1. Introduction

Plastic injection molding (PIM) is commonly utilized in industries such as automotive, home appliances, and electronics due to its advantages in efficient production, precise control, and the ability to manufacture complex shapes in large volumes. In the context of new energy vehicles, connectors, as critical components of the electrical system, face increasingly stringent performance requirements, such as heat resistance, reliability, and vibration resistance. At the same time, the structural diversity and fine precision requirements of connectors have led to a growing demand aimed at improving injection molding parameter settings [

1]. During the injection molding process, there exists a complex geometric nonlinearity between process parameters, and different parameters may contradict each other, thereby affecting the molding quality. For example, increasing injection speed may help improve filling performance and reduce short shots, but it could also result in greater gas entrapment, leading to weld lines or surface defects. Lowering mold temperature might reduce warpage, but it may also cause uneven cooling of the material, resulting in uneven shrinkage or surface imperfections [

2]. Systematic adjustment of process parameters is vital for reducing production costs and mitigating defects like warpage, volume shrinkage, weld lines, and incomplete filling in injection molding.

To gain deeper insights into how process parameters influence molding quality, researchers have conducted extensive studies. Mourya et al. [

3] provided a detailed description of how variations in molding process parameters affect defects in plastic parts. Given the critical role that in-mold temperature control plays in improving warpage quality. Hopmann et al. [

4] proposed a new strategy for initiating heating and cooling elements in advance to predict and regulate in-mold temperature. Chen et al. [

5] optimized the velocity–pressure changeover point and the hold pressure according to changes in rod strain characteristics to ensure the stability of the injection-molded part’s quality. Gim et al. [

6] utilized neural networks as surrogate models to study the impact of cavity pressure distribution on part quality. Chen et al. [

7] discovered that temperature and melt temperature are key parameters in the optimization of PET bottle preform warpage.

With the development of computer-aided technologies, the integration of injection molding simulation with optimization design methods has become the mainstream approach for process parameter optimization, significantly reducing computation time and production trial costs. Moayyedian et al. [

8] utilized methods such as Finite Element Analysis (FEA), the Taguchi method, and artificial neural networks (ANNs) to effectively identify optimal process parameters, achieving the best final product quality. Shen et al. [

9] integrated artificial neural networks (ANNs) with genetic algorithms (GAs) to optimize the injection molding process. By incorporating the Taguchi design approach with Moldflow analysis, shrinkage-induced deformation during the injection process was effectively minimized, leading to improved roundness and concentricity of the component [

10]. Mohammad et al. [

11] employed the Taguchi method and numerical simulation to minimize sink marks and warpage in plastic gears. Feng et al. [

12] applied a combination of the Taguchi design approach, ANOVA, and hybrid ANN-MOGA methods to automate the optimization process for thin-walled plastic products. Otieno et al. [

13] minimized warpage and shrinkage through fuzzy logic and pattern search optimization methods. Lockner et al. [

14] proposed a data-driven injection molding process parameter optimization approach using transfer learning based on inductive networks to decrease the quantity of data from the injection molding process required for neural network training. In the optimization of warpage and shrinkage, Otieno et al. [

13] established a predictive model grounded in process parameters. The Taguchi L25 design was utilized to generate training datasets, and a fuzzy logic model was employed for defect forecasting. The model was subsequently refined using pattern search algorithms, which minimized the square root of the average squared error and error of the regression model, thereby enhancing the precision of the predictions. This methodology substantially augments both product quality and operational efficiency. Wu et al. [

15] undertook an investigation into the nonlinear shrinkage of micro-small-module plastic gears, utilizing a response surface model and NSGA-II for multi-objective optimization. The results showed that the error rates for key shrinkage dimensions were all below 2%, with shrinkage variables reduced by 5.60%, 8.23%, 11.71%, and 11.39%, respectively. Additionally, the tooth profile deviations were reduced by up to 49.96%.

Moreover, the implementation of smart algorithms has gradually gained attention in injection molding process optimization. As a recent swarm intelligence approach, the Dung Beetle Optimization (DBO) algorithm exhibits remarkable performance in terms of convergence rate, solution precision, and stability [

16]. Liu et al. [

17] introduced a multi-strategy improvement in the DBO algorithm (MI-DBO) to enhance operational efficiency. Wang et al. [

18] refined the standard dung beetle optimization algorithm by adding tent chaotic mapping for initial population generation, a golden sinusoidal approach for position updating, and the Lévy flight mechanism to achieve a balance between exploration and exploitation. Lu et al. [

19] employed the improved method to optimize the parameters of the grinding process, focusing on balancing carbon emissions, processing time, and cost. The experimental results revealed that after optimization, carbon emissions, costs, and processing times were reduced by 11.7%, 7.7%, and 6.7%, respectively.

In addition to process parameter optimization, the optimization of mold structure and conformal cooling channels is also a crucial approach to improving injection molding quality and efficiency. Proper gate placement can effectively avoid filling defects and jetting issues. For parts with complex geometries that are difficult to parametrize, Walale et al. [

20] proposed a method for optimizing the gate position on complex curved surfaces, significantly enhancing the optimization efficiency. Research has shown that adding rectangular inserts before the flow channel gate can optimize the melt heat distribution, improving the surface quality of injection-molded automotive components [

21]. Compared to traditional straight-drilled cooling systems, conformal cooling systems offer more uniform and efficient cooling, thereby enhancing product quality and production efficiency. In the context of conformal cooling channel design, numerous optimization strategies have been proposed in the literature, including but not limited to helical configurations [

22], linear (serpentine) arrangements [

23], non-circular cross-sectional geometries [

24], modular/parametric design approaches [

25], and lattice/porous structures [

26]. Furthermore, these primary cooling channel designs can be synergistically integrated with auxiliary techniques such as bubble generators or baffles [

24], thereby achieving enhanced cooling performance through multi-physics optimization. Studies indicate that conformal cooling systems have a significant advantage in reducing weld line defects [

27,

28,

29].

Despite the aforementioned research progress, there is a gap in existing studies on the injection molding of multi-porous thin-walled connectors, as well as on the complex nonlinear and conflicting relationships between multiple quality indicators, such as molding quality and production cost. Additionally, the high dimensionality and interdependence of process parameters further increase the difficulty of effective optimization. While simulation-based and data-driven methods show promising application prospects, their performance largely depends on the accuracy of the surrogate models and the efficiency of the optimization strategies used. The motivation for this study primarily includes the following aspects:

Multi-objective optimization is a critical issue in injection molding. The challenge is to optimize processes in a way that improves product quality, increases efficiency, and meets the growing demands for increasingly diverse injection-molded products. This requires identifying the extent to which process parameters influence the product.

