Preparation and Characterization of Graphene-Nanosheet-Reinforced Ni-17Mo Alloy Composites for Advanced Nuclear Reactor Applications

Abstract

1. Introduction

2. Experimental Procedures

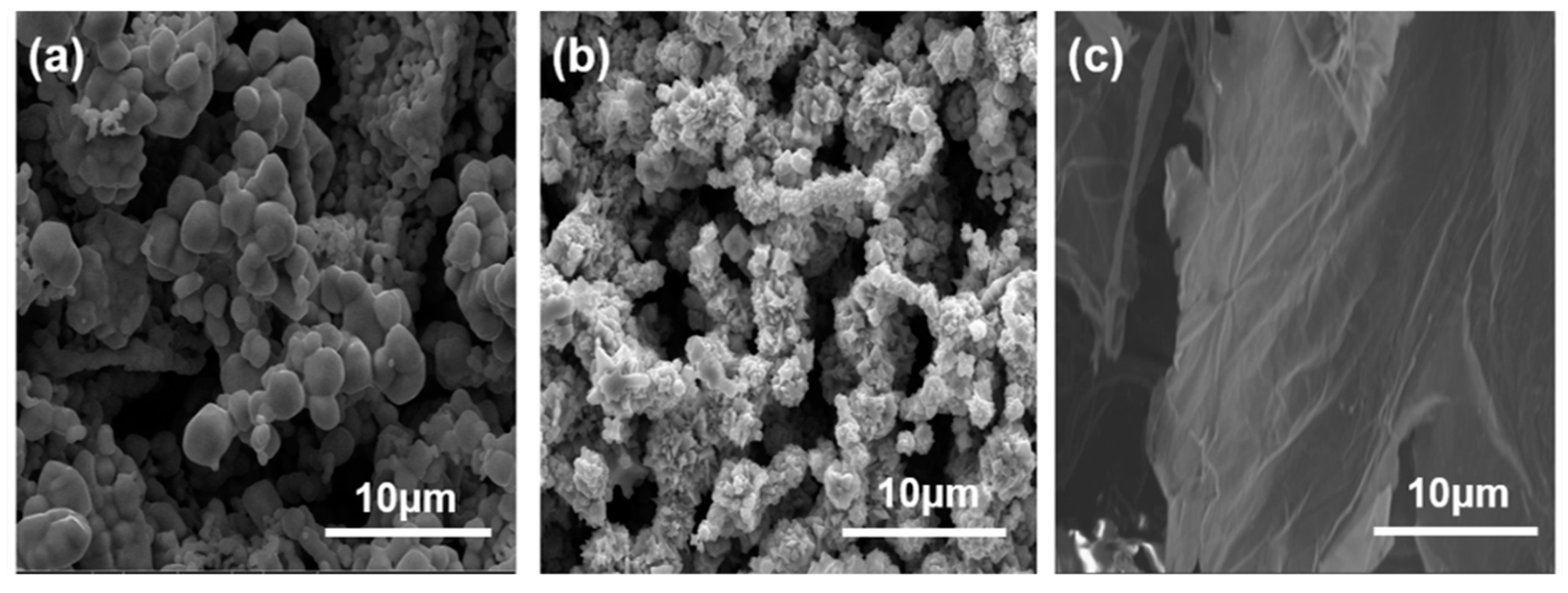

2.1. Raw Powder Preparation

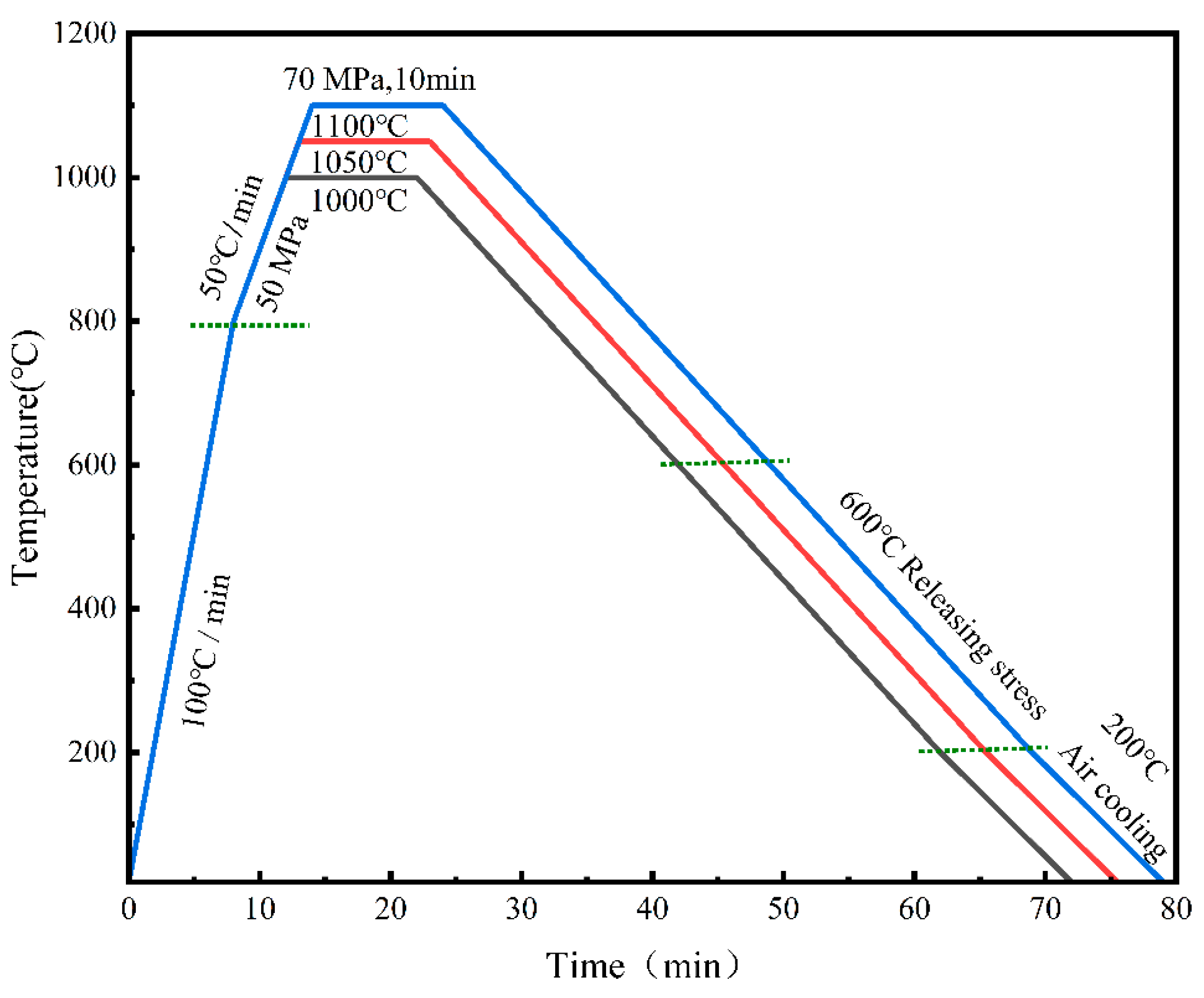

2.2. Synthesis of Alloy and Composite Bulk

2.3. Microstructure Characterization and Property Measurements

3. Results and Discussion

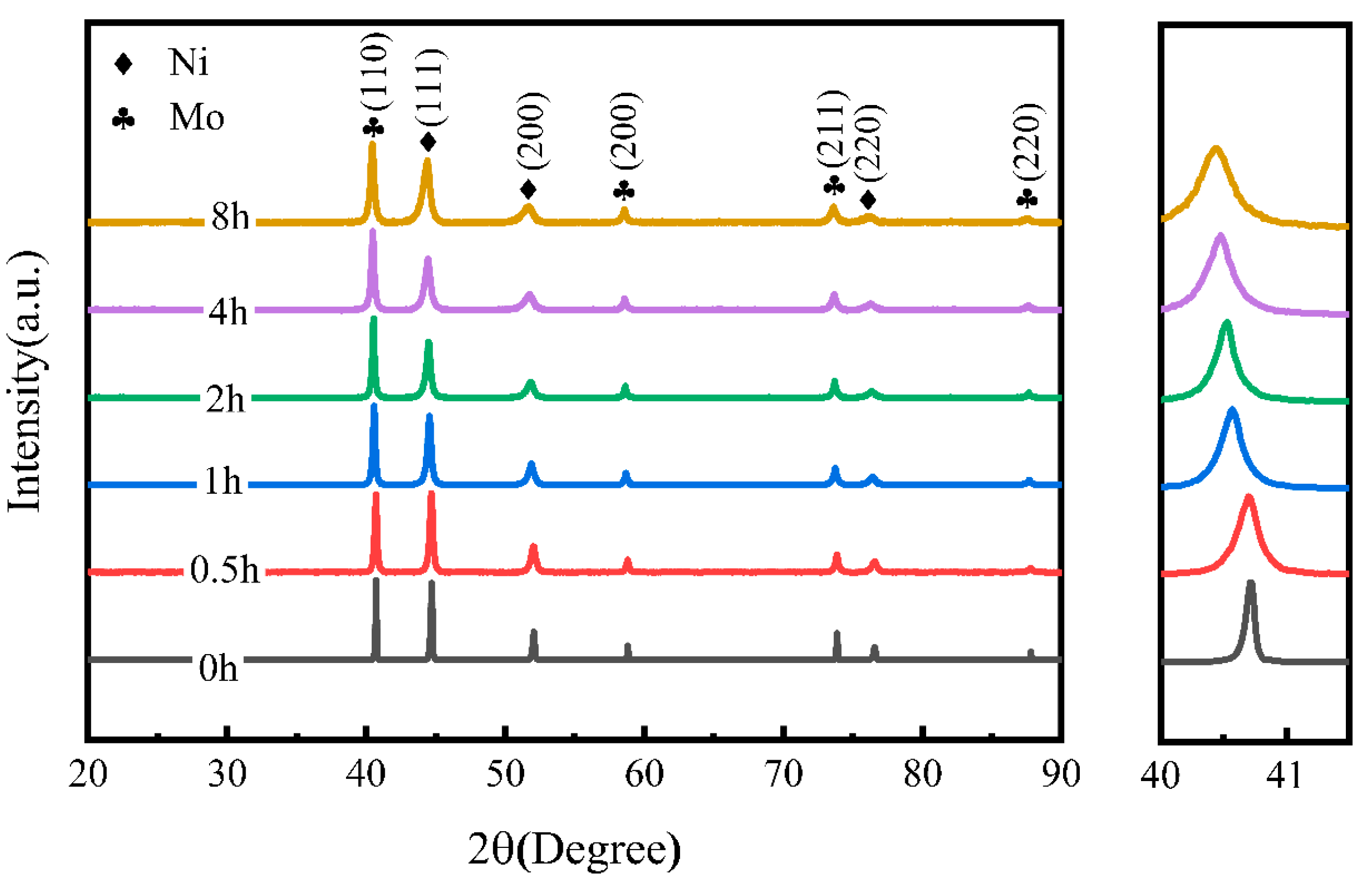

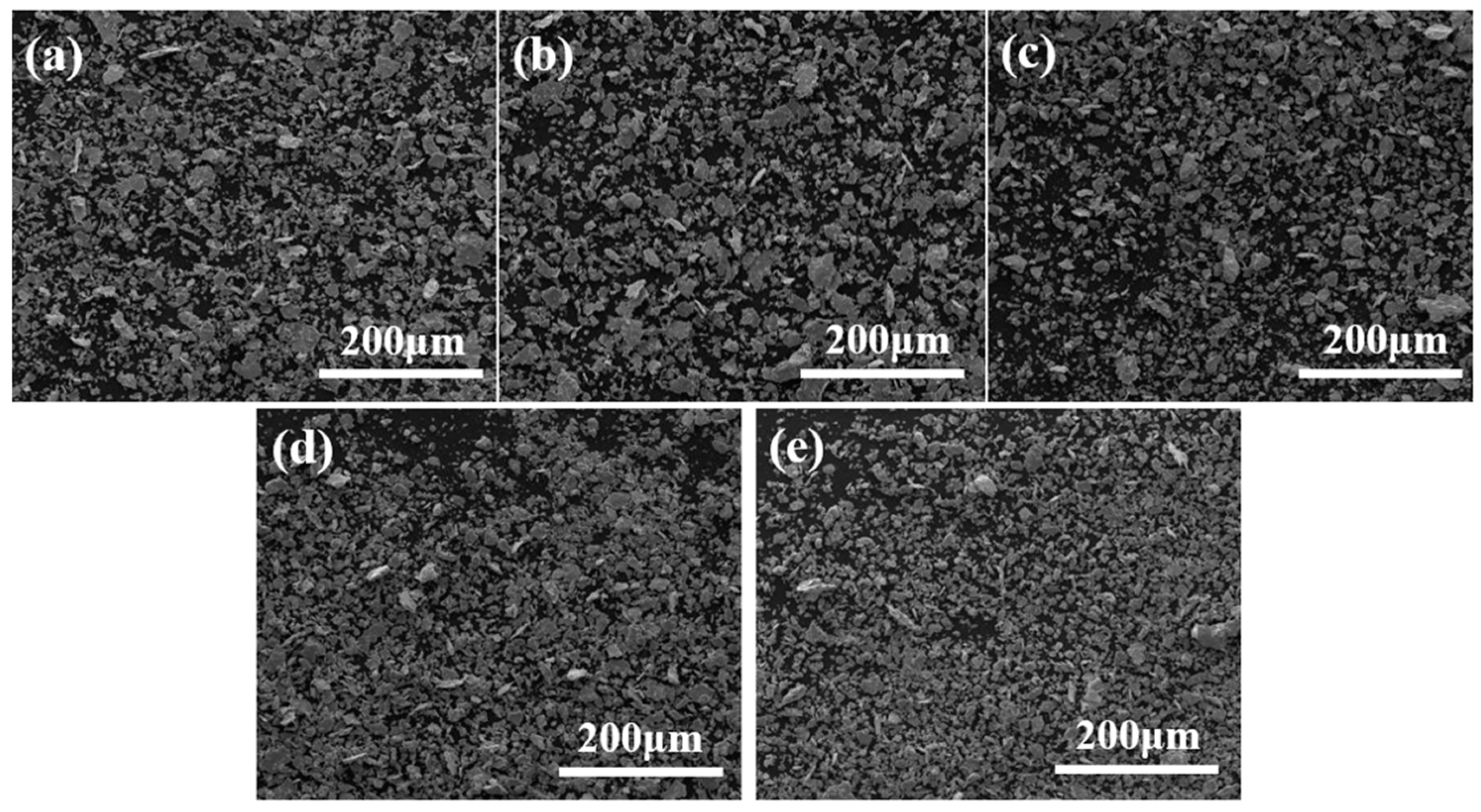

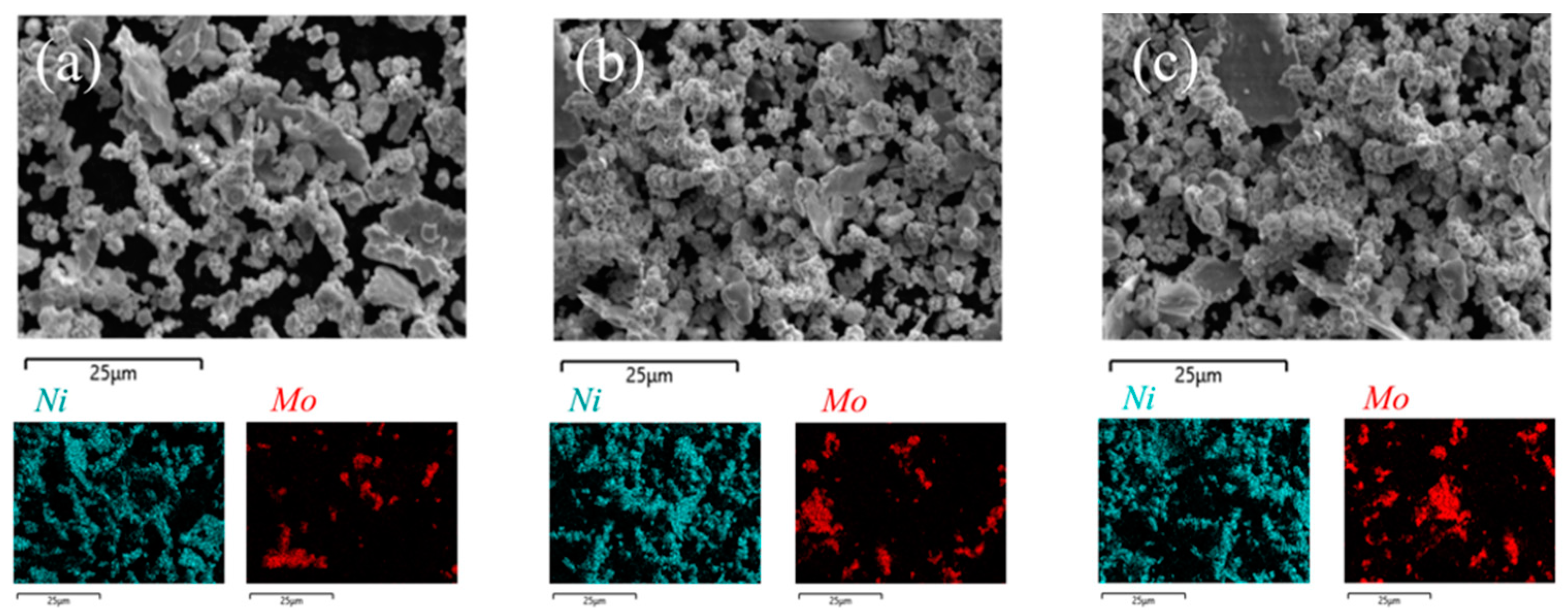

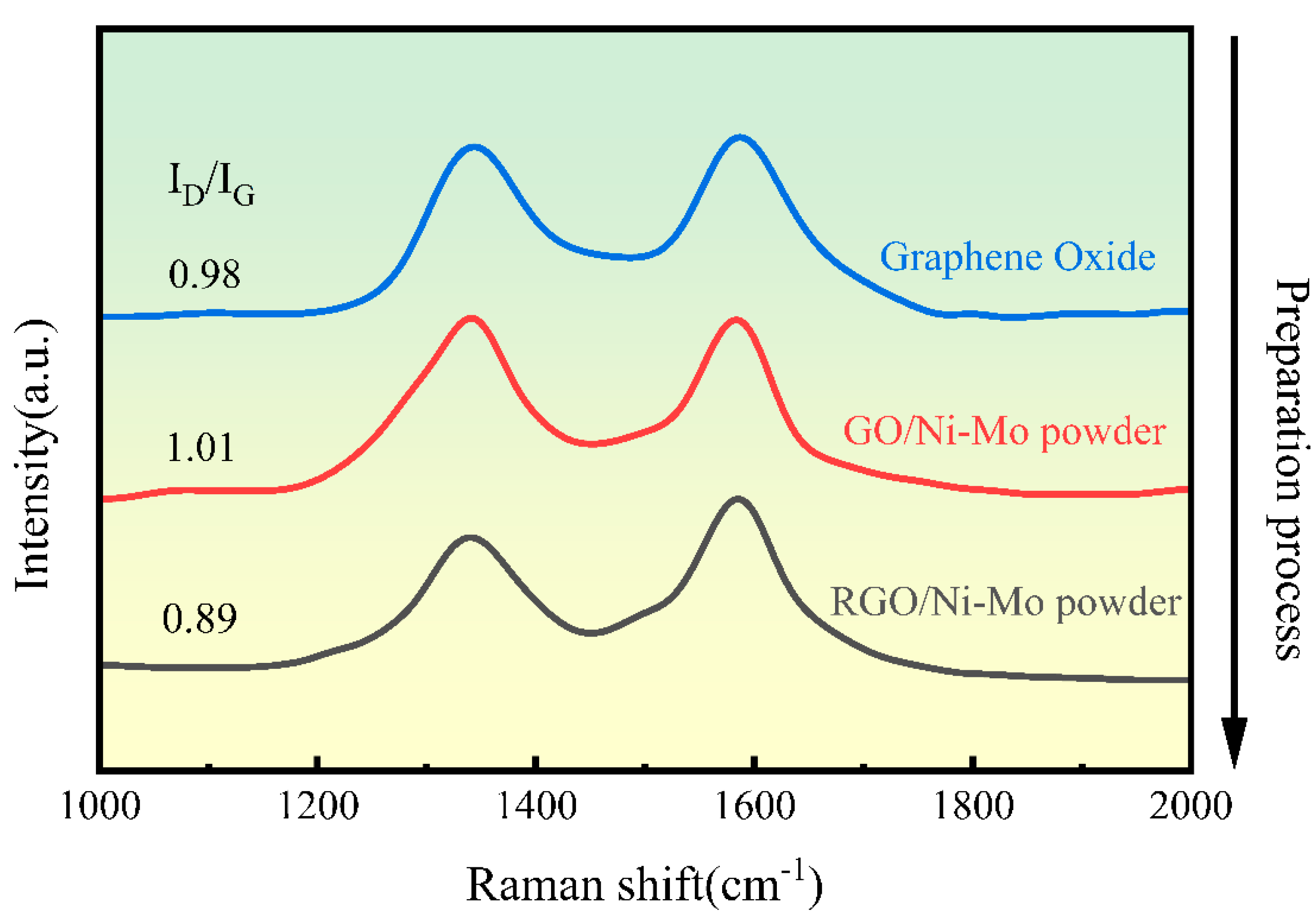

3.1. Effect of Milling Time on Powder Mixture

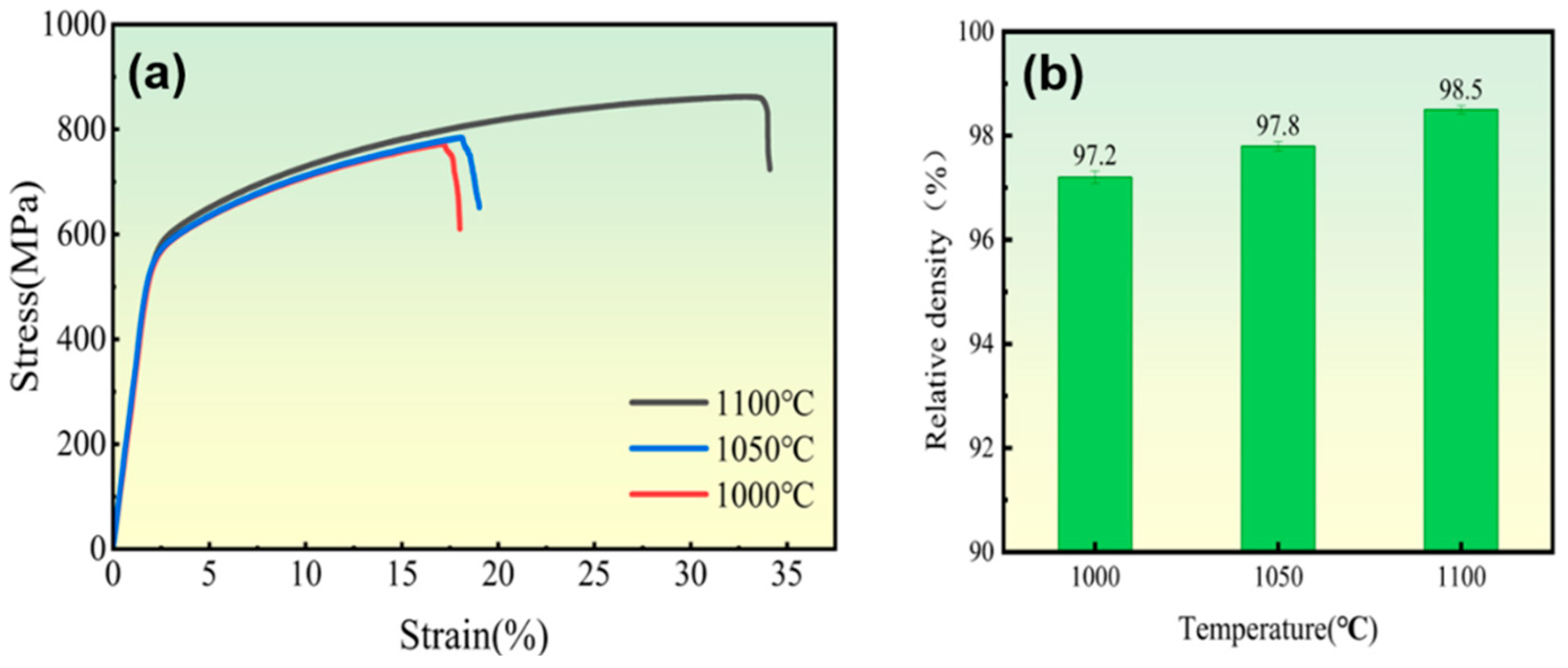

3.2. Effect of Process Parameters on Properties

