The Role of Ceramics in the Configuration of a New Solar Thermal Collection System for Domestic Hot Water and Heating

Abstract

:1. Introduction

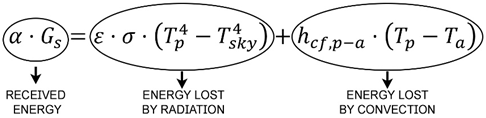

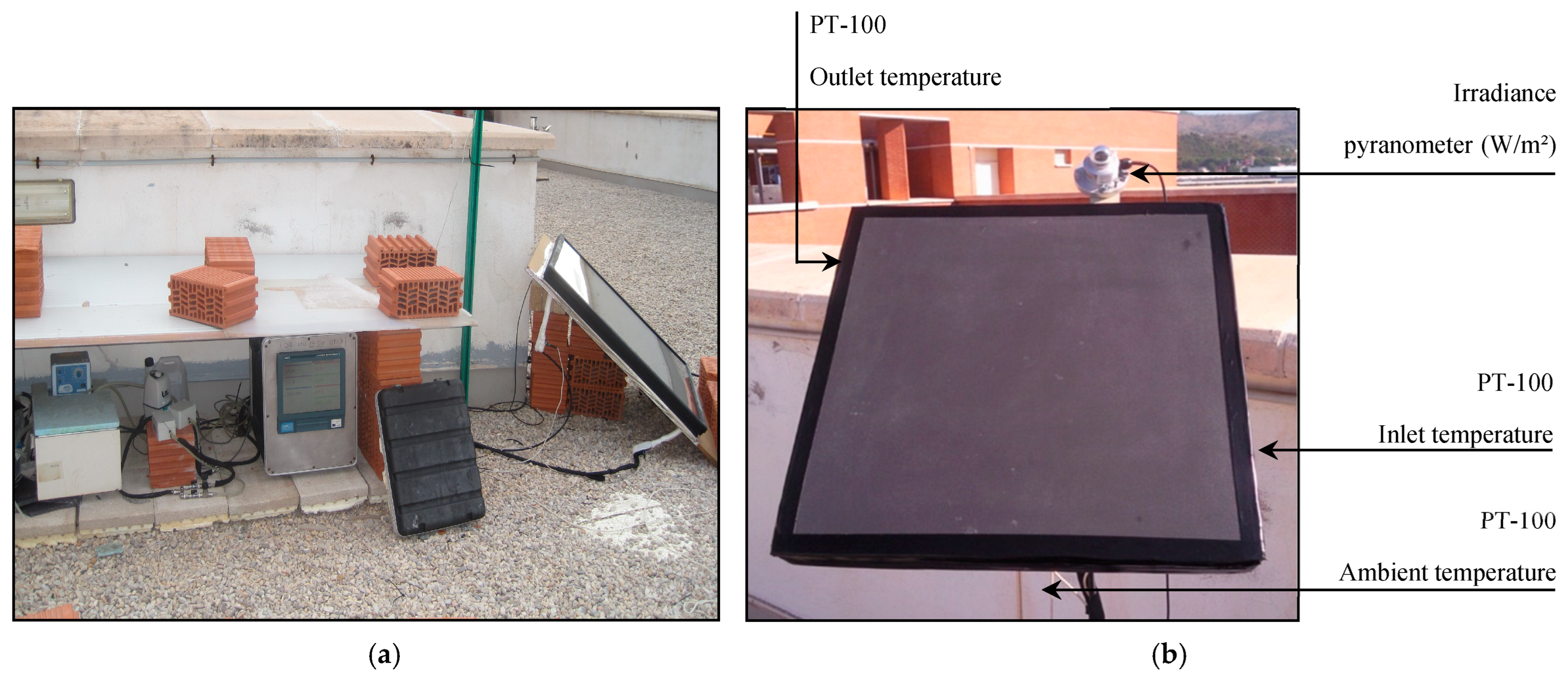

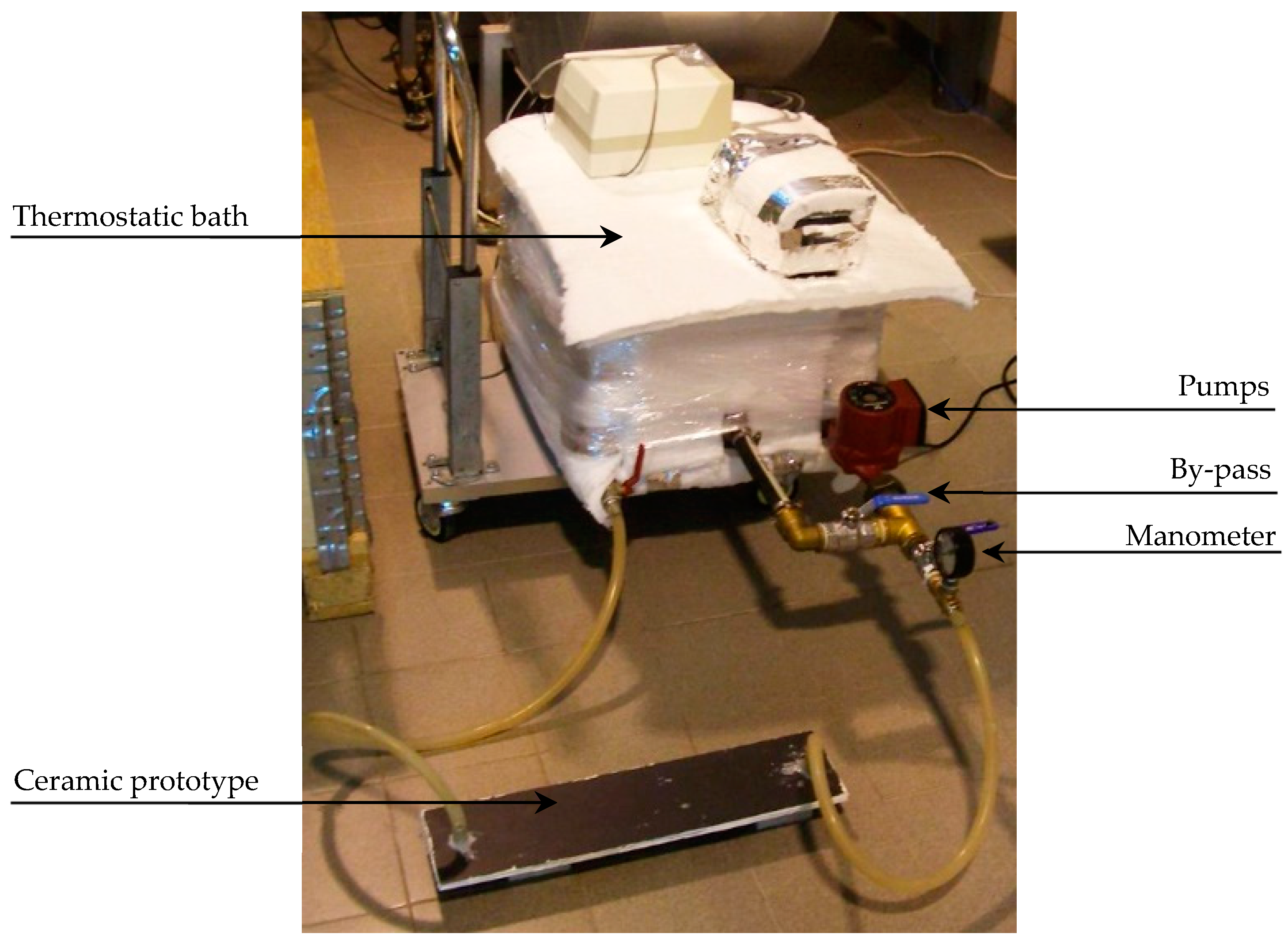

2. Materials and Methods

- A data acquisition system: This collects the values of all the measured properties at a frequency of 1 min;

- A thermostatically controlled bath: This device has a heating and a cooling system that keeps the water temperature constant above the ambient temperature;

- A diaphragm pump: This is for the impulse of the water through the circuit in the thermostated collector bath;

- A flow meter: It allows us to know the flow rate of the water circulating in the circuit (Qv);

- Two four-wire Pt-100 resistance thermometers placed in the solar collector itself: They are used to measure the inlet and outlet water temperatures of the collector;

- An overhead four-wire Pt-100 resistance thermometer placed at the bottom of the solar collector: This is used to measure the ambient temperature;

- A thermopile pyranometer to measure the incident solar radiation (Gs): It is installed in the same plane as the solar collector’s opening.

