Quantitative Measurement of the Tack for Carbon Fiber Reinforced Epoxy Prepreg by Using a Compression-to-Tension Method

Abstract

1. Introduction

2. Experimental Details

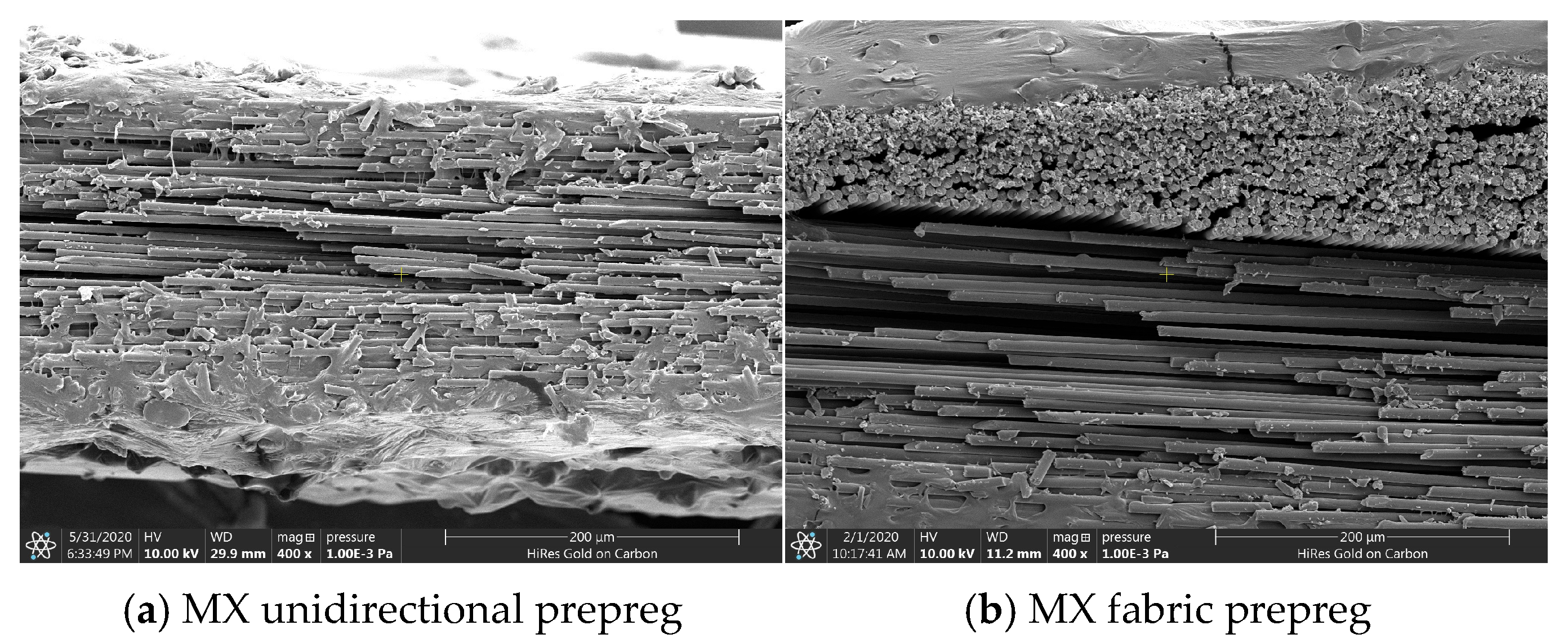

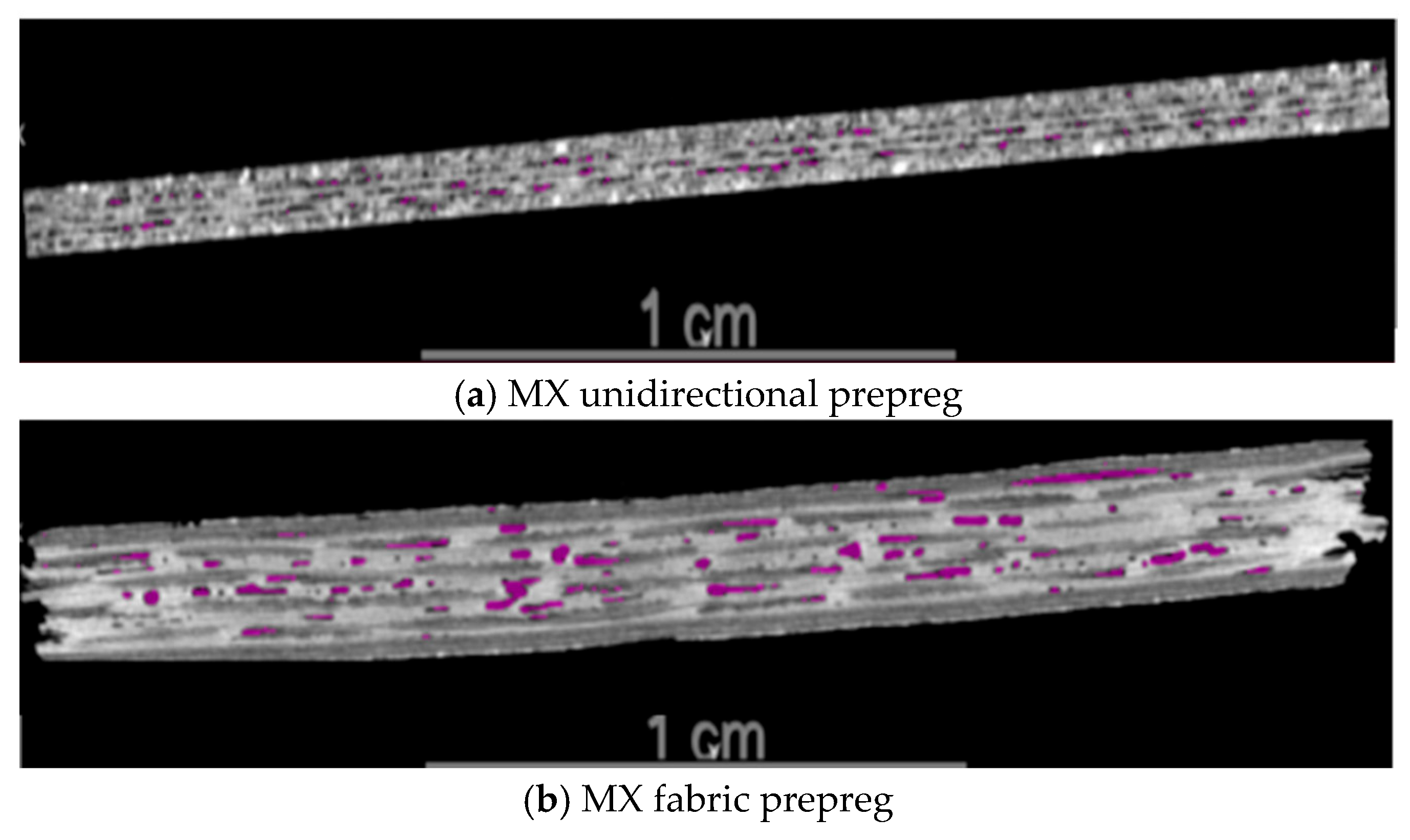

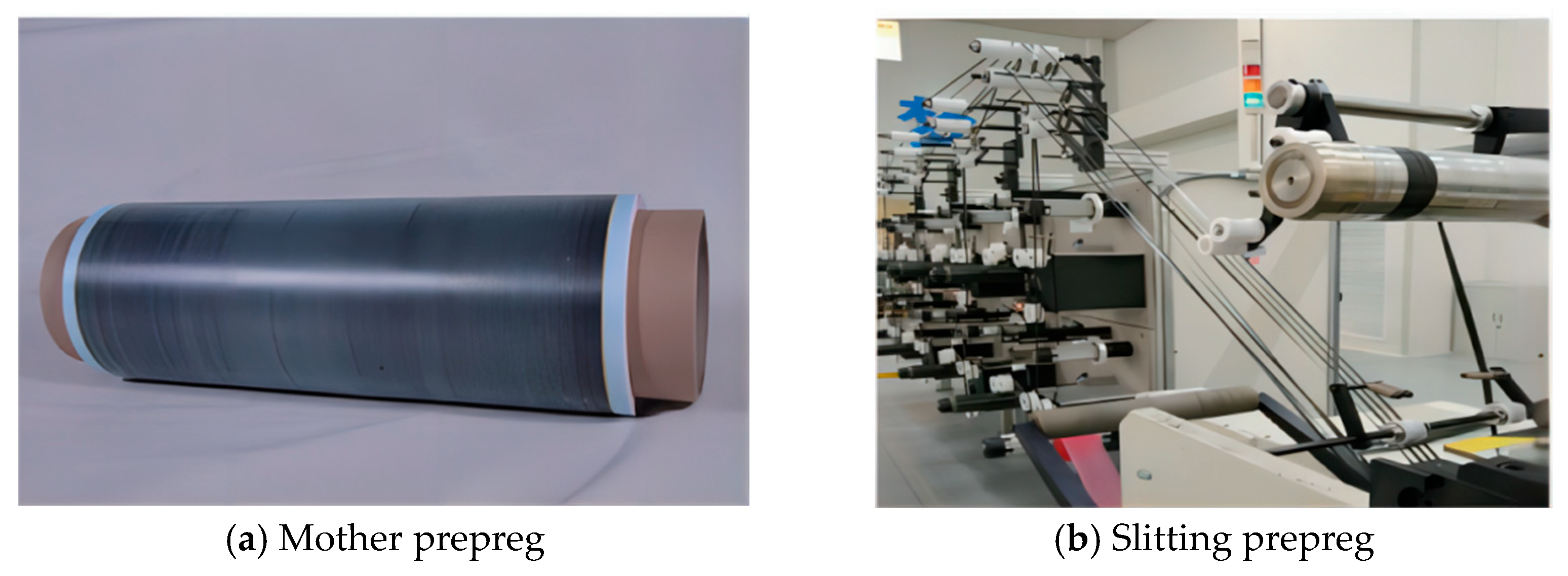

2.1. Material and Equipment

2.2. Tack Measurement

2.2.1. Conditioning and Preparation of Samples

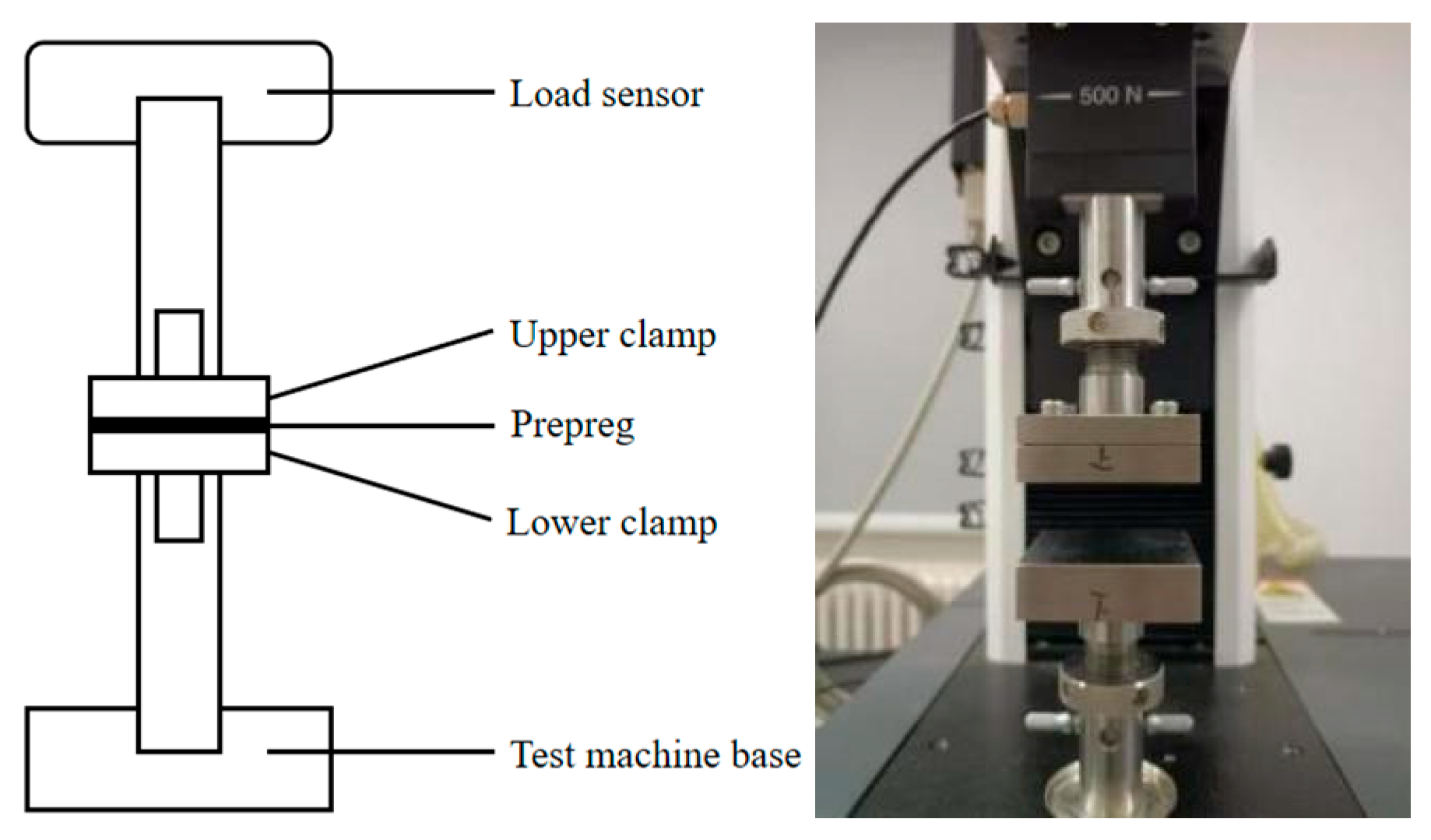

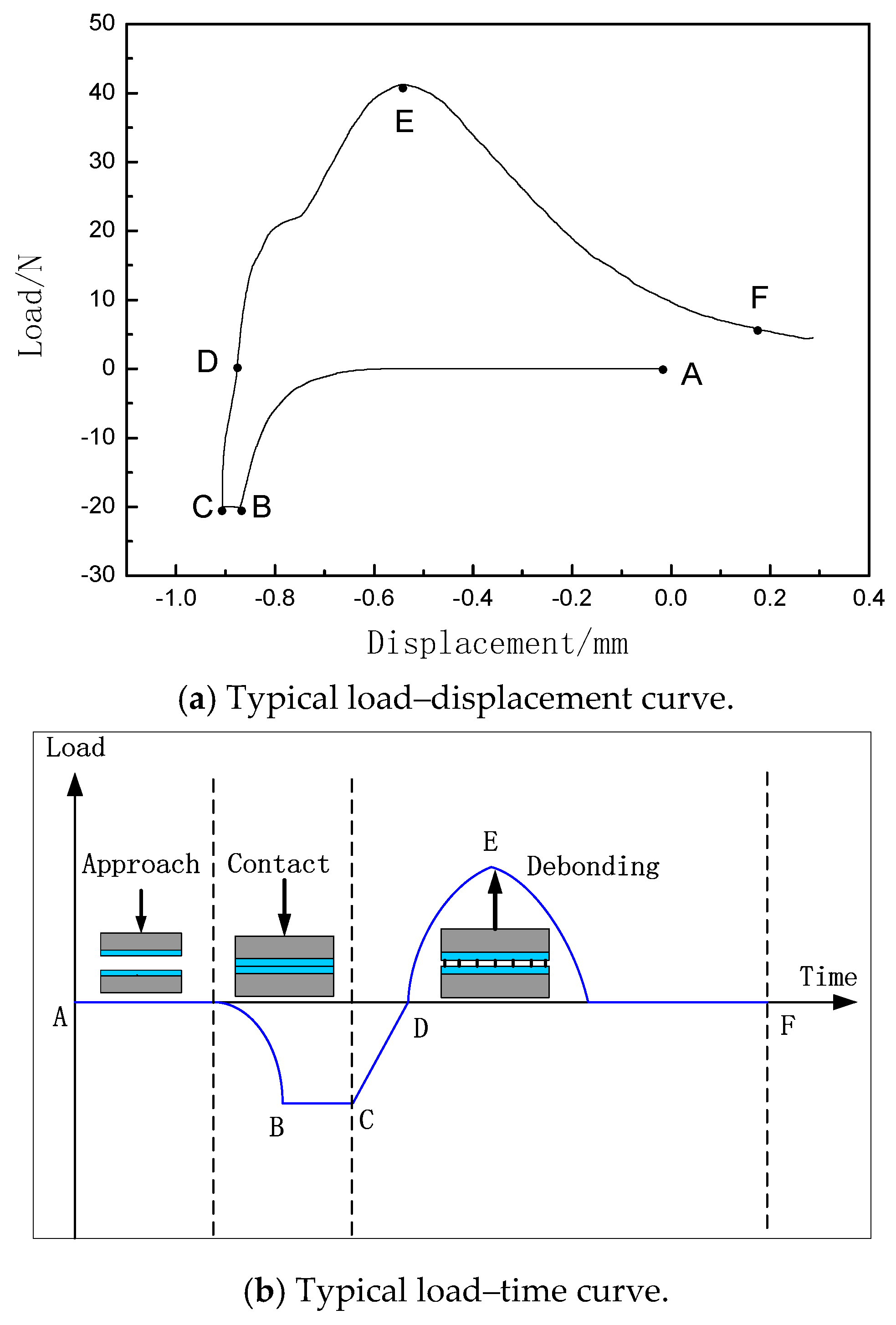

2.2.2. Compression-to-Tension Method

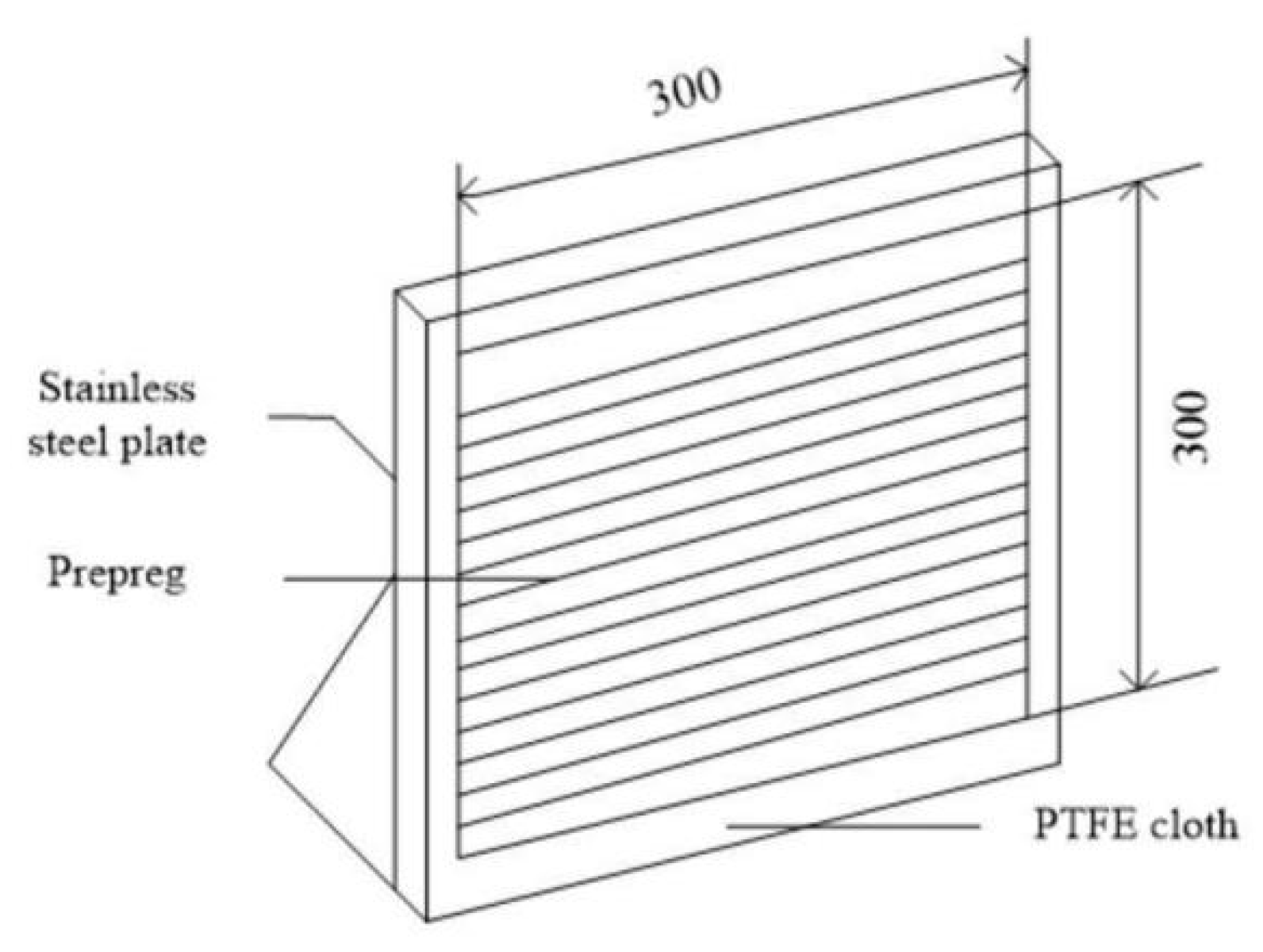

2.2.3. Vertical Metal Plate Method

3. Results and Discussion

