Design of Fe-Co-Cr-Ni-Mn-Al-Ti Multi-Principal Element Alloys Based on Machine Learning

Abstract

1. Introduction

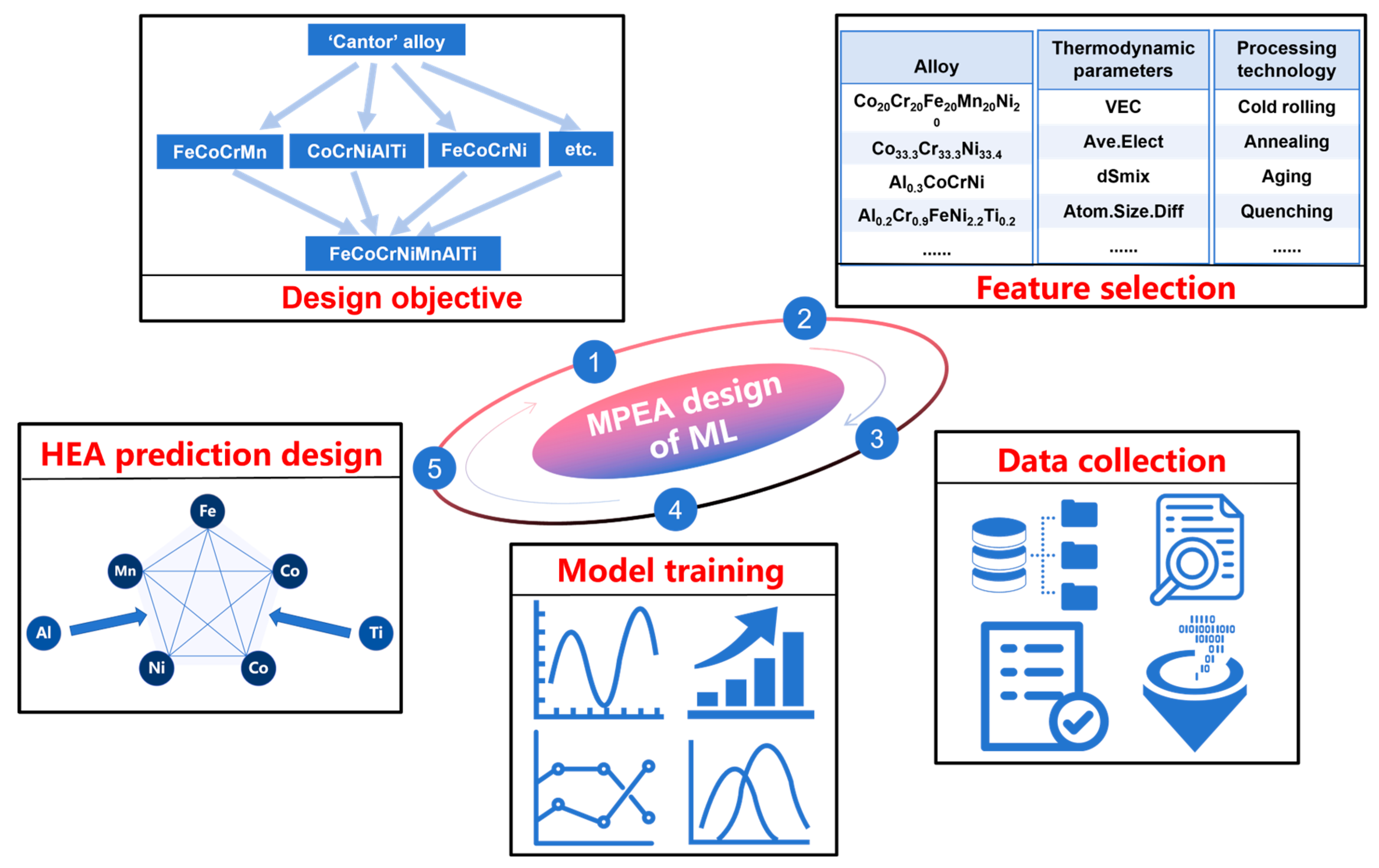

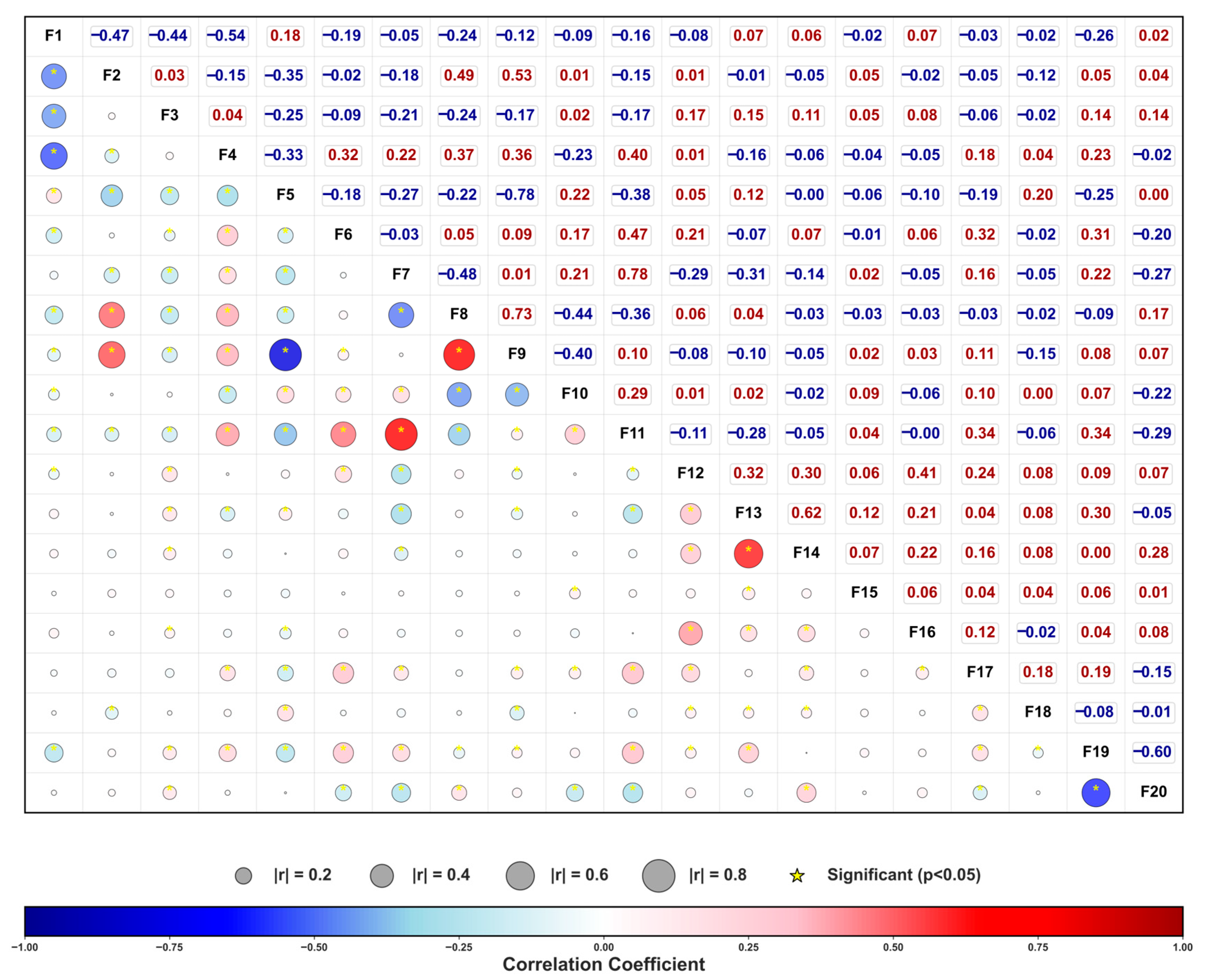

2. Methodology

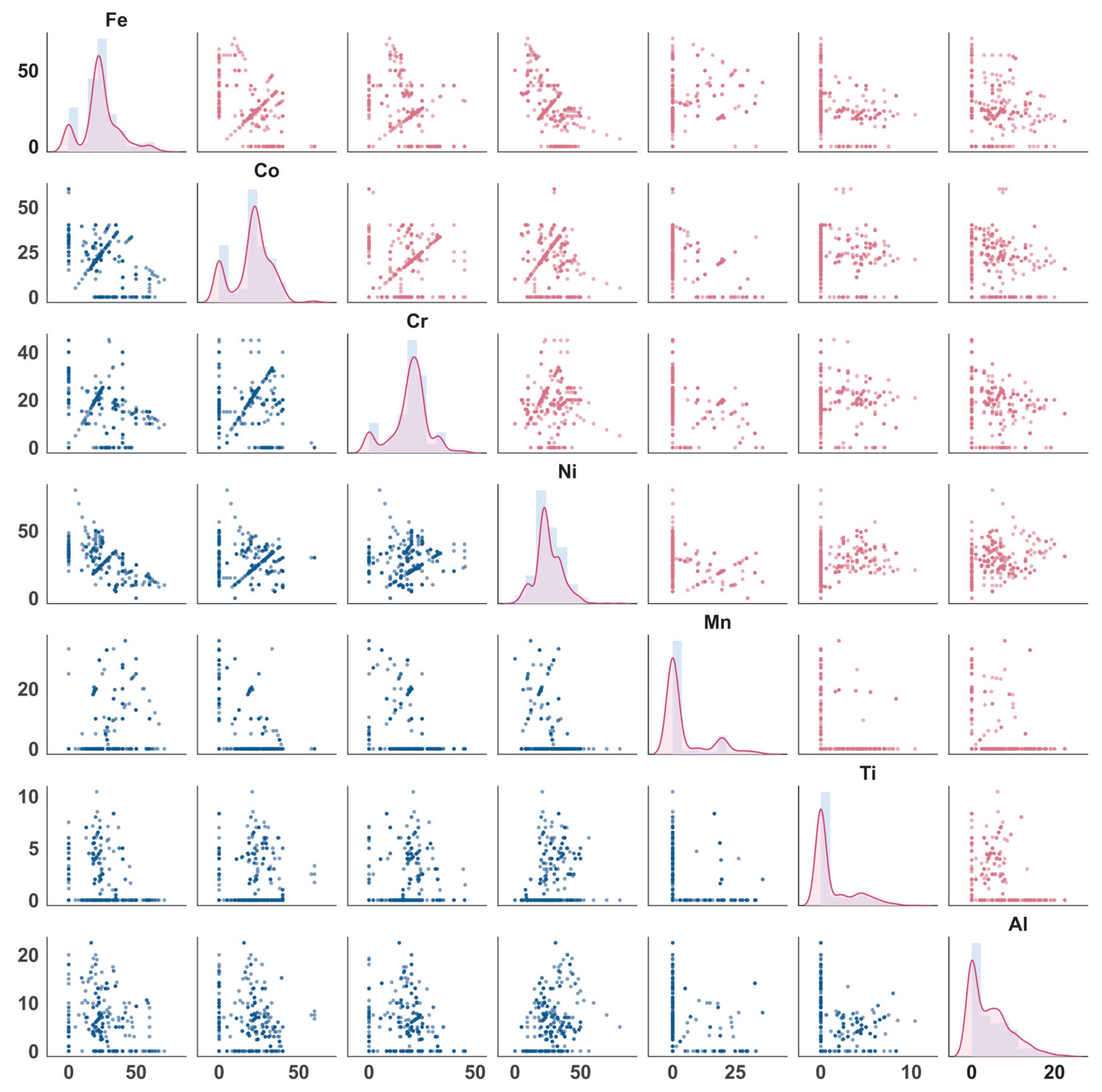

2.1. Database and ML Model

- Furnace Cooling: 0.1 K/s. At this point, the sample is in a quasi-equilibrium state, and atoms diffuse sufficiently.

- Air Cooling: 5.0 K/s. Convection cooling, partially suppressing diffusion.

- Liquid Nitrogen Quenching: 40.0 K/s. Although the final temperature is low, due to the film barrier effect caused by the Leidenfrost effect, its high-temperature cooling rate is lower than that of water quenching [37].

- Water Quenching: 500.0 K/s. The nuclear boiling mechanism is dominant, exhibiting the highest quenching intensity and maximizing the retention of supersaturated vacancies and solid-solution atoms.

