Axial Tensile Adhesively Bonded Performance of Carbon Fiber Composite Tubes Under Room-Temperature and Low-Temperature Circulation

Highlights

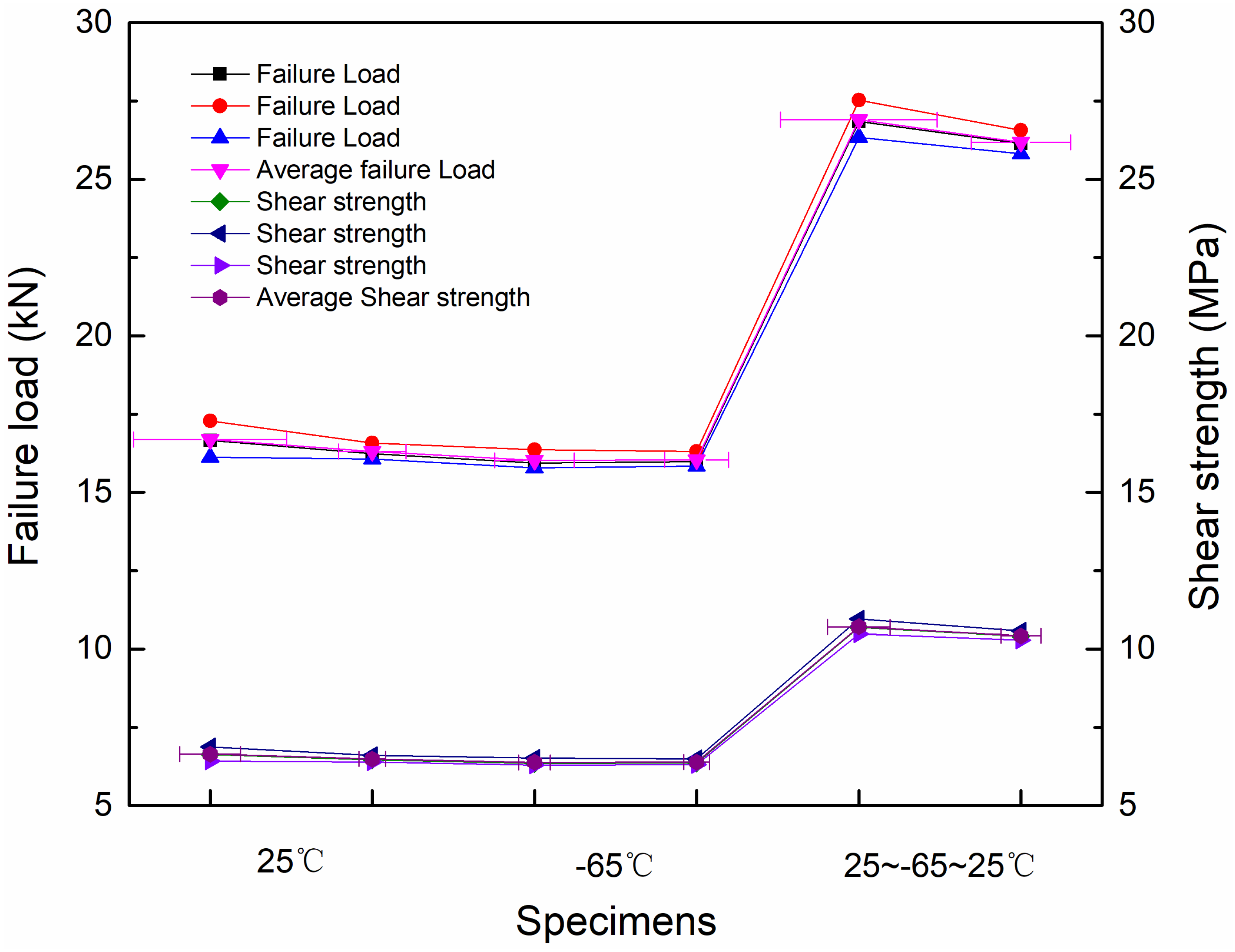

- The tensile failure limit of the adhesively bonded joint specimen under low-temperature cycling was greater by approximately 61% than those under room- or low-temperature conditions;

- Low-temperature cycling can improve the bearing capacity;

- Adhesive spew fillet exerted an insignificant effect on the bonding strength of the adhesively bonded joints;

- The mismatch of thermal expansion coefficient between titanium alloy and composite improves the performance of bonding interface;

- Different temperature environments have different effects on the bearing strength.

Abstract

1. Introduction

2. Experimental Study

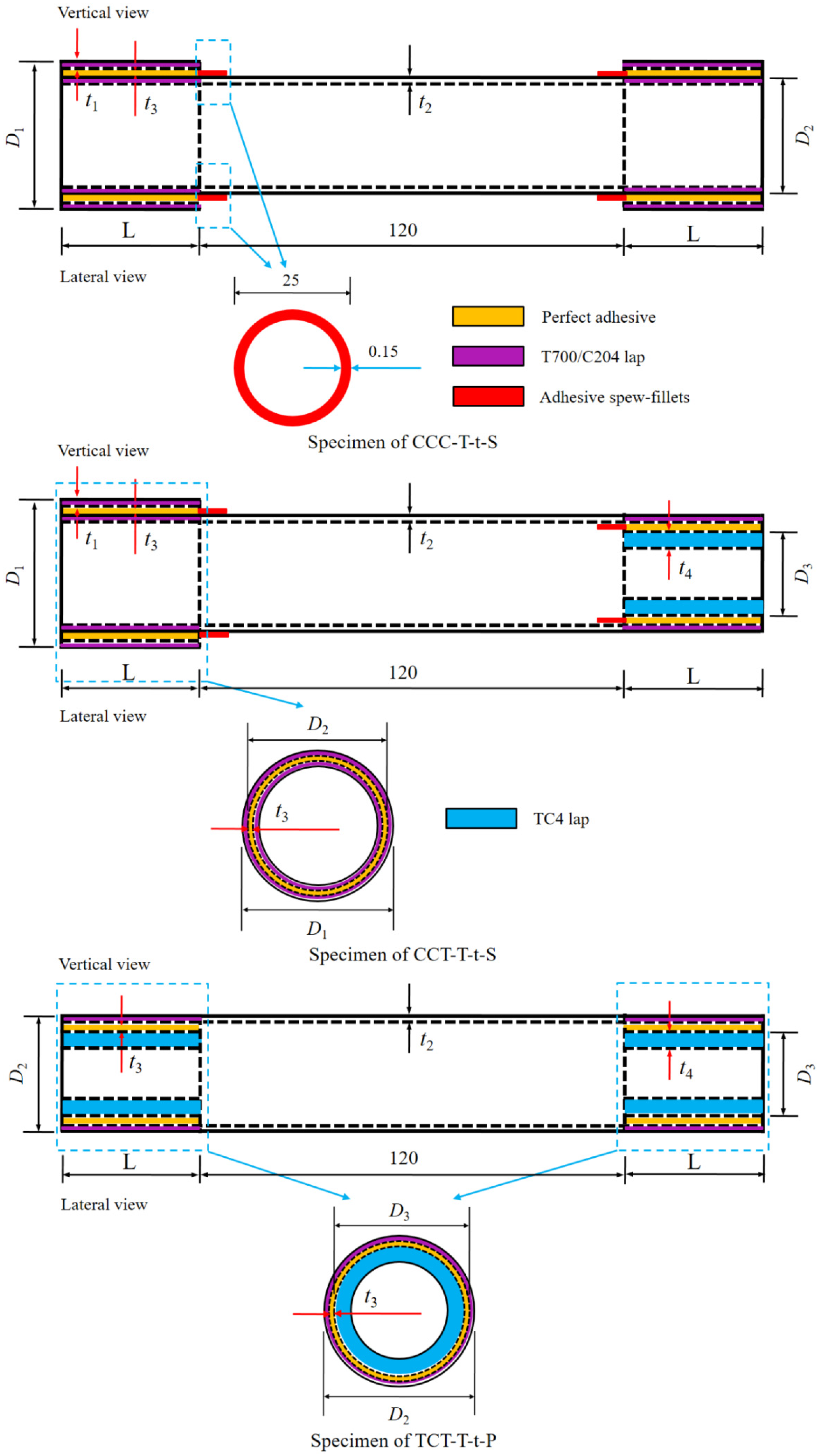

2.1. Specimen Details

- CCC-T-t-S specimens consisted of two carbon fiber three-way tubes adhesively bonded at both ends.

