Bimodal Microstructure and Strengthening Mechanisms of a Mg-RE Alloy Processed by Asymmetric Upsetting–Extrusion

Abstract

1. Introduction

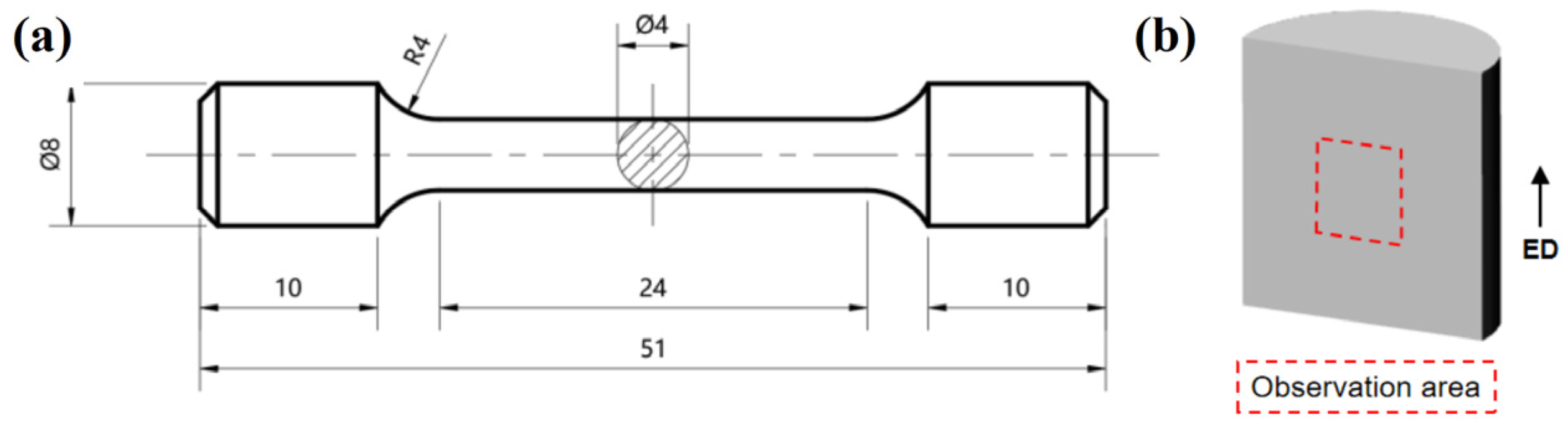

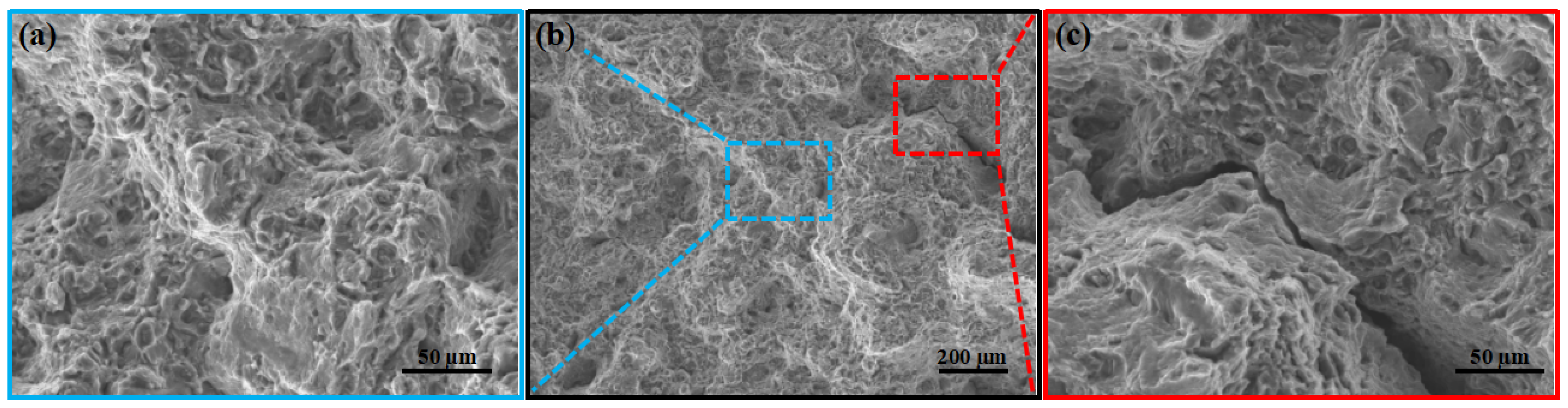

2. Experimental Procedure

2.1. Sample Preparation

2.2. Finite Element Simulation

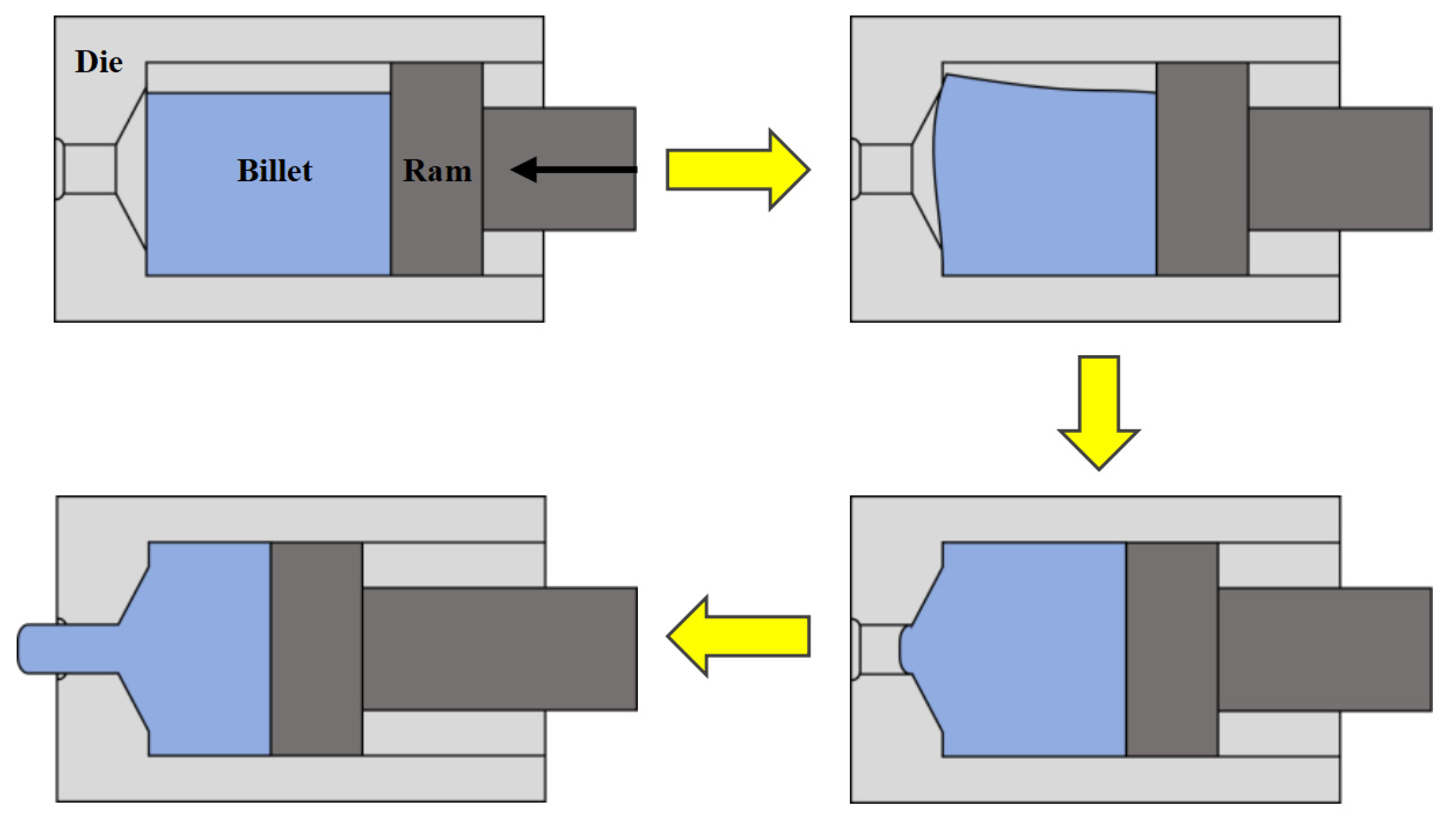

2.3. AUE Process

2.4. Microscopic Characterization Experiment

3. Results and Discussion