2.2. Experimental Validation

3. Results

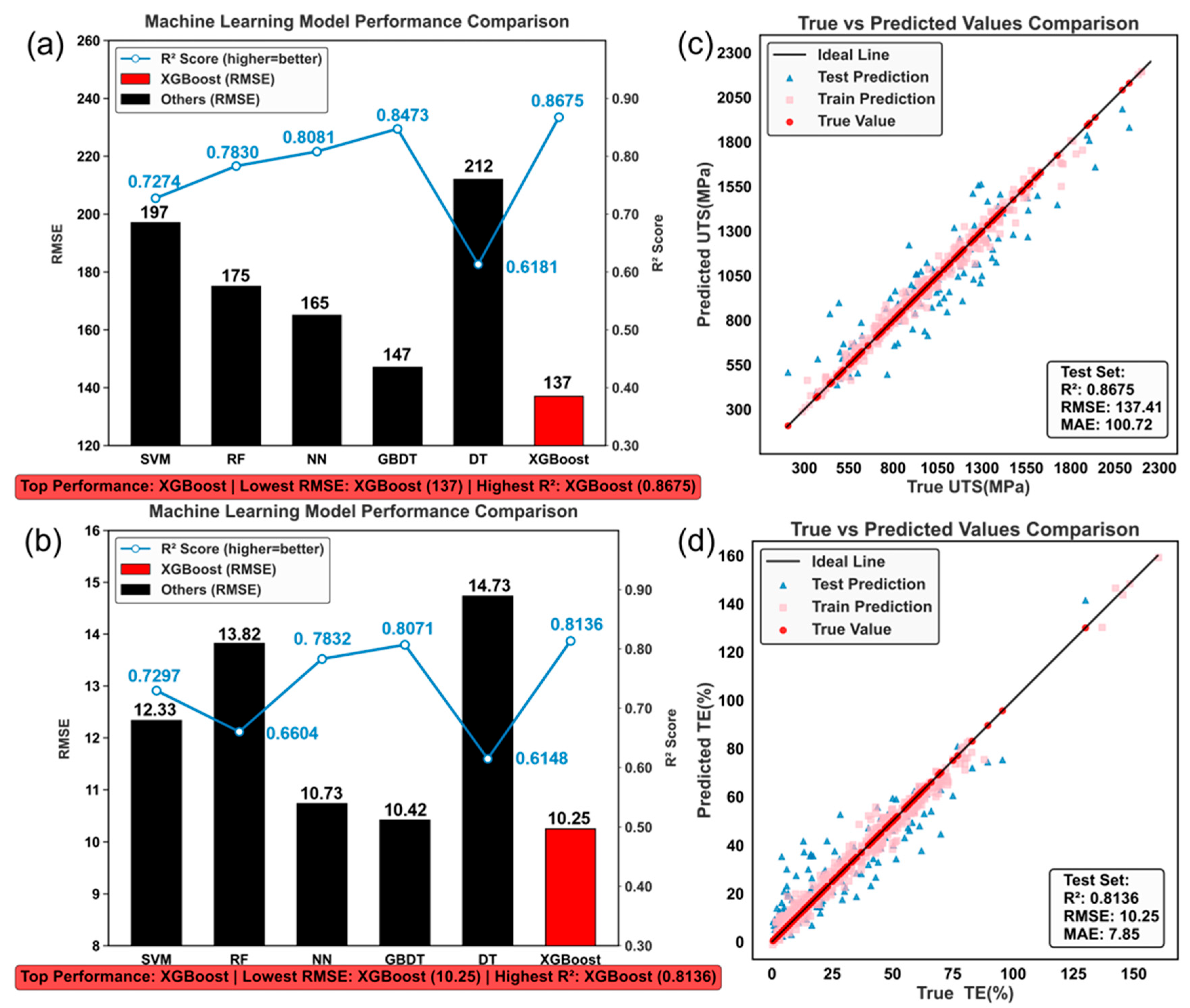

3.1. Performance Evaluation of Machine Learning Models

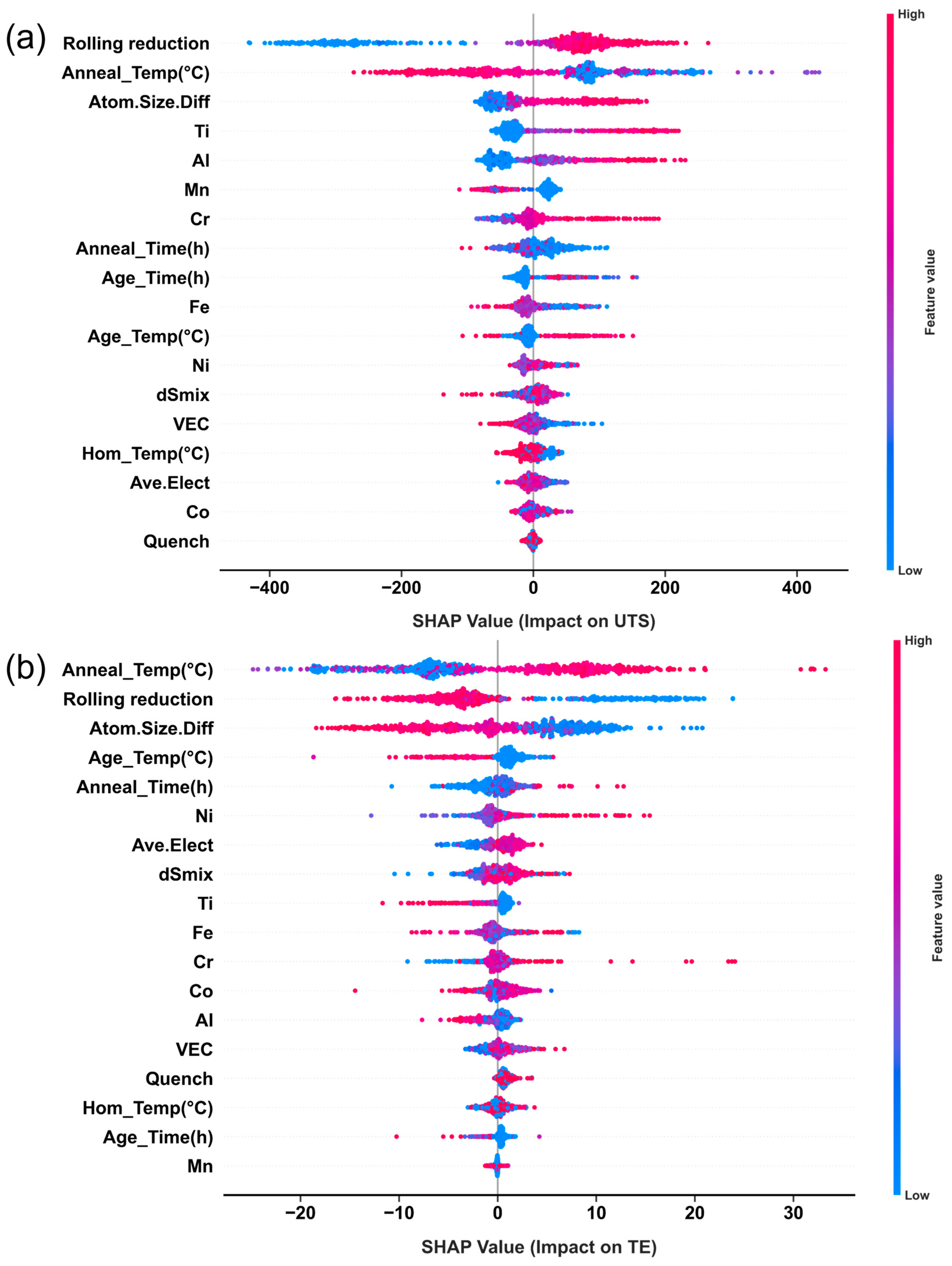

