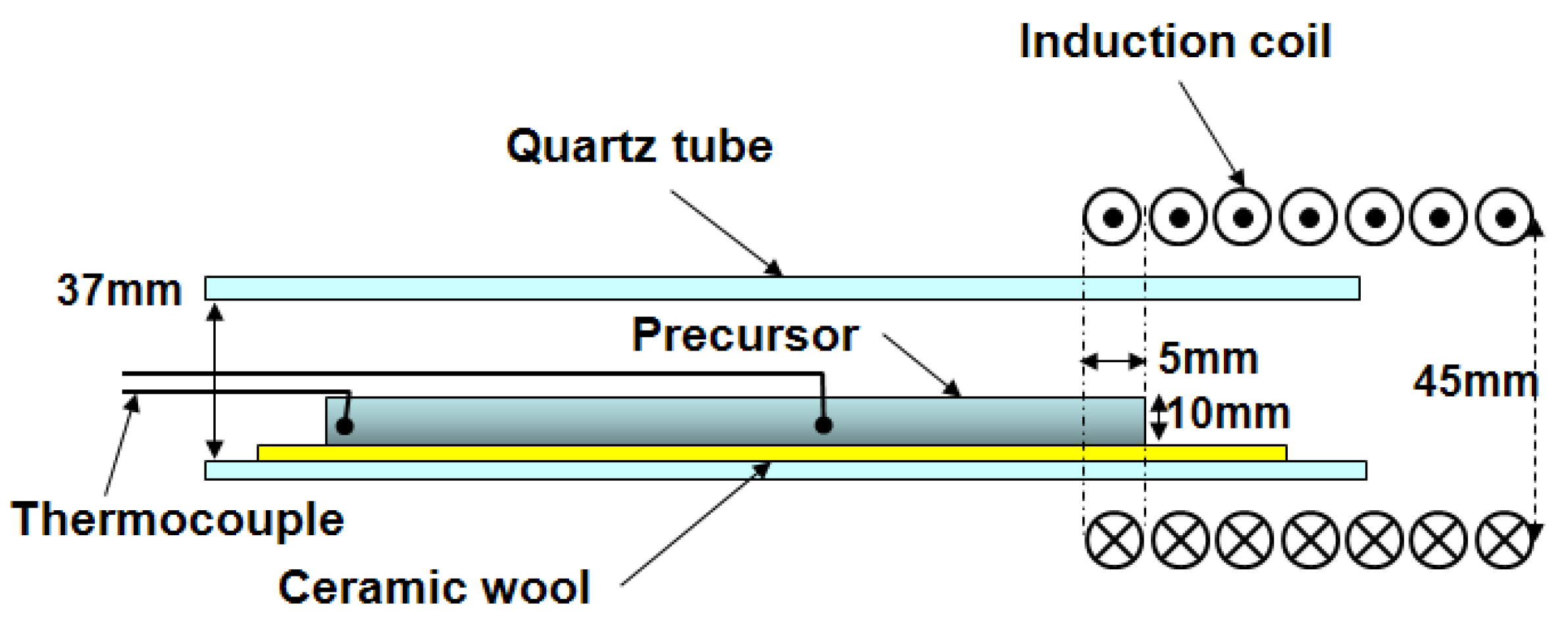

2.2. Self-Propagating Blowing Process

3. Results and Discussion

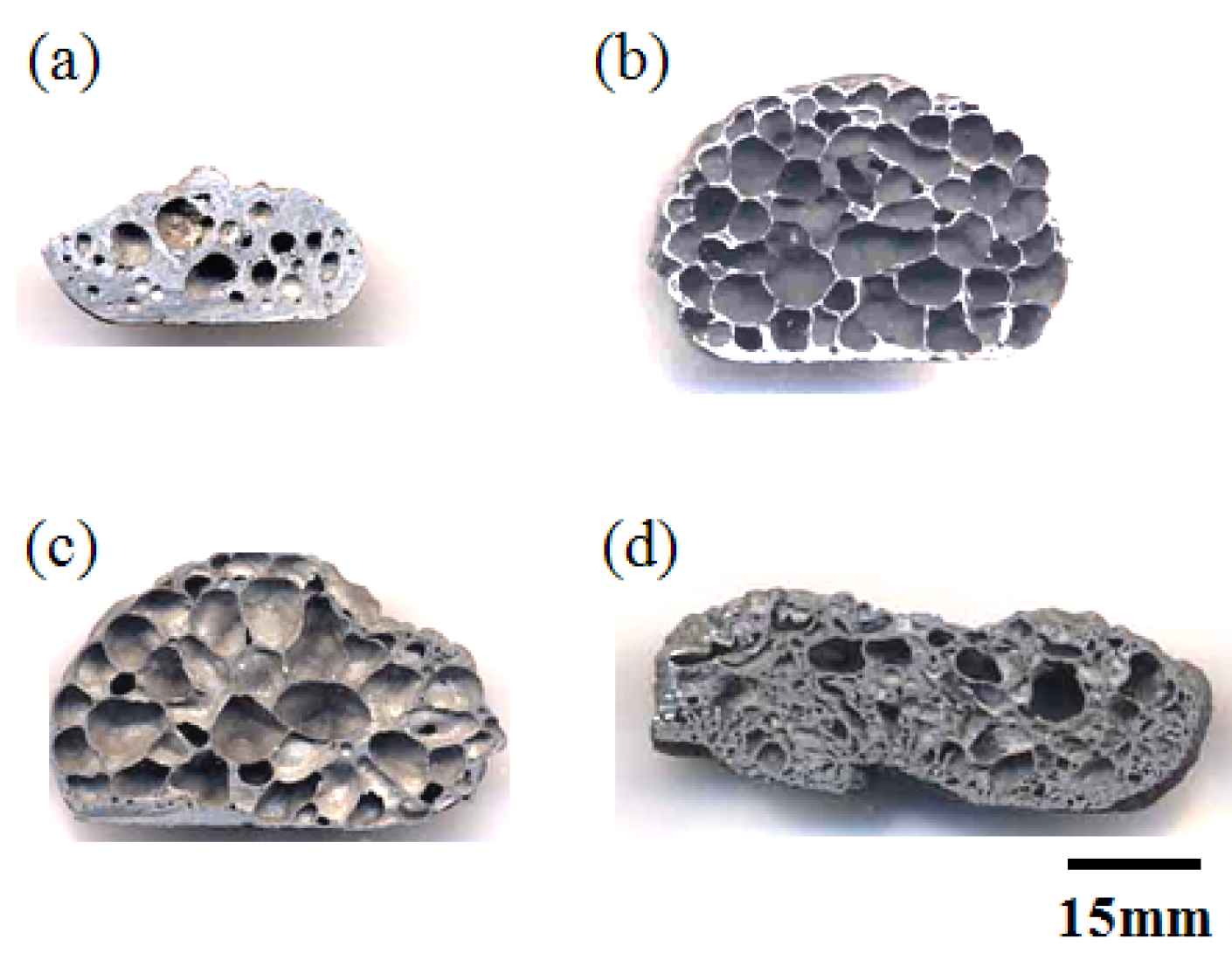

3.1. Fundamental Foaming Behavior of Al-Ni Precursor by Thermal Explosion Mode

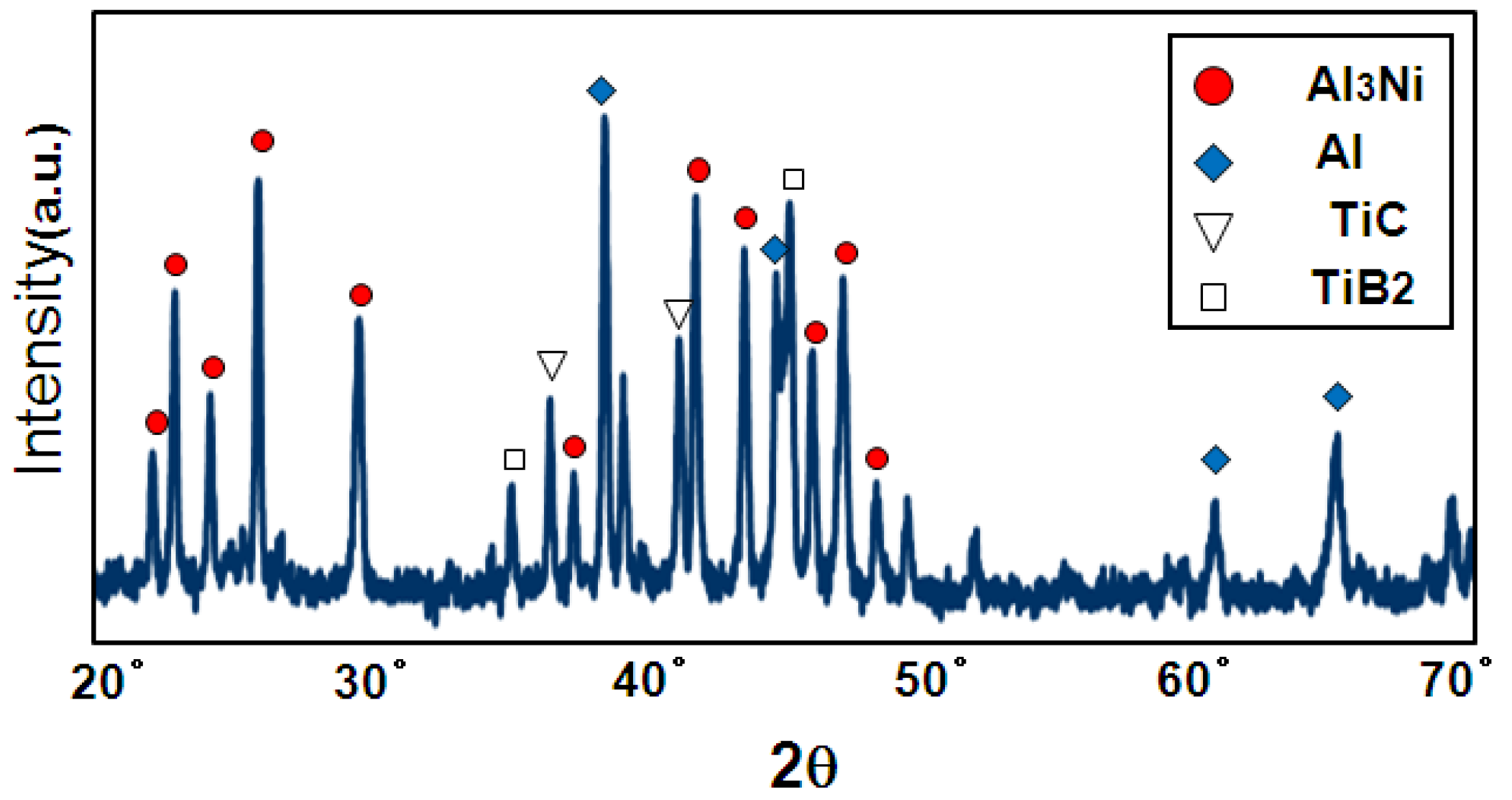

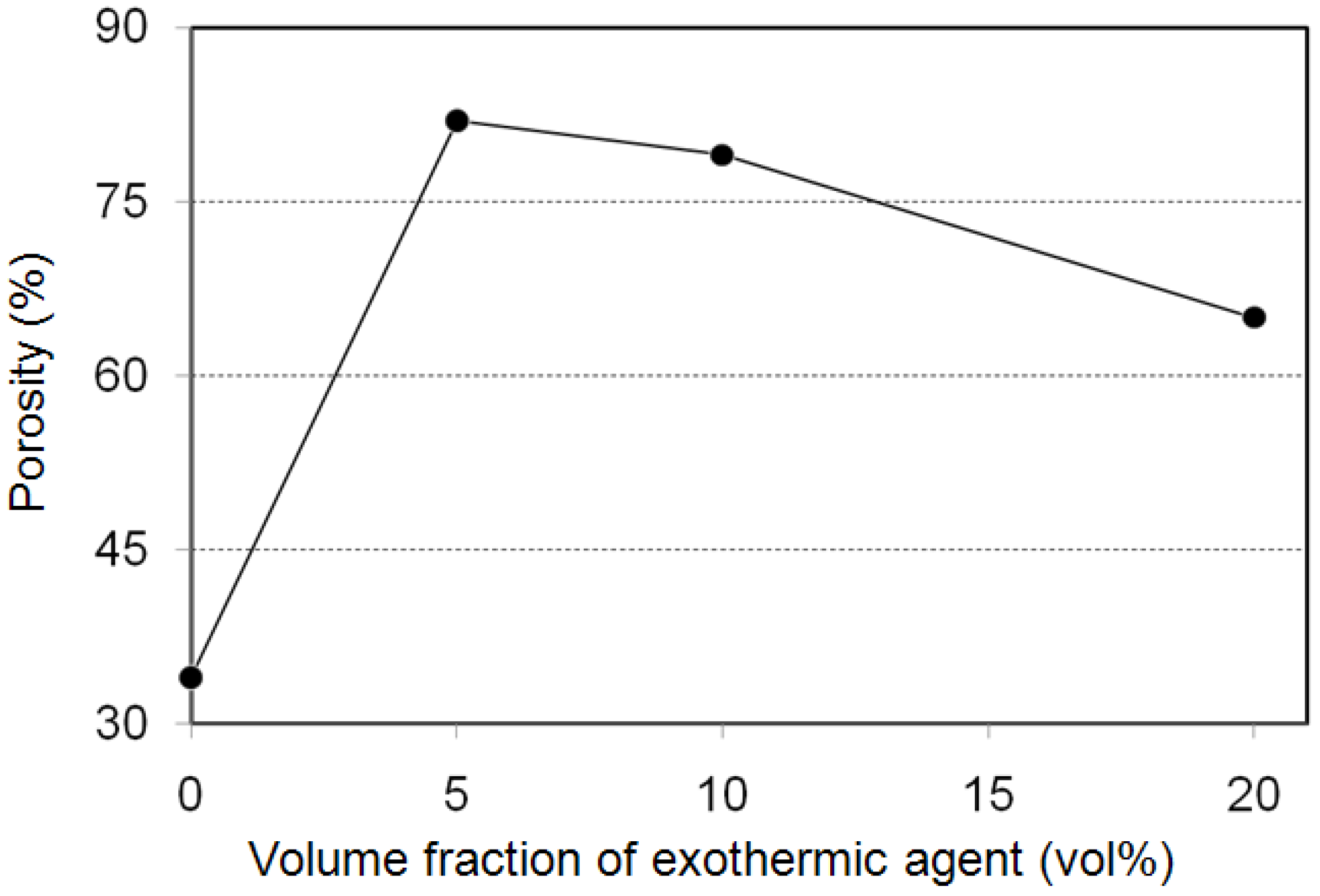

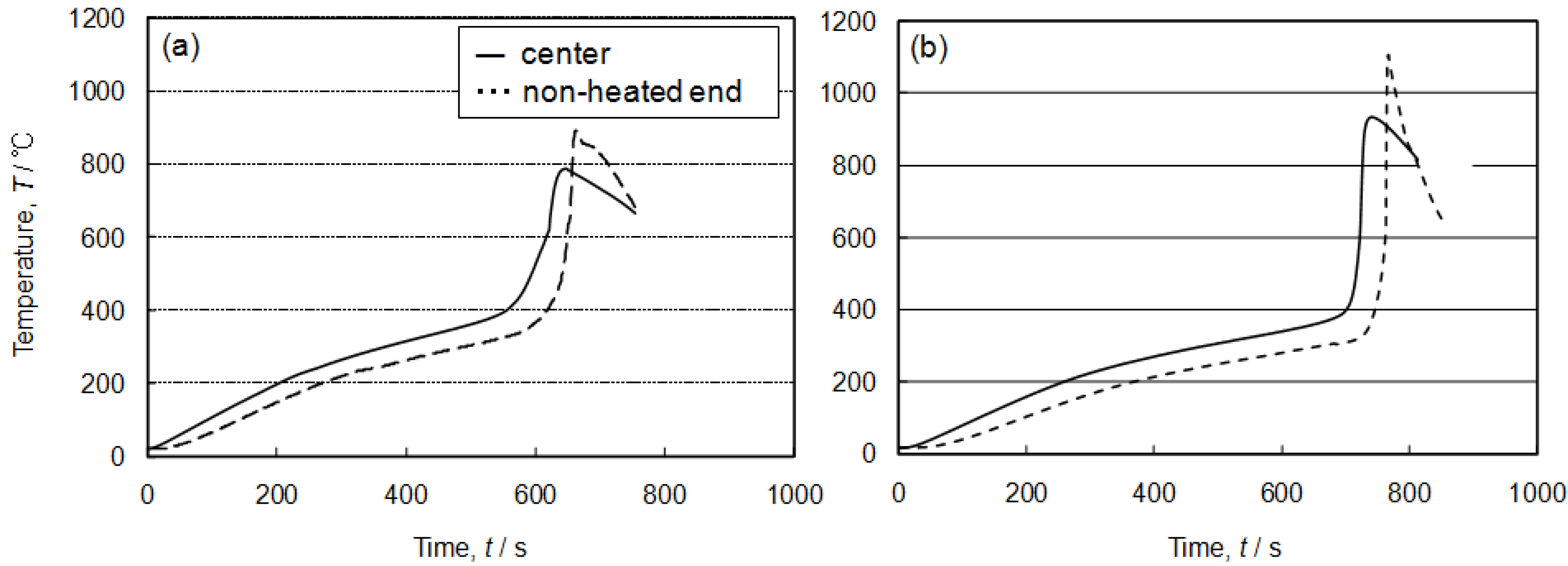

