Experimental Investigation of Ultra-High Molecular Weight Polyethylene Fibers and Fabric for Flexural Reinforcement in Ultra-High-Performance Concrete

Abstract

1. Introduction

2. Experimental Program

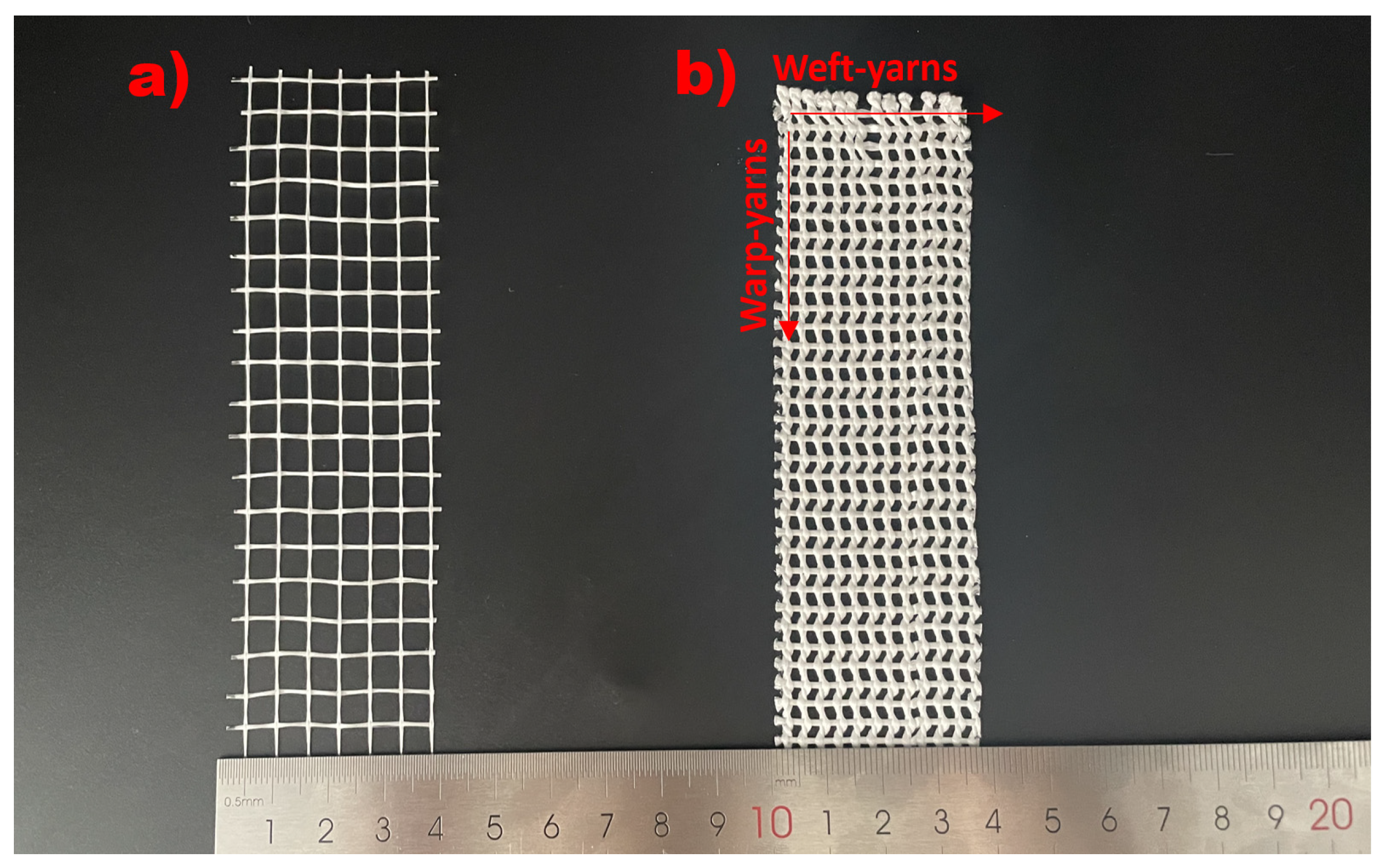

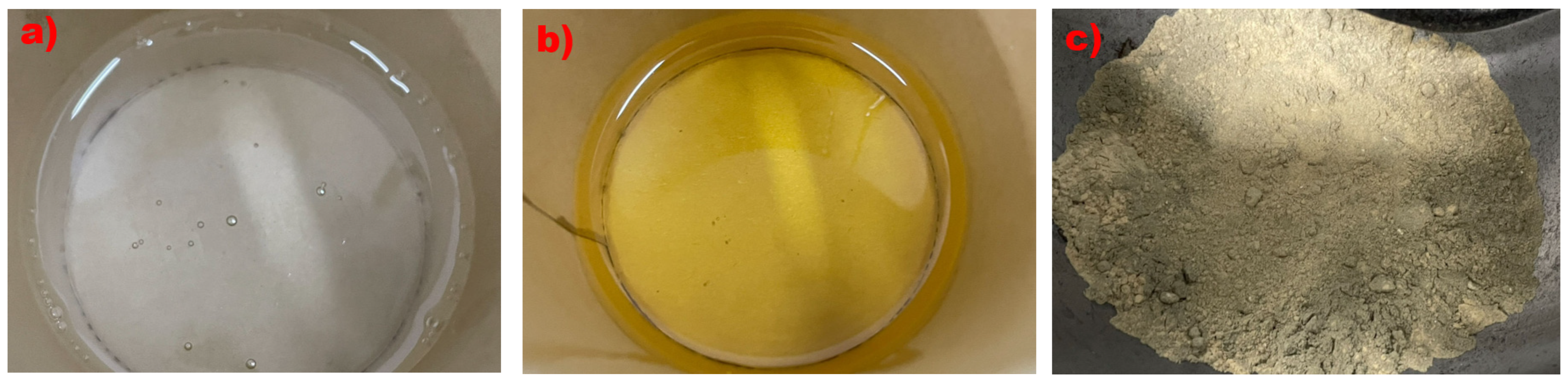

2.1. Materials

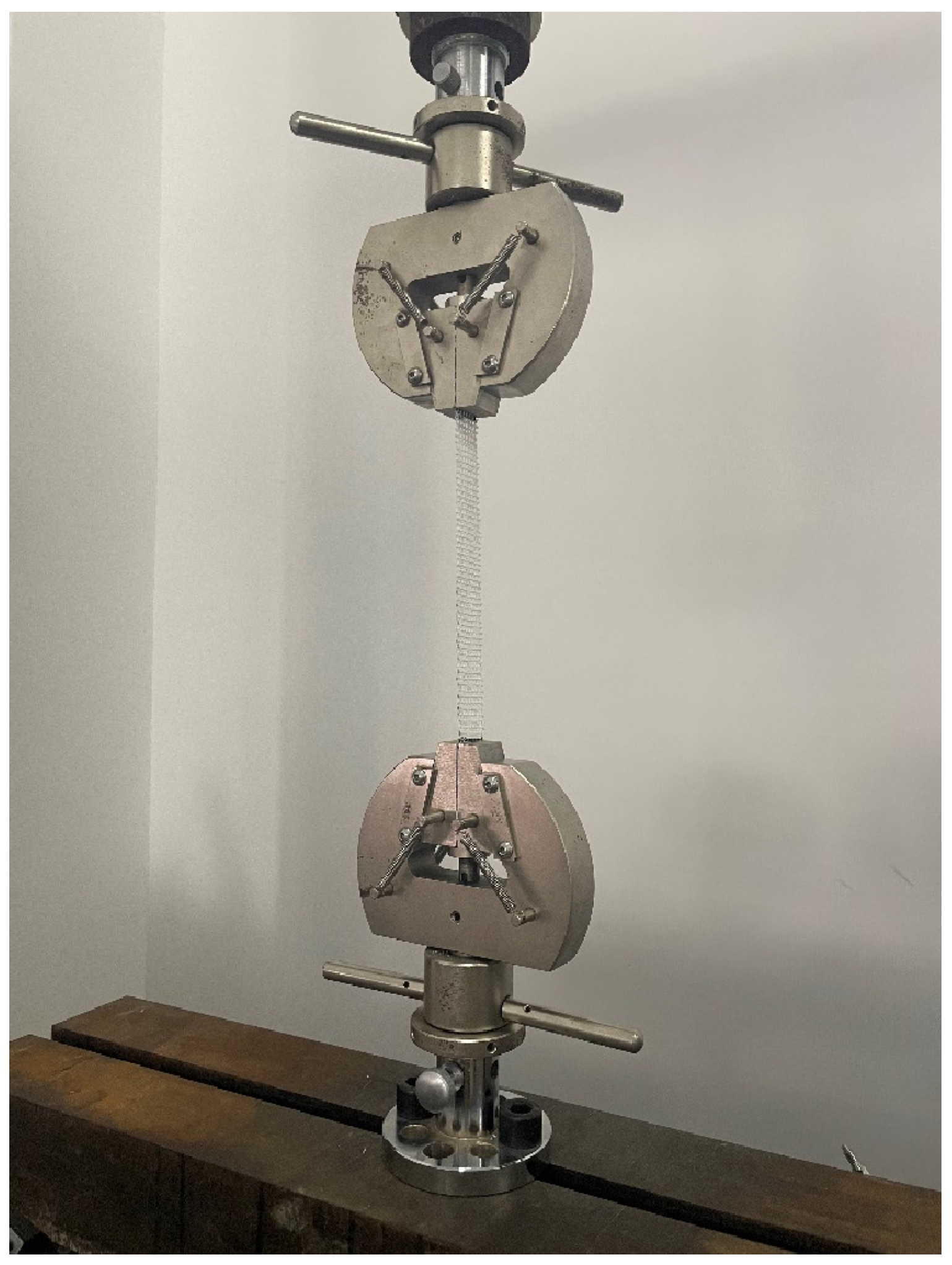