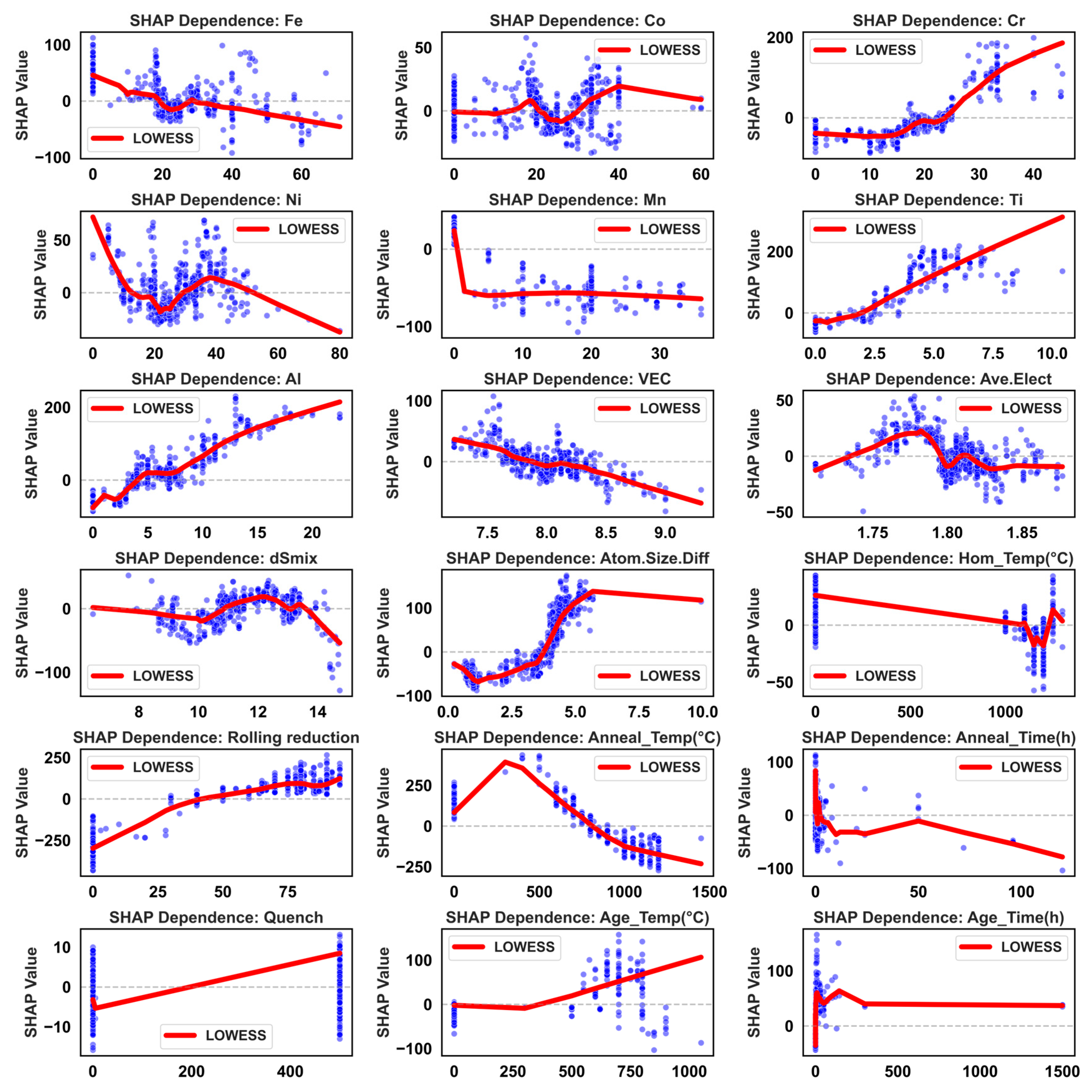

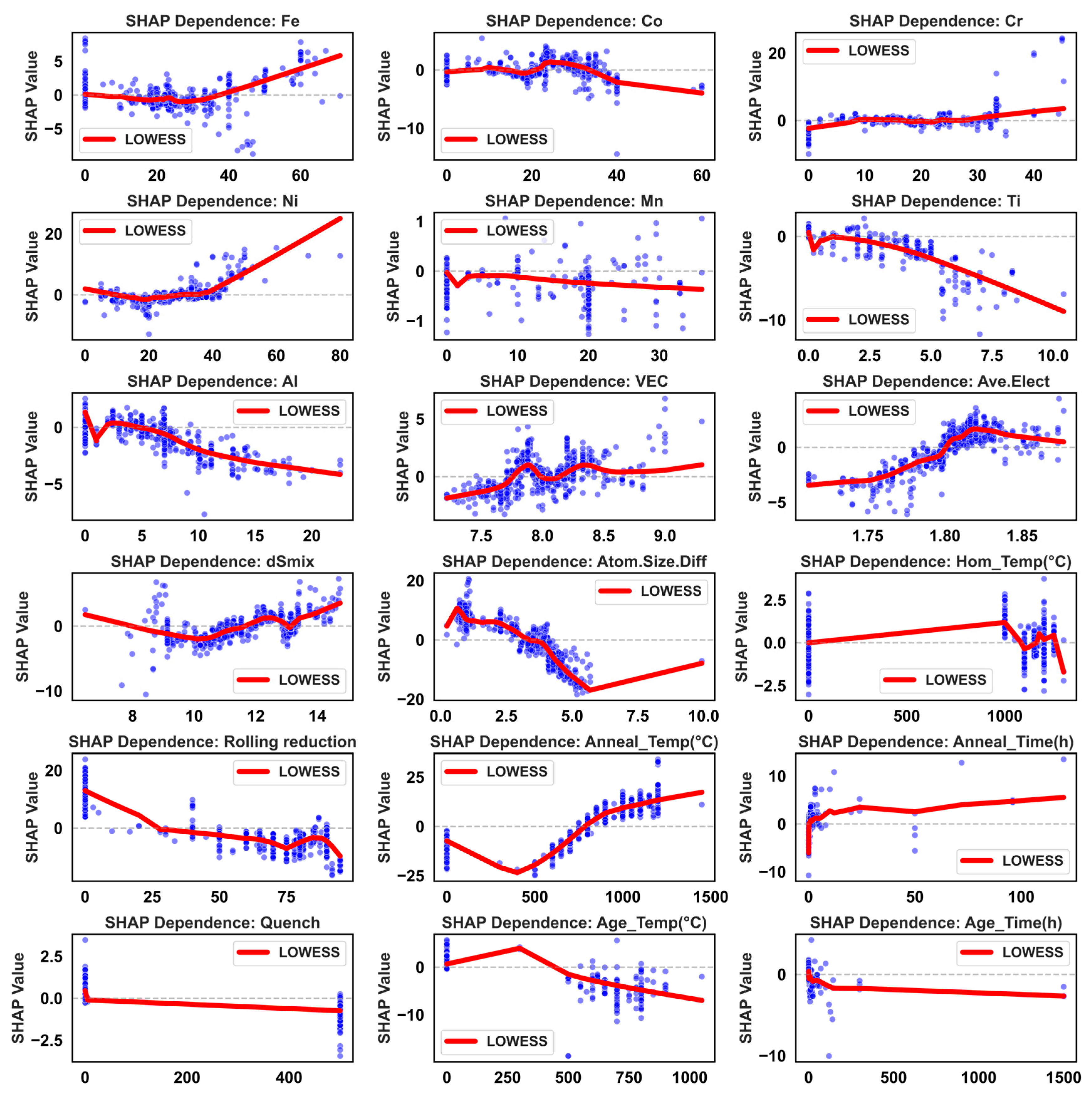

3.2. SHAP Analysis

4. Discussion

5. Conclusions

- (1)