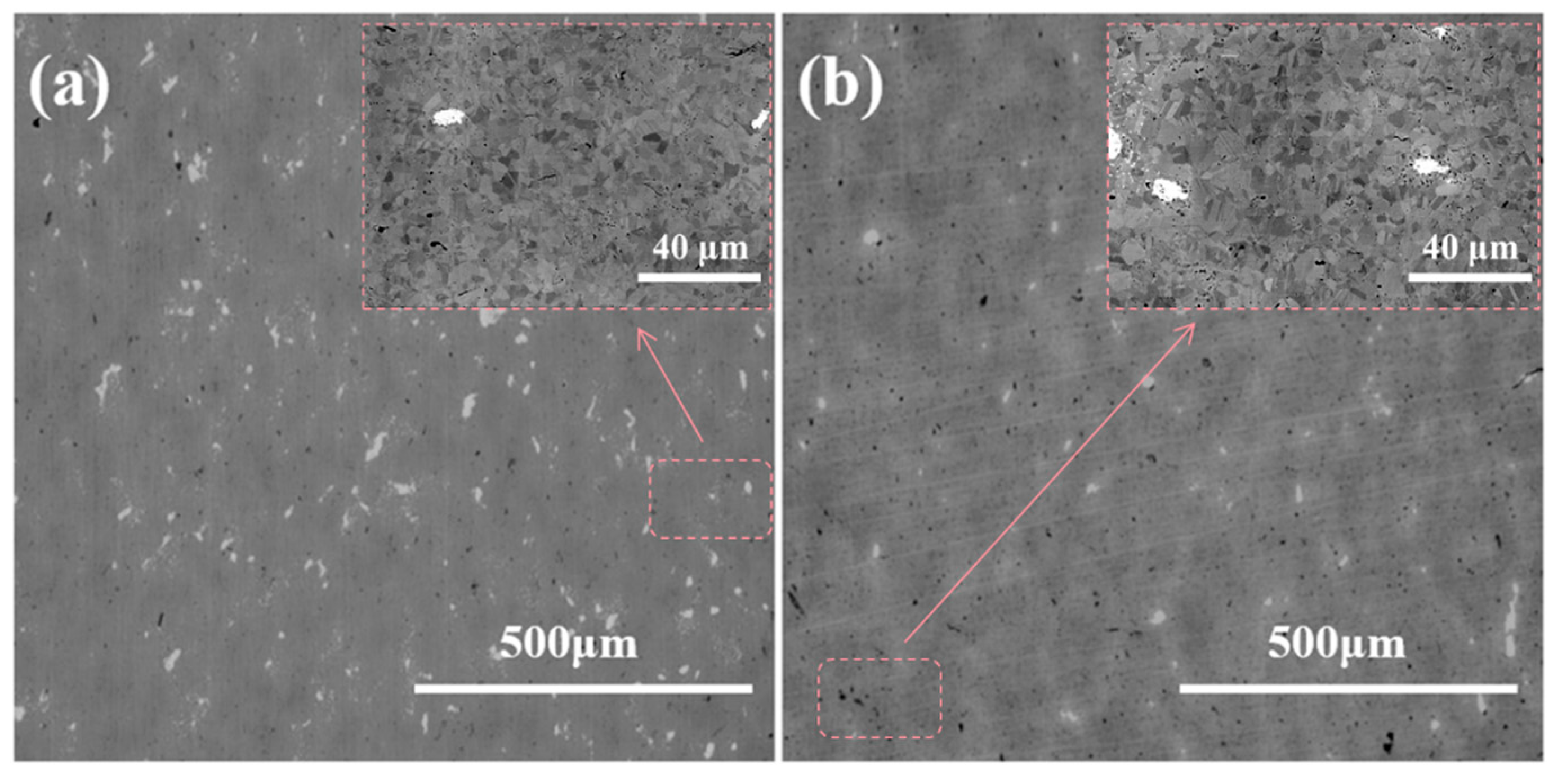

3.3. Effect of Adding Gr on Alloy Matrix

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- LeBlanc, D. Molten salt reactors: A new beginning for an old idea. Nucl. Eng. Des. 2010, 240, 1644–1656. [Google Scholar] [CrossRef]

- Patel, N.S.; Pavlík, V.; Boča, M. High-Temperature Corrosion Behavior of Superalloys in Molten Salts—A Review. Crit. Rev. Solid State Mater. Sci. 2016, 42, 83–97. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, J.; Wu, W.; Zhou, W. Corrosion in the molten fluoride and chloride salts and materials development for nuclear applications. Prog. Mater. Sci. 2018, 97, 448–487. [Google Scholar] [CrossRef]