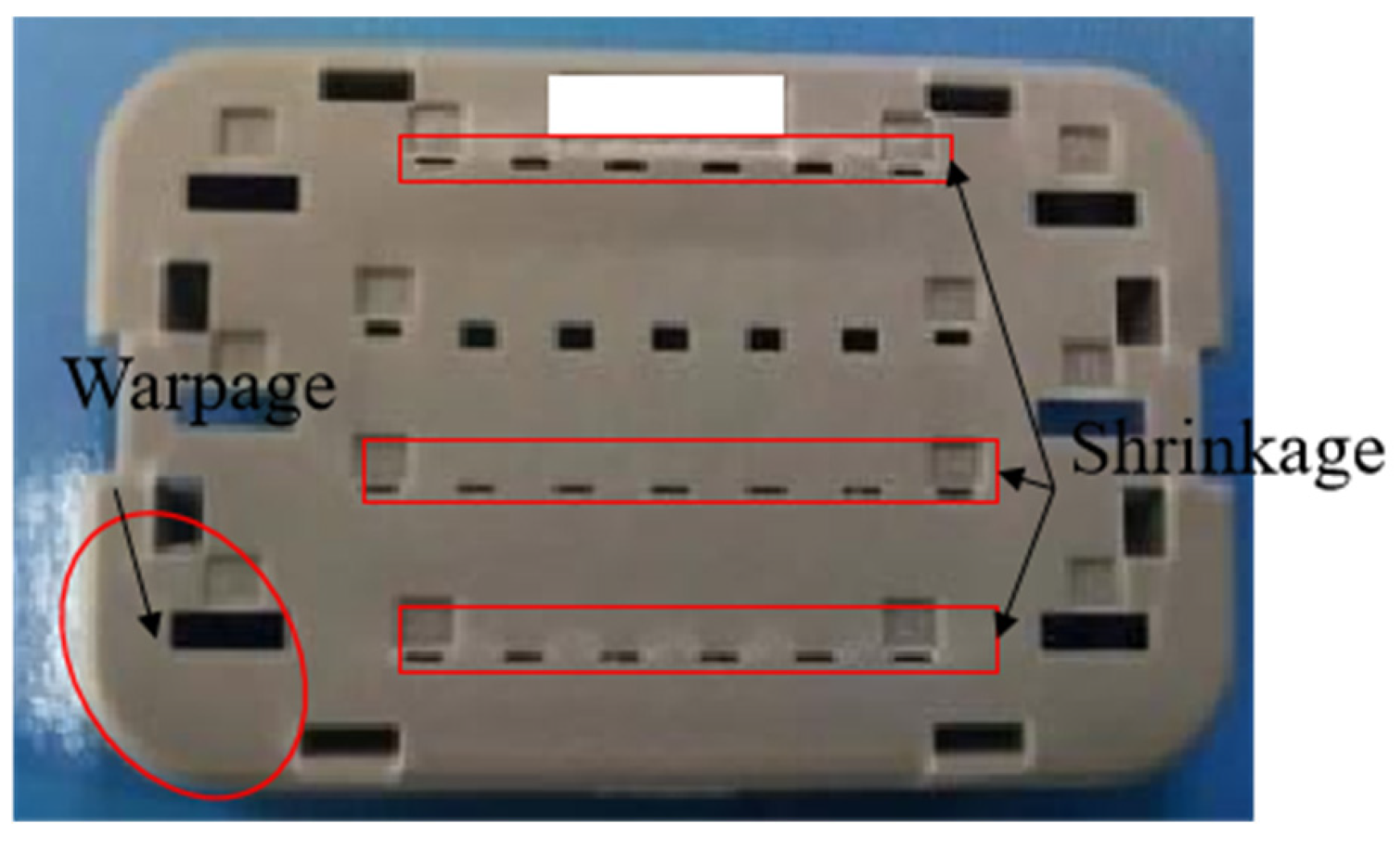

Warping deformation is a significant problem in injection molding. To ensure dimensional accuracy and maintain product shape precision, it is necessary to minimize warpage, reduce shrinkage, and control clamping force.

This paper applies Dung Beetle Optimization (DBO) to improve the prediction accuracy of the BP neural network, thereby enhancing the performance of multi-objective optimization.

