Recent Advances in Pulsed Laser Deposition of REBa2Cu3O7−δ High-Temperature Superconducting Coated Conductors and Artificial Flux Pinning

Abstract

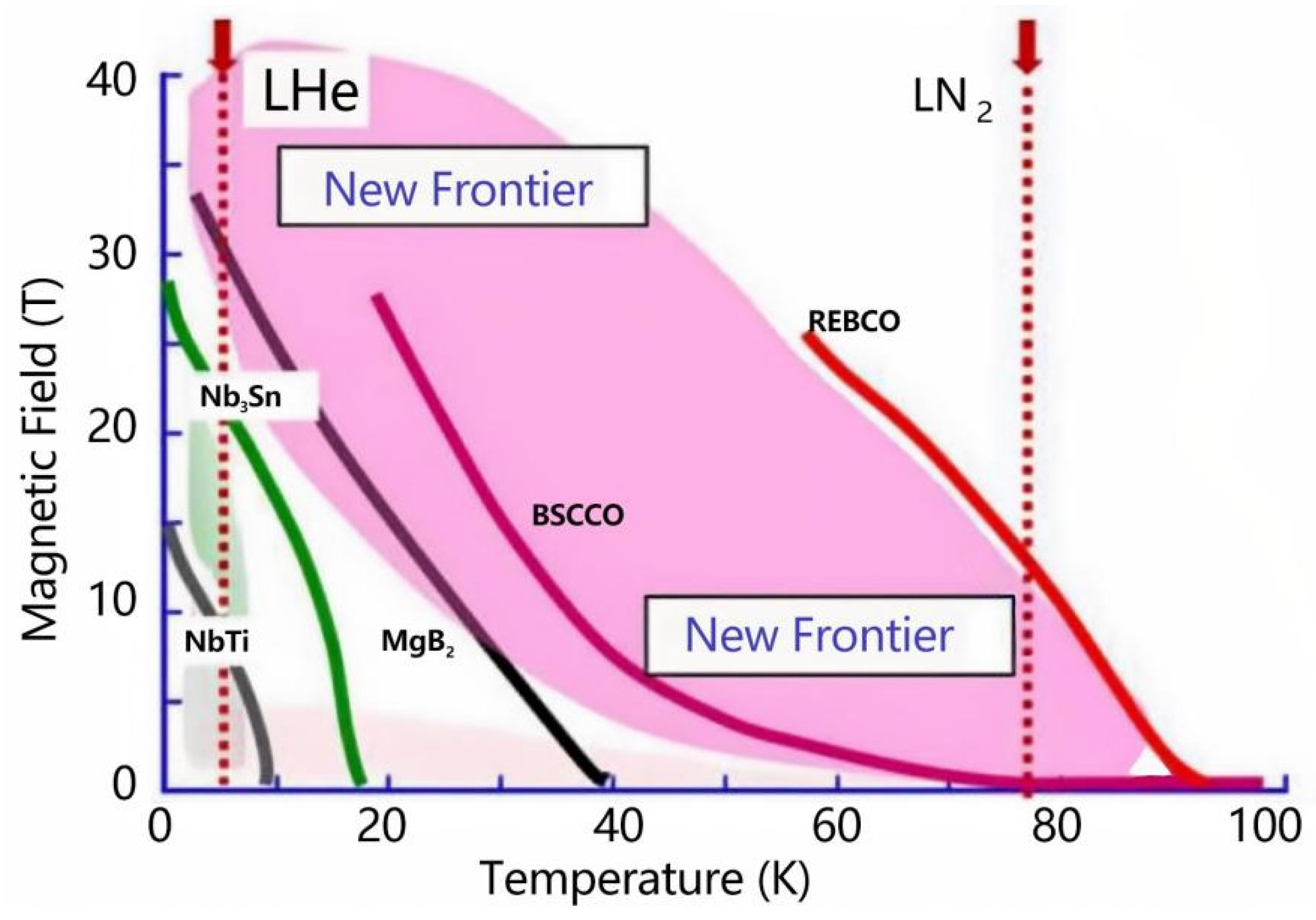

1. Introduction

2. Fabrication Technologies of REBCO High-Temperature Superconducting Tapes

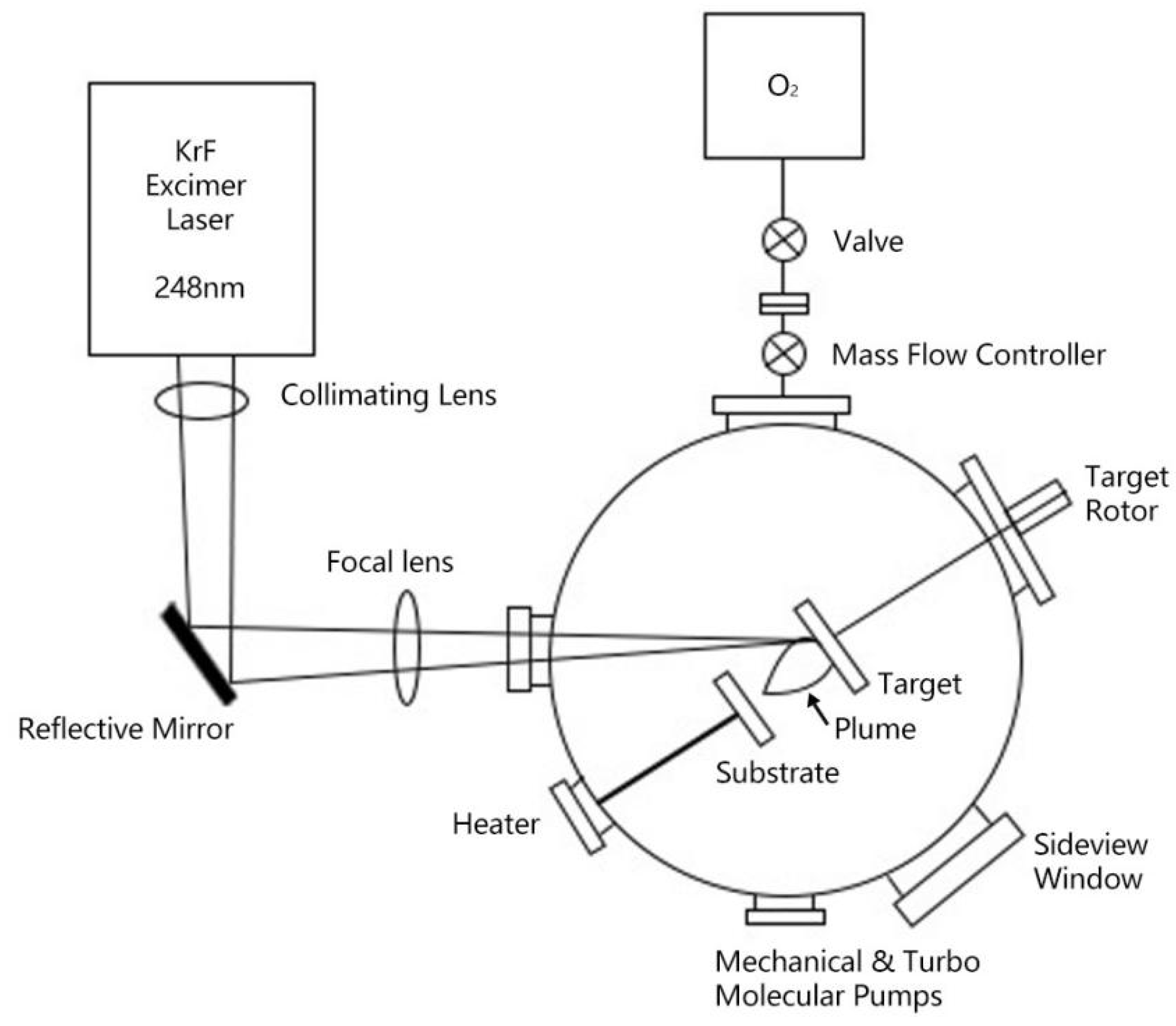

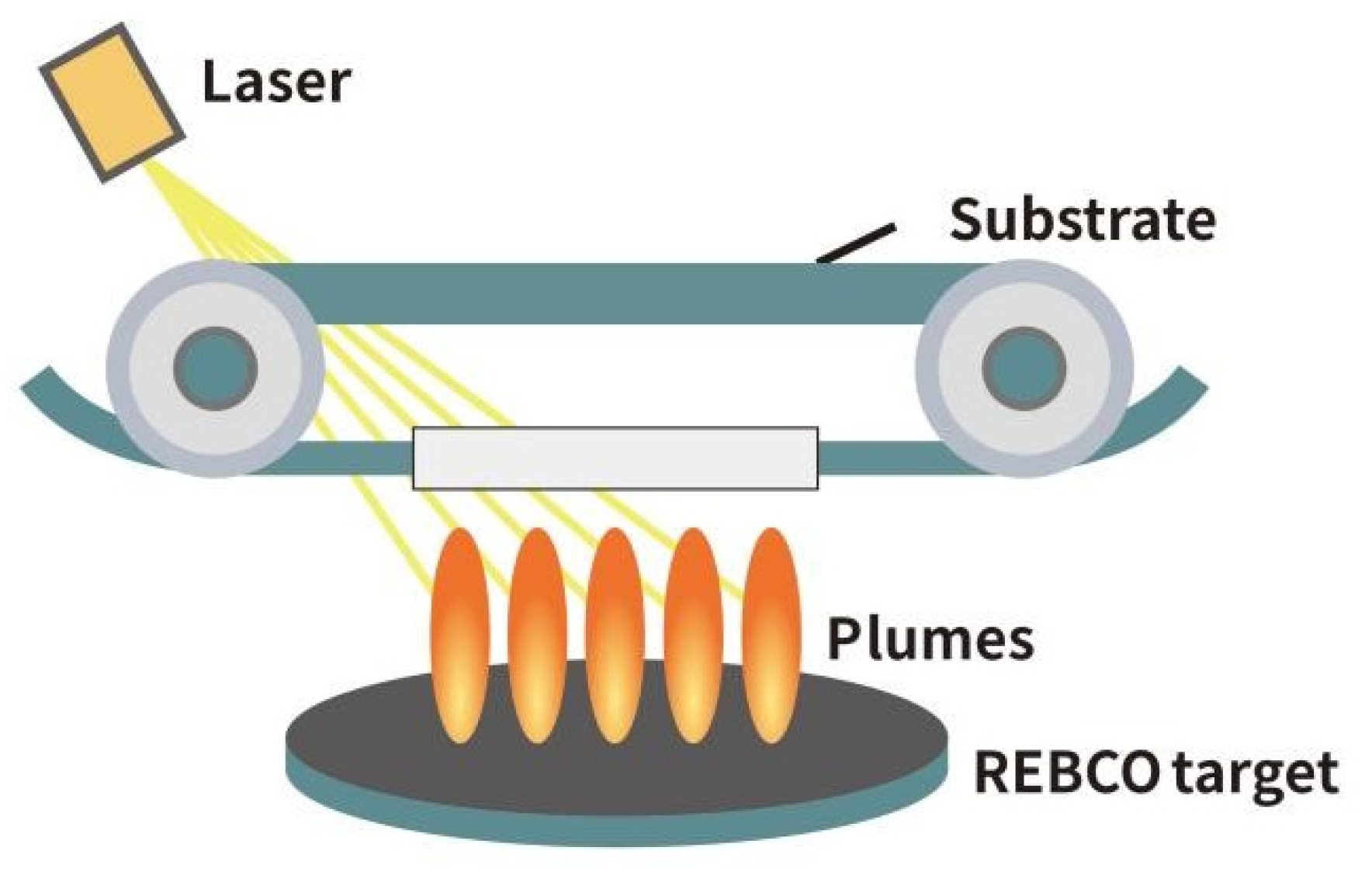

3. PLD Method: Key Principles, Advantages, and Development

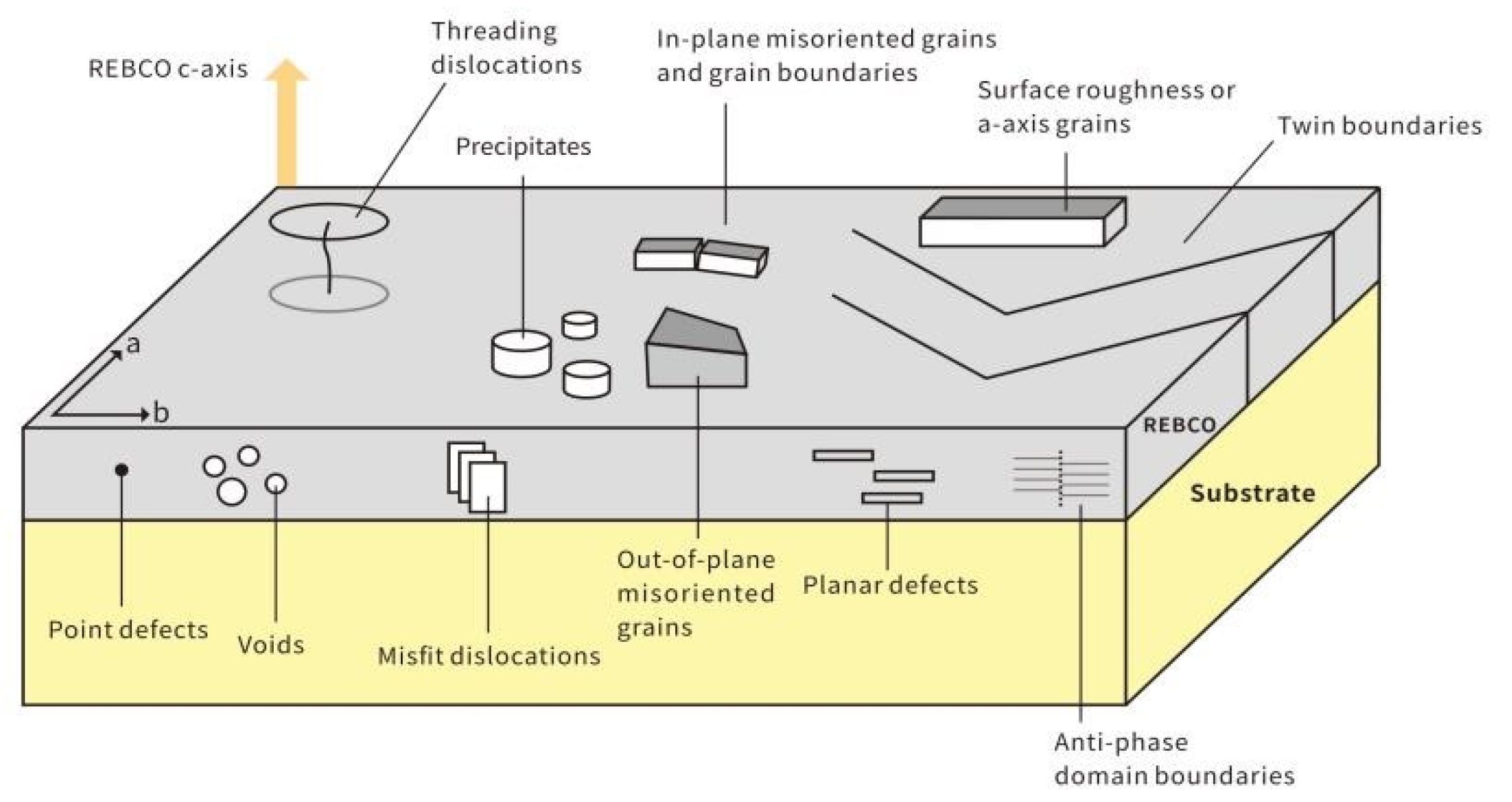

4. Flux Pinning and Natural Pinning Centers in REBCO

5. Enhancement of Jc Through the Introduction of Artificial Pinning Centers

5.1. Doping of Rare-Earth Elements (Addition and/or Substitution)

5.2. Substrate Surface Decoration

5.3. Introduction of Nanoscale Secondary Phases

6. Conclusions

- Compatibility of high-throughput PLD with complex pinning architectures—enabling precise control of nanostructures while maintaining high deposition rates.