- CCT-T-t-S specimens featured a carbon fiber three-way tube adhesively bonded at one end and a titanium alloy tube at the other end.

- TCT-T-t-P/S specimens comprised two titanium alloy tubes adhesively bonded at both ends.

- T represents the average thickness of the adhesively bonded circular tube.

- t denotes the thickness of the adhesive layer.

- P indicates a perfect lap joint.

- S refers to the adhesive configuration with a spew-fillet at the end of the lap region.

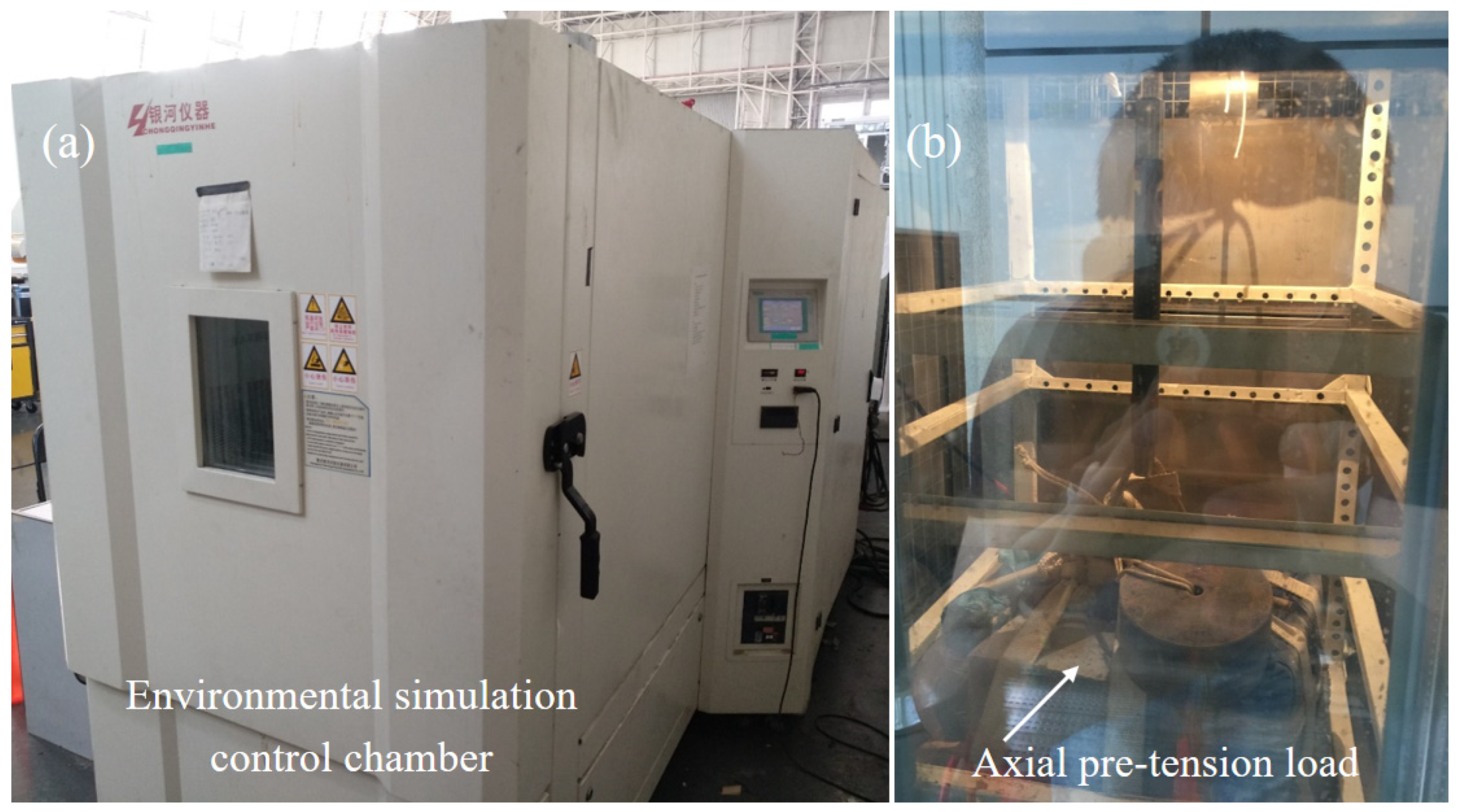

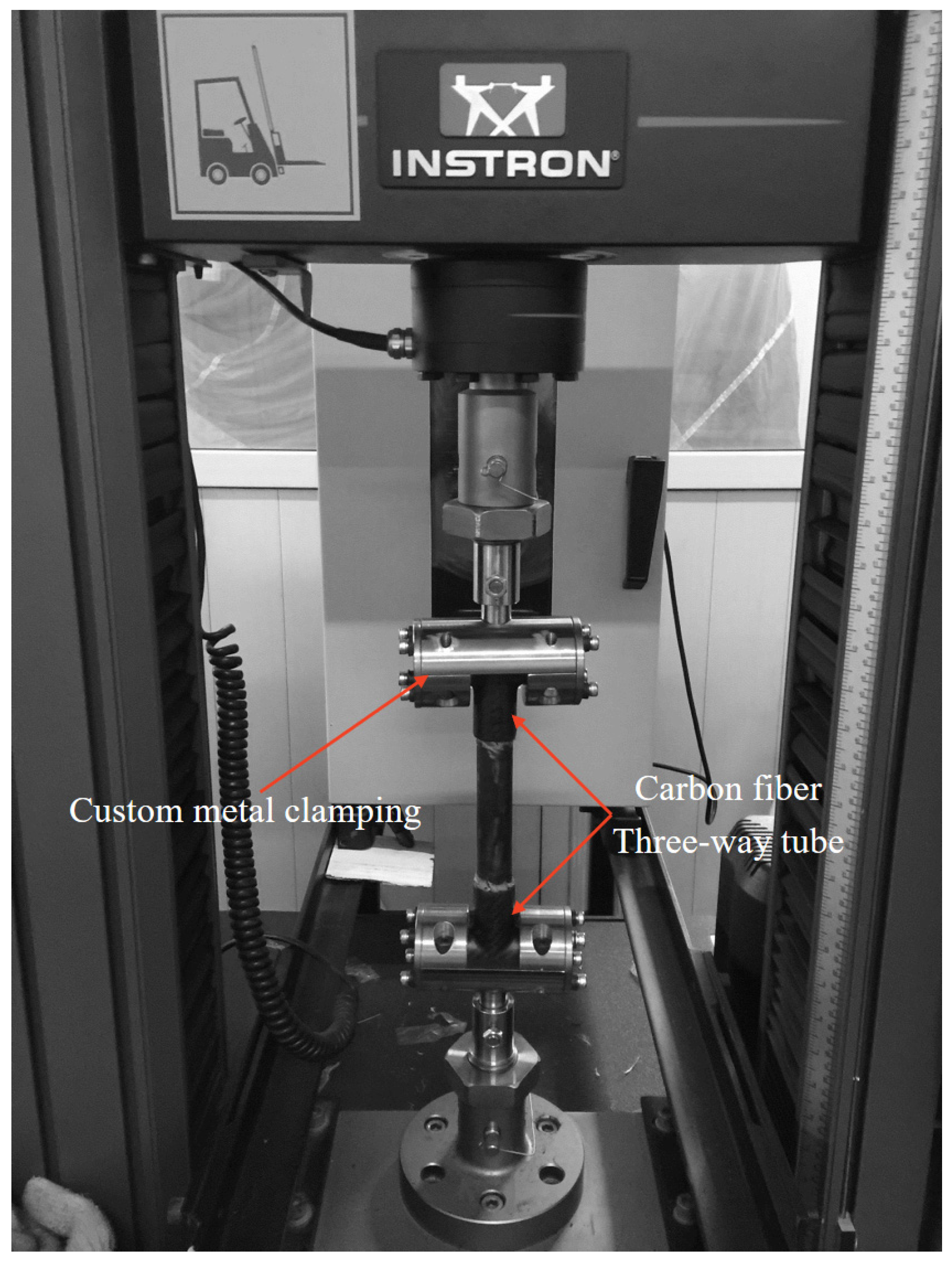

2.2. Test Method

3. Test Results and Discussions

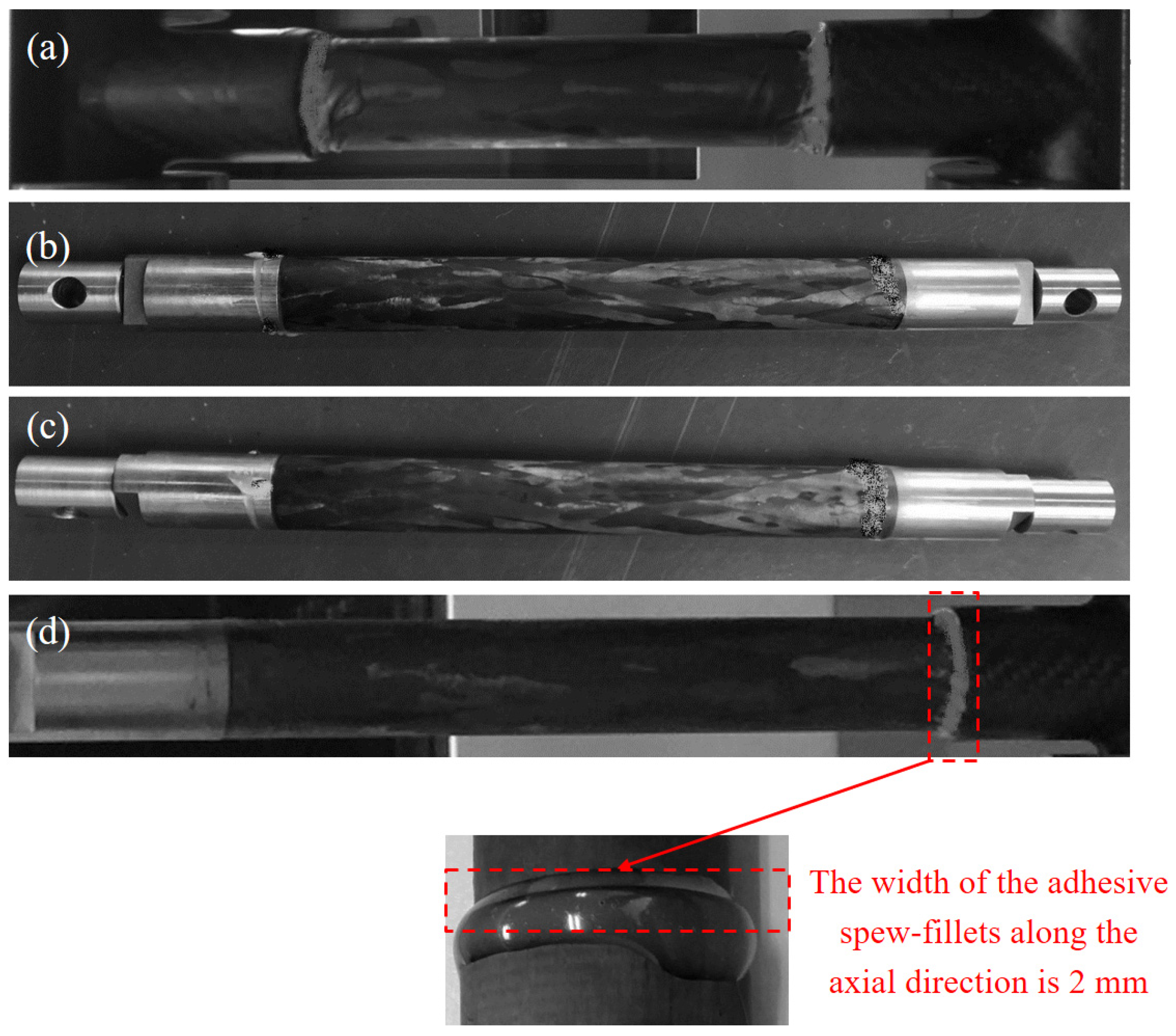

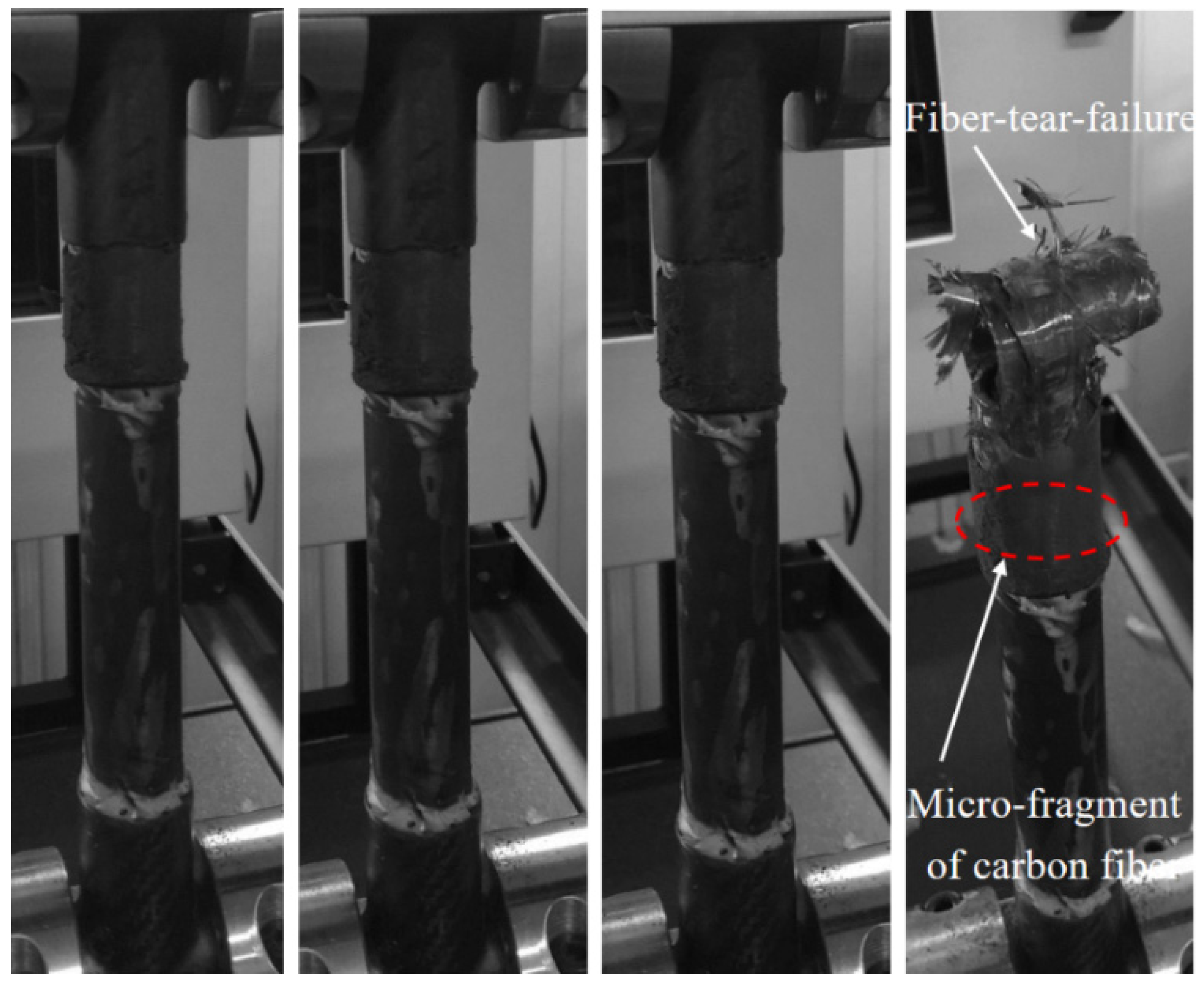

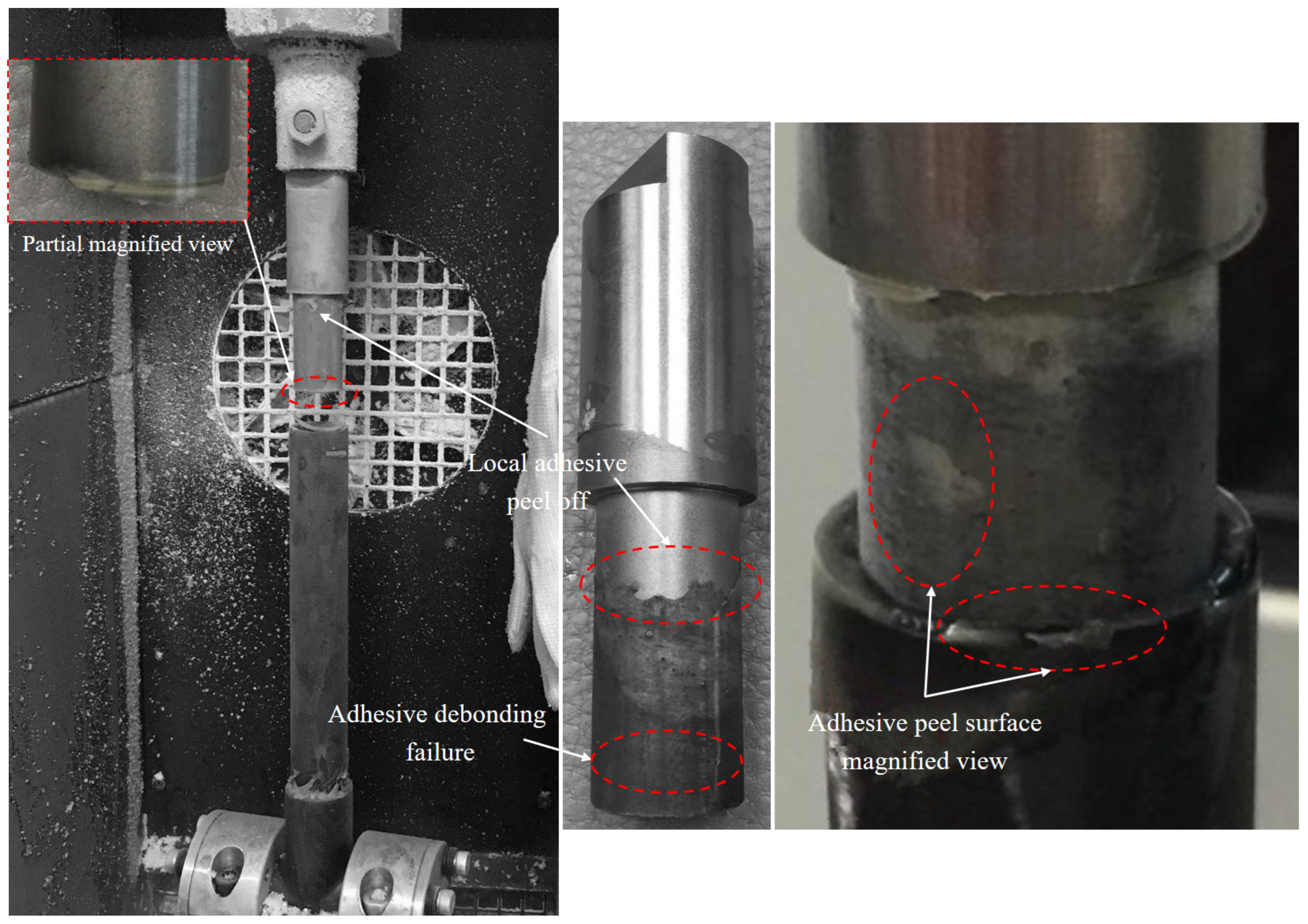

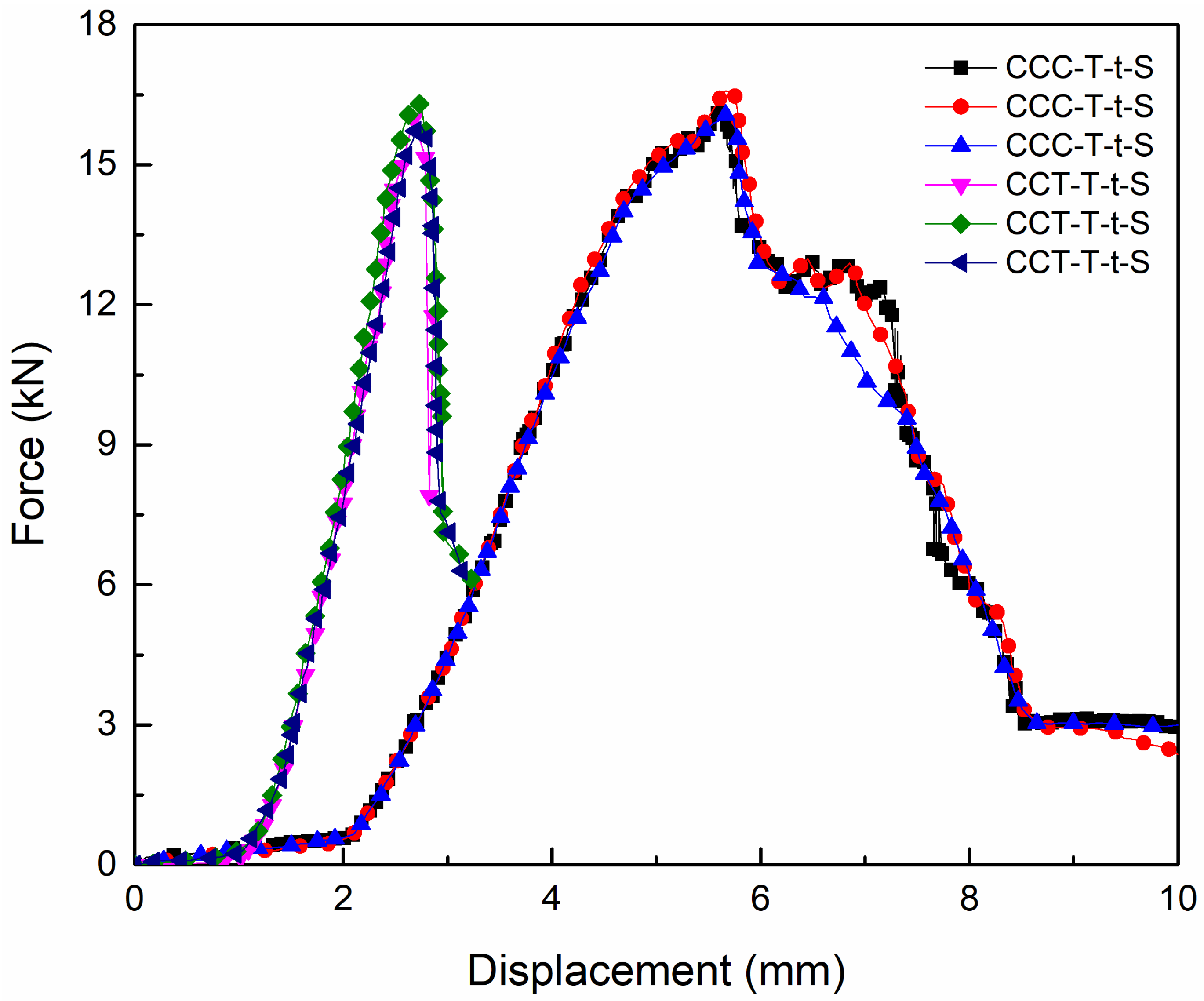

3.1. Influence of Failure Modes at Room Temperature

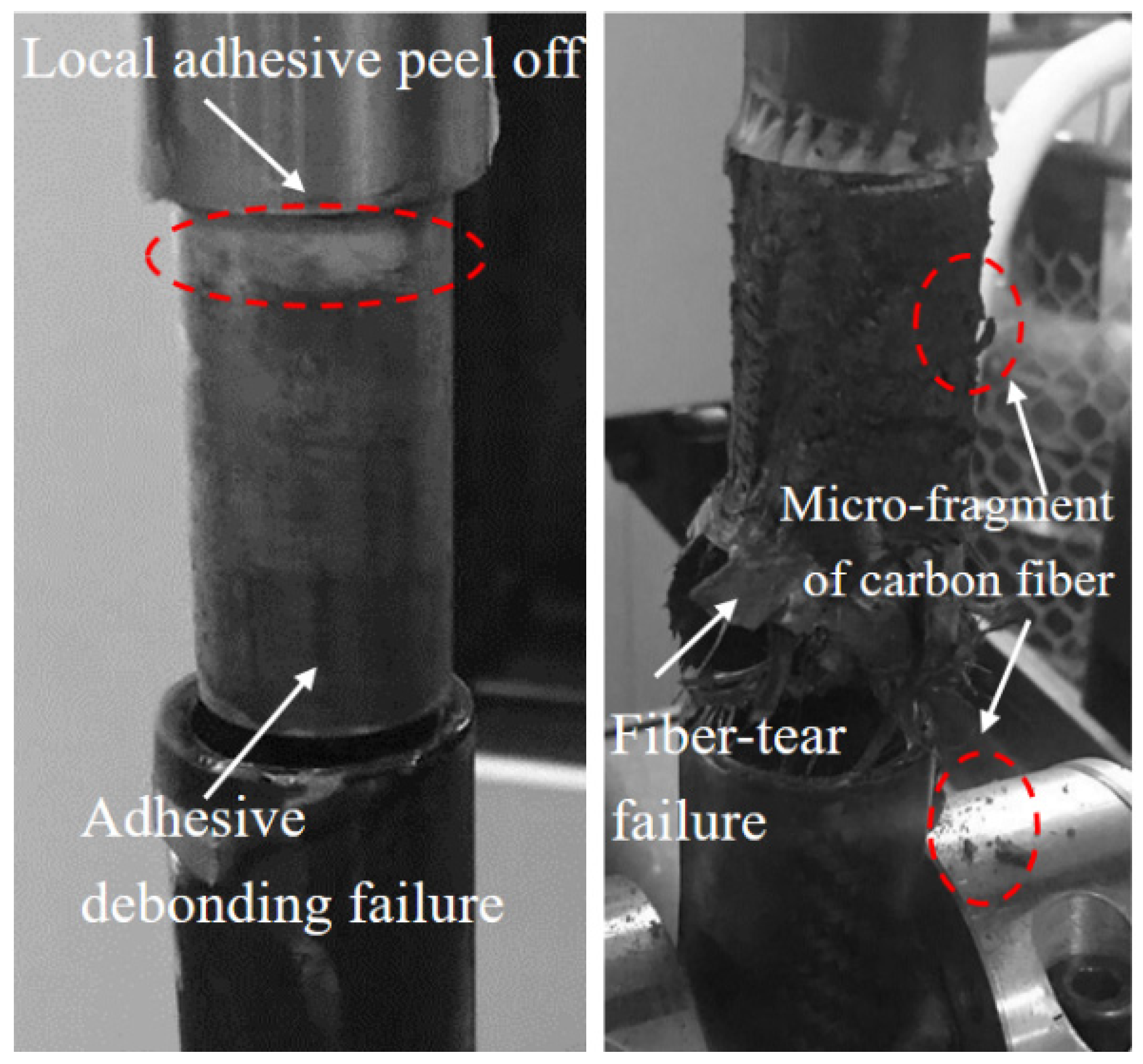

3.2. Influence of Failure Modes at Low Temperature

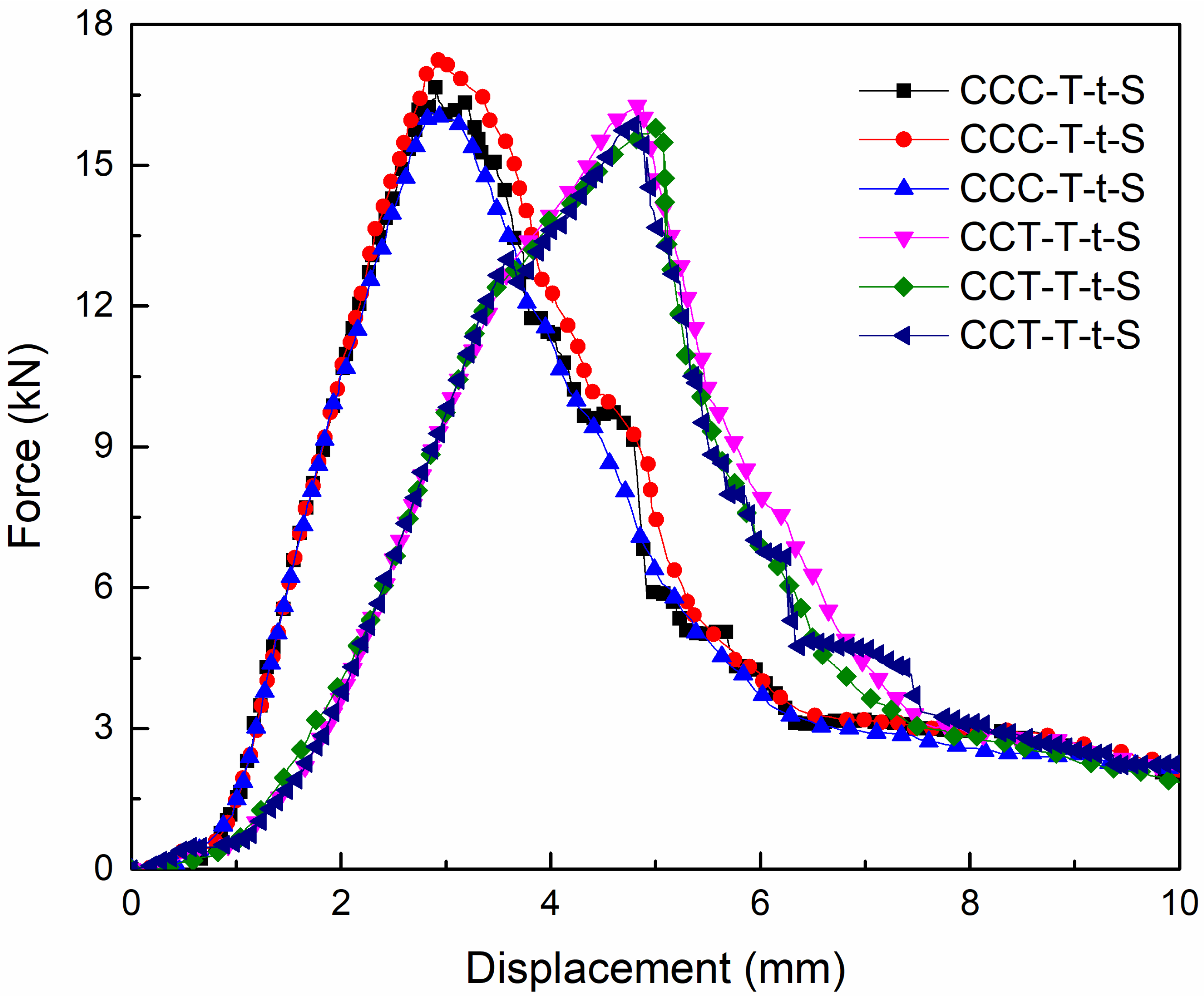

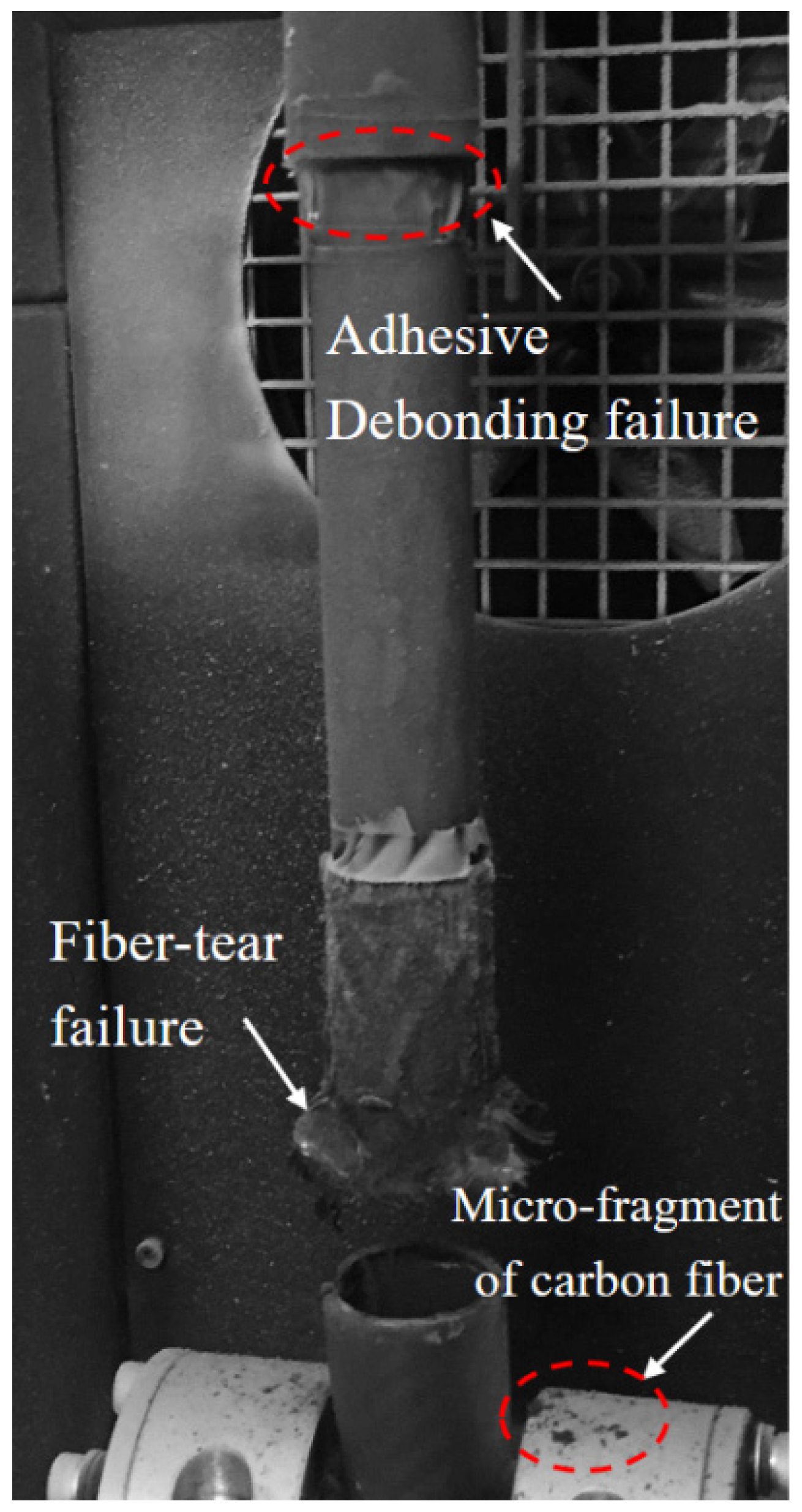

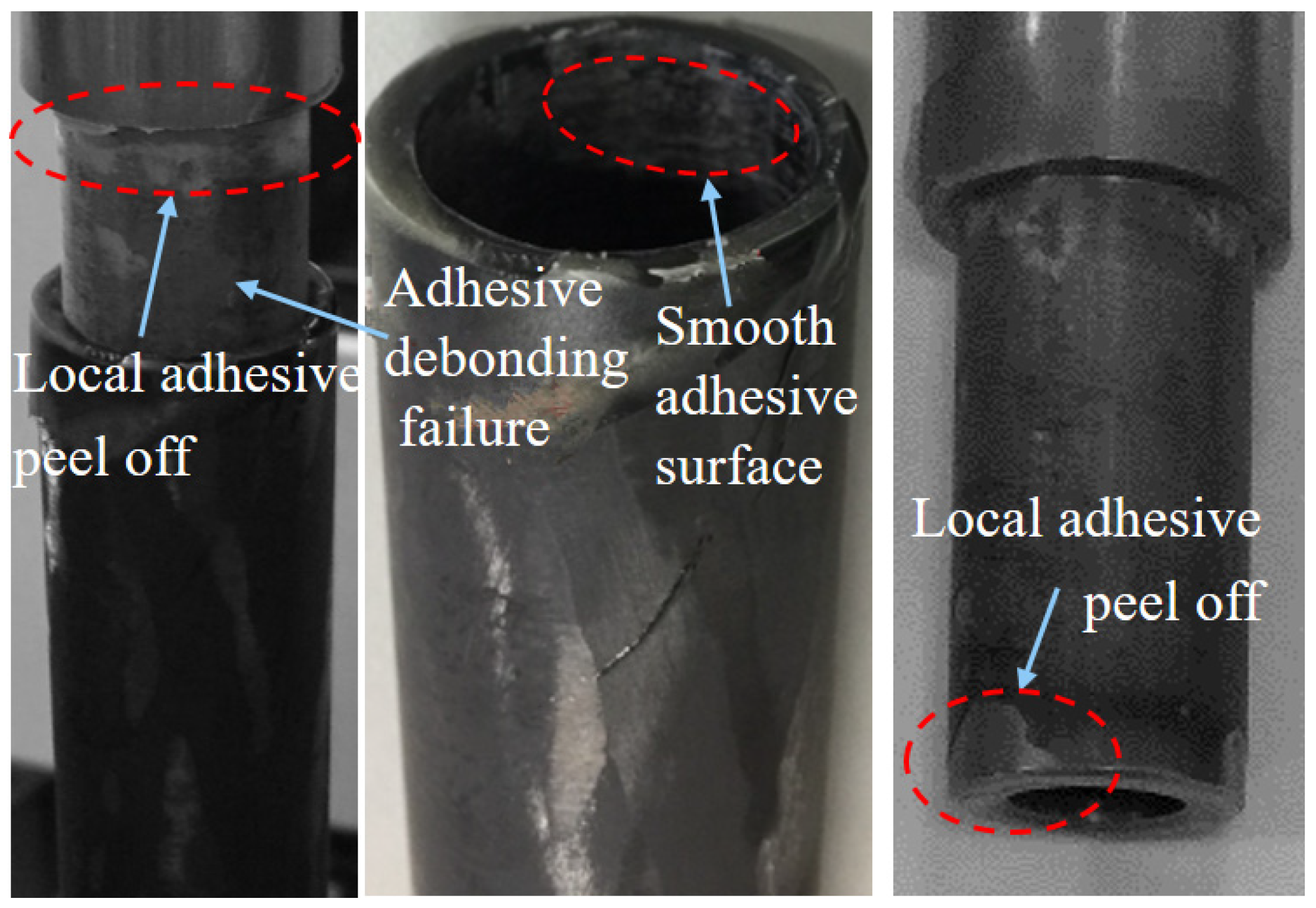

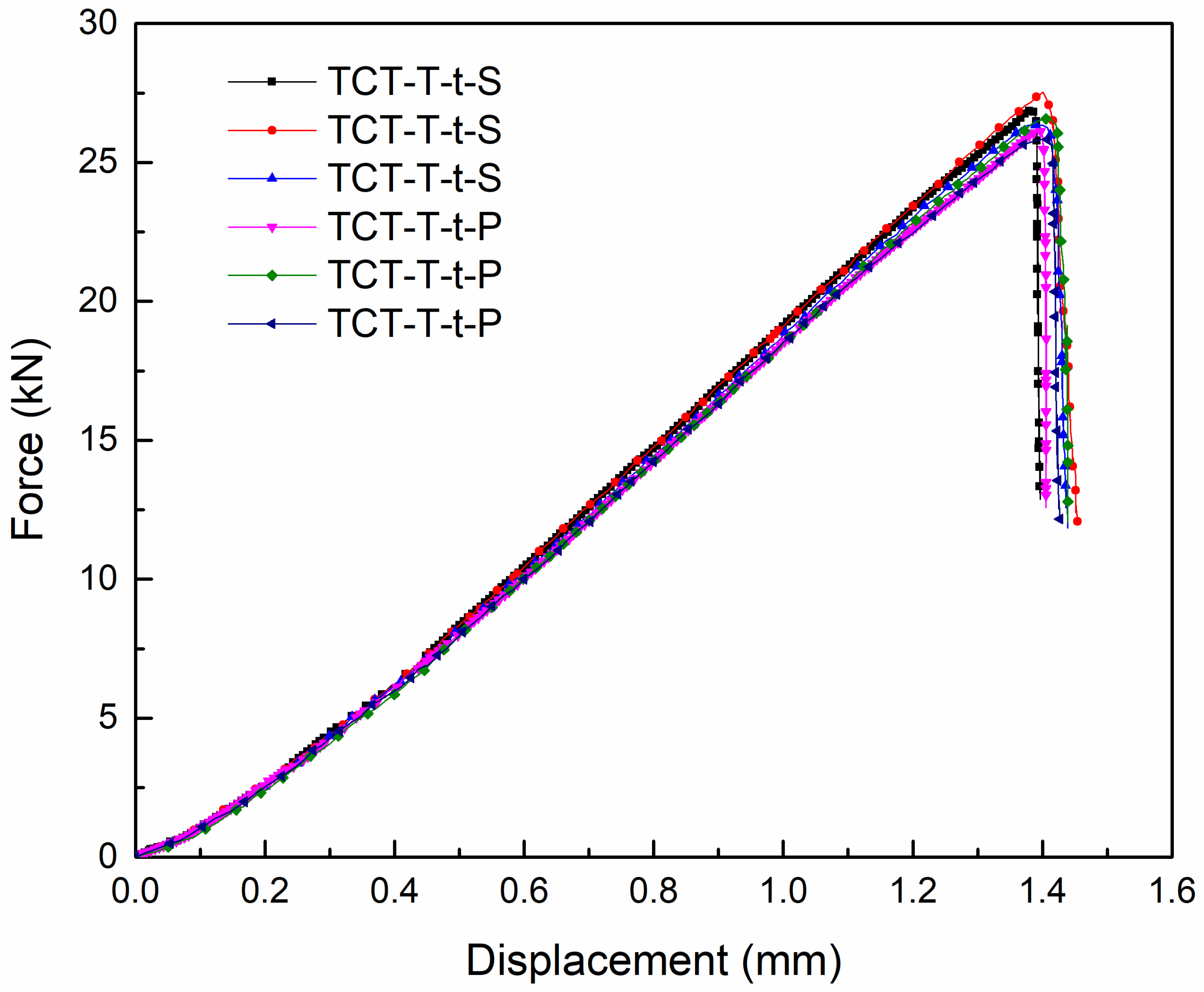

3.3. Influence of Failure Modes Under Room–Low–Room-Temperature Cycling

4. Analysis of Failure Load and Lap Shear Strength

5. Conclusions