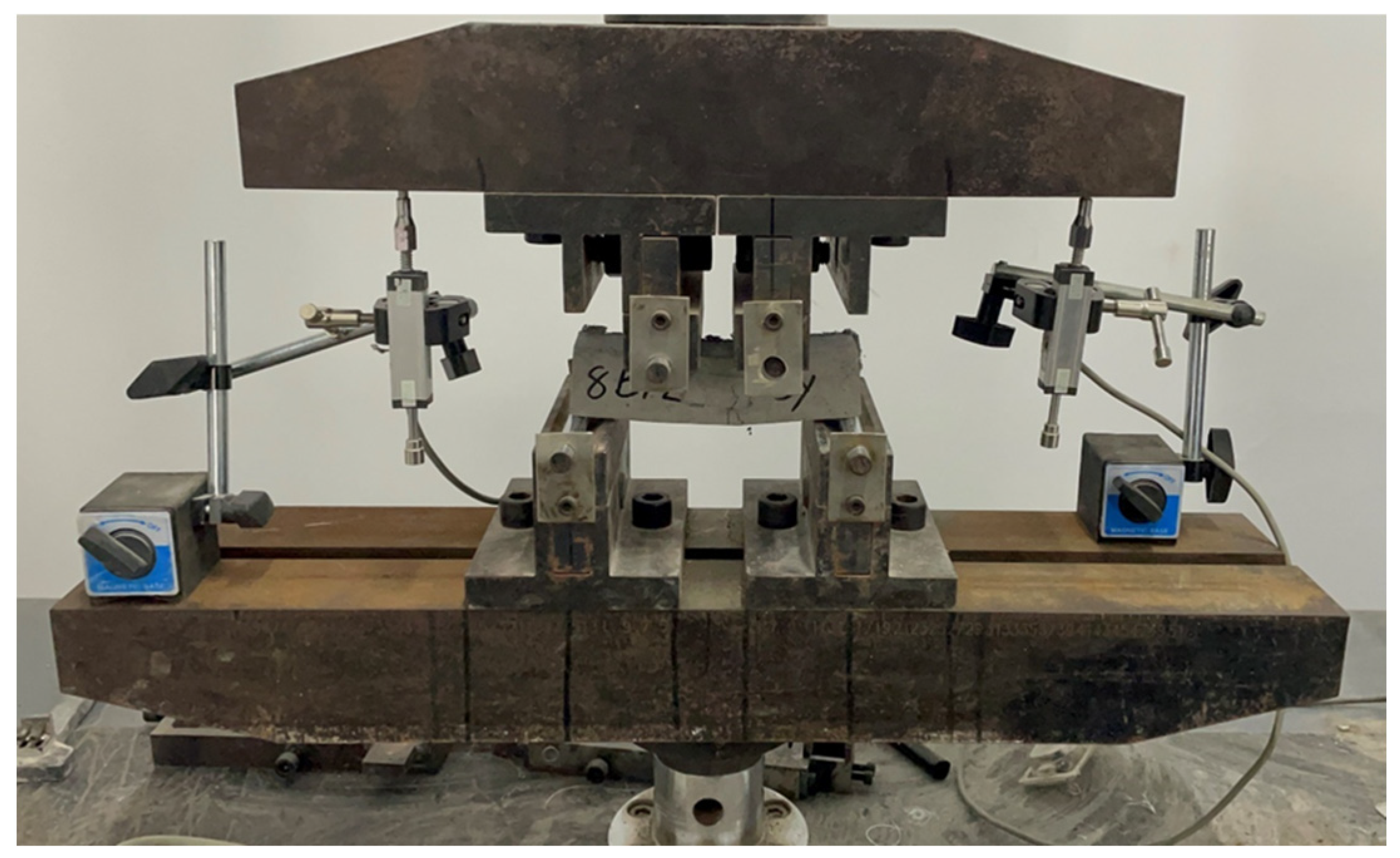

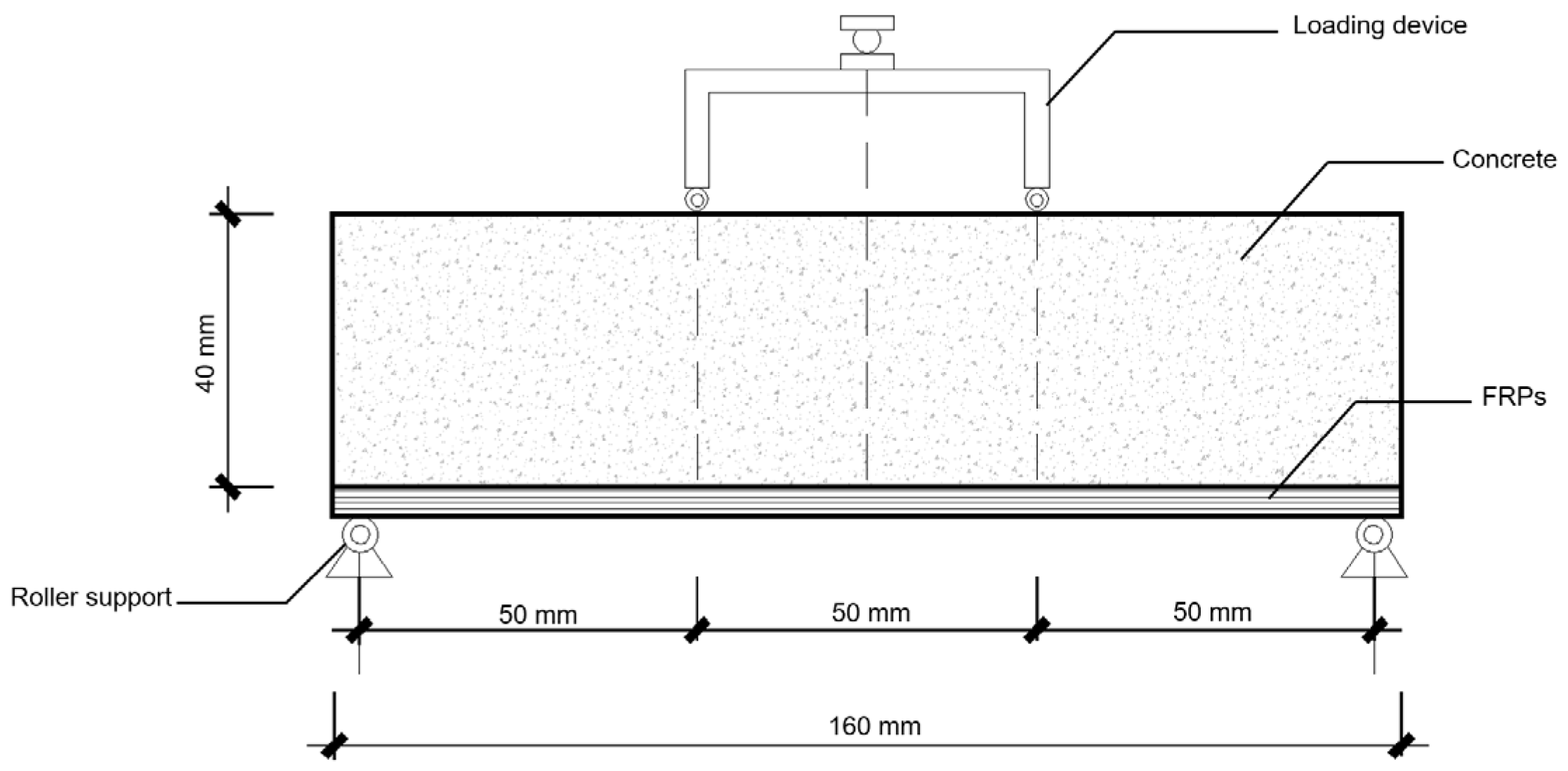

2.2. Experimental Setup

3. Results and Discussion

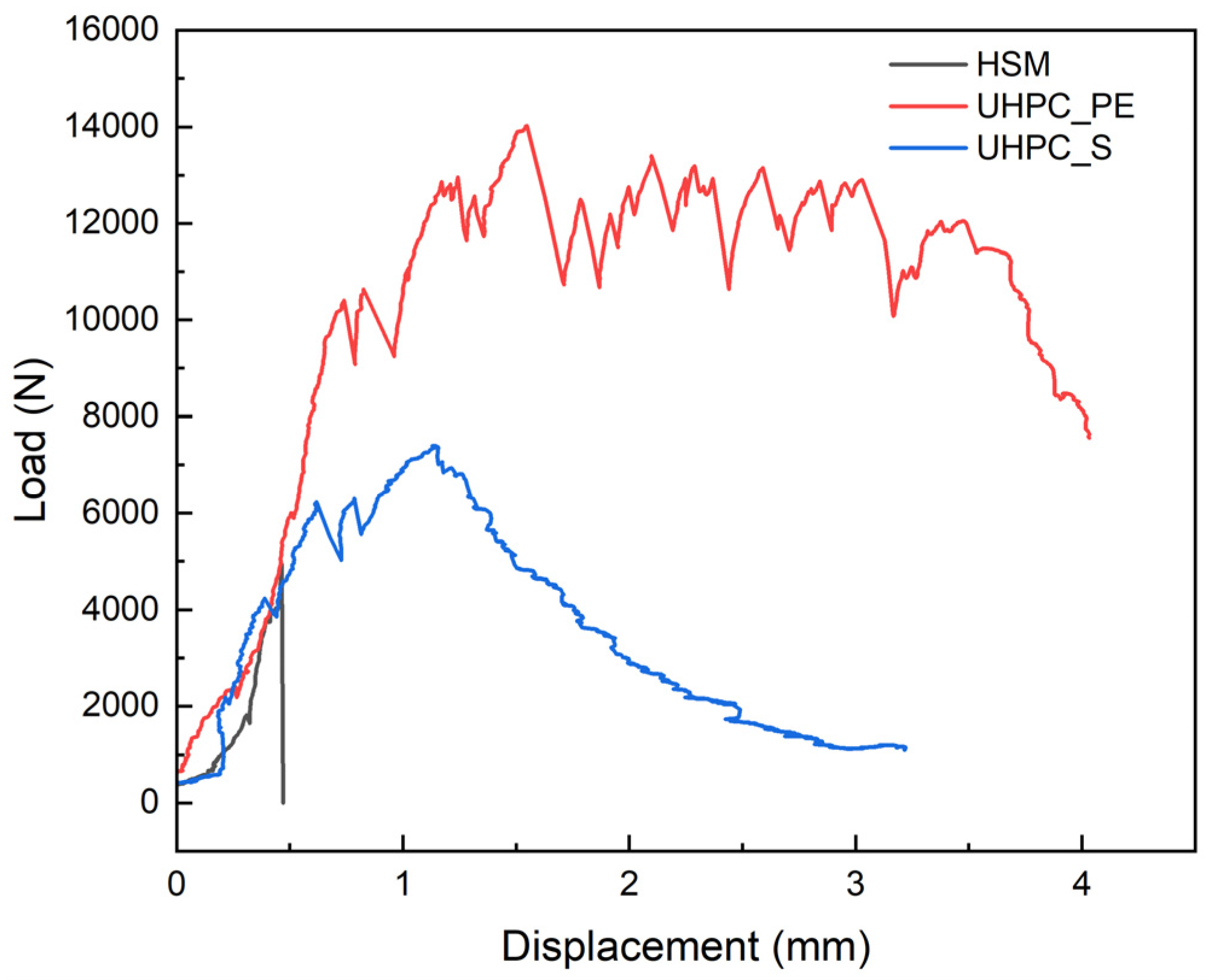

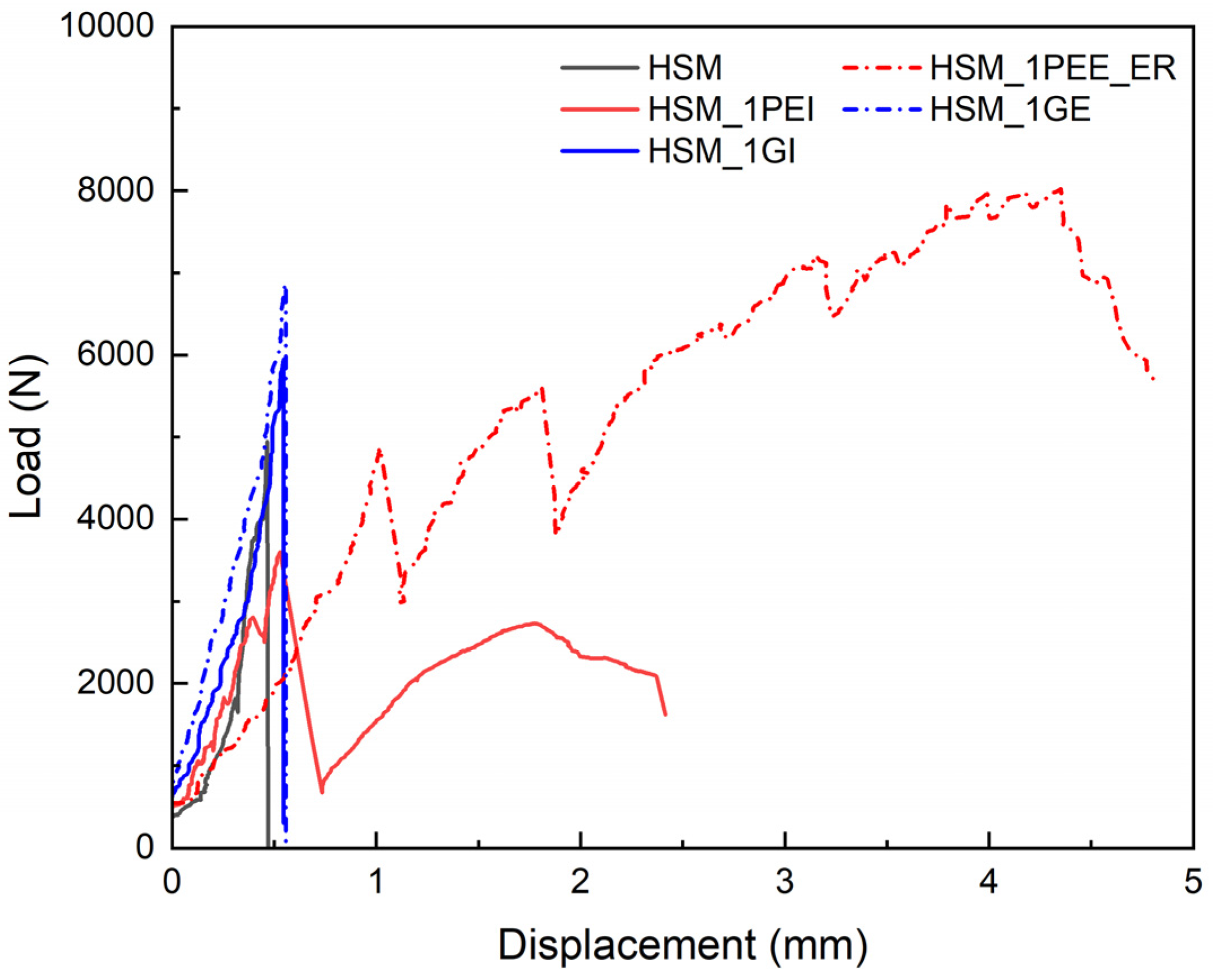

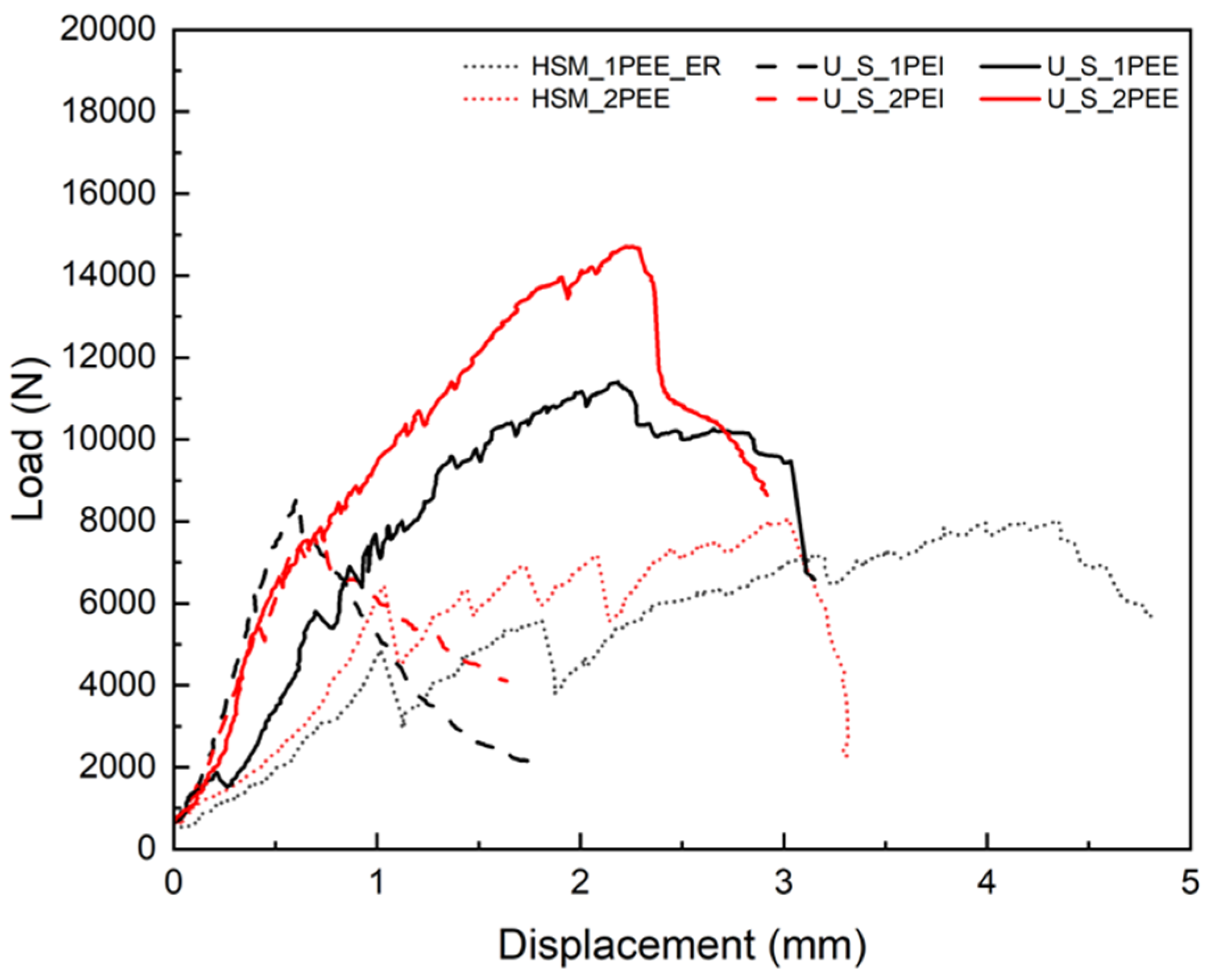

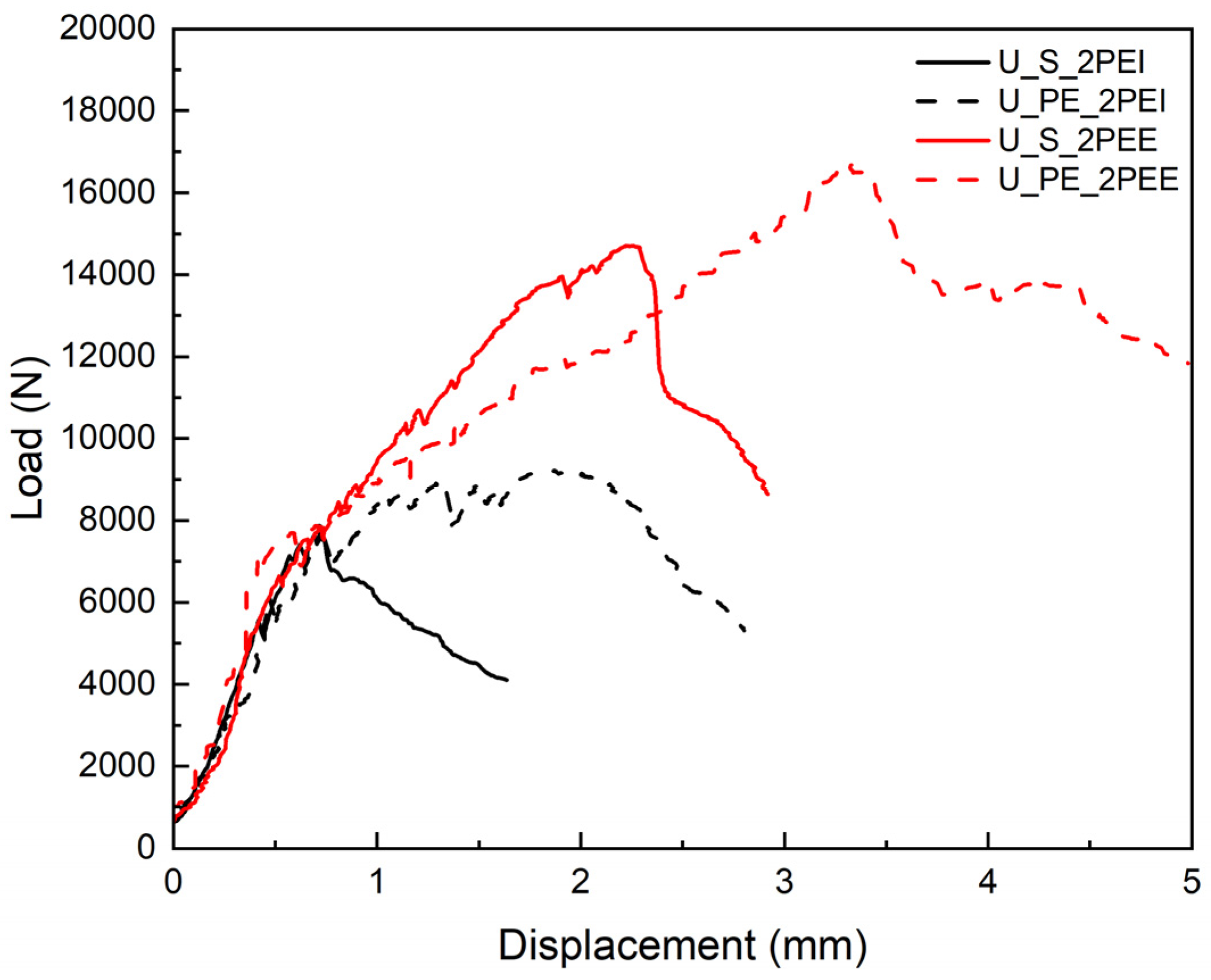

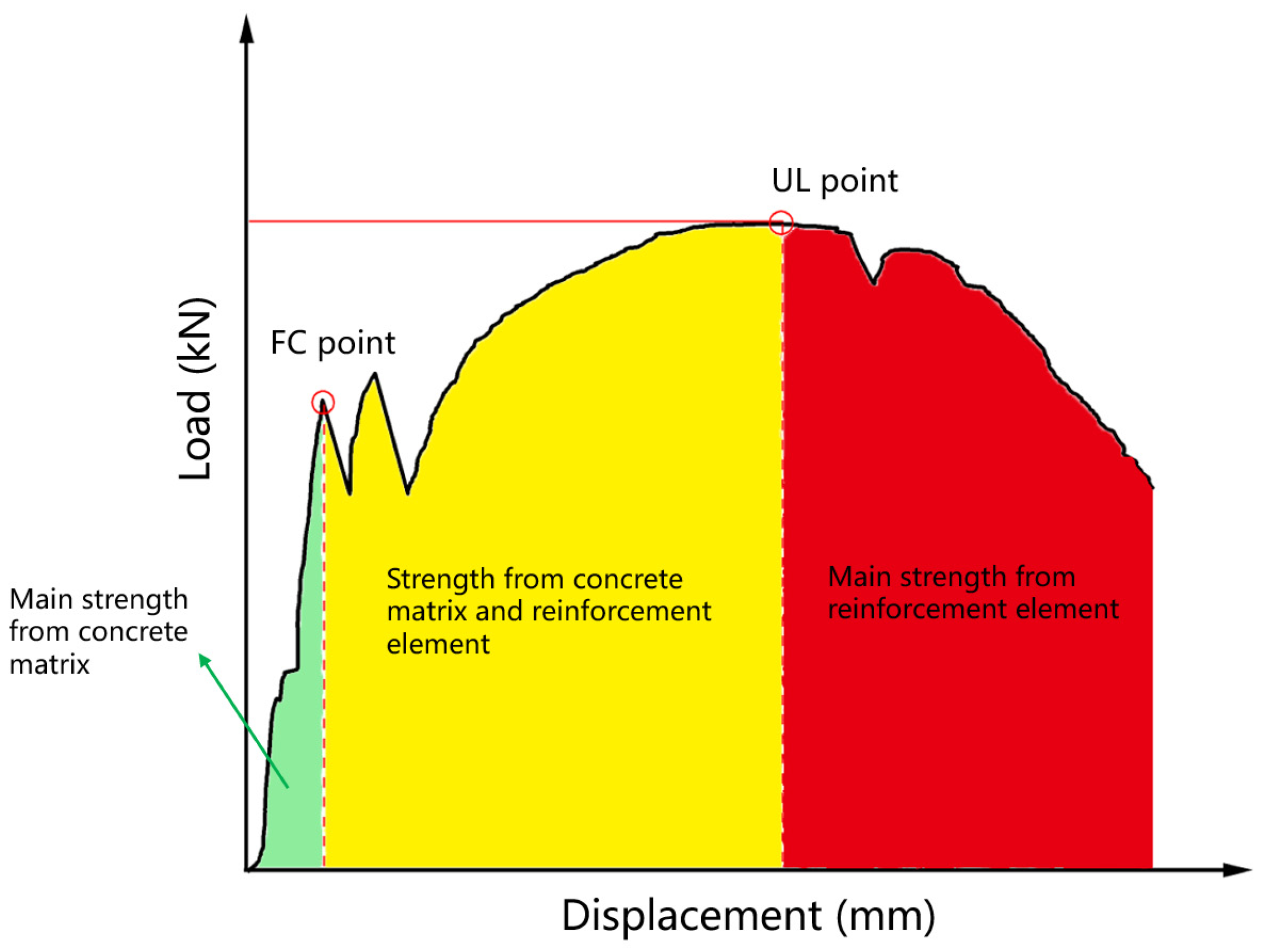

3.1. Load–Displacement Curves