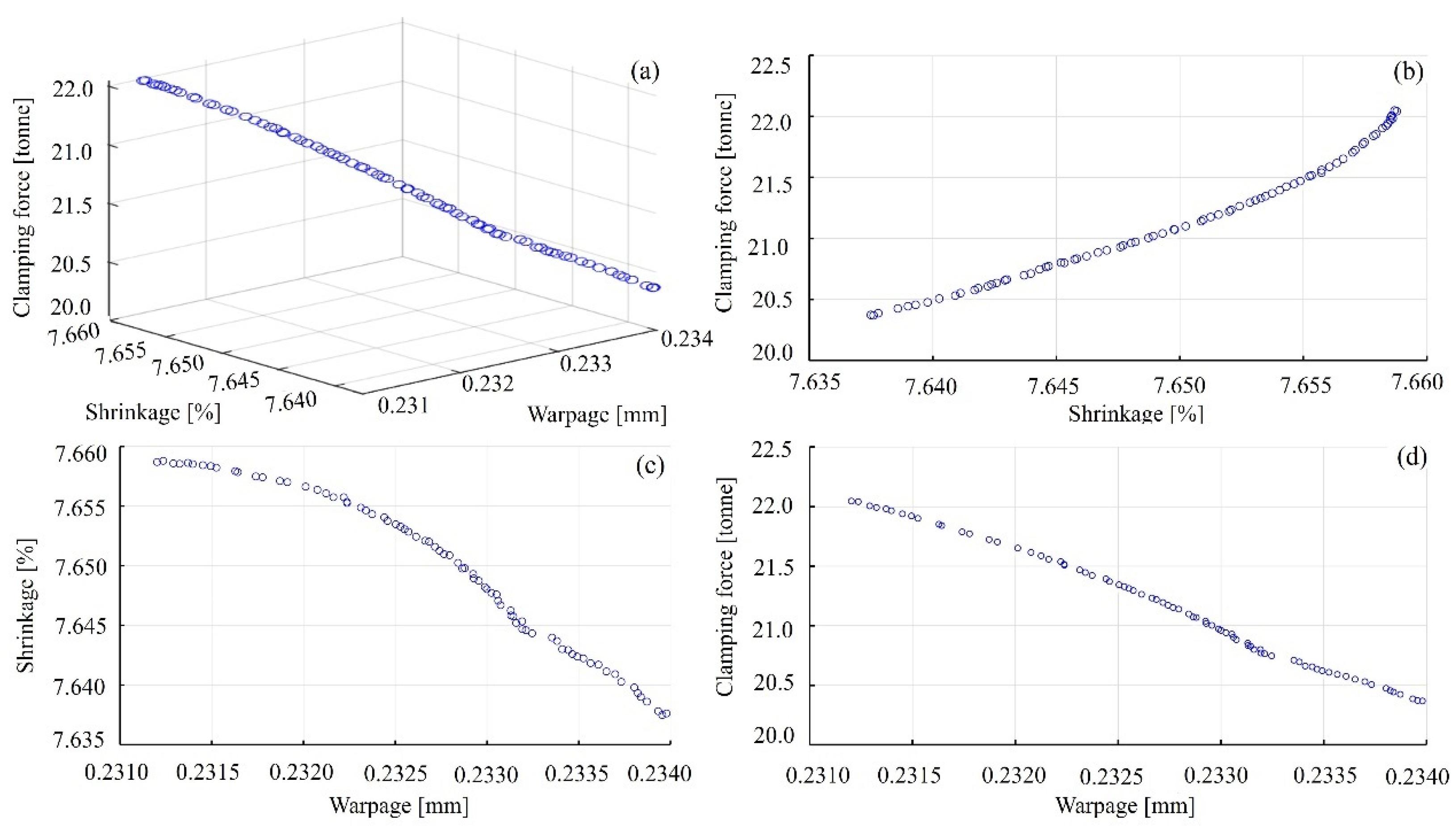

Typically, warpage, shrinkage, and clamping force cannot be simultaneously optimized to their ideal values. Therefore, trade-off analysis is conducted to make decisions regarding multi-objective optimization.

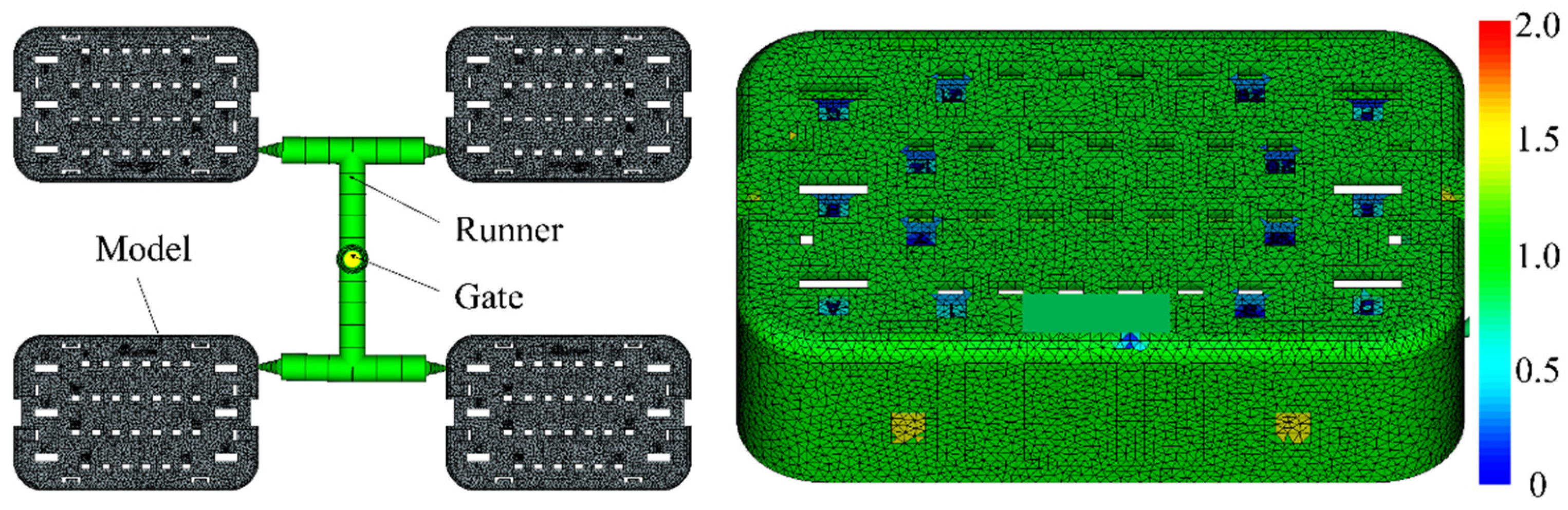

To achieve this, a methodology combining sampling strategies, numerical simulation, neural networks, and multi-objective optimization algorithms is proposed. Latin Hypercube Sampling (LHS) is used for sample point selection, followed by simulation analysis using Moldflow 2019 version to evaluate the results. With reference to the response points and experimental data, a predictive model is built using the DBO-BP neural network. Finally, NSGA-II is applied for multi-objective optimization to identify the solutions.

Section 1 summarizes the current research directions and methods for optimizing injection molding parameters.

Section 2 analyzes the multi-objective optimization problems in injection molding, including mathematical models, optimization objectives, design parameters, and trade-off analysis methods.

Section 3 introduces the research methods and principles of the beetle optimization algorithm and NSGA-II used in this paper.

Section 4 describes the multi-objective optimization analysis and verification of wire harness terminals as the research object.

2. Overview of Multi-Objective Optimization Problem

2.1. Multi-Objective Optimization Model

The injection molding process involves multiple key performance indicators and complex process constraints and requires a balance between production costs and efficiency. This process is inherently a multi-objective optimization problem, and its mathematical representation is given by the following core equations:

In this context, x represents the vector of process parameter combinations, where (i = 1, 2, …, n) represents the i-th process parameter. Here, n represents the total number of process parameters. (j = 1, 2, …, k) is the j-th objective function to be reduced, and k represents the total number of objective functions. and indicate the minimum and maximum values of the i-th process parameter.

