Selective Laser Melting of Molybdenum Alloy on Silicon Carbide Substrate

Abstract

1. Introduction

| Reference | Feedstock Composition | SLM Parameters | Achieved Density | Other Properties |

|---|---|---|---|---|

| [12] | Mo | Spot velocity—556 mm/s Layer thickness—25 µm Overlap—20 µm Laser power—200 W Energy input—480 J/mm3 | 82.5% | Heat conductivity—142 W/mK (at 20 °C) and 105 W/mK (at 1000 °C) Young’s modulus—330 GPa (at 20 °C) and 280 (at 800 °C) |

| [13] | Mo—0.45 wt% C | Layer thickness—0.03 mm, hatch distance—0.1 mm, island scanning, zig-zag pattern, layer rotation −67°, layer shift—0.5 mm, energy input—0.66 J/mm Substrate plate temperature 800 °C | 99.6 ± 0.2% | Bending strength—1180 ± 310 MPa Vickers hardness—343 ± 5 HV10 |

| Mo | 97.7 ± 0.2% | Bending strength—267 ± 51 MPa Vickers hardness—208 ± 4 HV10 | ||

| [14] | Mo | Line energy density—1142 J/m Scanning rotation—67° Spot size—75 µm | 99.1% | |

| [15] | Mo | Laser power—100–350 W Scan speed—400–4000 mm/s Layer thickness—20–60 μm Hatch distance—70 μm Substrate temperature—150 °C Layer rotation—67° | >90% | |

| [17] | Mo | Laser power—200 W Layer thickness—0.02 mm Hatch distance—0.05 mm Scanning speeds—200–1000 mm/s. | NA | Flexural strength—329 MPa |

| [18] | Mo | Laser speed—314 (100–600) mm/s, build atm—3.3% H2/96.6% N2 (0–5% H2 in N2) | NA | Ultimate tensile stress—835 MPa, yield stress—760 MPa, ultimate tensile strain—0.017 mm/mm, final strain—0.01 mm/mm, Young’s modulus—77,313 N/m2. |

| [19] | Mo | Layer energy density—0.51 J/mm Laser power—200 W Velosity—400 mm/s Overlap rate—20% | 99.1% | Hardness—260 HV Bending strength—280 ± 52 MPa |