- Among the six regression algorithms trained on the unified 18-dimensional feature space, XGBoost delivered the best overall accuracy and generalization for both UTS and TE, and was adopted for subsequent screening and inverse design. The prediction for UTS is robust across the studied strength range, whereas TE remains more difficult to capture—particularly in the low-ductility regime—highlighting the need for more microstructure-sensitive inputs.

- (2)

- SHAP-based interpretation identifies Ti, Al and Cr as primary strength-promoting elements within the investigated processing window, consistent with the combined effects of solid-solution hardening, precipitation strengthening and lattice distortion. In addition, a moderate atomic-size mismatch (δ ~4%) is associated with a more favorable strength–ductility synergy, suggesting that carefully tuned size mismatch is beneficial while excessive mismatch can penalize plasticity.

- (3)

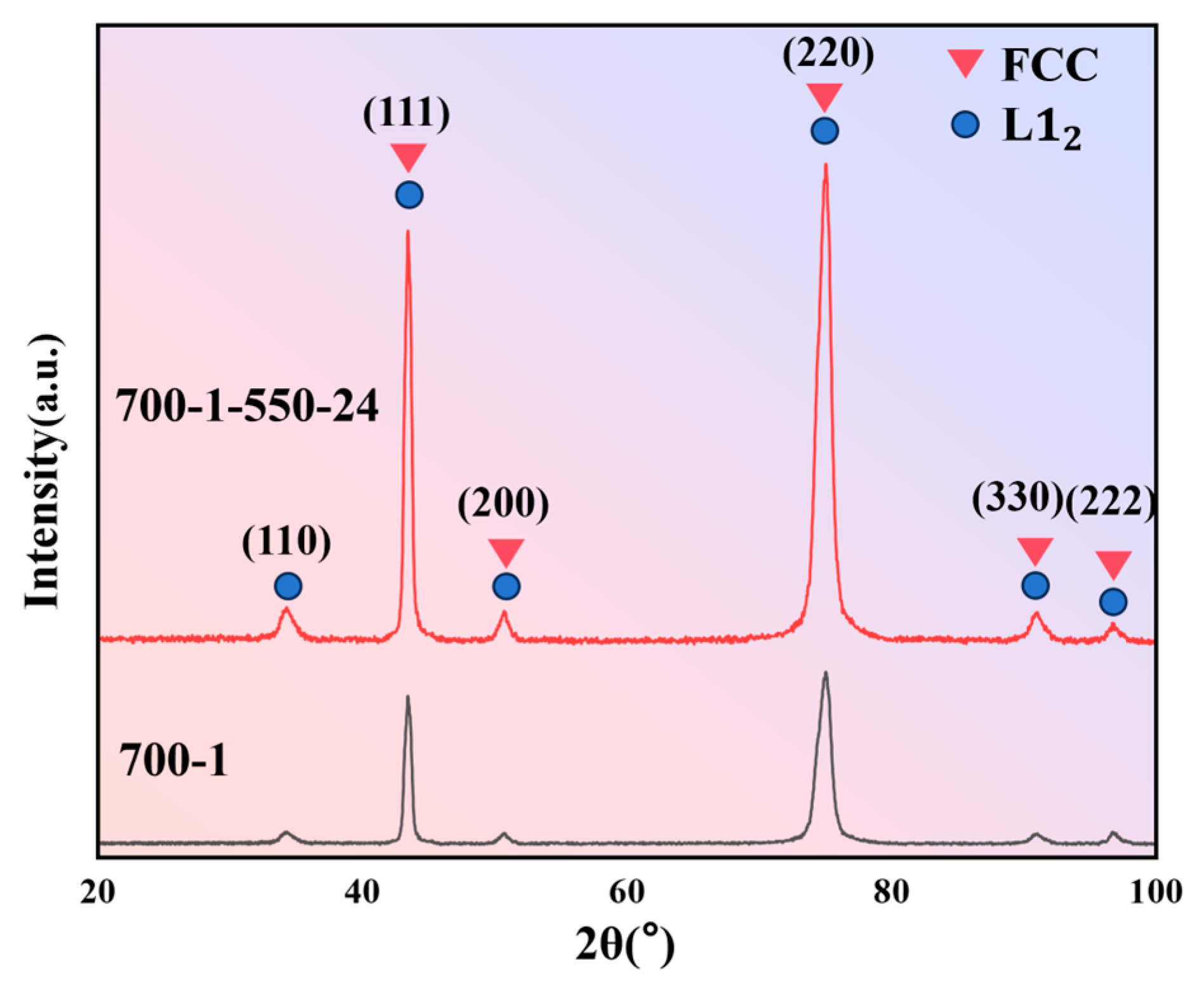

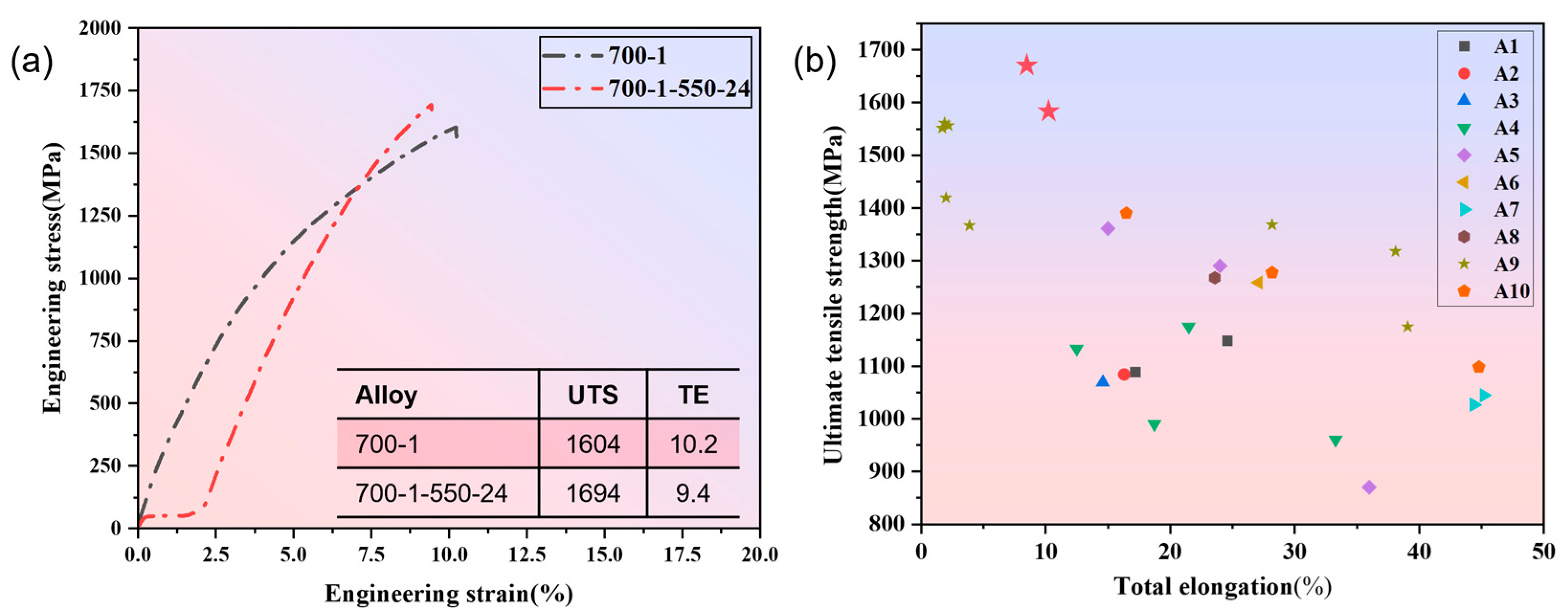

- Guided by the trained model under physically constrained conditions, two candidate alloy/process routes were proposed and experimentally validated. The 700 °C/1 h annealed condition achieved a UTS of 1604 MPa with a TE of 10.2%, while additional aging at 550 °C for 24 h increased the UTS to 1694 MPa with a TE of 9.4%. Both conditions fall within the ultra-high-strength (≥1600 MPa) regime with near-10% ductility, supporting the reliability of the inverse-design strategy.

- (4)

- The model–experiment comparison further suggests that a relatively high cooling rate (e.g., water or liquid-nitrogen quenching), annealing around 700 ± 20 °C and avoiding excessively long aging are effective levers to mitigate premature embrittlement while retaining high strength. The remaining deviations in TE prediction indicate that future improvements should incorporate explicit microstructural descriptors (e.g., grain size, precipitate fraction/morphology, interfacial energy and segregation-related metrics) to better quantify brittleness thresholds associated with phase transformations.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yeh, J.-W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375, 213–218. [Google Scholar] [CrossRef]

- Zhang, Y.; Zuo, T.T.; Tang, Z.; Gao, M.C.; Dahmen, K.A.; Liaw, P.K.; Lu, Z.P. Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 2014, 61, 1–93. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Pei, Z. An overview of modeling the stacking faults in lightweight and high-entropy alloys: Theory and application. Mater. Sci. Eng. A 2018, 737, 132–150. [Google Scholar] [CrossRef]