- Integration of multiple fabrication routes—combining PLD with techniques such as MOCVD and MOD to optimize both performance and cost.

- Exploration of novel secondary phases—future studies should focus on the discovery and controlled incorporation of unconventional secondary phases beyond conventional perovskite oxides and rare-earth oxides. The development of novel nanostructured compounds or heterostructures with enhanced chemical compatibility and tunable functionalities may enable new flux pinning mechanisms, thereby offering additional opportunities to further improve the in-field performance of REBCO coated conductors.

- Further optimization of reel-to-reel technologies—validating process stability and uniformity in kilometer-scale conductors.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, D.-X.; Chen, J.; Zhou, D.-F.; Cai, C.-B. Development of Metal-Organic Deposition-Derived Second-Generation High-Temperature Superconductor Tapes and Artificial Flux Pinning. Adv. Manuf. 2023, 11, 523–540. [Google Scholar] [CrossRef]

- Namburi, D.K.; Shi, Y.; Cardwell, D.A. The Processing and Properties of Bulk (RE)BCO High Temperature Superconductors: Current Status and Future Perspectives. Supercond. Sci. Technol. 2021, 34, 53002. [Google Scholar] [CrossRef]

- Goddard, K.F.; Lukasik, B.; Rotaru, M.; Sykulski, J.K. Design Study of a High Temperature Superconducting Generator with YBCO Windings. In Proceedings of the ISEF 2009—XIVth International Symposium on Electromagnetic Fields in Mechatronics Electrical and Electronic Engineering, Arras, France, 10 September 2009. [Google Scholar]

- Al-Mosawi, M.K.; Bailey, W.; Beduz, C.; Goddard, K.; Yang, Y. Development of a Coreless HTS Synchronous Generator Operating at Sub-Cooled Liquid Nitrogen Temperatures. J. Phys. Conf. Ser. 2008, 97, 12205. [Google Scholar] [CrossRef]

- Abrahamsen, A.B.; Mijatovic, N.; Seiler, E.; Sorensen, M.P.; Koch, M.; Norgard, P.B.; Pedersen, N.F.; Traeholt, C.; Andersen, N.H.; Ostergard, J. Design Study of 10 kW Superconducting Generator for Wind Turbine Applications. IEEE Trans. Appl. Supercond. 2009, 19, 1678–1682. [Google Scholar] [CrossRef]

- Gieras, J.F. Advancements in Electric Machines; Power Systems; Springer: Dordrecht, The Netherlands, 2008; ISBN 978-1-4020-9006-6. [Google Scholar]

- Gung, C.Y.; Michael, P.C.; Randall, R.N.; Smith, B.A.; Hrycaj, T.; Minervini, J.V.; Montgomery, D.B. Design and Manufacture of the US-ITER Pre Prototype Joint Sample. IEEE Trans. Appl. Supercond. 1997, 7, 469–472. [Google Scholar] [CrossRef]

- Kotoyori, T.; Ohnishi, H.; Masui, Y.; Ishiyama, A.; Tomonori, W.; Hirano, N.; Nagaya, S.; Shikimachi, K. Evaluation of Conduction Cooling Effect of Cryocooler-Cooled HTS Coils for SMES Application. IEEE Trans. Appl. Supercond. 2013, 23, 3800604. [Google Scholar] [CrossRef]

- Bondarenko, S.I.; Koverya, V.P.; Krevsun, A.V.; Link, S.I. High-Temperature Superconductors of the Family (RE)Ba2Cu3O7−δ and Their Application (Review Article). Low Temp. Phys. 2017, 43, 1125–1151. [Google Scholar] [CrossRef]

- Jha, A.K.; Matsumoto, K. Superconductive REBCO Thin Films and Their Nanocomposites: The Role of Rare-Earth Oxides in Promoting Sustainable Energy. Front. Phys. 2019, 7, 82. [Google Scholar] [CrossRef]

- Wesche, R. High-Temperature Superconductors. In Springer Handbook of Electronic and Photonic Materials; Kasap, S., Capper, P., Eds.; Springer International Publishing: Cham, Switzerland, 2017; p. 1. ISBN 978-3-319-48931-5. [Google Scholar]

- Bussmann-Holder, A.; Keller, H. High-Temperature Superconductors: Underlying Physics and Applications. Z. Für Naturforschung B 2020, 75, 3–14. [Google Scholar] [CrossRef]

- Habermeier, H.-U. Science and Technology of Cuprate-Based High Temperature Superconductor Thin Films, Heterostructures and Superlattices—The First 30 Years (Review Article). Low Temp. Phys. 2016, 42, 840–862. [Google Scholar] [CrossRef]

- Chen, J.; Huang, R.; Zhou, X.; Wu, W.; Du, Y.; Liu, Z.; Li, M.; Wang, G.; Cai, C. Optimizing BaHfO3 Nanocrystal Size and Concentration to Enhance MOD-YBCO Film Performance. IEEE Trans. Appl. Supercond. 2025, 35, 6603405. [Google Scholar] [CrossRef]

- Suzuki, T.; Sakuma, K.; Ohta, J.; Ogimoto, Y.; Takahashi, K.; Ozaki, T.; Ibi, A.; Izumi, T.; Yamaki, T.; Okazaki, H.; et al. Role of Defects in Increasing the Critical Current Density of Reel-to-Reel PLD (Eu,Er)Ba2Cu3Oy+BaHfO3-Coated Conductors. Jpn. J. Appl. Phys. 2024, 63, 60901. [Google Scholar] [CrossRef]

- Matias, V.; Hanisch, J.; Reagor, D.; Rowley, E.J.; Sheehan, C. Reactive Co-Evaporation of YBCO as a Low-Cost Process for Fabricating Coated Conductors. IEEE Trans. Appl. Supercond. 2009, 19, 3172–3175. [Google Scholar] [CrossRef]

- Thevalappilly Paulose, M.; Sandra, J.S.; Sayeed, M.A.; Selvamanickam, V. Development of REBCO Thin Films Using MOCVD on Non-Standard Buffers and Substrates. IEEE Trans. Appl. Supercond. 2025, 35, 6601905. [Google Scholar] [CrossRef]

- Rao, M.C. Pulsed Laser Deposition—Ablation Mechanism and Applications. Int. J. Mod. Phys. Conf. Ser. 2013, 22, 355–360. [Google Scholar] [CrossRef]

- Tsuchiya, K.; Wang, X.; Fujita, S.; Ichinose, A.; Yamada, K.; Terashima, A.; Kikuchi, A. Superconducting Properties of Commercial REBCO-Coated Conductors with Artificial Pinning Centers. Supercond. Sci. Technol. 2021, 34, 105005. [Google Scholar] [CrossRef]