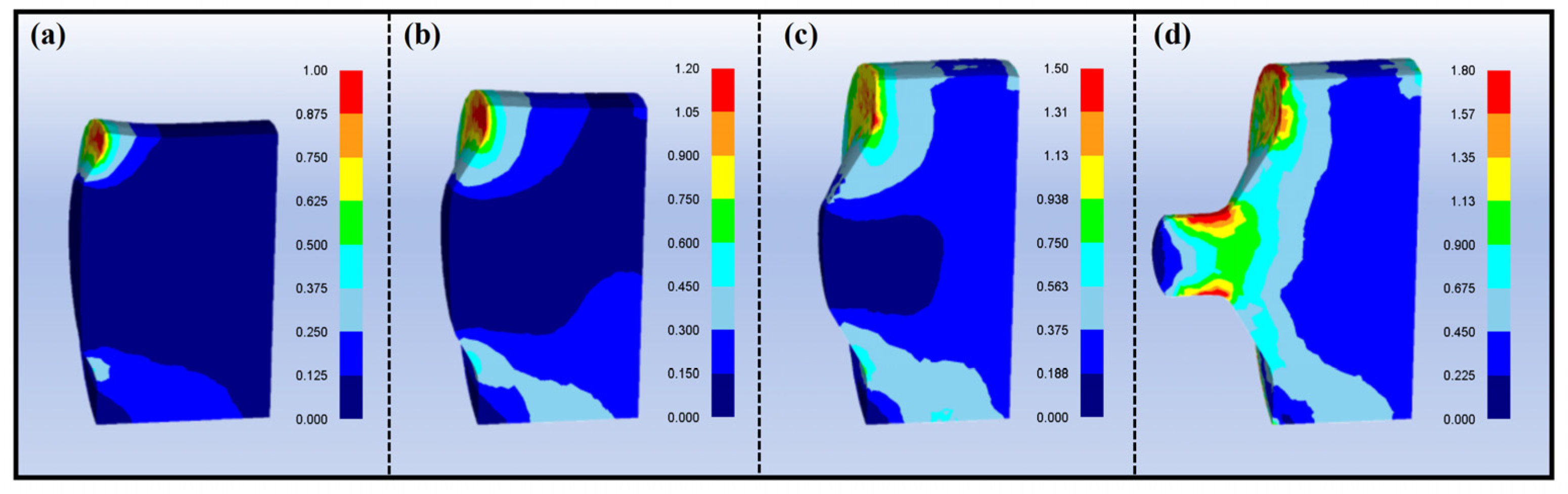

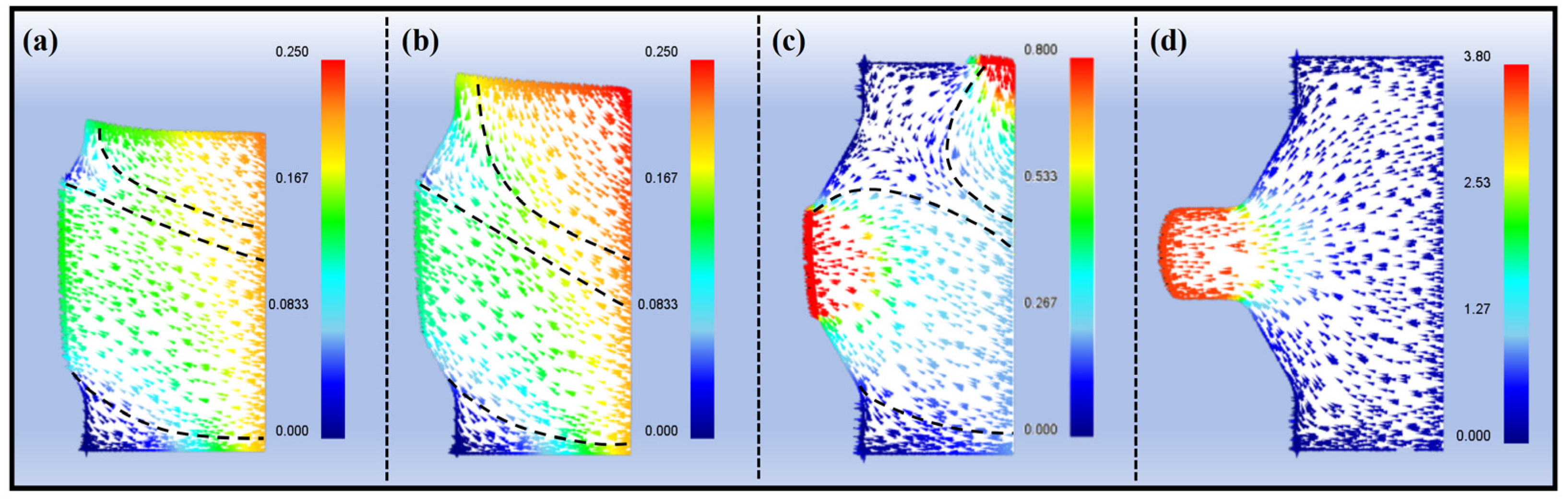

3.1. Finite Element Analysis

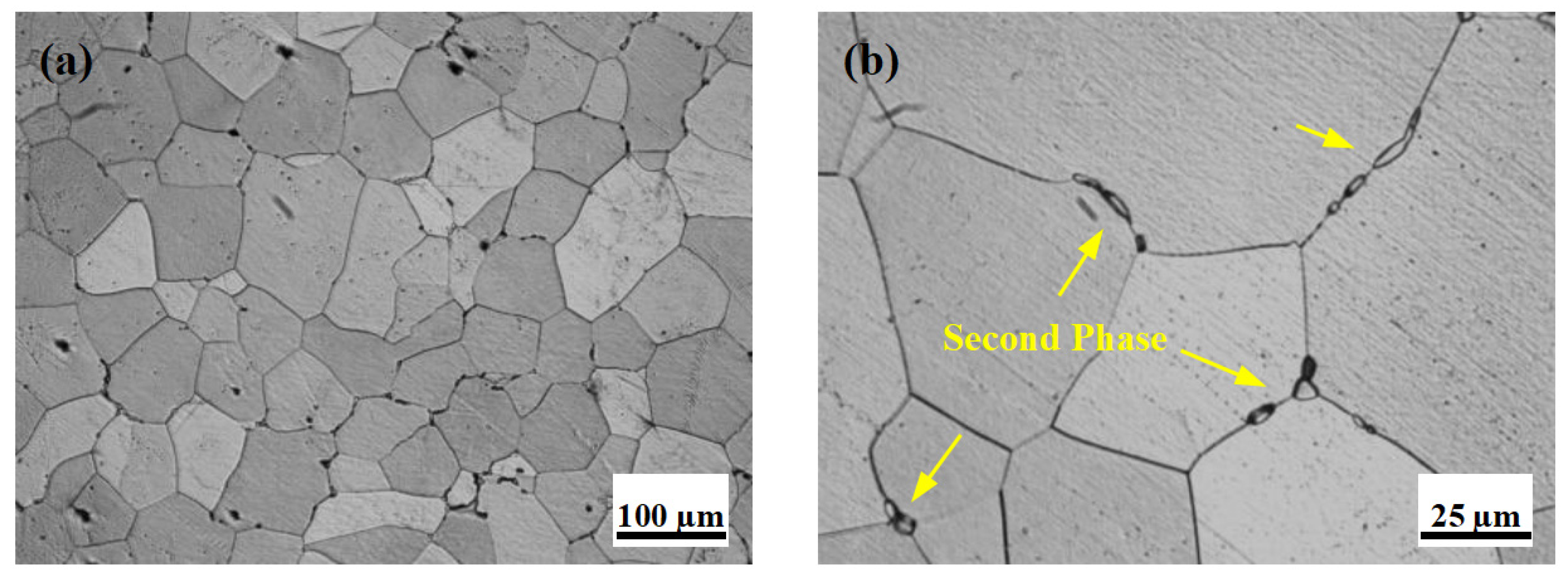

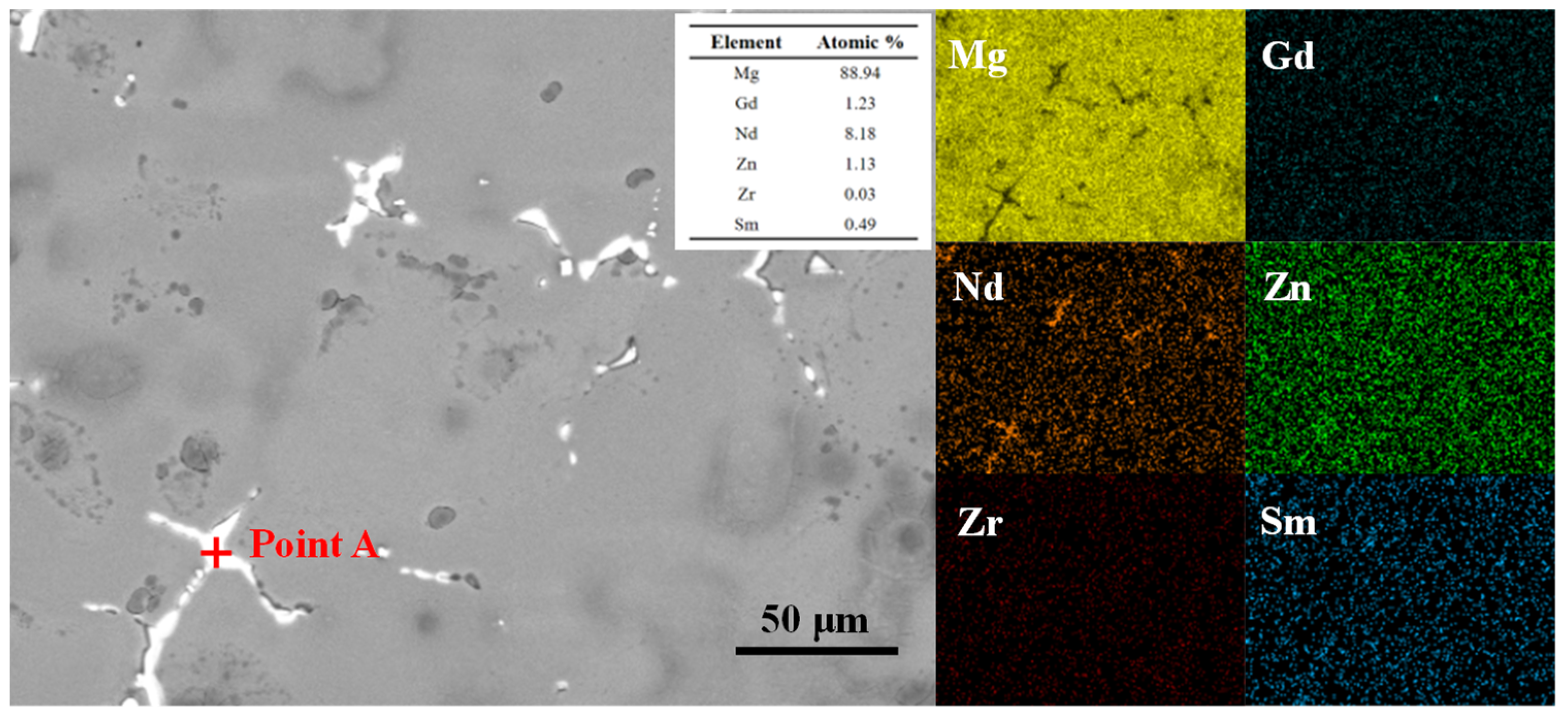

3.2. Initial Microstructure

3.3. Extruded Microstructure and Mechanical Properties

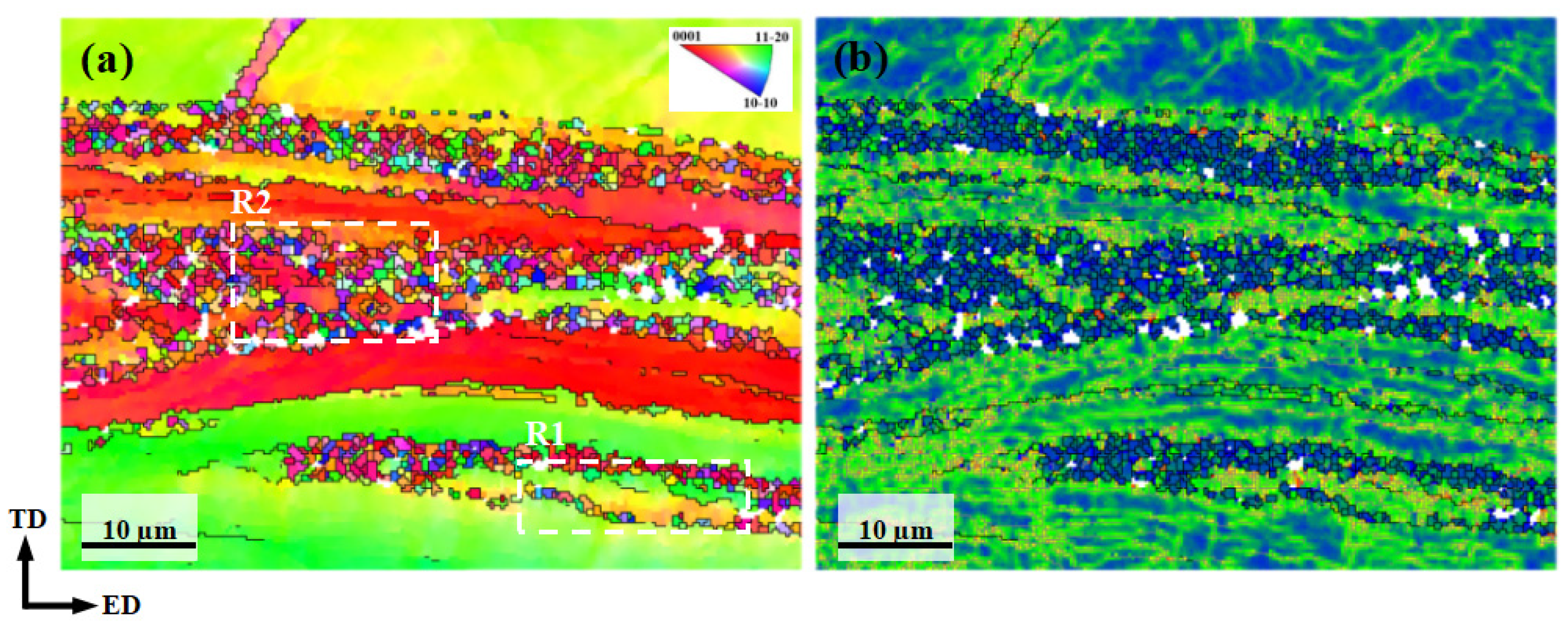

3.4. Dynamic Recrystallization and Strengthening Mechanisms

4. Conclusions

- (1)

- Finite element simulation reveals a unique shear deformation mode during the asymmetric upsetting–filling stage. Under the combined effects of gravity and die constraints, the billet undergoes intense asymmetric shear strain and flow, which introduces high deformation stored energy in advance. This lays the foundation for subsequent DRX nucleation and texture evolution during subsequent deformation.

- (2)

- Utilizing a process combining low-speed extrusion with a high extrusion ratio at 370 °C and asymmetric upsetting, an ultra-high strength magnesium alloy with an ultrafine-grained bimodal microstructure was successfully fabricated at 370 °C. This constitutes one of the primary reasons for its high UTS of 457.9 MPa.

- (3)

- CDRX is the primary grain refinement mechanism during AUE370. It significantly refined a portion of the grains. However, it failed to completely eliminate the coarse deformed grains, resulting in the formation of a bimodal microstructure.

- (4)

