Bayesian Updating of Fatigue Crack Growth Parameters for Failure Prognosis of Miter Gates

Abstract

1. Introduction

2. Materials and Methods

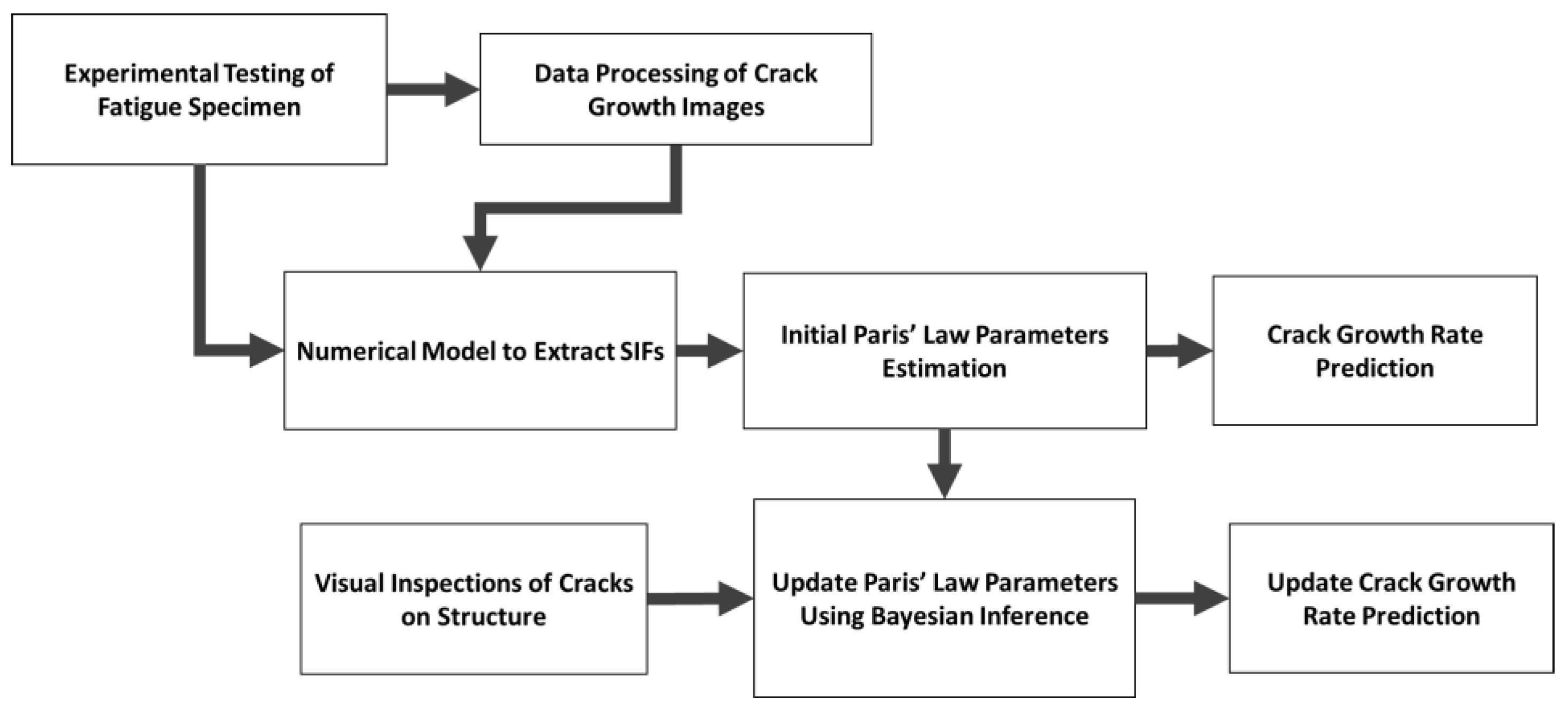

2.1. Methodology

2.1.1. Determination of Paris’ Law Parameters

2.1.2. Updating of Paris’ Law Parameters

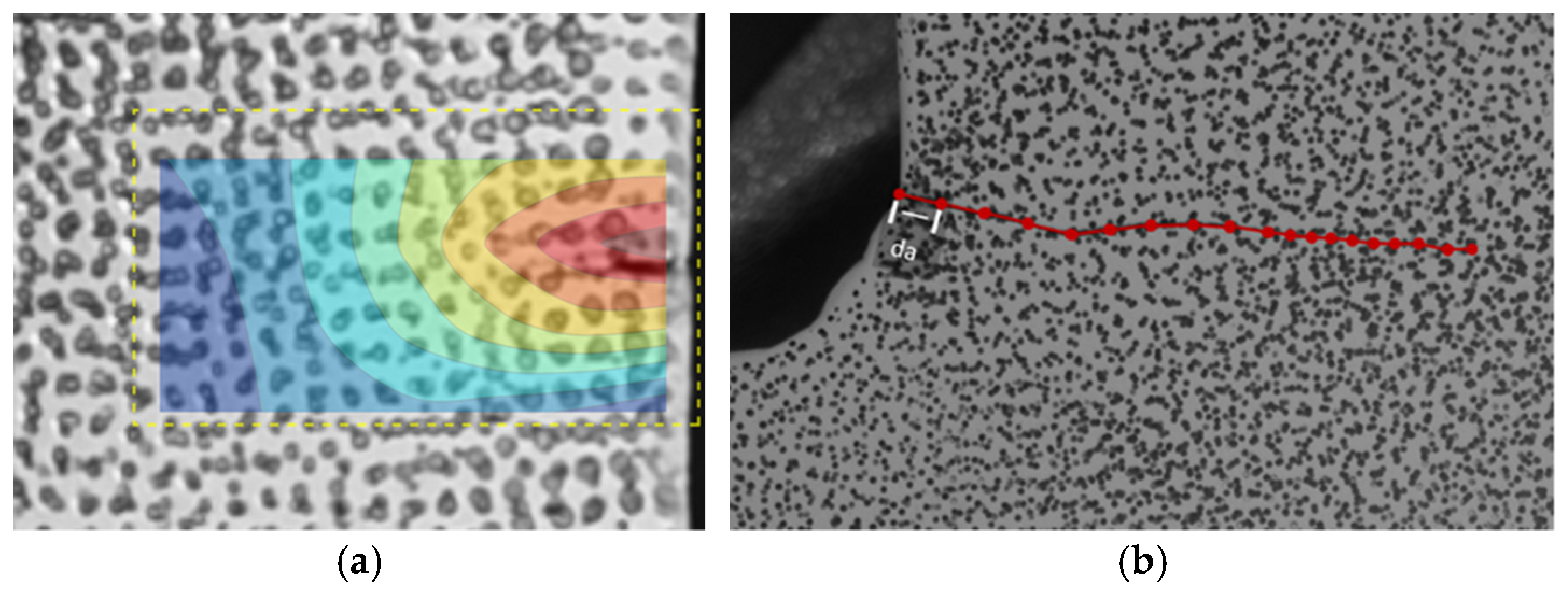

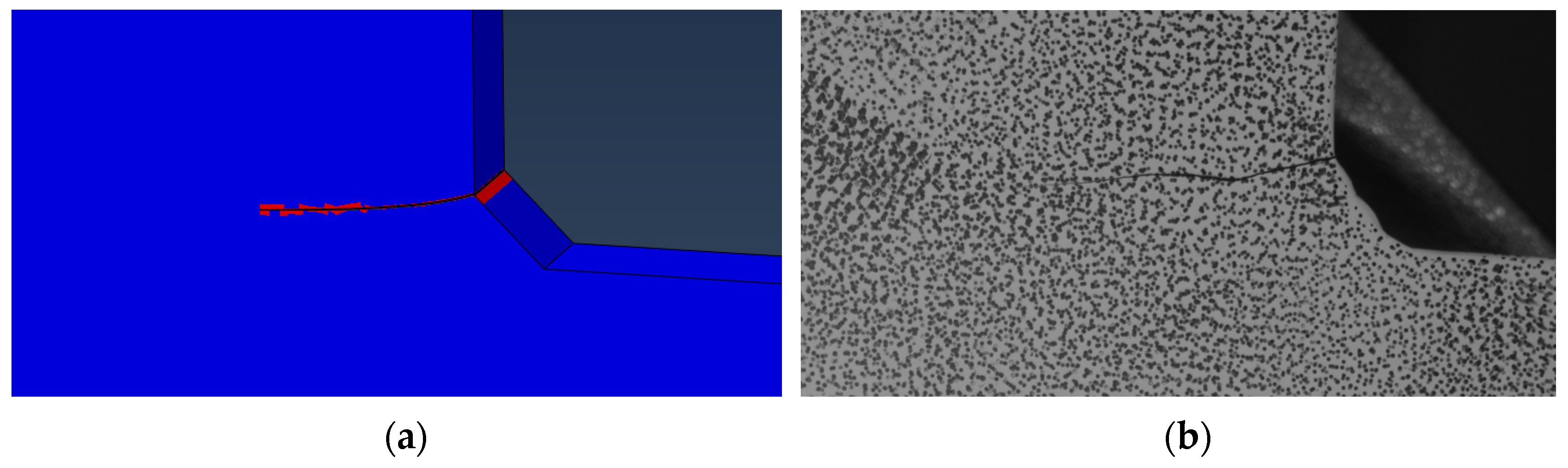

2.1.3. Finding Through Laboratory Testing and Digital Image Correlation (DIC)

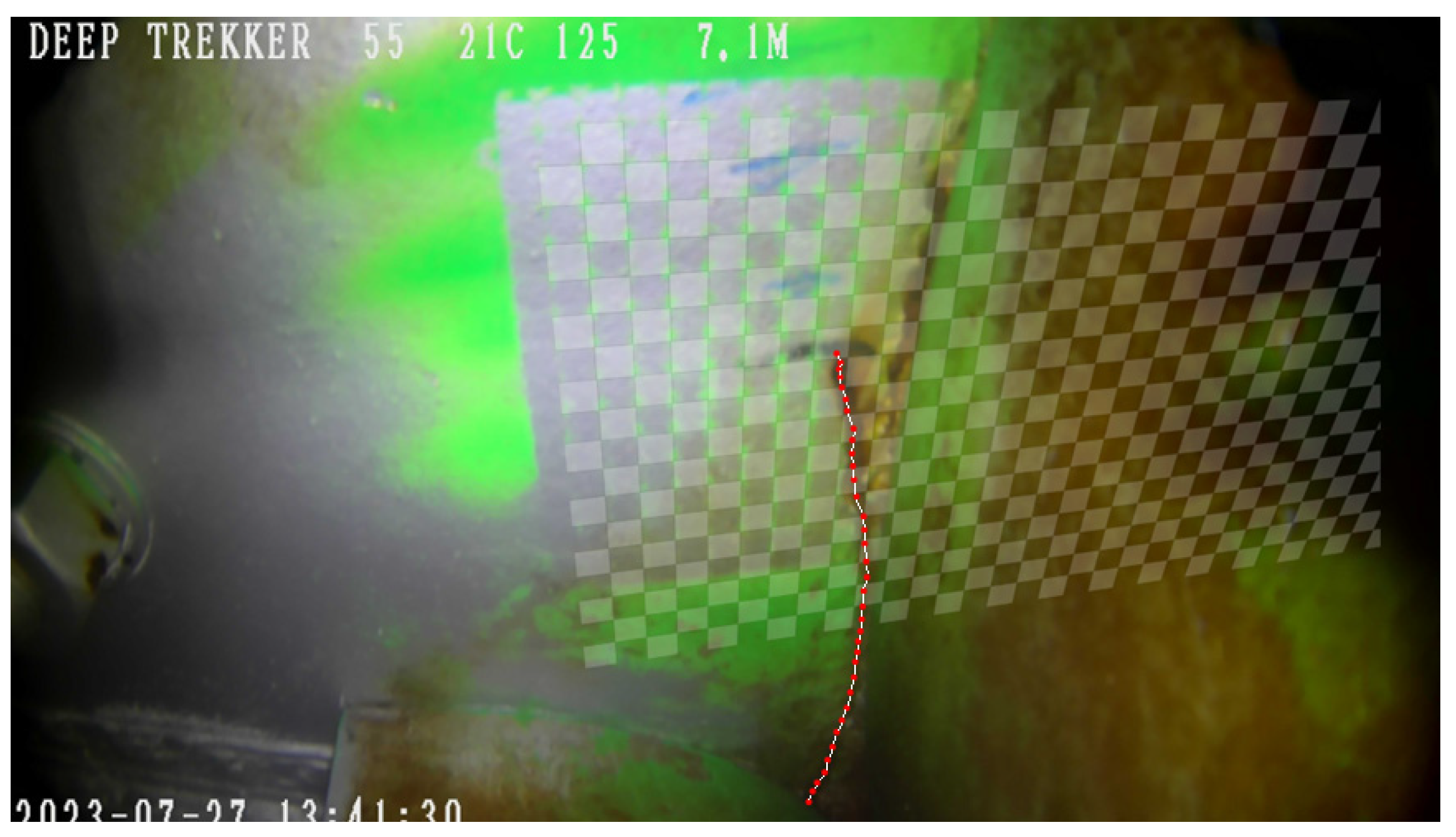

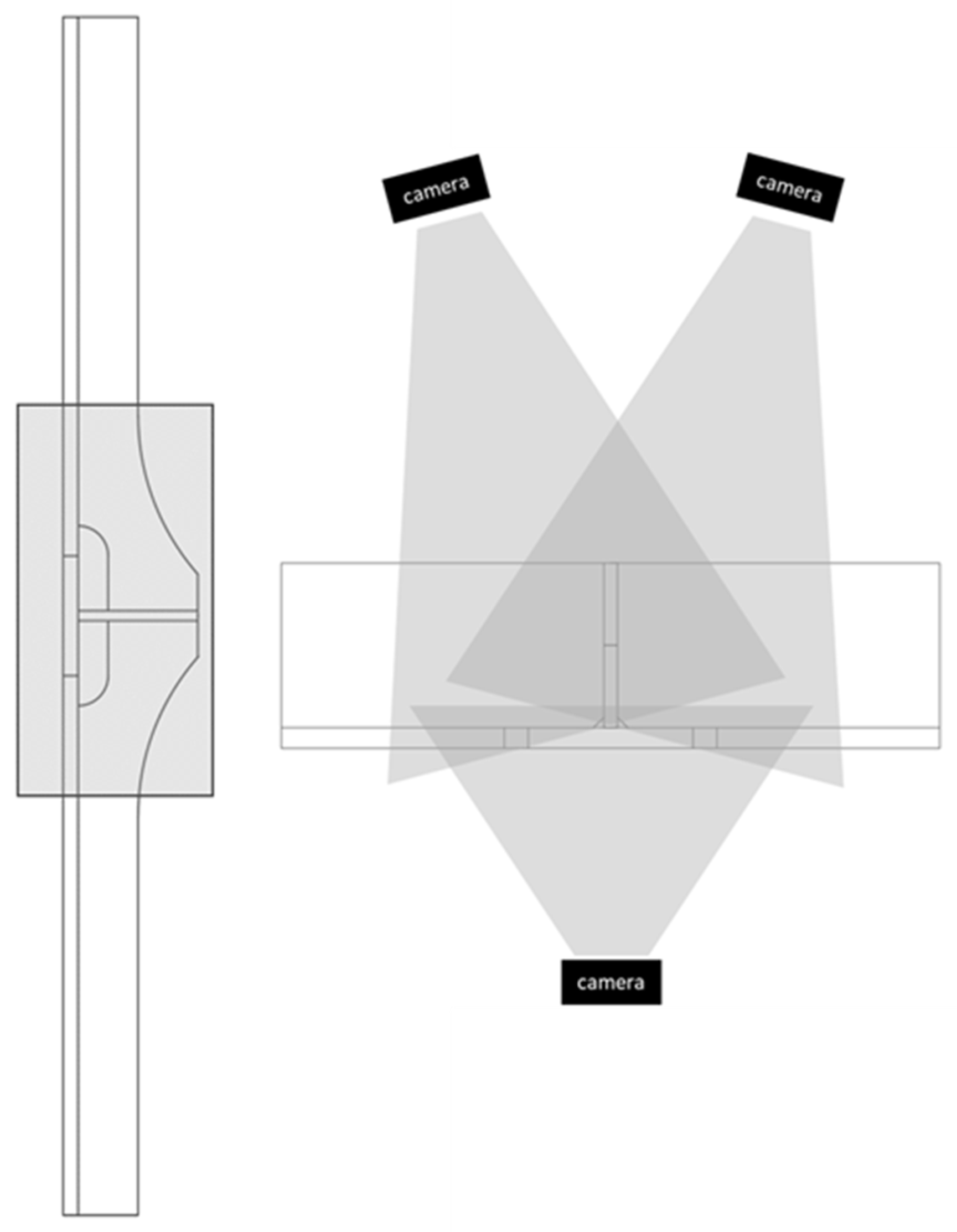

2.1.4. Finding Through Analysis of Inspection Images

2.1.5. Finding ∆K Through Numerical Modeling

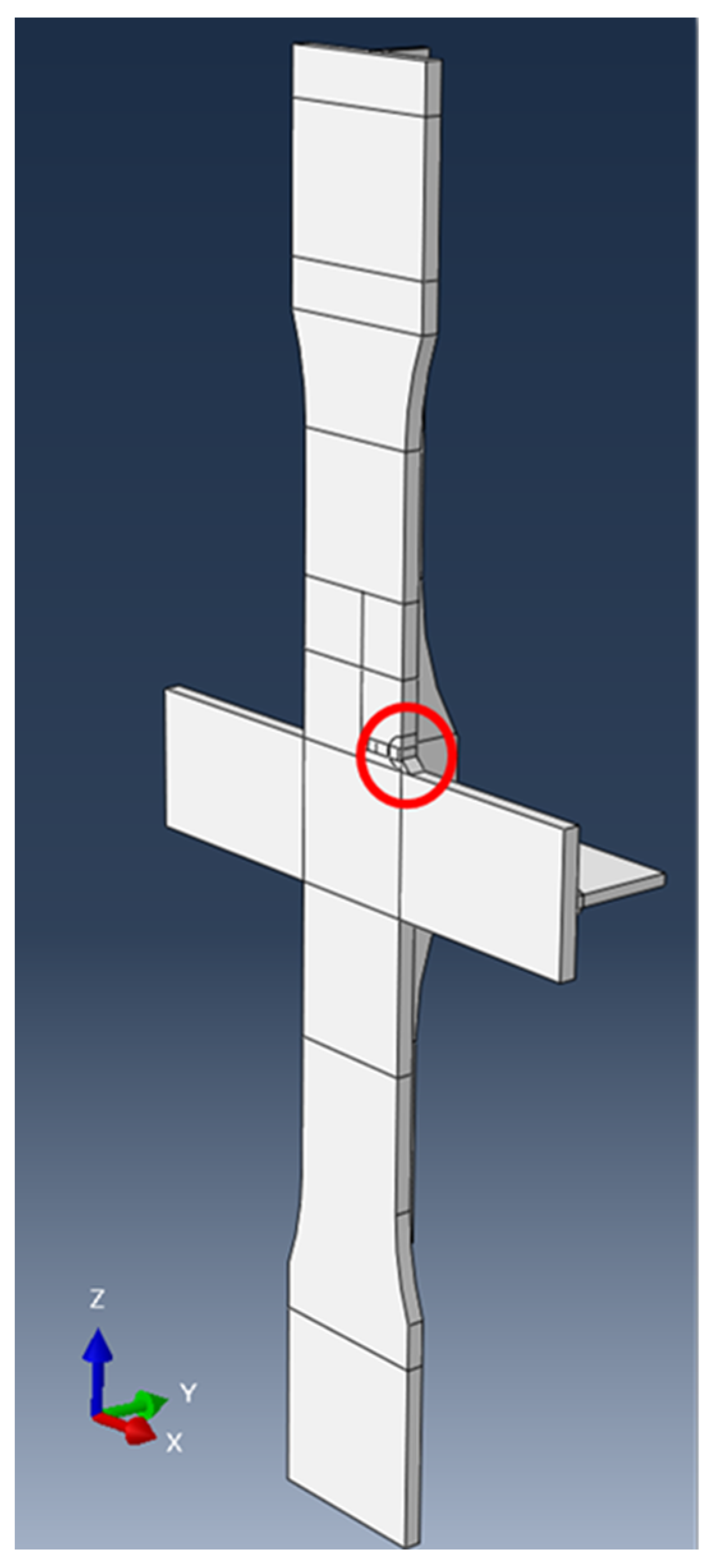

2.2. Example: Experimental Study and In Situ Miter Gate

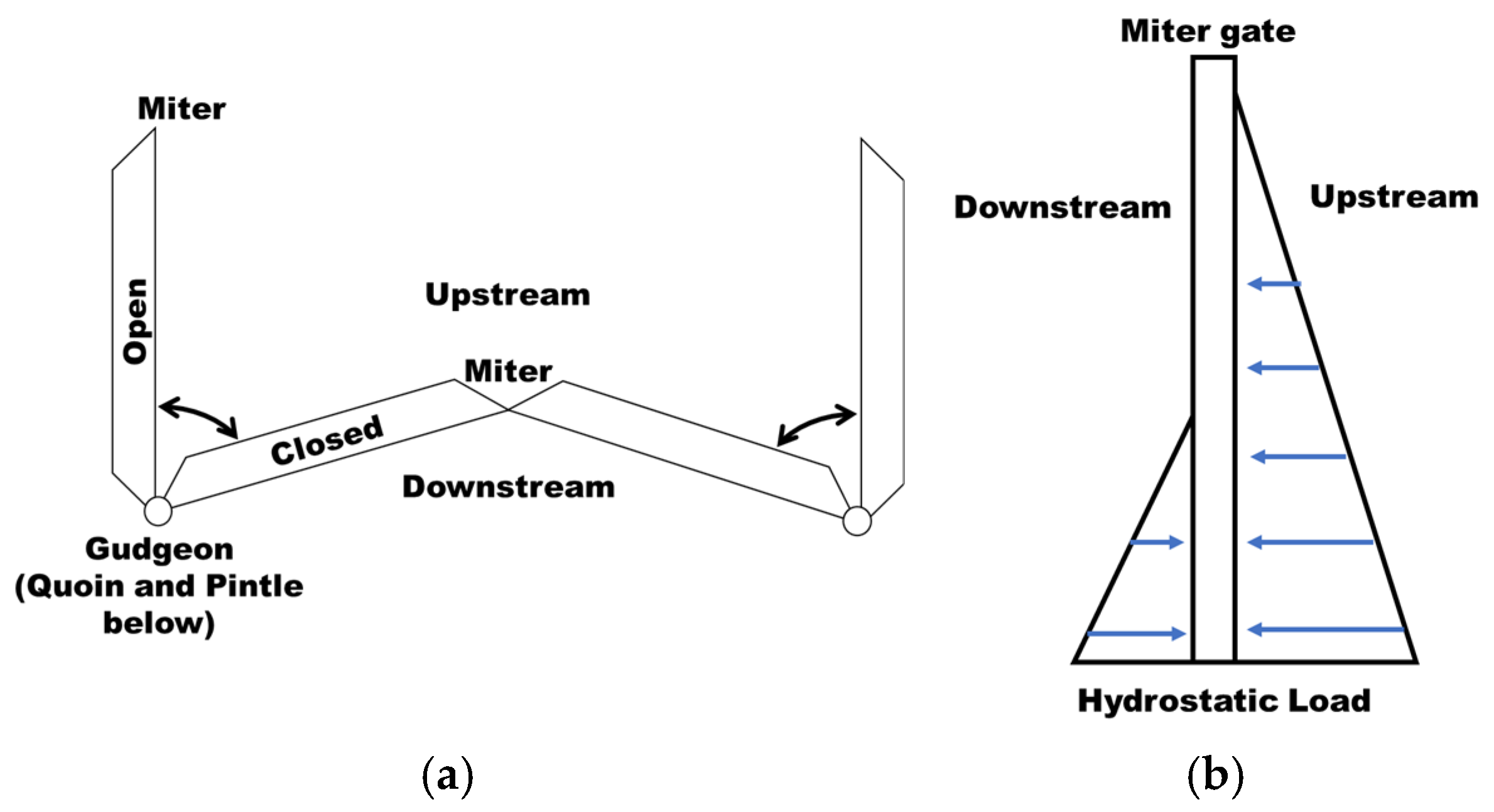

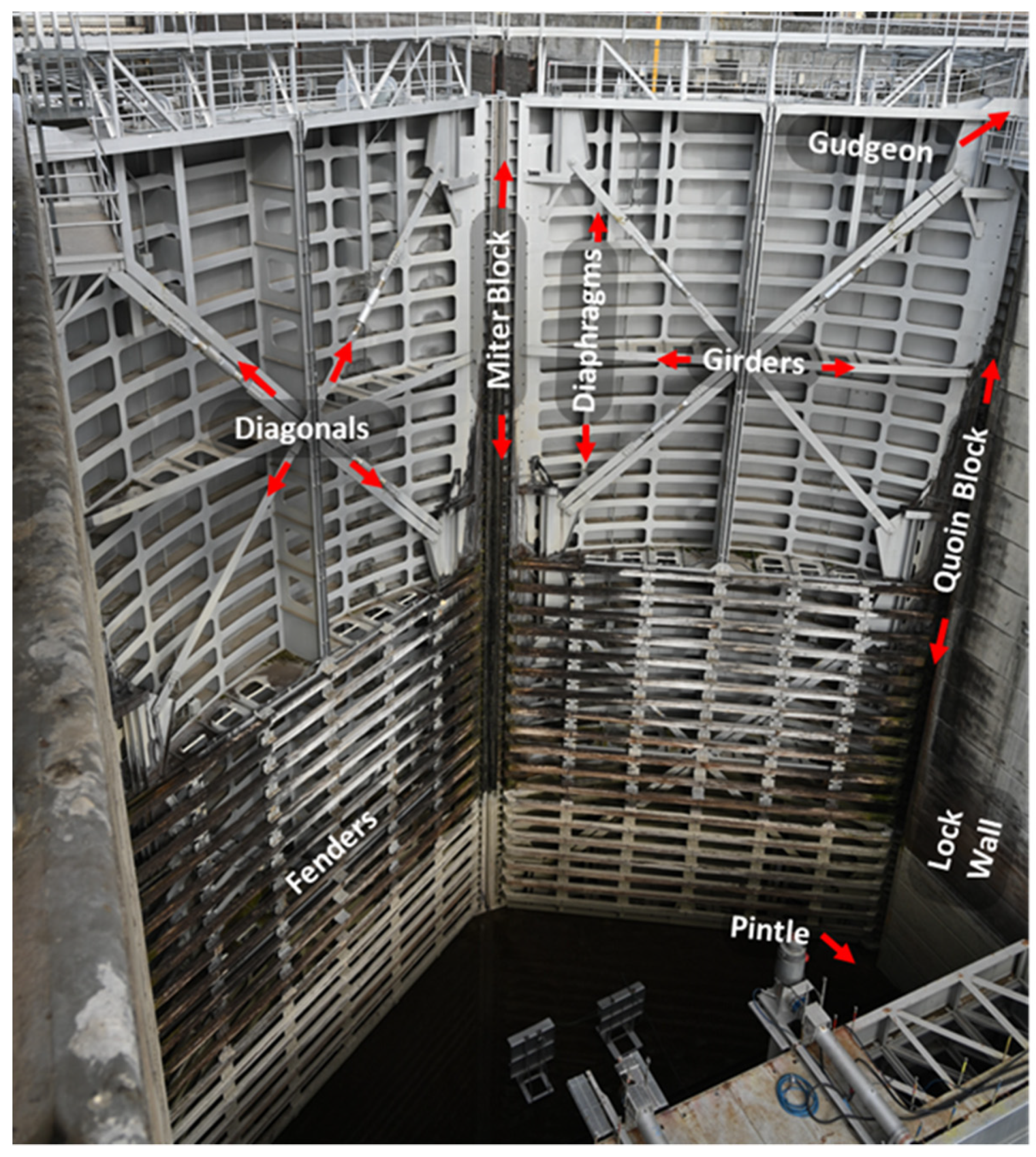

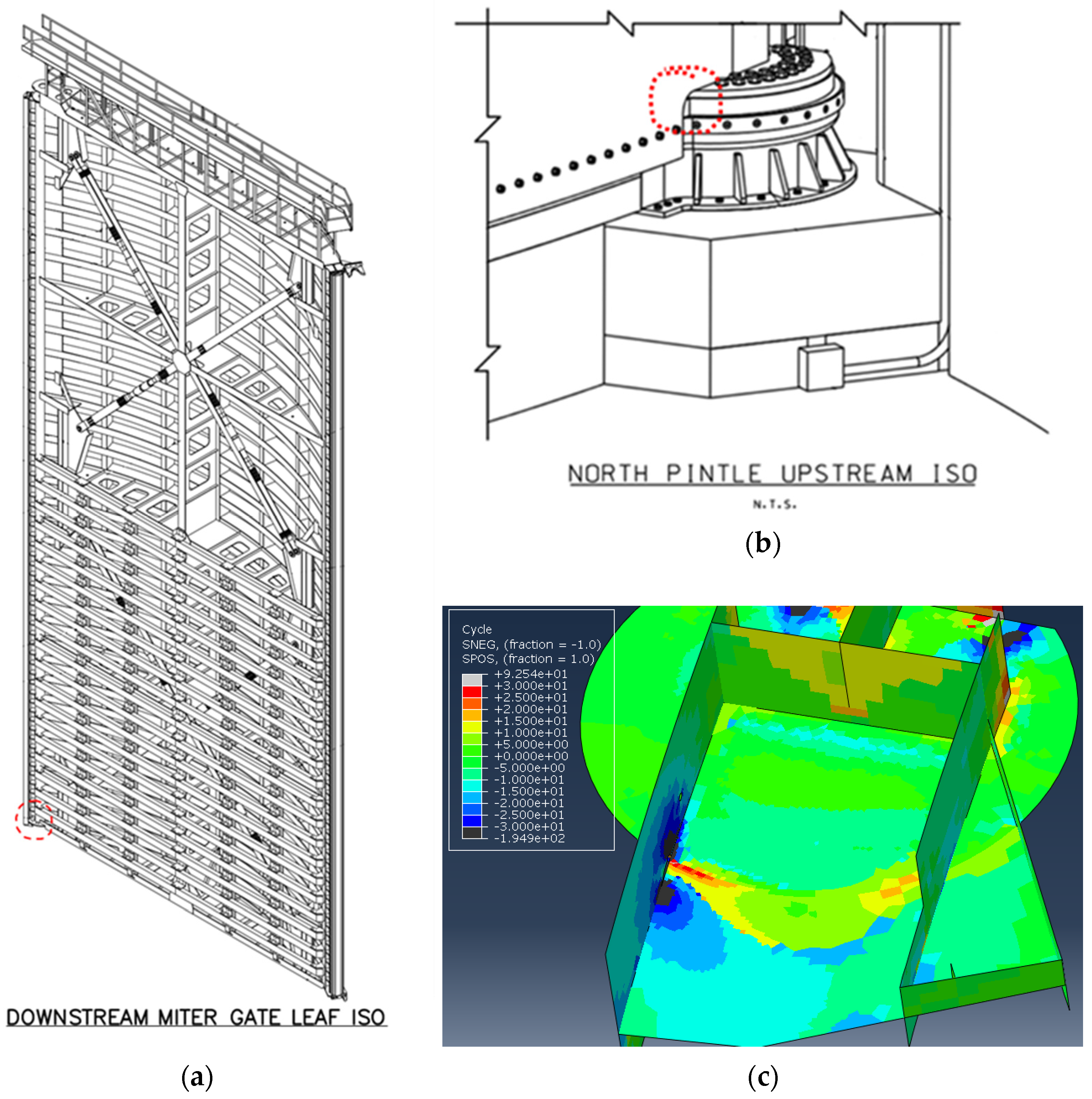

