Influence of Embedding Microcapsules on Tribological Properties of Alumina Ceramics Prepared by Gel Casting

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

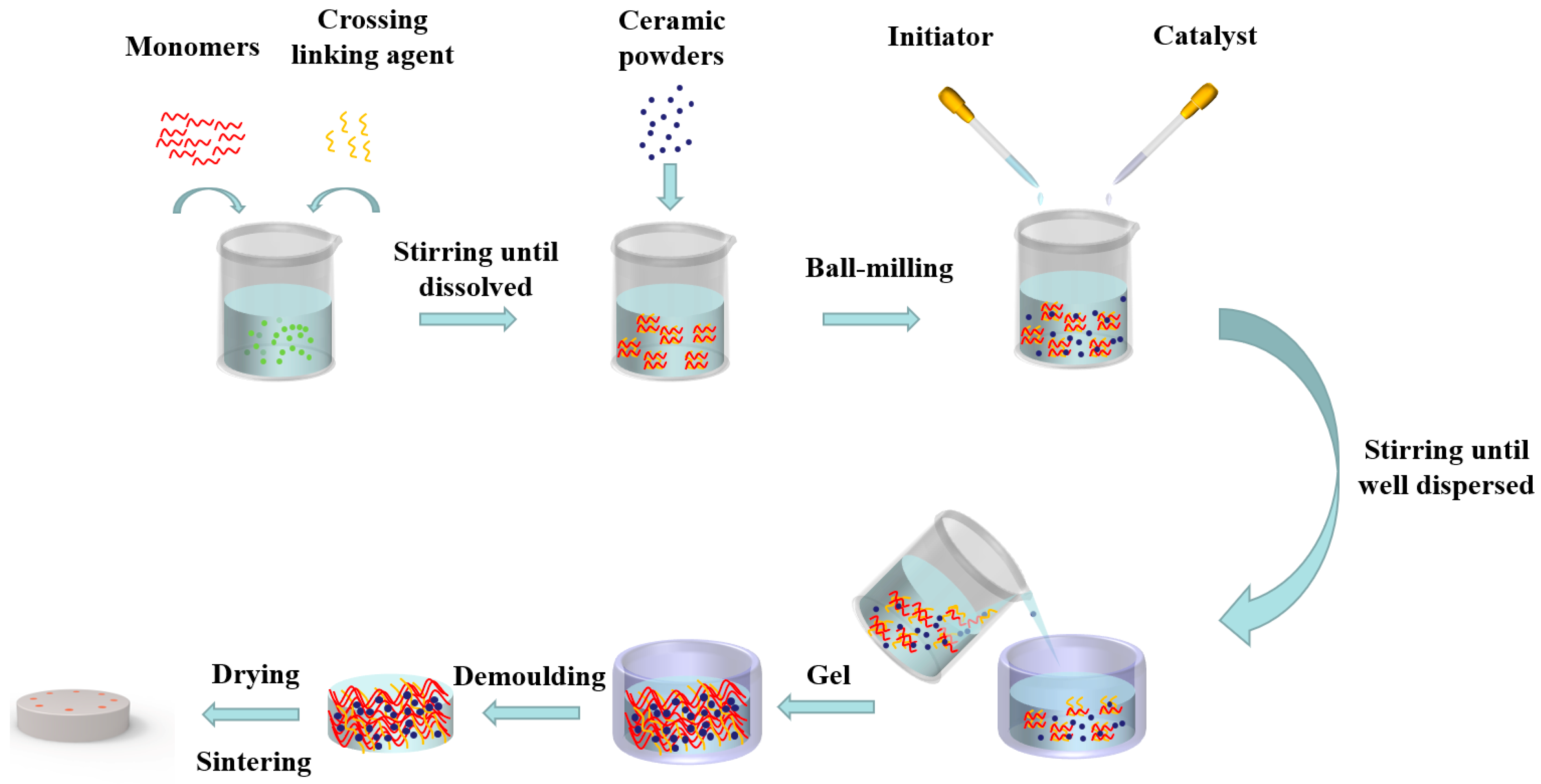

2.2. Gel Casting of Alumina Ceramics

2.3. Characterization

3. Results and Discussion

3.1. Pourability of Ceramic Slurry

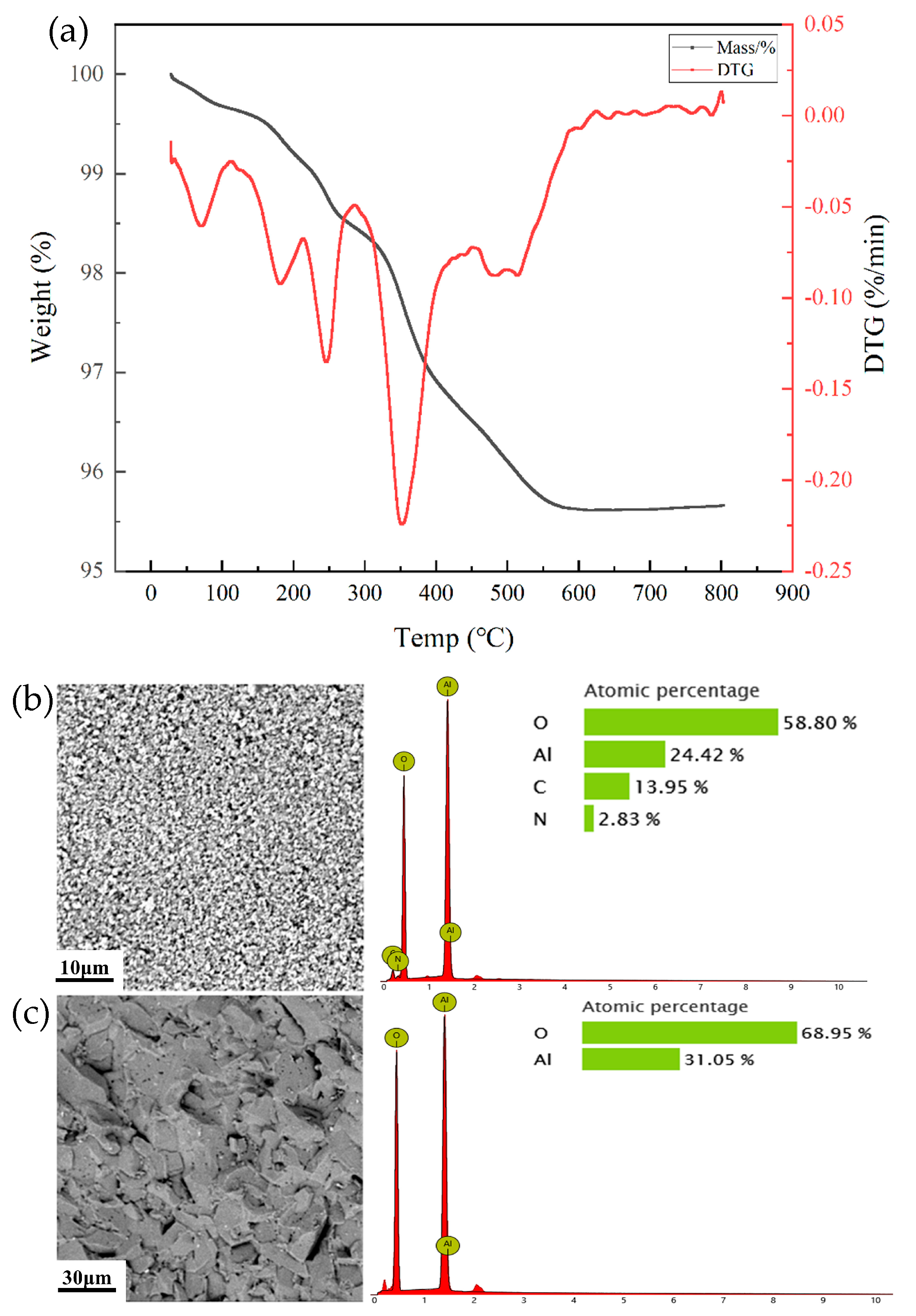

3.2. Characterization of the Alumina

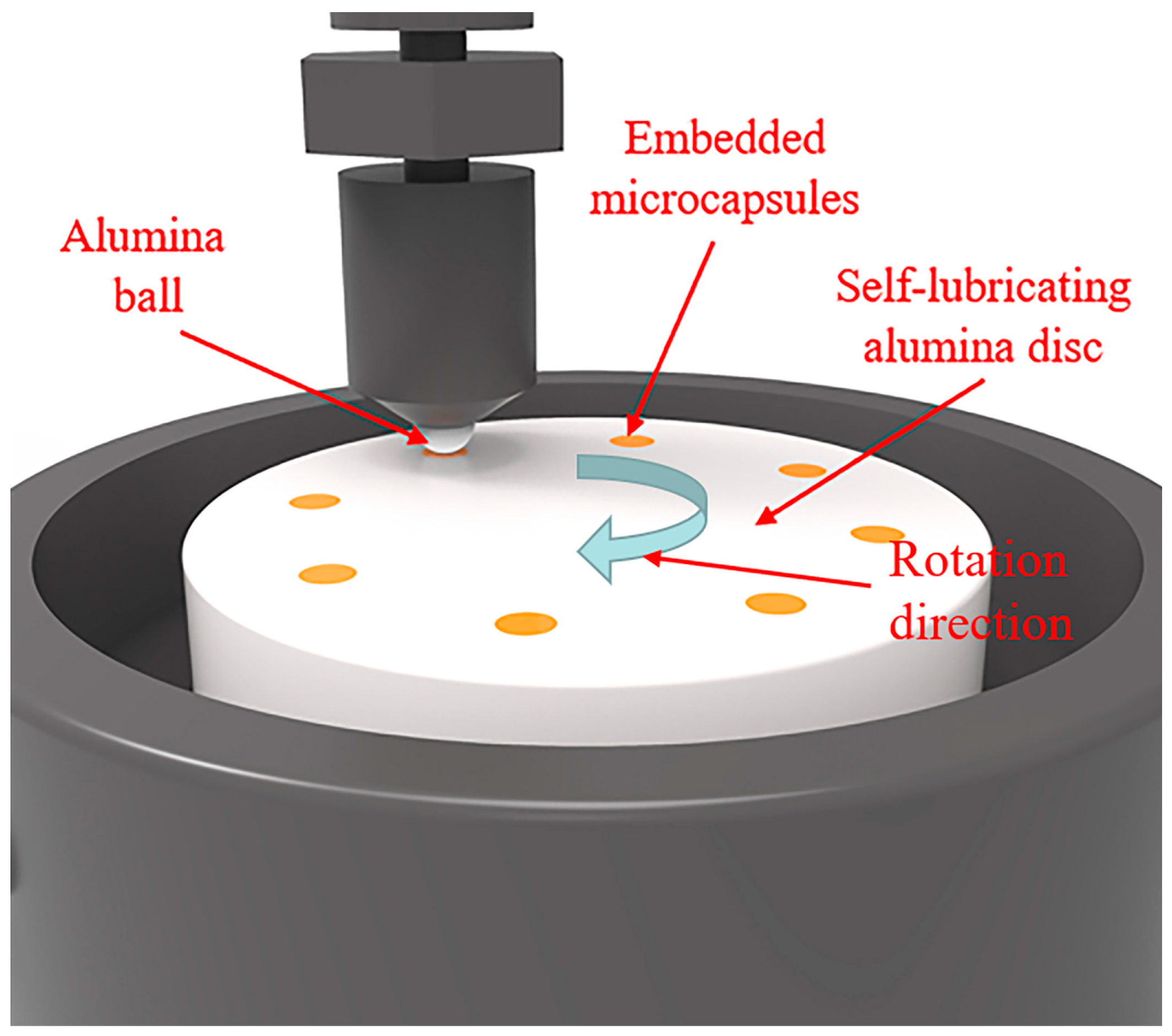

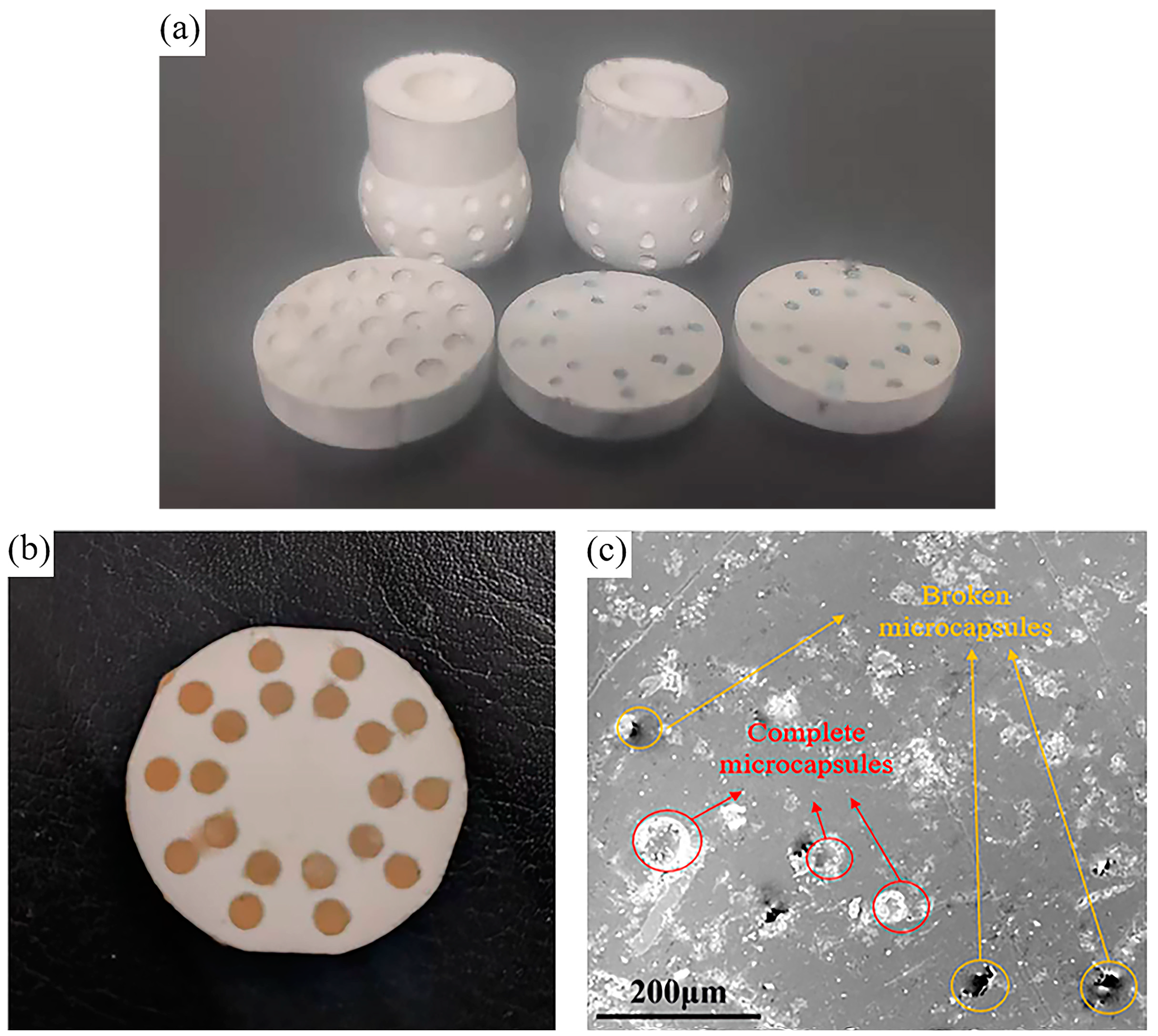

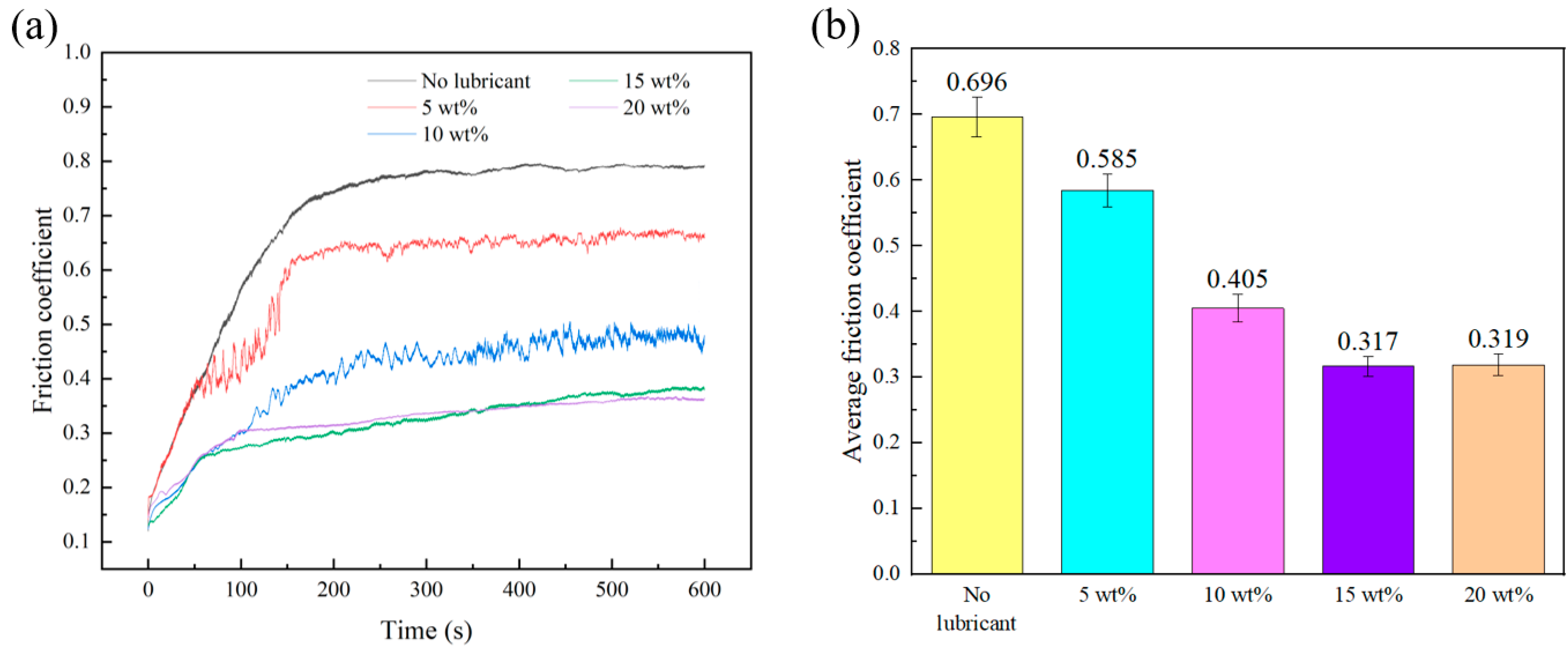

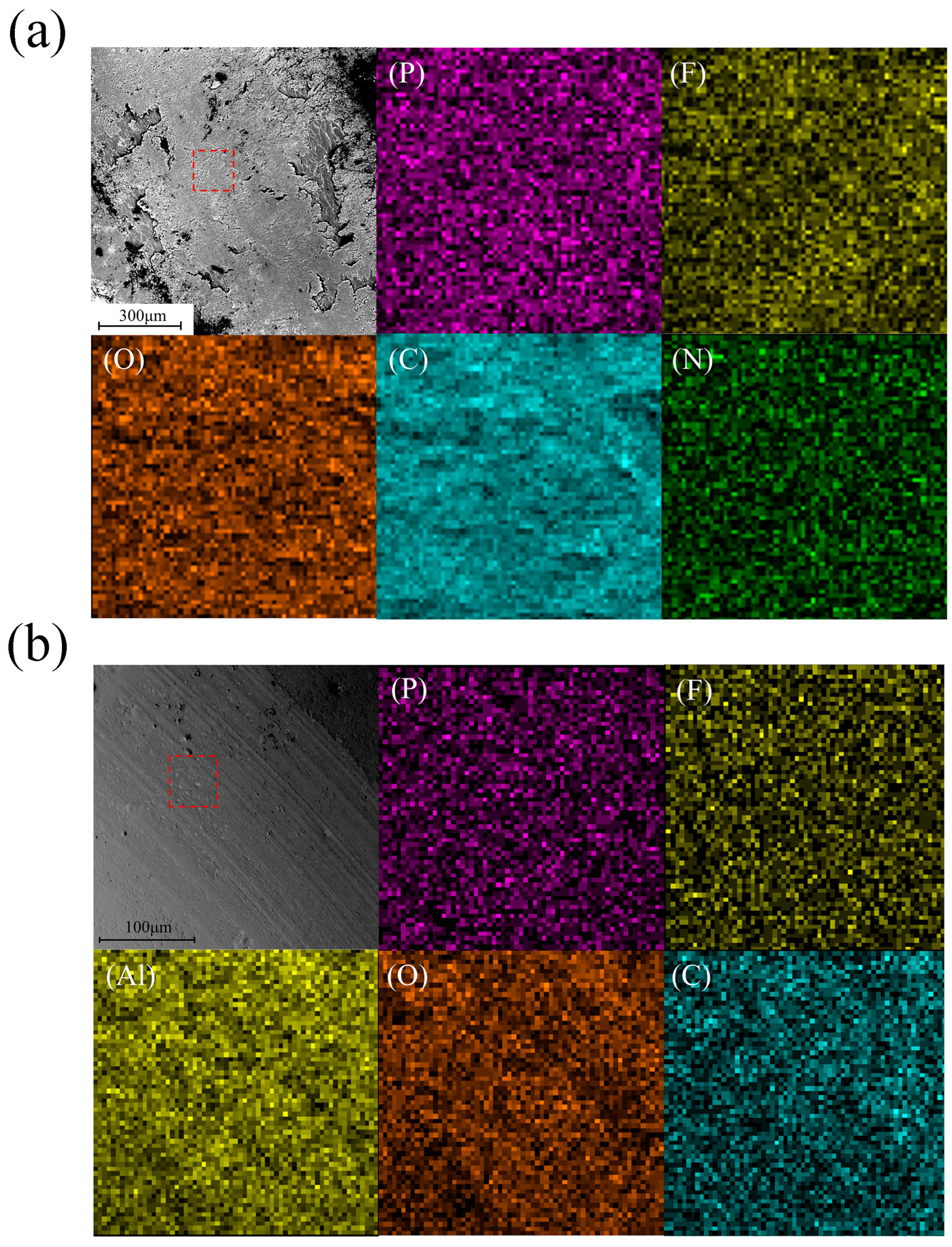

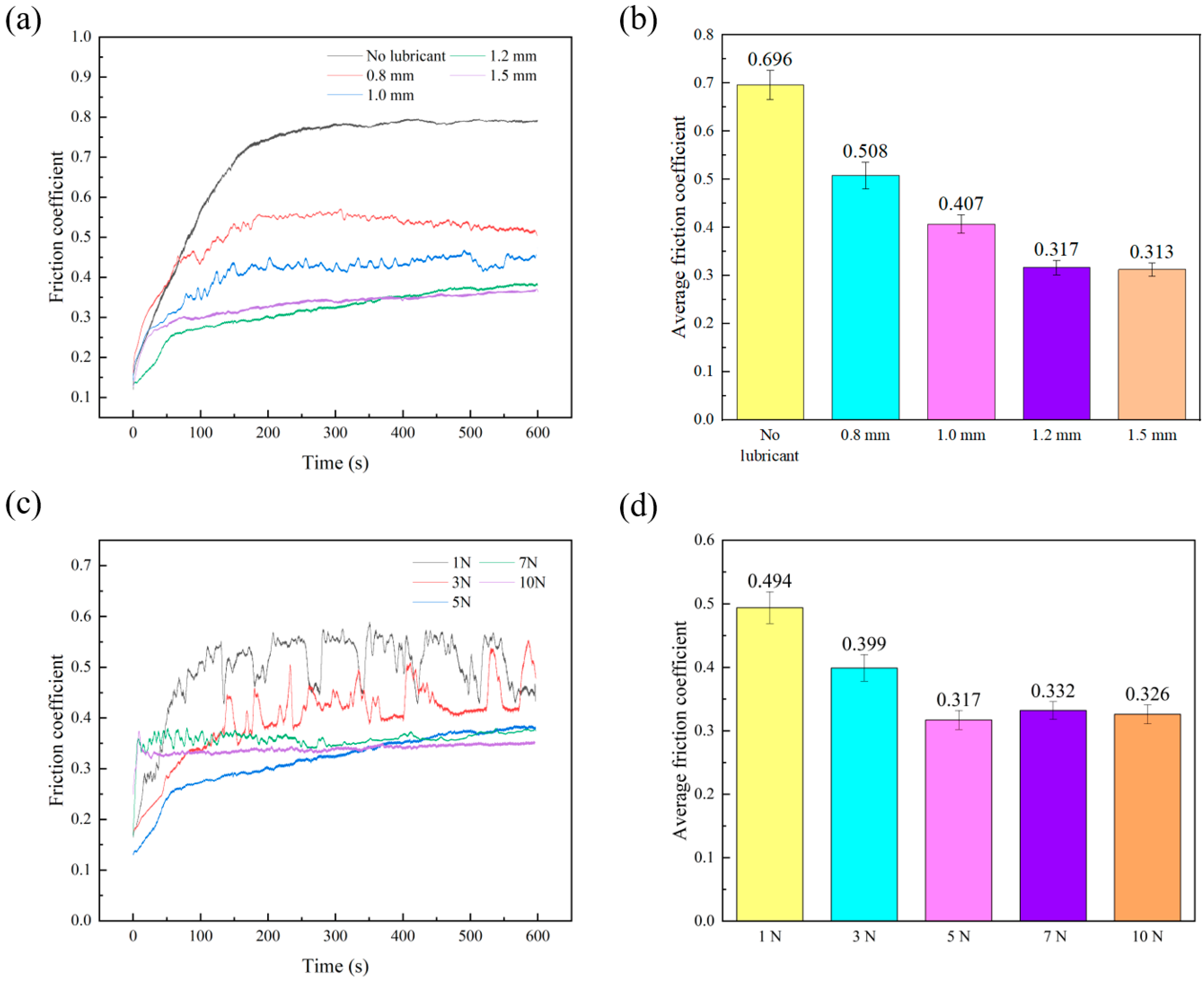

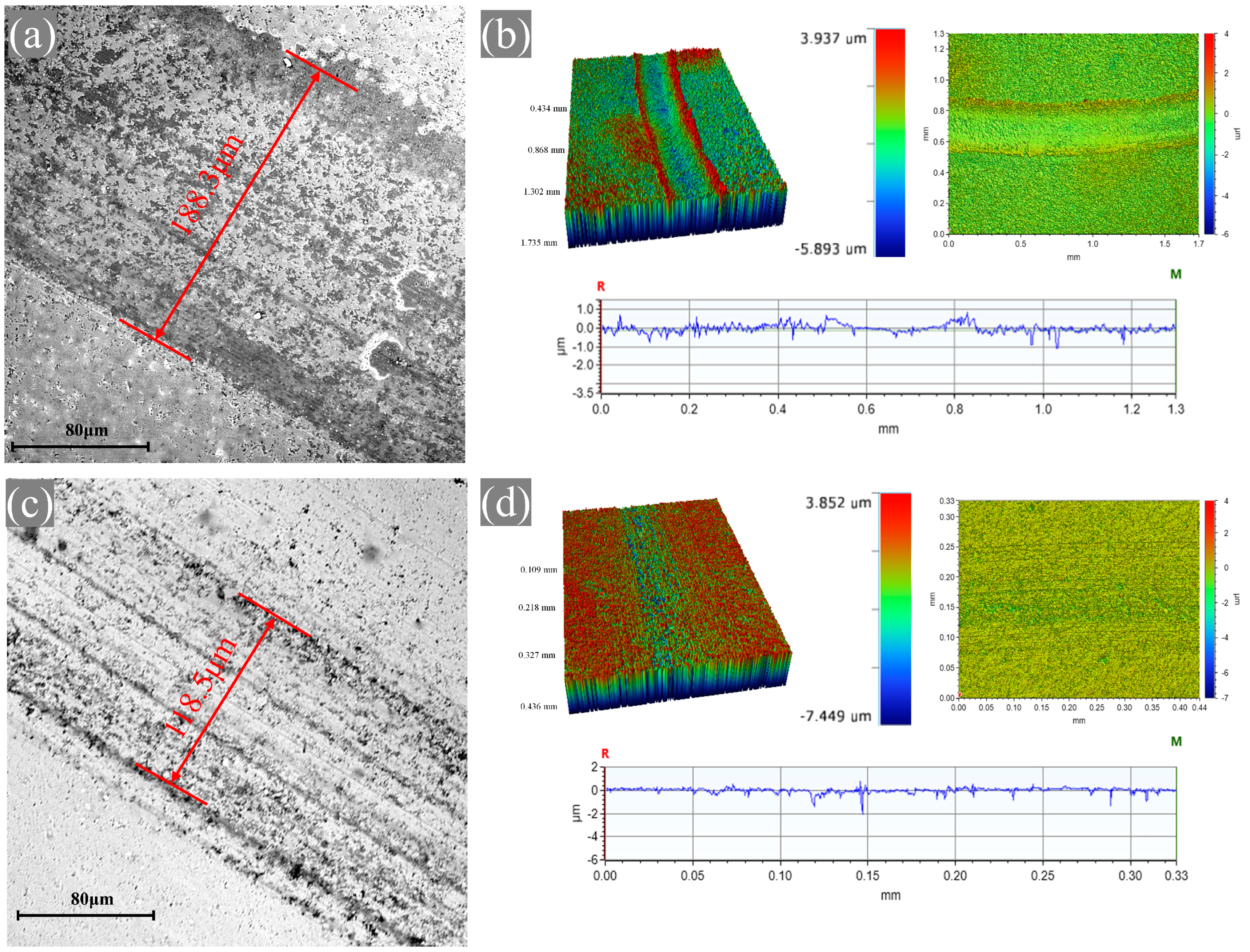

3.3. The Tribological Properties of the Material

4. Conclusions