- Pei, Z.; Li, R.; Gao, M.C.; Stocks, G.M. Statistics of the nicocr medium-entropy alloy: Novel aspects of an old puzzle. NPJ Comput. Mater. 2020, 6, 1–6. [Google Scholar] [CrossRef]

- Pei, Z.; Yin, J.; Hawk, J.A.; Alman, D.E.; Gao, M.C. Machine-learning informed prediction of high entropy solid solution formation: Beyond the Hume Rothery rules. NPJ Comput. Mater. 2020, 6, 50. [Google Scholar] [CrossRef]

- Zhang, R.; Zhao, S.; Ding, J.; Chong, Y.; Jia, T.; Ophus, C.; Minor, A.M. Short-Range Order Its Impact Crconi Medium-Entropy alloy. Nature 2020, 581, 283–287. [Google Scholar] [CrossRef]

- Yin, B.; Yoshida, S.; Tsuji, N.; Curtin, W. Yield strength and misfit volumes of nicocr and implications for shortrange-order. Nat. Commun. 2020, 11, 1–7. [Google Scholar] [CrossRef]

- Körmann, F.; Ruban, A.V.; Sluiter, M.H. Longranged interactions in bcc nbmotaw high-entropy alloys. Mater. Res. Lett. 2017, 5, 35–40. [Google Scholar]

- Miracle, D.B.; Senkov, O.N. A critical review of high entropy alloys and related concepts. Acta. Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef]

- Chuang, M.H.; Tsai, M.H.; Wang, W.R.; Lin, S.J.; Yeh, J.W. Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys. Acta. Mater. 2011, 59, 6308–6317. [Google Scholar] [CrossRef]

- Ding, J.; Inoue, A.; Han, Y.; Kong, F.L.; Zhu, S.L.; Wang, Z.; Al-Marzouki, F. High entropy effect on structure and properties of (Fe,Co,Ni,Cr)-B amorphous alloys. J. Alloy. Compd. 2017, 696, 345–352. [Google Scholar] [CrossRef]

- Nene, S.S.; Frank, M.; Liu, K.; Sinha, S.; Mishra, R.S.; McWilliams, B.A.; Cho, K.C. Corrosion-resistant high entropy alloy with high strength and ductility. Scr. Mater. 2019, 166, 168–172. [Google Scholar] [CrossRef]

- Kwon, H.; Moon, J.; Bae, J.W.; Park, J.M.; Son, S.; Do, H.S.; Kim, H.S. Precipitation-Driven Metastability Eng. Carbon-Doped CoCrFeNiMo Medium-Entropy Alloys Cryog. temperature. Scr. Mater. 2020, 188, 140–145. [Google Scholar] [CrossRef]

- Karati, A.; Guruvidyathri, K.; Hariharan VSMurty, B.S. Thermal stability of AlCoFeMnNi high-entropy alloy. Scr. Mater. 2019, 162, 465–467. [Google Scholar] [CrossRef]

- Wu, Z.; Bei, H.; Pharr, G.M.; George, E.P. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. Acta Mater. 2014, 81, 428–441. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef]

- Yang, G.; Kang, J.; Kim, J.-K.; Park, J.H. Enhanced strength-ductility balance of the (CoCrFeNiMn)95.2Al3.2Ti1.6 high-entropy alloy by co-precipitation of the B2 and sigma phases. Mater. Sci. Eng. A 2023, 873, 145039. [Google Scholar] [CrossRef]

- Song, S.; Wang, X.; Zhang, Z.; Ren, X. Investigation on effect of L12 and B2 phases on tensile properties and mechanisms of Al0.3CoCrFeNi high entropy alloy through aging treatment. J. Alloys Compd. 2024, 1010, 177435. [Google Scholar] [CrossRef]