2.2.1. Background to Miter Gate Structures

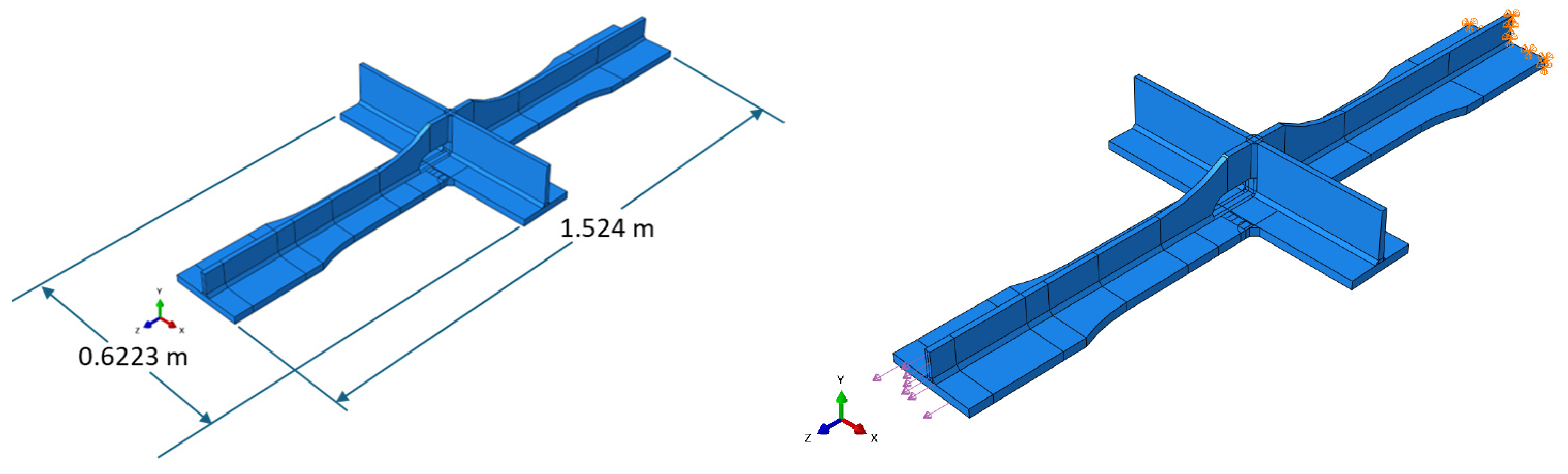

2.2.2. Paris’ Law Procedures for Laboratory Testing

2.2.3. In Situ Structure Paris’ Law Bayesian Updating

3. Results and Discussion

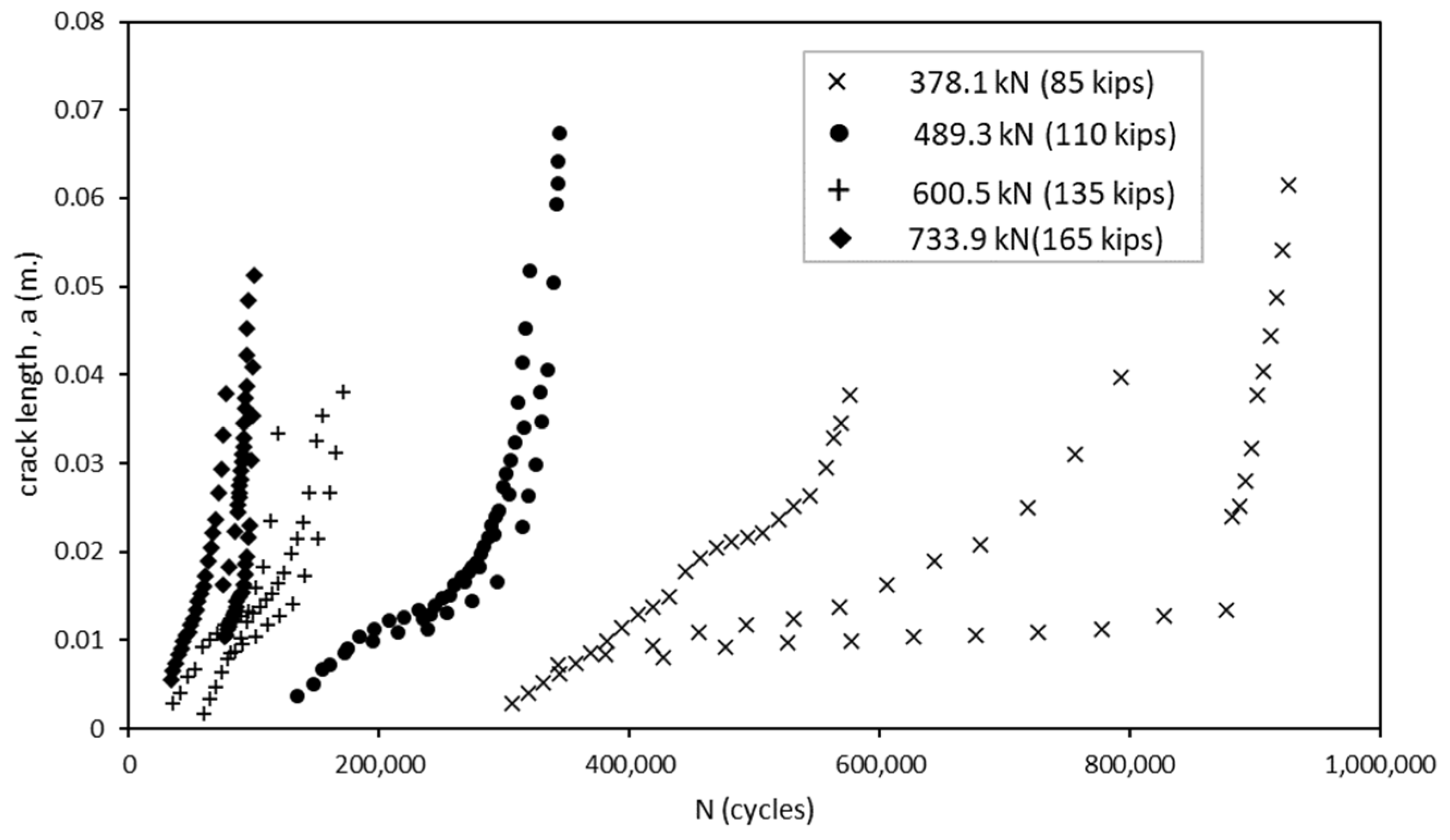

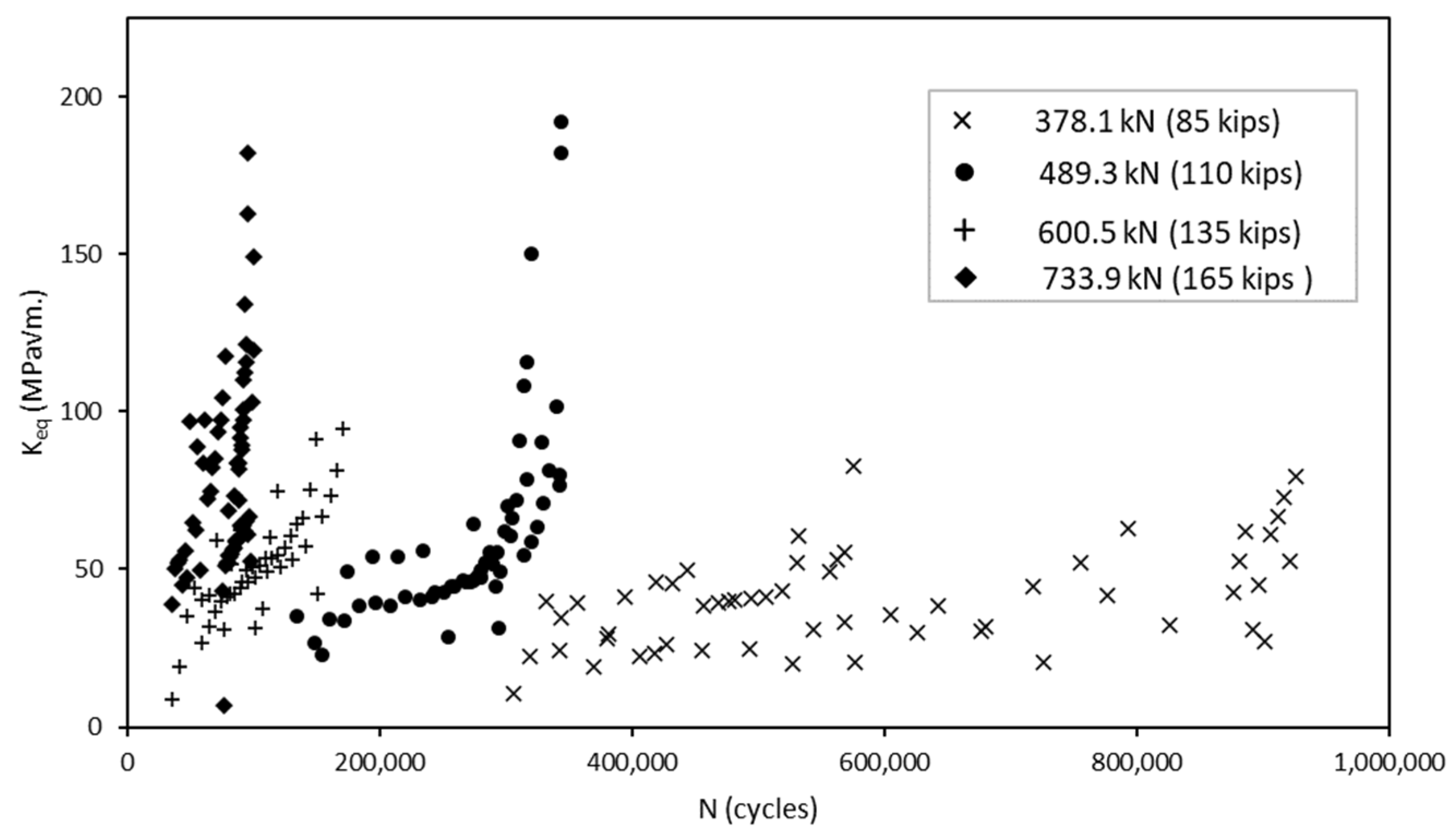

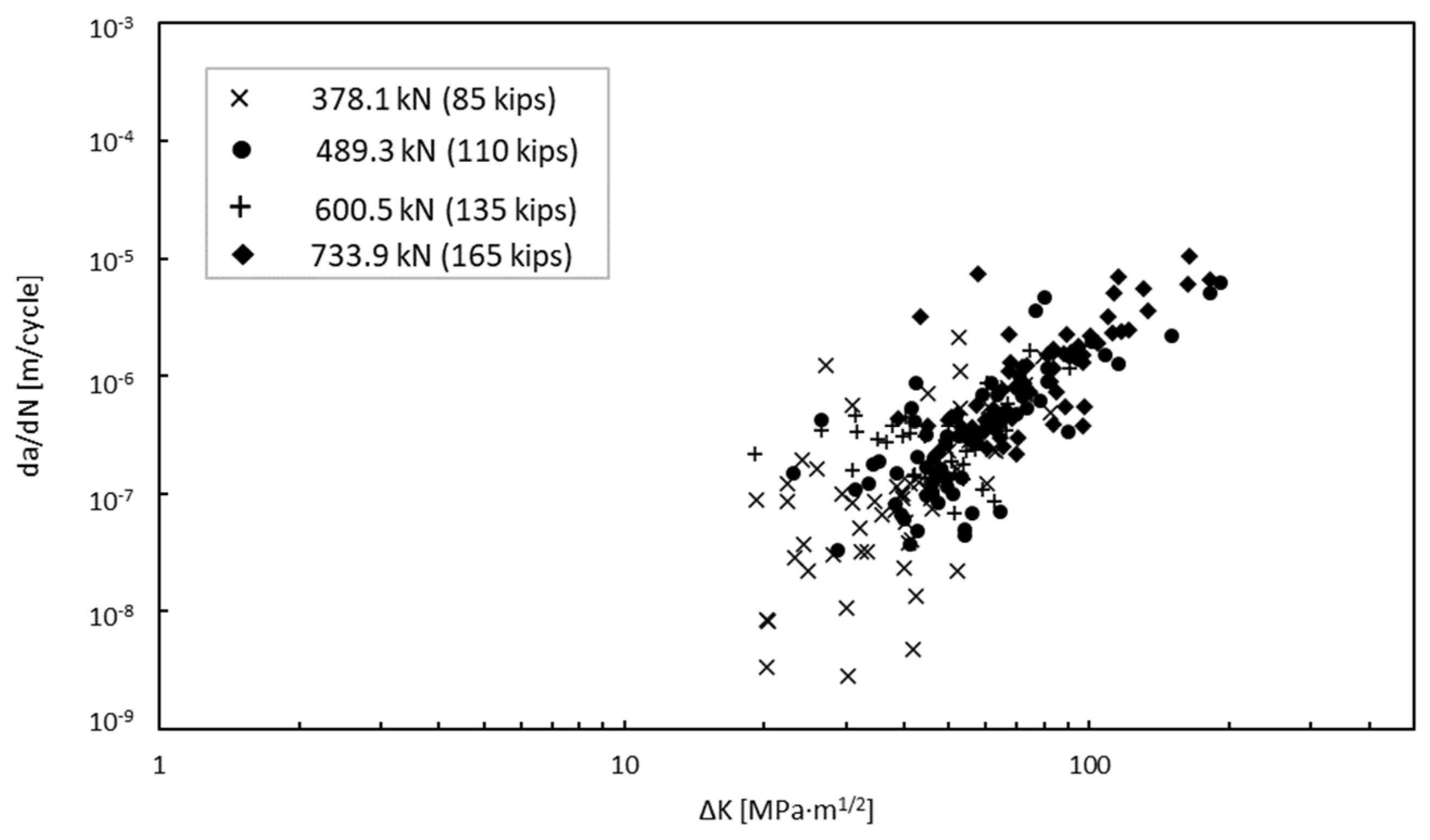

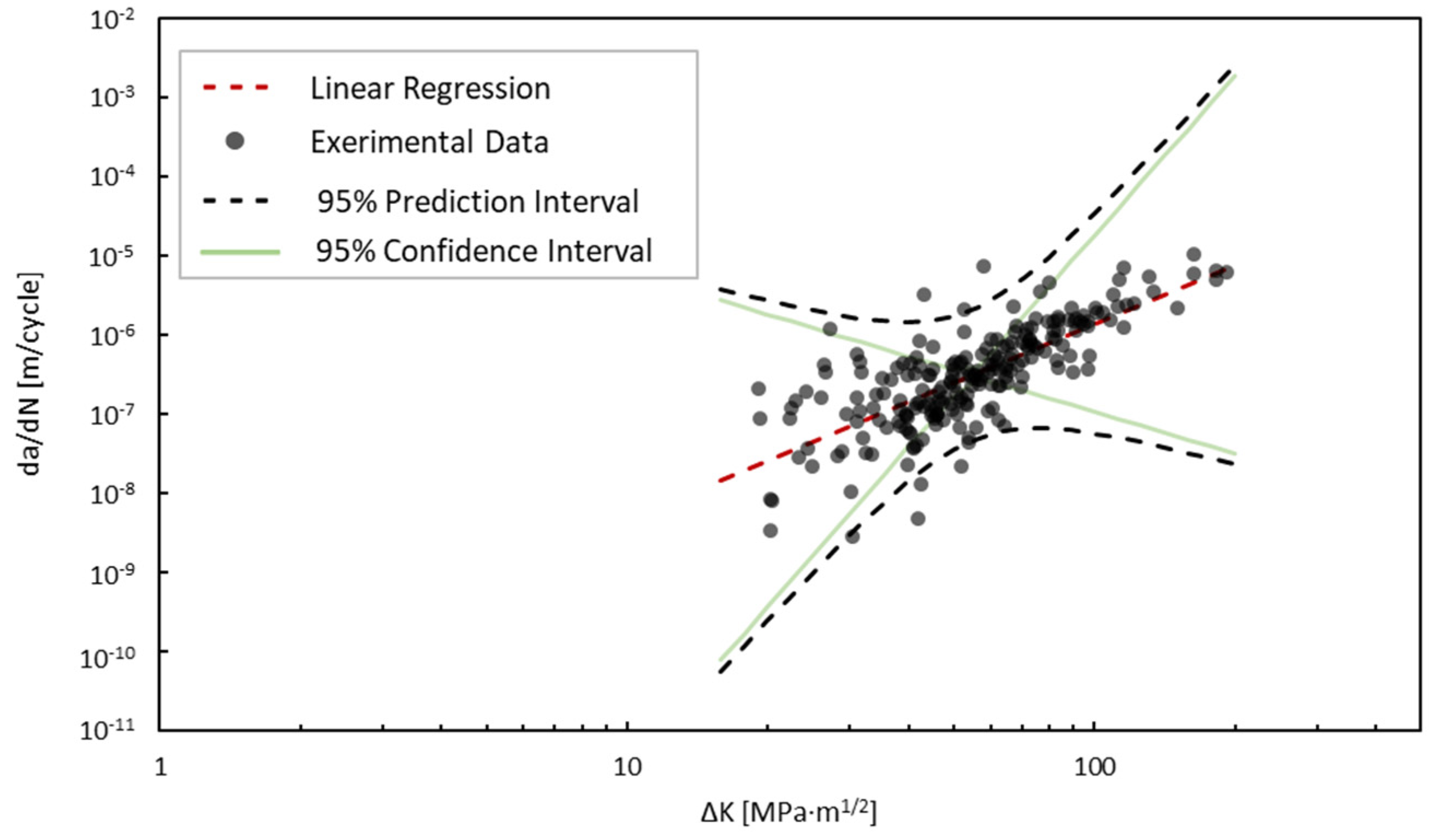

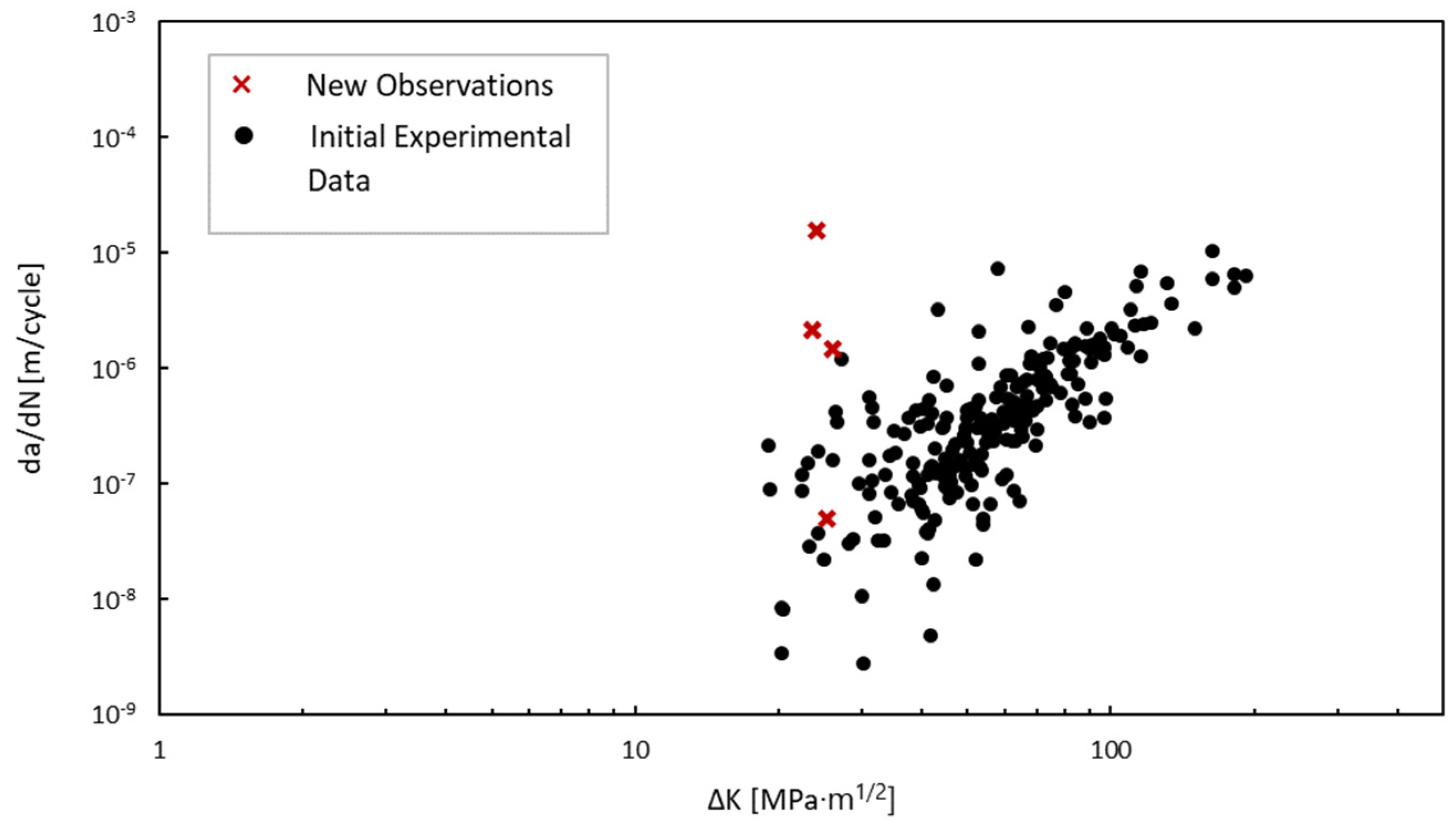

3.1. Parameters from Experimental Results

3.2. Bayesian Updating of Parameters from Inspection Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ASTM | American Society for Testing and Materials |

| CJP | Complete Joint Penetration |

| DIC | Digital Image Correlation |

| DICe | Digital Image Correlation Engine |

| FEA | Finite Element Analysis |

| FEM | Finite Element Method |

| GFEM | Generalized Finite Element Method |