2. Materials and Methods

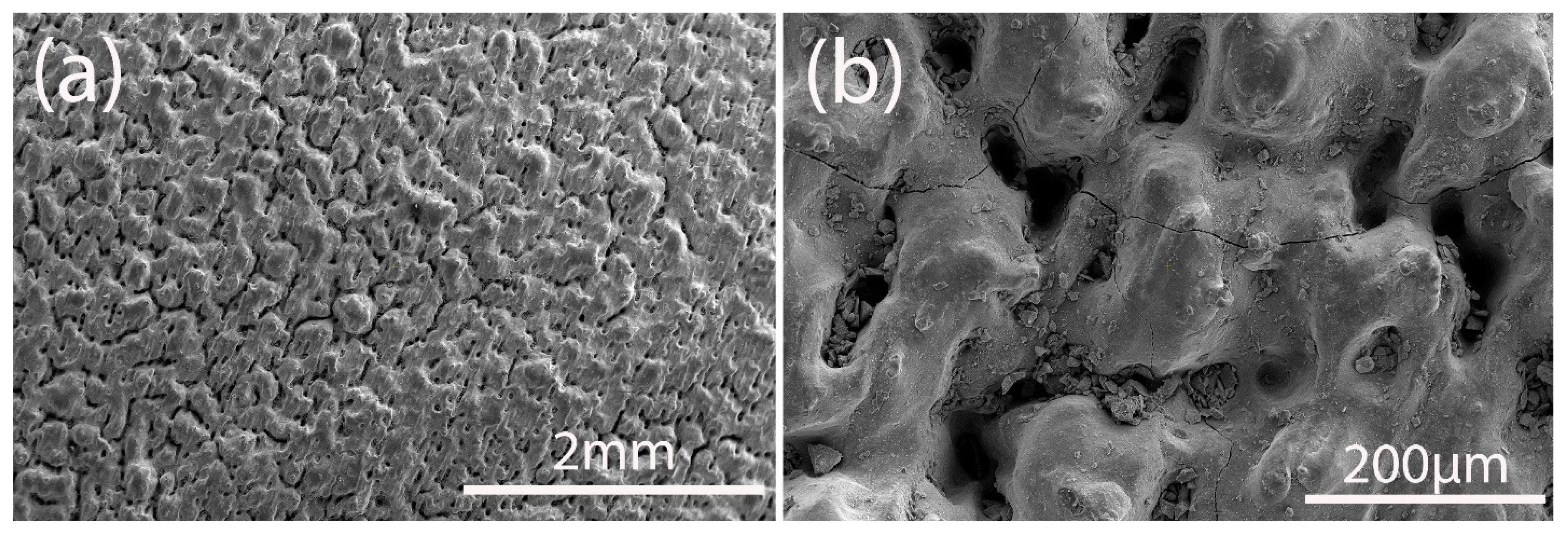

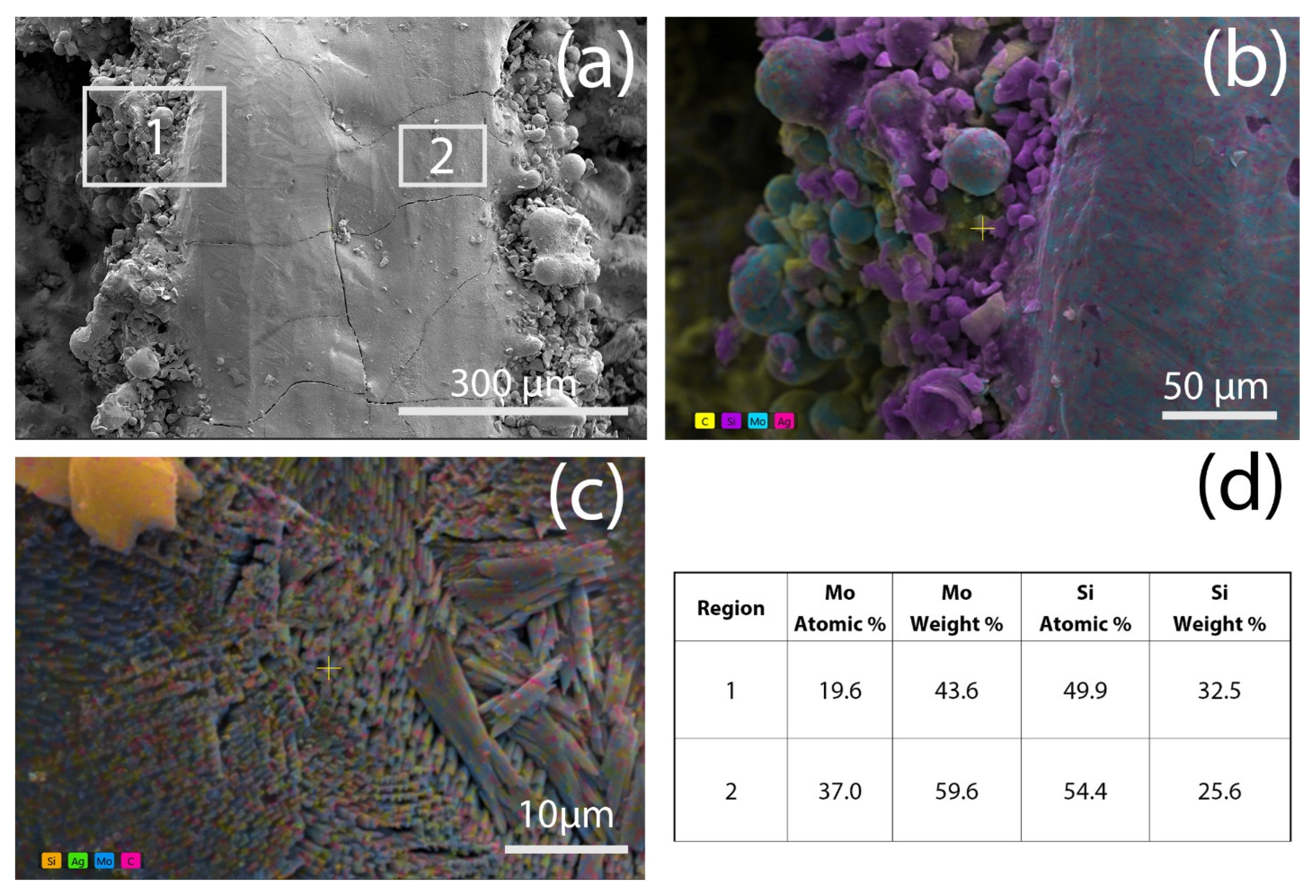

3. Results and Discussion

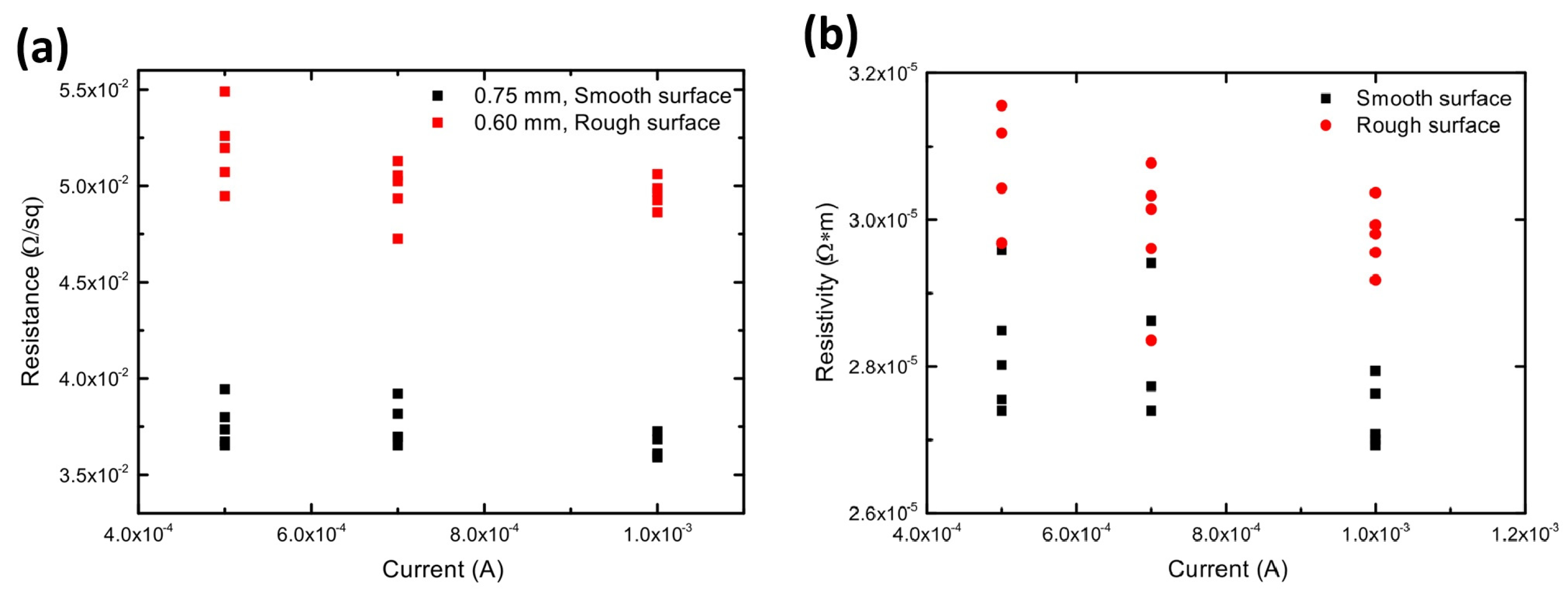

Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sarkar, J. Sputtering Targets and Thin Films for Flat Panel Displays and Photovoltaics. In Sputtering Materials for VLSI and Thin Film Devices; Elsevier: Amsterdam, The Netherlands, 2014; pp. 417–499. [Google Scholar] [CrossRef]

- Rafaja, D.; Köstenbauer, H.; Mühle, U.; Löffler, C.; Schreiber, G.; Kathrein, M.; Winkler, J. Effect of the deposition process and substrate temperature on the microstructure defects and electrical conductivity of molybdenum thin films. Thin Solid Films 2013, 528, 42–48. [Google Scholar] [CrossRef]

- Hidnert, P.; Gero, W.B. Thermal Expansion of Molybdenum; Scientific Papers of the Bureau of Standards; US Department of Commerce, Bureau of Standards: Gaithersburg, MD, USA, 1924; Volume 19, p. 429. [CrossRef]