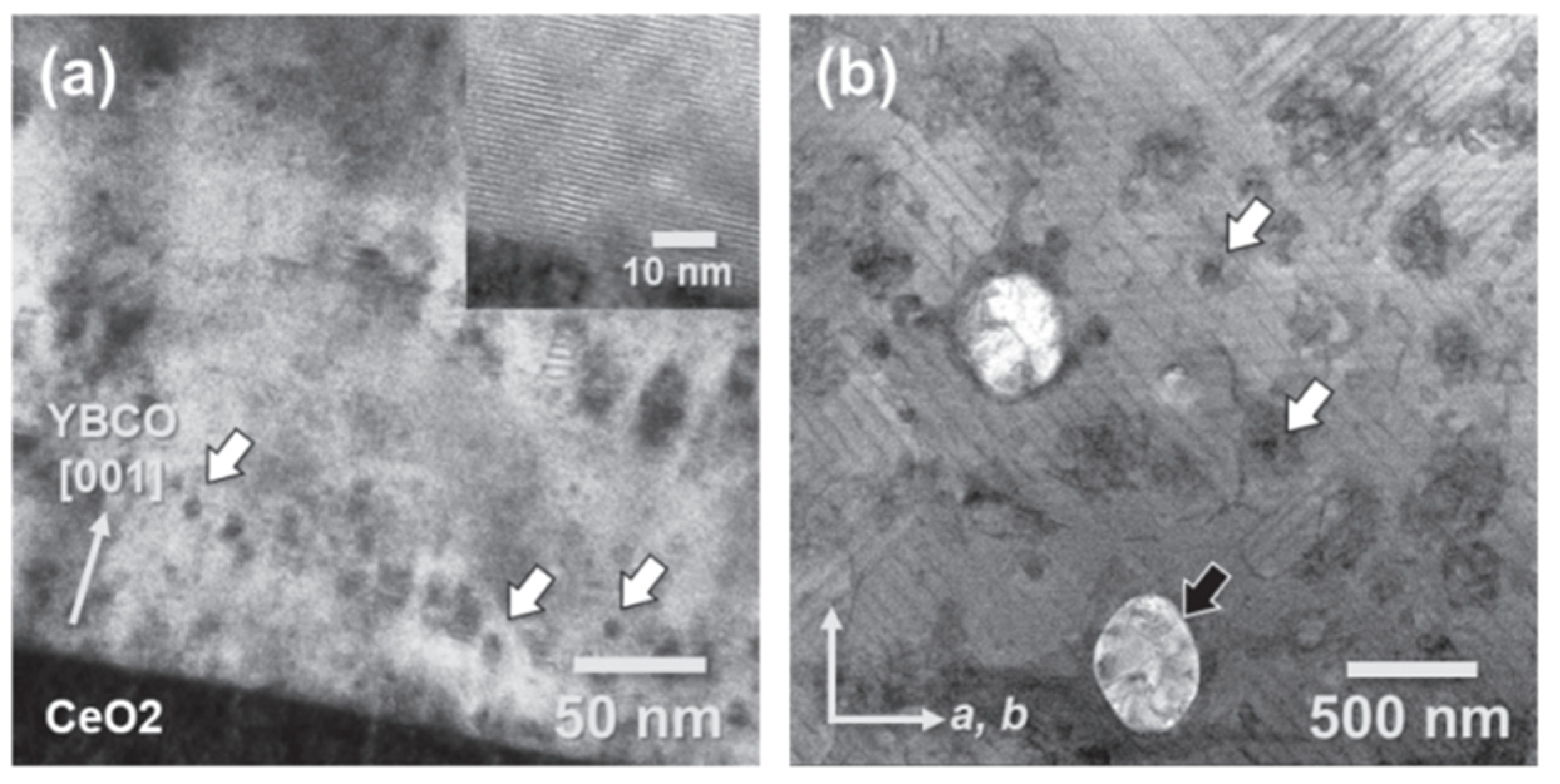

- Kuroki, M.; Horide, T.; Matsumoto, K.; Ishimaru, M. Nano- to Microscale Structural and Compositional Heterogeneity of Artificial Pinning Centers in Pulsed-Laser-Deposited YBa2Cu3O7−y Thin Films. J. Appl. Phys. 2023, 134, 45302. [Google Scholar] [CrossRef]

- Chen, S.; Sebastian, M.A.; Gautam, B.; Wilt, J.; Haugan, T.; Xing, Z.; Wu, J. Enhancement of Isotropic Pinning Force in YBCO Films with BaZrO3 Nanorods and Y2O3 Nanoparticles. IEEE Trans. Appl. Supercond. 2017, 27, 8000205. [Google Scholar] [CrossRef]

- Guo, M.; Li, J.; Jia, J. Growth of YBa2Cu3O7−δ Superconducting Films under Different Atmospheres by Pulsed Laser Deposition. Phys. C Supercond. Its Appl. 2023, 605, 1354206. [Google Scholar] [CrossRef]

- Dai, X.H.; Song, J.M.; Zhao, L.; Wang, Y.L.; Zhao, H.D.; Liu, B.T. YBa2Cu3O7–δ Films Prepared by Pulsed Laser Deposition in O2/Ar Mixture Atmosphere. Appl. Phys. A 2020, 126, 895. [Google Scholar] [CrossRef]

- Wang, W.; Liu, L.; Zheng, T.; Liu, S.; Li, Y. Superconducting Properties and Microstructures of CeO2 Doped YBa2Cu3O7−δ Films Fabricated by Pulsed Laser Deposition. Ceram. Int. 2019, 45, 1998–2002. [Google Scholar] [CrossRef]

- Lee, S.; Petrykin, V.; Molodyk, A.; Samoilenkov, S.; Kaul, A.; Vavilov, A.; Vysotsky, V.; Fetisov, S. Development and Production of Second Generation High-Tc Superconducting Tapes at SuperOx and First Tests of Model Cables. Supercond. Sci. Technol. 2014, 27, 44022. [Google Scholar] [CrossRef]

- Batulin, R.; Cherosov, M.; Kiiamov, A.; Rudnev, I.; Khokhorin, S.; Uvin, D.; Rogov, A.; Tayurskii, D. The Physical Properties of Hastelloy® C-276TM and Hastelloy® C-276TM with Al2O3/Y2O3/MgO/LaMnO3 Buffer Layers down to Cryogenic Temperatures for Applications in Superconducting Magnets. Cryogenics 2024, 137, 103776. [Google Scholar] [CrossRef]

- Sayeed, M.A.; Paulose, M.; Sandra, J.S.; Sherin, S.; Prabhakaran, A.; Sharma, S.; Selvamanickam, V. Development of Electrically Conductive Buffer for REBCO Conductors. IEEE Trans. Appl. Supercond. 2025, 35, 6602604. [Google Scholar] [CrossRef]

- Li, Y.; Liu, L.; Xu, D.; Zhu, S.; Wang, Y.; Zhu, P. Fabrication Technology of REBCO Coated Conductor and Its Development. Mater. China 2011, 30, 16–21. [Google Scholar]

- Senatore, C.; Alessandrini, M.; Lucarelli, A.; Tediosi, R.; Uglietti, D.; Iwasa, Y. Progresses and Challenges in the Development of High-Field Solenoidal Magnets Based on RE123 Coated Conductors. Supercond. Sci. Technol. 2014, 27, 103001. [Google Scholar] [CrossRef]

- Shipulin, I.A.; Nielsch, K.; Hühne, R. Comprehensive Study of Epitaxial (Nd,Eu,Gd)Ba2Cu3O7−δ Films Grown on Textured Templates. Phys. Scr. 2024, 99, 115965. [Google Scholar] [CrossRef]

- Holleis, S.; Shipulin, I.A.; Hühne, R.; Bernardi, J.; Eisterer, M. Reduced Granularity in BHO-Doped YBCO Films on RABiTS Templates. Supercond. Sci. Technol. 2022, 35, 104001. [Google Scholar] [CrossRef]

- Rivasto, E.; Khan, M.Z.; Wu, Y.; Zhao, Y.; Chen, C.; Zhu, J.; Huhtinen, H.; Paturi, P. Lattice Defect Induced Nanorod Growth in YBCO Films Deposited on an Advanced IBAD-MgO Template. Supercond. Sci. Technol. 2020, 33, 75008. [Google Scholar] [CrossRef]

- Prusseit, W.; Sigl, G.; Nemetschek, R.; Hoffmann, C.; Handke, J.; Lumkemann, A.; Kinder, H. Commercial Coated Conductor Fabrication Based on Inclined Substrate Deposition. IEEE Trans. Appl. Supercond. 2005, 15, 2608–2610. [Google Scholar] [CrossRef]

- Troshyn, O.; Hoffmann, C.; Große, V.; Hänisch, J.; Holzapfel, B. Parameter Boundaries for the Heteroepitaxial Growth of REBCO Films by E-Beam Quantitative Evaporation on Inclined Substrate Deposited MgO Buffered Hastelloy Tapes. J. Phys. Conf. Ser. 2020, 1559, 12035. [Google Scholar] [CrossRef]