2.2. Objective Functions

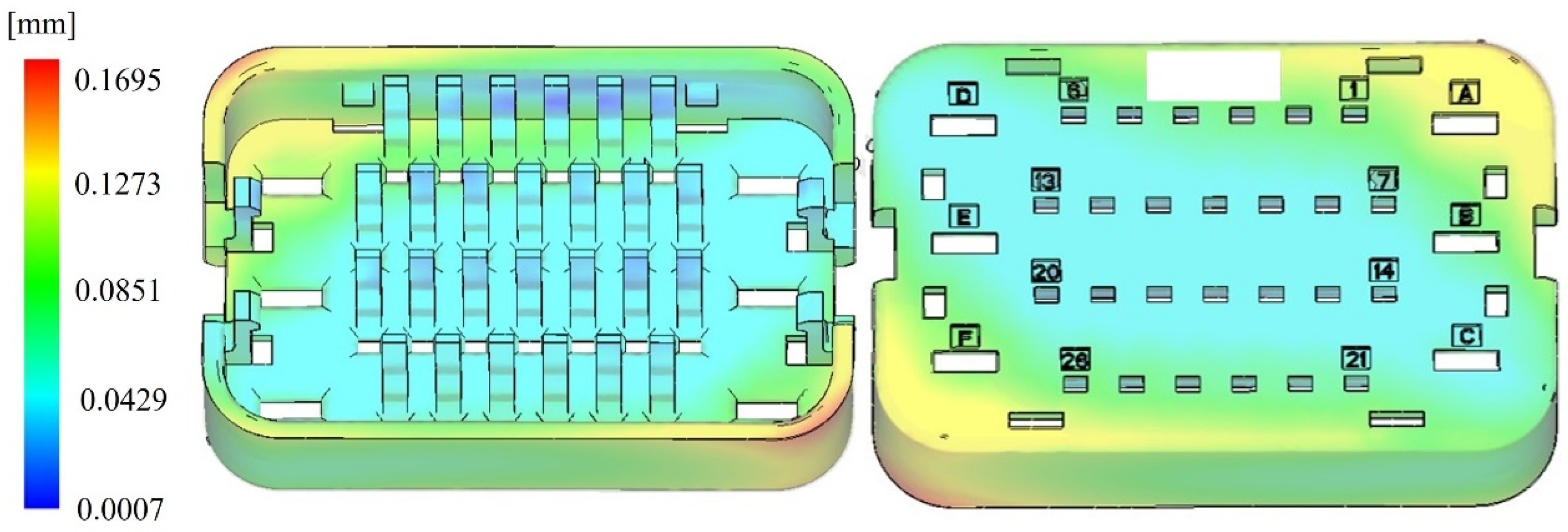

Warping is a shape deformation caused by uneven distribution of cooling-induced internal stresses through the injection molding procedure, and it is a member of the major issues affecting the characteristics of the molded products. It can lead to dimensional inaccuracies, appearance defects, and functional failures, ultimately affecting assembly performance and service life. Since warping directly impacts production efficiency and economic benefits, it is typically minimized as the first objective function, , in injection molding process optimization to enhance part quality and performance.

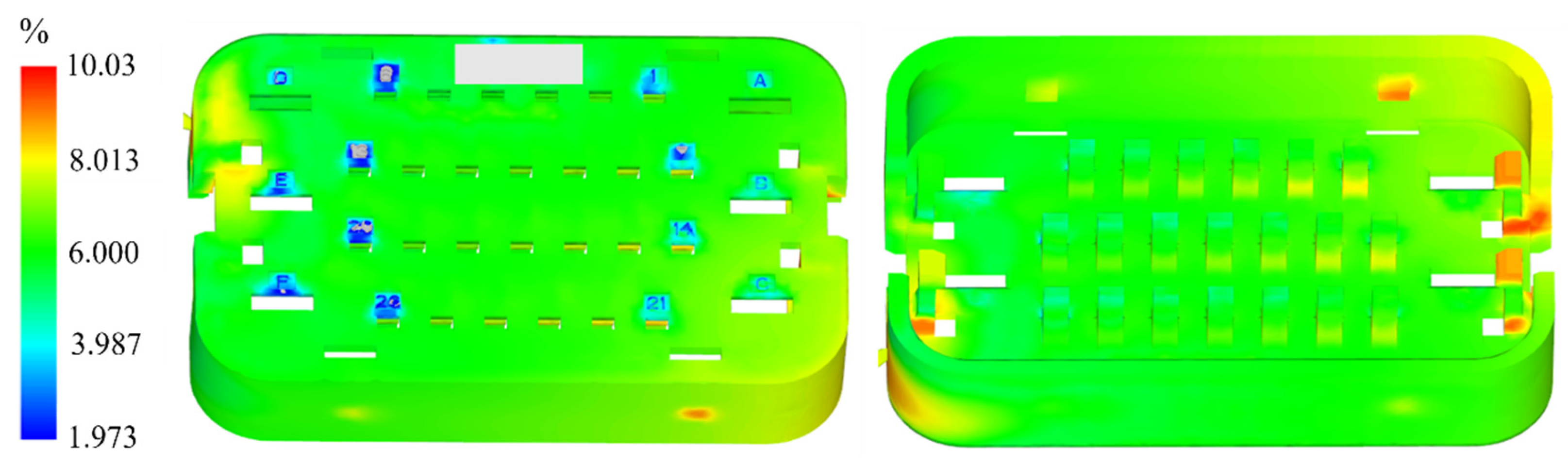

Volume shrinkage rate is an important quality indicator in injection molding, reflecting the change in the part’s volume during the cooling process. Excessive volume shrinkage can result in dimensional errors, warping, and appearance defects, which negatively impact product performance and assembly accuracy. Therefore, in process optimization, the volume shrinkage rate can act as the second goal function, , with the goal of minimizing it to optimize the dimensional precision and shape steadiness of the molded part while reducing the occurrence of defects.