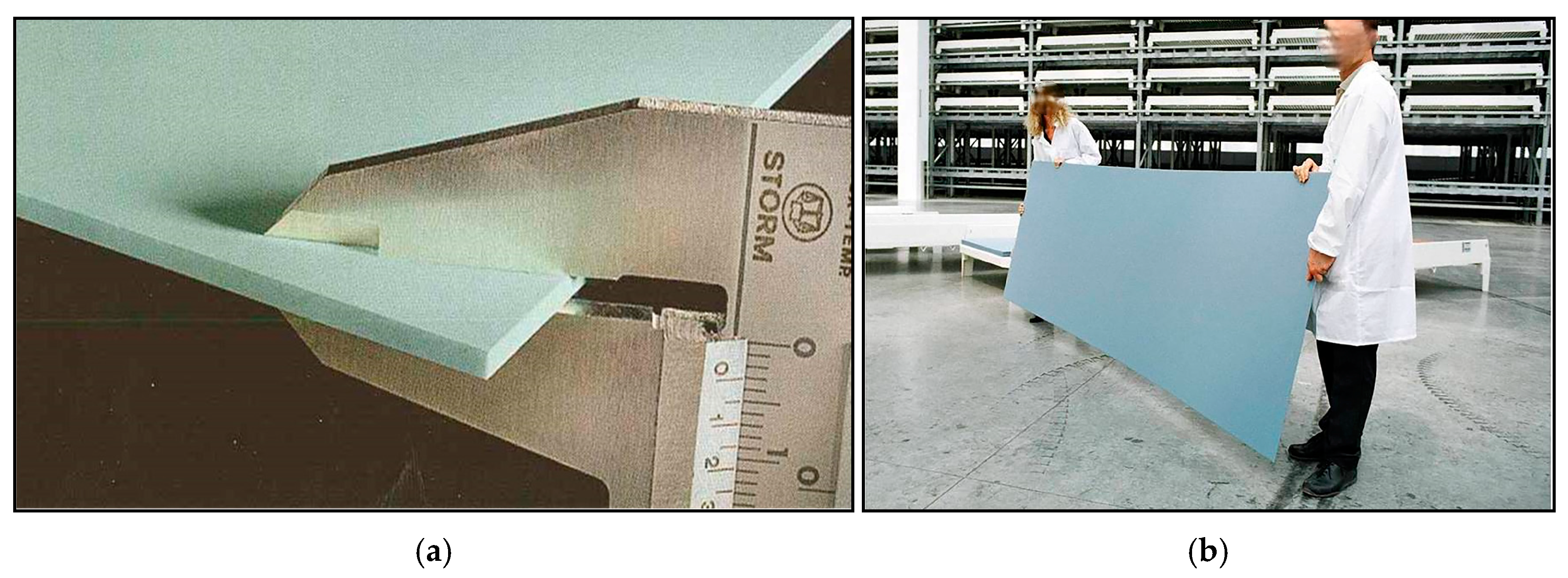

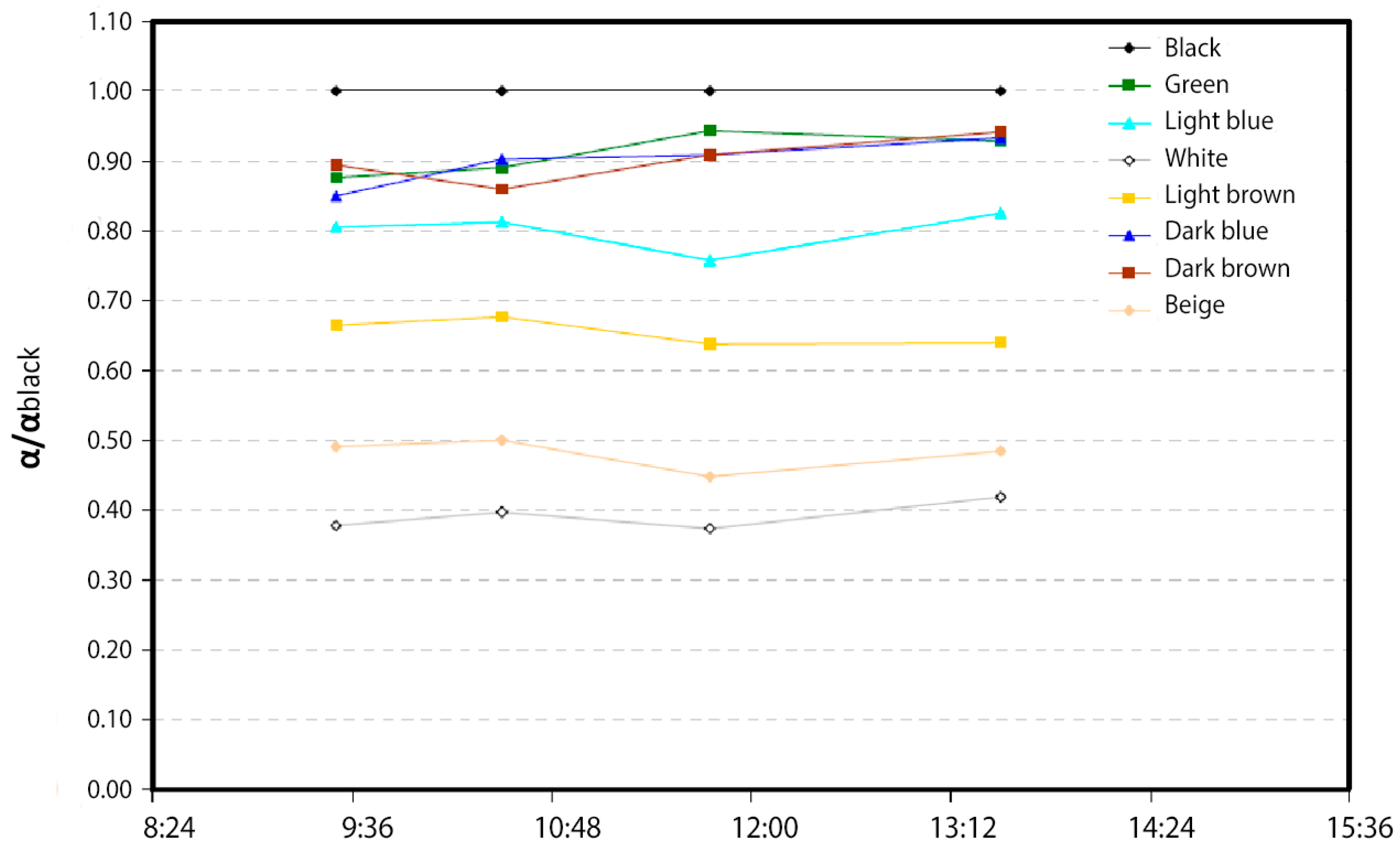

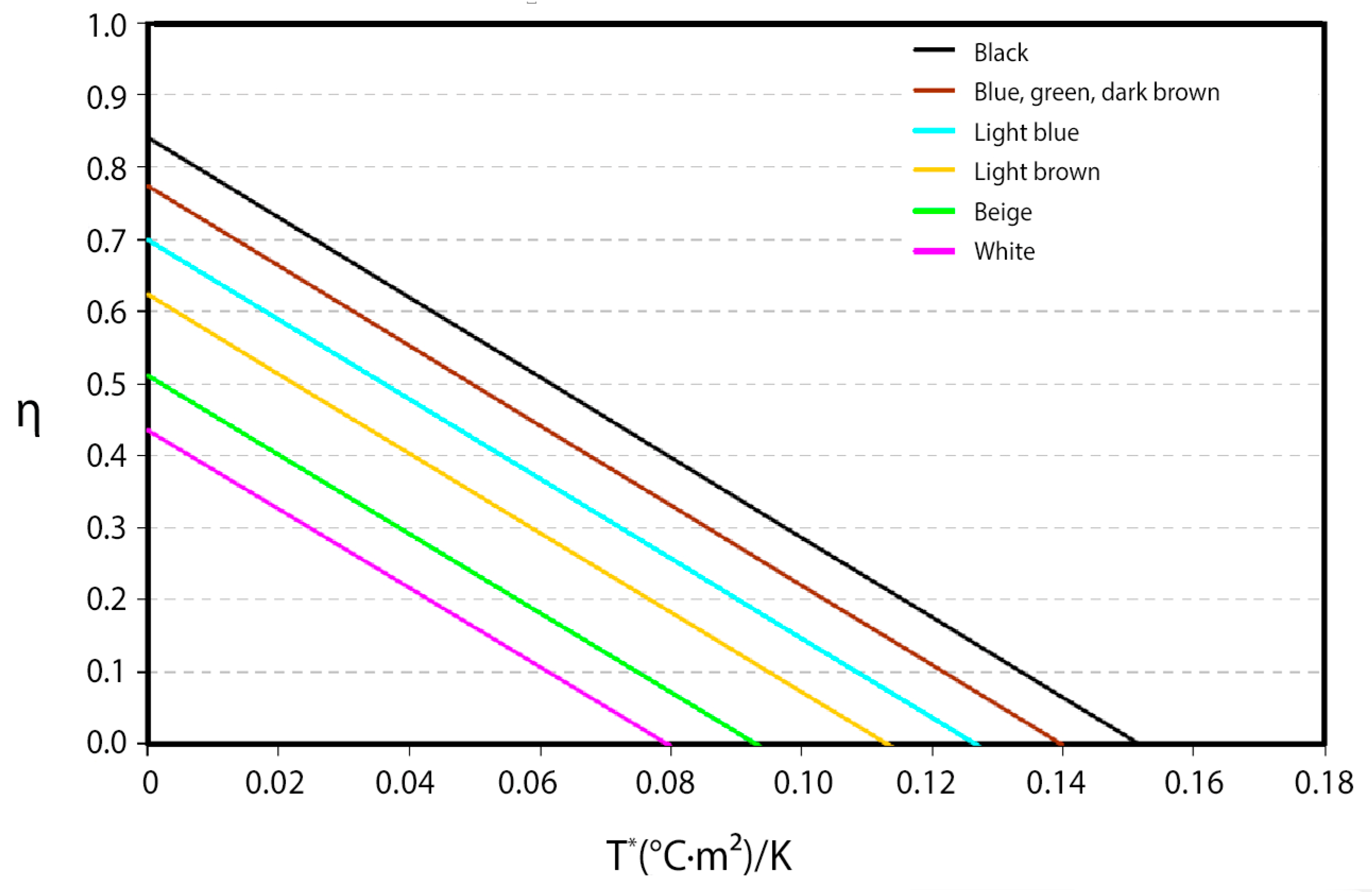

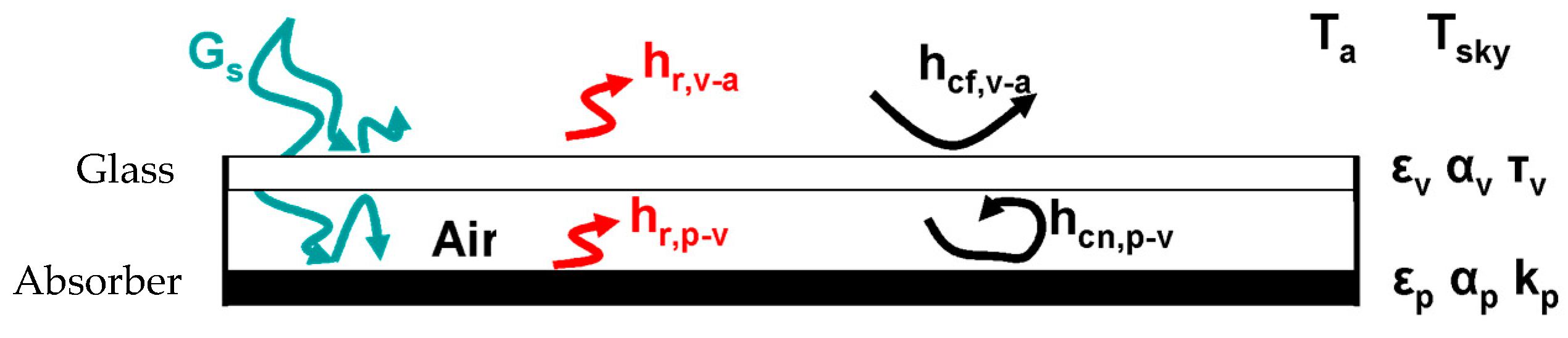

2.1. Ceramic Selection and Its Influence on Efficiency

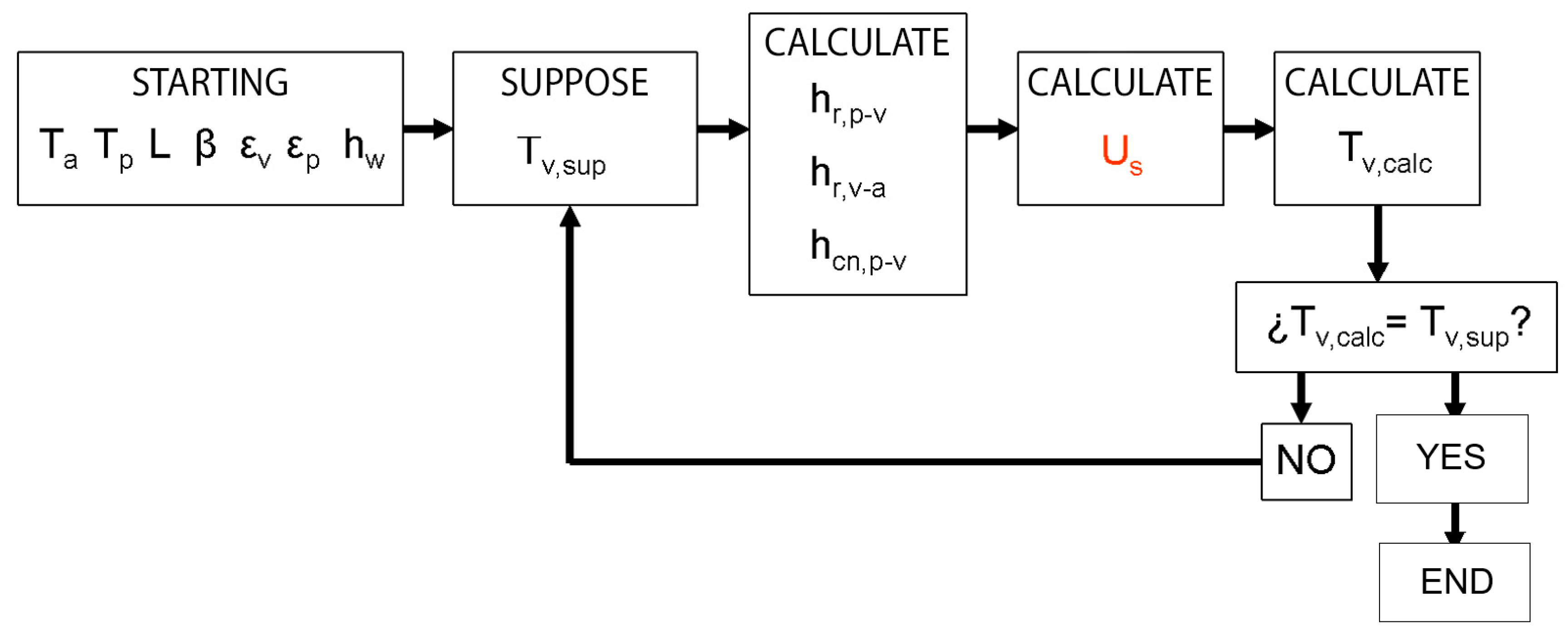