- Li, C.; Lei, G.; Liu, J.; Liu, A.; Ren, C.L.; Huang, H. A potential candidate structural material for molten salt reactor: ODS nickel-based alloy. J. Mater. Sci. Technol. 2022, 109, 129–139. [Google Scholar] [CrossRef]

- Vacik, J.; Naramoto, H.; Cervena, J.; Hnatowicz, V.; Peka, I.; Fink, D. Absorption of molten fluoride salts in glassy carbon, pyrographite and Hastelloy B. J. Nucl. Mater. 2001, 289, 308–314. [Google Scholar] [CrossRef]

- Volkov, S.; Omel’chuk, A.; Azhazha, V.; Bakai, A. Corrosion stability of irradiated Hastelloy-type alloys in molten NaF-ZrF4 mixture. J. New Mater. Electrochem. Syst. 2006, 9, 305–311. [Google Scholar]

- Murty, K.L.; Charit, I. Structural materials for Gen-IV nuclear reactors: Challenges and opportunities. J. Nucl. Mater. 2008, 383, 189–195. [Google Scholar] [CrossRef]

- Ye, Y.; Ma, L.; Tang, T.; Liu, T.; Chen, F.; Ge, X.; Jiang, Y.; Yu, X.; Huang, H. Characterization of microstructure and properties of Ti35 alloy and its high-fluence hydrogen irradiation-induced surface exfoliation. Eur. Phys. J. Plus 2024, 139, 822. [Google Scholar] [CrossRef]

- Qiu, S.; Liu, H.; Jiang, M.; Min, S.; Gu, Y.; Wang, Q.; Yang, J.; Li, X.; Chen, Z.; Hou, J. A Brief Review on He Ion Irradiation Research of Steel and Iron-Based Alloys in Nuclear Power Plants. Acta Metall. Sin. (Eng. Lett.) 2022, 36, 529–551. [Google Scholar] [CrossRef]

- Zemła, M.R.; Wróbel, J.S.; Wejrzanowski, T.; Nguyen-Manh, D.; Kurzydłowski, K.J. The helium effect at grain boundaries in Fe-Cr alloys: A first-principles study. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2017, 393, 118–121. [Google Scholar] [CrossRef]