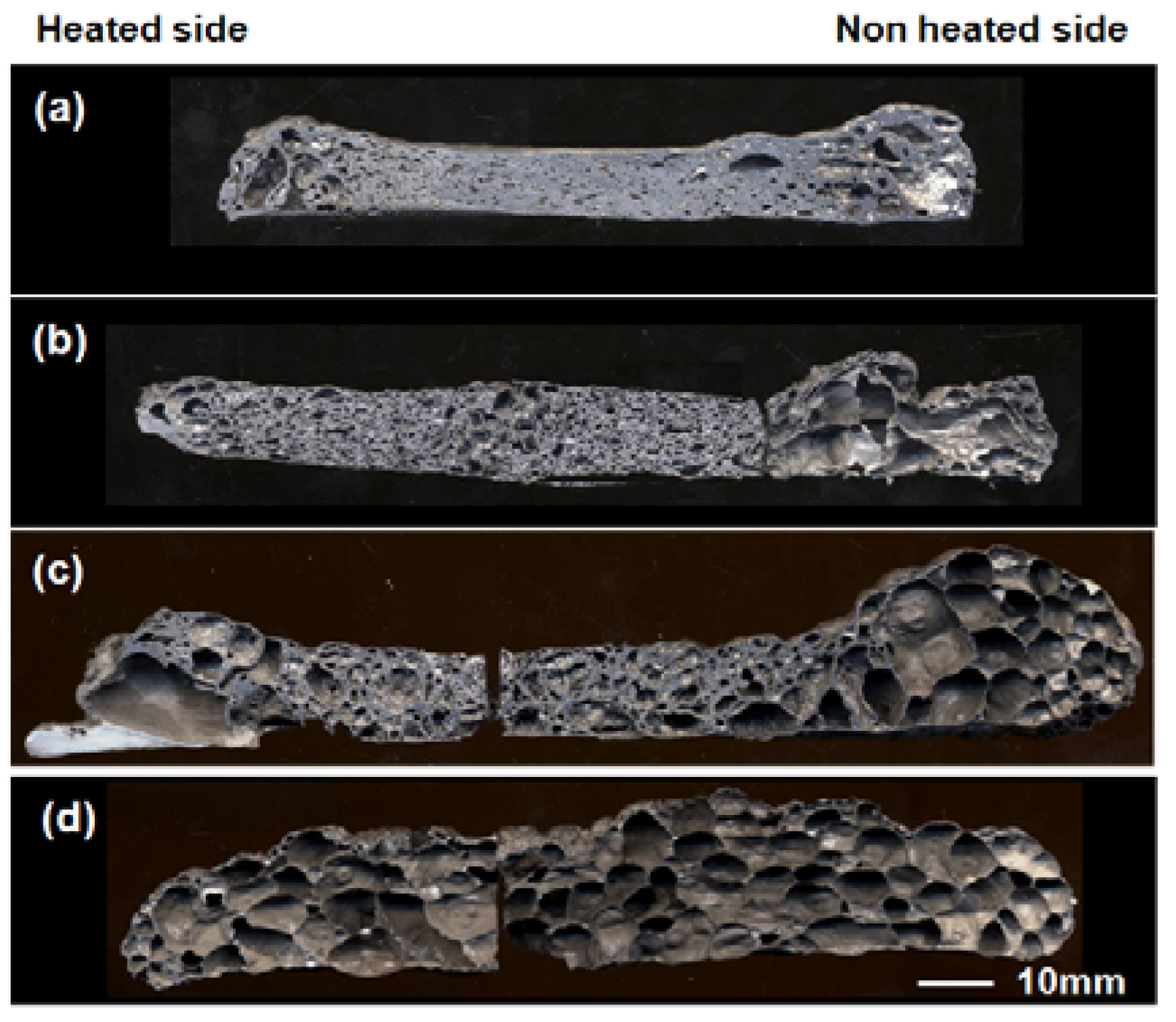

3.2. Effect of Reactive Exothermic Agent on Foaming Behavior by Self-Propagating Mode

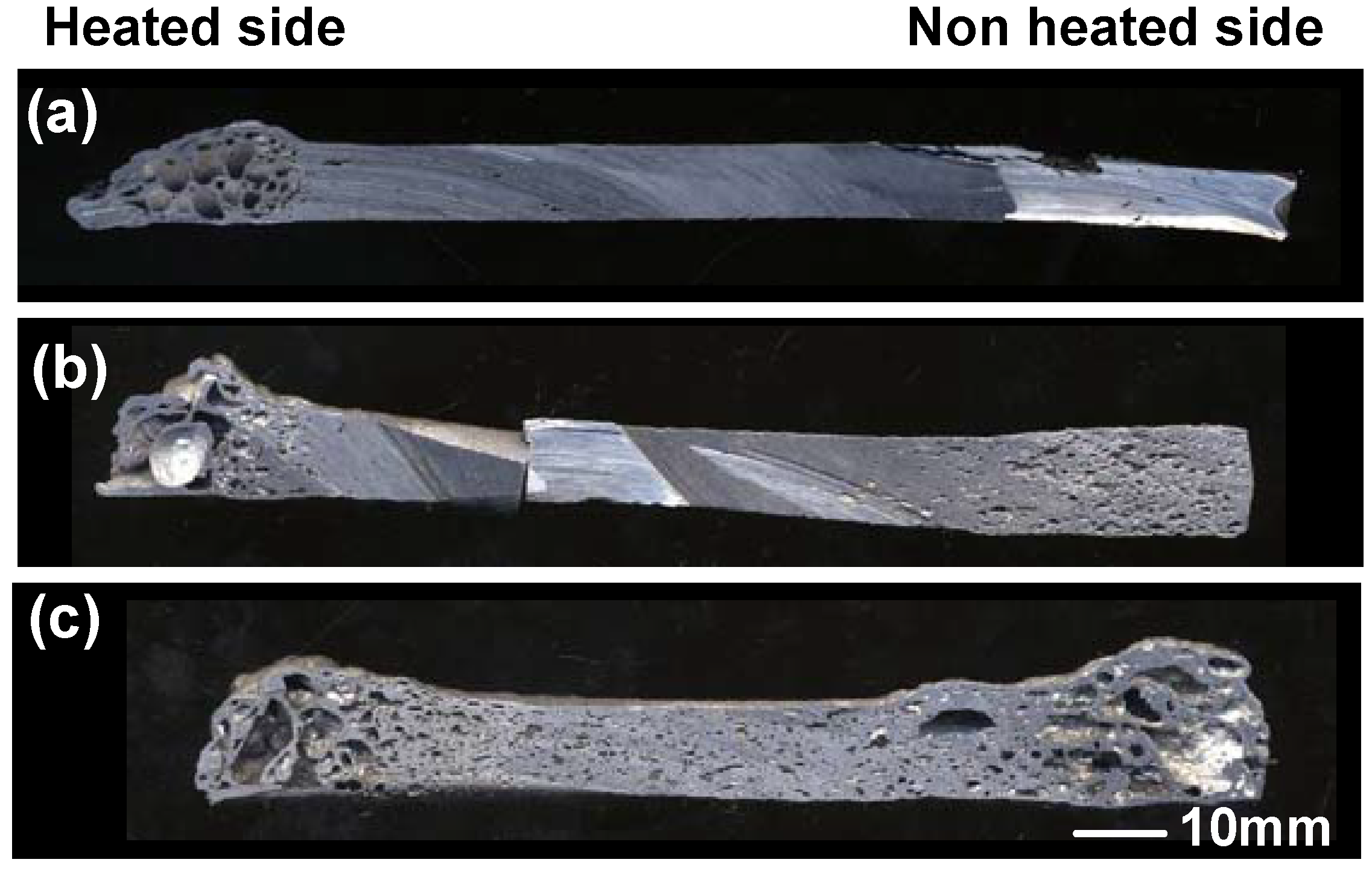

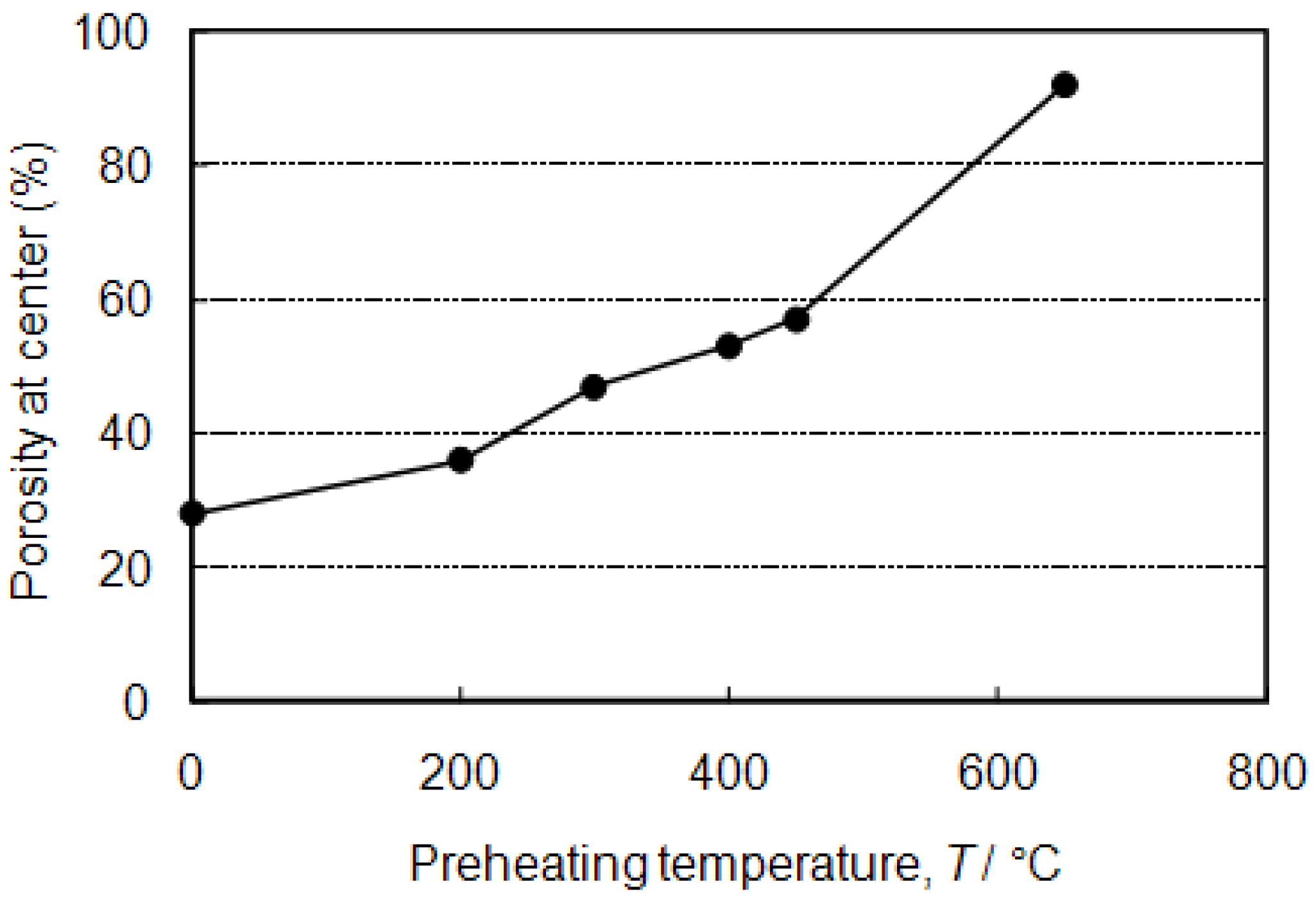

3.3. Effect of Preheating

4. Conclusions

- With regards to the thermal explosion mode, the specimens after the reaction