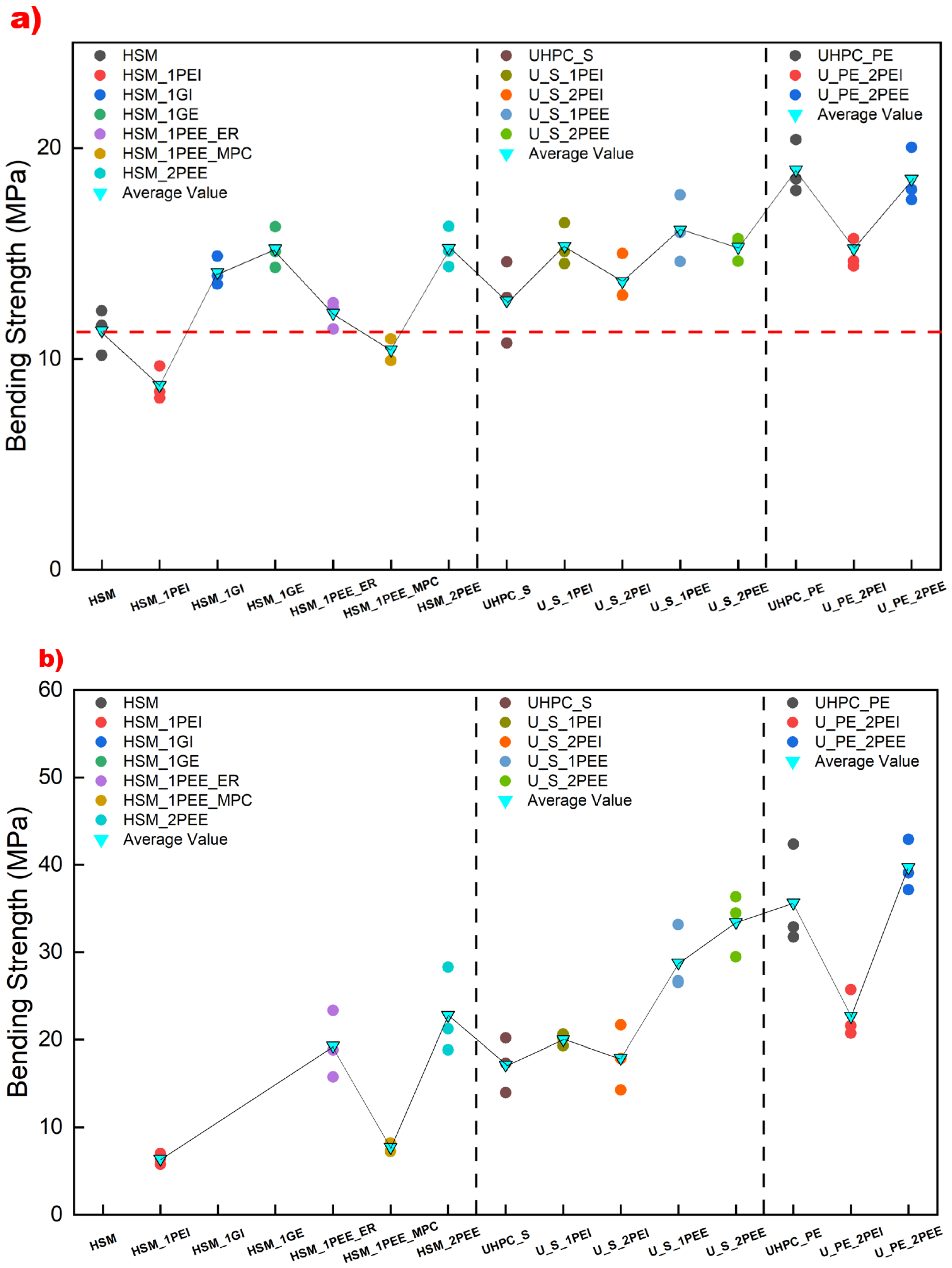

3.2. Flexural Properties

3.3. Load-Carrying Capacity—Strength

3.4. Ductility—Displacement

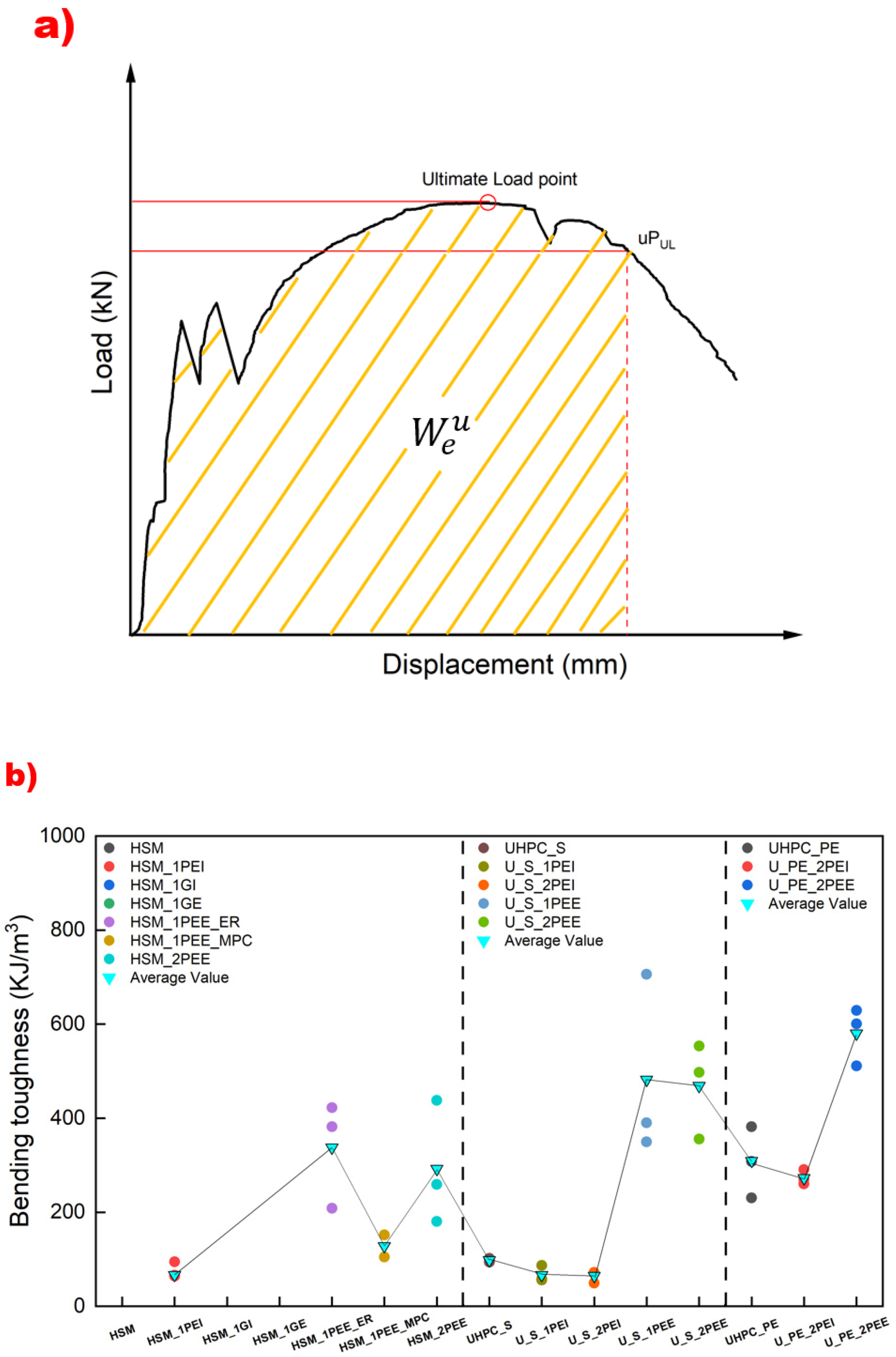

3.5. Energy Absorption Capacity—Toughness

3.6. Cost–Performance Analysis

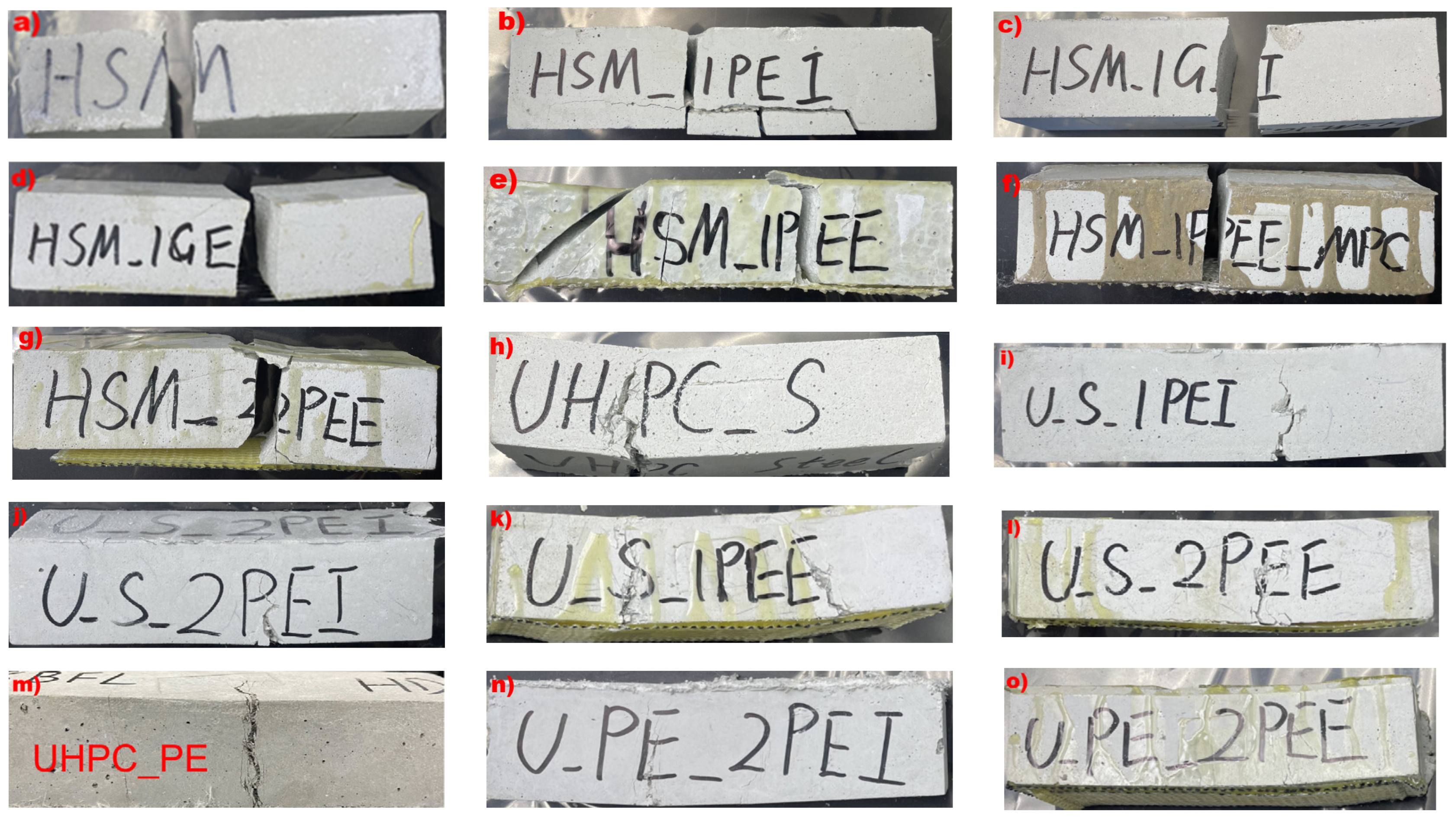

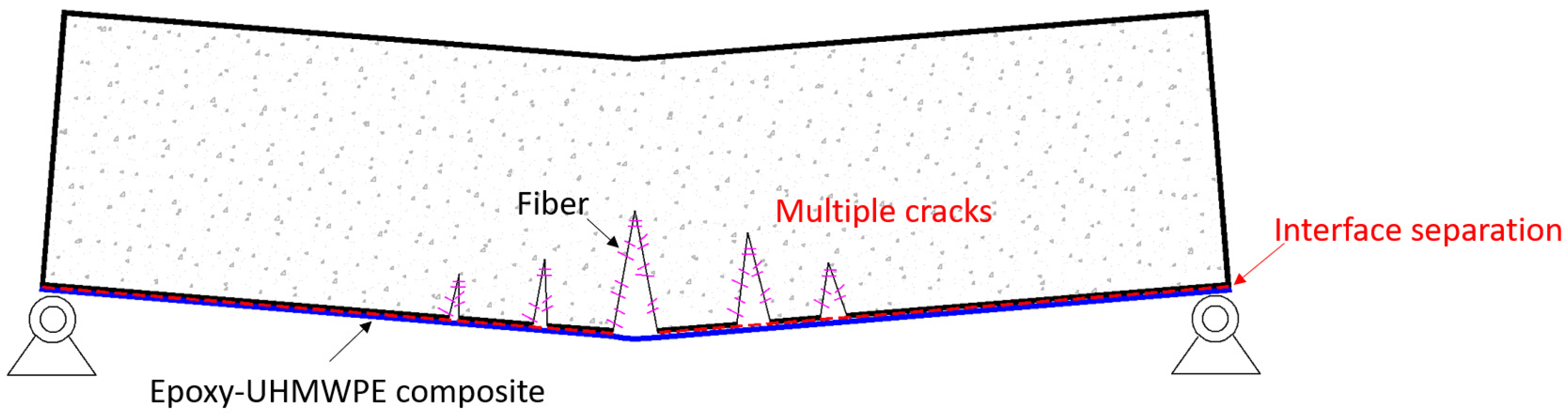