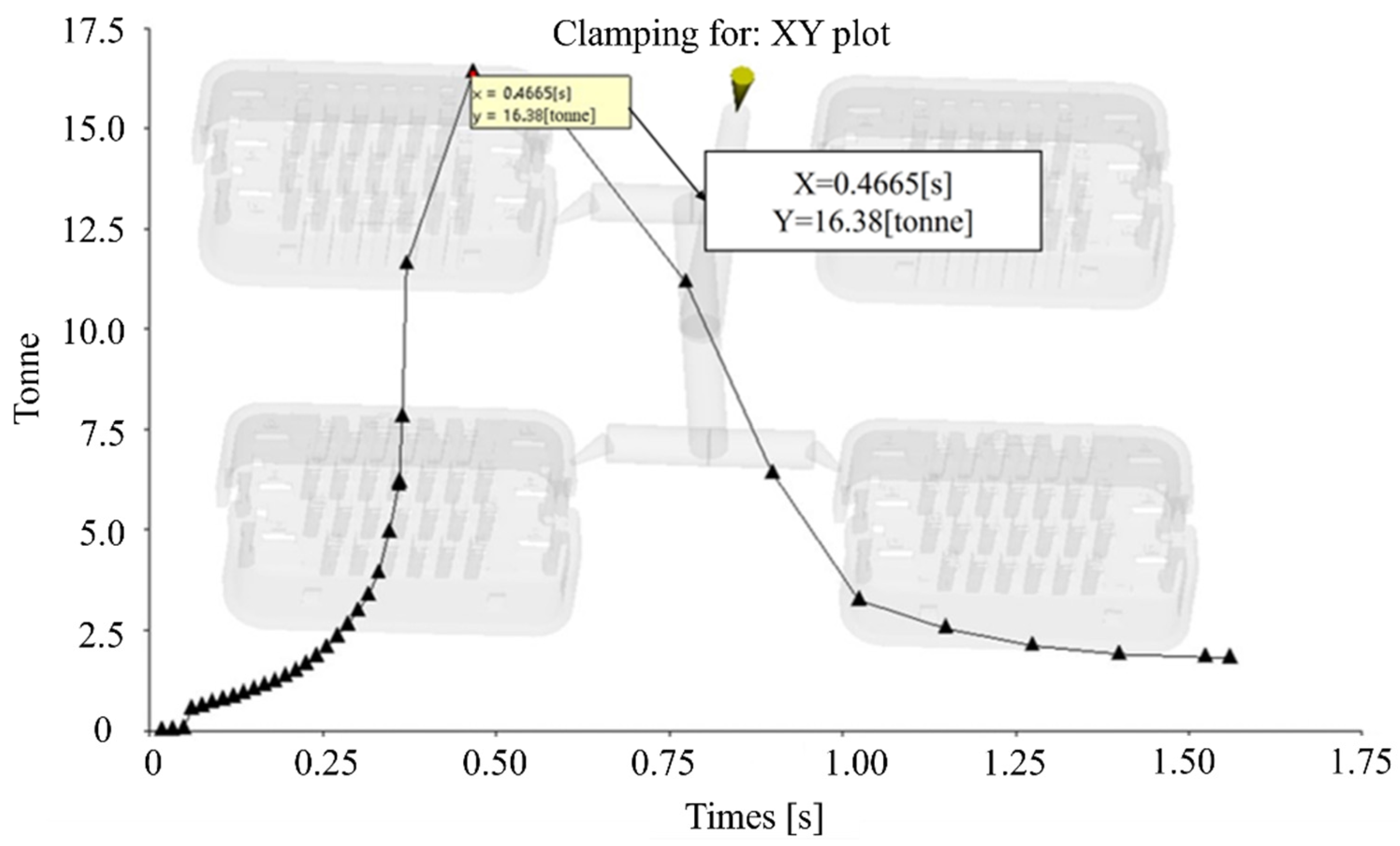

Clamping force is a critical element in the injection molding process, as it keeps the mold closed during injection and prevents defects such as short shots or leakage. Insufficient clamping force can lead to incomplete filling, while excessive force can cause mold wear and increase production costs. Clamping force is selected as the third objective function, , in the course of optimization. The goal is to minimize clamping force while ensuring proper mold closure, improving production efficiency, reducing costs, and extending mold life without compromising part quality.

2.3. Design Variables

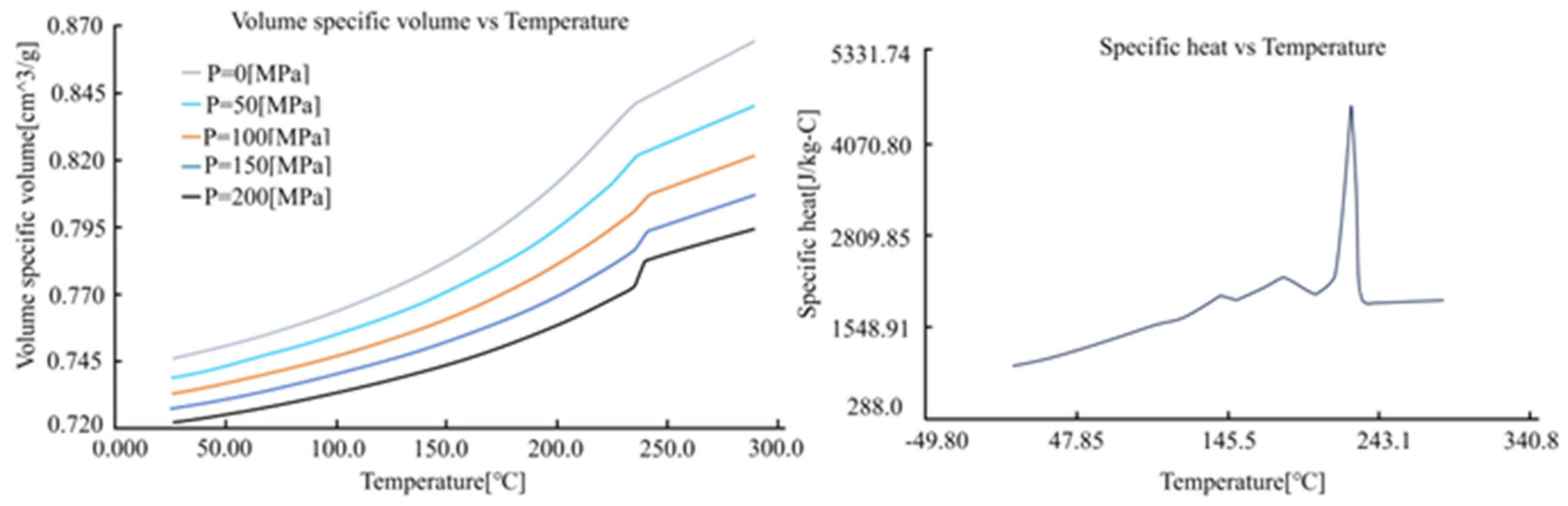

Table 1 enumerates the design parameters and their respective admissible ranges that constrain the optimization problem formulation. The process parameters—melt temperature (

), mold temperature (

), injection time (

), holding pressure (

), and holding time (

)—are considered as input variables. Melt temperature determines the flowability of the plastic melt. An appropriate melt temperature facilitates smooth filling of the mold, preventing issues such as incomplete filling and degradation. Mold temperature controls the cooling rate and the curing process of the molded part, ensuring uniform cooling and reducing warping and dimensional errors. Injection time directly impacts the completeness and density of the filling process. A reasonable injection time ensures rapid and uniform mold filling, preventing incomplete filling. Holding pressure is applied after injection to compensate for voids created by shrinkage, and an appropriate holding pressure can reduce warping and dimensional deviations while improving part density. Holding time determines the duration of the holding pressure, and adequate holding time ensures complete filling of the mold and prevents excessive shrinkage during cooling. By optimizing these parameters, the quality and accuracy of the injection-molded parts can be effectively improved.

