Analysis of Late Antique and Medieval Glass from Koper (Capodistria, SI): Insights into Glass Consumption and Production at the Turn of the First Millennium CE

Abstract

:1. Introduction

2. The Analytical Method

2.1. Experimental

2.2. Determination of Glass Types According to the Euclidean Distance

3. Results

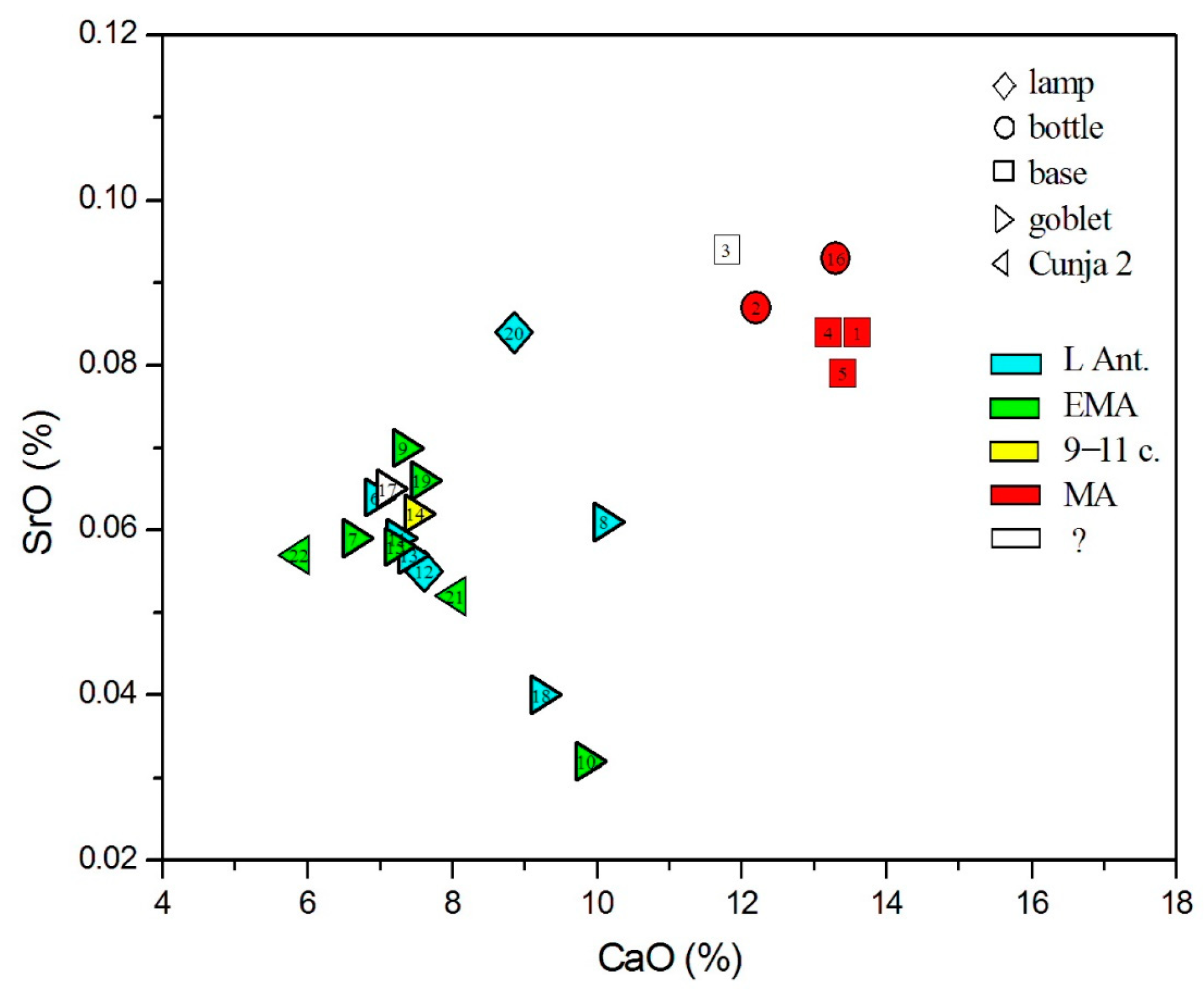

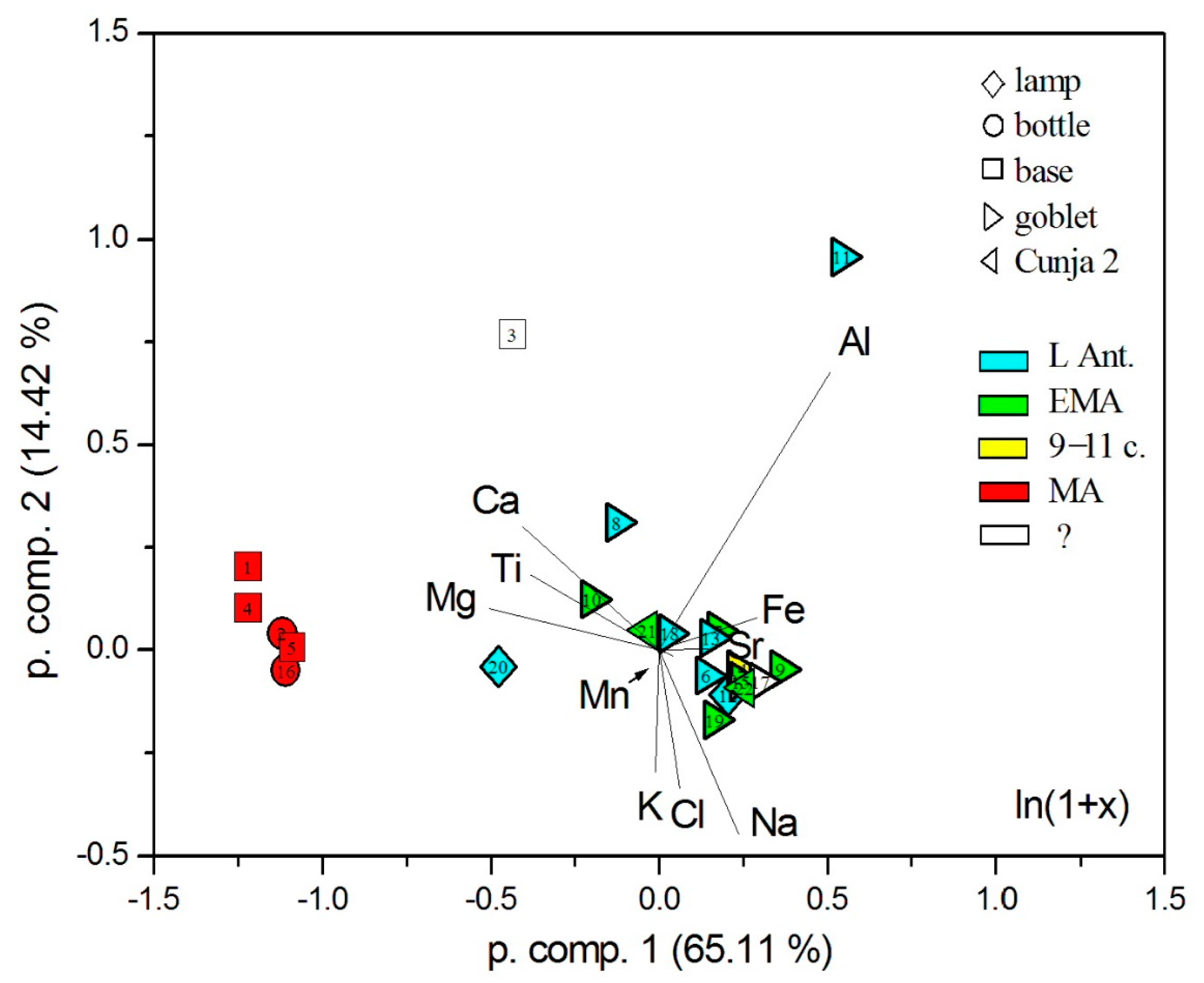

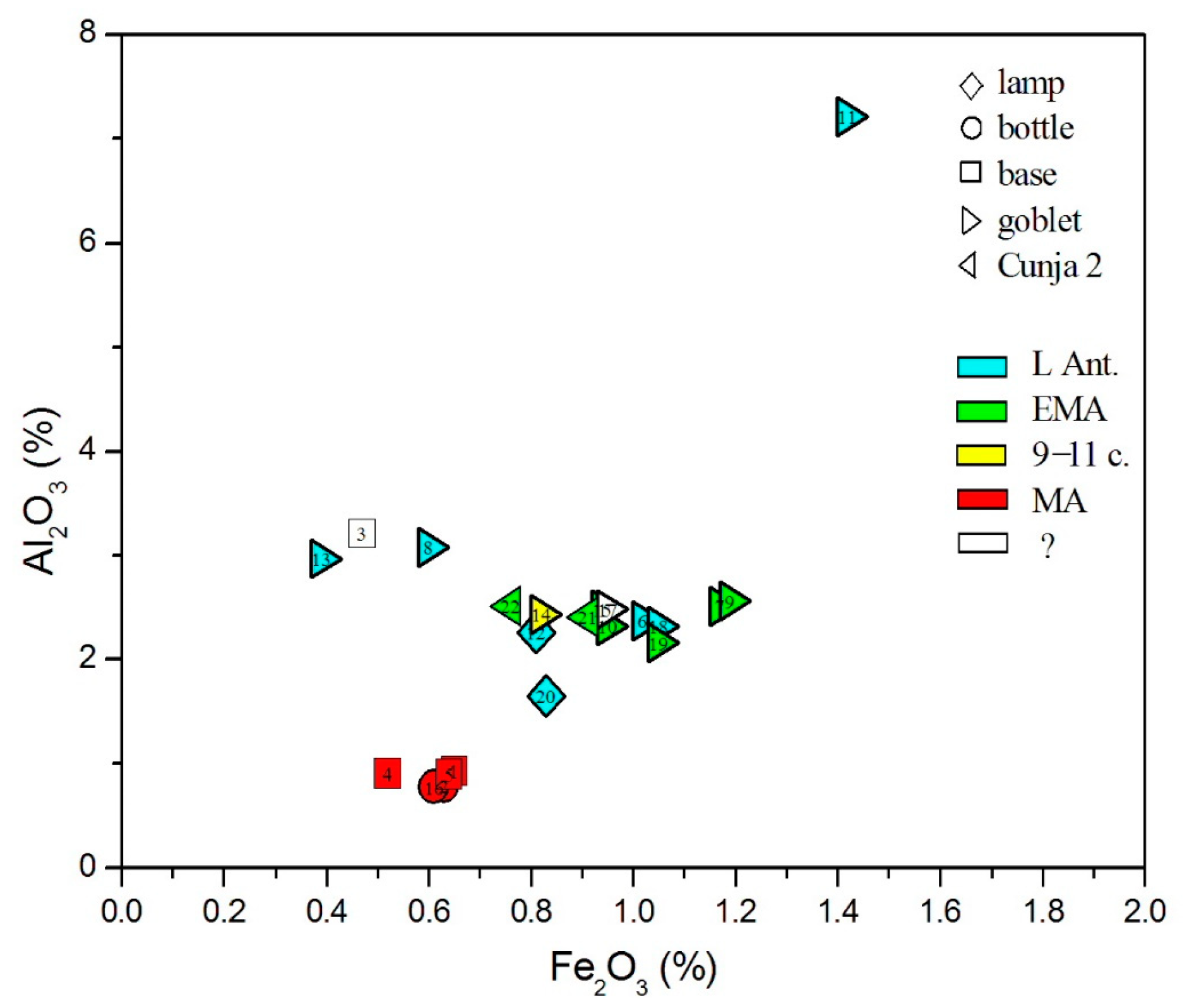

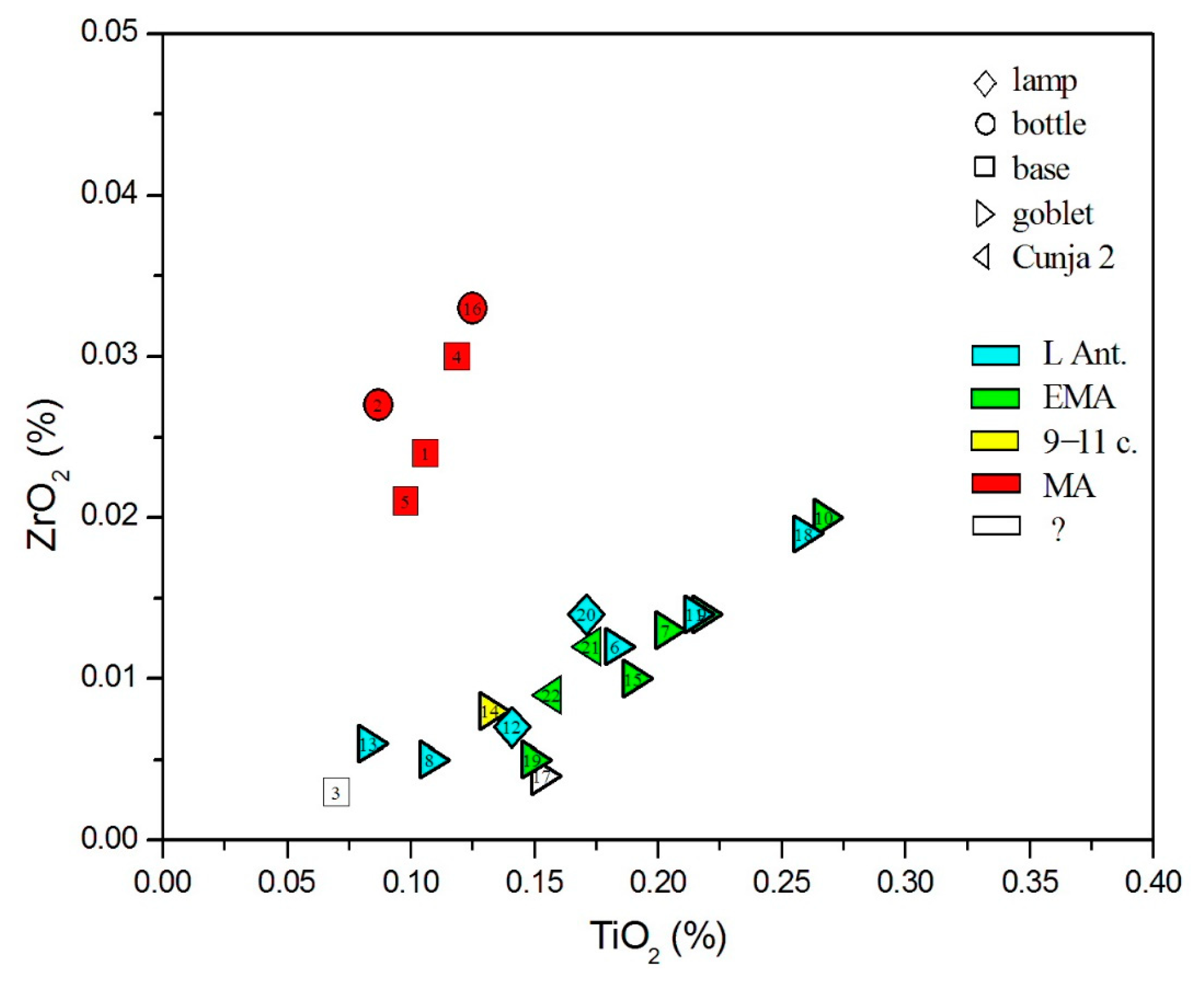

3.1. Elemental Concentrations and Broad Distribution into Groups

3.2. Natron-Type Glass

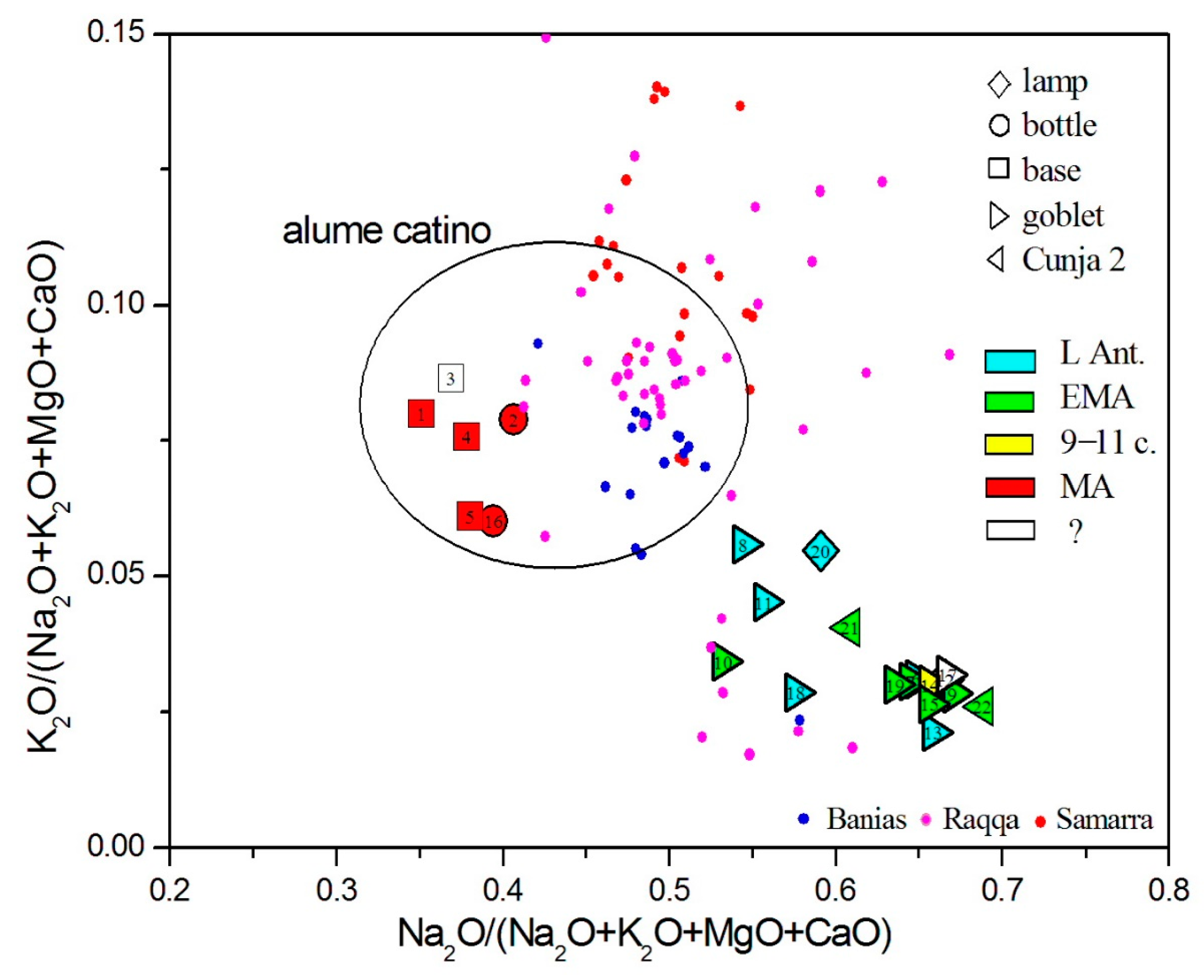

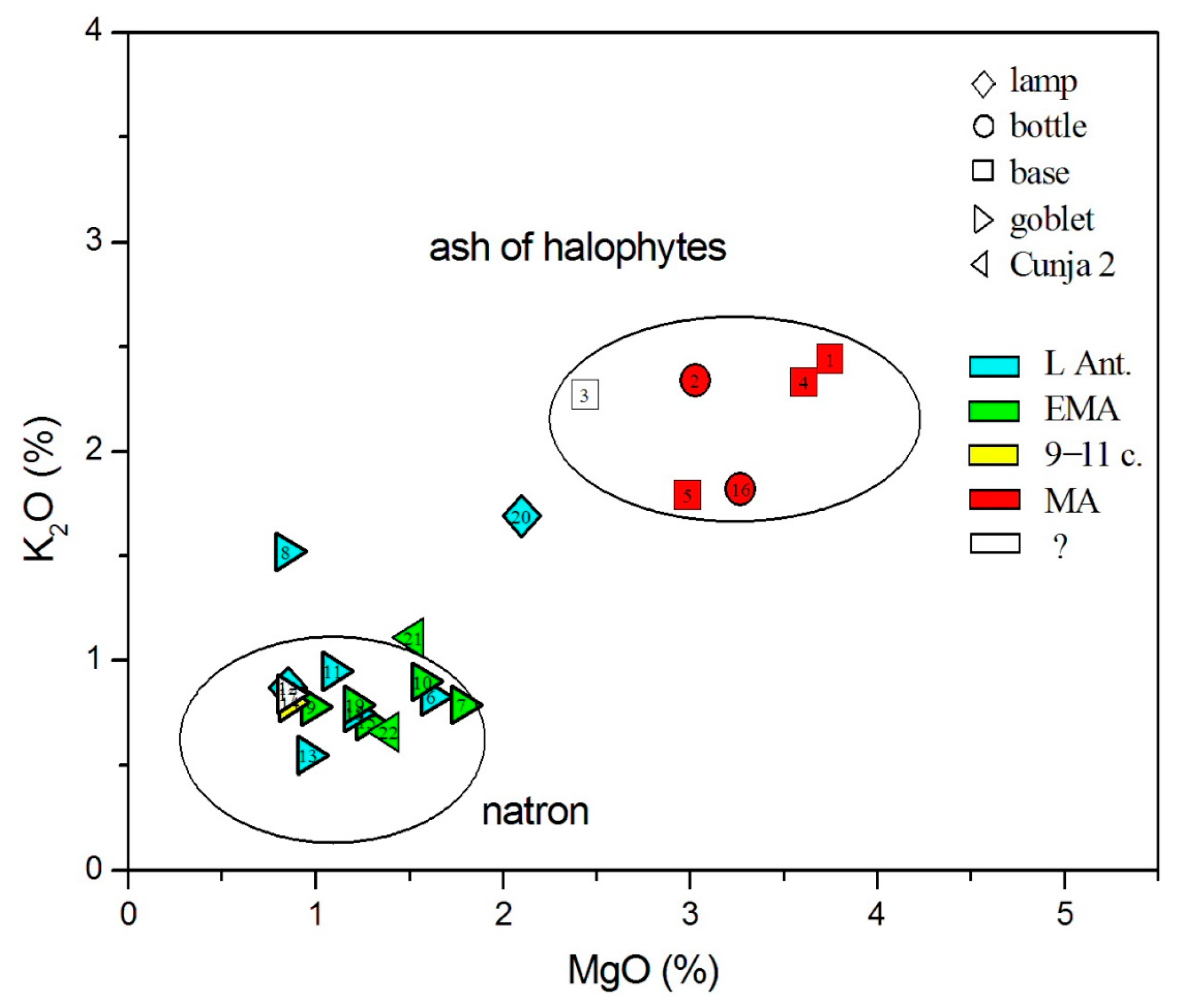

3.3. Plant Ash Glass

4. Discussion

4.1. Natron Glass

4.2. Plant Ash Glass

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PIXE | Particle- induced X-ray emission |

| PIGE | Proton-induced gamma-ray emission |

| PCA | Principle Component Analysis |

References

- Nenna, M.-D.; Gratuze, B. Étude diachronique des compositions de verre employés dans les vases mosaïqués antiques: Résultats préliminaire. In Annales du 17e de l‘Association Internationale pour l’Histoire du Verre; Janssens, K., Degryse, P., Cosyns, P., Caen, J., Van’t dack, L., Eds.; AIHV: Antwerp, Belgium, 2006; pp. 199–205. [Google Scholar]

- Jackson, C.M.; Cottam, S. ‘A green thought in a green shade’; Compositional and typological observations concerning the production of emerald green glass vessels in the 1st century A.D. J. Archaeol. Sci. 2015, 61, 139–148. [Google Scholar] [CrossRef]

- Oikonomou, A.; Rehren, T.; Fiolotaki, A. An Early Byzantine glass workshop at Argyroupolis, Crete: Insights into complex glass supply networks. J. Archaeol. Sci. Rep. 2021, 35, 102766. [Google Scholar] [CrossRef]