- Selvamanickam, V.; Chen, Y.; Xiong, X.; Xie, Y.; Zhang, X.; Rar, A.; Martchevskii, M.; Schmidt, R.; Lenseth, K.; Herrin, J. Progress in Second-Generation HTS Wire Development and Manufacturing. Phys. C Supercond. 2008, 468, 1504–1509. [Google Scholar] [CrossRef]

- Qi, X. Liquid Phase Epitaxy Processing for High Temperature Superconductor Tapes. Curr. Opin. Solid State Mater. Sci. 2001, 5, 291–300. [Google Scholar] [CrossRef]

- Honda, G.; Yoshihara, T.; Inagaki, M.; Ito, T.; Nagaishi, T.; Kobayashi, S.; Kanie, K.; Okada, T.; Awaji, S. Development of Fluorine-Free MOD REBCO Tape with BaHfO3 Artificial Pinning Centers. IEEE Trans. Appl. Supercond. 2025, 35, 6603106. [Google Scholar] [CrossRef]

- Pullanikkat, V.; Paulose, M.T.; Rajamohan, S.; Schmidt, R.; Diwan, S.; Majkic, G.; Selvamanickam, V. Next-Generation Advanced MOCVD for Long REBCO Tapes. IEEE Trans. Appl. Supercond. 2025, 35, 6602005. [Google Scholar] [CrossRef]

- Lee, J.W.; Yoo, S.I. Progress in the Co-Evaporation Technologies Developed for High Performance REBa2Cu3O7−δ Films and Coated Conductors. Prog. Supercond. Cryog. 2012, 14, 5–11. [Google Scholar] [CrossRef]

- Wang, X.; Tsuchiya, K.; Terashima, A.; Tanabe, S.; Negishi, N.; Kikuchi, A. Critical Current Measurements on Round Cables Made with a REBCO Stack Conductor. IEEE Trans. Appl. Supercond. 2025, 35, 4800505. [Google Scholar] [CrossRef]

- Tsuchiya, K.; Kikuchi, A.; Terashima, A.; Suzuki, K.; Norimoto, K.; Tawada, M.; Masuzawa, M.; Ohuchi, N.; Wang, X.; Iijima, Y.; et al. Critical Current Characterization of Commercial REBCO Coated Conductors at 4.2 and 77 K. IEEE Trans. Appl. Supercond. 2017, 27, 6600205. [Google Scholar] [CrossRef]

- Shanghai Creative Superconductor Technologies Co., Ltd. Product Description. Available online: http://www.shscsc.com/HomeEN/CaseEN (accessed on 17 August 2025).

- Eastsuper Copper Plated Strip. Available online: https://www.eastsuper.com/cn/proshow.php?id=830 (accessed on 17 August 2025).

- Supermag Technology New Generation High-Temperature Superconducting Tapes. Available online: https://www.supermaghts.com/en/product_show.php?id=3 (accessed on 17 August 2025).

- Wimbush, S.; Strickland, N. A High-Temperature Superconducting (HTS) Wire Critical Current Database. Figshare 2016. [Google Scholar] [CrossRef]

- Din, F.U.; Shaari, A.H.; Kien, C.S.; Talib, Z.A.; Din, A.U.; Pah, L.K. Conversion of YBCO Pellet into Single Layer Thin Film Using Pulse Laser Deposition. J. Phys. Conf. Ser. 2018, 1082, 12024. [Google Scholar] [CrossRef]

- Singh, R.K.; Kumar, D. Pulsed Laser Deposition and Characterization of High-Tc YBa2Cu3O7−x Superconducting Thin Films. Mater. Sci. Eng. R Rep. 1998, 22, 113–185. [Google Scholar] [CrossRef]

- Ibi, A.; Yoshida, T.; Taneda, T.; Yoshizumi, M.; Izumi, T.; Shiohara, Y. Development of Long REBCO with BMO Coated Conductors by PLD Method with High Production Rate. Phys. Procedia 2015, 65, 121–124. [Google Scholar] [CrossRef]

- Ibi, A.; Miyata, S.; Taneda, T.; Yoshizumi, M.; Chikumoto, N.; Yamada, Y.; Izumi, T.; Tanabe, K.; Shiohara, Y.; Yamamoto, A.; et al. Development of High I Long REBCO Tapes with High Production Rate by PLD Method. Phys. Procedia 2013, 45, 145–148. [Google Scholar] [CrossRef]

- Liu, L.; Wang, W.; Zheng, T.; Liu, S.; Wang, Y.; Li, Y. The Influence of Substrate Temperature of Seed Layer on the Structure and Superconducting Property of BaHfO3-Doped Y0.5Gd0.5Ba2Cu3O7−δ Film Prepared by Pulsed Laser Deposition. J. Supercond. Nov. Magn. 2019, 32, 1149–1155. [Google Scholar] [CrossRef]

- Greer, J.A. History and Current Status of Commercial Pulsed Laser Deposition Equipment. J. Phys. Appl. Phys. 2014, 47, 34005. [Google Scholar] [CrossRef]

- Siegert, M.; Zander, W.; Lisoni, J.; Schubert, J.; Buchal, C. Off-Axis Pulsed Laser Deposition System for Epitaxial Oxide Growth on Substrates up to 2 Inches in Diameter. Appl. Phys. Mater. Sci. Process. 1999, 69, S779–S781. [Google Scholar] [CrossRef]

- Shepelin, N.A.; Tehrani, Z.P.; Ohannessian, N.; Schneider, C.W.; Pergolesi, D.; Lippert, T. A Practical Guide to Pulsed Laser Deposition. Chem. Soc. Rev. 2023, 52, 2294–2321. [Google Scholar] [CrossRef]

- Ye, B.; Miao, T.; Zhu, Y.; Huang, H.; Yang, Y.; Shuai, M.; Zhu, Z.; Guo, H.; Wang, W.; Zhu, Y.; et al. Pulsed Laser Deposition of Large-Sized Superlattice Films with High Uniformity. Rev. Sci. Instrum. 2021, 92, 113906. [Google Scholar] [CrossRef]

- Vakulov, Z.; Khakhulin, D.; Zamburg, E.; Mikhaylichenko, A.; Smirnov, V.A.; Tominov, R.; Klimin, V.S.; Ageev, O.A. Towards Scalable Large-Area Pulsed Laser Deposition. Materials 2021, 14, 4854. [Google Scholar] [CrossRef]

- Darwish, A.M.; Moore, S.; Mohammed, A.; Alexander, D.; Bastian, T.; Dorlus, W.; Sarkisov, S.S.; Patel, D.N.; Mele, P.; Koplitz, B. Organic-Inorganic Nano-Composite Films for Photonic Applications Made by Multi-Beam Multi-Target Pulsed Laser Deposition with Remote Control of the Plume Directions. In Photonic Fiber and Crystal Devices: Advances in Materials and Innovations in Device Applications X; Yin, S., Guo, R., Eds.; SPIE: San Diego, CA, USA, 2016; p. 995802. [Google Scholar]

- Watanabe, T.; Kuriki, R.; Iwai, H.; Muroga, T.; Miyata, S.; Ibi, A.; Yamada, Y.; Shiohara, Y. High Rate Deposition by PLD of YBCO Films for Coated Conductors. IEEE Trans. Appl. Supercond. 2005, 15, 2566–2569. [Google Scholar] [CrossRef]

- Yang, J.; Shi, D.Q.; Zhang, H.; Wang, S.M.; Dou, S.X. Reel-to-Reel PLD Fabrication of YBCO Coated Conductor by Single and Multi-Coating Processes. J. Supercond. Novel Magn. 2013, 26, 3159–3164. [Google Scholar] [CrossRef]