- Su, W.; Pan, M.; Mo, D.; Xu, H. Mechanical and thermal properties of Mo for packaging HgCdTe IRFPA detector at cryogenic temperatures. Infrared Phys. Technol. 2022, 127, 104373. [Google Scholar] [CrossRef]

- Berczik, D.M. Method for Enhancing the Oxidation Resistance of a Molybdenum Alloy, and a Method of Making a Molybdenum Alloy. U.S. Patent 5,595,616, 21 January 1997. [Google Scholar]

- Guo, S.; Zhou, W.; Zhou, Z.; Nomura, N. Laser additive manufacturing of pure molybdenum using freeze-dry pulsated orifice ejection method-produced powders. J. Mater. Res. Technol. 2022, 16, 1508–1516. [Google Scholar] [CrossRef]

- Rebesan, P. Characterization of Molybdenum Produced by Laser Powder Bed Fusion for the High-Temperature Ion Sources of the INFN SPES Facility. 2022. Available online: https://www.politesi.polimi.it/handle/10589/189834 (accessed on 17 April 2025).

- Ma, W.; Ning, J.; Zhang, L.-J.; Na, S.-J. Regulation of microstructures and properties of molybdenum-silicon-boron alloy subjected to selective laser melting. J. Manuf. Process. 2021, 69, 593–601. [Google Scholar] [CrossRef]

- Wu, Y.; Wu, Q.; Li, M.; Wang, J.; Yao, D.; Luo, H.; An, X.; Fu, H.; Zhang, H.; Yang, X.; et al. Numerical investigation on effects of operating conditions and final dimension predictions in laser powder bed fusion of molybdenum. Addit. Manuf. 2023, 76, 103783. [Google Scholar] [CrossRef]

- Leclercq, A.; Mouret, T.; Brailovski, V. Laser powder bed fusion of molybdenum: Density, structure and mechanical properties at room and elevated temperatures. Mater. Sci. Eng. A 2025, 929, 148004. [Google Scholar] [CrossRef]

- Alinejadian, N.; Wang, P.; Kollo, L.; Prashanth, K.G. Selective Laser Melting of Commercially Pure Molybdenum by Laser Rescanning. 3D Print. Addit. Manuf. 2023, 10, 785–791. [Google Scholar] [CrossRef]

- Faidel, D.; Jonas, D.; Natour, G.; Behr, W. Investigation of the selective laser melting process with molybdenum powder. Addit. Manuf. 2015, 8, 88–94. [Google Scholar] [CrossRef]

- Kaserer, L.; Braun, J.; Stajkovic, J.; Leitz, K.-H.; Tabernig, B.; Singer, P.; Letofsky-Papst, I.; Kestler, H.; Leichtfried, G. Fully dense and crack free molybdenum manufactured by Selective Laser Melting through alloying with carbon. Int. J. Refract. Met. Hard Mater. 2019, 84, 105000. [Google Scholar] [CrossRef]

- Wang, D.; Yu, C.; Ma, J.; Liu, W.; Shen, Z. Densification and crack suppression in selective laser melting of pure molybdenum. Mater. Des. 2017, 129, 44–52. [Google Scholar] [CrossRef]

- Higashi, M.; Ozaki, T. Selective laser melting of pure molybdenum: Evolution of defect and crystallographic texture with process parameters. Mater. Des. 2020, 191, 108588. [Google Scholar] [CrossRef]

- Kinkade, R.X.; Eckley, C.C.; Sexton, B.M.; Shelton, T.E.; Schubert-Kabban, C.M.; Hartsfield, C.R.; Brewer, J.S.; Kemnitz, R.A. Evaluating Molybdenum-Rhenium Alloys Through Additive Manufacturing. SSRN Electron. J. 2022. [Google Scholar] [CrossRef]

- Eckley, C.C.; Kinkade, R.X.; Sexton, B.M.; Shelton, T.E.; Schubert-Kabban, C.; Hartsfield, C.R.; Brewer, J.S.; Kemnitz, R.A. Evaluating Molybdenum-Rhenium Alloys Through Additive Manufacturing. JOM 2023, 75, 1928–1940. [Google Scholar] [CrossRef]

- Bustin, M.L. Additive Manufacturing of Molybdenum for High Temperature Structural Applications, 2022. Theses and Dissertations. 5531. Available online: https://scholar.afit.edu/etd/5531 (accessed on 17 April 2025).