2.4. Trade-Off Analysis

The purpose of multi-objective optimization problems is typically to minimize all objectives simultaneously. However, due to potential conflicts or the non-comparability among different objectives, identifying a single solution that simultaneously optimizes all objectives is often not possible. As a result, such problems do not produce a single optimal solution but instead generate a set of Pareto optimal solutions, each representing a trade-off between the competing objectives. This article explores the distribution of Pareto front solutions through the NSGAII optimization algorithm, considering that warping and shrinkage are equally important and greater than the locking force. Therefore, the multi-objective weights in this article are determined manually.

3. Optimization Methodologies

3.1. Multi-Objective Optimization Framework

A process parameter optimization method based on sampling strategies, numerical simulation, surrogate modeling, and multi-objective optimization algorithms has been developed to optimize the PIM process parameters with the objective of reducing warpage and volumetric shrinkage. The design space is discretized using a structured sampling approach, generating point distributions at multiple parameter level configurations. Concerning each sample point, numerical simulations are performed using Moldflow to compute the responses (warpage, volumetric shrinkage, and clamping force). In light of the sample data points and their associated responses, surrogate modeling techniques are used to approximate the mathematical relationships between design variables (process parameters) and responses, constructing a BP neural network model to compute the system responses corresponding to arbitrary sampling locations within the global design space. Subsequently, Pareto-optimal solutions are obtained through NSGA-II implementation, with the metamodel predictions constituting the multi-objective fitness evaluation. The architecture of the multi-objective process parameter optimization system for PIM is visualized in the flowchart presented in

Figure 1. The principal stages of this approach encompass the generation and analysis of sample points, the development of response prediction models, and the execution of multi-objective optimization. The comprehensive procedure can be outlined as follows:

Step 1: The system responses are designated as optimization objectives, while the corresponding process parameters are identified as design variables, with their respective operating ranges specified as boundary constraints within the optimization framework.

Step 2: The Latin Hypercube Sampling (LHS) technique is employed to generate a space-filling, statistically representative set of sample points across the multidimensional design space. These sampled configurations are subsequently evaluated via high-fidelity numerical simulations in Moldflow to quantify their corresponding response metrics. In parallel, a global sensitivity analysis is conducted to identify and rank the dominant design variables exerting the most significant influence on the specified performance objectives.

Step 3: Develop a BP neural network model utilizing surrogate modeling techniques. Employ the sample points gathered in Step 2 as the training dataset and construct an enhanced DBOBP neural network model, evaluating its performance through the cumulative error.

Step 4: The multi-objective optimization framework utilizes NSGA-II to explore the parameter space and determine the Pareto frontier of optimal process conditions. Establish the initial parameters for the NSGA-II framework, and subsequently employ the predicted outcomes from the network model developed in Step 4 as the objective function for global multi-objective optimization to identify the Pareto optimal set. A subsequent trade-off analysis is conducted on the Pareto optimal solutions to determine the optimal compromise solution.

3.2. DBOBP-Optimized Neural Network Model

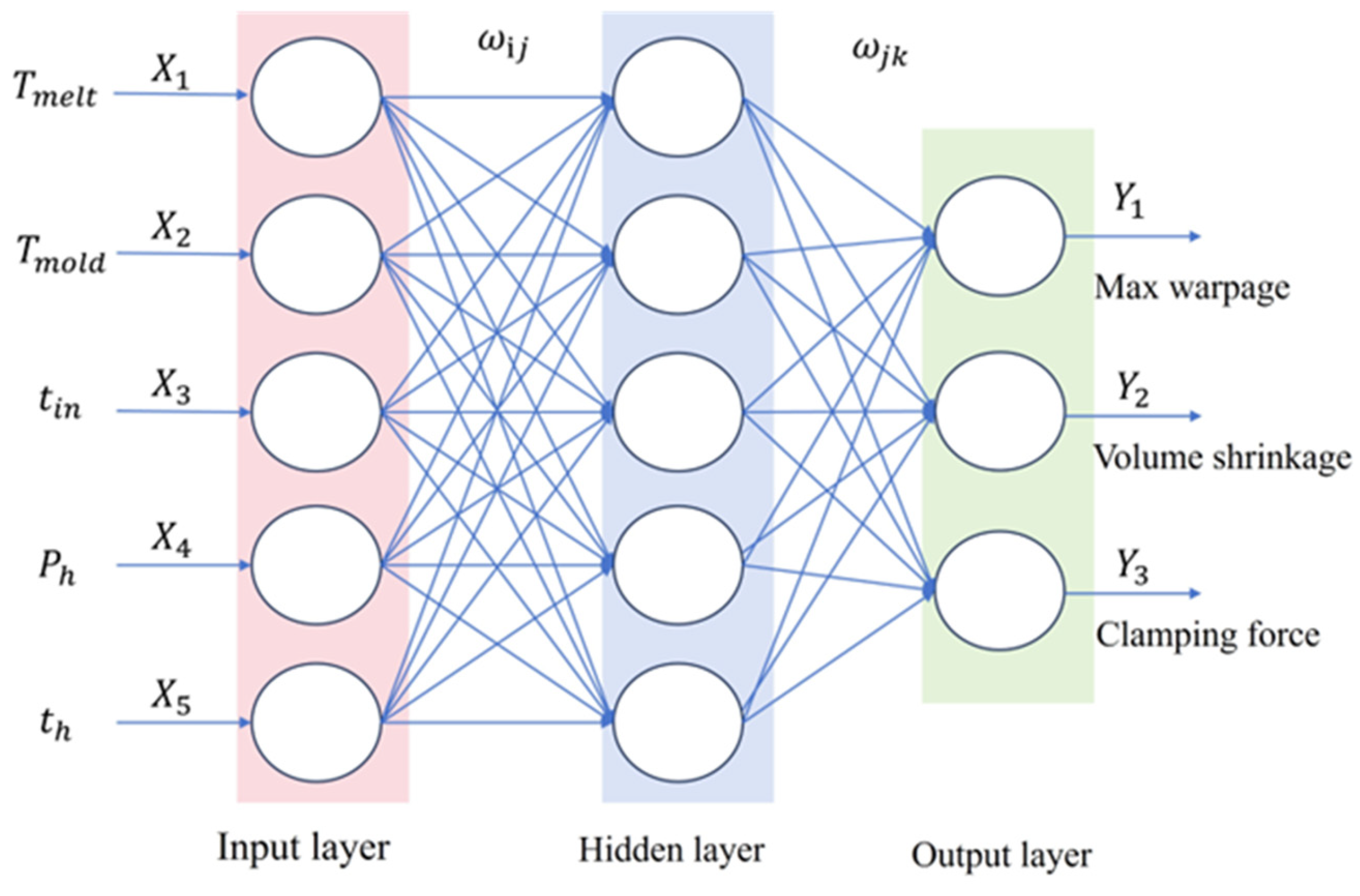

BP Neural Network (Backpropagation Neural Network) is extensively applied across disciplines, including classification, regression, and pattern recognition, due to its strong nonlinear fitting ability and adaptive learning characteristics. The network architecture shown in