- Sharma, S.S.; Parashar, A. Effect of helium on thermal transport properties in single-and bi-crystals of Ni: A study based on molecular dynamics. J. Phys. D Appl. Phys. 2023, 57, 055304. [Google Scholar] [CrossRef]

- Ma, L.; Liu, T.; Cai, B.; Liu, Z.; Zhang, G.; Li, J.; Li, H.; Huang, H. Molecular dynamics studies of primary irradiation damage in α-type Ti35 alloy. Phys. Status Soldi B 2023, 260, 2200560. [Google Scholar] [CrossRef]

- Barr, C.M.; El-Atwani, O.; Kaoumi, D.; Hattar, K. Interplay Between Grain Boundaries and Radiation Damage. JOM 2019, 71, 1233–1244. [Google Scholar] [CrossRef]

- Su, Z.; Jiang, H.; Li, H.; Zhang, Y.; Chen, J.; Zhao, J.; Ma, Y. Recent progress on interfaces in nanomaterials for nuclear radiation resistance. ChemNanoMat 2023, 9, e202200477. [Google Scholar] [CrossRef]

- Huang, H.; Tang, X.; Chen, F.; Liu, J.; Sun, X.; Ji, L. Radiation tolerance of nickel–graphene nanocomposite with disordered graphene. J. Nucl. Mater. 2018, 510, 1–9. [Google Scholar] [CrossRef]

- Nieto, A.; Bisht, A.; Lahiri, D.; Zhang, C.; Agarwal, A. Graphene reinforced metal and ceramic matrix composites: A review. Int. Mater. Rev. 2016, 62, 241–302. [Google Scholar] [CrossRef]

- Razaq, A.; Bibi, F.; Zheng, X.; Papadakis, R.; Jafri, S.H.M.; Li, H. Review on graphene-, graphene oxide-, reduced graphene oxide-based flexible composites: From fabrication to applications. Materials 2022, 15, 1012. [Google Scholar] [CrossRef]