- For the NMAM gel casting system, the optimal parameters for preparing alumina slurries were achieved with the addition of 0.3 wt% PAA dispersant, a pH value of 10, and a solid loading of 54%.

- The prepared alumina ceramics achieved a relative density of 98.2%, a hardness of 16 GPa, and a flexural strength of 276 MPa after binder removal at 600 °C for 1 h and pressureless sintering at 1500 °C for 2 h. The mechanical properties of the materials prepared by gel casting are comparable to those of alumina ceramics prepared by traditional powder metallurgy.

- Embedding ionic liquid-containing microcapsules into the surface holes significantly improved the tribological performance of alumina. When the embedded hole diameter was 1.2 mm and the microcapsule content was 15 wt%, the friction coefficient decreased by 54.5% under a 5 N load. At a 10 N load, the friction coefficient was comparable to that at 5 N. Compared to pure alumina, the embedding microcapsules alumina demonstrated a 37% reduction in wear track width along with significantly decreased wear depth. Embedding microcapsules effectively improve the tribological properties of alumina.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AM | Acrylamide |

| DMAM | N, N-dimethylacrylamide |

| EDS | Energy dispersive spectrometer |

| h-NB | Hexagonal boron nitride |

| MAM | Methacrylamide |

| NMAM | N-hydroxy methacrylamide |

| PUF | Polyurea-formaldehyde |

| SEM | Scanning electron microscope |