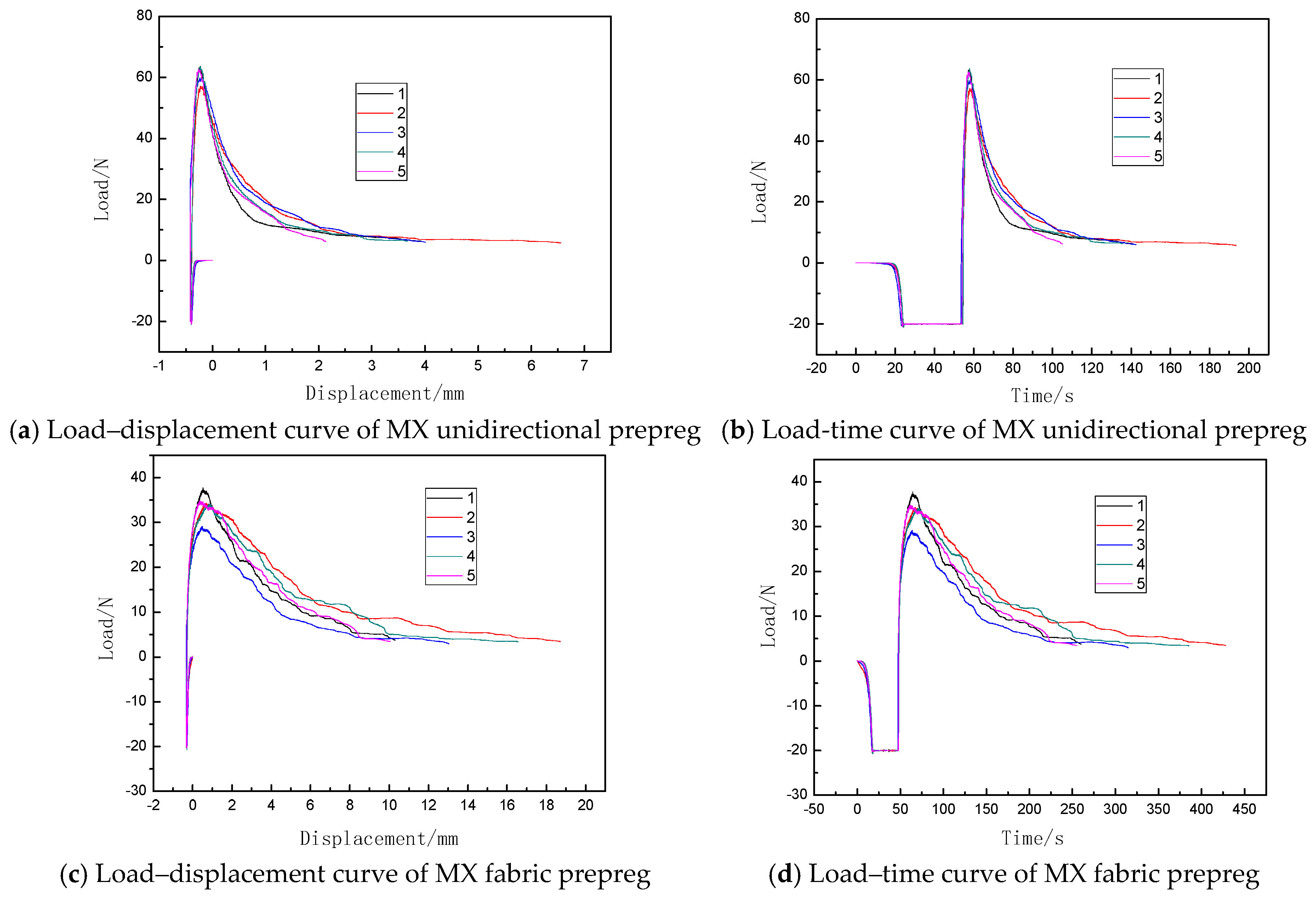

3.1. Prepreg Tack Test by Compression-to-Tension Method

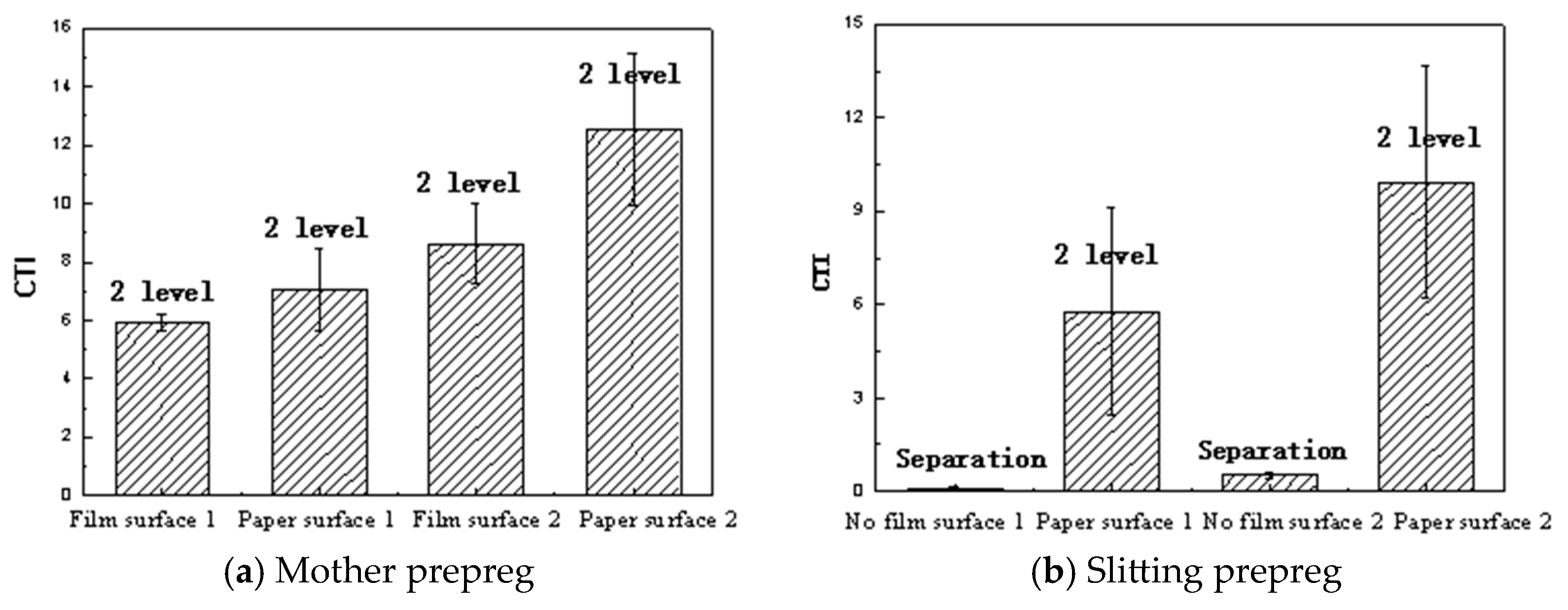

3.2. Comparison Between Compression-to-Tension Method and Vertical Metal Plate Method

3.2.1. Vertical Metal Plate Method

3.2.2. Compression-to-Tension Method

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Budelmanna, D.; Schmidt, C.; Meiners, D. Prepreg tack: A review of mechanisms, measurement, and manufacturing implication. Polym. Compos. 2020, 41, 3440–3458. [Google Scholar] [CrossRef]