2.2. Definition of the Distance Between the Glass Plate and the Ceramic Absorber

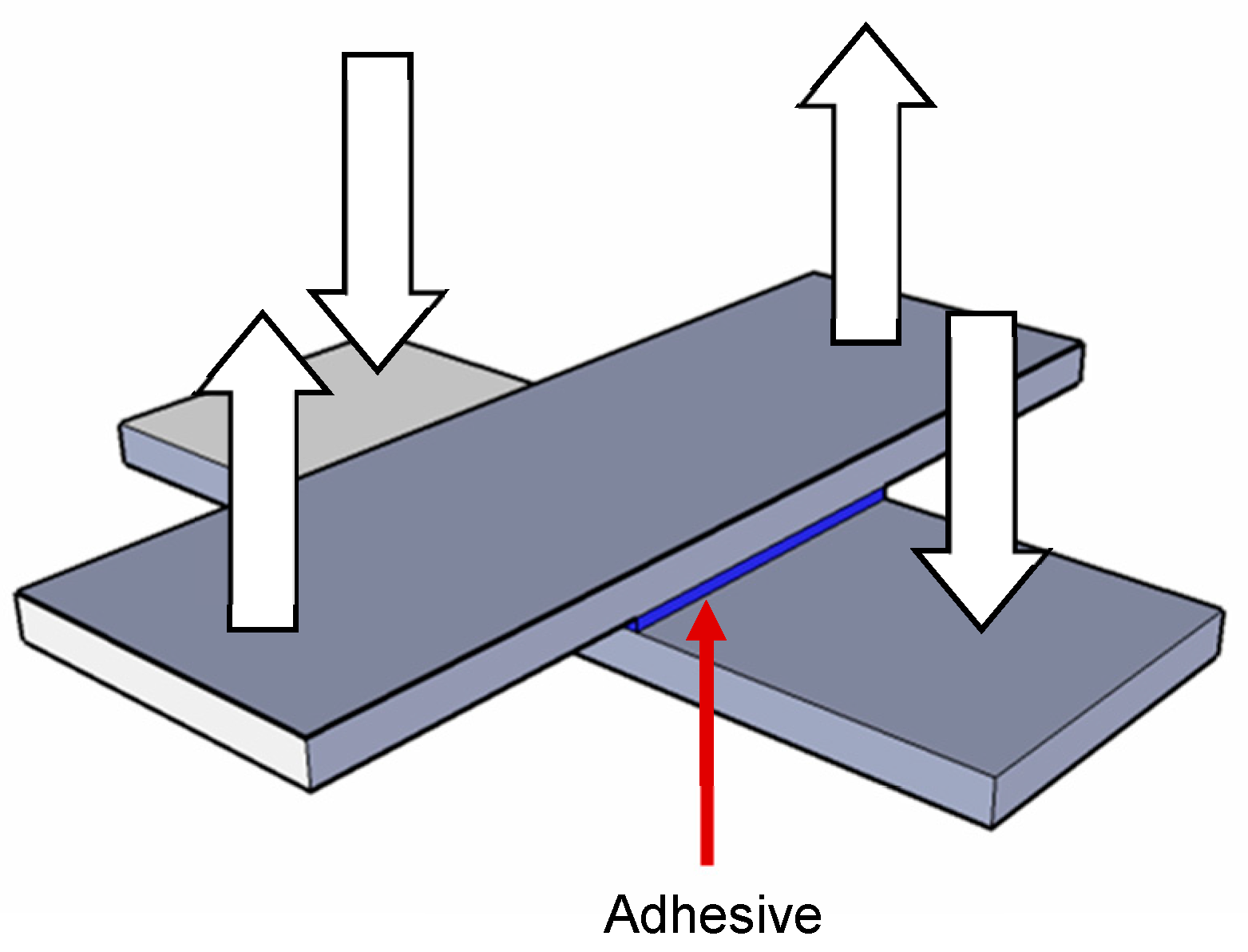

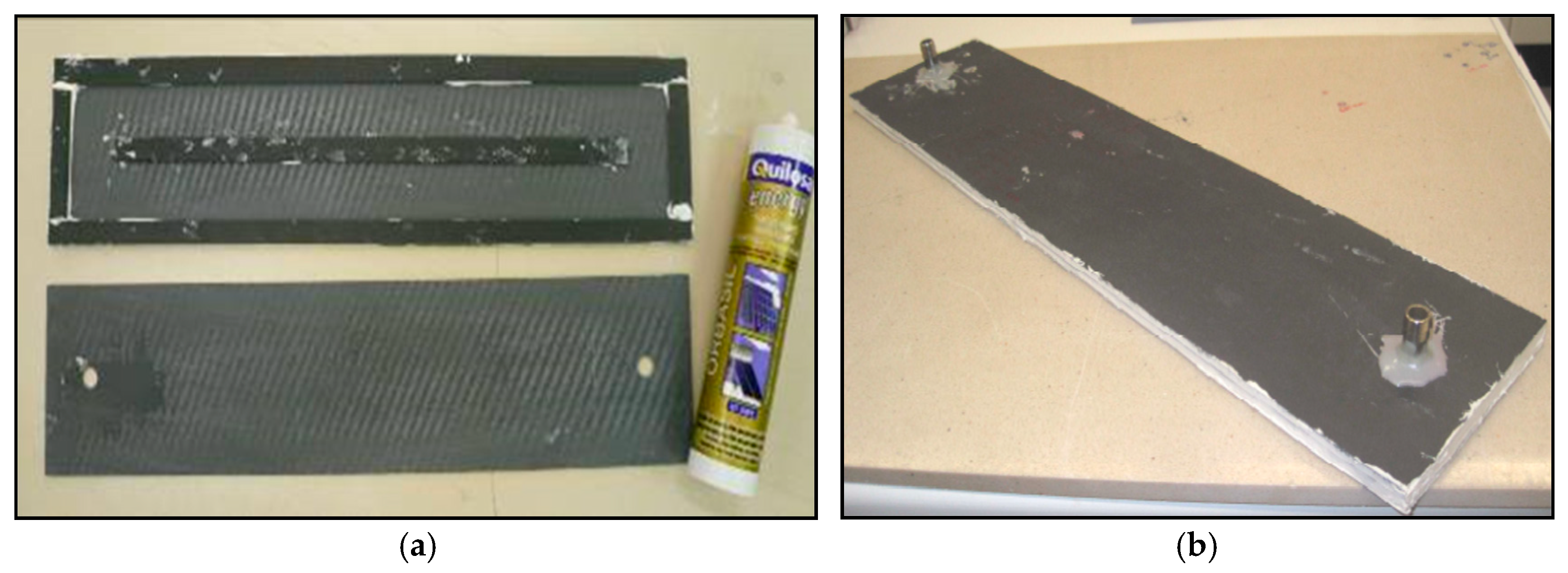

2.3. Selection and Use of Adhesives

3. Results and Discussion