- Drauschke, J.; Greiff, S. Early Byzantine glass from Caričin grad/Iustiniana prima (Serbia): First results concerning the composition of raw glass chunks. In Glass Along the Silk Road from 200 BC to AD 100; Zorn, B., Hilgner, A., Eds.; RGZM Mainz: Mainz, Germany, 2010; pp. 53–67. [Google Scholar]

- Balvanović, R.; Šmit, Ž.; Marić-Stojanović, M.; Spasić-Đurić, D.; Špehar, P.; Milović, O. Late Roman glass from Viminacium and Egeta (Serbia): Glass making patterns on Iron Gates Danubian Limes. Archaeol. Anthropol. Sci. 2022, 14, 79. [Google Scholar] [CrossRef]

- Silvestri, A.; Pescarin Volpato, M.; Marcante, A. A review of medieval glass composition from northern and central Italy: A statistical approach. In Le Verre du VIIIe du XVIe Siècle en Europe Occidentale. Actes du 8e Colloque International de l’AFAV, Collection les Cahiers de la MSHE Ledoux. Série Dynamiques Territoriales, Besançon, France, 5–7 December 2016; Pactat, I., Munier, C., Eds.; Presses Universitaires de Franche-Comté: Besançon, France, 2020; pp. 47–79. [Google Scholar]

- Neri, E. Produzione e circolazione del vetro nell’alto medioevo: Une entrée en matière. In Il Vetro in Transizione (IV–XII Secolo) Produzione e Commercio in Italia Meridionale e nell’Adriatico; Coscarella, A., Noyé, G., Neri, E., Eds.; Firenze University Press: Florence, Italy, 2021; pp. 19–31. [Google Scholar]

- Uboldi, M.; Verità, M. Composizione chimica e processi produttivi del vetro tra tarda antichità e medioevo in Lombardia. In Il Vetro in Transizione (IV–XII Secolo) Produzione e Commercio in Italia Meridionale e nell’Adriatico; Coscarella, A., Noyé, G., Neri, E., Eds.; Firenze University Press: Florence, Italy, 2021; pp. 235–244. [Google Scholar]

- Bertini, C.; Henderson, J.; Chenery, S. Seventh to eleventh century CE glass from Northern Italy: Between continuity and innovation. Archaeol. Anthropol. Sci. 2020, 12, 120. [Google Scholar] [CrossRef]

