Edgewise Compressive Properties of Ecological Sandwich Panels with Engineered Bamboo Face Sheets and Bamboo Culm Core

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Properties

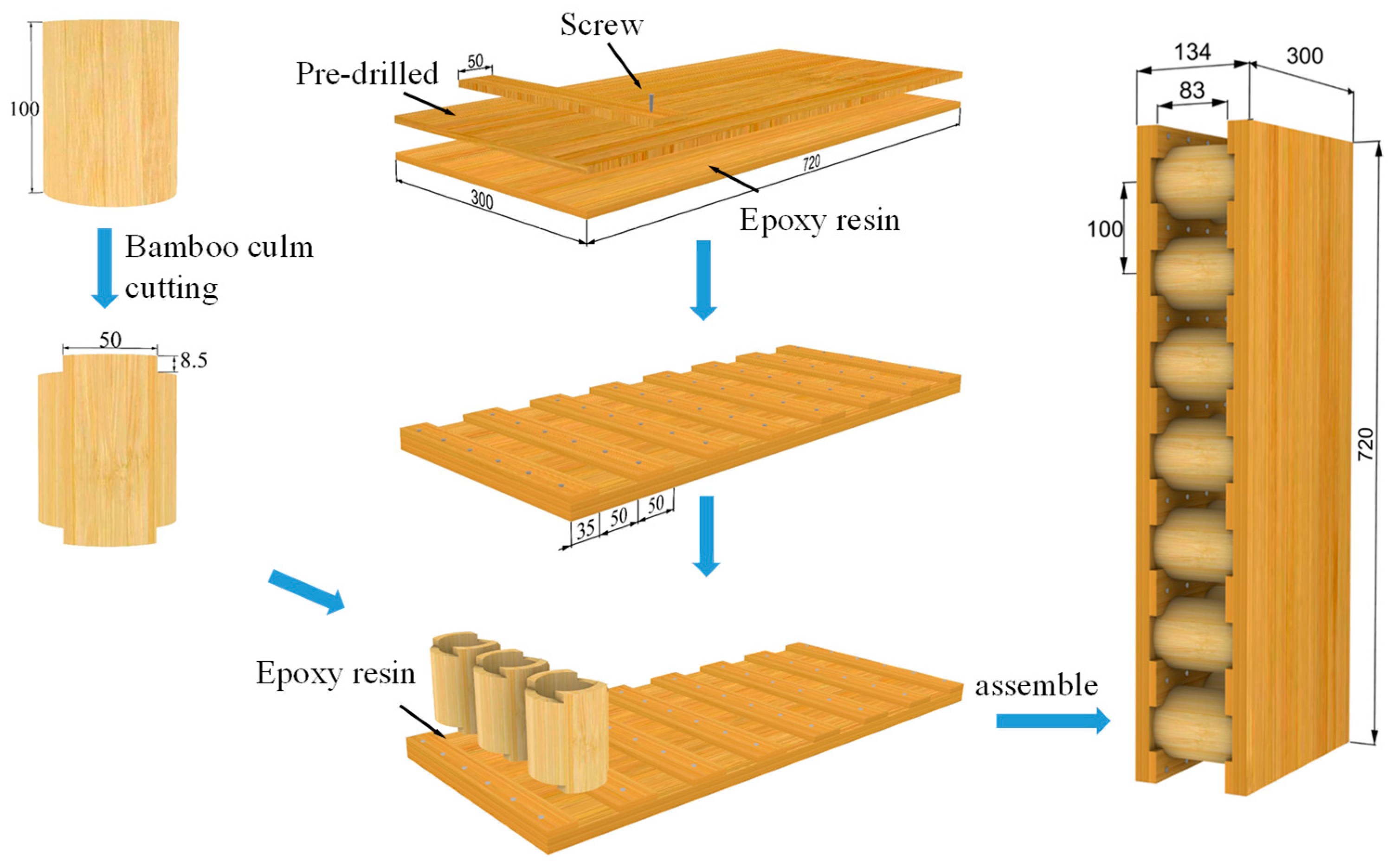

2.2. Manufacturing

2.3. Setup and Instrumentation

3. Results

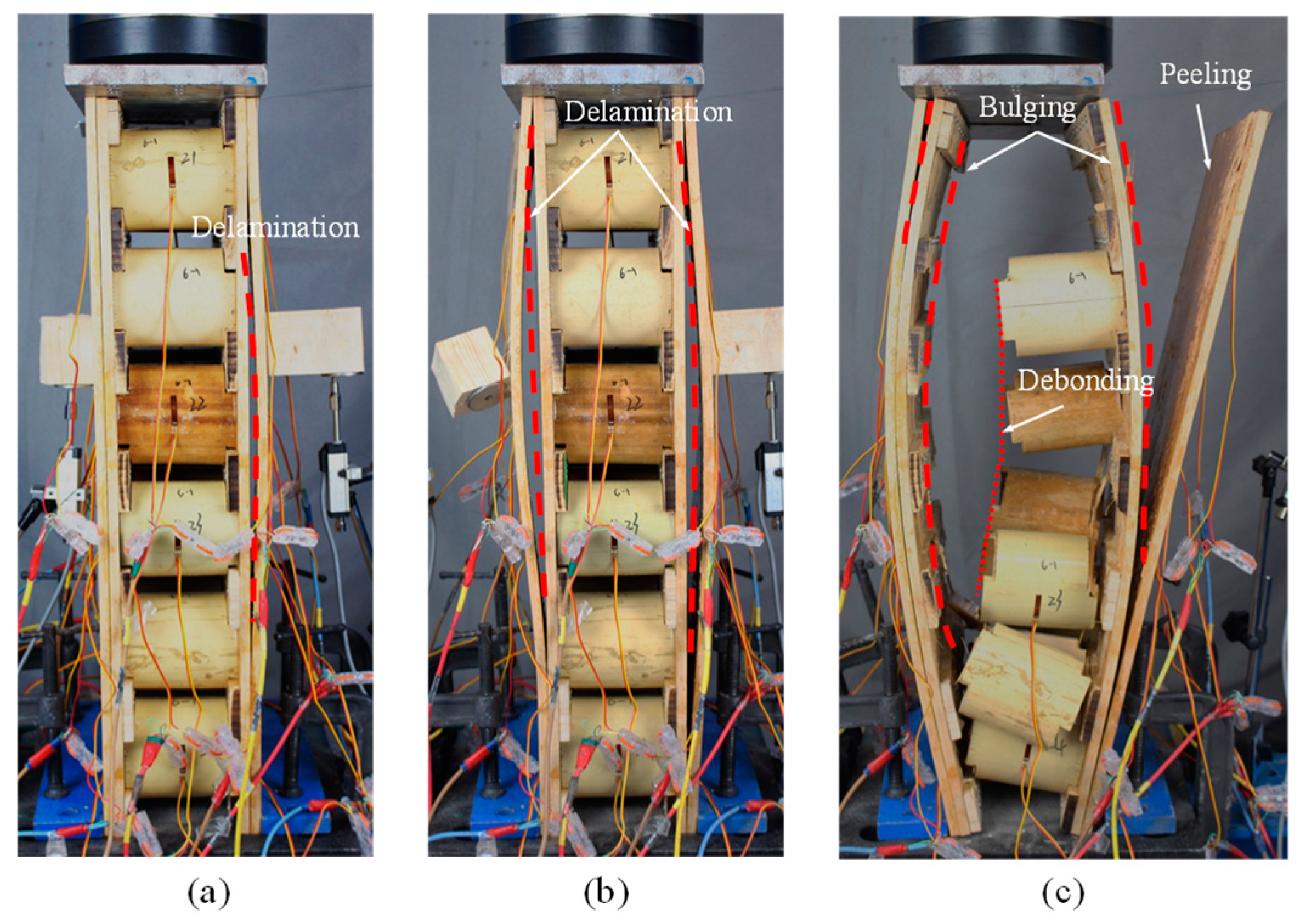

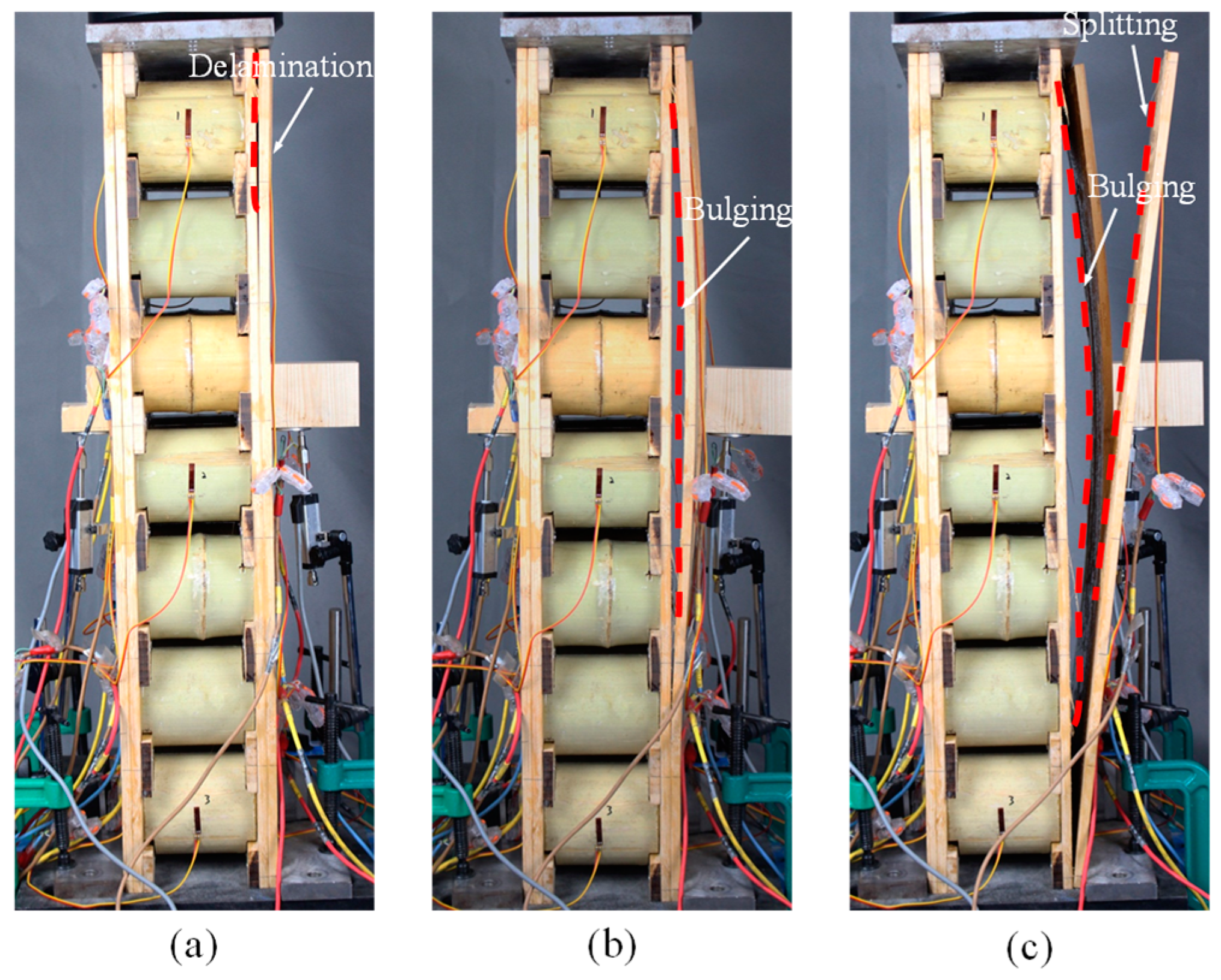

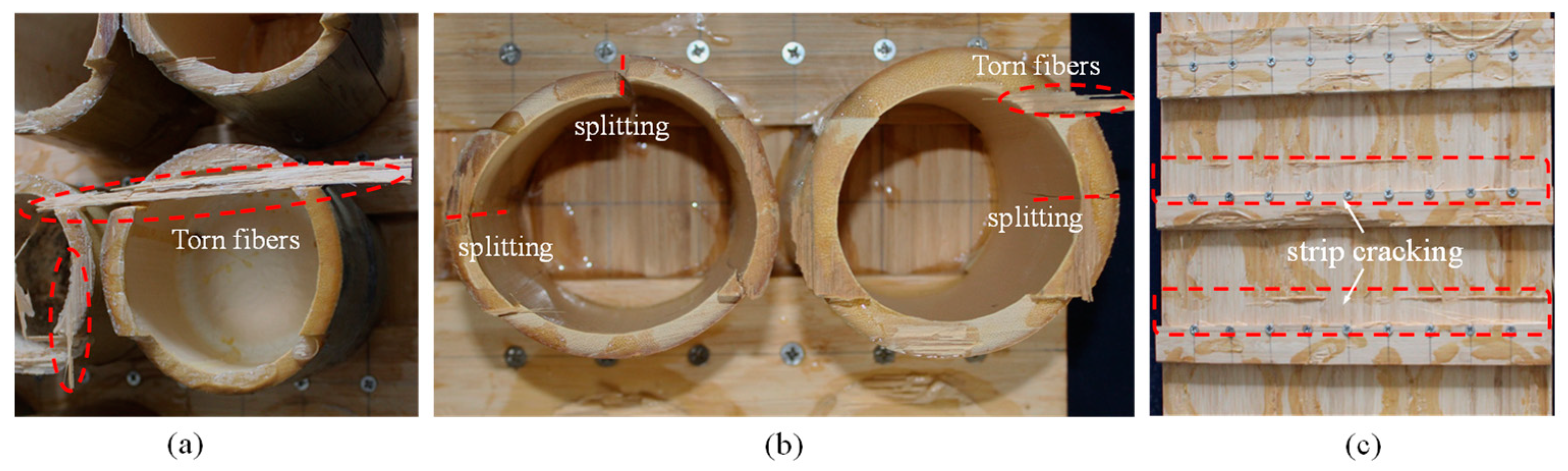

3.1. Experimental Observations and Failure Modes

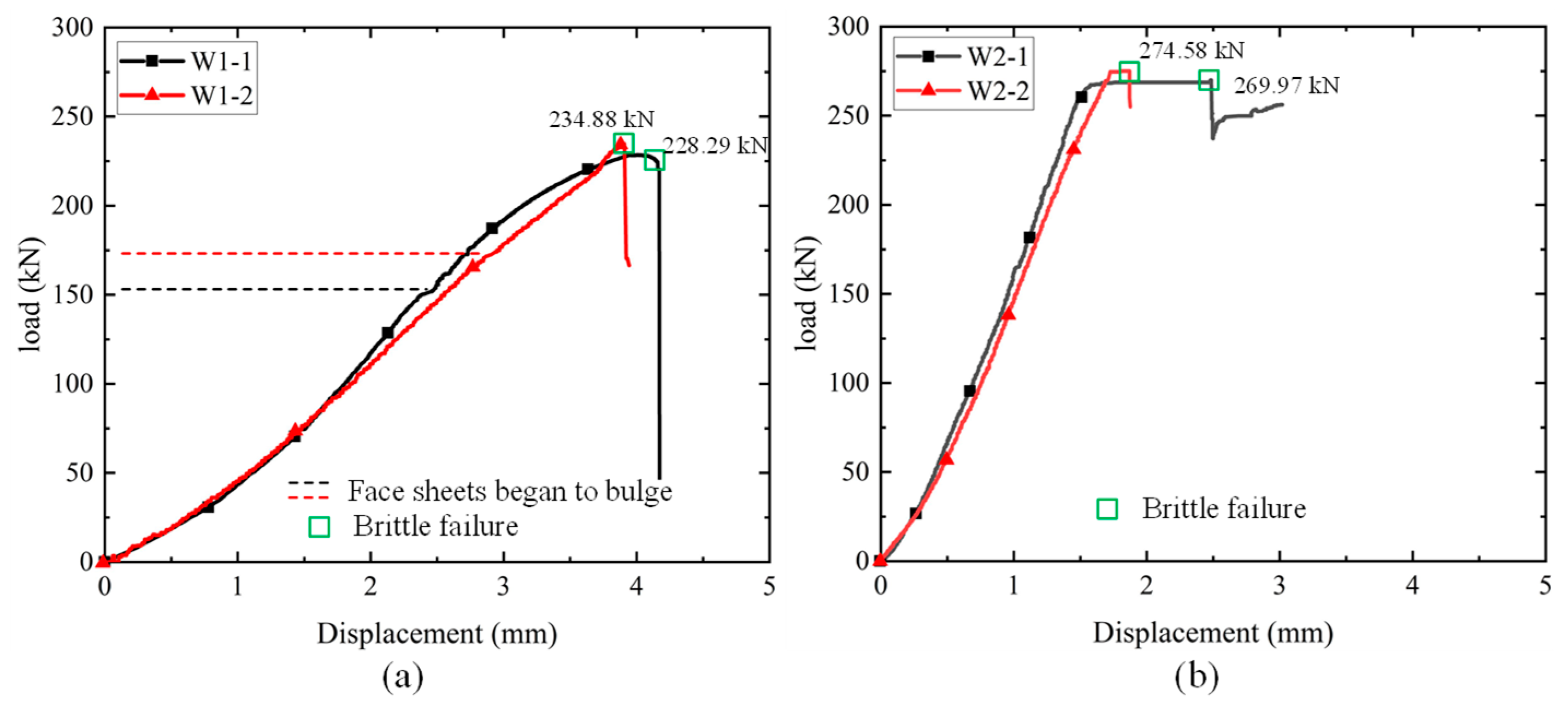

3.2. Axial Load-Displacement Relationships