showed high porosity after blending appropriate amounts of foaming agent (5, 10 vol%). However, excessive addition (>20 vol%) resulted in the collapsed cell morphology and low porosity. This may be related to the high fraction of Al-Ni molten phase during the combustion reaction.

- In the self-propagating mode, the specimen without exothermic agent did not show clear pore formation, except at the heated end. However, by adding 5 vol% of exothermic agent, pore formation was realized. Relatively high porosity was achieved near both ends of the precursor (heated and non-heated ends), but the pore formation was not satisfactory in the center. A preheating treatment was effective to obtain a high porosity. By preheating at 650 °C, high porosity was achieved, even in the center part, and a homogeneous porous structure was thus obtained.

Acknowledgements

References and Notes

- Banhart, J. Manufacture, characterisation and application of cellular metals and metal foams. Prog. Mater. Sci. 2001, 46, 559–632. [Google Scholar]

- Chino, Y.; Nakanishi, H.; Kobata, M.; Iwasaki, H.; Mabuchi, M. Processing of a porous 7075 Al alloy by bubble expansion in a semi-solid state. Scr. Mater. 2002, 47, 769–773. [Google Scholar]

- Duarte, I.; Banhart, J. A study of aluminium foam formation-kinetics and microstructure. Acta Mater. 2000, 48, 2349–2362. [Google Scholar]

- Asavavisithchai, S.; Kennedy, A.R. The effect of compaction method on the expansion and stability of aluminium foams. Adv. Eng. Mater. 2006, 8, 810–815. [Google Scholar] [CrossRef]

- Bonaccorsi, L.; Proverbio, E. Powder compaction effect on foaming behavior of uni-axial pressed PM precursors. Adv. Eng. Mater. 2006, 8, 864–869. [Google Scholar] [CrossRef]