- Gliozzo, E.; Braschi, E.; Ferri, M. New data and insights on the secondary glass workshop in Comacchio (Italy): MgO contents, steatite crucibles and alternatives to recycling. Archaeol. Anthropol. Sci. 2024, 16, 114. [Google Scholar] [CrossRef]

- Boschetti, C.; Kindberg Jacobsen, J.; Parisi Presicce, C.; Raja, R.; Schibille, N.; Vitti, M. Glass in Rome during the transition from late antiquity to the early Middle Ages: Materials from the Forum of Caesar. Herit. Sci. 2022, 10, 95. [Google Scholar] [CrossRef]

- Sannazaro, M.; Guglielmetti, A.; Uboldi, M. Manufatti del quotidiano: Pietra ollare, ceramiche e vetri tra VIII e XIII secolo. In 1287 e Dintorni. Ricerche su Castelseprio a 730 Anni Dalla Distruzione; Sannazaro, M., Lusuardi Siena, S., Giostra, C., Eds.; SAP Società Archeologica: Quingentole, Italy, 2017; pp. 129–159. [Google Scholar]

- Uboldi, M. San Tomé di Carvico: I vetri. In San Tomé di Carvico. Archeologia di Una Chiesa Altomedievale; Brogiolo, G.P., Ed.; Comune di Carvico: Carvico, Italy, 2016; pp. 197–204. [Google Scholar]

- Cunja, R. Poznoantični in srednjeveški Koper. Arheološka izkopavanja na bivšem Kapucinskem vrtu v letih 1986-1987 v luči drobnih najdb od 5. do 9. stoletja stoletja/Capodistria tardoromana e altomedievale. Lo scavo archeologico nell’ex orto dei Cappuccini negli anni 1986–1987 alla luce dei reperti dal V al IX secolo d. C. In Založba Annales; ZRS Koper: Koper, Slovenia, 1996. [Google Scholar]

- Kos, P. Die Fundmünzen der Römischen Zeit in Slowenien; Mann: Berlin, Germany, 1988. [Google Scholar]

- Štih, P. Il diploma del re Berengario I del 908 e il monastero femminile di Capodistria. Atti Del Cent. Di Ric. Storiche Rovigno 2010, 40, 67–98. [Google Scholar]