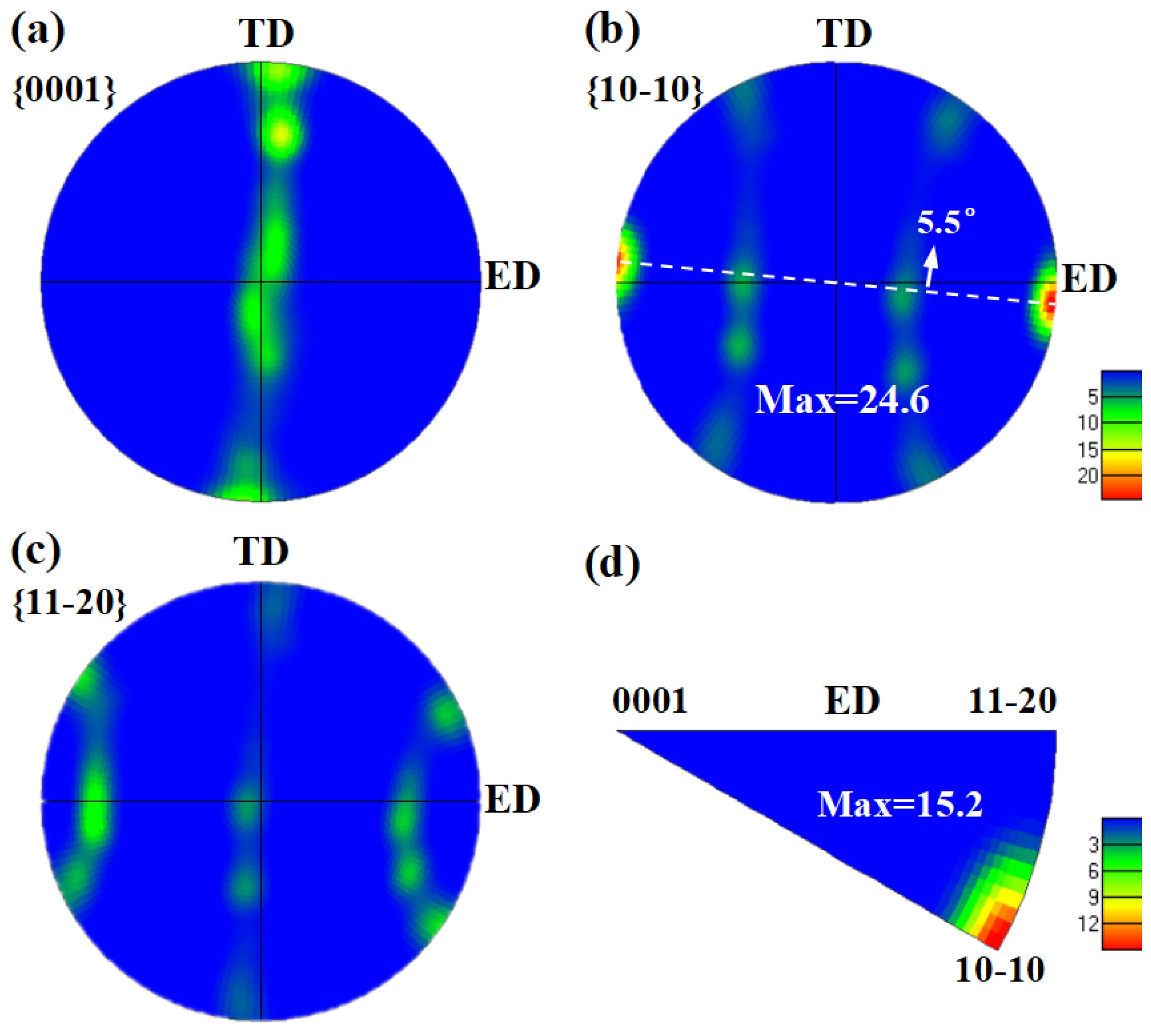

- The strong <10-10>//ED basal fiber texture is one of the key factors responsible for the high strength and low ductility of the AUE370 alloy. This texture strongly inhibits the activation of basal slip (average SF merely 0.123) and forces plastic deformation to rely on harder-to-activate non-basal slip systems.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| UE | Upsetting extrusion |

| UTS | Ultimate tensile strength |

| EL | Elongation |

| DRX | Dynamic recrystallization |

| YS | Yield strength |

| ED | Extrusion direction |

| CRSS | Critical resolved shear stresses |

| AUE | Asymmetric upsetting–extrusion |

| OM | Optical microscopy |

| SEM | Scanning electron microscopy |

| EBSD | Electron backscatter diffraction |

| RE | Rare-earth |

| AUE370 | 370 °C AUE |

| IPF | Inverse pole figure |

| KAM | Kernel average misorientation |

| CDRX | Continuous dynamic recrystallization |

| SF | Schmid factor |

References

- Chen, X.; Zhang, J.; Wang, M.; Wang, W.; Zhao, D.; Huang, H.; Zhao, Q.; Xu, X.; Zhang, H.; Huang, G. Research Progress of Heterogeneous Structure Magnesium Alloys: A Review. J. Magnes. Alloys 2024, 12, 2147–2181. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, Y.J.; Kim, H.J.; Jin, S.-C.; Lee, J.U.; Komissarov, A.; Shin, K.S. Recent Research Progress on Magnesium Alloys in Korea: A Review. J. Magnes. Alloys 2023, 11, 3545–3584. [Google Scholar] [CrossRef]

- Fan, Y.; Lu, L.; Zhao, H.; Wu, Z.; Xue, Y.; Wang, W. Effect of Deformation Temperatures on Microstructure of AQ80 Magnesium Alloy under Repeated Upsetting-Extrusion. Acta Metall. Sin. 2023, 36, 1649–1664. [Google Scholar] [CrossRef]

