Research on the Mechanical Properties and Microstructural Evolution of Al-Si Alloy for Automotive Rear Floors Based on Simulation-Assisted Casting

Abstract

1. Introduction

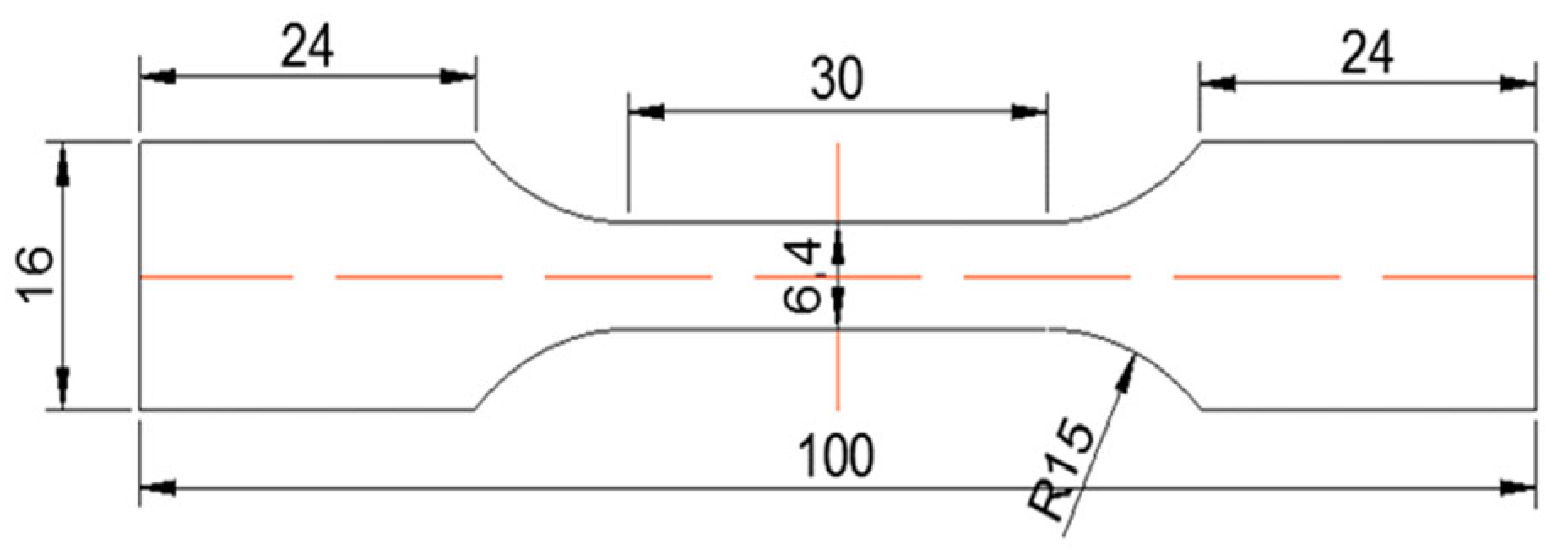

2. Experimental Procedures

2.1. Materials Preparation

2.2. Microstructural Characterization

3. Results

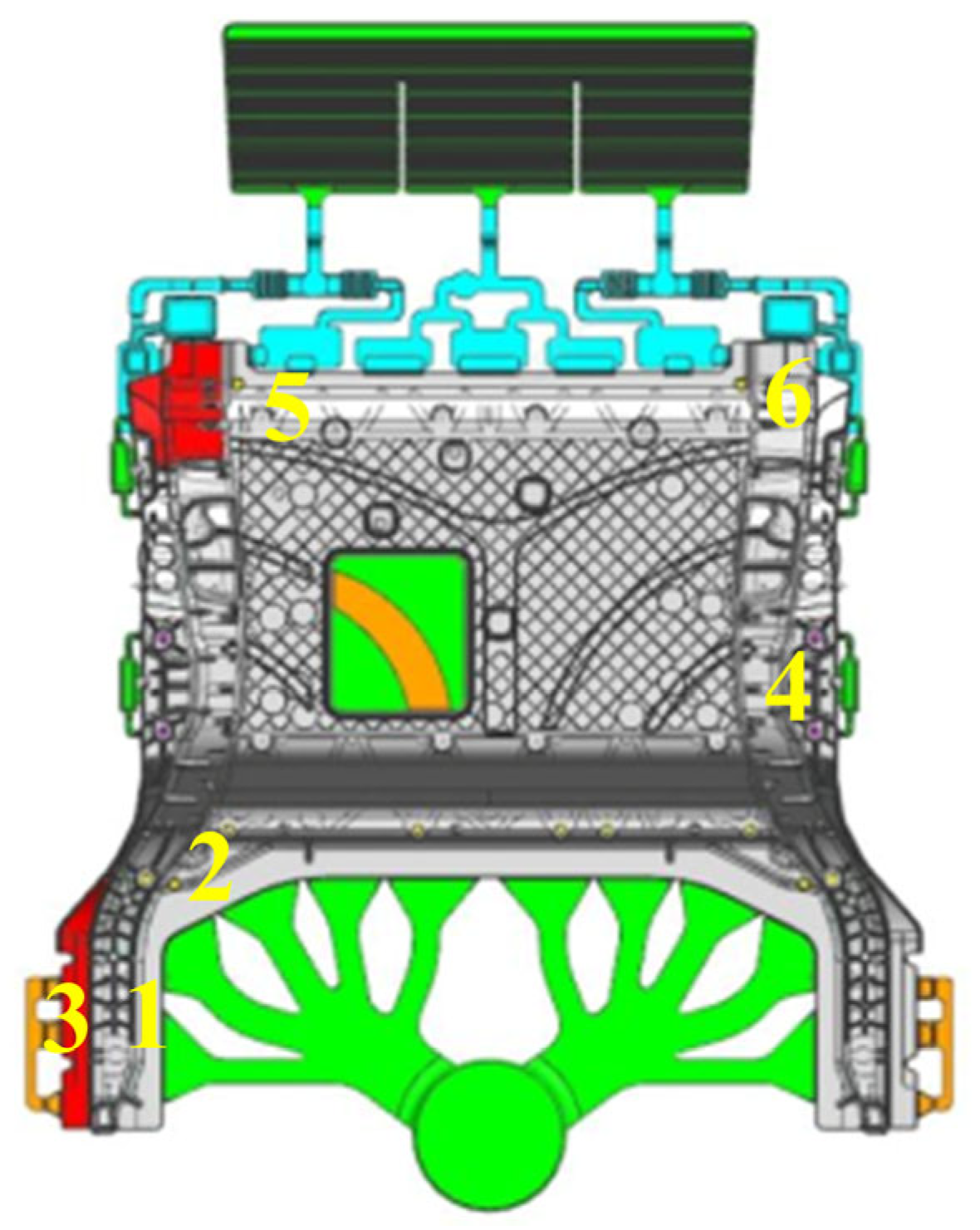

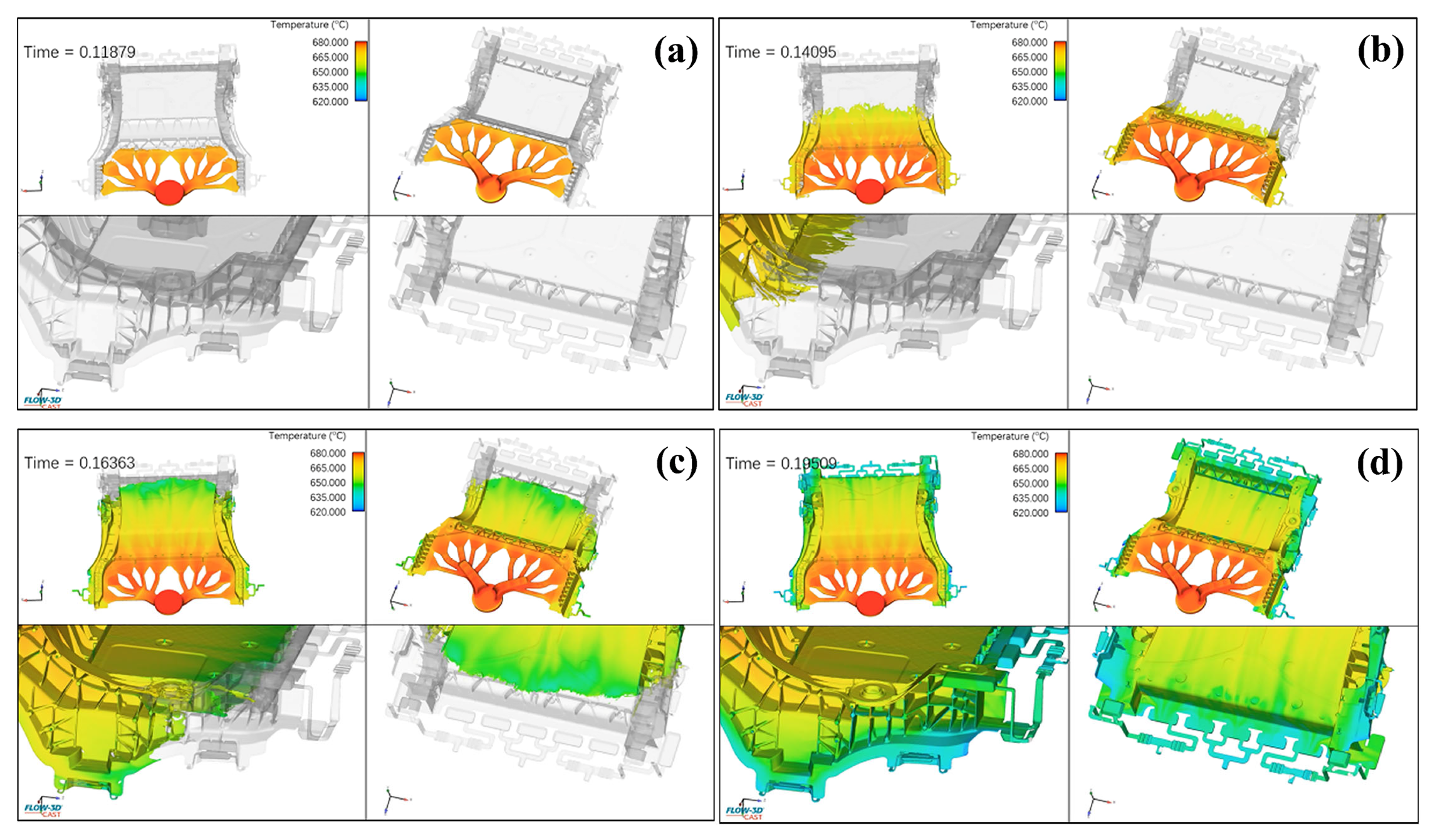

3.1. Filling Process

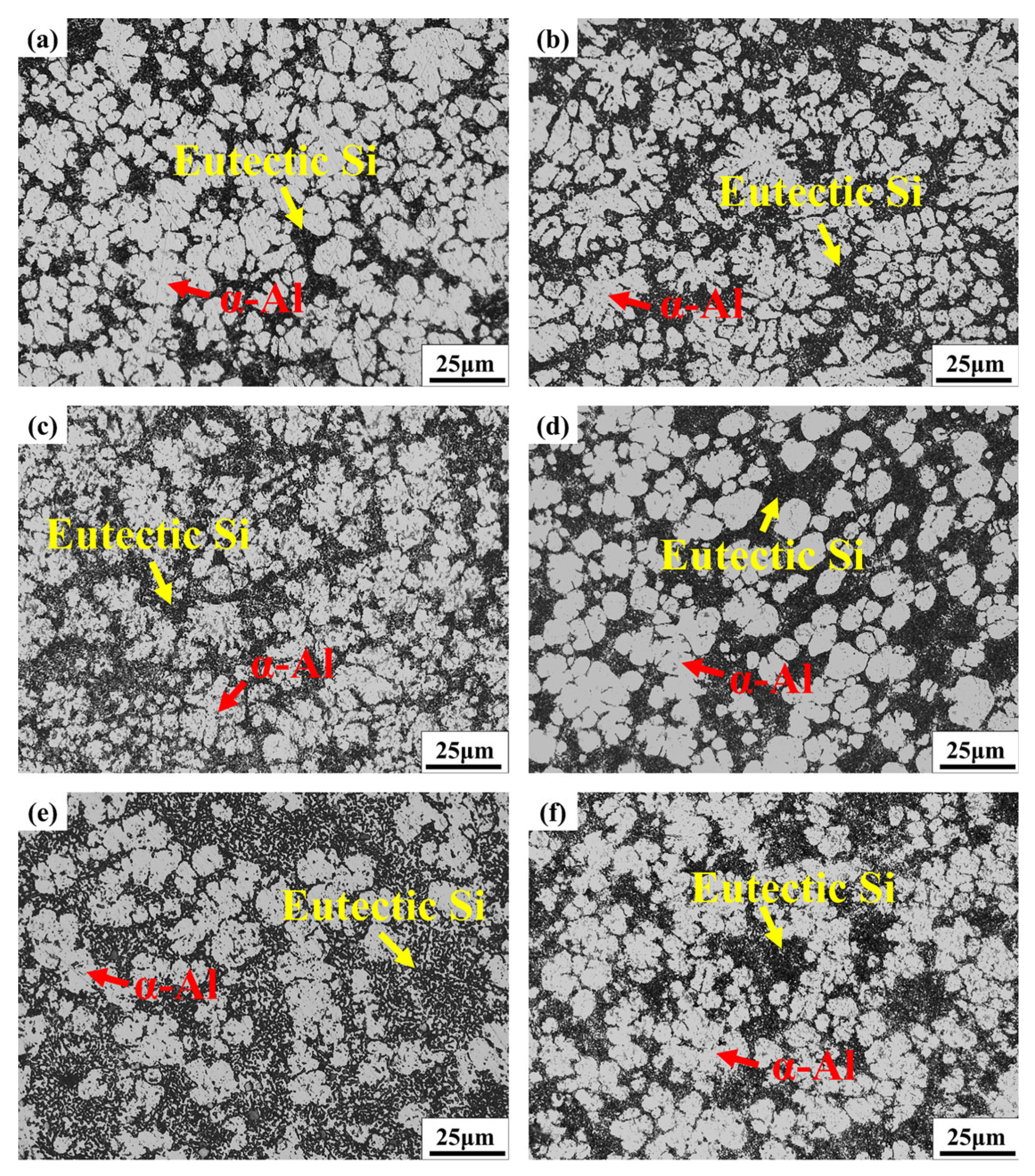