- Mlacović, D. Koper v poznem srednjem veku: Opažanja o mestu in njegovih portah po pregledu knjig koprskih vicedominov s konca 14. stoletja (Late Medieval Koper: Observations about the Town and Its Portae from a Survey of the Books of the Koper Vicedomini from the End of the 14th Century). Acta Histriae 2022, 30, 819–854. [Google Scholar]

- Mlacović, D. Kartuzija Bistra in Koper v 14. stoletju (The Bistra Carthusian Monastery and Koper in the 14th Century). Zgod. Časopis 2023, 77, 98–346. [Google Scholar]

- Milavec, T. The elusive early medieval glass. Remarks on vessels from the Nin—Ždrijac cemetery, Croatia. Pril. Instituta Arheol. Zagrebu 2018, 35, 239–250. [Google Scholar] [CrossRef]

- Cunja, R. Archeologia urbana in Slovenia. Alcuni risultati e considerazioni degli scavi a Capodistria. Archeol. Mediev. 1998, 25, 199–212. [Google Scholar]

- Cunja, R. Koper med Rimom in Benetkami. Izkopavanje na Vrtu Kapucinskega Samostana: [Razstava] = Capodistria Tra Roma e Venezia. Gli Scavi Nel Convento dei Cappuccini: [Mostra]; Medobčinski zavod za varstvo naravne in kulturne dediščine = Istituto intercomunale per la tutela dei beni naturali e culturali: Piran, Slovenia, 1989. [Google Scholar]

- Gelichi, S.; Negrelli, C.; Ferri, M.; Cadamuro, S.; Cianciosi, A.; Grandi, E. Importare, produrre e consumare nella laguna di Venezia dal IV al XII secolo Anfore, vetri e ceramiche. In Adriatico Altomedievale (VI–XI Secolo) Scambi, Porti, Produzioni; Gelichi, S., Negrelli, C., Eds.; Studi e Ricerche 4: Venezia, Italy, 2017; pp. 23–114. [Google Scholar]

- Ferri, M. Il Vetro Nell’alto Adriatico fra V e XV Secolo; All’insegna del Giglio: Sesto Fiorentino, Italy, 2022. [Google Scholar]

- Arena, M.S.; Delogu, P.; Paroli, L.; Ricci, M.; Saguì, L.; Vendittelli, R. (Eds.) Roma Dall’antichità al Medioevo, Archeologia e Storia; Museo Nazionale Romano Crypta Balbi: Milano, Italy, 2004. [Google Scholar]

- Del Vecchio, F. I vetri di IX-XII secolo dalla domus porticata del foro di Nerva. In Il Vetro Nell’alto Medioevo. Atti VII Giornate di Studio A.I.H.V.; Ferrari, D., Ed.; Comitato Nazionale Italiano: Imola, Italy, 2005; pp. 45–48. [Google Scholar]

- Uboldi, M.; Lerma, S.; Marcante, A.; Medici, T.; Mendera, M. Le verre au Moyen Âge en Italie (VIIIe-XVIe siècle): État des connaissances et mise à jour. In Le Verre du VIIIe au XVIe Siècle en Europe Occidentale; Pactat, I., Munier, C., Eds.; Presses universitaires de Franche-Comté: Besançon, France, 2020; pp. 31–47. [Google Scholar] [CrossRef]

- Šmit, Ž. Glass analysis in relation to historical questions. In Bridging Science and Heritage in the Balkans: Studies in Archaeometry, Cultural Heritage Restoration and Conservation; Palincaş, N., Ponta, C.C., Eds.; Archaeopress: Oxford, UK, 2019; pp. 103–109. [Google Scholar]

- Lilyquist, C.; Brill, R.H. Studies in Early Egyptian Glass; The Metropolitan Museum of Art: New York, NY, USA, 1993; p. 56. [Google Scholar]

- Paynter, S.; Jackson, C. Re-used Roman rubbish: A thousand years of recycling glass. Eur. J. Postclassical Archaeol. 2016, 6, 31–52. [Google Scholar]

- Al-Bashaireh, K.; Al-Mustafa, S.; Freestone, I.C.; Al Housan, A.Q. Composition of Byzantine glasses from Umm el Jimal, northeast Jordan: Insights into glass origins and recycling. J. Cult. Herit. 2016, 21, 809–818. [Google Scholar] [CrossRef]

- Schibille, N.; Meek, A.; Tobias, B.; Entwistle, C.; Avisseau-Broustet, M.; Da Mota, H.; Gratuze, B. Comprehensive chemical characterization of Byzantine glass weights. PLoS ONE 2016, 11, e0168289. [Google Scholar] [CrossRef]

- Duewer, D.L.; Kowalski, B.R. Source identification of oil spills by pattern recognition analysis of natural elemental composition. Anal. Chem. 1975, 47, 1573–1583. [Google Scholar] [CrossRef]

- Freestone, I.C.; Degryse, P.; Lankton, J.; Gratuze, B.; Schneider, J. HIMT, glass composition and commodity branding in the primary glass industry. In Things That Travelled. Mediterranean Glass in the First Millennium CE; Rosenow, D., Phelps, M., Meek, A., Freestone, I., Eds.; UCL Press: London, UK, 2018; pp. 159–190. [Google Scholar]

- Foy, D.; Picon, M.; Vichy, M.; Thirion-Merle, V. Caractérisation des verres de la fin de l’Antiquité en Méditerranée occidentale: L’émergence de nouveaux courants commerciaux. In Échange et Commerce du Verre Dans le Monde Antique. Actes du Colloque de l’Association Française pour l’Archéologie du Verre, Aix-en-Provence et Marseille; Foy, D., Nenna, M.D., Eds.; Éditions Monique Mergoil: Montagnac, France, 2003; pp. 41–85. [Google Scholar]

- Gliozzo, E.; Santagostino, A.; D’Acapito, F. Waste glass, vessels and window-panes from Thamusida (Morocco): Grouping natron-based blue-green and colorless Roman glasses. Archaeometry 2013, 55, 609–639. [Google Scholar] [CrossRef]

- Gliozzo, E. The composition of colourless glass: A review. Archaeol. Anthropol. Sci. 2017, 9, 455–483. [Google Scholar] [CrossRef]

- Freestone, I.C. Appendix: Chemical analysis of ‘raw’ glass fragments. In Excavations of Carthage Vol. II 1. The Circular Harbour North Side. The Site and Finds Other than Pottery. British Academy Monographs in Archaeology No. 4; Hurst, H.R., Ed.; Oxford University Press: Oxford, UK, 1994; p. 290. [Google Scholar]

- Mirti, P.; Casoli, A.; Appolonia, L. Scientific analysis of Roman glass from Augusta Praetoria. Archaeometry 1993, 35, 225–240. [Google Scholar] [CrossRef]

- Ceglia, A.; Cosyns, P.; Nys, K.; Terryn, H.; Thienpont, H.; Meulenbroeck, W. Late antique glass distribution and consumption in Cyprus: A chemical study. J. Archaeol. Sci. 2015, 61, 213–222. [Google Scholar] [CrossRef]

- Balvanović, R.; Šmit, Ž. Emerging Glass Industry Patterns in Late Antiquity Balkans and Beyond: New Analytical Findings on Foy 3.2 and Foy 2.1 Glass Types. Materials 2022, 15, 1086. [Google Scholar] [CrossRef]

- Freestone, I.C.; Gorin-Rosen, Y.; Hughes, M.J. Primary glass from Israel and the production of glass in Late Antiquity and the Early Islamic period. In La Route du Verre; Nenna, M.D., Ed.; Maison de l’Orient et de la Méditerranée Jean Pouilloux: Lyon, France, 2000; pp. 64–83. [Google Scholar]

- Freestone, I.C. The provenance of ancient glass through compositional analysis. Mater. Res. Soc. Proceeding 2005, 852, OO8.1.1-13. [Google Scholar] [CrossRef]

- Schibille, N.; Gratuze, B.; Ollivier, E.; Blondeau, E. Chronology of early Islamic glass compositions from Egypt. J. Archaeol. Sci. 2019, 104, 10–18. [Google Scholar] [CrossRef]

- Schibille, N. Late Byzantine mineral soda high alumina glasses from Asia Minor: A new primary glass production group. PLoS ONE 2011, 6, e1897. [Google Scholar] [CrossRef] [PubMed]

- De Juan Ares, J.; Vigil-Escalera Guirado, A.; Cáceres Gutiérez, Y.; Schibille, N. Change in the supply of eastern Mediterranean glasses to Visigothic Spain. J. Archaeol. Sci. 2019, 107, 23–31. [Google Scholar] [CrossRef]

- Schibille, N. Islamic Glass in the Making—Chronological and Geographic Dimensions; Leuven University Press: Leuven, Belgium, 2022. [Google Scholar]

- Baxter, M.J.; Cool, H.E.M.; Jackson, C.M. Further studies in the compositional variability of colourless Romano-British vessel glass. Archaeometry 2005, 47, 47–68. [Google Scholar] [CrossRef]

- Degryse, P. Glass Making in the Greco-Roman World: Results of the ARCHGLASS Project; Leuven University Press: Leuven, Belgium, 2014. [Google Scholar]

- Gratuze, B. Contribution à l’étude des verres décolorés à l’antimoine produits le 1er s. et la fin du IIIe s. de notre ère: Nouvelles données analytiques. In Verres Incolores de l’Antiquité Romaine en Gaule at Aux Marges de la Gaule. Vol. 2: Typologie et Analyses; Foy, D., Labaune-Jean, F., Leblond, C., Pruvot, C.M., Marty, M.-T., Massart, C., Munier, C., Robin, L., Roussel-Ode, J., Adrian, Y.-M., et al., Eds.; Archaeopress Roman Archaeology 42: Oxford, UK, 2018; pp. 682–714. [Google Scholar]