3.1. Expansion and Tightness Tests

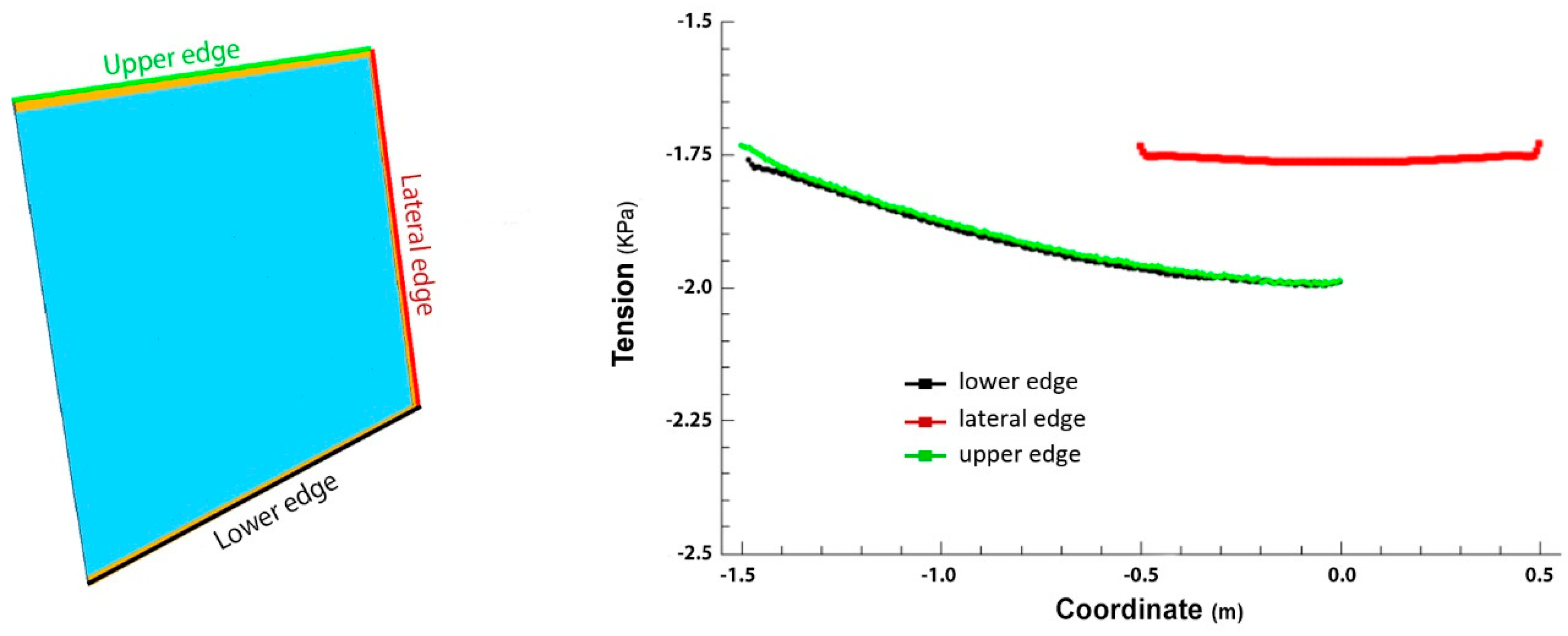

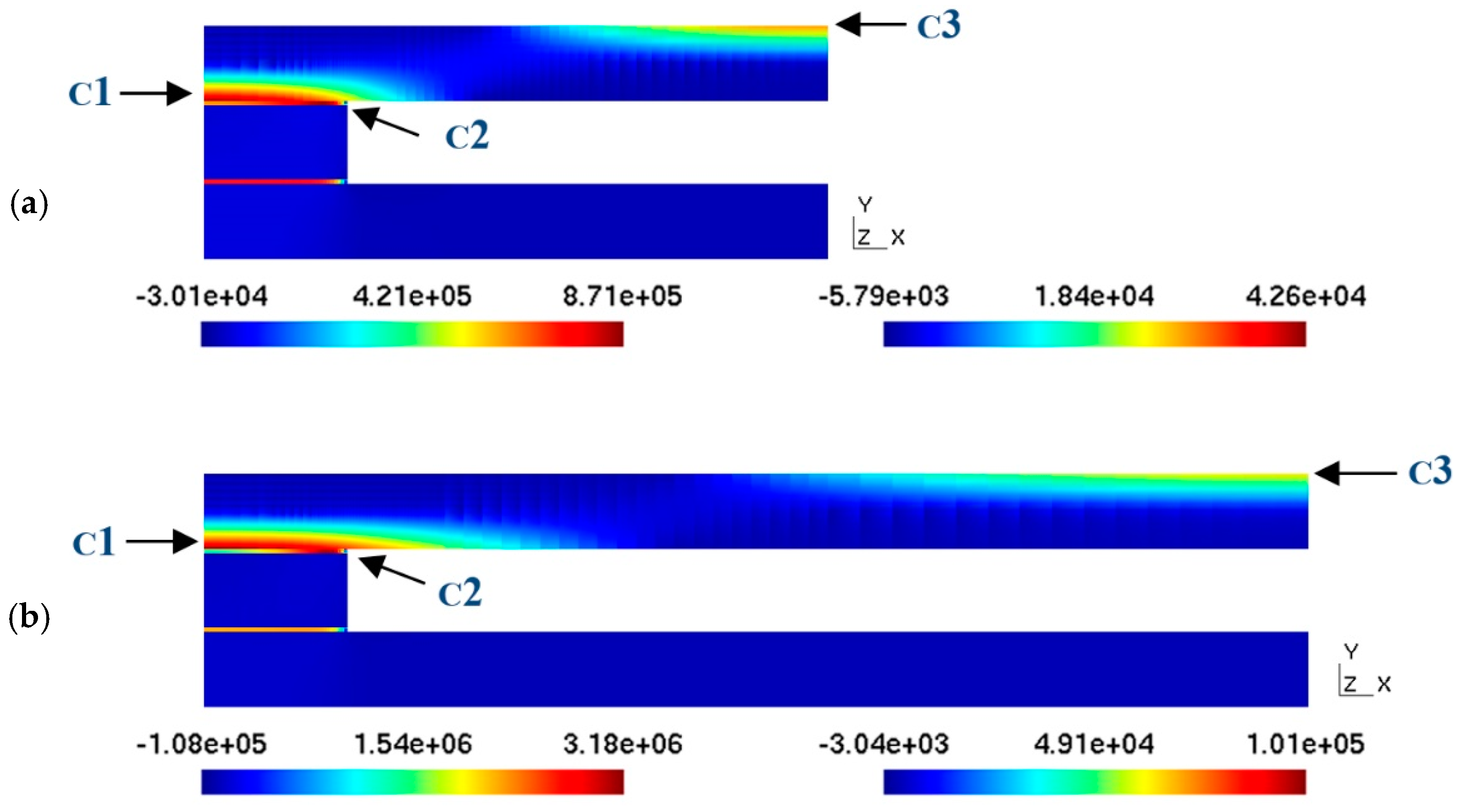

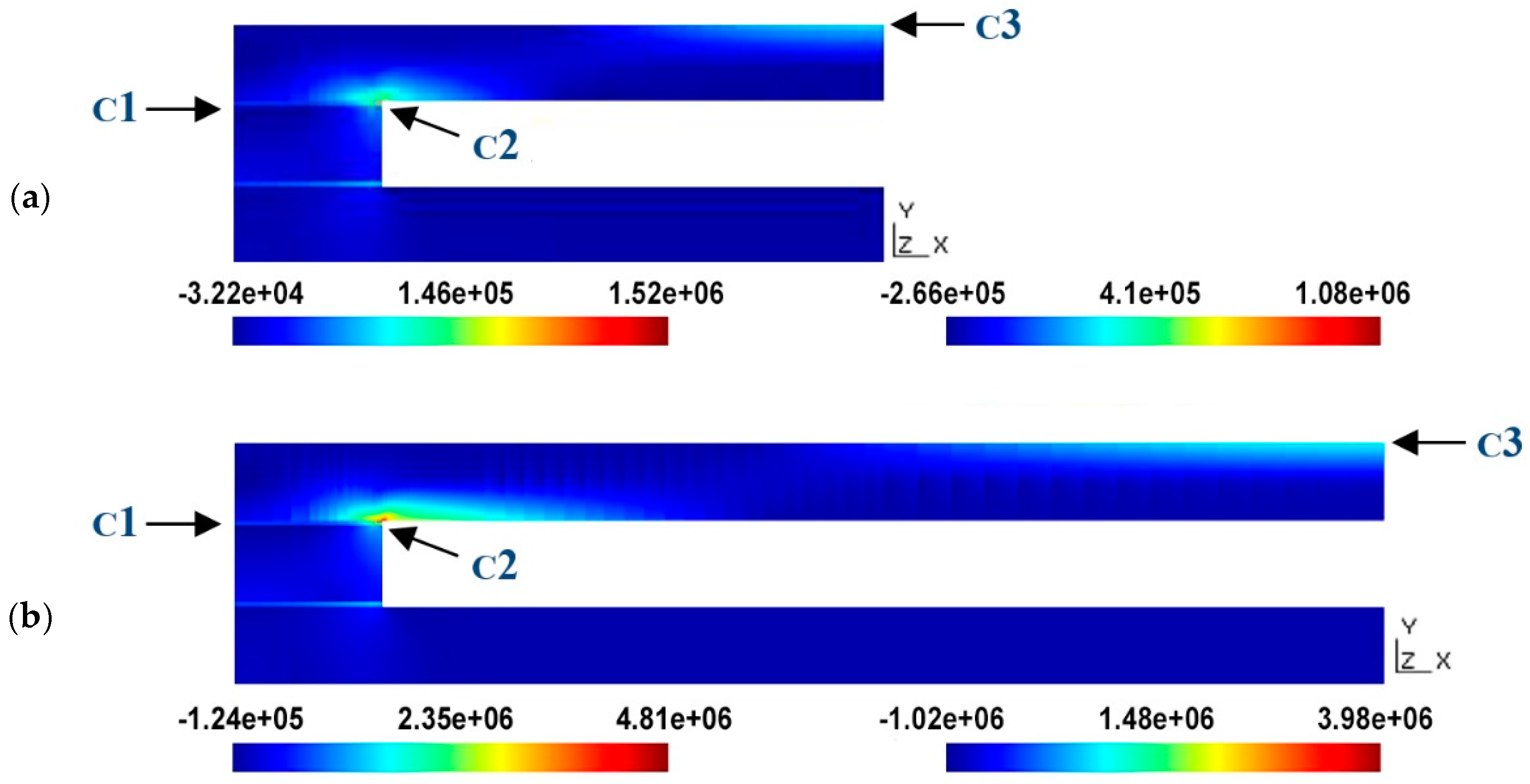

3.2. Pressure Resistance of the Collector

- ○

- the fluid pressure;

- ○

- the fluid temperature;