3.7. Fracture Mechanism

4. Conclusions

- Incorporating UHMWPE fiber into the HSM matrix resulted in superior flexural performance compared to steel fiber. The average bending strength with UHMWPE fiber and steel fiber was 36 MPa and 17 MPa, respectively. Their average ductility was 1.7 mm and 1 mm, while their toughness was 98 KJ/m3 and 307 KJ/m3, respectively.

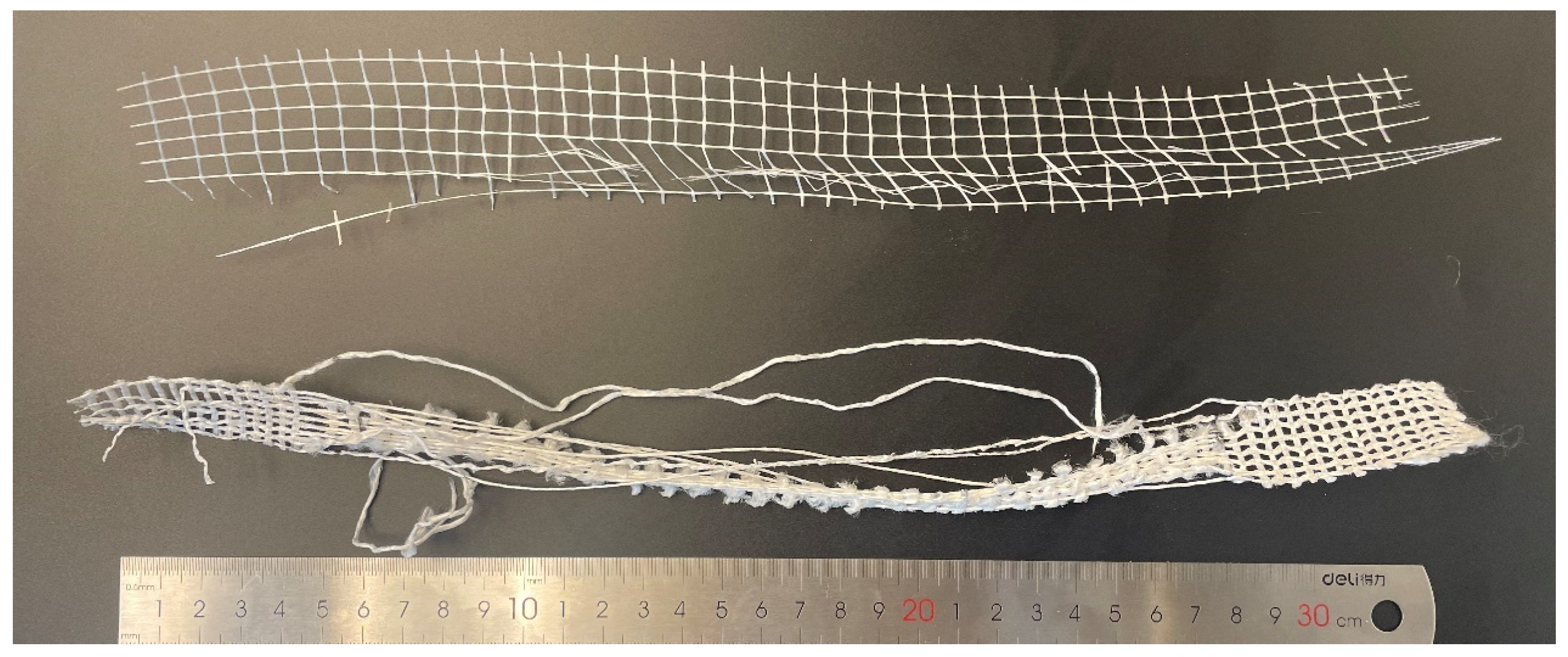

- The UHMWPE mesh fabric has higher strength and greater elongation capacity than glass fabric. Therefore, reinforcing the matrix with both internally and externally bonded UHMWPE fabric can better accommodate matrix deformation, improving ductility and toughness and thereby maintaining structural integrity.