- Under both room-temperature and low-temperature conditions, the temperature had minimal impact on the tensile failure load of the joints. At room temperature, the primary failure mode observed in the carbon fiber three-way tube was fiber-tear failure. In contrast, at low temperatures (−65 °C), the titanium alloy tube predominantly exhibited adhesive debonding failure at one end of the specimen, while the carbon fiber three-way tube primarily showed fiber-tear failure at the opposite end. The presence of a spew-fillet at the end of the lap region in the adhesive did not significantly enhance the strength of the adhesively bonded joints. Notably, severe shear stress concentration was observed at the end of the lap region across various types of adhesively bonded joints, marking the initial point of joint failure.

- Under simulated conditions of room temperature to low temperature and back to room temperature, the adhesive bonding between the carbon fiber circular tube and the titanium alloy joint achieved the maximum load-bearing capacity 27.522 kN and the highest shear strength 10.956 MPa. The failure mode of the adhesively bonded joints primarily exhibited irregular adhesive interface debonding. These specimens achieved higher failure loads and bonding strengths compared to other groups after undergoing room–low–room-temperature cycling. The tensile failure limit increased by approximately 61% relative to that observed under room-temperature or low-temperature conditions alone; however, the average tensile failure displacement remained relatively low. Following thermal cycling, the bonding strength of the single-lap joints was significantly enhanced.