- Sinha, A.; Ranjan, P.; Thakur, A.D. Effect of characterization probes on the properties of graphene oxide and reduced graphene oxide. Appl. Phys. A 2021, 127, 585. [Google Scholar] [CrossRef]

- Chen, D.; Li, J.; Sun, K.; Fan, J. Graphene-reinforced metal matrix composites: Fabrication, properties, and challenges. Int. J. Adv. Manuf. Technol. 2023, 125, 2925–2965. [Google Scholar] [CrossRef]

- Liu, T.; Yuan, X.; Huang, H. Primary irradiation damage in Ni–graphene nanocomposites with pre-existing hydrogen: Insights from atomistic simulations. Eur. Phys. J. Plus 2024, 139, 22. [Google Scholar] [CrossRef]

- Huang, H.; Tang, X.; Xie, K.; Peng, Q. Enhanced self-healing of irradiation defects near a Ni–graphene interface by damaged graphene: Insights from atomistic modeling. J. Phys. Chem. Solids 2021, 151, 109909. [Google Scholar] [CrossRef]

- Si, S.; Li, W.; Zhao, X.; Han, M.; Yue, Y.; Wu, W.; Guo, S.; Zhang, X.; Dai, Z.; Wang, X.; et al. Significant radiation tolerance and moderate reduction in thermal transport of a tungsten nanofilm by inserting monolayer graphene. Adv. Mater. 2017, 29, 1604623. [Google Scholar] [CrossRef]

- Liu, Y.; Zeng, Y.; Guo, Q.; Zhang, J.; Li, Z.; Xiong, D.-B.; Li, X.; Zhang, D. Bulk nanolaminated graphene (reduced graphene oxide)–aluminum composite tolerant of radiation damage. Acta Mater. 2020, 196, 17–29. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, S.; Yao, Y.; Fan, L.; Wang, J.; Wu, Y.; Jing, L.; Han, P.; Zhang, C. Enhancement of strength-ductility synergy of in situ synthesized graphene/Ni composite via Mo microalloying. Mater. Sci. Eng. A 2025, 919, 147496. [Google Scholar] [CrossRef]

- Gürbüz, M.; Mutuk, T. Effect of process parameters on hardness and microstructure of graphene reinforced titanium composites. J. Compos. Mater. 2017, 52, 543–551. [Google Scholar] [CrossRef]

- Sadhu, K.K.; Mandal, N.; Sahoo, R.R. SiC/graphene reinforced aluminum metal matrix composites prepared by powder metallurgy: A review. J. Manuf. Process. 2023, 91, 10–43. [Google Scholar] [CrossRef]

- Rahimian, M.; Ehsani, N.; Parvin, N.; Baharvandi, H.R. The effect of particle size, sintering temperature and sintering time on the properties of Al–Al2O3 composites, made by powder metallurgy. J. Mater. Process. Tech. 2009, 209, 5387–5393. [Google Scholar] [CrossRef]

- Sathish, T.; Saravanan, R.; Kumar, A.; Prakash, C.; Shahazad, M.; Gupta, M.; Senthilkumar, N.; Pandit, B.; Ubaidullah, M.; Smirnov, V.A. Influence of synthesizing parameters on surface qualities of aluminium alloy AA5083/CNT/MoS2 nanocomposite in powder metallurgy technique. J. Mater. Res. Technol. 2023, 27, 1611–1629. [Google Scholar] [CrossRef]

- Ponhan, K.; Tassenberg, K.; Weston, D.; Nicholls, K.G.M.; Thornton, R. Effect of SiC nanoparticle content and milling time on the microstructural characteristics and properties of Mg-SiC nanocomposites synthesized with powder metallurgy incorporating high-energy ball milling. Ceram. Int. 2020, 46, 26956–26969. [Google Scholar] [CrossRef]

- Salur, E.; Aslan, A.; Kuntoğlu, M.; Acarer, M. Effect of ball milling time on the structural characteristics and mechanical properties of nano-sized Y2O3 particle reinforced aluminum matrix composites produced by powder metallurgy route. Adv. Powder Technol. 2021, 32, 3826–3844. [Google Scholar] [CrossRef]

- Du, S.; Xu, L.; Zhang, X.; Hu, P.; Han, W. Effect of sintering temperature and holding time on the microstructure and mechanical properties of ZrB2–SiCw composites. Mater. Chem. Phys. 2009, 116, 76–80. [Google Scholar] [CrossRef]

- Kang, P.; Zhao, Q.; Guo, S.; Xue, W.; Liu, H.; Chao, Z.; Jiang, L.; Wu, G. Optimisation of the spark plasma sintering process for high volume fraction SiCp/Al composites by orthogonal experimental design. Ceram. Int. 2021, 47, 3816–3825. [Google Scholar] [CrossRef]

- Hu, C.; Liu, J.; Xu, L.; Yu, L.; Zhu, B. Effect of Sintering Temperature on Properties of Carbon Fiber-Reinforced Titanium Matrix Composites. ACS Omega 2022, 7, 30087–30092. [Google Scholar] [CrossRef] [PubMed]

- Zhan, J.; Lei, Z.; Zhang, Y. Non-covalent interactions of graphene surface: Mechanisms and applications. Chem 2022, 8, 947–979. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Y.; Liu, X.; Zhang, J.; Chen, X.; Wu, Y.; Jing, L.; Wu, X.; Zhao, M.; Han, P. In-situ grown few-layer graphene reinforced Ni matrix composites with simultaneously enhanced strength and ductility. Mater. Sci. Eng. A 2021, 828, 142118. [Google Scholar] [CrossRef]

- Chen, F.Y.; Ying, J.M.; Wang, Y.F.; Du, S.Y.; Liu, Z.P.; Huang, Q. Effects of graphene content on the microstructure and properties of copper matrix composites. Carbon 2016, 96, 836–842. [Google Scholar] [CrossRef]