Figure 2 incorporates the following three sequential layers: an input layer for data acquisition and scaling, a hidden layer with sigmoid activation functions for pattern recognition, and an output layer that delivers the system’s predictions. This structure facilitates the modeling of complex input-output relationships in engineered systems. However, BP networks have some limitations, such as the tendency to get trapped in local optima, high computational cost, and overfitting issues, which affect their performance in handling complex tasks. To overcome these challenges, the Dung Beetle Optimization (DBO) algorithm has been suggested for the optimization of the weights associated with BP networks. DBO effectively avoids local optima through a global search mechanism, thus improving the network’s accuracy and generalization ability and enhancing its performance in complex tasks. The calculation principle of dung beetle optimization (DBO) is as follows [

16]:

The Dung Beetle Optimization (DBO) algorithm is inspired by five typical behaviors of dung beetles—rolling, dancing, breeding, foraging, and stealing—each representing a unique search strategy. The rolling behavior, for example, simulates the beetle’s straight-line navigation relying on celestial markers (e.g., the Sun and Moon) while pushing dung balls. This enables adaptive positioning in a dynamic objective space and can be mathematically formulated as follows:

In the equation, t signifies the present iteration and denotes the spatial location of the i-th dung beetle at the t-th iteration. The parameter is a fixed constant that represents the deviation coefficient, and is a random number. , where 1 indicates no deviation and −1 represents a deviation from the original direction. In this study, to simulate the complex environment of the real world, a probabilistic approach is used to set σ to either 1 or −1. xxx represents the environmental change, and X represents the worst position in the existing population.

Upon encountering an obstruction that prevents further movement, the dung beetle adjusts its trajectory by “dancing”, thereby reorienting itself to establish an alternative route. The positional adjustment at this stage is governed by a tangent function, as represented by the following equation:

In the equation, denotes the deviation angle. Due to the periodic nature of the tangent function, only the values residing in the interval [0, π] are relevant. Term represents the displacement of the i-th dung beetle between the t-th and (t − 1)-th iterations. It is essential to note that for θ = 0/π, 2/π, tan(θ) is undefined, resulting in no change in the beetle’s position.

The boundary delineation strategy is mathematically formulated as follows:

Within the update rules, X* maintains the current best-known position, dynamically updated through pairwise comparisons across the population’s objective vectors. Lb refers to the lower limit of the search domain, while Ub represents the upper boundary. and define the lower and upper limits of the egg-laying zone, respectively. R indicates the inertia coefficient, and represents the maximum iteration count.

Upon identifying a secure location, the female dung beetle chooses this area to deposit its reproductive sphere. The velocity-driven relocation of the breeding particle in the solution space is mathematically described by the following equation:

denotes the position of the

i-th dung beetle at the

t-th iteration, while

and

are two independent random vectors of size 1 × D, where D is the dimensionality of the optimization problem. The position of the breeding sphere is strictly confined within a certain range, known as the oviposition area. This foraging region also employs a dynamic boundary approach:

identifies the universal optimum configuration, while the specification of the ideal foraging zone boundaries [

,

] enables the derivation of dung beetle foraging dynamics through the following position update operator:

The decision variable

encodes the

i-th optimizer’s candidate solution at generation t in the n-dimensional search space. The parameter

follows a standard normal distribution N(0,1), whereas

is uniformly sampled from the unit interval U(0,1). The resultant displacement dynamics for the thieving dung beetle follow this stochastic update rule as follows:

Within the update rule, the decision variable represents the current position of the i-th resource-acquiring optimizer at generation t. g is a stochastic vector of dimension 1 × D, drawn from a normal distribution, and F is a fixed constant.