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Park, Y.B.; Song, M.G.; Kim, J.J.; Kweon, J.H.; Choi, J.H. Strength of carbon/epoxy composite single-lap bonded joints in various environmental conditions. Compos. Struct. 2010, 92, 2173–2180. [Google Scholar] [CrossRef]

- Moya-Sanz, E.M.; Ivañez, I.; Shirley, K. Garcia-Castillo. Effect of the geometry in the strength of single-lap adhesive joints of composite laminates under uniaxial tensile load. Int. J. Adhes. Adhes. 2017, 72, 23–29. [Google Scholar] [CrossRef]

- Stuparu, F.A.; Apostol, D.A.; Constantinescu, D.M.; Picu, C.R.; Sandu, M.; Sorohan, S. Local evaluation of adhesive failure in similar and dissimilar single-lap joints. Eng. Fract. Mech. 2017, 183, 39–52. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, P.; Duan, M. A mesh-independent technique to evaluate stress singularities in adhesive joints. Int. J. Adhes. Adhes. 2015, 57, 105–117. [Google Scholar] [CrossRef]

- Dimitrienko, Y.I. Thermomechanics of Composite Structures Under High Temperatures; Springer: Dordrect, The Netherlands, 2016. [Google Scholar]

- Ma, J.; Sun, Y.; Li, B.W. Spectral collocation method for transient thermal analysis of coupled conductive, convective and radiative heat transfer in the moving plate with temperature dependent properties and heat generation. Int. J. Heat Mass Transf. 2017, 114, 469–482. [Google Scholar] [CrossRef]

- Riccio, A.; Russo, A.; Raimondo, A.; Cirillo, P.; Caraviello, A. A numerical/experimental study on the induction heating of adhesives for composite materials bonding. Mater. Today Commun. 2018, 15, 203–213. [Google Scholar] [CrossRef]

- Kumar, R.; Mohanty, S.; Sanjay, K. Nayak. Study on epoxy resin based thermal adhesive composite incorporated with expanded graphite/silver flake hybrids. Mater. Today Commun. 2019, 20, 100561. [Google Scholar] [CrossRef]

- Volkersen, O. Die Nietkraftverteilung in zugbeanspruchten Nietverbindungen mit konstanten Laschenquerschnitten. Luftfahrtforschung 1938, 15, 41–47. [Google Scholar]

- Goland, M.; Reissner, E. The stresses in cemented joints. J. Appl. Mech. 1944, 11, A17–A27. [Google Scholar] [CrossRef]

- Hart-Smith, L.J. Adhesive-Bonded Single-Lap Joints; Langley Research Center: Hampton, VA, USA, 1973. [Google Scholar]

- Adams, R.D.; Peppiatt, N.A. Stress analysis of adhesive-bonded lap joints. J. Strain Anal. Eng. Des. 1974, 9, 185–196. [Google Scholar] [CrossRef]

- Renton, W.J.; Vinson, J.R. The efficient design of adhesive bonded joints. J. Adhes. 1975, 7, 175–193. [Google Scholar] [CrossRef]