- ○

- the separation between the ceramic plates;

- ○

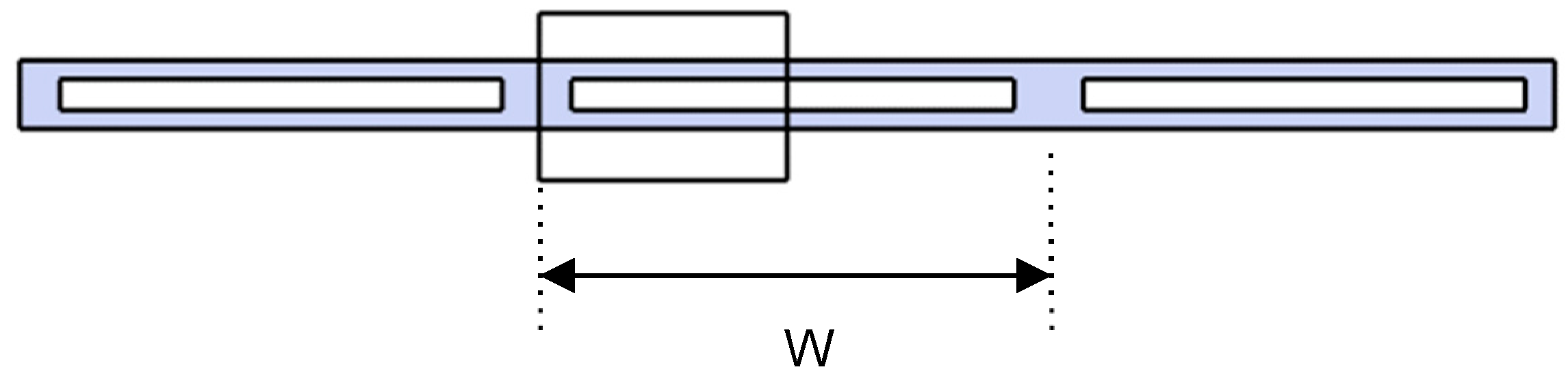

- the width of the channels through which the water circulates (w);

- ○

- the material properties (ceramic sheets, spacers, and adhesive).