3.3. Axial Load–Strain Response

4. Analysis and Discussion

4.1. Strength

4.2. Rigidity

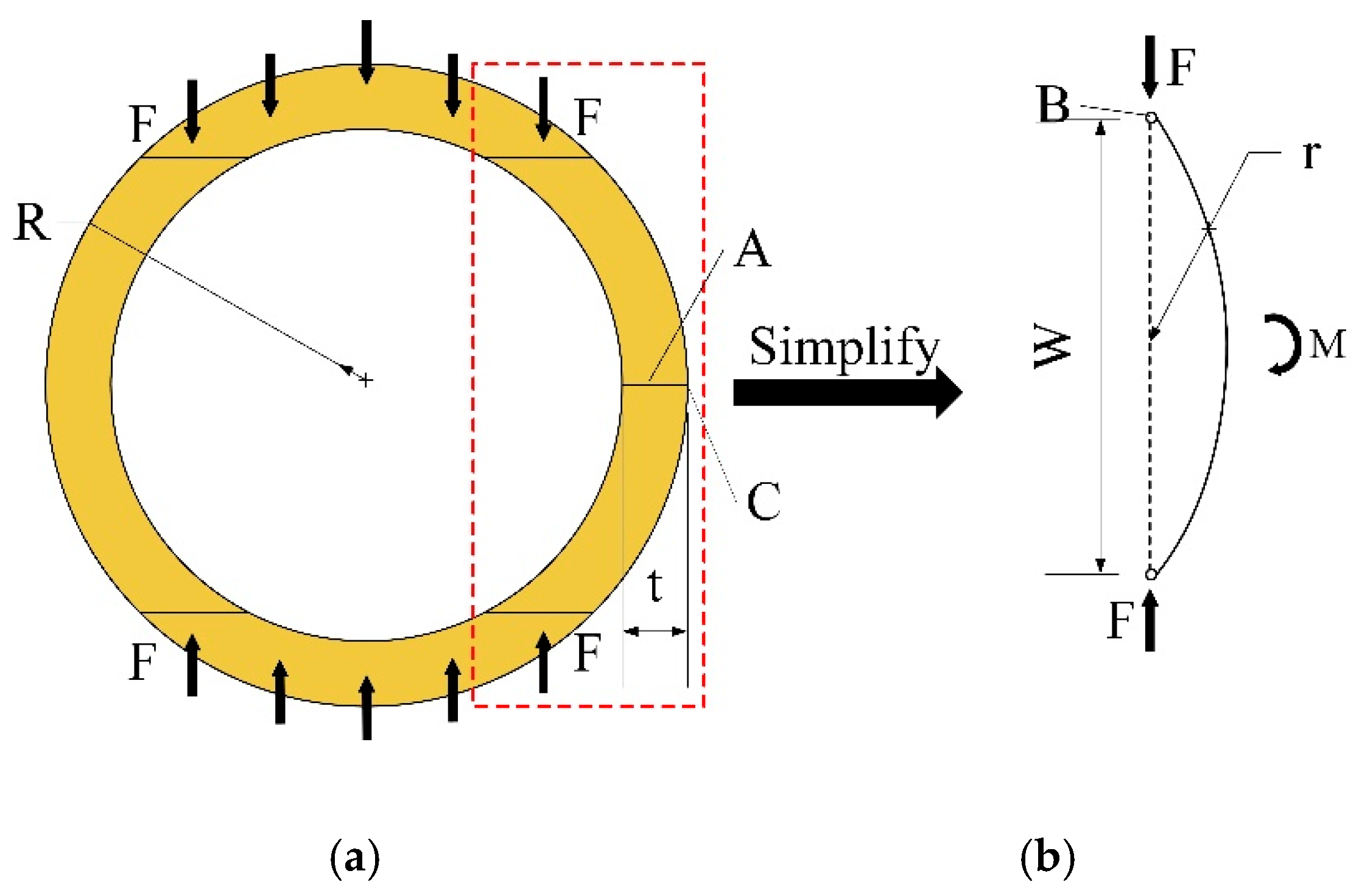

4.3. Stability Verification

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xiao, F.M.; Fan, S.H.; Wang, S.L.; Xiong, C.Y.; Zhang, C.; Liu, S.P. Carbon storage and spatial distribution in Phyllostachy pubescens and Cunninghamia lanceolata plantation ecosystem. Acta Phytoecol. Sin. 2007, 27, 2791–2801. [Google Scholar]

- Uchimura, E. Bamboo as a genetic resource and its utilization from the world wide view point. J. Agric. Sci. Technol. B 2013, 3, 239–245. [Google Scholar]