- Allman, D.J. A theory for elastic stresses in adhesive bonded lap joints. Q. J. Mech. Appl. Math. 1977, 30, 415–436. [Google Scholar] [CrossRef]

- Groth, H.L.; Brottare, I. Evaluation of singular intensity factors in elastic-plastic materials. J. Test. Eval. 1988, 16, 291–297. [Google Scholar] [CrossRef]

- Wahab, M.A.; Ashcroft, I.A.; Crocombe, A.D.; Shaw, S.J. Prediction of fatigue thresholds in adhesively bonded joints using damage mechanics and fracture mechanics. J. Adhes. Sci. Technol. 2001, 15, 763–781. [Google Scholar] [CrossRef]

- De Moura, M.F.S.F.; Gonçalves, J.P.M.; Chousal, J.A.G.; Campilho, R.D.S. G Cohesive and continuum mixed-mode damage models applied to the simulation of the mechanical behaviour of bonded joints. Int. J. Adhes. Adhes. 2008, 28, 419–426. [Google Scholar] [CrossRef]

- Anyfantis, K.N.; Tsouvalis, N.G. A 3D ductile constitutive mixed-mode model of cohesive elements for the finite element analysis of adhesive joints. J. Adhes. Sci. Technol. 2013, 27, 1146–1178. [Google Scholar] [CrossRef]

- Luo, H.B.; Yan, Y.; Zhang, T.T.; Liang, Z.D. Progressive failure and experimental study of adhesively bonded composite single-lap joints subjected to axial tensile loads. J. Adhes. Sci. Technol. 2016, 30, 894–914. [Google Scholar] [CrossRef]

- Li, J.F.; Yan, Y.; Zhang, T.T.; Liang, Z.D. Experimental study of adhesively bonded CFRP joints subjected to tensile loads. Int. J. Adhes. Adhes. 2015, 57, 95–104. [Google Scholar] [CrossRef]