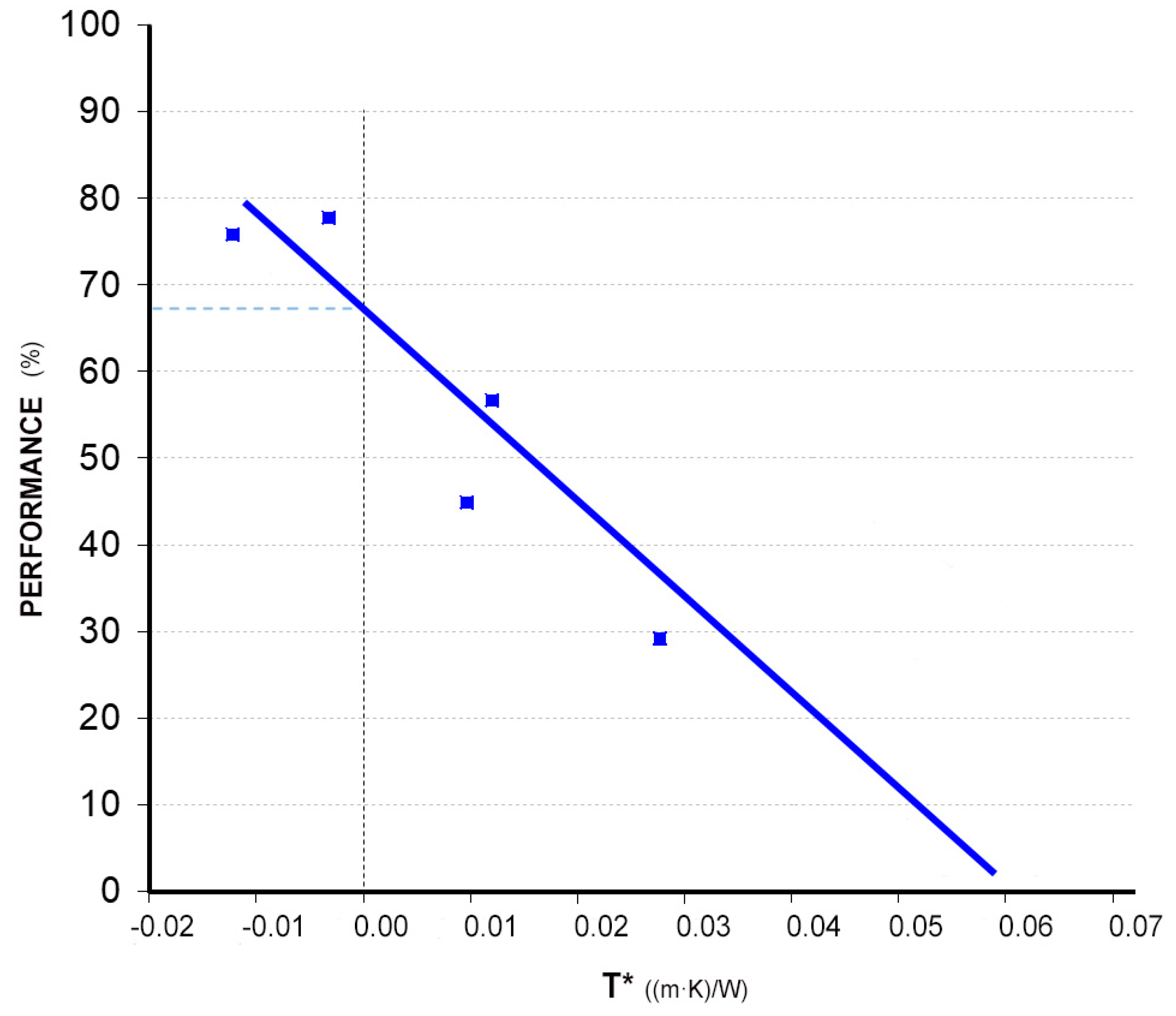

3.3. Characterization of the Ceramic Solar Collector

- ○

- The hemispheric solar irradiance at the collector opening’s plane is greater than 600 W/m2 prior to the test;

- ○

- The fluid flow rate is set at approximately 0.02 kilograms per second per square meter of the collector opening’s area and is kept constant throughout the test;

- ○

- The test can only be performed if the wind velocity does not exceed 4 m/s.

- The optical efficiency (η|T*=0): It is the value of the ordinate at the origin of the straight line and corresponds to the collector efficiency value when the T* parameter is equal to zero, i.e., the water inlet temperature is equal to the ambient temperature. This is the maximum efficiency that can be obtained with a collector. The higher it is, the better the thermal performance of the collector;

- The overall loss coefficient: It is the value of the slope of the characteristic curve and refers to the heat losses of the collector. The better insulated and designed a collector is, the lower the value of this parameter;

- The stagnation temperature (T*|η=0): This is the value of the parameter T* for which the collector efficiency is zero, i.e., the collector cannot raise the incoming water temperature for given ambient conditions. The higher the optical efficiency and/or the lower the overall loss coefficient is/are, the higher the value of this parameter.

4. Conclusions

- The first ceramic prototype without a glass cover has shown an excessively low performance so that to increase it, it is necessary to place a glass cover and its respective infrared trap in front of the collector. The tests carried out with the same prototype, but with a glass cover, continue to show a low performance, but they are sufficient, considering the low performance required in this project because of its suitability to the Mediterranean climate and large-surface application (roofs and façades);

- The influence of ceramics on the efficiency is first calculated by calculating the absorbances of various ceramic pieces of different colors. The values obtained confirm the possibility of using ceramics of darker colors, such as black, blue, green, and dark brown. Blue and light brown ceramics present an intermediate situation, being able to be used in areas of high solar radiation, and white and beige ceramics are totally discarded because of their excessively reduced performances;

- The optimal distance between the absorber plate and the glass (infrared trap) is defined as 10 mm;

- The adhesive selected from a total of six adhesives from three different manufacturers was Orbasil Energy from Quilosa. This adhesive, because of its good results in tests and its low cost, is the most suitable for bonding the different elements that make up the collector (ceramic–ceramic and glass–ceramic joints);

- The expansion and tightness tests verified that the prototypes, tested at different temperatures and pressures, did not show any leaks. Nor have cracks been observed because of thermal expansion;

- The pressure tests of the collector define a cavity width (the distance between separators, as measured from their axis through which the heat transfer fluid will circulate) of a 50 mm maximum (W = 50 mm);

- According to the thermal performance characterization of the ceramic collector, the results show that the characteristic curve falls within the typical range of those for commercial collectors (with 82% for the optimal commercial collector and 65% for the minimum commercial collector) and that its thermal performance is good.

5. Future Prospects

- Enhancing the integration of the collector’s envelope by eliminating the glass cover on the collector elements: This objective involves analyzing new material configurations and possibly incorporating new components to define a collector panel with a 100% ceramic exterior finish, without a glass cover, while maintaining or improving the achieved energy performance;

- Analyzing and assessing the final cost of the proposed system and its maintenance cost: This objective aims to develop a real production project for the system, bringing it as close as possible to actual manufacturing and installation conditions for the collector panel in a building’s envelope. This would provide a more accurate and realistic cost per square meter (including production and installation costs);

- Studying solutions for the increasing use of flat and walkable roofs in construction: It is necessary to explore the possibility of designing a ceramic collector that can be installed as a flooring system for a flat and accessible roof. This application would likely require modifications in the material configuration, fastening system, and connection methods.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Government of Spain, Ministry for the Ecological Transition and the Demographic Challenge. Energy in Spain; MITECO: Madrid, Spain, 2020. [Google Scholar]

- IEA. Clean Energy Market Monitor. 2024. Available online: https://www.iea.org/reports/clean-energy-market-monitor-march-2024 (accessed on 12 December 2024).

- European Commission. Energy, Transport and Environment Indicators. Eurostat. 2022. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Air_transport_statistics (accessed on 18 July 2024).

- United Actions. COP28. Available online: https://www.un.org/es/climatechange/cop28 (accessed on 11 October 2024).

- Karamanis, D.; Liu, H.-Y.; Skandalos, N.; Makis, A.; Kapsalis, V.; D’Agostino, D.; Maduta, C.; Tolis, A.; Trandafir, S.; Parker, P. Transitioning to building integration of photovoltaics and greenery (BIPVGREEN): Case studies up-scaling from cities informal settlements. Environ. Res. Infrastruct. Sustain. 2024, 4, 042001. [Google Scholar] [CrossRef]

- Borrallo-Jiménez, M.; Lopez De Asiain, M.; Esquivias, P.M.; Delgado-Trujillo, D. Comparative study between the Passive House Standard in warm climates and Nearly Zero Energy Buildings under Spanish Technical Building Code in a dwelling design in Seville. Energy Build. 2022, 254, 111570. [Google Scholar] [CrossRef]

- European Commission. Directive 2010/31/EU of European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings (Recast). Off. J. Eur. Union 2010, L153, 13–35. Available online: http://data.europa.eu/eli/dir/2010/31/oj (accessed on 11 April 2024).

- European Commission. Directive 2002/91/EC of the European Parliament and of the Council of 16 December 2002 on the Energy Performance of Buildings. Off. J. Eur. Commun. 2003, L1, 65–70. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2003:001:0065:0071:EN:PDF (accessed on 16 April 2024).