- Compared to MPC, epoxy resin exhibited better material properties. As a result, epoxy resin adhered more effectively to UHMWPE fabric on the concrete surface. The epoxy resin–UHMWPE composite achieved a strong synergistic effect with the concrete matrix.

- Applying more layers can improve the flexural performance of externally bonded UHMWPE fabric, but it does not benefit the strengthening technique when the fabric is embedded internally. Therefore, increasing the number of layers is only advantageous when the strengthening technique ensures good mechanical cooperation.

5. Limitations and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Abbreviation | Full Form |

| UHPC | Ultra-High-Performance Concrete |

| UHWMPE | Ultra-High Molecular Weight Polyethylene |

| FRP | Fiber-Reinforced Polymer |

| HSM | High-Strength Mortar |

| MPC | Magnesium Phosphate Cement |

Appendix A

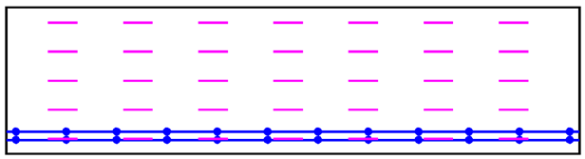

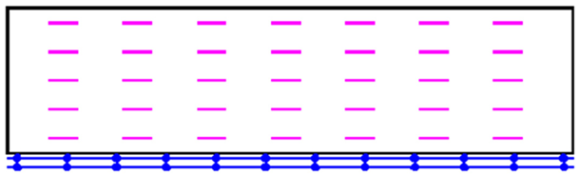

| Group Name | Schematic Diagram |

|---|---|

| HSM (reference) |  |

| UHPC_PE |  |

| UHPC_S |  |

| HSM_1PEI |  |

| HSM_1GI |  |

| HSM_1PEE_ER |  |

| HSM_1PEE_MPC |  |

| HSM_2PEE_ER (the subsequent groups all used ER) |  |

| HSM_1GE |  |

| U_S_1PEE |  |

| U_S_1PEI |  |

| U_S_2PEI |  |

| U_S_2PEE |  |

| U_PE_2PEI |  |

| U_PE_2PEE |  |

References

- Yao, Y.; Silva, F.A.; Butler, M.; Mechtcherine, V.; Mobasher, B. Tensile and Flexural Behavior of Ultra-High Performance Concrete (UHPC) under Impact Loading. Int. J. Impact Eng. 2021, 153, 103866. [Google Scholar] [CrossRef]

- Li, J.; Wu, Z.; Shi, C.; Yuan, Q.; Zhang, Z. Durability of Ultra-High Performance Concrete—A Review. Constr. Build. Mater. 2020, 255, 119296. [Google Scholar] [CrossRef]

- Piérard, J.; Dooms, B.; Cauberg, N. Durability Evaluation of Different Types of UHPC. In Proceedings of the RILEM-fib-AFGC International Symposium on Ultra-High Performance Fiber-Reinforced Concrete, UHPFRC, Marseille, France, 1–3 October 2013; pp. 275–284. [Google Scholar]

- Du, J.; Meng, W.; Khayat, K.H.; Bao, Y.; Guo, P.; Lyu, Z.; Abu-Obeidah, A.; Nassif, H.; Wang, H. New Development of Ultra-High-Performance Concrete (UHPC). Compos. Part B Eng. 2021, 224, 109220. [Google Scholar] [CrossRef]

- Wang, R.; Gao, X.; Zhang, J.; Han, G. Spatial Distribution of Steel Fibers and Air Bubbles in UHPC Cylinder Determined by X-Ray CT Method. Constr. Build. Mater. 2018, 160, 39–47. [Google Scholar] [CrossRef]

- Khan, M.; Lao, J.; Dai, J.-G. Comparative Study of Advanced Computational Techniques for Estimating the Compressive Strength of UHPC. J. Asian Concr. Fed. 2022, 8, 51–68. [Google Scholar] [CrossRef]

- Mishra, O.; Singh, S.P. An Overview of Microstructural and Material Properties of Ultra-High-Performance Concrete. J. Sustain. Cem. Mater. 2019, 8, 97–143. [Google Scholar] [CrossRef]

- Shafieifar, M.; Farzad, M.; Azizinamini, A. Experimental and Numerical Study on Mechanical Properties of Ultra High Performance Concrete (UHPC). Constr. Build. Mater. 2017, 156, 402–411. [Google Scholar] [CrossRef]

- Yazici, H.; Yardimci, M.Y.; Yiǧiter, H.; Aydin, S.; Türkel, S. Mechanical Properties of Reactive Powder Concrete Containing High Volumes of Ground Granulated Blast Furnace Slag. Cem. Concr. Compos. 2010, 32, 639–648. [Google Scholar] [CrossRef]

- Yang, I.H.; Park, J.; Bui, T.Q.; Kim, K.C.; Joh, C.; Lee, H. An Experimental Study on the Ductility and Flexural Toughness of Ultrahigh-Performance Concrete Beams Subjected to Bending. Materials 2020, 13, 2225. [Google Scholar] [CrossRef]

- Graybeal, B.; Tanesi, J. Durability of an Ultrahigh-Performance Concrete. J. Mater. Civ. Eng. 2007, 19, 848–854. [Google Scholar] [CrossRef]

- Schmidt, M.; Fehling, E. Ultra-High-Performance Concrete: Research, Development and Application in Europe; American Concrete Institute, ACI Special Publication: Moscow, Russia, 2005; Volume 228, pp. 51–77. [Google Scholar] [CrossRef]

- Shao, Y.; Billington, S.L. Impact of Cyclic Loading on Longitudinally-Reinforced UHPC Flexural Members with Different Fiber Volumes and Reinforcing Ratios. Eng. Struct. 2021, 241, 112454. [Google Scholar] [CrossRef]

- Pyo, S.; Alkaysi, M.; El-Tawil, S. Crack Propagation Speed in Ultra High Performance Concrete (UHPC). Constr. Build. Mater. 2016, 114, 109–118. [Google Scholar] [CrossRef]

- Niu, Y.; Wei, J.; Jiao, C. Crack Propagation Behavior of Ultra-High-Performance Concrete (UHPC) Reinforced with Hybrid Steel Fibers under Flexural Loading. Constr. Build. Mater. 2021, 294, 123510. [Google Scholar] [CrossRef]

- Amran, M.; Huang, S.S.; Onaizi, A.M.; Makul, N.; Abdelgader, H.S.; Ozbakkaloglu, T. Recent Trends in Ultra-High Performance Concrete (UHPC): Current Status, Challenges, and Future Prospects. Constr. Build. Mater. 2022, 352, 129029. [Google Scholar] [CrossRef]

- Zhang, D.; Tan, K.H. Effect of Various Polymer Fibers on Spalling Mitigation of Ultra-High Performance Concrete at High Temperature. Cem. Concr. Compos. 2020, 114, 103815. [Google Scholar] [CrossRef]

- Liu, J.; Wu, C.; Su, Y.; Li, J.; Shao, R.; Chen, G.; Liu, Z. Experimental and Numerical Studies of Ultra-High Performance Concrete Targets against High-Velocity Projectile Impacts. Eng. Struct. 2018, 173, 166–179. [Google Scholar] [CrossRef]

- Jauffrès, D.; Lame, O.; Vigier, G.; Doré, F. Microstructural Origin of Physical and Mechanical Properties of Ultra High Molecular Weight Polyethylene Processed by High Velocity Compaction. Polymer 2007, 48, 6374–6383. [Google Scholar] [CrossRef]

- Pan, Z.; Tuladhar, R.; Yin, S.; Shi, F.; Dang, F. Feasibility of Repairing Concrete with Ultra-High Molecular Weight Polyethylene Fiber Cloth: A Comprehensive Literature Review. Buildings 2024, 14, 1631. [Google Scholar] [CrossRef]

- Wang, Y.; Hou, R. Research Progress on Surface Modification and Application Status of UHMWPE Fiber. J. Phys. Conf. Ser. 2022, 2263, 012016. [Google Scholar] [CrossRef]

- Khalil, Y.; Hopkinson, N.; Kowalski, A.; Fairclough, J.P.A. Characterisation of UHMWPE Polymer Powder for Laser Sintering. Materials 2019, 12, 3496. [Google Scholar] [CrossRef]

- Kurtz, S.M. A Primer on UHMWPE, 3rd ed.; Elsevier Inc.: Philadelphia, PA, USA, 2015; ISBN 9780323354011. [Google Scholar]

- Li, J.; Luo, C.; Jie, J.; Cui, H. Rheological Properties and Microscopic Morphology Evaluation of UHMWPE-Modified Corn Stover Oil Bio-Asphalt. Buildings 2023, 13, 2167. [Google Scholar] [CrossRef]

- Hajiesmaeili, A.; Denarié, E. Next Generation UHPFRC for Sustainable Structural Applications; American Concrete Institute, ACI Special Publication: Moscow, Russia, 2018. [Google Scholar] [CrossRef]

- Abbas, S.; Nehdi, M.L.; Saleem, M.A. Ultra-High Performance Concrete: Mechanical Performance, Durability, Sustainability and Implementation Challenges. Int. J. Concr. Struct. Mater. 2016, 10, 271–295. [Google Scholar] [CrossRef]

- Al-Sunna, R.; Pilakoutas, K.; Hajirasouliha, I.; Guadagnini, M. Deflection Behaviour of FRP Reinforced Concrete Beams and Slabs: An Experimental Investigation. Compos. Part B Eng. 2012, 43, 2125–2134. [Google Scholar] [CrossRef]

- Miàs, C.; Torres, L.; Turon, A.; Sharaky, I.A. Effect of Material Properties on Long-Term Deflections of GFRP Reinforced Concrete Beams. Constr. Build. Mater. 2013, 41, 99–108. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H.; Bao, Y. Flexural Behaviors of Fiber-Reinforced Polymer Fabric Reinforced Ultra-High-Performance Concrete Panels. Cem. Concr. Compos. 2018, 93, 43–53. [Google Scholar] [CrossRef]