| TGA | Thermogravimetric analysis |

| ISOBAM | Isobutene-maleic anhydride copolymer |

References

- Stojanovic, B.; Glisovic, J. Application of Ceramic Matrix Composite in Automotive Industry. In Encyclopedia of Materials: Composites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 275–292. [Google Scholar] [CrossRef]

- Salam, A.; Xie, G.; Guo, D.; Xu, W. Fabrication and tribological behavior of self-lubricating composite impregnated with synthesized inorganic hollow fullerene-like MoS2. Compos. Part B Eng. 2020, 200, 108284. [Google Scholar] [CrossRef]

- Klimczyk, P.; Cura, M.; Vlaicu, A.; Mercioniu, I.; Wyżga, P.; Jaworska, L.; Hannula, S.-P. Al2O3–cBN composites sintered by SPS and HPHT methods. J. Eur. Ceram. Soc. 2016, 36, 1783–1789. [Google Scholar] [CrossRef]

- Qi, Y.; Zhang, Y.; Fang, Y.; Hu, L. Design and preparation of high-performance alumina functional graded self-lubricated ceramic composites. Compos. Part B Eng. 2013, 47, 145–149. [Google Scholar] [CrossRef]

- Yang, X.; Wang, Z.; Song, P.; Cheng, J.; Gu, J.; Ma, T. Dry Sliding Wear Behavior of Al2O3-TiC Ceramic Composites Added with Solid Lubricant CaF2 by Cold Pressing and Sintering. Tribol. Trans. 2014, 58, 231–239. [Google Scholar] [CrossRef]

- Chen, Z.; Ji, L.; Guo, R.; Xu, C.; Li, Q. Mechanical properties and microstructure of Al2O3/Ti(C, N)/CaF2@Al2O3 self-lubricating ceramic tool. Int. J. Refract. Met. Hard Mater. 2019, 80, 144–150. [Google Scholar] [CrossRef]

- Chen, H.; Xu, C.; Xiao, G.; Chen, Z.; Ma, J.; Wu, G. Synthesis of (h-BN)/SiO2 core–shell powder for improved self-lubricating ceramic composites. Ceram. Int. 2016, 42, 5504–5511. [Google Scholar] [CrossRef]

- Zhang, W.; Yi, M.; Xiao, G.; Ma, J.; Wu, G.; Xu, C. Al2O3 -coated h-BN composite powders and as-prepared Si3N4-based self-lubricating ceramic cutting tool material. Int. J. Refract. Met. Hard Mater. 2018, 71, 1–7. [Google Scholar] [CrossRef]

- Ding, Y.; Song, P.Y. The research progress of embedded solid lubricant materials. In Proceedings of the 2nd International Conference on Advanced Engineering Materials and Technology (AEMT), Zhuhai, China, 6–8 July 2012; pp. 1369–1373. [Google Scholar]