- Li, A.X.; Kang, K.W.; Yu, S.B.; Zhang, J.S.; Xu, M.K.; Huang, D.; Che, C.N.; Liu, S.K.; Jiang, Y.T.; Li, G. Heterogeneous structure and dual precipitates induced excellent strength-ductility combination in CoCrNiTi0.1 medium entropy alloy. Mater. Sci. Eng. A 2024, 912, 146992. [Google Scholar] [CrossRef]

- Tung, S.-Y.; Hsu, T.-E.; Zhu, Y.; Tsai, M.-H. Recrystallized hard zone and resultant tri-modal microstructure produces superior mechanical properties in a single-phase hetero structured high-entropy alloy. Acta Mater. 2024, 273, 119957. [Google Scholar] [CrossRef]

- Feng, S.; Zhou, H.; Dong, H. Application of deep transfer learning to predicting crystal structures of inorganic substances. Comput. Mater. Sci. 2021, 195, 110476. [Google Scholar] [CrossRef]

- Rao, Z.; Tung, P.Y.; Xie, R.; Wei, Y.; Zhang, H.; Ferrari, A.; Klaver, T.; Körmann, F.; Sukumar, P.T.; da Silva, Y.A.K.; et al. Machine learning enabled high-entropy alloy discovery. Science 2022, 378, 78–85. [Google Scholar] [CrossRef]

- Zhang, H.; Fu, X.; He, C.; Wang, L.; Jiang, L.; Chen, Q.; Xie, J. Dramatically enhanced combination of ultimate tensile strength and electric conductivity of alloys via machine learning screening. Acta Mater. 2020, 200, 803–810. [Google Scholar] [CrossRef]

- Zhang, H.; Fu, H.; Zhu, S.; Yong, W.; Xie, J. Machine learning assisted composition effective design for precipitation strengthened copper alloys. Acta Mater. 2021, 215, 117118. [Google Scholar] [CrossRef]

- Hu, Y.; Zhou, G.; Yuan, X.; Li, D.; Cao, L.; Zhang, W.; Wu, P. An artificial neural network based model for roping prediction in aluminum alloy sheet. Acta Mater. 2023, 245, 118605. [Google Scholar] [CrossRef]

- Liu, P.; Huang, H.; Jiang, X.; Zhang, Y.; Omori, T.; Lookman, T.; Su, Y. Evolution analysis of γ′ precipitate coarsening in co-based superalloys using kinetic theory and machine learning. Acta Mater. 2022, 235, 118101. [Google Scholar] [CrossRef]

- Jiang, L.; Wang, C.; Fu, H.; Shen, J.; Zhang, Z.; Xie, J. Discovery of aluminum alloys with ultra-strength and high-toughness via a property-oriented design strategy. J. Mater. Sci. Technol. 2022, 98, 33–43. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhou, Y.; He, Q.; Ding, Z.; Li, F.; Yang, Y. Machine learning guided appraisal and exploration of phase design for high entropy alloys. NPJ Comput. Mater. 2019, 5, 128. [Google Scholar] [CrossRef]

- Huang, X.; Jin, C.; Zhang, C.; Zhang, H.; Fu, H. Machine learning assisted modelling and design of solid solution hardened high entropy alloys. Mater. Des. 2021, 211, 110177. [Google Scholar] [CrossRef]

- Wen, C.; Zhang, Y.; Wang, C.; Xue, D.; Bai, Y.; Antonov, S.; Dai, L.; Lookman, T.; Su, Y. Machine learning assisted design of high entropy alloys with desired property. Acta Mater. 2019, 170, 109–117. [Google Scholar] [CrossRef]

- Kaufmann, K.; Vecchio, K.S. Searching for high entropy alloys: A machine learning approach. Acta Mater. 2020, 198, 178–222. [Google Scholar] [CrossRef]

- Wang, J.; Kwon, H.; Kim, H.S.; Lee, B.-J. A neural network model for high entropy alloy design. NPJ Comput. Mater. 2023, 9, 60. [Google Scholar] [CrossRef]

- Singh, S.K.; Mahanta, B.K.; Rawat, P.; Kumar, S. Machine Learning-Assisted Design of High-Entropy Alloys for Optimal Strength and Ductility. J. Alloys Compd. 2024, 1007, 176282. [Google Scholar] [CrossRef]

- Zhang, Y.; Weyland, M.; Milkereit, B.; Reich, M.; Rometsch, P.A. Precipitation of A New Platelet Phase Dur. Quenching Al-Zn-Mg-Cu alloy. Sci. Rep. 2016, 6, 23109. [Google Scholar] [CrossRef]

- Zhengjiu, X.; Youxue, Z. Quench rates in air, water, and liquid nitrogen, and inference of temperature in volcanic eruption columns. Earth Planet. Sci. Lett. 2002, 200, 315–330. [Google Scholar] [CrossRef]

- Zhu, L.; Li, N.; Childs, P.R.N. Light-weighting in aerospace component and system design. Propuls. Power Res. 2018, 7, 103–119. [Google Scholar] [CrossRef]

- Liu, X.S.; Li, R.; Fan, X.F.; Liu, Q.Q.; Tong, X.; Li, A.X.; Xu, S.; Yang, H.; Yu, S.B.; Jiang, M.H.; et al. Excellent strength-ductility combination in Co36Cr15Fe18Ni18Al8Ti4Mo1 multi-principal element alloys by dual-morphology B2 precipitates strengthening. J. Mater. Sci. Technol. 2022, 134, 60–66. [Google Scholar] [CrossRef]

- Huang, D.; Zhuang, Y. Break the strength-ductility trade-off in a transformation-induced plasticity high-entropy alloy reinforced with precipitation strengthening. J. Mater. Sci. Technol. 2021, 108, 125–132. [Google Scholar] [CrossRef]

- Qin, S.; Yang, M.; Jiang, P.; Yuan, F.; Wu, X. Excellent tensile properties induced by heterogeneous grain structure and dual nanoprecipitates in high entropy alloys. Mater. Charact. 2022, 186, 111779. [Google Scholar] [CrossRef]

- Li, A.X.; Liu, X.S.; Li, R.; Yu, S.B.; Jiang, M.H.; Zhang, J.S.; Che, C.N.; Huang, D.; Yu, P.F.; Li, G. Double heterogeneous structures induced excellent strength–ductility synergy in Ni40Co30Cr20Al5Ti5 medium-entropy alloy. J. Mater. Sci. Amp. Technol. 2024, 181, 176–188. [Google Scholar]

- Xiong, T.; Zheng, S.; Pang, J.; Ma, X. High-strength and high-ductility AlCoCrFeNi2.1 eutectic high-entropy alloy achieved via precipitation strengthening in a heterogeneous structure. Scr. Mater. 2020, 186, 336–340. [Google Scholar]