- Rabehi, B.; Ghernouti, Y.; Li, A.; Boumchedda, K. Comparative Behavior under Compression of Concrete Columns Repaired by Fiber Reinforced Polymer (FRP) Jacketing and Ultra High-Performance Fiber Reinforced Concrete (UHPFRC). J. Adhes. Sci. Technol. 2014, 28, 2327–2346. [Google Scholar] [CrossRef]

- Zhang, F.; Gao, L.; Wu, Y.F.; Liu, J. Flexural Design of Reinforced Concrete Structures Strengthened with Hybrid Bonded FRP. Compos. Struct. 2021, 269, 113996. [Google Scholar] [CrossRef]

- Kumar, R.; Mikkelsen, L.P.; Lilholt, H.; Madsen, B. Understanding the Mechanical Response of Glass and Carbon Fibres: Stress-Strain Analysis and Modulus Determination. IOP Conf. Ser. Mater. Sci. Eng. 2020, 942, 012033. [Google Scholar] [CrossRef]

- Nodehi, M. Epoxy, Polyester and Vinyl Ester Based Polymer Concrete: A Review. Innov. Infrastruct. Solut. 2022, 7, 64. [Google Scholar] [CrossRef]

- Chen, Y.; Wu, C.; Chen, C.; Chen, F. Effect of Using Magnesium Phosphate Cement on the Strengthening of Concrete Bonded with Different Fiber Cloths. IOP Conf. Ser. Earth Environ. Sci. 2018, 186, 012065. [Google Scholar] [CrossRef]

- Kejia, L.; Chengyou, W.; Baikiin, C.; Panpan, L.; Ruiyang, P.; Yuwen, L. Repair Effect of Magnesium Phosphate Cement and Carbon Fiber Cloth on Concrete Structure. IOP Conf. Ser. Earth Environ. Sci. 2018, 189, 032016. [Google Scholar] [CrossRef]

- Mészöly, T.; Ofner, S.; Randl, N. Effect of Combining Fiber and Textile Reinforcement on the Flexural Behavior of UHPC Plates. Adv. Mater. Sci. Eng. 2020, 2020, 9891619. [Google Scholar] [CrossRef]

- Yao, Y.; Sun, Y.; Zhai, M.; Chen, C.; Lu, C.; Wang, J. Tensile Behavior of Textile Reinforced Ultra-High Performance Concrete. Constr. Build. Mater. 2024, 411, 9891619. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Y.; Hussein, H.H.; Chen, G. Flexural Strengthening of Reinforced Concrete Beams or Slabs Using Ultra-High Performance Concrete (UHPC): A State of the Art Review. Eng. Struct. 2020, 205, 110035. [Google Scholar] [CrossRef]

- Wang, W.; Wu, C.; Liu, Z.; Si, H. Compressive Behavior of Ultra-High Performance Fiber-Reinforced Concrete (UHPFRC) Confined with FRP. Compos. Struct. 2018, 204, 419–437. [Google Scholar] [CrossRef]

- Abbas, E.M.A.; Ge, Y.; Zhang, Z.; Chen, Y.; Ashour, A.; Ge, W.; Tang, R.; Yang, Z.; Khailah, E.Y.; Yao, S.; et al. Flexural Behavior of UHPCbeam Reinforced with Steel-FRP Composite Bars. Case Stud. Constr. Mater. 2022, 16, e01110. [Google Scholar] [CrossRef]

- El-Hacha, R.; Chen, D. Behaviour of Hybrid FRP-UHPC Beams Subjected to Static Flexural Loading. Compos. Part B Eng. 2012, 43, 582–593. [Google Scholar] [CrossRef]

- Jia, L.; Fang, Z.; Huang, Z.; Pilakoutas, K.; Wang, Q.; Tan, X. Flexural Behavior of Uhpc Beams Prestressed with External Cfrp Tendons. Appl. Sci. 2021, 11, 9189. [Google Scholar] [CrossRef]

- Zhou, Y.; Xi, B.; Yu, K.; Sui, L.; Xing, F. Mechanical Properties of Hybrid Ultra-High Performance Engineered Cementitous Composites Incorporating Steel and Polyethylene Fibers. Materials 2018, 11, 1448. [Google Scholar] [CrossRef]

- Chu, S.H. Strain-Hardening Ultra-High Performance Concrete (UHPC) with Hybrid Steel and Ultra-High Molecular Weight Polyethylene Fibers. Constr. Build. Mater. 2024, 438, 136716. [Google Scholar] [CrossRef]

- Shi, F.; Yin, S.; Pham, T.M.; Tuladhar, R.; Hao, H. Pullout and Flexural Performance of Silane Groups and Hydrophilic Groups Grafted Polypropylene Fibre Reinforced UHPC. Constr. Build. Mater. 2021, 277, 122335. [Google Scholar] [CrossRef]

- Lin, J.X.; Luo, R.H.; Su, J.Y.; Guo, Y.C.; Chen, W.S. Coarse Synthetic Fibers (PP and POM) as a Replacement to Steel Fibers in UHPC: Tensile Behavior, Environmental and Economic Assessment. Constr. Build. Mater. 2024, 412, 134654. [Google Scholar] [CrossRef]

- Fu, J.; Zhang, Y.; Qin, Y. Experimental Investigation of TR-UHPC Composites and Flexural Behavior of TR-UHPC Composite Slab. Appl. Sci. 2024, 14, 3161. [Google Scholar] [CrossRef]

- Kartikeya, K.; Chouhan, H.; Ahmed, A.; Bhatnagar, N. Determination of Tensile Strength of UHMWPE Fiber-Reinforced Polymer Composites. Polym. Test. 2020, 82, 106293. [Google Scholar] [CrossRef]

- De Caso y Basalo, F.J.; Matta, F.; Nanni, A. Fiber Reinforced Cementitious-Matrix Composites for Infrastructure Rehabilitation. Proc. Compos. Poly. 2009, 1–12. [Google Scholar]

- Thomoglou, A.K.; Karabinisa, A.I. Experimental Investigation of the Shear Strength of Hollow Brick Unreinforced Masonry Walls Retrofitted with TRM System. Earthq. Struct. 2022, 22, 355–372. [Google Scholar] [CrossRef]

- Mercimek, Ö.; Ghoroubi, R.; Özdemir, A.; Anil, Ö.; Erbaş, Y. Investigation of Strengthened Low Slenderness RC Column by Using Textile Reinforced Mortar Strip under Axial Load. Eng. Struct. 2022, 259, 114191. [Google Scholar] [CrossRef]

- Mangat, P.S.; Gurusamy, K. Flexural Strength of Steel Fibre-Reinforced Cement Composites. J. Mater. Sci. 1987, 22, 3103–3110. [Google Scholar] [CrossRef]

- Li, J.; Niu, J.; Wan, C.; Liu, X.; Jin, Z. Comparison of Flexural Property between High Performance Polypropylene Fiber Reinforced Lightweight Aggregate Concrete and Steel Fiber Reinforced Lightweight Aggregate Concrete. Constr. Build. Mater. 2017, 157, 729–736. [Google Scholar] [CrossRef]

- Sun, Z.Y.; Yang, Y.; Qin, W.H.; Ren, S.T.; Wu, G. Experimental Study on Flexural Behavior of Concrete Beams Reinforced by Steel-Fiber Reinforced Polymer Composite Bars. J. Reinf. Plast. Compos. 2012, 31, 1737–1745. [Google Scholar] [CrossRef]

- Khan, Q.U.Z.; Labibzadeh, M.; Pourfalah, S.; Ahmad, A. Investigation of the Load-Carrying Capacity of One-Way Hybrid Fiber-Reinforced Concrete Slabs. Innov. Infrastruct. Solut. 2022, 7, 323. [Google Scholar] [CrossRef]

- Pan, K.; Yu, R.C.; Ruiz, G.; Zhang, X.; Wu, Z.; De La Rosa, Á. The Propagation Speed of Multiple Dynamic Cracks in Fiber-Reinforced Cement-Based Composites Measured Using DIC. Cem. Concr. Compos. 2021, 122, 104140. [Google Scholar] [CrossRef]

- Al-Gemeel, A.N.; Zhuge, Y.; Youssf, O. Use of Hollow Glass Microspheres and Hybrid Fibres to Improve the Mechanical Properties of Engineered Cementitious Composite. Constr. Build. Mater. 2018, 171, 858–870. [Google Scholar] [CrossRef]

- Liang, X.; Xing, P.; Xu, J. Experimental and Numerical Investigations of the Seismic Performance of Columns with Fiber-Reinforced Concrete in the Plastic Hinge Region. Adv. Struct. Eng. 2016, 19, 1484–1499. [Google Scholar] [CrossRef]

- Lakavath, C.; Bhosale, A.B.; Prakash, S.S.; Sharma, A. Effectiveness of Hybrid Fibers on the Fracture and Shear Behavior of Prestressed Concrete Beams. Fibers 2022, 10, 26. [Google Scholar] [CrossRef]

- Al-Majidi, M.H.; Lampropoulos, A.P.; Cundy, A.B.; Tsioulou, O.T.; Al-Rekabi, S. A Novel Corrosion Resistant Repair Technique for Existing Reinforced Concrete (RC) Elements Using Polyvinyl Alcohol Fibre Reinforced Geopolymer Concrete (PVAFRGC). Constr. Build. Mater. 2018, 164, 603–619. [Google Scholar] [CrossRef]

- Tosun-Felekoglu, K.; Felekoglu, B. Effects of Fibre Hybridization on Multiple Cracking Potential of Cement-Based Composites under Flexural Loading. Constr. Build. Mater. 2013, 41, 15–20. [Google Scholar] [CrossRef]

- Lakavath, C.; Suriya Prakash, S.; Dirar, S. Experimental and Numerical Studies on Shear Behaviour of Macro-Synthetic Fibre Reinforced Prestressed Concrete Beams. Constr. Build. Mater. 2021, 291, 123313. [Google Scholar] [CrossRef]

- Ling, J.H.; Lim, Y.T.; Jusli, E. Methods to Determine Ductility of Strufctural Members: A Review. J. Civ. Eng. Forum 2023, 9, 181–194. [Google Scholar] [CrossRef]

- Hassanli, R.; Youssf, O.; Mills, J.; Fakharifar, M. Analytical Study of Force—Displacement Behavior and Ductility of Self-Centering Segmental Concrete Columns. Int. J. Concr. Struct. Mater. 2017, 11, 489–511. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, H.; Zhen, X.; Wen, C.; Chen, G. Effects of Steel Fi Ber on the Fl Exural Behavior and Ductility of Concrete Beams Reinforced with BFRP Rebars under Repeated Loading. Compos. Struct. 2021, 270, 114072. [Google Scholar] [CrossRef]