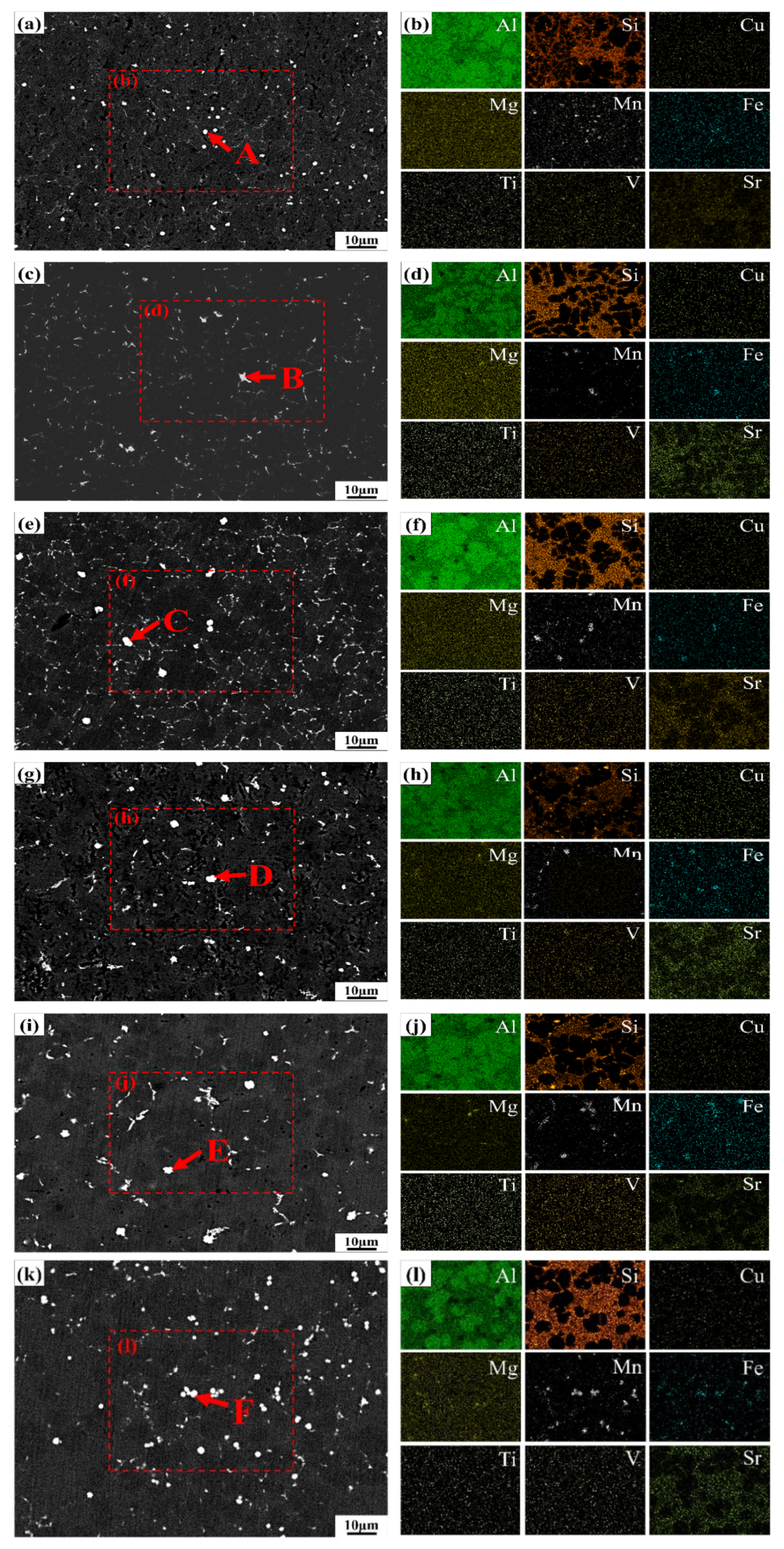

3.2. Microstructure Evolution

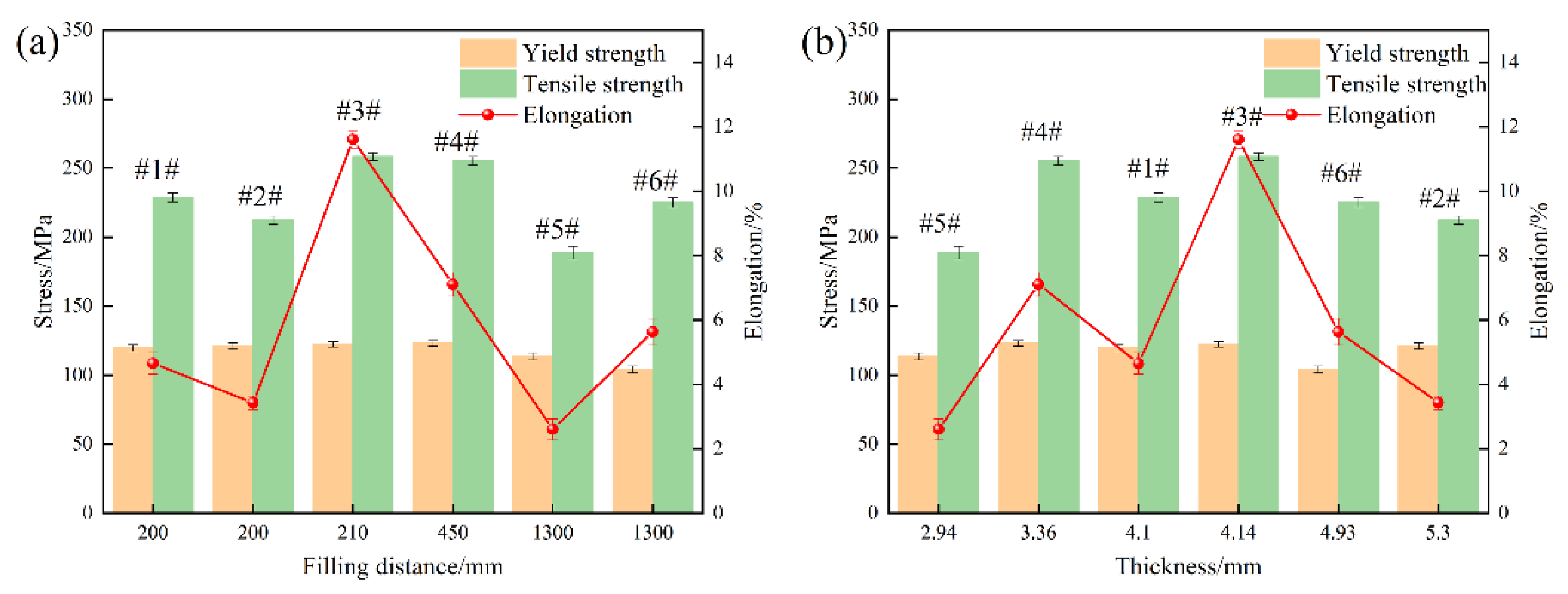

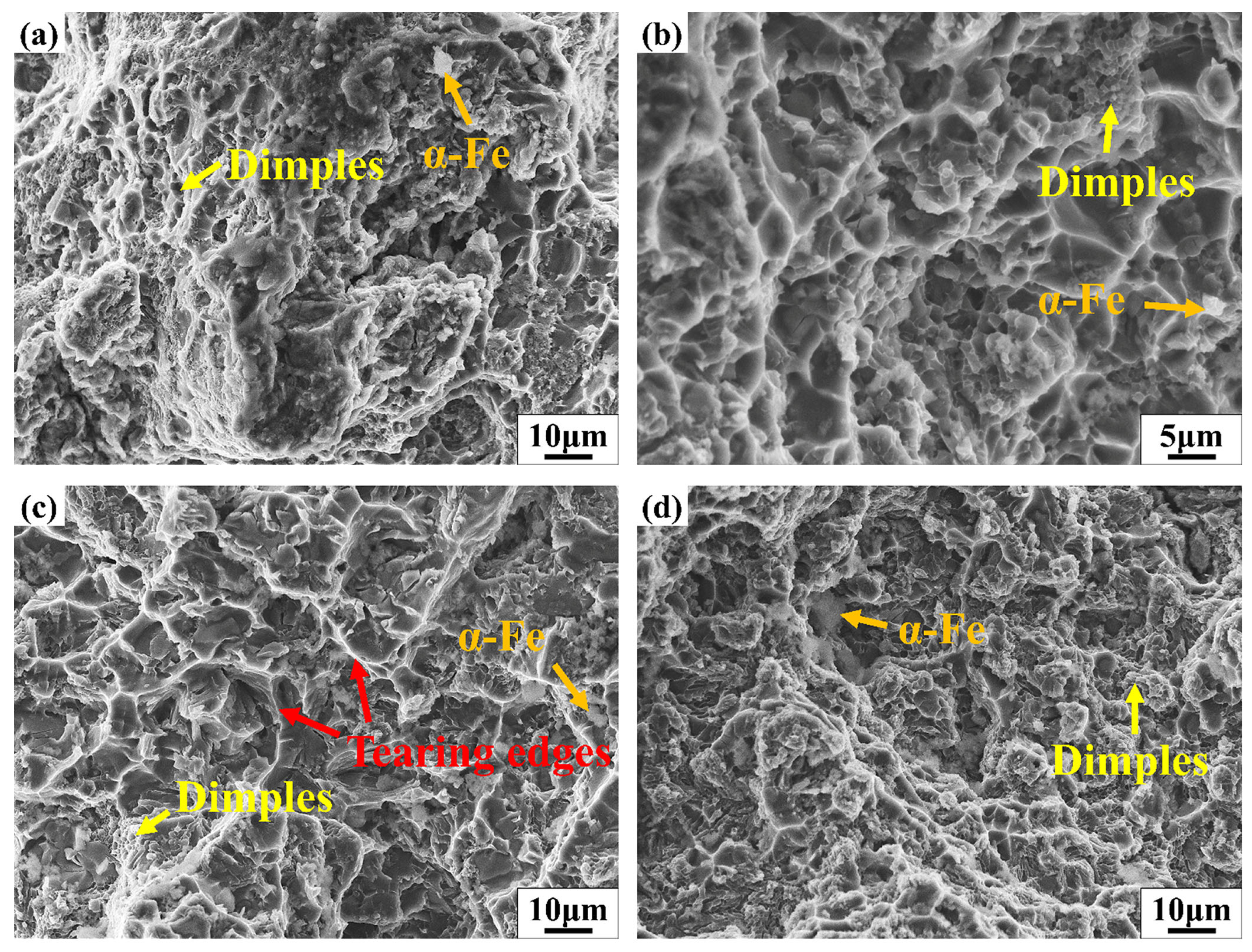

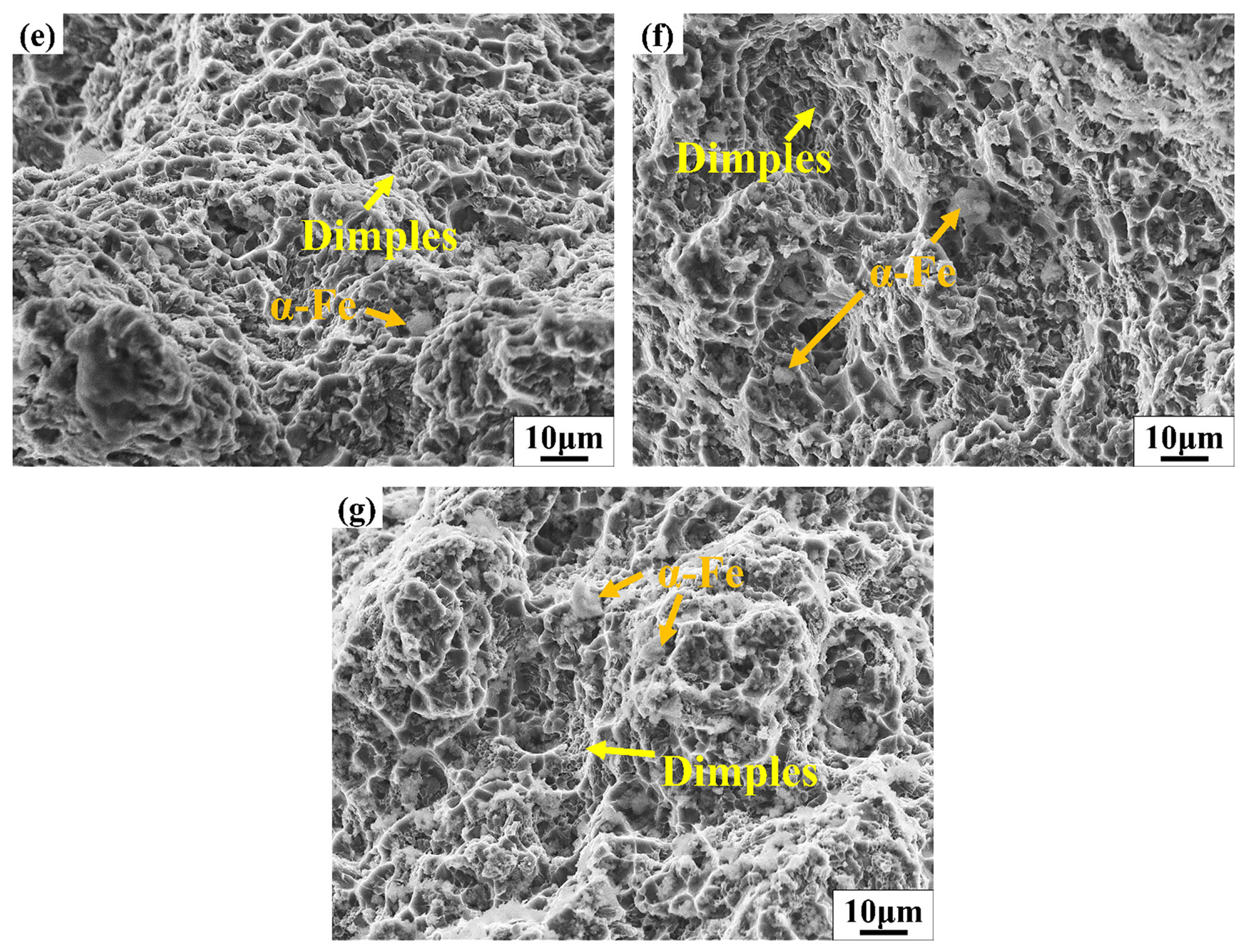

3.3. Mechanical Property Analysis

4. Conclusions

- (1)

- The alloy microstructure consists of α-Al, an Al-Si eutectic, and the Al15(Mn,Fe)3Si2 intermetallic phases. Near the gate, the higher molten metal temperature promotes the formation of well-developed