- Goh, Y.; Yap, S.P.; Tong, T.Y. Bamboo: The emerging renewable material for sustainable construction. Encyc. Renew. Sustain. Mater. 2020, 2, 365–376. [Google Scholar]

- Huang, Z.; Sun, Y.; Musso, F. Assessment of bamboo application in building envelope by comparison with reference timber. Constr. Build. Mater. 2017, 156, 844–860. [Google Scholar] [CrossRef]

- Meng, X.; Zhang, Z.; Wu, Y.; Xu, F.; Feng, P. A comprehensive evaluation of the effects of bamboo nodes on the mechanical properties of bamboo culms. Eng. Struct. 2023, 297, 116975. [Google Scholar] [CrossRef]

- Chen, Z.; Ma, R.; Du, Y.; Wang, X. State-of-the-art review on research and application of original bamboo-based composite components in structural engineering. Structures 2022, 35, 1010–1029. [Google Scholar] [CrossRef]

- Xu, Q.; Harries, K.; Li, X.; Liu, Q.; Gottron, J. Mechanical properties of structural bamboo following immersion in water. Eng. Struct. 2014, 81, 230–239. [Google Scholar] [CrossRef]

- Hone, T.; Cahill, L.; Robinson, A.; Korde, C.; Taylor, D. The splitting of bamboo in response to changes in humidity and temperature. J. Mech. Behav. Biomed. Mater. 2020, 111, 103990. [Google Scholar] [CrossRef]

- Sharma, B.; Gatoo, A.; Bock, M.; Mulligan, H.; Ramage, M. Engineered bamboo: State of the art. Proc. Inst. Civ. Eng. Constr. Mater. 2015, 168, 57–67. [Google Scholar] [CrossRef]

- Sulastiningsih, I.M.; Nurwati. Physical and mechanical properties of laminated bamboo board. J. Trop. For. Sci. 2009, 21, 246–251. [Google Scholar]

- Sun, X.; He, M.; Li, Z. Novel engineered wood and bamboo composites for structural applications: State-of-art of manufacturing technology and mechanical performance evaluation. Constr. Build. Mater. 2020, 249, 118751. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Q.; Wu, G. Stress-strain model of side pressure laminated bamboo under compression. J. Southeast Univ. Engl. Ed. 2015, 45, 1130–1134. [Google Scholar]

- Liu, X.M.; Smith, G.D.; Jiang, Z.H.; Bock, M.C.D.; Boeck, F.; Frith, O.; Gatóo, A.; Liu, K.; Mulligan, H.; Semple, K.E.; et al. Nomenclature for engineered bamboo. BioResources 2016, 11, 1141–1161. [Google Scholar] [CrossRef]