- Zhang, Z.; Huang, Y.; Xu, Q.; Fellner, S.; Hohenwarter, A.; Wurster, S.; Song, K.; Gammer, C.; Jürgen, E. Equiaxed microstructure design enables strength-ductility synergy in the eutectic high-entropy alloy. J. Mater. Res. Technol. 2024, 33, 103–114. [Google Scholar] [CrossRef]

- Liu, Z.; Xiong, Z.; Chen, K.; Cheng, X. Large-size high-strength and high-ductility AlCoCrFeNi2.1 eutectic high-entropy alloy produced by hot-rolling and subsequent aging. Mater. Lett. 2022, 315, 131933. [Google Scholar] [CrossRef]

- Luo, Z.; Liu, Q.; Wei, J.; Huang, X.; Gao, Z.; Wang, Z.; Ma, X. Enhancing the strength-ductility synergy of dual-phase Al0.3CoCrFeNiTi0.3 high-entropy alloys through the regulation of B2 phase content. Mater. Sci. Eng. A 2024, 916, 147346. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, Y.; Yu, L.; Zeng, S.; Wang, A.; Fu, H.; Zhang, H.; Zhang, H.; Zhu, Z. Enhancing strength-ductility combination of Fe–Ni–Cr–Al–Ti high-entropy alloys via co-precipitation of sigma and L21 phases. Mater. Sci. Eng. A 2024, 913, 147062. [Google Scholar]

- Xu, X.; Li, H.; Zhao, Y.; Zhang, X.; Pan, Y.; Liaw, P.K.; Hou, H. Enhancement of strength-ductility trade-off in Al5Fe25Cr25Ni42.5Ti2.5 high entropy alloy through annealing twins. Mater. Sci. Eng. A 2024, 921, 147519. [Google Scholar]

- Wu, W.; Gan, K.; Yang, Q.; Yan, D.; Zhang, Y.; Li, Z. Modulating hierarchical microstructural components to enhance strength-ductility synergy of a high-entropy alloy containing brittle sigma phase. Mater. Sci. Eng. A 2024, 900, 146511. [Google Scholar]

- Yang, T.; Zhao, Y.L.; Tong, Y.; Jiao, Z.B.; Wei, J.; Cai, J.X.; Han, X.D.; Chen, D.; Hu, A.; Kai, J.J.; et al. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science 2018, 362, 933–937. [Google Scholar] [CrossRef]

- Jeong, H.T.; Xing, Y.; Park, H.K.; Na, T.W.; Oh, S.H.; Kim, W.J. Achieving high strength and uniform ductility in high-entropy alloys via dynamic-precipitation accelerated transformation-induced plasticity. Acta Mater. 2024, 272, 119945. [Google Scholar] [CrossRef]

- Liu, X.X.; Ma, S.G.; Wang, J.J.; Zhao, D.; Jiao, Z.M.; Zhang, T.W.; Qiao, L.; Chen, X.Z.; Wang, Z.H. Achieving well-balanced strength and ductility via dual nanoscale precipitate structures in Co-free high-entropy alloys. J. Mater. Res. Technol. 2024, 29, 5539–5549. [Google Scholar] [CrossRef]

| Feature Category | Parameter | Unit/Encoding | Physical Interpretation |

|---|---|---|---|

| Composition | Fe, Co, Cr, Ni, Mn | at.% | Solvent matrix effects; SFE modulation. |

| Al, Ti | at.% | Solute strengthening. Precipitate formers (γ’-L12). | |

| Thermodynamics | VEC | - | Phase stability criterion (FCC vs. BCC/). Threshold ~8.0. |

| % | Lattice distortion energy. Solution hardening potential. | ||

| - | Average Electronegativity. The overall electron affinity of the alloy and the chemical bonding properties between atoms | ||

| J/(mol·K) | Configurational Mixing Entropy. A higher mixing entropy can reduce the Gibbs free energy of the system (G = H − TS), thereby stabilizing the solid solution phase (such as FCC or BCC) at high temperatures and inhibiting the formation of intermetallic compounds. | ||

| Processing | Cooling Rate | K/s (Log scale) | Replaces ordinal codes. Controls vacancy retention & supersaturation. Values: Furnace (0.1), Air (5), Liquid Nitrogen (40), Water (500). |

| Aging Temp/Time | °C/h | Kinetics of precipitation (Ostwald ripening control). | |

| Annealing temp/Time | °C/h | Recrystallization kinetics. Resuscitation–Recrystallization–Grain Growth and “Dissolution/Homogeneity” | |

| Homogenization Temp | °C/h | The degree of elimination of as-cast compositional segregation and the solubility tendency of coarse second phase. | |

| Rolling reduction | % | Cold working plastic deformation degree |

| Parameter | 700-1 | 700-1-550-24 |

|---|---|---|

| Fe(at%) | 0 | 0 |

| Co(at%) | 30 | 30 |

| Cr(at%) | 15 | 15 |

| Ni(at%) | 45 | 45 |

| Mn(at%) | 0 | 0 |

| Al(at%) | 5 | 5 |

| Ti(at%) | 5 | 5 |

| Homogenization temp. (°C) | 1200 | 1200 |

| Reduction rate (%) | 80 | 80 |

| Annealing temp. (°C) | 700 | 700 |

| Annealing time (h) | 1 | 1 |

| Cooling method | Water quenching (500) | Water quenching (500) |

| Aging temp. (°C) | 0 | 550 |

| Aging time (h) | 0 | 24 |

| Predicted UTS (MPa) | 1711 | 1695 |

| Predicted TE (%) | 32 | 22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Xu, X.; He, Z.; Zheng, K.; Che, L.; Zhao, F.; Hua, D. Design of Fe-Co-Cr-Ni-Mn-Al-Ti Multi-Principal Element Alloys Based on Machine Learning. Materials 2026, 19, 422. https://doi.org/10.3390/ma19020422

Xu X, He Z, Zheng K, Che L, Zhao F, Hua D. Design of Fe-Co-Cr-Ni-Mn-Al-Ti Multi-Principal Element Alloys Based on Machine Learning. Materials. 2026; 19(2):422. https://doi.org/10.3390/ma19020422

Chicago/Turabian StyleXu, Xiaotian, Zhongping He, Kaiyuan Zheng, Lun Che, Feng Zhao, and Deng Hua. 2026. "Design of Fe-Co-Cr-Ni-Mn-Al-Ti Multi-Principal Element Alloys Based on Machine Learning" Materials 19, no. 2: 422. https://doi.org/10.3390/ma19020422

APA StyleXu, X., He, Z., Zheng, K., Che, L., Zhao, F., & Hua, D. (2026). Design of Fe-Co-Cr-Ni-Mn-Al-Ti Multi-Principal Element Alloys Based on Machine Learning. Materials, 19(2), 422. https://doi.org/10.3390/ma19020422