- Young, A.C.; Omatete, O.O.; Janney, M.A.; Menchhofer, P.A. Gelcasting of Alumina. J. Am. Ceram. Soc. 1991, 74, 612–618. [Google Scholar] [CrossRef]

- Lu, Y.; Gan, K.; Huo, W.; Lv, L.; Liu, J.; Zhang, X.; Yan, S.; Yang, J. Dispersion and gelation behavior of alumina suspensions with Isobam. Ceram. Int. 2018, 44, 11357–11363. [Google Scholar] [CrossRef]

- Kheyrinia, L.; Baharvandi, H.R.; Ehsani, N.; Yaghobizadeh, O. Fabrication of SiC bodies by optimized gel-casting method. Int. J. Refract. Met. Hard Mater. 2019, 81, 225–232. [Google Scholar] [CrossRef]

- Yang, J.; Yu, J.; Huang, Y. Recent developments in gelcasting of ceramics. J. Eur. Ceram. Soc. 2011, 31, 2569–2591. [Google Scholar] [CrossRef]

- Topateş, G.; Akça, E.; Tür, Y.K.; Duran, C. Functionally graded Al2O3-based ceramic systems by gel casting method. Int. J. Appl. Ceram. Technol. 2024, 22, e14898. [Google Scholar] [CrossRef]

- Yang, Z.; Zhao, Z.; Yu, J.; Ren, Z. Effect of TiB2 addition on grain orientation of porous Si3N4-TiB2 composites by magnetic field alignment technology. Int. J. Appl. Ceram. Technol. 2019, 16, 1381–1389. [Google Scholar] [CrossRef]

- Kacar, S.; Sahinturk, V. The Protective Agents Used against Acrylamide Toxicity: An In Vitro Cell Culture Study-Based Review. Cell J. 2021, 23, 367–381. [Google Scholar] [CrossRef] [PubMed]

- Huang, M.; He, P.; Yang, J.; Duan, F.; Lim, S.C.; Yip, M.S. Fabrication and characterization of mini alumina ceramic turbine rotor using a tailored gelcasting process. Ceram. Int. 2014, 40, 7711–7722. [Google Scholar] [CrossRef]

- Zhou, P.; Du, J.H. Research on Polymerization of PMN-PZT Piezoelectric Ceramic by Gelcasting Using NMAM System. In Proceedings of the 3rd International Conference on Advances in Materials Manufacturing (ICAMMP 2012), Beihai, China, 22–23 December 2012; p. 312. [Google Scholar]

- Guo, J.; Sun, Y.J.; Yang, H.Y.; Qiu, T.; Xue, W. Gelating and Drying Process of Aqueous Gelcasting Aluminum Nitride Ceramics. Int. J. Appl. Ceram. Technol. 2014, 12, E23–E32. [Google Scholar] [CrossRef]

- Montanaro, L.; Coppola, B.; Palmero, P.; Tulliani, J.-M. A review on aqueous gelcasting: A versatile and low-toxic technique to shape ceramics. Ceram. Int. 2019, 45, 9653–9673. [Google Scholar] [CrossRef]

- Mao, D.; Yin, S.; Fang, X.; Wang, Y.; Li, Q.; Yang, J. Preparation and properties of fused silica ceramics by Isobam spontaneous coagulation casting. Ceram. Int. 2022, 48, 5130–5138. [Google Scholar] [CrossRef]

- Zhang, L.; Yao, Q.; Yuan, Z.; Jiang, Z.; Gu, L.; Sun, B.; Shao, C.; Zhou, T.; Bu, W.; Wang, Y.; et al. Ammonium citrate assisted surface modification and gel casting of YAG transparent ceramics. Ceram. Int. 2018, 44, 21921–21927. [Google Scholar] [CrossRef]

- Yang, H.; Wang, Z.; Sun, M.; Chen, F.; Ji, J.; Chen, S.; Chen, Y.; Ma, D.; Zhang, Z.; Pan, B.; et al. Effect of pH, milling time, and Isobam content on porous silicon nitride ceramics prepared by gel casting. Adv. Powder Mater. 2022, 2, 100060. [Google Scholar] [CrossRef]

- Xie, R.; Zhang, D.; Zhang, X.; Zhou, K.; Button, T.W. Gelcasting of alumina ceramics with improved green strength. Ceram. Int. 2012, 38, 6923–6926. [Google Scholar] [CrossRef]

- Munro, C.D.; Plucknett, K.P. Agar-Based Aqueous Gel Casting of Barium Titanate Ceramics. Int. J. Appl. Ceram. Technol. 2011, 8, 597–609. [Google Scholar] [CrossRef]

- Chandradass, J.; Kim, K.H.; Bae, D.S.; Prasad, K.; Balachandar, G.; Divya, S.A.; Balasubramanian, M. Starch consolidation of alumina: Fabrication and mechanical properties. J. Eur. Ceram. Soc. 2009, 29, 2219–2224. [Google Scholar] [CrossRef]

- Santacruz, I.; Nieto, M.I.; Moreno, R. Rheological characterization of synergistic mixtures of carrageenan and locust bean gum for aqueous gelcasting of alumina. J. Am. Ceram. Soc. 2002, 85, 2432–2436. [Google Scholar] [CrossRef]

- Jia, Y.; Kanno, Y.; Xie, Z.-P. New gel-casting process for alumina ceramics based on gelation of alginate. J. Eur. Ceram. Soc. 2002, 22, 1911–1916. [Google Scholar] [CrossRef]

- Zhang, H.H.; Wang, Q.; Li, Y.; Mao, J.H.; Zheng, X. Preparation and characterization of damage indication and self-healing microcapsules for surface micro-cracks in mortar coating. J. Appl. Polym. Sci. 2022, 139, 52198. [Google Scholar] [CrossRef]