- Bao, J.W.; Zhong, X.Y.; Zhang, D.J. Progress in high strength intermediate modulus carbon fiber and its high toughness resin matrix composites in China. J. Mater. Eng. 2020, 48, 33–48. (In Chinese) [Google Scholar]

- HB7736.8-2004; Test Method of Physical Properties of Composite Material Prepreg Part 8: Determination of Tack. The Commission of Science, Technology and Industry for National Defense (COSTIND) of China: Beijing, China, 2004.

- Smith, R.; Qureshi, Z.; Scaif, R. Limitations of processing carbon fibre reinforced plastic/polymer material using automated fibre placement technology. J. Reinf. Plast. Compos. 2016, 35, 1527–1542. [Google Scholar] [CrossRef]

- Banks, R.; Mouritz, A.P.; John, S. Development of a new structural prepreg: Characterisation of handling, drape and tack properties. Compos. Struct. 2004, 66, 169–174. [Google Scholar] [CrossRef]

- Endruweit, A.; Choong, G.Y.H.; Ghose, S. Characterisation of tack for uni-directional prepreg tape employing a continuous application-and-peel test method. Compos. Part A Appl. Sci. Manuf. 2018, 114, 295–306. [Google Scholar] [CrossRef]

- Pan, H.L.; Qu, W.W.; Yang, D. Analysis and characterization of interlaminar tack for different prepreg materials during automated fiber placement. Polym. Compos. 2022, 43, 4737–4748. [Google Scholar] [CrossRef]