- Jackson, C.M. Making colourless glass in the Roman period. Archaeometry 2005, 47, 763–780. [Google Scholar] [CrossRef]

- Paynter, S. Analyses of colourless Roman glass from Binchester, County Durham. J. Archaeol. Sci. 2006, 33, 1037–1057. [Google Scholar] [CrossRef]

- Silvestri, A. The coloured glass of Iulia Felix. J. Archaeol. Sci. 2008, 35, 1489–1501. [Google Scholar] [CrossRef]

- Silvestri, A.; Molin, G.; Salviulo, G. The colourless glass of Iulia Felix. J. Archeol. Sci. 2008, 35, 331–341. [Google Scholar] [CrossRef]

- Silvestri, A.; Molin, G.; Salviulo, G. Roman and medieval glass from the Italian area: Bulk characterization and relationships with production technologies. Archaeometry 2005, 47, 797–816. [Google Scholar] [CrossRef]

- Jackson, C.M.; Paynter, S. A great big melting pot: Exploring patterns of glass supply, consumption and recycling in Roman Coppergate, York. Archaeometry 2016, 58, 68–95. [Google Scholar] [CrossRef]

- Schibille, N.; Degryse, P.; O’Hea, M.; Izmer, A.; Vanhaecke, F.; McKenzie, J. Late Roman glass from the ‘Great Temple’ at Petra and Khirbet et-Tannur, Jordan—Technology and Provenance. Archaeometry 2012, 54, 997–1022. [Google Scholar] [CrossRef]

- Schibille, N.; Sterrett-Krause, A.; Freestone, I.C. Glass groups, glass supply and recycling in late Roman Carthage. Archaeol. Anthropol. Sci. 2017, 9, 1223–1241. [Google Scholar] [CrossRef]

- Ceglia, A.; Cosyns, P.; Schibille, N.; Meulebroeck, W. Unravelling provenance and recycling of late antique glass from Cyprus with trace elements. Archaeol. Antropol. Sci. 2019, 11, 279–291. [Google Scholar] [CrossRef]

- Balvanović, R.; Stojanović Marić, M.; Šmit, Ž. Exploring the unknown Balkans: Early Byzantine glass from Jelica Mt. in Serbia and its contemporary neighbours. J. Radioanal. Nucl. Chem. 2018, 317, 1175–1189. [Google Scholar] [CrossRef]

- Cholakova, A.; Rehren, T.h. A late antique manganese decolourised glass composition: Interpreting patterns and mechanisms of distribution. In Things That Travelled: Mediterranean Glass in the First Millenium CE; Rosenow, D., Phelps, M., Meeks, A., Freestone, I., Eds.; UCL Press: London, UK, 2018; pp. 46–71. [Google Scholar]

- Gallo, F.; Marcante, A.; Silvestri, A.; Molin, G. The glass of the “Casa delle Bestie Ferite”: A first systematic archaeometric study on late Roman vessels from Aquileia. J. Archaeol. Sci. 2014, 41, 7–20. [Google Scholar] [CrossRef]

- Maltoni, S.; Chinni, T.; Vandini, M.; Cirelli, E.; Silvestri, A.; Molin, G. Archaeological and archaeometric study of the glass finds from the ancient harbour of Classe (Ravenna-Italy): New evidence. Herit. Sci. 2015, 3, 13. [Google Scholar] [CrossRef]

- Brill, R.H.; Rising, B.A. Chemical Analyses of Early Glasses, Volume 2; The Corning Museum of Glass: Corning, NY, USA, 1999; pp. 178–187. [Google Scholar]

- Balvanović, R.; Šmit, Ž.; Marić Stojanović, M.; Špehar, P.; Milović, O. Sixth-century Byzantine glass form Limes Fortifications on Serbian Danube. Archaeol. Anthrop. Sci. 2023, 15, 166. [Google Scholar] [CrossRef]

- Brill, R.H. Scientific investigations of Jalame glass and related finds. In Excavations in Jalame: Site of a Glass Factory in Late Roman Palestine: Excavations Conducted by a Joint Expedition of the University of Missouri and the Corning Museum of Glass; Weinberg, G.D., Ed.; University of Missouri: Columbia, MO, USA, 1988; pp. 257–294. [Google Scholar]

- Brems, D.; Freestone, I.C.; Gorin-Rosen, Y.; Scott, R.; Devulder, V.; Vanhaecke, F.; Degryse, P. Characterisation of Byzantine and early Islamic primary tank furnace glass. J. Archaeol. Sci. Rep. 2018, 20, 722–735. [Google Scholar] [CrossRef]

- Freestone, I.C.; Hughes, M.J.; Stapleton, C.P. The composition and production of Anglo-Saxon glass. In Catalogue of Anglo-Saxon Glass in the British Museum; Evison, V.I., Ed.; British Museum: London, UK, 2008; pp. 29–46. [Google Scholar]

- Freestone, I.C. The recycling and reuse of Roman glass: Analytical approaches. J. Glass Stud. 2015, 57, 29–40. [Google Scholar]

- Phelps, M.; Freestone, I.C.; Gorin-Rosen, Y.; Gratuze, B. Natron glass production and supply in the late antique and early medieval Near East: The effect of the Byzantine-Islamic transition. J. Archaeol. Sci. 2016, 75, 57–71. [Google Scholar] [CrossRef]

- Gratuze, B.; Barrandon, J.N. Islamic glass weights and stamps: Analysis using nuclear techniques. Archaeometry 1990, 32, 155–162. [Google Scholar] [CrossRef]

- Kato, N.; Nakai, I.; Shindo, Y. Change in chemical composition of early Islamic glass excavated in Raya, Sinai Peninsula, Egypt: On-site analysis using a portable X-ray fluorescence spectrometer. J. Archaeol. Sci. 2009, 36, 1698–1707. [Google Scholar] [CrossRef]

- De Juan Ares, J.; Schibille, N.; Molina Vidal, J.; Sánchez de Prado, M.D. The supply of glass at Portus Ilicitanus (Alicante, Spain): A meta-analysis of HIMT glasses. Archaeometry 2019, 61, 647–662. [Google Scholar] [CrossRef] [PubMed]

- Freestone, I.C.; Jackson-Tal, R.E.; Tal, O. Raw glass and the production of glass vessels at late Byzantine Apollonia-Arsuf, Israel. J. Glass Stud. 2008, 50, 67–80. [Google Scholar]

- Phelps, M. Glass supply and trade in early Islamic Ramla: An investigation of the plant ash glass. In Things That Travelled: Mediterranean Glass in the First Millenium CE; Rosenow, D., Phelps, M., Meeks, A., Freestone, I., Eds.; UCL Press: London, UK, 2018; pp. 236–282. [Google Scholar]

- Gliozzo, E.; Braschi, E.; Langone, A.; Ignelzi, A.; Favia, P.; Giuliani, R. New geochemical and Sr-Nd isotopic data on medieval plant ash-based glass: The glass collection from San Lorenzo in Carmignano (12th–14th centuries AD, Italy). Microchem. J. 2021, 168, 106371. [Google Scholar] [CrossRef]

- Balvanović, R.; Šmit, Ž.; Marić Stojanović, M.; Spasić-Đurić, D.; Branković, T. Colored glass bracelets from Middle Byzantine (11th–12th century CE) Morava and Braničevo (Serbia). J. Arch. Sci. Rep. 2025, 61, 104950. [Google Scholar]

- Freestone, I.C. Composition and affinities of glass from the furnaces on the island site, Tyre. J. Glass Stud. 2002, 44, 67–76. [Google Scholar]

- Henderson, J.; Chenery, S.; Faber, E.; Kröger, J. The use of electron probe microanalysis and laser ablation-inductively coupled plasma-mass spectrometry for the investigation of 8th–14th century plant ash glasses from the Middle East. Microchem. J. 2016, 128, 134–152. [Google Scholar] [CrossRef]

- Henderson, J.; McLoughlin, S.D.; McPhal, D.S. Radical changes in Islamic glass technology: Evidence for conservatism and experimentation with new glass recipes from early and middle Islamic Raqqa, Syria. Archaeometry 2004, 46, 439–468. [Google Scholar] [CrossRef]

- Swan, C.M.; Rehren, T.; Lankton, J.; Gratuze, B.; Brill, R.H. Compositional observations for Islamic Glass from Sirāf, Iran, in the Corning Museum of Glass collection. J. Archaeol. Sci. Rep. 2017, 16, 102–116. [Google Scholar] [CrossRef]

- Lauwers, V.; Degryse, P.; Waelkens, M. Middle Byzantine (10–13th century A.D.) glass bracelets at Sagalassos (SW Turkey). In Glass in Byzantium—Production, Usage, Analyses. RGZM Tagungen, Band 8; Drauschke, J., Keller, D., Eds.; Verlag des Römisch—Germanischen Zentralmuseum: Mainz, Germany, 2010; pp. 145–152. [Google Scholar]

- Modrijan, Z.; Milavec, T. Late Antique Fortified Settlement Tonovcov Grad near Kobarid; Opera Instituti Archaeologici Sloveniae: Ljubljana, Slovenia, 2011; Volume 24, pp. 121–219. [Google Scholar]

- Silvestri, A.; Marcante, A. The glass of Nogara (Verona): A “window” on production technology of mid-Medieval times in Northern Italy. J. Archaeol. Sci. 2011, 38, 2509–2522. [Google Scholar] [CrossRef]

- Gratuze, B.; Castelli, L.M.; Bianchi, G. The glass finds from the Vetricella site (9th–12th c.) Introduction. Mélanges L’école Française Rome 2023, 135, 349–359. [Google Scholar] [CrossRef]