- Kumar, S.B.; Sridhar, I.; Sivashanker, S.; Osiyemi, S.O.; Bag, A. Tensile failure of adhesively bonded CFRP composite scarf joints. Mater. Sci. Eng. B 2006, 132, 113–120. [Google Scholar] [CrossRef]

- Gunnion, A.J.; Herszberg, I. Parametric study of scarf joints in composite structures. Compos. Struct. 2006, 75, 364–376. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G.; De Moura, M.F.S.F.; Pinto, A.M.G.; Morais, J.J.L.; Domingues, J.J.M.S. Modelling the tensile fracture behaviour of CFRP scarf repairs. Compos. Part B Eng. 2009, 40, 149–157. [Google Scholar] [CrossRef]

- Kwon, Y.W.; Marron, A. Scarf joints of composite materials: Testing and analysis. Appl. Compos. Mater. 2009, 16, 365–378. [Google Scholar] [CrossRef]

- He, D.; Sawa, T.; Iwamoto, T.; Hirayama, Y. Stress analysis and strength evaluation of scarf adhesive joints subjected to static tensile loadings. Int. J. Adhes. Adhes. 2010, 30, 387–392. [Google Scholar] [CrossRef]

- Adin, H. The investigation of the effect of angle on the failure load and strength of scarf lap joints. Int. J. Mech. Sci. 2012, 61, 24–31. [Google Scholar] [CrossRef]

- Liao, L.; Huang, C.; Sawa, T. Effect of adhesive thickness, adhesive type and scarf angle on the mechanical properties of scarf adhesive joints. Int. J. Solids Struct. 2013, 50, 4333–4340. [Google Scholar] [CrossRef]