3.3. NSGA-II Is Used to Locate the Pareto Optimal Solution

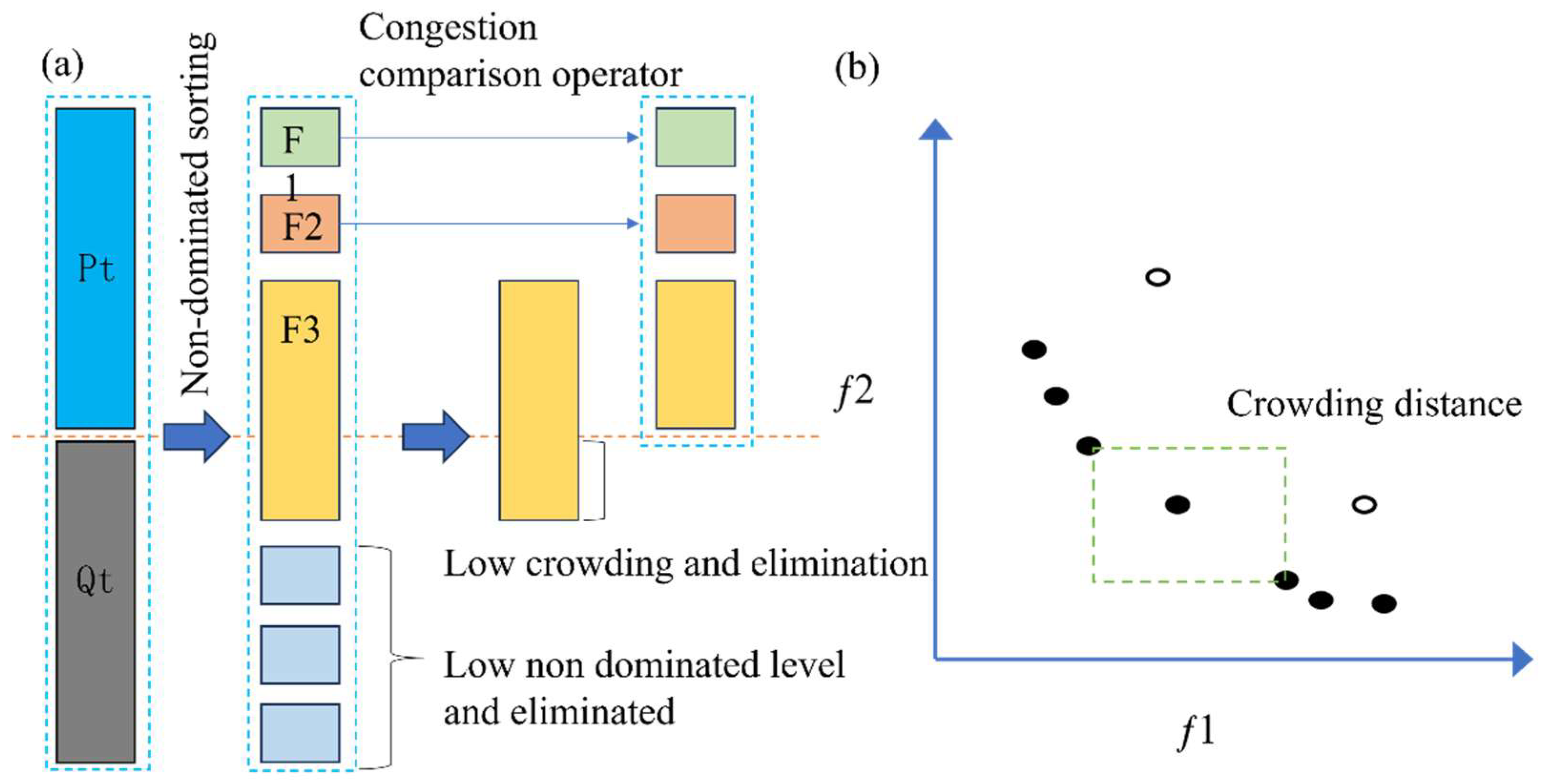

As shown in

Figure 3, NSGA-II is a robust genetic algorithm for multi-objective optimization, extensively applied to address intricate optimization challenges involving competing objectives. Its core principles include non-dominated sorting, congestion comparison, and elite strategy. It can layer the solution set through non-dominated sorting to ensure that excellent solutions are retained first and maintain the diversity of solutions through congestion calculation. NSGA-II preserves the optimal solution of parents and children through elite strategy so as to promote the algorithm to converge to the Pareto frontier quickly. Its main advantage is that it can optimize multiple objectives at the same time and effectively balance the convergence and diversity. It can provide a set of optimal Pareto solutions for decision makers to help make more comprehensive and scientific decisions.

3.4. Data Analysis

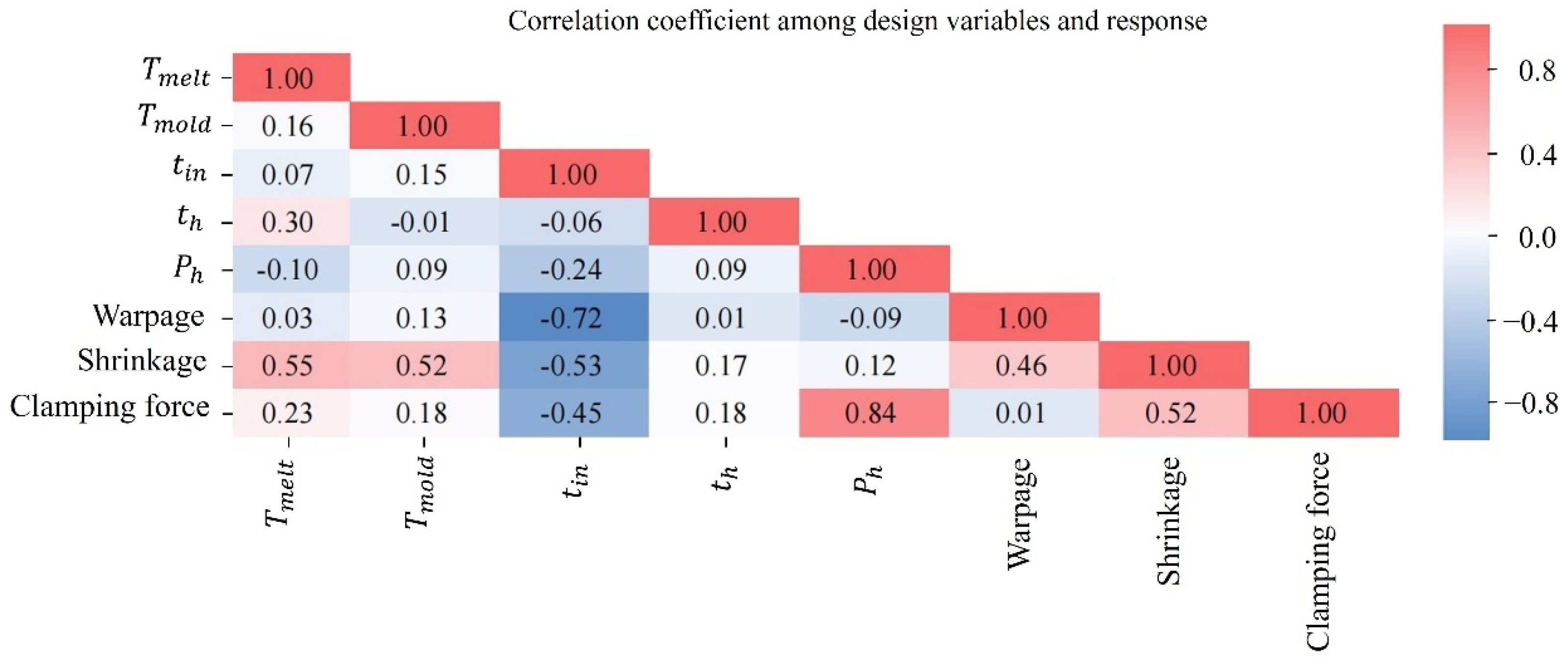

3.4.1. Sensitivity Analysis

Sensitivity analysis is utilized to determine the critical process parameters (design variables) that significantly influence the response (objectives). This approach aids in eliminating irrelevant parameters, thereby reducing the dimensionality of the design space. The sensitivity between the process parameters and the response is quantified using the correlation coefficient, which can be computed employing the subsequent equation:

The statistical relationship between random vectors X and Y is characterized by the measures joint variation, Var(X) and Var(Y) quantify individual spread, and ρ ∈ [−1, 1] indicates linear dependence.

3.4.2. Prediction Accuracy Analysis

For the concurrent engineering optimization tasks, the response model is utilized as the objective function in the optimization process for the NSGA-II algorithm. The predictive capability of the metamodel critically affects the quality of obtained Pareto solutions in engineering design optimization, potentially leading to non-convergence of the optimization algorithm. Hence, the model’s predictive performance is evaluated through three key metrics: root mean square error (RMSE), quantifying average deviation magnitude; mean absolute error (MAE), measuring absolute discrepancies; and coefficient of determination (

R2), assessing explained variance, each computed by comparing simulated responses with model predictions.

k is the total number of objectives;

n is the number of validation sampling points. Here,

and

represent the

j-th response for the

k-th sampling point predicted by the respective response predictor and obtained from simulation experiments, respectively.

represents the mean of the

j-th response.