- Zori, C.; Fulton, J.; Tropper, P.; Zori, D. Glass from the 11th–13th century medieval castle of San Giuliano (Lazio Province, Central Italy). J. Archaeol. Sci. Rep. 2023, 47, 103731. [Google Scholar] [CrossRef]

- Colangeli, F.; Schibille, N. Glass from Islamic Sicily: Typology and composition from an urban and a rural site. Mélanges L’école Française Rome 2023, 135, 321–331. [Google Scholar] [CrossRef]

- Neri, E.; Biron, I.; Verità, M. New insights into Byzantine glass technology from loose mosaic tesserae from Hierapolis (Turkey): PIXE/PIGE and EPMA analyses. Archaeol. Anthropol. Sci. 2018, 10, 1751–1768. [Google Scholar] [CrossRef]

- Siu, I.; Henderson, J.; Dashu, Q.; Ding, Y.; Ciu, J. A study of 11th–15th century AD glass beads from Mambrui, Kenya: An archaeological and chemical approach. J. Archaeol. Sci. Rep. 2021, 36, 102750. [Google Scholar]

- Cagno, S.; Mendera, M.; Jeffries, T.; Janssens, K. Raw materials for medieval to post-medieval Tuscan glassmaking: New insight from LA-ICP-MS analyses. J. Archaeol. Sci. 2010, 37, 3030–3036. [Google Scholar] [CrossRef]

- Henderson, J.; Ma, H.; Evans, J. Glass production of the Silk Road? Provenance and trade of Islamic glasses using isotopic and chemical analyses in a geological context. J. Archaeol. Sci. 2020, 119, 105164. [Google Scholar] [CrossRef]

- Lane, F.C. Venice, A Maritime Republic; John Hopkins University Press: Baltimore, MD, USA, 1973. [Google Scholar]

- Verità, M. Venetian Soda Glass. In Modern Methods for Analysing Archaeological and Historical Glass; Janssens, K., Ed.; John Wiley & Sons: Chichester, UK, 2013; pp. 515–536. [Google Scholar]

- Šmit, Ž.; Janssens, K.; Schalm, O.; Kos, M. Spread of façon-de-Venise glassmaking through central and western Europe. Nucl. Instrum. Methods Phys. Res. Sect. B 2004, 213, 717–722. [Google Scholar] [CrossRef]

- Šmit, Ž.; Stamati, F.; Civici, N.; Vevecka-Priftaj, A.; Kos, M.; Jezeršek, D. Analysis of Venetian-type glass fragments from the ancient city of Lezha (Albania). Nucl. Instrum. Methods Phys. Res. Sect. B 2009, 267, 2538–2544. [Google Scholar] [CrossRef]

- De Raedt, I.; Janssens, K.; Veeckman, J.; Vincze, L.; Vekemans, B.; Jeffries, T.E. Trace analysis for distinguishing between Venetian and façon-de-Venise glass vessels of the 16th and 17th century. J. Anal. At. Spectrom. 2001, 16, 1012–1017. [Google Scholar] [CrossRef]

- Lü, Q.-Q.; Chen, Y.-X.; Henderson, J.; Bayon, G. A large-scale Sr and Nd isotope baseline for archaeological provenance in Silk Road regions and its application in plant-ash glass. J. Arhaeol. Sci. 2023, 149, 105695. [Google Scholar] [CrossRef]

- Coutinho, I.; Medici, T.; Alves, L.C.; Gratuze, B.; Vilarigues, M. Provenance studies on façon-de-Venise glass excavated in Portugal. J. Archaeol. Sci. Rep. 2017, 13, 185–198. [Google Scholar] [CrossRef]

- Occari, V.; Freestone, I.C.; Fenwick, C. Raw materials and technology of Medieval Glass from Venice: The Basilica of SS. Maria e Donato in Murano. J Archaeol. Sci. Rep. 2021, 37, 102981. [Google Scholar] [CrossRef]

- Zmaić Kralj, V.; Beltrame, C.; Miholjek, I.; Ferri, M. A Byzantine shipwreck from Cape Stoba, Mljet, Croatia: An interim report. Int. J. Nautical. Archaeol. 2016, 45, 42–58. [Google Scholar] [CrossRef]

- Bass, G.F.; Matthews, S.D.; Steffy, J.R.; van Doorninck, F.H. Serce Limani. An Eleventh-Century Shipwreck. Volume I and II; Texas A&M University Press: College Station, TX, USA, 2004. [Google Scholar]

- Gasparri, S.; Gelichi, S. (Eds.) The Age of Affirmation. Venice, the Adriatic and the Hinterland Between the 9th and 10th Centuries; Brepols: Turnhout, Belgium, 2018. [Google Scholar]

- Miholjek, I.; Zmaić, V.; Ferri, M. The Byzantine Shipwreck of Cape Stoba (Mljet, Croatia). In Adriatico Altomedievale (VI–XI Secolo) Scambi, Porti, Produzioni; Gelichi, S., Negrelli, C., Eds.; Studi e Ricerche 4: Venezia, Italy, 2017; pp. 227–246. [Google Scholar]

- Gorin Rosen, Y. The Hospitaller Compound: The Glass Finds. In Akko III: The 1991–1998 Excavations: The Late Periods. Part I, The Hospitaller Compound; Stern, E., Syon, D., Eds.; Israel Antiquities Authority Reports: Jerusalem, Israel, 2023; pp. 181–239. [Google Scholar]

- Chinni, T. Le bottiglie kropfflasche: Testimonianze dal monastero di San Severo di Classe (Ravenna). Archeol. Mediev. 2017, 44, 297–304. [Google Scholar]

- Winter, T. Lucid Transformations. The Byzantine–Islamic Transition as Reflected in Glass Assemblages from Jerusalem and Its Environs, 450–800 CE; BAR International Series: Oxford, UK, 2019; pp. 136–139. [Google Scholar]

- Gliozzo, E.; Ferri, M.; Giannetti, F.; Turchiano, M. Glass trade through the Adriatic Sea: Preliminary report of an ongoing project. J. Archaeol. Sci. Rep. 2023, 51, 104180. [Google Scholar] [CrossRef]

- Foster, H.; Jackson, C. The composition of ‘naturally colored’ late Roman vessel glass from Britain and the implications for models of glass production and supply. J. Archaeol. Sci. 2009, 36, 189–204. [Google Scholar] [CrossRef]

- Pactat, I.; Čaušević-Bully, M.; Bully, S.; Perović, Š.; Starac, R.; Gratuze, B.; Schibille, N. Origines et usages du verre issu de quelques sites ecclésiaux et monastiques tardo-antiques et haut médiévaux du littoral nord Croate. In Il Vetro in Transizione (IV–XII Secolo) Produzione e Commercio in Italia Meridionale e nell’Adriatico; Coscarella, A., Noyé, G., Neri, E., Eds.; Edipuglia: Bari, Italy, 2021; pp. 289–302. [Google Scholar]

- Milavec, T.; Šmit, Ž. Glass from late antique hilltop site Korinjski hrib above Veliki Korinj/Steklo s poznoantične višinske postojanke Korinjski hrib nad Velikim Korinjem. Arheol. Vestn. 2020, 71, 271–282. [Google Scholar]

- Natan, E.; Gorin-Rosen, Y.; Benzonelli, A.; Cvikel, D. Maritime trade in early Islamic-period glass: New evidence from the Ma’agan Mikhael B shipwreck. J. Archaeol. Sci. Rep. 2021, 37, 102903. [Google Scholar] [CrossRef]

- Schibille, N.; Colangeli, F. Transformations of the Mediterranean glass supply in medieval Mazara del Vallo (Sicily). In Mazara/Māzar: Nel Ventre Della Città Medievale (Secoli VII–XV). Edizione Critica Degli Scavi (1997) in via Tenente Gaspare Romano; Molinari, A., Meo, A., Eds.; All’Insegna del Giglio: Sesto Fiorentini, Italy, 2021; pp. 491–505. [Google Scholar]