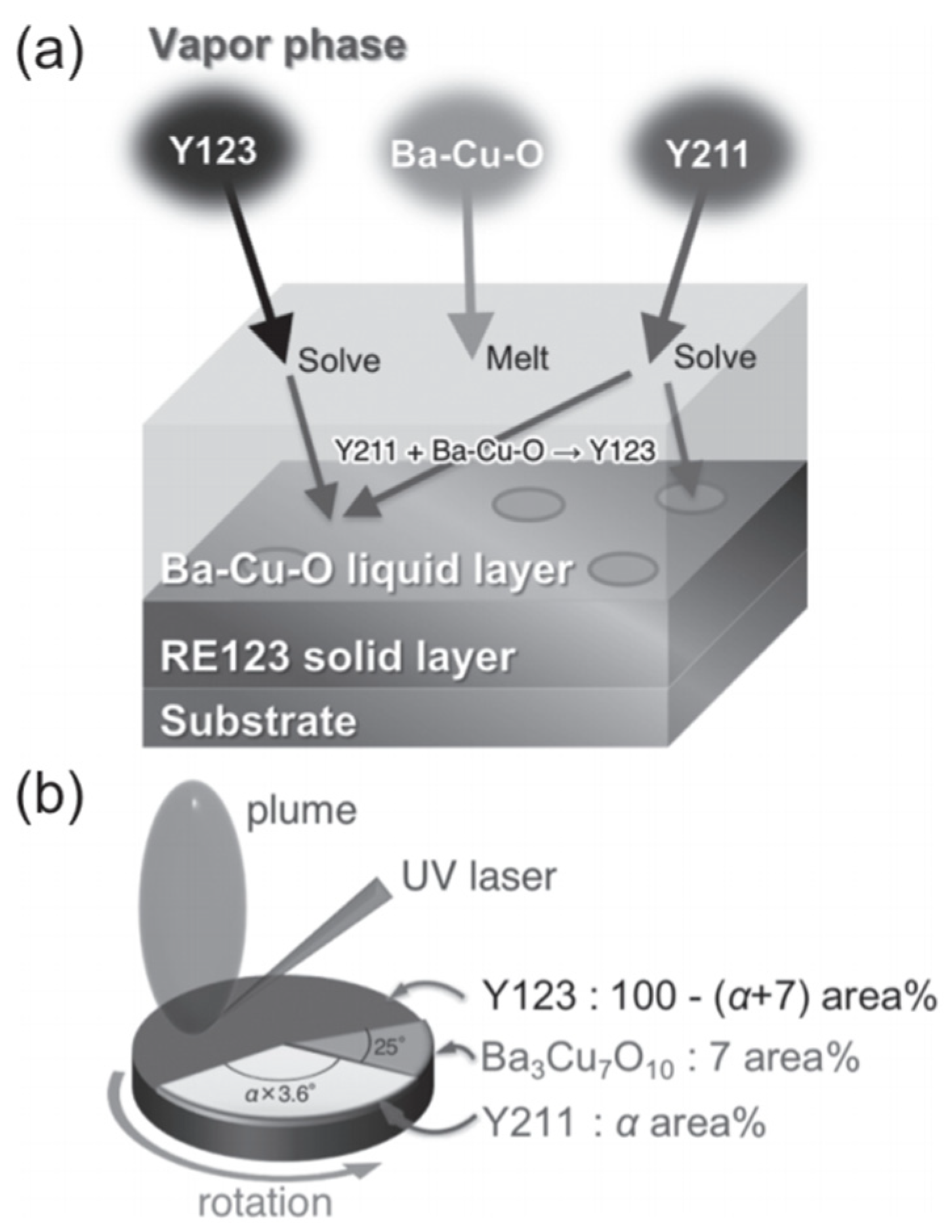

- Wu, Y.; Zhao, Y.; Han, X.; Jiang, G.; Shi, J.; Liu, P.; Khan, M.Z.; Huhtinen, H.; Zhu, J.; Jin, Z.; et al. Ultra-fast growth of cuprate superconducting films: Dual-phase liquid assisted epitaxy and strong flux pinning. Mater. Today Phys. 2021, 18, 100400. [Google Scholar] [CrossRef]

- Li, Y.; Liu, L.; Hong, Z.; Wu, X. Progress of REBCO Coated Conductor Program at SJTU and SSTC. IEEE Trans. Appl. Supercond. 2018, 28, 6602804. [Google Scholar] [CrossRef]

- Shanghai Superconductor Technology. Company Events. Available online: https://www.shsctec.com/company/events (accessed on 12 October 2025).

- Wu, Y.; Shi, J.; Guo, C.; Jiang, G.; Suo, H.; Wu, W.; Li, X.; Wang, Y.; Zhao, Y. Ultra-fast dynamic deposition of EuBa2Cu3O7−δ-BaHfO3 nanocomposite films: Self-assembly structure modulation and flux pinning behaviors. Mater. Des. 2022, 224, 111406. [Google Scholar] [CrossRef]

- Wu, Y.; Jiang, G.; Zhu, J.; Wu, D.; Quan, X.; Shi, J.; Suo, H.; Zhao, Y. Ultra-fast growth (up to 100 nm/s) of heavily doped EuBa2Cu3O7 film with highly aligned BaHfO3 nanocolumn structure. Supercond. Sci. Technol. 2021, 34, 05LT01. [Google Scholar] [CrossRef]

- Jetybayeva, A.; Mukanova, A.; Nurpeissova, A.; Bakenov, Z.; Petrykin, V.; Lee, S. REBCO superconductors by pulsed laser deposition: Key innovations and large-scale applications. iScience 2025, 28, 113260. [Google Scholar] [CrossRef] [PubMed]

- Llordés, A.; Palau, A.; Gázquez, J.; Coll, M.; Vlad, R.; Pomar, A.; Arbiol, J.; Guzmán, R.; Ye, S.; Rouco, V.; et al. Nanoscale Strain-Induced Pair Suppression as a Vortex-Pinning Mechanism in High-Temperature Superconductors. Nat. Mater. 2012, 11, 329–336. [Google Scholar] [CrossRef]

- Rivasto, E.; Huhtinen, H.; Hynninen, T.; Paturi, P. Vortex Dynamics Simulation for Pinning Structure Optimization in the Applications of High-Temperature Superconductors. J. Phys. Condens. Matter 2022, 34, 235902. [Google Scholar] [CrossRef]

- Cornejo, H.S.; Domínguez, A.B.; Holmes, S.N.; Seo, J.W.; Aguiar, J.A.; Silva, V.A.J.; Barnes, C.H.W.; Valladares, L.D.L.S. Vortex Dynamics Study on an Uniaxially Textured YBCO/MgO Superconducting Film from Magnetic Measurements. Supercond. Sci. Technol. 2025, 38, 35028. [Google Scholar] [CrossRef]

- Derevyanko, V.V.; Sukhareva, T.V.; Finkel’, V.A. Phase Transitions and Vortex Structure Evolution in Two-Level High-Temperature Granular Superconductor YBa2Cu3O7−δ under Temperature and Magnetic Field. Phys. Solid State 2017, 59, 1492–1500. [Google Scholar] [CrossRef]

- Foltyn, S.R.; Civale, L.; MacManus-Driscoll, J.L.; Jia, Q.X.; Maiorov, B.; Wang, H.; Maley, M. Materials Science Challenges for High-Temperature Superconducting Wire. Nat. Mater. 2007, 6, 631–642. [Google Scholar] [CrossRef]