- Wang, H.; Luo, X.C.; Zhang, D.T.; Qiu, C.; Chen, D.L. High-Strength Extruded Magnesium Alloys: A Critical Review. J. Mater. Sci. Technol. 2024, 199, 27–52. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, Z.; Zhang, Z.; Xue, Y. Effect of Temperature on the Microstructure and Mechanical Properties of Mg-Gd-Y-Zn-Zr Alloy during the Large Height-to-Diameter Ratio Upsetting and Extrusion. J. Mater. Res. Technol. 2023, 26, 8036–8047. [Google Scholar] [CrossRef]

- Wu, G.; Li, Z.; Yu, J.; Liu, Y.; Zhang, Z.; Dong, B.; Huang, H. Optimization in Strength-Ductility of Mg-RE-Zn Alloy Based on Different Repetitive Upsetting Extrusion Deformation Paths. Mater. Des. 2023, 232, 112114. [Google Scholar] [CrossRef]

- Han, X.; Lu, R.; Liu, Y.; Liu, Q.; Zhang, Z.; Yu, J.; Li, L. Effects of Different Temperature Paths during Reciprocating Upsetting-Extrusion on Dynamic Recrystallization Refinement of VW93A Alloy. Met. Mater. Int. 2025, 31, 2692–2709. [Google Scholar] [CrossRef]

- Zhang, D.; Yang, Q.; Guan, K.; Li, B.; Wang, N.; Qin, P.; Jiang, B.; Sun, C.; Qin, X.; Tian, Z.; et al. A High-Strength Low-Rare-Earth-Alloyed Magnesium Alloy via Traditional Hot-Extrusion. J. Alloys Compd. 2019, 810, 151967. [Google Scholar] [CrossRef]

- Xu, C.; Fan, G.H.; Nakata, T.; Liang, X.; Chi, Y.Q.; Qiao, X.G.; Cao, G.J.; Zhang, T.T.; Huang, M.; Miao, K.S.; et al. Deformation Behavior of Ultra-Strong and Ductile Mg-Gd-Y-Zn-Zr Alloy with Bimodal Microstructure. Metall. Mater. Trans. A 2018, 49, 1931–1947. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, X. Heterostructured Materials. Prog. Mater. Sci. 2023, 131, 101019. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, J.; Xie, J.; Liu, S.; He, Y.; Guan, K.; Wu, R. Developing a Low-Alloyed Fine-Grained Mg Alloy with High Strength-Ductility Based on Dislocation Evolution and Grain Boundary Segregation. Scr. Mater. 2022, 209, 114414. [Google Scholar] [CrossRef]