- European Commission. The Energy Efficiency of Buildings. Brussels. 2020. Available online: https://commission.europa.eu/news/focus-energy-efficiency-buildings-2020-02-17_en (accessed on 10 April 2024).

- European Commission. Directive 2012/27/EU of European Parliament and of the Council of 25 October 2012 on Energy Efficiency, Amending Directive 2009/125/EC and 2010/30/EU and Repealing Directives 2004/8/EC and 2006/32/EC. Off. J. Eur. Union 2012, L315, 1–56. Available online: https://eur-lex.europa.eu/eli/dir/2012/27/oj/eng (accessed on 10 April 2024).

- Olasolo-Alonso, P.; López-Ochoa, L.-M.; Las-Heras-Casas, J.; López-González, L.-M. Energy Performance of Buildings Directive Implementation in Southern European Countries: A Review. Energy Build. 2023, 281, 112751. [Google Scholar] [CrossRef]

- Technical Building Code (CTE). Basic Document on Energy Savings DB-HE; Spanish Ministry of Housing: Madrid, Spain, 2022; Available online: https://www.codigotecnico.org/pdf/Documentos/HE/DBHE.html (accessed on 11 April 2024).

- National Integrated Energy and Climate Plan 2021–2030. 2019. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/es_final_necp_main_en.pdf (accessed on 10 May 2024).

- Maduta, C.; Melica, G.; D’Agostino, D.; Bertoldi, P. Towards a Decarbonised Building Stock by 2050: The Meaning and the Role of Zero Emission Buildings (ZEBs) in Europe. Energy Strategy Rev. 2022, 44, 101009. [Google Scholar] [CrossRef]

- Golić, K.; Kosorić, V.; Krstić Furundžić, A. General Model of Solar Water Heating System Integration in Residential Building refurbishment: Potential Energy Savings and Environmental Impact. Renew. Sustain. Energy Rev. 2011, 153, 1533–1544. [Google Scholar] [CrossRef]

- Tsalikis, G.; Martinopoulos, G. Solar Energy Systems Potential for Nearly Net Zero Energy Residential Buildings. Sol. Energy 2015, 115, 743–756. [Google Scholar] [CrossRef]

- Colclough, S.; McGrath, T. Net Energy Analysis of a Solar Combi System with Seasonal Thermal Energy Store. Appl. Energy 2015, 147, 611–616. [Google Scholar] [CrossRef]

- Cao, S.; Hasan, A.; Sirén, K. Matching Analysis for on-Site Hybrid Renewable Energy Systems of Office Buildings with Extended Indices. Appl. Energy 2014, 113, 230–247. [Google Scholar] [CrossRef]

- Yau, Y.H.; Lim, K.S. Energy Analysis of Green Office Buildings in the tropics-Photovoltaic System. Energy Build. 2016, 126, 177–193. [Google Scholar] [CrossRef]

- Solar Heating and Cooling Programme of the International Energy Agency (SHC). Solar Heat Worlwide, 2024 ed.; IEA: Paris, France, 2024. [Google Scholar]

- Solar Heat Europe (ESTIF). Decarbonising Heat with Solar Thermal—Market Outlook 2022/2023; ESTIF: Brussels, Belgium, 2023. [Google Scholar]

- Vahidhosseini, S.M.; Rashidi, S.; Hsu, S.H.; Yan, W.M.; Rashidi, A. Integration of Solar Thermal Collectors and Heat Pumps with Thermal Energy Storage Systems for Building Energy Demand Reduction: A Comprehensive Review. J. Energy Storage 2024, 95, 112568. [Google Scholar] [CrossRef]

- Bock, M. A Building Integrated Solar Thermal Collector with Active Steel Skins. Energy Build. 2019, 201, 134–147. [Google Scholar] [CrossRef]

- Galione, P. Altas Temperaturas y Presiones en Sistemas Solares Térmicos: Estancamiento; Informe Técnico Facultad de Ingeniería UDELAR: Montevideo, Uruguay, 2022. [Google Scholar]

- Prieto, J.; García, D. Global Solar Radiation Models: A Critical Review from the Point of View of Homogeneity and Case Study. Renew. Sustain. Energy Rev. 2022, 155, 111856. [Google Scholar] [CrossRef]

- Instituto para La Diversificación y Ahorro de la Energía (IDAE) y la Asociación Solar de la Industria Térmica (ASIT). Guía Técnica de Energía Solar Térmica; IDAE/ASIT: Madrid, Spain, 2022. [Google Scholar]

- Cruz-Peragon, F.; Palomar, J.M.; Casanova, P.J.; Dorado, M.P.; Manzano-Agugliaro, F. Characterization of Solar Flat Plate Collectors. Renew. Sustain. Energy Rev. 2012, 163, 1709–1720. [Google Scholar] [CrossRef]

- Srinivasan, K.N.; Shanmugam, N.V.; Selvam, M.; John, S.; Shenoi, B.A. Nickel-Black Solar Absorber Coatings. Energy Convers. Manag. 1984, 244, 255–258. [Google Scholar] [CrossRef]

- Shanker, K.; Holloway, P.H. Electrodeposition of Black Chrome Selective Solar Absorber Coatings with Improved Thermal Stability. Thin Solid Film. 1985, 1273, 181–189. [Google Scholar] [CrossRef]

- Vince, J.; Šurca Vuk, A.; Opara Krašovec, U.; Orel, B.; Köhl, M.; Heck, M. Solar Absorber Coatings Based on CoCuMnOx Spinels Prepared Via the Sol-gel Process: Structural and Optical Properties. Sol. Energy Mater. Sol. Cells 2003, 793, 313–330. [Google Scholar] [CrossRef]

- Xiao, X.; Miao, L.; Xu, G.; Lu, L.; Su, Z.; Wang, N.; Tanemura, S. A Facile Process to Prepare Copper Oxide Thin Films as Solar Selective Absorbers. Appl. Surf. Sci. 2011, 25724, 10729–10736. [Google Scholar] [CrossRef]

- Roro, K.T.; Tile, N.; Forbes, A. Preparation and Characterization of Carbon/Nickel Oxide Nanocomposite Coatings for Solar Absorber Applications. Appl. Surf. Sci. 2012, 25818, 7174–7180. [Google Scholar] [CrossRef]

- Isravel, R.S.; Saravanan, S.; Vijayan, V. A Review of Material and Coatings in Solar Collectors. Mater. Today Proc. 2020, 21, 497–499. [Google Scholar] [CrossRef]

- Liu, W.; Liu, X.; Pan, C.; Li, C.; Lau, W.; Lyu, Y. Potential application of a novel building-integrated solar facade water heating system in a subtropical climate: A case study for school canteen. Build. Simul. 2023, 16, 1987–2004. [Google Scholar] [CrossRef]

- Roviras, J.; Sarrablo, V.; Armengou, J.; Casanova, M. Architectural integration of ceramic solar thermal collectors for Mediterranean climate. Inf. Construcción Ceram. Innov. 2016, 68, 43–56. [Google Scholar]

- McCormick, P.G.; Suehrcke, H. The Effect of Intermittent Solar Radiation on the Performance of PV Systems. Sol. Energy 2018, 171, 667–674. [Google Scholar] [CrossRef]

- Liu, W.; Jin, X.; Chow, T.; Pan, C.; Lau, W. Sensitivity Study of Heat-Pipe-Ring Embedded Building Façade for Solar Absorption. Energy Build. 2023, 288, 113023. [Google Scholar] [CrossRef]

- Roviras Miñana, J.; Sarrablo Moreno, V. Design of a New Solar Thermal Collector with Ceramic Materials Integrated into the Building Facades. Designs 2018, 2, 44. [Google Scholar] [CrossRef]

- Energie Solaire. Documentation Technique Capteurs Solaires AS: Toiture Solaire AS. 2024. Available online: https://www.energie-solaire.com/doctec-capteursas (accessed on 15 January 2025).

- Juanicó, L.E. New Design of Solar Roof for Household Heating and Cooling. Int. J. Hydrogen Energy 2010, 35, 5823–5826. [Google Scholar] [CrossRef]

- Juanicó, L.E. A new design of roof-integrated water solar collector for domestic heating and cooling. Sol. Energy 2008, 82, 481–492. [Google Scholar] [CrossRef]

- Cupa Group’s Thermoslate. The Only Solar Collector Made of Natural Slate That Allows Generating Energy for Air Conditioning and Domestic Hot Water 2024. Available online: https://www.cupapizarras.com/es/thermoslate/ (accessed on 15 December 2024).

- SolTech Energy Mediterráneo. El Techo Solar. Available online: https://soltechenergy.wordpress.com/ (accessed on 15 October 2024).

- Eternit. Solar Force. Technical Catalogue of Solar Force System. 2023. Available online: https://media.eternit.world/pd45429/original/1487976259/euronit---pv-panel-roof-guideline_010623_eng.pdf (accessed on 15 October 2024).