- Yan, A.; Atif, A.M.; Wang, X.; Lan, T.; Wang, Z. The Microstructure and Cracking Behaviors of Pure Molybdenum Fabricated by Selective Laser Melting. Materials 2022, 15, 6230. [Google Scholar] [CrossRef]

- Lindemann, A. Measurement of the Thermophysical Properties of Pure Molybdenum; NETZSCH-Gerätebau GmbH: Selb, Germany, 2013. [Google Scholar]

- Braun, J.; Kaserer, L.; Stajkovic, J.; Leitz, K.-H.; Tabernig, B.; Singer, P.; Leibenguth, P.; Gspan, C.; Kestler, H.; Leichtfried, G. Molybdenum and tungsten manufactured by selective laser melting: Analysis of defect structure and solidification mechanisms. Int. J. Refract. Met. Hard Mater. 2019, 84, 104999. [Google Scholar] [CrossRef]

- Li, K.; Wang, D.; Xing, L.; Wang, Y.; Yu, C.; Chen, J.; Zhang, T.; Ma, J.; Liu, W.; Shen, Z. Crack suppression in additively manufactured tungsten by introducing secondary-phase nanoparticles into the matrix. Int. J. Refract. Met. Hard Mater. 2019, 79, 158–163. [Google Scholar] [CrossRef]

- Ghaltaghchyan, T.; Khachatryan, H.; Asatryan, K.; Rstakyan, V.; Aghayan, M. Effect of additives on selective laser sintering of silicon carbide. Boletín De La Soc. Española De Cerámica y Vidrio 2023, 62, 504–514. [Google Scholar] [CrossRef]

- Kharatyan, S.L.; Aghayan, M.A.; Chatilyan, H.A. Interaction modes in Mo/Si diffusion couple at non-isothermal conditions. Int. J. Self-Propagating High-Temp. Synth. 2014, 23, 138–140. [Google Scholar] [CrossRef]

- Baras, F.; Kondepudi, D.K.; Bernard, F. Combustion synthesis of MoSi2 and MoSi2–Mo5Si3 composites: Multilayer modeling and control of the microstructure. J. Alloys Compd. 2010, 505, 43–53. [Google Scholar] [CrossRef]

- Kharatyan, S.L.; Chatilyan, H.A.; Aghayan, M.A.; Rodriguez, M.A. Non-isothermal phenomena in Mo/Si diffusion couple: Reaction kinetics and structure formation. Int. J. Self-Propagating High-Temp. Synth. 2013, 22, 18–26. [Google Scholar] [CrossRef]

- Czerny, A.K.; Ma, W.; Hausner, C.S.; Franke, P.; Rohde, M.; Seifert, H.J. Thermodynamic Assessment of the Mo–Si System. Adv. Eng. Mater. 2024, 26, 2302085. [Google Scholar] [CrossRef]

| Resistance | |||

| Data | N Total | Mean/Ω | Standard Deviation |

| smooth surface | 5 | 0.03642 | 5.94953 × 10−4 |

| rough surface | 5 | 0.04961 | 7.3647 × 10−4 |

| Resistivity | |||

| Data | N Total | Mean/Ω·m | Standard Deviation |

| smooth surface | 5 | 2.73167 × 10−5 | 4.46215 × 10−5 |

| rough surface | 5 | 2.97681 × 10−5 | 4.41883 × 10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aghayan, M.; Ghaltaghchyan, T. Selective Laser Melting of Molybdenum Alloy on Silicon Carbide Substrate. Materials 2025, 18, 2121. https://doi.org/10.3390/ma18092121

Aghayan M, Ghaltaghchyan T. Selective Laser Melting of Molybdenum Alloy on Silicon Carbide Substrate. Materials. 2025; 18(9):2121. https://doi.org/10.3390/ma18092121

Chicago/Turabian StyleAghayan, Marina, and Tsovinar Ghaltaghchyan. 2025. "Selective Laser Melting of Molybdenum Alloy on Silicon Carbide Substrate" Materials 18, no. 9: 2121. https://doi.org/10.3390/ma18092121

APA StyleAghayan, M., & Ghaltaghchyan, T. (2025). Selective Laser Melting of Molybdenum Alloy on Silicon Carbide Substrate. Materials, 18(9), 2121. https://doi.org/10.3390/ma18092121