- Liu, S.; Yang, F.; Yang, H.; Huang, G.; Tang, A.; Chen, X.; Jiang, B.; Pan, F. High-Resolution Mapping of the Strain Heterogeneity in Heterogeneous and Homogeneous Structured Mg13Gd Alloy. Mater. Charact. 2022, 193, 112335. [Google Scholar] [CrossRef]

- Tang, J.; Chen, L.; Zhao, G.; Zhang, C.; Sun, L.; Yu, J. Experimental Study on Tensile Deformation Behaviors under Room and Elevated Temperatures Induced by Microstructure Inhomogeneity of ZK60 Mg with a Longitudinal Weld. J. Magnes. Alloys 2023, 11, 4338–4356. [Google Scholar] [CrossRef]

- Pan, H.; Qin, G.; Huang, Y.; Ren, Y.; Sha, X.; Han, X.; Liu, Z.-Q.; Li, C.; Wu, X.; Chen, H.; et al. Development of Low-Alloyed and Rare-Earth-Free Magnesium Alloys Having Ultra-High Strength. Acta Mater. 2018, 149, 350–363. [Google Scholar] [CrossRef]

- Li, R.G.; Zhou, S.Q.; Zhang, H.; Wu, R.Z.; Wu, D.; Li, J.R.; Liu, B.S.; Li, S.S.; Li, X.; Wang, B.J. Rapid Drop in Ductility of the Bimodal-Structured Mg–15Gd Binary Alloy during Early Aging. J. Magnes. Alloys 2024, 12, 3772–3779. [Google Scholar] [CrossRef]

- Zhou, X.; Xiong, W.; Zeng, G.; Xiao, H.; Zhang, J.; Lu, X.; Chen, X. Combined Effects of LPSO Orientation and α-Mg Texture on Tensile Anisotropy of an Extruded Mg-Gd-Y-Zn-Zr Alloy. Mater. Sci. Eng. A 2021, 805, 140596. [Google Scholar] [CrossRef]

- Garcés, G.; Máthis, K.; Medina, J.; Horváth, K.; Drozdenko, D.; Oñorbe, E.; Dobroň, P.; Pérez, P.; Klaus, M.; Adeva, P. Combination of In-Situ Diffraction Experiments and Acoustic Emission Testing to Understand the Compression Behavior of Mg-Y-Zn Alloys Containing LPSO Phase under Different Loading Conditions. Int. J. Plast. 2018, 106, 107–128. [Google Scholar] [CrossRef]

- Zhao, T.; Hu, Y.; Zhang, C.; He, B.; Zheng, T.; Tang, A.; Pan, F. Influence of Extrusion Conditions on Microstructure and Mechanical Properties of Mg-2Gd-0.3Zr Magnesium Alloy. J. Magnes. Alloys 2022, 10, 387–399. [Google Scholar] [CrossRef]

- Wang, Y.; Li, F.; Wang, Y.; Xiao, X.M. Texture Property and Weakening Mechanism of Mg-3Al-1Zn Alloy by Interactive Alternating Forward Extrusion. J. Magnes. Alloys 2023, 11, 684–693. [Google Scholar] [CrossRef]

- Luo, Q.; Guo, Y.; Liu, B.; Feng, Y.; Zhang, J.; Li, Q.; Chou, K. Thermodynamics and Kinetics of Phase Transformation in Rare Earth–Magnesium Alloys: A Critical Review. J. Mater. Sci. Technol. 2020, 44, 171–190. [Google Scholar] [CrossRef]

- Zheng, J.; Chen, Z.; Yan, Z.; Zhang, Z.; Xue, Y. An Alternating Ageing-Annealing Process for Enhancing Strength and Ductility of a Mg-Gd-Y-Zn-Zr Alloy. Mater. Sci. Eng. A 2021, 828, 142103. [Google Scholar] [CrossRef]

- Bai, J.; Yang, Y.; Wen, C.; Chen, J.; Zhou, G.; Jiang, B.; Peng, X.; Pan, F. Applications of Magnesium Alloys for Aerospace: A Review. J. Magnes. Alloys 2023, 11, 3609–3619. [Google Scholar] [CrossRef]

- Sun, W.; Wu, B.; Fu, H.; Yang, X.-S.; Qiao, X.; Zheng, M.; He, Y.; Lu, J.; Shi, S.-Q. Combining Gradient Structure and Supersaturated Solid Solution to Achieve Superior Mechanical Properties in WE43 Magnesium Alloy. J. Mater. Sci. Technol. 2022, 99, 223–238. [Google Scholar] [CrossRef]

- Xu, C.; Zheng, M.Y.; Wu, K.; Wang, E.D.; Fan, G.H.; Xu, S.W.; Kamado, S.; Liu, X.D.; Wang, G.J.; Lv, X.Y. Influence of Rolling Temperature on the Microstructure and Mechanical Properties of Mg–Gd–Y–Zn–Zr Alloy Sheets. Mater. Sci. Eng. A 2013, 559, 615–622. [Google Scholar] [CrossRef]

- Kumar, N.; Ferraz, F.M.B.; Buzolin, R.H.; Shahryari, E.; Poletti, M.C.; Yadav, S.D. A Meso-Scale Model to Predict Flow Stress and Microstructure during Hot Deformation of IN718WP. Int. J. Plast. 2025, 187, 104271. [Google Scholar] [CrossRef]

- Yang, Q.; Jiang, B.; Song, B.; Yu, Z.; He, D.; Chai, Y.; Zhang, J.; Pan, F. The Effects of Orientation Control via Tension-Compression on Microstructural Evolution and Mechanical Behavior of AZ31 Mg Alloy Sheet. J. Magnes. Alloys 2022, 10, 411–422. [Google Scholar] [CrossRef]