| MCMC | Markov Chain Monte Carlo |

| MDPI | Multidisciplinary Digital Publishing Institute |

| NUTS | No-U-Turn Sampler |

| ROV | Remotely Operated Vehicle |

| SIF | Stress Intensity Factor |

| USACE | United States Army Corps of Engineers |

| XFEM | Extended Finite Element Method |

References

- Gillerman, M. Barge traffic moving again on Mississipppi River. St. Louis Today, 2013. Available online: https://www.stltoday.com/news/local/illinois/barge-traffic-moving-again-on-mississippi-river/article_2e23e9b1-8e74-5b55-8c25-fd68a0b6e11c.html (accessed on 24 February 2025).

- Roux-Langlois, C.; Gravouil, A.; Baietto, M.C.; Rethore, J.; Mathieu, F.; Hild, F.; Roux, S. DIC identification and X-FEM simulation of fatigue crack growth based on the Williams’ series. Int. J. Solids Struct. 2015, 53, 38–47. [Google Scholar] [CrossRef]

- Wang, W.; Yang, Y.F.; Li, M.Z.; Liu, W.K.; Liu, Z.P. Prediction of fatigue crack propagation based on dynamic Bayesian network. Adv. Mech. Eng. 2022, 14, 1–12. [Google Scholar] [CrossRef]

- Yang, G.; Gao, Z.L.; Xu, F.; Wang, X.G. An Experiment of Fatigue Crack Growth under Different R-ratio for 2024-T4 Aluminum Alloy. Appl. Mech. Mater. 2011, 66–68, 1477–1482. [Google Scholar] [CrossRef]

- Wu, W.F.; Ni, C.C. A study of stochastic fatigue crack growth modeling through experimental data. Probabilistic Eng. Mech. 2003, 18, 107–118. [Google Scholar] [CrossRef]

- Sobczyk, K. Modelling of random fatigue crack growth. Eng. Fract. Mech. 1986, 24, 609–623. [Google Scholar] [CrossRef]

- Mikulski, Z.; Lassen, T. Fatigue crack initiation and subsequent crack growth in fillet welded steel joints. Int. J. Fatigue 2019, 120, 303–318. [Google Scholar] [CrossRef]