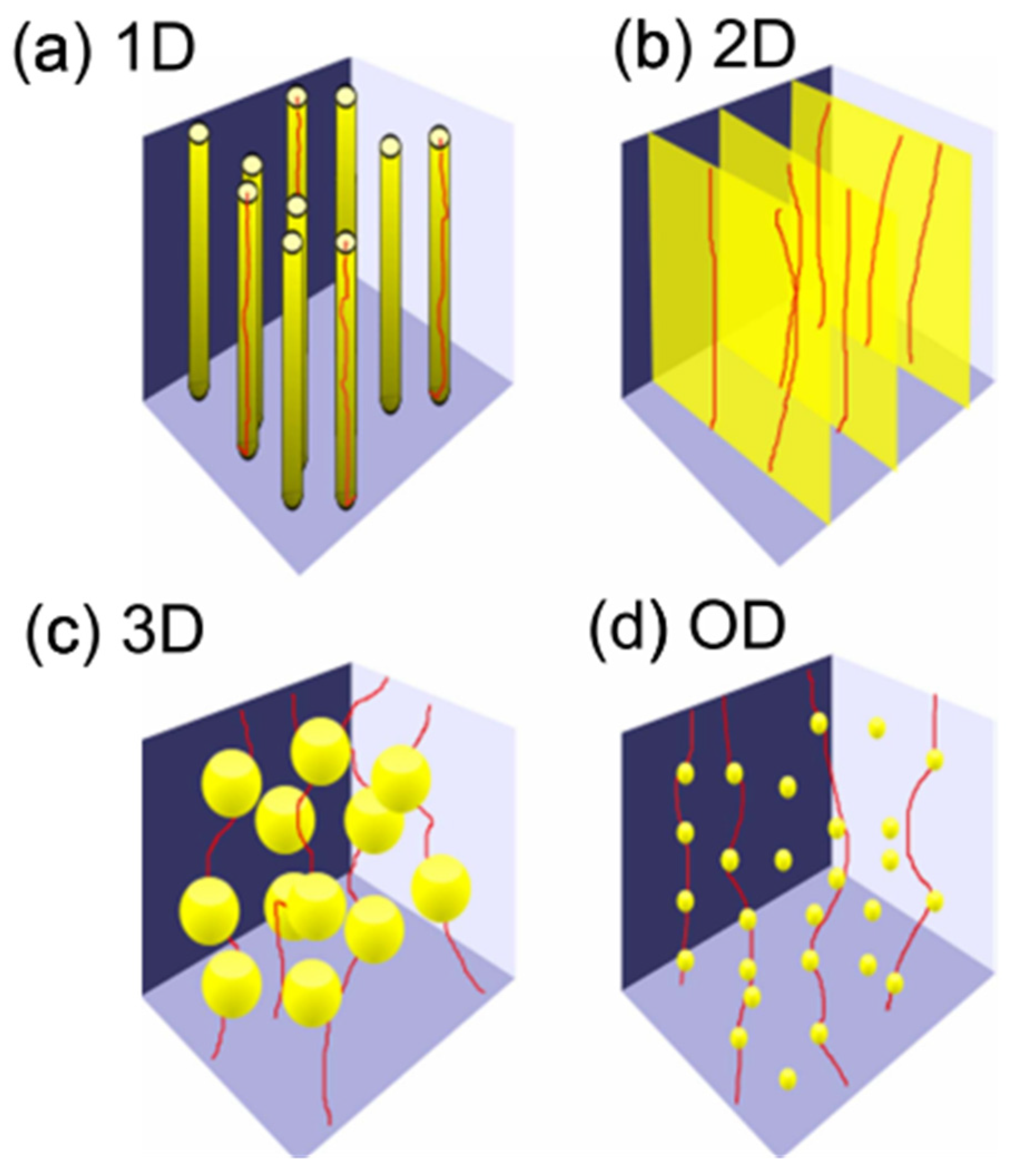

- Feighan, J.P.F.; Kursumovic, A.; MacManus-Driscoll, J.L. Materials Design for Artificial Pinning Centres in Superconductor PLD Coated Conductors. Supercond. Sci. Technol. 2017, 30, 123001. [Google Scholar] [CrossRef]

- Ichinose, A.; Mukaida, M.; Horii, S.; Kita, R.; Matsumoto, K.; Yoshida, Y. Microstructures of High-TC Superconducting Films Introduced Zero-Dimensional and One-Dimensional Artificial Pinning Centers. IEEE Trans. Appl. Supercond. 2007, 17, 3701–3704. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, H.; Zhao, G.; Han, L.; Zhang, J. Progress in the Study of Vortex Pinning Centers in High-Temperature Superconducting Films. Nanomaterials 2022, 12, 4000. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Panth, M.; Ogunjimi, V.; Gautam, B.; Shi, J.; Sebastian, M.A.; Haugan, T.; Ebbing, C.; Zhang, D.; Jian, J.; et al. Artificial Pinning Centers and the Quest of High Critical Current Densities in HTS Nanocomposites. IEEE Trans. Appl. Supercond. 2023, 33, 8000908. [Google Scholar] [CrossRef]

- Maeda, T.; Kaneko, K.; Yamada, K.; Roy, A.; Sato, Y.; Teranishi, R.; Kato, T.; Izumi, T.; Shiohara, Y. Nanostructural Characterization of Artificial Pinning Centers in PLD-Processed REBa2Cu3O7−δ Films. Ultramicroscopy 2017, 176, 151–160. [Google Scholar] [CrossRef]

- Dam, B.; Huijbregtse, J.M.; Klaassen, F.C.; Van Der Geest, R.C.F.; Doornbos, G.; Rector, J.H.; Testa, A.M.; Freisem, S.; Martinez, J.C.; Stäuble-Pümpin, B.; et al. Origin of High Critical Currents in YBa2Cu3O7−δ Superconducting Thin Films. Nature 1999, 399, 439–442. [Google Scholar] [CrossRef]

- Huijbregtse, J.M.; Klaassen, F.C.; Szepielow, A.; Rector, J.H.; Dam, B.; Griessen, R.; Kooi, B.J.; Hosson, J.T.M.D. Vortex Pinning by Natural Defects in Thin Films of YBa2Cu3O7−δ. Supercond. Sci. Technol. 2002, 15, 395–404. [Google Scholar] [CrossRef]

- Shiohara, Y.; Nakaoka, K.; Izumi, T.; Kato, T. Development of REBCO Coated Conductors: Relationship between Microstructure and Critical Current Characteristics. Nippon Kinzoku Gakkaishi 2016, 80, 406–419. [Google Scholar] [CrossRef]

- Lin, J.G.; Huang, C.Y.; Xue, Y.Y.; Chu, C.W.; Cao, X.W.; Ho, J.C. Origin of the R-Ion Effect on Tc in RBa2Cu3O7. Phys. Rev. B 1995, 51, 12900–12903. [Google Scholar] [CrossRef]

- Jia, Q.X.; Maiorov, B.; Wang, H.; Lin, Y.; Foltyn, S.R.; Civale, L.; MacManus-Driscoll, J.L. Comparative Study of REBa2Cu3O7 Films for Coated Conductors. IEEE Trans. Appl. Supercond. 2005, 15, 2723–2726. [Google Scholar] [CrossRef]

- Shit, S.; Namburi, D.K.; Das, S.D.; Nath, T.K. Revealing the Vortex Phases and Second Magnetization Peaks in SmBCO Superconductors. J. Appl. Phys. 2024, 136, 173904. [Google Scholar] [CrossRef]

- MacManus-Driscoll, J.L.; Foltyn, S.R.; Maiorov, B.; Jia, Q.X.; Wang, H.; Serquis, A.; Civale, L.; Lin, Y.; Hawley, M.E.; Maley, M.P.; et al. Rare Earth Ion Size Effects and Enhanced Critical Current Densities in Y2/3Sm1/3Ba2Cu3O7−x Coated Conductors. Appl. Phys. Lett. 2005, 86, 32505. [Google Scholar] [CrossRef]

- Wang, M.J.; Wang, W.T.; Liu, L.; Tian, Z.J.; Zhao, Y. The Electromagnetic Properties of YGdBCO Coated Conductors with Periodic Micro-Holes Arrays. J. Alloys Compd. 2021, 877, 160138. [Google Scholar] [CrossRef]

- Li, X.-F.; Grivel, J.-C.; Zhao, Y.; He, D. Pinning Properties of PLD (NdxSmxGd1−2x)Ba2Cu3O7−δ Thin Films. Phys. Procedia 2012, 36, 463–467. [Google Scholar] [CrossRef]