- Mao, Y.-J.; Gao, P.-P.; Sun, Z.-B.; Tang, J.-H.; Dai, K.; Lin, H.; Zhong, G.-J.; Li, Z.-M. Tribological Properties of Self-Lubricating Thermoplastic Polyurethane/Oil-Loaded Microcapsule Composites Based on Melt Processing. Ind. Eng. Chem. Res. 2021, 60, 16023–16031. [Google Scholar] [CrossRef]

- Wang, L.; Liu, J.; Gao, C.; Yan, X.; Liu, J. Preparation, Characterization, and Bioactivity Evaluation of Lambda-Cyhalothrin Microcapsules for Slow-Controlled Release System. ACS Omega 2024, 9, 8229–8238. [Google Scholar] [CrossRef]

- Li, H.Y.; Cui, Y.X.; Wang, H.Y.; Zhu, Y.J.; Wang, B.H. Preparation and application of polysulfone microcapsules containing tung oil in self-healing and self-lubricating epoxy coating. Colloids Surf. A-Physicochem. Eng. Asp. 2017, 518, 181–187. [Google Scholar] [CrossRef]

- Li, Z.K.; Zhou, R.; Li, X.; Li, X.K.; Li, H.Y.; Wang, H.Y. Facile preparation of high-temperature-resistant ionic liquid@porous hollow glass microcapsules for self-lubricating PA6 composites. Colloids Surf. A Physicochem. Eng. Asp. 2022, 656, 130522. [Google Scholar] [CrossRef]

- Shi, T.; Livi, S.; Duchet, J.; Gérard, J.-F. Ionic Liquids-Containing Silica Microcapsules: A Potential Tunable Platform for Shaping-Up Epoxy-Based Composite Materials? Nanomaterials 2020, 10, 881. [Google Scholar] [CrossRef] [PubMed]

- Pandey, S.K.; Gupta, R.N.; Singh, M.K. Synthesis, fabrication and tribo-mechanical studies of microcapsules filled and Al2O3/glass fibre reinforced UHMWPE based self-lubricating and self-healing composites. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2024, 1–10. [Google Scholar] [CrossRef]

- Mu, B.; Dai, X.; Li, Y.; Li, W.; Kou, B.; Zhang, W.; Du, K.; Li, Y.; Tian, L.; Cui, J.; et al. Tribological properties of oil impregnated carbon nanocapsules modified with polydopamine-polyethyleneimine. Colloids Surf. A Physicochem. Eng. Asp. 2024, 705, 135558. [Google Scholar] [CrossRef]

- Li, M.; Liu, S.; Cao, M.; Zhou, Z.; Rao, J.; Zhang, Y. Fabrication of natural mesoporous Diatom biosilica microcapsules with high oil-carrying capacity and tribological property. Tribol. Int. 2024, 200, 110170. [Google Scholar] [CrossRef]

- Chen, C.; Yang, Q.; Chen, Q.; Wang, Y.; Xu, D.; Li, H.; Zhang, X.; Harvey, C.M.; Liu, J. Tribological properties of copper-embedded self-lubricating bearing materials. Ind. Lubr. Tribol. 2022, 74, 796–803. [Google Scholar] [CrossRef]

- Gutiérrez-Mora, F.; Cano-Crespo, R.; Rincón, A.; Moreno, R.; Domínguez-Rodríguez, A. Friction and wear behavior of alumina-based graphene and CNFs composites. J. Eur. Ceram. Soc. 2017, 37, 3805–3812. [Google Scholar] [CrossRef]

| Reagent Name | Chemical Formula | Purity | Manufacturer | |

|---|---|---|---|---|

| Solvent | Deionized water | H2O | - | - |

| Monomer | NMAM | C4H7NO2 | 98% | Shanghai Aladdin Biochemical Technology Co., Ltd., Shanghai, China |

| Crosslinking agent | MBAM | C7H10N2O2 | 99% | Tianjin Xien Si Biochemical Technology Co., Ltd., Tianjin, China |

| Dispersant | PAA | C3H7NO2 | 40% | Shanghai Aladdin Biochemical Technology Co., Ltd., Shanghai, China |

| Initiator | Ammonium persulfate | (NH4)2S2O8 | 98.5% | Shanghai Yien Chemical Technology Co., Ltd., Shanghai, China |

| Catalyst | Tetramethylethylenediamine | C6H16N2 | 99% | Shanghai Yien Chemical Technology Co., Ltd., Shanghai, China |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Z.; Chen, H.; Meng, X.; Xiao, G.; Chen, Z.; Yi, M.; Zhang, J.; Liu, W.; Xu, C. Influence of Embedding Microcapsules on Tribological Properties of Alumina Ceramics Prepared by Gel Casting. Materials 2025, 18, 2110. https://doi.org/10.3390/ma18092110

Sun Z, Chen H, Meng X, Xiao G, Chen Z, Yi M, Zhang J, Liu W, Xu C. Influence of Embedding Microcapsules on Tribological Properties of Alumina Ceramics Prepared by Gel Casting. Materials. 2025; 18(9):2110. https://doi.org/10.3390/ma18092110

Chicago/Turabian StyleSun, Ze, Hui Chen, Xianglong Meng, Guangchun Xiao, Zhaoqiang Chen, Mingdong Yi, Jingjie Zhang, Wenyu Liu, and Chonghai Xu. 2025. "Influence of Embedding Microcapsules on Tribological Properties of Alumina Ceramics Prepared by Gel Casting" Materials 18, no. 9: 2110. https://doi.org/10.3390/ma18092110

APA StyleSun, Z., Chen, H., Meng, X., Xiao, G., Chen, Z., Yi, M., Zhang, J., Liu, W., & Xu, C. (2025). Influence of Embedding Microcapsules on Tribological Properties of Alumina Ceramics Prepared by Gel Casting. Materials, 18(9), 2110. https://doi.org/10.3390/ma18092110