- Sharma, B.; Gatoo, A.; Bock, M.; Ramage, M. Engineered bamboo for structural applications. Constr. Build. Mater. 2015, 81, 66–73. [Google Scholar] [CrossRef]

- Verma, C.S.; Chariar, V.M. Development of layered laminate bamboo composite and their mechanical properties. Compos. Part B 2012, 43, 1063–1069. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Q.; Huang, D.; Deeks, A.J. Compressive performance of laminated bamboo. Compos. Part B 2013, 54, 319–328. [Google Scholar] [CrossRef]

- Yeh, M.C.; Lin, Y.L. Finger joint performance of structural laminated bamboo member. J. Wood Sci. 2012, 58, 120–127. [Google Scholar] [CrossRef]

- Ahmad, M.; Kamke, F.A. Properties of parallel strand lumber from Calcutta bamboo (Dendrocalamus strictus). Wood Sci. Technol. 2011, 45, 63–72. [Google Scholar] [CrossRef]

- Nugroho, N.; Ando, N. Development of structural composite products made from bamboo II: Fundamental properties of laminated bamboo lumber. J. Wood Sci. 2001, 47, 237–242. [Google Scholar] [CrossRef]

- Zhang, D.; Yan, L.; Meng, X.; Sewar, Y.Y.A.; Zhang, Z.; Gao, Y. Mechanical properties of a novel laminated veneer bamboo using curved cross-sectional strips. Ind. Crops Prod. 2024, 220, 119290. [Google Scholar] [CrossRef]

- Sewar, Y.Y.; Zhang, Z.; Meng, X.; Wahan, M.Y.; Qi, H.; Al-Shami, Q.M.; Luo, S. Mechanical properties and constitutive relationship of the high-durable parallel strand bamboo. J. Renew. Mater. 2022, 10, 219. [Google Scholar] [CrossRef]

- Mahdavi, M.; Clouston, P.L.; Arwade, S.R. A low-technology approach toward fabrication of Laminated Bamboo Lumber. Constr. Build. Mater. 2012, 29, 257–262. [Google Scholar] [CrossRef]

- Chen, J.; Guagliano, M.; Shi, M.; Jiang, X.; Zhou, H. A comprehensive overview of bamboo scrimber and its new development in China. Eur. J. Wood Wood Prod. 2021, 79, 363–379. [Google Scholar] [CrossRef]

- Xiao, Y.; Yang, R.Z.; Shan, B. Production, environmental impact and mechanical properties of glubam. Constr. Build. Mater. 2013, 44, 765–773. [Google Scholar] [CrossRef]

- Tian, L.; Kou, Y.; Hao, J. Axial compressive behaviour of sprayed composite mortar–original bamboo composite columns. Constr. Build. Mater. 2019, 215, 726–736. [Google Scholar] [CrossRef]

- Alla Fadlelmola, A.B.; Chen, Z.; Du, Y.; Ma, R.; Ma, J. Experimental investigations and design method on a lightweight bamboo-concrete sandwich panel under axial load. J. Build. Eng. 2021, 42, 103077. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, L.; Zhang, Z.; Mwambala, M.A. Study on bending performance of laminated bamboo sandwich panels with different lattice core layers: Cleaner production of green material. Case Stud. Constr. Mater. 2024, 20, e03379. [Google Scholar] [CrossRef]

- Darzi, S.; Karampour, H.; Bailleres, H.; Gilbert, B.P.; Fernando, D. Load bearing sandwich timber walls with plywood faces and bamboo core. Structures. 2020, 27, 2437–2450. [Google Scholar] [CrossRef]

- González, O.M.; García, A.; Guachambala, M.; Navas, J.F. Innovative sandwich-like composite biopanels—Towards a new building biomaterials concept for structural applications in nonconventional building systems. Wood Mater. Sci. Eng. 2020, 16, 132–148. [Google Scholar] [CrossRef]

- Wang, R.; Wei, S.Q.; Li, Z.; Xiao, Y. Performance of connection system used in lightweight glubam shear wall. Constr. Build. Mater. 2019, 206, 419–431. [Google Scholar] [CrossRef]