petal-like α-Al dendrites. In contrast, the increased cooling rate in the distant thin-walled regions facilitates the formation of equiaxed grains. With an increasing filling distance, the Al15(Mn,Fe)3Si2 phase tends to segregate and coarsen.

- (2)

- The coupled effect of thickness and filling distance is the primary factor influencing the variation in mechanical properties. The optimal filling distance of the alloy ranges from 210 mm to 450 mm, while the optimal thickness ranges from 3.36 mm to 4.14 mm.

- (3)

- With a filling distance and thickness increase, the yield strength, tensile strength, and elongation of the alloy initially increase and then decrease. The optimal properties are achieved when the filling distance is 210 mm and the thickness is 4.14 mm, with a yield strength of 122.35 MPa, tensile strength of 258.43 MPa, and elongation of 11.60%.

- (4)

- At the same filling distance, near the gate position, when the thickness increases from 4.1 mm to 5.3 mm, the alloy’s tensile strength and elongation decrease. However, at positions farther from the gate, when the thickness increases from 2.94 mm to 4.93 mm, both the tensile strength and elongation of the alloy increase.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tisza, M.; Czinege, I. Comparative study of the application of steels and aluminium in lightweight production of automotive parts. Int. J. Lightweight Mater. Manuf. 2018, 1, 229–238. [Google Scholar] [CrossRef]

- Czerwinski, F. Current trends in automotive lightweighting strategies and materials. Materials 2021, 14, 6631. [Google Scholar] [CrossRef] [PubMed]

- Okayasu, M.; Ota, K.; Takeuchi, S.; Ohfuji, H.; Shiraishi, T. Influence of microstructural characteristics on mechanical properties of ADC12 aluminum alloy. Mater. Sci. Eng. A 2014, 592, 189–200. [Google Scholar] [CrossRef]