- Tulyaganov, D.U.; Alves, M.F.; Dimitriadis, K.; Murtazaev, S.; Agathopoulos, S.; Fernandes, H.R. Fundamentals and Advances in Production and Application of Non-Stoichiometric Lithium Disilicate Glass-Ceramics: A Brief Review. Ceram. Int. 2025. [CrossRef]

- Wang, X.; Zou, B.; Li, L.; Xing, H.; Huang, C.; Wang, Y.; Shi, Z.; Liu, J.; Yao, P.; Xue, K. Manufacturing of a Ceramic Groove Part Based on Additive and Subtractive Technologies. Ceram. Int. 2021, 471, 740–747. [Google Scholar] [CrossRef]

- Sun, H.; Zou, B.; Wang, X.; Chen, W.; Zhang, G.; Quan, T.; Huang, C. Advancements in Multi-Material Additive Manufacturing of Advanced Ceramics: A Review of Strategies, Techniques and Equipment. Mater. Chem. Phys. 2024, 319, 129337. [Google Scholar] [CrossRef]

- Coverlam (Grespania). Syntehrized Stone. 2025. Available online: https://www.coverlambygrespania.com/en/ (accessed on 25 May 2024).

- Yang, Y.; Wang, Q.; Xiu, D.; Zhao, Z.; Sun, Q. A Building Integrated Solar Collector: All-Ceramic Solar Collector. Energy Build. 2013, 62, 15–17. [Google Scholar] [CrossRef]

- Sun, X.Y.; Sun, X.D.; Li, X.G.; Wang, Z.Q.; He, J.; Wang, B.S. Performance and Building Integration of all-Ceramic Solar Collectors. Energy Build. 2014, 75, 176–180. [Google Scholar] [CrossRef]

- Munari Probst, M.C.; Roecker, C. Towards an improved architectural quality of building-integrated solar thermal systems (BIST). Sol. Energy 2007, 81, 1104–1116. [Google Scholar] [CrossRef]

- Munari Probst, M.C.; Roecker, C. Architectural Integration and Design of Solar Thermal Systems; EPFL Press: Lausanne, Switzerland, 2011. [Google Scholar]

- Georgiou, L.; Souliotis, M.; Leontiou, T.; Šadauskienė, J.; Vaičiūnas, J.; Papaefthimiou, S.; Fokaides, P.A. Numerical investigation of building integrated solar thermal collectors under diverse conditions. Int. J. Sustain. Energy 2023, 42, 1042–1062. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Q.; Yao, W.; Zhang, W.; Cao, J.; He, H. Research on Temperature Distribution Characteristics and Energy Saving Potential of Wall Implanted with Heat Pipes in Heating Season. Renew. Energy 2022, 195, 1037–1049. [Google Scholar] [CrossRef]

- Neolith Gallery. 2025. Available online: https://a.storyblok.com/f/150360/x/dcb0591c8e/neolith_gallery.pdf (accessed on 22 November 2024).

- UNE-EN ISO 10545; Ceramic Tiles—Test Methods. Asociación Española de Normalización: Madrid, Spain, 1995; multiple parts.

- European Commission. Commission Implementing Decision (EU) 2016/364 of 1 March 2016 on the Identification of the European List of Harmonised Standards for Construction Products in Support of Regulation (EU) No 305/2011 of the European Parliament and of the Council; Official Journal of the European Union: Brussels, Belgium, 15 March 2016; Volume L68, pp. 4–52. [Google Scholar]

- EN 13501-1:2019; Fire Classification of Construction Products and Building Elements—Part 1: Classification Using Data from Reaction to Fire Tests. European Committee for Standardization: Brussels, Belgium, 2019.

- ISO 11341:2004; Paints and Varnishes—Artificial Weathering and Exposure to Artificial Radiation—Exposure to Filtered Xenon-Arc Radiation. International Organization for Standardization: Geneva, Switzerland, 2004.

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 4th ed.; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Incropera, F.P.; DeWitt, D.P. Fundamentals of Heat and Mass Transfer, 7th ed.; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Sika. Construction Adhesives. 2025. Available online: https://www.sika.com/en/construction/construction-adhesives.html (accessed on 5 June 2024).

- Quilosa. Adhesives. 2025. Available online: https://quilosa.com/en/family/adhesives/ (accessed on 5 June 2024).

- 3M. Adhesives. 2025. Available online: https://www.3m.com/3M/en_US/p/c/adhesives/ (accessed on 5 June 2024).

- Bostik. Global Adhesive Solutions. 2025. Available online: https://www.bostik.com/global/en/ (accessed on 5 June 2024).

- Bohle. Official Website. 2025. Available online: https://www.bohle.com/ (accessed on 5 June 2024).

- UNE-EN 12975-2006; Thermal Solar Systems and Components. Solar Collectors. Part 2: Test Methods. Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2006.

| Basic Requirements | Standard | Essential Characteristics | UD |

|---|---|---|---|

| Flexural strength and breaking load | UNE EN ISO 10545-4 [56] | Mean flexural strength | ≥45 N/mn2 |

| Breaking load | ≥13,000 N | ||

| Water absorption, open porosity, and densities | UNE EN ISO 10545-3 [56] | Water absorption by boiling | 0.10% |

| Water absorption by vacuum | 0.10% | ||

| Apparent relative density | ≥2.4 g/cm3 | ||

| Relative density | ≥2.4 g/cm3 | ||

| Impact resistance determination | UNE EN ISO 10545-5 [56] | Mean restitution coefficient | ≥0.85 |

| Linear thermal expansion determination | UNE EN ISO 10545-8 [56] | Expansion between 30 and 100 °C | ≤6.5 × 10−6 |

| Fire safety | (UE) 2016/364 [57] y EN 13501-1 [58] | Reaction to fire | Class A1 |

| UV radiation stability | ISO 11341:2004 [59] | ΔΕ* < 1 | ≤5000 h |

| Color | Black | Green | Dark Blue | Dark Brown | Light Blue | Light Brown | Beige | White |

|---|---|---|---|---|---|---|---|---|

| α/αblack | 1.00 | 0.91 | 0.90 | 0.90 | 0.80 | 0.65 | 0.48 | 0.39 |

| Brand | Trade Name | Type | RT,tab (MPa) | RT,exp (MPa) |

|---|---|---|---|---|

| Sika | Sikaflex-252 | Single-component polyurethane | ~4.00 | 1.71 ± 0.84 |

| Quilosa | Orbasil Energy | Neutral silicone | 1.70 | 0.54 ± 0.06 |

| Quilosa | Orbasil Structural | Structural neutral silicone | 2.36 | 0.56 ± 0.05 |

| 3M | SC 6151 | Structural acetoxy silicone | - | 0.63 ± 0.09 |

| Material | Young’s Modulus (GPa) | Poisson’s Ratio | Density (kg/m3) |

|---|---|---|---|

| Glass | 60 | 0.23 | 2500 |

| Adhesive | 0.001 | 0.48 | 1400 |

| Brand | Trade Name | Price (Euros per 330 mL Cartridge) |

|---|---|---|

| Sika | Sikaflex-252 | 13.00 |

| Quilosa | Orbasil Energy | 8.00 |

| Quilosa | Orbasil Structural | 12.00 |

| 3M | SC 6151 | 19.10 |

| 3M | DP-190 | 96.70 |

| 3M | DP-610 | 101.60 |

| Assay | Pressure (bar) | Temperature (°C) | Heat Transfer Fluid | Glass |

|---|---|---|---|---|

| 1 | 0.1 | 60 | Water | No |

| 2 | 0.1 | 95 | Water | No |

| 3 | 0.2 | 60 | Water | No |

| 4 | 0.3 | 95 | Water | No |

| 5 | 0.5 | 95 | Water | No |

| 6 | 0.5 | 95 | Water | Yes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roviras Miñana, J.; Sarrablo Moreno, V. The Role of Ceramics in the Configuration of a New Solar Thermal Collection System for Domestic Hot Water and Heating. Materials 2025, 18, 1907. https://doi.org/10.3390/ma18091907

Roviras Miñana J, Sarrablo Moreno V. The Role of Ceramics in the Configuration of a New Solar Thermal Collection System for Domestic Hot Water and Heating. Materials. 2025; 18(9):1907. https://doi.org/10.3390/ma18091907

Chicago/Turabian StyleRoviras Miñana, Jordi, and Vicente Sarrablo Moreno. 2025. "The Role of Ceramics in the Configuration of a New Solar Thermal Collection System for Domestic Hot Water and Heating" Materials 18, no. 9: 1907. https://doi.org/10.3390/ma18091907

APA StyleRoviras Miñana, J., & Sarrablo Moreno, V. (2025). The Role of Ceramics in the Configuration of a New Solar Thermal Collection System for Domestic Hot Water and Heating. Materials, 18(9), 1907. https://doi.org/10.3390/ma18091907