- Dubois, O.J.; Lecam, B.; Beakou, A. Experimental analysis of prepreg tack. Exp. Mech. 2010, 50, 599–606. [Google Scholar] [CrossRef]

- Szpoganicz, E.; Demleitner, M.; Hubner, F. Phenolic prepregs for automated composites manufacturing–Correlation of rheological properties and environmental factors with prepreg tack. Compos. Sci. Technol. 2022, 218, 109188. [Google Scholar] [CrossRef]

- Bakhshi, N.; Hojjati, M. An experimental and simulative study on the defects appeared during tow steering in automated ffber placement. Compos. Part A Appl. Sci. Manuf. 2022, 113, 122–131. [Google Scholar] [CrossRef]

- Zu, L.; Xia, X.; Zhang, Q. Influence and optimization of parameters of prepreg viscosity during placement. Chin. J. Aeronaut. 2022, 35, 438–449. [Google Scholar] [CrossRef]

- Klaus, H.; David, C.; Klaus, D. Quantifying the Influence of Out-Time on Prepreg Material Properties and Out-Of-Plane Steering Defects During Automated Fiber Placement. Front. Mater. 2022, 9, 825809. [Google Scholar]

- Wang, Y.; Mahapatra, S.; Belnoue, J.P.H. Understanding tack behaviour during prepreg-based composites’ processing. Compos. Part A Appl. Sci. Manuf. 2023, 164, 107284. [Google Scholar] [CrossRef]

- Crossley, R.J.; Schubel, P.J.; Warrior, N.A. The experimental determination of prepreg tack and dynamic stiffness. Compos. Part A Appl. Sci. Manuf. 2012, 43, 423–434. [Google Scholar] [CrossRef]

- Crossley, R.J.; Schubel, P.J.; De focatiis, D.S.A. Time–temperature equivalence in the tack and dynamic stiffness of polymer prepreg and its application to automated composites manufacturing. Compos. Part A Appl. Sci. Manuf. 2013, 52, 126–133. [Google Scholar] [CrossRef]

- ASTM D8336-24; Standard Test Method for Characterizing Tack of Prepregs Using a Continuous Application-and-Peel Procedure. ASTM International: West Conshohocken, PA, USA, 2024.