- Zhang, X.; Jiang, Z.; Fei, B.; Fang, G.; Liu, H. Experimental performance of threaded steel glued into laminated bamboo. Constr. Build. Mater. 2020, 249, 118780. [Google Scholar] [CrossRef]

- Srivaro, S. Utilization of bamboo as lightweight sandwich panels. Mater. Sci. 2016, 22, 60–64. [Google Scholar] [CrossRef][Green Version]

- Wahan, M.Y.; Zhang, Z.; Meng, X.; Gao, Y.; Ji, X. Mechanical behavior of GFRP-bamboo composite shear connections. Constr. Build. Mater. 2022, 331, 127333. [Google Scholar] [CrossRef]

- Fang, H.; Sun, H.; Liu, W.; Wang, L.; Bai, Y.; Hui, D. Mechanical performance of innovative GFRP-bamboo-wood sandwich beams: Experimental and modelling investigation. Compos. Part B 2015, 79, 182–196. [Google Scholar] [CrossRef]

- GB/T 7124-2008; Adhesives—Determination of tensile lap-shear strength of rigid-to-rigid bonded assemblies. National Standards of People’s Republic of China: Beijing, China, 2008.

- GB/T 1454-2021; Test method for edgewise compressive properties of sandwich constructions. National Standards of People’s Republic of China: Beijing, China, 2021.

| Group | Specimen | Size (mm) | Height to Thickness Ratio | Number of Bamboo Culms |

|---|---|---|---|---|

| A | W1-1 | 620 × 300 × 134 | 4.63 | 18 |

| W1-2 | ||||

| B | W2-1 | 720 × 300 × 134 | 5.37 | 21 |

| W2-2 |

| Specimens | Peak Load Pmax (kN) | Compressive Strength σf (MPa) | Average Value (MPa) | Standard Deviation (MPa) |

|---|---|---|---|---|

| W1-1 | 228.29 | 22.38 | 22.705 | 0.460 |

| W1-2 | 234.88 | 23.03 | ||

| W2-1 | 269.97 | 26.47 | 26.695 | 0.318 |

| W2-2 | 274.58 | 26.92 |

| Specimens | Fitting Function | Slope | Rigidity (N) | Average Value (N) | Standard Deviation (N) |

|---|---|---|---|---|---|

| W1-1 | Linear | 0.05577 | 55.77 | 59.525 | 5.310 |

| W1-2 | 0.06328 | 63.28 | |||

| W2-1 | 0.08090 | 80.90 | 80.385 | 0.728 | |

| W2-2 | 0.07987 | 79.87 |

| Specimens | Radius of Gyration i (mm) | Slenderness Ratio λ | Rigidity EA (MPa) | P (kN) | Threshold Value λp |

|---|---|---|---|---|---|

| W1-1 | 58.64 | 10.57 | 55.77 | 228.29 | 49.10 |

| W1-2 | 63.28 | 234.88 | 51.57 | ||

| W2-1 | 12.28 | 80.90 | 269.97 | 54.38 | |

| W2-2 | 79.87 | 274.58 | 53.58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Deng, J.; Wang, M.; Meng, X.; Xu, L. Edgewise Compressive Properties of Ecological Sandwich Panels with Engineered Bamboo Face Sheets and Bamboo Culm Core. Materials 2025, 18, 2158. https://doi.org/10.3390/ma18092158

Liu X, Deng J, Wang M, Meng X, Xu L. Edgewise Compressive Properties of Ecological Sandwich Panels with Engineered Bamboo Face Sheets and Bamboo Culm Core. Materials. 2025; 18(9):2158. https://doi.org/10.3390/ma18092158

Chicago/Turabian StyleLiu, Xiaoran, Jingjing Deng, Mao Wang, Xinmiao Meng, and Lu Xu. 2025. "Edgewise Compressive Properties of Ecological Sandwich Panels with Engineered Bamboo Face Sheets and Bamboo Culm Core" Materials 18, no. 9: 2158. https://doi.org/10.3390/ma18092158

APA StyleLiu, X., Deng, J., Wang, M., Meng, X., & Xu, L. (2025). Edgewise Compressive Properties of Ecological Sandwich Panels with Engineered Bamboo Face Sheets and Bamboo Culm Core. Materials, 18(9), 2158. https://doi.org/10.3390/ma18092158