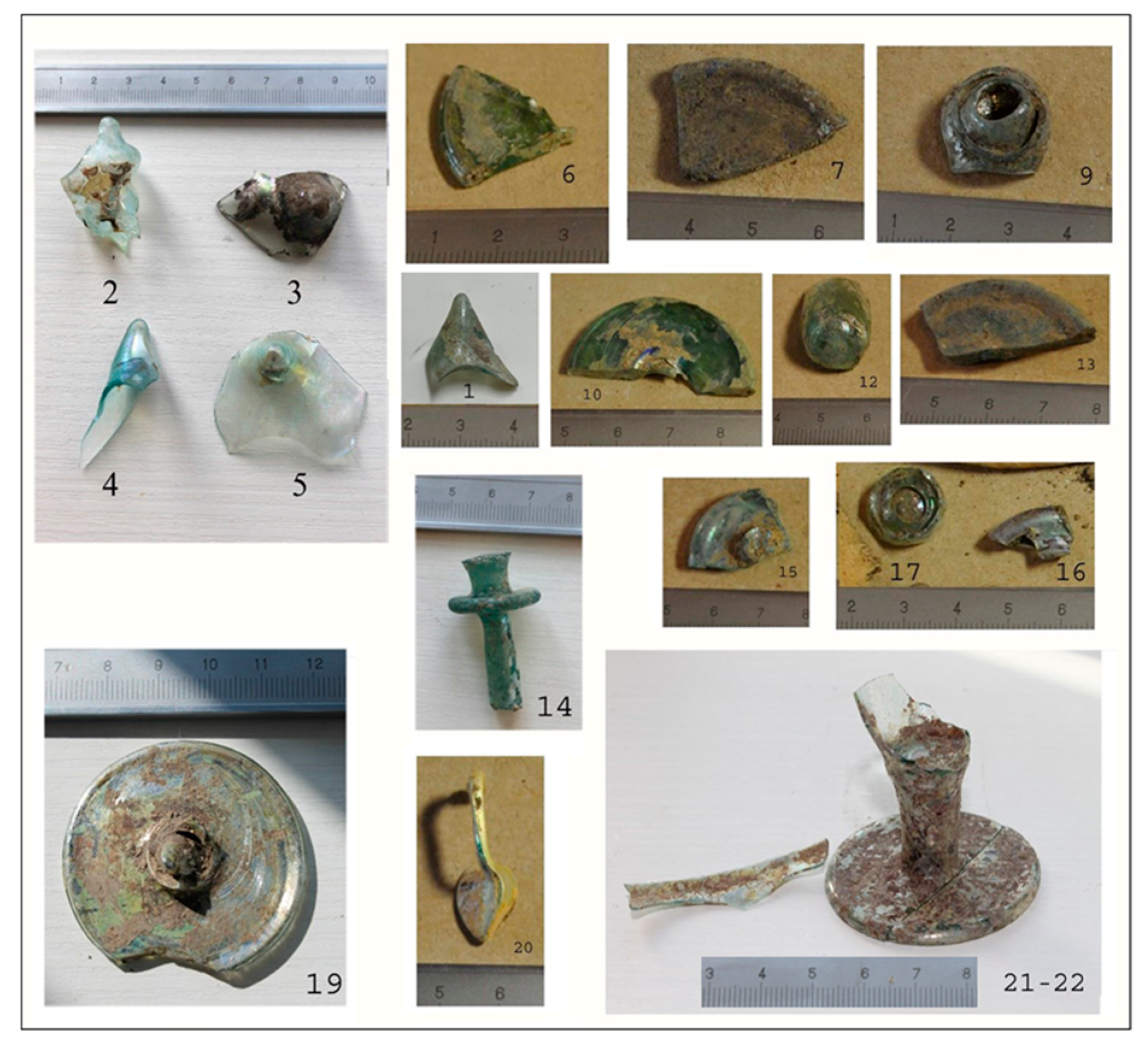

| No. | ID | Description | Color | Archaeological Dating |

|---|---|---|---|---|

| 1 | 626 | vessel base | aqua | Middle Ages? |

| 2 | 429 a | bottle neck | aqua | Middle Ages? |

| 3 | 429 b | vessel base | brown | indeterminable |

| 4 | 429 c | vessel base | aqua | Middle Ages? |

| 5 | 429 d | vessel base | aqua | Middle Ages? |

| 6 | 624 | goblet foot | aqua (patina) | Early Middle Ages? |

| 7 | 646 | goblet foot | greenish (patina) | Early Middle Ages? |

| 8 | 633 | goblet foot | aqua | Late Antiquity |

| 9 | 695 | vessel fragment | aqua | Early Middle Ages? |

| 10 | 601 | goblet foot | aqua | Early Middle Ages? |

| 11 | 447 | beaker base | indeterm. (patina) | Antiquity/Late Antiquity |

| 12 | 619 | lamp/balsamarium | aqua | LA/EMA |

| 13 | 151 | goblet foot | aqua | Late Antiquity |

| 14 | 594 | goblet stem | aqua | EMA/MA |

| 15 | 715 | goblet foot | aqua | Early Middle Ages? |

| 16 | 417 a | rim of a small bottle | indeterm. (patina) | Middle Ages? |

| 17 | 417 b | vessel fragment | aqua | Early Middle Ages? |

| 18 | 875 | goblet foot | aqua | Late Antiquity? |

| 19 | 647 | goblet foot | greenish (patina) | Early Middle Ages? |

| 20 | 186 | lamp handle | aqua (patina) | Late Antiquity? |

| 21 | 170 a | goblet rim | aqua | Early Middle Ages |

| 22 | 170 b | goblet stem and foot | greenish (patina) | Early Middle Ages (C2) |

| Na2O | MgO | Al2O3 | SiO2 | SO3 | Cl | K2O | CaO | TiO2 | MnO | Fe2O3 | CuO | ZnO | Br | Rb2O | SrO | ZrO2 | BaO | PbO | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 10.7 | 3.75 | 0.93 | 66.2 | 0.43 | 0.77 | 2.44 | 13.6 | 0.106 | 0.27 | 0.65 | 57 | 127 | 33 | 14 | 841 | 241 | 0 | 95 |

| 2 | 12.1 | 3.03 | 0.79 | 67.3 | 0.43 | 0.84 | 2.34 | 12.2 | 0.087 | 0.18 | 0.63 | 29 | 83 | 61 | 19 | 866 | 271 | 0 | 12 |

| 3 | 9.65 | 2.44 | 3.21 | 67.3 | 0.33 | 0.83 | 2.27 | 11.8 | 0.070 | 1.47 | 0.47 | 16 | 34 | 55 | 27 | 937 | 32 | 446 | 0 |

| 4 | 11.7 | 3.61 | 0.91 | 66.1 | 0.48 | 0.86 | 2.33 | 13.2 | 0.119 | 0.08 | 0.52 | 39 | 157 | 59 | 12 | 837 | 299 | 0 | 58 |

| 5 | 11.2 | 2.99 | 0.90 | 67.3 | 0.63 | 0.92 | 1.79 | 13.4 | 0.098 | 0.03 | 0.64 | 19 | 348 | 49 | 12 | 791 | 209 | 0 | 15 |

| 6 | 17.3 | 1.62 | 2.37 | 66.3 | 0.81 | 1.00 | 0.83 | 6.94 | 0.183 | 0.98 | 1.02 | 1300 | 74 | 7 | 8 | 645 | 117 | 0 | 2230 |

| 7 | 16.7 | 1.78 | 2.51 | 66.8 | 0.63 | 0.79 | 0.79 | 6.63 | 0.203 | 1.13 | 1.17 | 1950 | 96 | 10 | 9 | 590 | 125 | 0 | 4830 |

| 8 | 14.8 | 0.84 | 3.08 | 67.6 | 0.37 | 0.91 | 1.52 | 10.1 | 0.108 | 0.02 | 0.60 | 13 | 11 | 5 | 11 | 609 | 53 | 0 | 30 |

| 9 | 18.5 | 0.98 | 2.56 | 65.0 | 0.71 | 0.95 | 0.78 | 7.32 | 0.218 | 1.22 | 1.19 | 1290 | 62 | 13 | 5 | 697 | 136 | 0 | 2470 |

| 10 | 14.0 | 1.57 | 2.32 | 68.4 | 0.45 | 0.96 | 0.90 | 9.85 | 0.267 | 0.20 | 0.95 | 430 | 35 | 7 | 5 | 319 | 198 | 0 | 172 |

| 11 | 11.7 | 1.09 | 7.21 | 68.5 | 0.26 | 0.24 | 0.95 | 7.24 | 0.215 | 0.67 | 1.42 | 1050 | 69 | 10 | 7 | 588 | 145 | 0 | 2770 |

| 12 | 18.6 | 0.85 | 2.26 | 66.4 | 0.58 | 1.09 | 0.87 | 7.61 | 0.141 | 0.69 | 0.81 | 355 | 36 | 7 | 11 | 550 | 72 | 0 | 438 |

| 13 | 17.2 | 0.96 | 2.97 | 69.1 | 0.56 | 0.69 | 0.55 | 7.40 | 0.083 | 0.02 | 0.39 | 4 | 6 | 3 | 8 | 567 | 58 | 0 | 8 |

| 14 | 17.5 | 0.86 | 2.43 | 67.4 | 0.55 | 1.03 | 0.80 | 7.49 | 0.132 | 0.70 | 0.82 | 649 | 55 | 7 | 9 | 624 | 79 | 0 | 703 |

| 15 | 17.6 | 1.27 | 2.48 | 66.2 | 0.74 | 1.09 | 0.71 | 7.21 | 0.190 | 0.99 | 0.94 | 1070 | 54 | 10 | 9 | 580 | 102 | 0 | 2620 |

| 16 | 11.9 | 3.27 | 0.78 | 66.2 | 0.61 | 0.99 | 1.82 | 13.3 | 0.125 | 0.18 | 0.61 | 14 | 594 | 53 | 10 | 930 | 326 | 0 | 63 |

| 17 | 17.6 | 0.85 | 2.48 | 66.2 | 0.88 | 0.87 | 0.84 | 7.10 | 0.153 | 0.82 | 0.95 | 3030 | 177 | 15 | 0 | 649 | 39 | 0 | 6000 |

| 18 | 15.2 | 1.21 | 2.32 | 67.7 | 0.52 | 0.97 | 0.75 | 9.23 | 0.259 | 0.53 | 1.05 | 399 | 78 | 4 | 11 | 399 | 187 | 0 | 1150 |

| 19 | 16.7 | 1.21 | 2.16 | 65.8 | 1.14 | 1.07 | 0.79 | 7.58 | 0.149 | 0.90 | 1.05 | 3190 | 102 | 11 | 19 | 656 | 49 | 0 | 7160 |

| 20 | 18.3 | 2.10 | 1.65 | 64.8 | 0.64 | 0.70 | 1.69 | 8.85 | 0.171 | 0.13 | 0.83 | 12 | 17 | 4 | 9 | 845 | 138 | 0 | 19 |

| 21 | 16.6 | 1.52 | 2.41 | 66.7 | 0.66 | 0.92 | 1.11 | 8.04 | 0.173 | 0.55 | 0.91 | 895 | 96 | 4 | 7 | 522 | 123 | 0 | 1980 |

| 22 | 17.5 | 1.39 | 2.51 | 68.0 | 0.72 | 0.98 | 0.66 | 5.88 | 0.157 | 0.80 | 0.76 | 576 | 36 | 9 | 2 | 566 | 94 | 0 | 2110 |