- Li, X.; Luo, H.; Zhang, H.; Wang, S.; Han, X.; Wu, H. Experimental and numerical investigations of adhesively bonded carbon/carbon composites subjected to interlaminar shear loads. J. Adhes. Sci. Technol. 2019, 33, 2207–2226. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, Z.; Guo, Y.; Wu, L. Effect of defects in the adhesive layer on strength of adhesively bonded single-lap composites joints. Acta Mater. Compos. Sinica. 2012, 29, 157–163. [Google Scholar]

- Khalili, S.M.R.; Khalili, S.; Pirouzhashemi, M.R.; Shokuhfar, A.; Mittal, R.K. Numerical study of lap joints with composite adhesives and composite adherends subjected to in-plane and transverse loads. Int. J. Adhes. Adhes. 2008, 28, 411–418. [Google Scholar] [CrossRef]

- de Castro, J.; Keller, T. Ductile double-lap joints from brittle GFRP laminates and ductile adhesives, Part II: Numerical investigation and joint strength prediction. Compos. Part B 2008, 39, 282–291. [Google Scholar] [CrossRef]

- Mokhtari, M.; Madani, K.; Belhouari, M.; Touzain, S.; Feaugas, X.; Ratwani, M. Effects of composite adherend properties on stresses in double lap bonded joints. Mater. Des. 2013, 44, 633–639. [Google Scholar] [CrossRef]

- Rahman, N.M.; Sun, C.T. Strength calculation of composite single lap joints with Fiber-Tear-Failure. Compos. Part B 2014, 62, 249–255. [Google Scholar] [CrossRef]

- Shishesaz, M.; Ghamarian, A.H.; Mosalmani, R. The Effects of Defects and Adherend Material on Adhesive Stress Distribution in Laminated Composite Tubular Joints Under Axial Tensile Loads. J. Appl. Comput. Mech. 2025. [Google Scholar] [CrossRef]

- Kaiser, I.; Zhang, C.; Tan, K.T. Mechanical behavior and failure mechanisms of CFRP and Titanium tubular adhesive lap joints at extreme temperatures. Compos. Struct. 2022, 290, 115528. [Google Scholar] [CrossRef]

- Lavalette, N.P.; Bergsma, O.K.; Zarouchas, D.; Benedictus, R. Influence of geometrical parameters on the strength of Hybrid CFRP-aluminium tubular adhesive joints. Compos. Struct. 2020, 240, 112077. [Google Scholar] [CrossRef]

- Higgoda, T.M.; Elchalakani, M.; Kimiaei, M.; Yang, B.; Guo, X. Experimental investigation on the structural behaviour of novel non-metallic pultruded circular tubular GFRP T-joints under axial compression. Thin-Walled Struct. 2023, 184, 110512. [Google Scholar] [CrossRef]

- Barzegar, M.; Moallem, M.D.; Mokhtari, M. Progressive damage analysis of an adhesively bonded composite T-joint under bending, considering micro-scale effects of fiber volume fraction of adherends. Compos. Struct. 2021, 258, 113374. [Google Scholar] [CrossRef]

- Luo, H.B.; Wang, Q.; Yang, Y.C.; He, X.H.; Feng, H.; Nie, Y.; Li, T. Experimental study on the mechanical properties of three-dimensional braided composite circular tubes with preembedded licker-in. Polym. Compos. 2023, 44, 5433–5449. [Google Scholar] [CrossRef]

- Luo, H.; Li, X.; Li, Y.; He, X.; Ye, J.; Li, Z. Damage properties of pre-embedded connection of carbon ffber wound composite tubes. Mater. Today Commun. 2020, 25, 101525. [Google Scholar] [CrossRef]

- Huang, Z.Y.; Wang, Q.Y.; Wagner, D.; Bathias, C. Avery high cycle fatigue thermal dissipation investigation for titanium alloy TC4. Mater. Sci. Eng. A 2014, 600, 153–158. [Google Scholar] [CrossRef]

- ASTM D5868-95; Standard Test Method for Lap Shear Adhesion for Fiber Reinforced Plastic (FRP) Bonding. American Society for Testing and Materials: West Conshohocken, PA, USA, 2014.

| Materials | Properties | |||

|---|---|---|---|---|

| T700/C204 | E1 = 130 GPa | G12 = 5.0 GPa | ν12 = 0.40 | ρ = 1.65 g/cm3 |

| E2 = 9.1 GPa | G23 = 4.3 GPa | ν23 = 0.38 | ||

| E3 = 9.1 GPa | G31 = 5.0 GPa | ν31 = 0.02 | ||

| TC4 | E = 110 GPa | - | ν = 0.34 | ρ = 4.5 g/cm3 |

| σ = 1100 MPa | ||||

| J-250 | E = 1 GPa | - | ν = 0.3 | ρ = 0.6 g/cm3 |

| σ = 24.5 MPa | τ = 25 MPa |

| Specimens | Ply Sequences | Adherend Thickness (mm) | Adhesive Thickness (mm) | Single-Lap Forms | No. of Specimens |

|---|---|---|---|---|---|

| CCC-T-t-S | [0/±45/0]2S | 2.5/2.5 | 0.15 | Adhesive spew-fillets (25 °C)/ Adhesive spew-fillets (−65 °C) | 3/3 |

| CCT-T-t-S | [0/±45/0]2S | 2.5/4.0 | 0.15 | Adhesive spew-fillets (25 °C)/ Adhesive spew-fillets (−65 °C) | 3/3 |

| TCT-T-t-P/S | [0/±45/0]2S | 2.5/4.0 | 0.15 | Perfect lap (25~−65~25 °C)/ Adhesive spew-fillets (25~−65~25 °C) | 3/3 |

| Specimens | Failure Load/kN | Average Failure Load/kN | Standard Deviation | Shear Strength/MPa | Average Shear Strength/MPa | Standard Deviation | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| CCC-T-t-S (25 °C) | 16.655 | 17.277 | 16.124 | 16.686 | 0.471 | 6.630 | 6.878 | 6.419 | 6.642 | 0.188 |

| CCC-T-t-S (−65 °C) | 16.237 | 16.572 | 16.068 | 16.311 | 0.209 | 6.464 | 6.597 | 6.397 | 6.486 | 0.083 |

| CCT-T-t-S (25 °C) | 15.939 | 16.365 | 15.787 | 16.030 | 0.245 | 6.345 | 6.515 | 6.285 | 6.382 | 0.097 |

| CCT-T-t-S (−65 °C) | 15.976 | 16.315 | 15.847 | 16.046 | 0.197 | 6.360 | 6.495 | 6.309 | 6.388 | 0.078 |

| TCT-T-t-S (25 °C~−65 °C~25 °C) | 26.852 | 27.522 | 26.340 | 26.905 | 0.484 | 10.690 | 10.956 | 10.486 | 10.710 | 0.193 |

| TCT-T-t-P (25 °C~−65 °C~25 °C) | 26.145 | 26.571 | 25.821 | 26.179 | 0.307 | 10.408 | 10.578 | 10.279 | 10.422 | 0.122 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, H.; Wang, Q.; Yang, Y.; Li, T.; Wu, J.; Gong, W.; Feng, H.; He, X. Axial Tensile Adhesively Bonded Performance of Carbon Fiber Composite Tubes Under Room-Temperature and Low-Temperature Circulation. Materials 2025, 18, 1124. https://doi.org/10.3390/ma18051124

Luo H, Wang Q, Yang Y, Li T, Wu J, Gong W, Feng H, He X. Axial Tensile Adhesively Bonded Performance of Carbon Fiber Composite Tubes Under Room-Temperature and Low-Temperature Circulation. Materials. 2025; 18(5):1124. https://doi.org/10.3390/ma18051124

Chicago/Turabian StyleLuo, Haibo, Qian Wang, Yanchu Yang, Tao Li, Jun Wu, Wentao Gong, Hui Feng, and Xiaohui He. 2025. "Axial Tensile Adhesively Bonded Performance of Carbon Fiber Composite Tubes Under Room-Temperature and Low-Temperature Circulation" Materials 18, no. 5: 1124. https://doi.org/10.3390/ma18051124

APA StyleLuo, H., Wang, Q., Yang, Y., Li, T., Wu, J., Gong, W., Feng, H., & He, X. (2025). Axial Tensile Adhesively Bonded Performance of Carbon Fiber Composite Tubes Under Room-Temperature and Low-Temperature Circulation. Materials, 18(5), 1124. https://doi.org/10.3390/ma18051124