- Moës, N.; Dolbow, J.; Belytschko, T. A finite element method for crack growth without remeshing. Int. J. Numer. Meth Eng. 1999, 46, 131–150. [Google Scholar] [CrossRef]

- Duarte, C.A.; Hamzeh, O.N.; Liszka, T.J.; Tworzydlo, W.W. A generalized finite element method for the simulation of three-dimensional dynamic crack propagation. Comput. Methods Appl. Mech. Eng. 2001, 190, 2227–2262. [Google Scholar] [CrossRef]

- Ramazani, A.; Abbasi, M.; Kazemiabnavi, S.; Schmauder, S.; Larson, R.; Prahl, U. Development and application of a microstructure-based approach to characterize and model failure initiation in DP steels using XFEM. Mater. Sci. Eng. A 2016, 660, 181–194. [Google Scholar] [CrossRef]

- Zhang, K. Development and Experimental Validation of Dynamic Bayesian Networks for System Reliability Prediction. Ph.D. Thesis, The University of Michigan, Ann Arbor, MI, USA, 2020. [Google Scholar]

- Warner, J.E.; Bomarito, G.F.; Hochhalter, J.D.; Leser, W.P.; Leser, P.E.; Newman, J.A. A Computationally-Efficient Probabilistic Approach to Model-Based Damage Diagnosis. Int. J. Progn. Health Manag. 2017, 8, 26. [Google Scholar] [CrossRef]

- Yan, G.; Sun, H.; Waisman, H. A guided Bayesian inference approach for detection of multiple flaws in structures using the extended finite element method. Comput. Struct. 2015, 152, 27–44. [Google Scholar] [CrossRef]

- Wu, Z.; Fillmore, T.B.; Vega, M.A.; Hu, Z.; Todd, M.D. Diagnostics and prognostics of multi-mode failure scenarios in miter gates using multiple data sources and a dynamic Bayesian network. Struct. Multidiscip. Optim. 2022, 65, 270. [Google Scholar] [CrossRef]

- Rocchetta, R.; Broggi, M.; Huchet, Q.; Patelli, E. On-line Bayesian model updating for structural health monitoring. Mech. Syst. Signal Process. 2018, 103, 174–195. [Google Scholar] [CrossRef]

- Zárate, B.A.; Caicedo, J.M.; Yu, J.; Ziehl, P. Bayesian model updating and prognosis of fatigue crack growth. Eng. Struct. 2012, 45, 53–61. [Google Scholar] [CrossRef]

- Caicedo, J.M.; Zárate, B.A.; Giurgiutiu, V.; Yu, L.; Ziehl, P. Bayesian finite element model updating for crack growth. In Structural Dynamics, Volume 3, Proceedings of the 28th IMAC, A Conference on Structural Dynamics, Jacksonville, FL, USA, 1–4 February 2010; Springer: New York, NY, USA, 2010; pp. 861–866. [Google Scholar]

- Karimi, J.; Nejati, H.R.; Ahmadi, M. Application of digital image correlation to derive Paris’ law constants in granite specimens. Theor. Appl. Fract. Mech. 2023, 128, 104166. [Google Scholar] [CrossRef]