- Dash, S.S.; Chen, D. A review on processing–microstructure–property relationships of Al-Si alloys: Recent advances in deformation behavior. Metals 2023, 13, 609. [Google Scholar] [CrossRef]

- Callegari, B.; Lima, T.N.; Coelho, R.S. The influence of alloying elements on the microstructure and properties of Al-Si-based casting alloys: A review. Metals 2023, 13, 1174. [Google Scholar] [CrossRef]

- Liu, B.; Tang, Y.X.; Wu, Y.; Wang, Z.Y.; Yang, Q.; Hu, T.G.; Xu, X.M. Study on Lightweight Design of Integrated Mega-casting Aluminum Alloy Vehicle Body Components. Automot. Eng. 2024, 46, 2154–2163. [Google Scholar]

- Zhang, X.H.; Kang, J.; Li, Z.K.; Wang, Z.Z.; Zhou, L.; Chen, Z.F.; Sheng, M.; Shen, S. Design and Research of Large Pressure-casting Rear Floor for Passenger Car Body. China Soc. Automot. Eng. 2023, 204–209. [Google Scholar]

- Taylor, T.; Clough, A. Critical review of automotive hot-stamped sheet steel from an industrial perspective. Mater. Sci. Technol. 2018, 34, 809–861. [Google Scholar] [CrossRef]

- Ma, D.H.; Ma, S.K.; Yan, L.P. Design of Electric Vehicle Body Structure and Lightweight Strategy. Automob. Appl. Technol. 2018, 10, 6–8. [Google Scholar]

- Zhang, S.; Lu, H.G.; Han, H.G. Research on application parts recommendation of high vacuum die casting aluminum alloy body. Automob. Appl. Technol. 2021, 46, 161–163. [Google Scholar]

- Zhang, N.; Deng, G.; Liu, G.; Du, W.; Zhang, Y.; Sun, G.; Ma, P. Lightweight simulation design of integrated die-casting body rear wheel cover and seat crossbeam. J. Phys. Conf. Ser. IOP Publ. 2024, 2775, 012034. [Google Scholar] [CrossRef]

- Zhang, Y.; Lordan, E.; Dou, K.; Wang, S.; Fan, Z. Influence of porosity characteristics on the variability in mechanical properties of high pressure die casting (HPDC) AlSi7MgMn alloys. J. Manuf. Process. 2020, 56, 500–509. [Google Scholar] [CrossRef]

- Xu, F.Y.; Yu, L.; Wang, X.Y.; Chen, Z.Y.; Chi, X.Q.; Zhen, S.L.; Huang, Z.Y.; Li, J.F. Leakage Defect Analysis and Measures of Al Alloy Die Casting Clutch Housing. Spec. Cast. Nonferrous Alloys 2014, 34, 715–718. [Google Scholar]

- Zhang, S.; Ren, P.; Wang, K.; Liu, B.; Meng, X. Influence of High-Speed Ram Transition Position on Porosity and Mechanical Properties of Large One-Piece Die-Casting Al-Si-Mn-Mg Aluminium Alloy. Materials 2024, 17, 6169. [Google Scholar] [CrossRef]

- Kang, J.; Liu, B.; Jing, T.; Shen, H. Intelligent casting: Empowering the future foundry industry. China Foundry 2024, 21, 409–426. [Google Scholar] [CrossRef]

- Lu, X.X.; Deng, Y.M.; Shu, X.D.; Sun, B.S.; Li, G.H. Numerical Simulation and Process Optimization of Die Casting for Aluminum Alloy Engine End Caps. Spec. Cast. Nonferrous Alloys 2024, 44, 424–427. [Google Scholar]

- Li, G.H.; Dong, C.Q.; Lu, X.X.; Sun, B.S.; Shu, X.D. Die Casting Process Optimization and Local Extrusion Design of Aluminum Alloy Rear End Cover. China Foundry 2024, 73, 216–219. [Google Scholar]

- Wang, Y.; Liu, G.C.; Gao, J.B.; Zhang, L.J. Boosting for concept design of casting aluminum alloys driven by combining computational thermodynamics and machine learning techniques. J. Mater. Inform. 2021, 1, 11. [Google Scholar]

- Zhao, F.; Su, X.P.; Zhou, D.S.; Yang, C. Die-casting Process Design and Numerical Simulation Optimization of Aluminum Alloy Gearbox Rear Shell. Hot Work. Technol. 2024, 53, 150–153. [Google Scholar]

- Jiao, X.Y.; Liu, C.F.; Guo, Z.P.; Nishat, H.; Tong, G.D.; Ma, S.L.; Bi, Y.; Zhang, Y.F.; Wiesner, S.; Xiong, S.M. On the characterization of primary iron-rich phase in a high-pressure die-cast hypoeutectic Al-Si alloy. J. Alloys Compd. 2021, 862, 158580. [Google Scholar] [CrossRef]

- Jiao, X.Y.; Liu, C.F.; Guo, Z.P.; Tong, G.D.; Ma, S.L.; Bi, Y.; Zhang, Y.F.; Xiong, S.M. The characterization of Fe-rich phases in a high-pressure die cast hypoeutectic aluminum-silicon alloy. J. Mater. Sci. Technol. 2020, 51, 54–62. [Google Scholar] [CrossRef]