| Na2O | MgO | Al2O3 | SiO2 | K2O | CaO | TiO2 | MnO | Fe2O3 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Roman Sb | 18.7 ± 1.3 | 0.41 ± 0.11 | 1.91 ± 0.21 | 71.4 ± 1.8 | 0.45 ± 0.09 | 5.53 ± 0.84 | 0.06 ± 0.02 | 0.01 ± 0.01 | 0.36 ± 0.1 |

| 2 | Roman Mn (Britain) | 18.31 ± 2.09 | 0.67 ± 0.14 | 2.32 ± 0.17 | 69.62 ± 2.62 | 0.74 ± 0.14 | 6.66 ± 1.06 | 0.10 ± 0.03 | 0.99 ± 0.12 | 0.59 ± 0.17 |

| 3 | Roman Mn (Italy) | 15.18 ± 0.84 | 0.57 ± 0.10 | 2.59 ± 0.13 | 70.29 ± 1.08 | 0.51 ± 0.07 | 7.83 ± 0.3 | 0.07 ± 0.01 | 1.39 ± 0.21 | 0.20 ± 0.16 |

| 4 | Roman Mn | 16.1 ± 1.3 | 0.54 ± 0.10 | 2.62 ± 0.24 | 69.6 ± 2.3 | 0.65 ± 0.23 | 7.92 ± 0.76 | 0.07 ± 0.02 | 0.74 ± 0.56 | 0.4 ± 0.15 |

| 5 | HIMTa | 18.33 ± 1.21 | 1.05 ± 0.18 | 2.99 ± 0.33 | 65.43 ± 1.44 | 0.47 ± 0.14 | 6.30 ± 1.02 | 0.43 ± 0.15 | 1.92 ± 0.57 | 1.79 ± 0.38 |

| 6 | HIMTb | 18.25 ± 0.11 | 1.17 ± 0.12 | 3.31 ± 0.25 | 63.8 1± 0.55 | 0.40 ± 0.03 | 5.70 ± 0.24 | 0.54 ± 0.07 | 1.69 ± 0.16 | 3.81 ± 0.22 |

| 7 | Foy Série 3.2 | 19.0 ± 1.1 | 0.64 ± 0.21 | 1.94 ± 0.19 | 68.1 ± 1.7 | 0.47 ± 0.16 | 6.61 ± 0.86 | 0.10 ± 0.03 | 0.83 ± 0.27 | 0.68 ± 0.16 |

| 8 | Foy Série 2.1 | 17.7 ± 1.3 | 1.12 ± 0.25 | 2.53± 0.23 | 65.7 ± 1.7 | 0.75 ± 0.19 | 8.12 ± 0.92 | 0.15 ± 0.02 | 1.41 ± 0.44 | 1.16 ± 0.5 |

| 9 | Jalame Mn | 15.89 ± 0.85 | 0.59 ± 0.10 | 2.69 ± 0.15 | 68.4 ±1.36 | 0.80 ± 0.08 | 8.77 ± 0.46 | 0.08 ± 0.02 | 1.93 ± 1.11 | 0.47 ± 0.08 |

| 10 | Jalame no Mn | 15.74 ± 0.81 | 0.60 ± 0.15 | 2.70 ± 0.13 | 70.55 ± 1.18 | 0.76 ± 0.12 | 8.77 ± 0.71 | 0.08 ± 0.02 | 0.11 ± 0.09 | 0.38 ± 0.06 |

| 11 | Jalame | 15.7 ± 0.9 | 0.59 ± 0.12 | 2.73 ± 0.17 | 69.9 ± 1.6 | 0.78 ± 0.13 | 8.74 ± 0.67 | 0.09 ± 0.02 | 0.65 ± 0.94 | 0.44 ± 0.19 |

| 12 | Apollonia (Lev. I) | 14.2 ± 1.1 | 0.68 ± 0.28 | 3.25 ± 0.18 | 71.2 ± 1.4 | 0.62 ± 0.19 | 8.43 ± 0.79 | 0.09 ± 0.02 | 0.02 ± 0.005 | 0.50 ± 0.11 |

| 13 | Bet Eli’ezer (Lev. II) | 12.3 ± 1.2 | 0.59 ± 0.12 | 3.38 ± 0.3 | 74.4 ± 1.5 | 0.48 ± 0.08 | 7.35 ± 0.7 | 0.11 ± 0.03 | 0.02 ± 0.004 | 0.69 ± 0.24 |

| 14 | Egypt I | 18.25 ± 1.38 | 0.93 ± 0.14 | 4.05 ± 0.29 | 70.05 ± 1.21 | 0.40 ± 0.11 | 3.03 ± 0.23 | 0.50 ± 0.12 | 0.051 ± 0.007 | 1.74 ± 0.28 |

| 15 | Egypt II | 17.26 ± 1.96 | 0.58 ± 0.13 | 2.19 ± 0.35 | 67.85 ± 1.90 | 0.32 ± 0.24 | 9.34 ± 1.27 | 0.27 ± 0.06 | 0.03 ± 0.015 | 0.98 ± 0.23 |

| 16 | Egypt 2 (<815) | 16.5 ± 1.0 | 0.47 ± 0.09 | 2.00 ± 0.31 | 69.7 ± 1.9 | 0.33 ± 0.09 | 8.51 ± 1.32 | 0.20 ± 0.03 | 0.045 ± 0.083 | 0.84 ± 0.31 |

| 17 | Egypt 2 (>815) | 13.4 ± 0.6 | 0.70 ± 0.15 | 2.52 ± 0.20 | 70.1 ± 1.4 | 0.51 ± 0.25 | 9.57 ± 0.54 | 0.27 ± 0.03 | 0.44 ± 0.47 | 1.18 ± 0.32 |

| 18 | High Al | 16.34 ± 1.74 | 1.14 ± 0.22 | 6.08 ± 2.30 | 62.38 ± 3.67 | 1.57 ± 0.37 | 8.38 ± 2.31 | 0.29 ± 0.25 | 1.22 ± 0.69 | 1.02 ± 0.52 |

| 19 | Magby | 16.3 ± 1.3 | 1.87 ± 0.25 | 2.03 ± 0.29 | 65.1 ± 1.7 | 1.54 ± 0.28 | 9.09 ± 0.78 | 0.17 ± 0.03 | 1.25 ± 0.92 | 1.27 ± 0.41 |

| No. | Type | Type | Recycling | d | Compositional a Dat |

|---|---|---|---|---|---|

| (Figure 6) | (Calculated) | Markers | (Equation (1)) | Dating | |

| 1 | plant ash | Tyre | 0.803 | 10th–11th c. | |

| 2 | plant ash | Raqqa 1 | 0.638 | 10th–11th c. | |

| 3 | plant ash | Tyre/Nishapur | 1.227/1.317 | 10th–11th c. | |

| 4 | plant ash | Tyre | 0.785 | 10th–11th c. | |

| 5 | plant ash | Raqqa 1 | 0.912 | 10th–11th c. | |

| 6 | Foy 2.1 | Foy 2.1 | x | 0.534 | 6th–7th c. |

| 7 | Foy 2.1 | Foy 2.1 | x | 0.709 | 6th–7th c. |

| 8 | Levantine I | Apollonia (Lev. I) | 1.009 | 6th c. | |

| 9 | Foy 2.1 | Foy 2.1 | x | 0.610 | 6th–7th c. |

| 10 | Egypt (?) | Egypt (?)/Maby | x | 0.888 | ? |

| 11 | ? | Indet./High Al | 0.636 | ? | |

| 12 | Foy 2.1 | Foy 2.1 | x | 0.449 | 6th–7th c. |

| 13 | Levantine I | Apollonia (Lev. I) | 0.668 | 6th c. | |

| 14 | Foy 2.1 | Foy 2.1 | x | 0.432 | 6th–7th c. |

| 15 | Foy 2.1 | Foy 2.1 | x | 0.429 | 6th–7th c. |

| 16 | plant ash | Tyre | 0.990 | 10th–11th c. | |

| 17 | Foy 2.1 | Foy 2.1 | x | 0.364 | 6th–7th c. |

| 18 | Egypt (?) | Magby | x | 0.852 | ? |

| 19 | Foy 2.1 | Foy 2.1 | x | 0.376 | 6th–7th c. |

| 20 | Magby | Magby | 0.471 | late 6th–7th c. | |

| 21 | Foy 2.1 | Magby | x | 0.531 | late 6th–7th c. |

| 22 | Foy 2.1 | Foy 2.1 | x | 0.574 | 6th–7th c. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šmit, Ž.; Milavec, T. Analysis of Late Antique and Medieval Glass from Koper (Capodistria, SI): Insights into Glass Consumption and Production at the Turn of the First Millennium CE. Materials 2025, 18, 2135. https://doi.org/10.3390/ma18092135

Šmit Ž, Milavec T. Analysis of Late Antique and Medieval Glass from Koper (Capodistria, SI): Insights into Glass Consumption and Production at the Turn of the First Millennium CE. Materials. 2025; 18(9):2135. https://doi.org/10.3390/ma18092135

Chicago/Turabian StyleŠmit, Žiga, and Tina Milavec. 2025. "Analysis of Late Antique and Medieval Glass from Koper (Capodistria, SI): Insights into Glass Consumption and Production at the Turn of the First Millennium CE" Materials 18, no. 9: 2135. https://doi.org/10.3390/ma18092135

APA StyleŠmit, Ž., & Milavec, T. (2025). Analysis of Late Antique and Medieval Glass from Koper (Capodistria, SI): Insights into Glass Consumption and Production at the Turn of the First Millennium CE. Materials, 18(9), 2135. https://doi.org/10.3390/ma18092135