- Sukontasukkul, P. Toughness Evaluation of Fibre Reinforced Concrete. Thammasat Int. J. Sci. Technol. 2004, 9, 35–41. [Google Scholar]

- Yimer, T.; Gebre, A. Effect of Fiber Treatments on the Mechanical Properties of Sisal Fiber-Reinforced Concrete Composites. Adv. Civ. Eng. 2023, 2023, 2293857. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, T.; Liu, X. Serviceability Performance of Fiber-Reinforced Lightweight Aggregate Concrete Beams with CFRP Bars. Adv. Struct. Eng. 2022, 25, 117–132. [Google Scholar] [CrossRef]

- Ghanem, H.; Chahal, S.; Khatib, J.; Elkordi, A. Flexural Behavior of Concrete Beams Reinforced with Recycled Plastic Mesh. Buildings 2022, 12, 2085. [Google Scholar] [CrossRef]

- Ghanem, H.; Chahal, S.; Khatib, J.; Elkordi, A. Experimental and Numerical Investigation of the Flexural Behavior of Mortar Beams Strengthened with Recycled Plastic Mesh. Sustainability 2023, 15, 5640. [Google Scholar] [CrossRef]

| Ingredient | Quantity (kg/t) | Ingredient | Quantity (kg/t) |

|---|---|---|---|

| 525 Cement | 350 | Medium sand (0.35–0.5 mm) | 350 |

| Fly ash | 100 | Find sand (0.25–0.35 mm) | 75 |

| Silica fume | 50 | Superplasticizer | 2.5 |

| Coarse sand (>0.5 mm) | 75 | Water–cement ratio | 0.17 |

| Fiber Type | Length (mm) | Aspect Ratio | Density (kg/m3) | Tensile Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|

| Steel | 13 | 65 | 7900 | 2850 | 250 |

| UHMWPE | 12 | 85 | 900 | 2000 | 105 |

| Fabric Material | Tensile Strength (MPa) | Young’s Modulus (GPa) | Elongation at Break (%) | Thickness (mm) |

|---|---|---|---|---|

| Glass | 301 | 8.99 | 3.4% | 0.3 |

| UHMWPE | 1432 | 12.36 | 7.0% | 0.8 |

| Adhesive Type | Compressive Strength (MPa) | Tensile Strength (MPa) | Tensile Modulus (GPa) | Bending Strength (MPa) |

|---|---|---|---|---|

| Epoxy resin | 70 | 40 | 2.5 | 50 |

| MPC | 56.3 | 6.5 | 2 | 8.1 |

| Specimen Name | Key Points | |||||

|---|---|---|---|---|---|---|

| FC Point | UL Point (Post-Cracking Phase) | |||||

(N) | (mm) | (MPa) | (N) | (mm) | (MPa) | |

| HSM | 4840.50 | 0.53 | 11.35 | - | - | - |

| HSM_1PEI | 3733.26 | 0.36 | 8.75 | 2727.71 | 1.76 | 6.40 |

| HSM_1GI | 6023.55 | 0.54 | 14.12 | - | - | - |

| HSM_1GE | 6499.11 | 0.46 | 15.23 | - | - | - |

| HSM_1PEE_ER | 5193.53 | 1.04 | 12.17 | 8244.23 | 3.81 | 19.32 |

| HSM_1PEE_MPC | 2337.13 | 0.36 | 5.48 | 4454.48 | 2.54 | 10.44 |

| HSM_2PEE | 6510.27 | 0.90 | 15.26 | 9723.18 | 2.91 | 22.79 |

| UHPC_S | 5444.43 | 0.52 | 12.76 | 7320.74 | 1.00 | 17.16 |

| U_S_1PEI | 6551.91 | 0.43 | 15.36 | 8548.61 | 0.63 | 20.04 |

| U_S_2PEI | 5835.95 | 0.37 | 13.68 | 7650.87 | 0.59 | 17.93 |

| U_S_1PEE | 6883.92 | 0.66 | 16.13 | 12,287.65 | 2.25 | 28.80 |

| U_S_2PEE | 6530.47 | 0.79 | 15.31 | 14,263.28 | 2.51 | 33.43 |

| UHPC_PE | 8096.46 | 0.49 | 18.98 | 14,029.9 | 1.67 | 35.66 |

| U_PE_2PEI | 6366.69 | 0.44 | 14.92 | 9677.88 | 1.81 | 22.68 |

| U_PE_2PEE | 7908.02 | 0.73 | 18.53 | 16,941.94 | 3.05 | 39.71 |

| Specimen Name | Key Points | |||||

|---|---|---|---|---|---|---|

| Strength | Displacement | |||||

| FC Point | UL Point | FC Point | ||||

| Mean (MPa) | Standard Deviation (MPa) | Mean (MPa) | Standard Deviation (N) | Mean (mm) | Standard Deviation (mm) | |

| HSM | 11.34 | 1.07 | - | - | 0.53 | 0.11 |

| HSM_1PEI | 8.75 | 0.81 | 6.39 | 0.61 | 0.36 | 0.15 |

| HSM_1GI | 14.12 | 0.68 | - | - | 0.54 | 0.01 |

| HSM_1GE | 15.2 | 2.58 | - | - | 0.46 | 0.14 |

| HSM_1PEE_ER | 12.17 | 0.66 | 19.32 | 3.81 | 1.04 | 0.06 |

| HSM_1PEE_MPC | 10.44 | 0.73 | 7.73 | 0.69 | 0.54 | 0.01 |

| HSM_2PEE | 15.26 | 0.96 | 22.79 | 4.91 | 1.06 | 0.04 |

| UHPC_S | 17.16 | 3.11 | 17.16 | 3.11 | 0.66 | 0.05 |

| U_S_1PEI | 15.36 | 1.00 | 20.04 | 0.66 | 0.43 | 0.03 |

| U_S_2PEI | 13.68 | 1.14 | 17.93 | 3.70 | 0.37 | 0.05 |

| U_S_1PEE | 15.36 | 1.00 | 28.80 | 3.76 | 0.66 | 0.13 |

| U_S_2PEE | 13.68 | 1.14 | 33.43 | 3.55 | 0.61 | 0.13 |

| UHPC_PE | 35.66 | 5.84 | 35.66 | 5.84 | 0.46 | 0.02 |

| U_PE_2PEI | 14.92 | 0.69 | 22.68 | 2.66 | 0.44 | 0.03 |

| U_PE_2PEE | 18.53 | 2.28 | 39.71 | 2.93 | 0.73 | 0.15 |

| Specimen Name | Displacement | Toughness | ||||

| UL Point | ||||||

| Mean (mm) | Standard Deviation (mm) | Mean (KJ/m3) | Standard Deviation (KJ/m3) | |||

| HSM | - | - | - | - | ||

| HSM_1PEI | 1.76 | 0.20 | 75.05 | 17.16 | ||

| HSM_1GI | - | - | - | - | ||

| HSM_1GE | - | - | - | - | ||

| HSM_1PEE_ER | 3.81 | 0.60 | 337.47 | 113.81 | ||

| HSM_1PEE_MPC | 2.54 | 0.55 | 128.24 | 33.31 | ||

| HSM_2PEE | 3.24 | 0.74 | 292.43 | 131.94 | ||

| UHPC_S | 1.01 | 0.20 | 98.11 | 3.64 | ||

| U_S_1PEI | 0.63 | 0.03 | 66.82 | 17.18 | ||

| U_S_2PEI | 0.59 | 0.09 | 64.60 | 13.18 | ||

| U_S_1PEE | 2.25 | 0.45 | 481.90 | 195.10 | ||

| U_S_2PEE | 2.51 | 0.22 | 468.82 | 102.07 | ||

| UHPC_PE | 1.68 | 0.19 | 306.80 | 75.80 | ||

| U_PE_2PEI | 1.54 | 0.02 | 273.58 | 15.35 | ||

| U_PE_2PEE | 3.05 | 0.46 | 580.19 | 61.41 | ||

| Specimen Name | Toughness (KJ/m3) | Estimated Fiber/Fabric Cost (USD/m3) | Toughness per Dollar (KJ/USD) |

|---|---|---|---|

| HSM | - | - | - |

| HSM_1PEI | 75.05 | 21.4 | 3.51 |

| HSM_1GI | - | 1.69 | - |

| HSM_1GE | - | 1.69 | - |

| HSM_1PEE_ER | 337.5 | 21.4 | 15.77 |

| HSM_1PEE_MPC | 128.2 | 21.4 | 5.99 |

| HSM_2PEE | 292.4 | 42.8 | 6.83 |

| UHPC_S | 98.1 | 95 | 1.0 |

| U_S_1PEI | 66.8 | 116.4 | 0.57 |

| U_S_2PEI | 64.6 | 137.8 | 0.47 |

| U_S_1PEE | 481.9 | 116.4 | 4.14 |

| U_S_2PEE | 468.8 | 137.8 | 3.40 |

| UHPC_PE | 306.8 | 40 | 7.67 |

| U_PE_2PEI | 273.58 | 82.8 | 3.30 |

| U_PE_2PEE | 580.2 | 82.8 | 7.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, Z.; Dang, F.; Tuladhar, R.; Yin, S.; Shi, F.; To, P.; Tang, Z. Experimental Investigation of Ultra-High Molecular Weight Polyethylene Fibers and Fabric for Flexural Reinforcement in Ultra-High-Performance Concrete. Materials 2025, 18, 2002. https://doi.org/10.3390/ma18092002

Pan Z, Dang F, Tuladhar R, Yin S, Shi F, To P, Tang Z. Experimental Investigation of Ultra-High Molecular Weight Polyethylene Fibers and Fabric for Flexural Reinforcement in Ultra-High-Performance Concrete. Materials. 2025; 18(9):2002. https://doi.org/10.3390/ma18092002

Chicago/Turabian StylePan, Zengrui, Faning Dang, Rabin Tuladhar, Shi Yin, Feng Shi, Peter To, and Zisheng Tang. 2025. "Experimental Investigation of Ultra-High Molecular Weight Polyethylene Fibers and Fabric for Flexural Reinforcement in Ultra-High-Performance Concrete" Materials 18, no. 9: 2002. https://doi.org/10.3390/ma18092002

APA StylePan, Z., Dang, F., Tuladhar, R., Yin, S., Shi, F., To, P., & Tang, Z. (2025). Experimental Investigation of Ultra-High Molecular Weight Polyethylene Fibers and Fabric for Flexural Reinforcement in Ultra-High-Performance Concrete. Materials, 18(9), 2002. https://doi.org/10.3390/ma18092002