- Matijasevic, B.; Banhart, J. Improvement of aluminium foam technology by tailoring of blowing agent. Scr. Mater. 2006, 54, 503–508. [Google Scholar] [CrossRef]

- Gergely, V.; Clyne, T.W. Drainage in standing liquid metal foams: modelling and experimental observations. Acta Mater. 2004, 52, 3047–3058. [Google Scholar] [CrossRef]

- Hodge, A.M.; Dunand, D.C. Synthesis of nickel–aluminide foams by pack-aluminization of nickel foams. Intermetallics 2001, 9, 581–589. [Google Scholar] [CrossRef]

- Darolia, R. Ductility and fracture toughness issues related to implementation of NiAl for gas turbine applications. Intermetallics 2000, 8, 1321–1327. [Google Scholar] [CrossRef]

- Zhao, Y.; Taya, M.; Kang, Y.; Kawasaki, A. Compression behavior of porous NiTi shape memory alloy. Acta Mater. 2005, 53, 337–343. [Google Scholar]

- Kobashi, M.; Kanetake, N. Processing of intermetallics foam by combustion reaction. Adv. Eng. Mater. 2002, 4, 745–747. [Google Scholar] [CrossRef]

- Kobashi, M.; Wang, R.; Inagaki, Y.; Kanetake, N. Effects of processing parameters on pore morphology of combustion synthesized Al-Ni foams. Mater. Trans. 2006, 47, 2172–2177. [Google Scholar] [CrossRef]

- Wang, R.; Kobashi, M.; Kanetake, N. Effect of powder blending ratio on pore morphology of combustion processed al-ni foams. Adv. Mater. Res. 2005, 16-18, 53–56. [Google Scholar]

- Kanetake, N.; Kobashi, M. Innovative processing of porous and cellular materials by chemical reaction. Scr. Mater. 2006, 54, 521–525. [Google Scholar] [CrossRef]

- Biswas, A.; Roy, S.K.; Gurumurthy, K.R.; Prabhu, N.; Banerjee, S. A study of self-propagating high-temperature synthesis of NiAl in thermal explosion mode. Acta Materialia 2002, 50, 757–773. [Google Scholar] [CrossRef]

- Curfs, C.; Turrillas, X.; Vaughan, G.B.M.; Terry, A.E.; Kvick, A.; Rodrıguez, M.A. Al-Ni intermetallics obtained by SHS; A time-resolved X-ray diffraction study. Intermetallics 2007, 15, 1163–1171. [Google Scholar] [CrossRef]

- Shen, P.; Zou, B.; Jin, S.; Jiang, Q. Reaction mechanism in self-propagating high temperature synthesis of TiC-TiB2/Al composites from an Al-Ti-B4C system. Mater. Sci. Eng. A 2007, 454–455, 300–309. [Google Scholar] [CrossRef]

- Schaffer, G.B.; McCormick, P.G. Displacement reactions during mechanical alloying. Metall. Trans. A 1990, 22, 2789–2794. [Google Scholar] [CrossRef]

- Matteazzi, P.; Le Caer, G. Synthesis of nanocrystalline alumina–metal composites by room-temperature ball-milling of metal oxides and aluminum. J. Am. Ceram. Soc. 1992, 75, 2749–2755. [Google Scholar] [CrossRef]

© 2009 by the authors; licensee Molecular Diversity Preservation International, Basel, Switzerland. This article is an open-access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Kobashi, M.; Kanetake, N. A Self-Propagating Foaming Process of Porous Al-Ni Intermetallics Assisted by Combustion Reactions. Materials 2009, 2, 2360-2368. https://doi.org/10.3390/ma2042360

Kobashi M, Kanetake N. A Self-Propagating Foaming Process of Porous Al-Ni Intermetallics Assisted by Combustion Reactions. Materials. 2009; 2(4):2360-2368. https://doi.org/10.3390/ma2042360

Chicago/Turabian StyleKobashi, Makoto, and Naoyuki Kanetake. 2009. "A Self-Propagating Foaming Process of Porous Al-Ni Intermetallics Assisted by Combustion Reactions" Materials 2, no. 4: 2360-2368. https://doi.org/10.3390/ma2042360

APA StyleKobashi, M., & Kanetake, N. (2009). A Self-Propagating Foaming Process of Porous Al-Ni Intermetallics Assisted by Combustion Reactions. Materials, 2(4), 2360-2368. https://doi.org/10.3390/ma2042360