- Mathieu, F.; Hild, F.; Roux, S. Identification of a crack propagation law by digital image correlation. Int. J. Fatigue 2012, 36, 146–154. [Google Scholar] [CrossRef]

- Mcallister, T.P.; Ellingwood, B.R. Reliability-based condition assessment of welded miter gate structures. J. Infrastruct. Syst. 2001, 7, 95–106. [Google Scholar] [CrossRef]

- Eick, B.A.; Brown, A.H.; Fillmore, T.; Spencer, B.F. Full-scale testing of miter gate component with multiple adjacent fillet and butt welds to estimate fatigue performance. J. Perform. Constr. Fac. 2024, 39, 04025008. [Google Scholar] [CrossRef]

- Paris, P.C.; Erdogan, F. A Critical Analysis of Crack Propagation Laws. J. Basic. Eng. 1963, 85, 528–533. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials, 2nd ed.; Cambridge University Press: Cambridge, MA, USA, 1998. [Google Scholar] [CrossRef]

- Sajith, S.; Murthy, K.S.R.K.; Robi, P.S. Prediction of Accurate Mixed Mode Fatigue Crack Growth Curves using the Paris’ Law. J. Inst. Eng. India Ser. C 2019, 100, 165–174. [Google Scholar] [CrossRef]

- Réthoré, J.; Gravouil, A.; Morestin, E.; Combescure, A. Estimation of mixed-mode stress intensity factors using digital image correlation and an interaction integral. Int. J. Fract. 2005, 132, 65–79. [Google Scholar] [CrossRef]

- Pook, L.P. Linear Elastic Fracture Mechanics for Engineers: Theory and Applications; WIT Press: London, UK, 2000. [Google Scholar]

- Richard, H.A.; Fulland, M.; Buchholz, F.G.; Schöllmann, M. 3D fracture criteria for structures with cracks. Steel Res. Int. 2003, 74, 491–497. [Google Scholar] [CrossRef]

- Pook, L.P. Mixed-mode fatigue crack growth thresholds: A personal historical review of work at the National Engineering Laboratory, 1975–1989. Eng. Fract. Mech. 2018, 187, 115–141. [Google Scholar] [CrossRef]

- Radhakrishnan, V.M. Parameter representation of fatigue crack growth. Eng. Fract. Mech. 1979, 11, 359–372. [Google Scholar] [CrossRef]

- Ye, H.W.; Huang, R.S.; Zhou, Y.; Liu, J.L. Calibration of Paris law constants for crack propagation analysis of damaged steel plates strengthened with prestressed CFRP. Theor. Appl. Fract. Mech. 2022, 117, 103208. [Google Scholar] [CrossRef]

- Hoff, P.D. A First Course in Bayesian Statistical Methods; Springer Texts Statistics; Springer: New York, NY, USA, 2009. [Google Scholar] [CrossRef]

- Benjamin, J.R.; Cornell, C.A. Probability, Statistics, and Decisions for Civil Engineers; Dover: New York, NY, USA, 2014. [Google Scholar]

- Salvatier, J.; Wiecki, T.V.; Fonnesbeck, C. Probabilistic programming in Python using PyMC3. PeerJ Comput. Sci. 2016, 2, e55. [Google Scholar] [CrossRef]

- Hartley, R.; Zisserman, A. Multiple View Geometry in Computer Vision, 2nd ed.; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar] [CrossRef]

- Rege, K.; Lemu, H.G. A review of fatigue crack propagation modelling techniques using FEM and XFEM. IOP Conf. Ser. Mater. Sci. Eng. 2017, 276, 012027. [Google Scholar] [CrossRef]

- Bergara, A.; Dorado, J.I.; Martin-Meizoso, A.; Martínez-Esnaola, J.M. Fatigue crack propagation in complex stress fields: Experiments and numerical simulations using the Extended Finite Element Method (XFEM). Int. J. Fatigue 2017, 103, 112–121. [Google Scholar] [CrossRef]

- Pang, J.H.L.; Tsang, K.S.; Hoh, H.J. 3D stress intensity factors for weld toe semi-elliptical surface cracks using XFEM. Mar. Struct. 2016, 48, 1–14. [Google Scholar] [CrossRef]

- Chen, Z.Y.; Bao, H.C.; Dai, Y.W.; Liu, Y.H. Numerical prediction based on XFEM for mixed-mode crack growth path and fatigue life under cyclic overload. Int. J. Fatigue 2022, 162, 10693. [Google Scholar] [CrossRef]

- Martínez, J.C.; Useche, L.V.V.; Wahab, M.A. Numerical prediction of fretting fatigue crack trajectory in a railway axle using XFEM. Int. J. Fatigue 2017, 100, 32–49. [Google Scholar] [CrossRef]

- Duran, E.T.; Demiral, M. Comparing and validating the numerical modeling of spot-welded fatigue failure using FEM and XFEM methods for HCF. Eng. Fail. Anal. 2024, 158, 108049. [Google Scholar] [CrossRef]

- Wang, Y.X.; Fincato, R.; Kotani, Y.; Tsutsumi, S.; Chan, T.M. Cyclic elastoplasticity and XFEM based fatigue life assessment of out-of-plane gusset welded joints. Int. J. Fatigue 2024, 178, 107961. [Google Scholar] [CrossRef]

- Chiarelli, M.; Frediani, A. A computation of the three-dimensional J-integral for elastic materials with a view to applications in fracture mechanics. Eng. Fract. Mech. 1993, 44, 763–788. [Google Scholar] [CrossRef]

- Han, Q.H.; Wang, Y.R.; Yin, Y.; Wang, D.N. Determination of stress intensity factor for mode I fatigue crack based on finite element analysis. Eng. Fract. Mech. 2015, 138, 118–126. [Google Scholar] [CrossRef]

- Jones, E.M.C.; Iadicola, M.A. A Good Practices Guide for Digital Image Correlation; International Digital Image Correlation Society, 2018; p. 101. [Google Scholar] [CrossRef]

- American Railway Engineering and Maintenance-of-Way Association. 15 Steel Structures. In 2006 Manual for Railway Engineering; American Railway Engineering and Maintenance-of-Way Association: Landover, MD, USA, 2006; Volume 2, p. 15. [Google Scholar]

- Eick, B.A. Structural Health Monitoring of Inland Navigation Infrastructure. Doctoral Dissertation, University of Illinois at Urbana-Champaign, Urbana, IL, USA, 2020. [Google Scholar]

- Ang, A.H.; Tang, W.H. Probability Concepts in Engineering Planning and Design; John Wiley and Sons: New York, NY, USA, 1975. [Google Scholar]

- Haldar, A.; Mahadevan, S. Probability, Reliability, and Statistical Methods in Engineering Design; John Wiley & Sons: New York, NY, USA, 2000. [Google Scholar] [CrossRef]

- Virkler, D.A.; Hillberry, B.M.; Goel, P.K. The statistical nature of fatigue crack propagation. J. Eng. Technol. 1979, 101, 148–153. [Google Scholar] [CrossRef]

| Parameter | Mean | Standard Deviation |

|---|---|---|

| m | 2.477 | 0.145 |

| logC | −10.805 | 0.253 |

| Other regression parameters | ||

| σ2 | 0.178 | |

| R2 | 0.570 | |

| Parameter | Mean | Standard Deviation |

|---|---|---|

| m | 2.605 | 0.138 |

| logC | −10.517 | 0.243 |

| σ | 0.981 | 0.206 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brown, A.; Eick, B.; Fillmore, T.; Nguyen, H. Bayesian Updating of Fatigue Crack Growth Parameters for Failure Prognosis of Miter Gates. Materials 2025, 18, 1172. https://doi.org/10.3390/ma18051172

Brown A, Eick B, Fillmore T, Nguyen H. Bayesian Updating of Fatigue Crack Growth Parameters for Failure Prognosis of Miter Gates. Materials. 2025; 18(5):1172. https://doi.org/10.3390/ma18051172

Chicago/Turabian StyleBrown, Anita, Brian Eick, Travis Fillmore, and Hai Nguyen. 2025. "Bayesian Updating of Fatigue Crack Growth Parameters for Failure Prognosis of Miter Gates" Materials 18, no. 5: 1172. https://doi.org/10.3390/ma18051172

APA StyleBrown, A., Eick, B., Fillmore, T., & Nguyen, H. (2025). Bayesian Updating of Fatigue Crack Growth Parameters for Failure Prognosis of Miter Gates. Materials, 18(5), 1172. https://doi.org/10.3390/ma18051172