- Jiang, R.; Zhou, X.; Liu, Z. Electroless Ni-plated graphene for tensile strength enhancement of copper. Mater. Sci. Eng. A. 2017, 679, 323–328. [Google Scholar] [CrossRef]

- Wang, J.; Li, Z.; Fan, G.; Pan, H.; Chen, Z.; Zhang, D. Reinforcement with graphene nanosheets in aluminum matrix composites. Scr. Mater. 2012, 66, 594–597. [Google Scholar] [CrossRef]

- Li, C.; Zhou, Y.; Xie, Y.; Zhou, D.; Zhang, D. Effects of milling time and sintering temperature on structural evolution, densification behavior and properties of a W-20wt.%Cu alloy. J. Alloys Compd. 2018, 731, 537–545. [Google Scholar] [CrossRef]

- Collins, T.J. ImageJ for microscopy. Biotechniques 2007, 43 (Suppl. S1), 25–30. [Google Scholar] [CrossRef]

- Singh, P.; Abhash, A.; Yadav, B.N.; Shafeeq, M.; Singh, I.B.; Mondal, D.P. Effect of milling time on powder characteristics and mechanical performance of Ti4wt%Al alloy. Powder Technol. 2019, 342, 275–287. [Google Scholar] [CrossRef]

- Li, D.; He, H.; Lou, J.; Li, Y.; He, Z.; Chen, Y.; Luo, F. Effect of oxygen contents on predominant sintering mechanism during initial stage of pure titanium powder. Powder Technol. 2020, 361, 617–623. [Google Scholar] [CrossRef]

- Cao, M.; Xiong, D.-B.; Tan, Z.; Ji, G.; Amin-Ahmadi, B.; Guo, Q.; Fan, G.; Guo, C.; Li, Z.; Zhang, D. Aligning graphene in bulk copper: Nacre-inspired nanolaminated architecture coupled with in-situ processing for enhanced mechanical properties and high electrical conductivity. Carbon 2017, 117, 65–74. [Google Scholar] [CrossRef]

- Fan, G.; Jiang, Y.; Tan, Z.; Guo, Q.; Xiong, D.-b.; Su, Y.; Lin, R.; Hu, L.; Li, Z.; Zhang, D. Enhanced interfacial bonding and mechanical properties in CNT/Al composites fabricated by flake powder metallurgy. Carbon 2018, 130, 333–339. [Google Scholar] [CrossRef]

- Zhong, Z.; Jiang, X.; Sun, H.; Pang, Y.; Wu, Z.; Yang, L. Effect of Cu alloying on the damping and compression properties of graphene nanoplatelets reinforced Al-30Zn-xCu alloy matrix composites. Mater. Sci. Eng. A 2024, 915, 147233. [Google Scholar] [CrossRef]

- Bokobza, L.; Couzi, M.; Bruneel, J.-L. Raman spectroscopy of polymer–carbon nanomaterial composites. Rubber Chem. Technol. 2017, 90, 37–59. [Google Scholar] [CrossRef]

- Yin, H.; Zhou, Y.; Liu, Q.; Wang, Y.; Tang, Z.; Yan, L. Corrosion behavior and mechanism of GH3535 alloy in NaOH, HF and H2O2 solution. J. Alloys Compd. 2021, 887, 161387. [Google Scholar] [CrossRef]

- Patil, A.; Nartu, M.S.K.K.Y.; Ozdemir, F.; Banerjee, R.; Gupta, R.K.; Borkar, T. Enhancement of the mechanical properties of graphene nanoplatelet (GNP) reinforced nickel matrix nanocomposites. Mater. Sci. Eng. A 2021, 817, 141324. [Google Scholar] [CrossRef]

| Samples | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) | Hardness (HV) |

|---|---|---|---|---|

| 1000 °C | 544.3 ± 7.4 | 771.6 ± 5.5 | 15.9 ± 2.0 | 259 ± 9 |

| 1050 °C | 557.2 ± 9.2 | 784.9 ± 15.2 | 16.7 ± 3.1 | 246 ± 7 |

| 1100 °C | 579.5 ± 4.5 | 859.6 ± 8.3 | 31.6 ± 2.5 | 190 ± 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, X.; Jiang, Y.; Yu, X.; Zhang, G.; Shi, Y.; Cai, B.; Peng, Q.; Huang, H. Preparation and Characterization of Graphene-Nanosheet-Reinforced Ni-17Mo Alloy Composites for Advanced Nuclear Reactor Applications. Materials 2025, 18, 1061. https://doi.org/10.3390/ma18051061

Ge X, Jiang Y, Yu X, Zhang G, Shi Y, Cai B, Peng Q, Huang H. Preparation and Characterization of Graphene-Nanosheet-Reinforced Ni-17Mo Alloy Composites for Advanced Nuclear Reactor Applications. Materials. 2025; 18(5):1061. https://doi.org/10.3390/ma18051061

Chicago/Turabian StyleGe, Xiaoxin, Yanxin Jiang, Xu Yu, Guopeng Zhang, Yunjia Shi, Bin Cai, Qing Peng, and Hai Huang. 2025. "Preparation and Characterization of Graphene-Nanosheet-Reinforced Ni-17Mo Alloy Composites for Advanced Nuclear Reactor Applications" Materials 18, no. 5: 1061. https://doi.org/10.3390/ma18051061

APA StyleGe, X., Jiang, Y., Yu, X., Zhang, G., Shi, Y., Cai, B., Peng, Q., & Huang, H. (2025). Preparation and Characterization of Graphene-Nanosheet-Reinforced Ni-17Mo Alloy Composites for Advanced Nuclear Reactor Applications. Materials, 18(5), 1061. https://doi.org/10.3390/ma18051061