- Joesbury, A.M.; Endruweit, A.; Budelmann, D. Repeatability and reproducibility of the measurement of prepreg tack following ASTM D8336: Results of a round-robin study. Compos. Part A Appl. Sci. Manuf. 2025, 188, 108561. [Google Scholar] [CrossRef]

- Davide, S.A.; Gabriel, Y.H.; Adam, J. Development of the ASTM D8336 21: Standard Test Method for Characterizing Tack of Prepregs using a Continuous Application and Peel Procedure. In Composites Meet Sustainability, Proceedings of the 20th European Conference on Composite Materials, ECCM20, Lausanne, Switzerland, 26–30 June 2022; Ecole Polytechnique Fédérale de Lausanne: Lausanne, Switzerland, 2022. [Google Scholar]

- Peng, X.; Shu, Z.; Dou, T. Peel simulating and test verification of prepreg based on laying process. Acta Aeronaut. Astronaut. Sin. 2018, 39, 422246. (In Chinese) [Google Scholar]

- Ahn, K.J.; Seferis, J.C.; Pelton, T. Analysis and characterization of prepreg tack. Polym. Compos. 1992, 13, 197–206. [Google Scholar] [CrossRef]

| Prepreg Type | Resin Content/wt% | Theoretical Calculated Fiber Volume/% | Area Density/g/m2 | Theoretical Single-Layer Thickness/mm |

|---|---|---|---|---|

| MX unidirectional prepreg | 34 | 59.2 | 294 | 0.184 |

| AX unidirectional prepreg | 35 | 58 | 223 | 0.14 |

| MX fabric prepreg | 40 | 55.8 | 475 | 0.285 |

| Level | Phenomenon |

|---|---|

| 1 | Prepregs adhered to each other, separated without damage, and adhered to stainless steel plates |

| 2 | Prepregs adhered to each other, separated with damage, and adhered to stainless steel plates |

| 3 | Prepregs adhered to each other, separated without damage, and did not adhere to stainless steel plates |

| 4 | Prepregs did not adhere to each other, separated without damage, and did not adhere to stainless steel plates |

| 5 | Prepregs adhered to each other, separated with damage, and did not adhere to stainless steel plates |

| Person A | Person B | Person C | |||

|---|---|---|---|---|---|

| Sample Number | CTI | Sample Number | CTI | Sample Number | CTI |

| 1 | 72 | 1 | 51.8 | 1 | 54.1 |

| 2 | 69.3 | 2 | 52.9 | 2 | 55 |

| 3 | 58.5 | 3 | 57.9 | 3 | 53 |

| 4 | 60.8 | 4 | 57.1 | 4 | 59.1 |

| 5 | 65.4 | 5 | 62.1 | 5 | 62.8 |

| 6 | 63.7 | 6 | 57.1 | 6 | 63.2 |

| 7 | 68.3 | 7 | 77.7 | 7 | 66.2 |

| 8 | 71.1 | 8 | 62.1 | 8 | 53.4 |

| 9 | 62.4 | 9 | 70.7 | 9 | 59.6 |

| 10 | 66.5 | 10 | 69.4 | 10 | 67.3 |

| Average value | 65.8 | Standard deviation | 61.88 | Standard deviation | 59.37 |

| Standard deviation | 4.47 | Standard deviation | 8.36 | Standard deviation | 5.37 |

| Prepreg Type | Batch Number | Surface | Tack Level |

|---|---|---|---|

| AX unidirectional prepreg—slitting | 1 | Surface without PE film | 5 |

| Paper surface | 2 | ||

| 2 | Surface without PE film | 5 | |

| Paper surface | 2 | ||

| AX unidirectional prepreg—mother | 1 | Film surface | 2 |

| Paper surface | 2 | ||

| 2 | Film surface | 2 | |

| Paper surface | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Li, G.; Liu, X.; Lin, X.; Pang, B. Quantitative Measurement of the Tack for Carbon Fiber Reinforced Epoxy Prepreg by Using a Compression-to-Tension Method. Materials 2025, 18, 5050. https://doi.org/10.3390/ma18215050

Wang X, Li G, Liu X, Lin X, Pang B. Quantitative Measurement of the Tack for Carbon Fiber Reinforced Epoxy Prepreg by Using a Compression-to-Tension Method. Materials. 2025; 18(21):5050. https://doi.org/10.3390/ma18215050

Chicago/Turabian StyleWang, Xueming, Guoli Li, Xiu Liu, Xiaofeng Lin, and Baolin Pang. 2025. "Quantitative Measurement of the Tack for Carbon Fiber Reinforced Epoxy Prepreg by Using a Compression-to-Tension Method" Materials 18, no. 21: 5050. https://doi.org/10.3390/ma18215050

APA StyleWang, X., Li, G., Liu, X., Lin, X., & Pang, B. (2025). Quantitative Measurement of the Tack for Carbon Fiber Reinforced Epoxy Prepreg by Using a Compression-to-Tension Method. Materials, 18(21), 5050. https://doi.org/10.3390/ma18215050