- Biswas, P.; Patra, S.; Roy, H.; Tiwary, C.S.; Paliwal, M.; Mondal, M.K. Effect of Mn addition on the mechanical properties of Al–12.6 Si alloy: Role of Al15(MnFe)3Si2 intermetallic and microstructure modification. Met. Mater. Int. 2021, 27, 1713–1727. [Google Scholar] [CrossRef]

- Meng, F.; Wu, Y.; Li, W.; Hu, K.; Zhao, K.; Yang, H.; Gao, T.; Sun, Y.; Liu, X.F. Influence of the evolution of heat-resistant phases on elevated-temperature strengthening mechanism and deformation behavior in Al–Si multicomponent alloys. Curr. Appl. Phys. 2022, 39, 239–247. [Google Scholar] [CrossRef]

- Kishor, M.; Ram, K.Y.; Nahid, S.A.; Ramavajjala, A.K.; Prasada Rao, A.K. Synergistic Effect of Mo and V Addition on Al–Si Alloys Containing High Iron Impurity. Int. J. Met. 2024, 18, 3538–3548. [Google Scholar] [CrossRef]

- Ganesh, M.R.; Reghunath, N.; Levin, M.J.; Prasad, A.; Doondi, S.; Shankar, K.V. Strontium in Al–Si–Mg alloy: A review. Met. Mater. Int. 2022, 28, 1–40. [Google Scholar] [CrossRef]

- Osipov, V. Influence of modifying elements on the structure and mechanical properties of casting Al–Si alloys. Tech. Phys. 2023, 68, 695–706. [Google Scholar] [CrossRef]

- Zou, J.; Zhang, H.; Yu, C.; Wu, Z.; Guo, C.; Nagaumi, H.; Zhu, K.; Li, B.; Cui, J. Investigating the influences of Fe, Mn and Mo additions on the evolution of microstructure and mechanical performances of Al–Si–Mg cast alloys. J. Mater. Res. Technol. 2023, 25, 319–332. [Google Scholar] [CrossRef]

- Chen, R.; Xu, Q.; Guo, H.; Xia, Z.; Wu, Q.; Liu, B. Correlation of solidification microstructure refining scale, Mg composition and heat treatment conditions with mechanical properties in Al-7Si-Mg cast aluminum alloys. Mater. Sci. Eng. A 2016, 685, 391–402. [Google Scholar] [CrossRef]

| Si | Mg | Mn | Fe | Zn | Ti | V | Sr | Al |

|---|---|---|---|---|---|---|---|---|

| 9.0 | 0.20 | 0.50 | 0.10 | 0.05 | 0.12 | 0.12 | 0.02 | Bal. |

| Parameters | Value |

|---|---|

| Diameter of the pressure chamber | 270 mm |

| Effective length of the pressure chamber | 1660 mm |

| Thickness of the charge cake | 40 mm |

| Low-speed phase of the plunger | 0.8 m/s |

| High-speed phase of the plunger | 5 m/s |

| Pouring temperature | 700 °C |

| Vacuum level | 50 mbar |

| Mold temperature | 200 °C |

| Point | Elements | ||||

|---|---|---|---|---|---|

| Al | Si | Mn | Fe | V | |

| A | 77.8 | 13.35 | 7.48 | 1.37 | 0 |

| B | 71.22 | 12.70 | 12.41 | 2.25 | 1.42 |

| C | 69.48 | 13.67 | 13.11 | 2.32 | 1.42 |

| D | 69.76 | 13.28 | 13.13 | 2.43 | 1.40 |

| E | 70.86 | 13.56 | 12.08 | 2.28 | 1.22 |

| F | 70.72 | 13.80 | 11.93 | 2.32 | 1.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, L.; Wang, Q.; Yang, Q.; Liu, W.; Jiang, B.; Qin, Y.; Chen, H.; Lan, S. Research on the Mechanical Properties and Microstructural Evolution of Al-Si Alloy for Automotive Rear Floors Based on Simulation-Assisted Casting. Materials 2025, 18, 2143. https://doi.org/10.3390/ma18092143

Gao L, Wang Q, Yang Q, Liu W, Jiang B, Qin Y, Chen H, Lan S. Research on the Mechanical Properties and Microstructural Evolution of Al-Si Alloy for Automotive Rear Floors Based on Simulation-Assisted Casting. Materials. 2025; 18(9):2143. https://doi.org/10.3390/ma18092143

Chicago/Turabian StyleGao, Liang, Qiang Wang, Qin Yang, Wenjun Liu, Bin Jiang, Yongrui Qin, Haoming Chen, and Sha Lan. 2025. "Research on the Mechanical Properties and Microstructural Evolution of Al-Si Alloy for Automotive Rear Floors Based on Simulation-Assisted Casting" Materials 18, no. 9: 2143. https://doi.org/10.3390/ma18092143

APA StyleGao, L., Wang, Q., Yang, Q., Liu, W., Jiang, B., Qin, Y., Chen, H., & Lan, S. (2025). Research on the Mechanical Properties and Microstructural Evolution of Al-Si Alloy for Automotive Rear Floors Based on Simulation-Assisted Casting. Materials, 18(9), 2143. https://doi.org/10.3390/ma18092143