- Jeong, H.T.; Kim, W.J. Effect of Roll Speed Ratio on the Texture and Microstructural Evolution of an FCC High-Entropy Alloy during Differential Speed Rolling. J. Mater. Sci. Technol. 2022, 111, 152–166. [Google Scholar] [CrossRef]

- Xie, B.; Yu, Z.; Jiang, H.; Xu, B.; Wang, C.; Zhang, J.; Sun, M.; Li, D.; Li, Y. Effects of Surface Roughness on Interfacial Dynamic Recrystallization and Mechanical Properties of Ti-6Al-3Nb-2Zr-1Mo Alloy Joints Produced by Hot-Compression Bonding. J. Mater. Sci. Technol. 2022, 96, 199–211. [Google Scholar] [CrossRef]

- Du, P.; Furusawa, S.; Furushima, T. Continuous Observation of Twinning and Dynamic Recrystallization in ZM21 Magnesium Alloy Tubes during Locally Heated Dieless Drawing. J. Magnes. Alloys 2022, 10, 730–742. [Google Scholar] [CrossRef]

- Nakata, T.; Kamado, S. Towards Tailoring Basal Texture of Rolled Mg Alloy Sheet by Recrystallization for High Room-Temperature Formability: A Review. J. Magnes. Alloys 2023, 11, 3992–4010. [Google Scholar] [CrossRef]

- Chen, M.; Ling, Z.; Wang, L.; Ma, K.; Zhang, D.; Li, Y.; Zhang, Z.; Zhao, Z.; Bai, P. Phase Transformation, Texture Evolution, and Mechanical Properties of Mg-9.5Gd-4Y-2Zn-0.3Zr Alloy Wires Fabricated Using Hot Drawing. Mater. Sci. Eng. A 2024, 897, 146323. [Google Scholar] [CrossRef]

- Zhou, W.; Lin, J.; Dean, T.A. Microstructure and Mechanical Properties of Curved AZ31 Magnesium Alloy Profiles Produced by Differential Velocity Sideways Extrusion. J. Magnes. Alloys 2023, 11, 493–508. [Google Scholar] [CrossRef]

- Li, M.; Huang, Y.; Liu, Y.; Wang, X.; Wang, Z. Effects of Heat Treatment before Extrusion on Dynamic Recrystallization Behavior, Texture and Mechanical Properties of as-Extruded Mg-Gd-Y-Zn-Zr Alloy. Mater. Sci. Eng. A 2022, 832, 142479. [Google Scholar] [CrossRef]

- Chen, R.; Sandlöbes, S.; Zeng, X.; Li, D.; Korte-Kerzel, S.; Raabe, D. Room Temperature Deformation of LPSO Structures by Non-Basal Slip. Mater. Sci. Eng. A 2017, 682, 354–358. [Google Scholar] [CrossRef]

- Hagihara, K.; Li, Z.; Yamasaki, M.; Kawamura, Y.; Nakano, T. Strengthening Mechanisms Acting in Extruded Mg-Based Long-Period Stacking Ordered (LPSO)-Phase Alloys. Acta Mater. 2019, 163, 226–239. [Google Scholar] [CrossRef]

- Al-Samman, T.; Gottstein, G. Room Temperature Formability of a Magnesium AZ31 Alloy: Examining the Role of Texture on the Deformation Mechanisms. Mater. Sci. Eng. A 2008, 488, 406–414. [Google Scholar] [CrossRef]

- Zhang, D.; Pan, H.; Pan, Z.; Zeng, Z.; Xie, D.; Tang, W.; Xie, H.; Li, R.; Qin, G. Unexpectedly High Precipitation Hardening Induced by Supersaturated Solute and Strong Texture in a Mg-13Gd Binary Alloy after Forging. Mater. Sci. Eng. A 2023, 872, 144984. [Google Scholar] [CrossRef]

- Gao, M.; Yang, K.; Tan, L.; Ma, Z. Improvement of Mechanical Property and Corrosion Resistance of Mg-Zn-Nd Alloy by Bi-Direction Drawing. J. Mater. Sci. Technol. 2021, 81, 88–96. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, N.; Jiang, B.; Xi, Y.; Jing, L.; Lu, L.; Li, Y. Bimodal Microstructure and Strengthening Mechanisms of a Mg-RE Alloy Processed by Asymmetric Upsetting–Extrusion. Materials 2025, 18, 5001. https://doi.org/10.3390/ma18215001

Chen N, Jiang B, Xi Y, Jing L, Lu L, Li Y. Bimodal Microstructure and Strengthening Mechanisms of a Mg-RE Alloy Processed by Asymmetric Upsetting–Extrusion. Materials. 2025; 18(21):5001. https://doi.org/10.3390/ma18215001

Chicago/Turabian StyleChen, Nanjiang, Bingchun Jiang, Yuze Xi, Lei Jing, Liwei Lu, and Yiquan Li. 2025. "Bimodal Microstructure and Strengthening Mechanisms of a Mg-RE Alloy Processed by Asymmetric Upsetting–Extrusion" Materials 18, no. 21: 5001. https://doi.org/10.3390/ma18215001

APA StyleChen, N., Jiang, B., Xi, Y., Jing, L., Lu, L., & Li, Y. (2025). Bimodal Microstructure and Strengthening Mechanisms of a Mg-RE Alloy Processed by Asymmetric Upsetting–Extrusion. Materials, 18(21), 5001. https://doi.org/10.3390/ma18215001