- Feighan, J.; Lai, M.H.; Kursumovic, A.; Zhang, D.; Wang, H.; Lee, J.H.; Moon, S.; MacManus-Driscoll, J.L. Strong Pinning at High Growth Rates in Rare Earth Barium Cuprate (REBCO) Superconductor Films Grown with Liquid-Assisted Processing (LAP) during Pulsed Laser Deposition. Supercond. Sci. Technol. 2021, 34, 45012. [Google Scholar] [CrossRef]

- Fujiwara, A.; Takeda, K.; Miura, K.; Kato, M.; Yamashita, T. Enhanced Superconducting Transition Temperature through a Small Amount of Nd Substitution for Ba in NdBa2Cu3Oy. Jpn. J. Appl. Phys. 2025, 64, 60903. [Google Scholar] [CrossRef]

- Wu, X. Effect of Laser Energy Density on Microstructure and Critical Current of YGBCO and HGBCO Films Fabricated by PLD. Phys. C Supercond. Its Appl. 2024, 623, 1354547. [Google Scholar] [CrossRef]

- Popov, R.; Hänisch, J.; Holzapfel, B. Oxygen Annealing of GdBa2Cu3O7−δ Superconducting Thin Films: Influence of Annealing Time. IEEE Trans. Appl. Supercond. 2024, 34, 7200104. [Google Scholar] [CrossRef]

- Queraltó, A.; Sieger, M.; Gupta, K.; Meledin, A.; Barusco, P.; Saltarelli, L.; De Palau, M.; Granados, X.; Obradors, X.; Puig, T. Transient Liquid Assisted Growth of Superconducting YBa2Cu3O7−x Films Based on Pulsed Laser Deposition. Supercond. Sci. Technol. 2023, 36, 25003. [Google Scholar] [CrossRef]

- Pahlke, P.; Hering, M.; Sieger, M.; Lao, M.; Eisterer, M.; Usoskin, A.; Stromer, J.; Holzapfel, B.; Schultz, L.; Huhne, R. Thick High Jc YBCO Films on ABAD-YSZ Templates. IEEE Trans. Appl. Supercond. 2015, 25, 6603804. [Google Scholar] [CrossRef]

- Chepikov, V.; Mineev, N.; Abin, D.; Petrykin, V.; Pokrovskii, S.; Amelichev, V.; Molodyk, A.; Lee, S.; Samoilenkov, S.; Rudnev, I.; et al. Pinning Properties of PLD-Obtained GdBa2Cu3O7−x Coated Conductors Doped with BaSnO3. IEEE Trans. Appl. Supercond. 2017, 27, 8000905. [Google Scholar] [CrossRef]

- Jiang, G.; Zhu, J.; Gao, Z.; Chen, Y.; Zhao, Y.; Yamada, Y. High-Speed Deposition of High-Performance REBCO Films by Using a Radiation Assisted Conductive Heating PLD System. IEEE Trans. Appl. Supercond. 2019, 29, 6600504. [Google Scholar] [CrossRef]

- Li, X.-F.; He, D.; Grivel, J.-C. Power-Law Index and Penetration Depth of (NdxSmxGd1−2x)Ba2Cu3O7−δ Films Studied by AC Susceptibility. J. Phys. Conf. Ser. 2012, 400, 22060. [Google Scholar] [CrossRef]

- Inoue, K.; Yoshida, Y.; Ichino, Y.; Takai, Y.; Matsumoto, K.; Ichinose, A.; Mukaida, M.; Horii, S. Superconducting Properties in Magnetic Field of (Nd, Eu, Gd)1+xBa2−xCu3Oy Thin Films Prepared by Low Temperature Growth Technique. Phys. C Supercond. 2008, 468, 1611–1614. [Google Scholar] [CrossRef]

- Murugesan, M.; Obara, H.; Kosaka, S.; Nakagawa, Y.; Nie, J.C.; Yamasaki, H. Growth and Characterization of PLD Grown Dy0.4Ho0.6Ba2Cu3Oz Thin Films. Phys. C Supercond. 2004, 411, 72–76. [Google Scholar] [CrossRef]

- Takahashi, Y.; Yoshida, Y.; Ichino, Y.; Takai, Y.; Takahashi, Y.; Yoshizumi, M.; Izumi, T.; Shiohara, Y.; Kato, T. Thickness Dependence of Ic and Jc of LTG-SmBCO Coated-Conductor on IBAD-MgO Tapes. Phys. C Supercond. Its Appl. 2011, 471, 937–939. [Google Scholar] [CrossRef]

- Ibi, A.; Machi, T.; Nakaoka, K.; Sato, M.; Izumi, T.; Nishimura, J.; Miura, M.; Yokoe, D.; Kato, T.; Hirayama, T. Improvement of In-Field Performance for EuBCO with Heavily Doped BHO Coated Conductors by PLD Method with High Temperature Deposition and Low Temperature Annealing. IOP Conf. Ser. Mater. Sci. Eng. 2020, 756, 12024. [Google Scholar] [CrossRef]

- Wee, S.H.; Moon, S.H.; Park, C.; Yoo, S.I. Effects of Substrates on the NdBa2Cu3O7−δ Films Fabricated by the PLD Process. Phys. C Supercond. Its Appl. 2005, 426–431, 996–1000. [Google Scholar] [CrossRef]

- Ko, R.-K.; Kwon, O.-J.; Song, K.-J.; Ahmad, D.; Park, C.; Lee, J.-H.; An, S.-S.; Lee, N.-J.; Oh, S.-S.; Kim, Y.-C. TmBa2Cu3O7−x Superconducting Thin Films Grown by Pulsed Laser Deposition. IEEE Trans. Appl. Supercond. 2007, 17, 3545–3548. [Google Scholar] [CrossRef]

- Teranishi, R.; Yasunaga, S.; Kai, H.; Yamada, K.; Mukaida, M.; Mori, N.; Fujiyoshi, T.; Ichinose, A.; Horii, S.; Matsumoto, K.; et al. Superconducting Properties of ErBCO Films with BaMO3 Nanorods (M = Zr and Sn) by Pulsed Laser Deposition. Phys. C Supercond. 2008, 468, 1522–1526. [Google Scholar] [CrossRef]

- Ohmatsu, K.; Ueyama, M.; Hasegawa, K.; Hahakura, S.; Kato, T.; Sato, K. Development of 200 Meter HoBCO Coated Conductors on Ni-Alloy Textured Substrates. IEEE Trans. Appl. Supercond. 2007, 17, 3390–3393. [Google Scholar] [CrossRef]

- Crisan, A.; Fujiwara, S.; Nie, J.C.; Sundaresan, A.; Ihara, H. Sputtered Nanodots: A Costless Method for Inducing Effective Pinning Centers in Superconducting Thin Films. Appl. Phys. Lett. 2001, 79, 4547–4549. [Google Scholar] [CrossRef]

- Aytug, T.; Paranthaman, M.; Gapud, A.A.; Kang, S.; Christen, H.M.; Leonard, K.J.; Martin, P.M.; Thompson, J.R.; Christen, D.K.; Meng, R.; et al. Enhancement of Flux Pinning and Critical Currents in YBa2Cu3O7−δ Films by Nanoscale Iridium Pretreatment of Substrate Surfaces. J. Appl. Phys. 2005, 98, 114309. [Google Scholar] [CrossRef]

- Selvamanickam, V.; Mallick, R.; Tao, X.; Yao, Y.; Gharahcheshmeh, M.H.; Xu, A.; Zhang, Y.; Galstyan, E.; Majkic, G. Improved Flux Pinning by Prefabricated SnO2 Nanowires Embedded in Epitaxial YBa2Cu3Ox Superconducting Thin Film Tapes. Supercond. Sci. Technol. 2016, 29, 85016. [Google Scholar] [CrossRef]

- Armenio, A.A.; Piperno, L.; Petrisor, T.; Vannozzi, A.; Pinto, V.; Rizzo, F.; Augieri, A.; Mancini, A.; Rufoloni, A.; Mos, R.B.; et al. Nanostructured Templates for Critical Current Density Enhancement in YBa2Cu3O7–x Films. Supercond. Sci. Technol. 2020, 33, 94003. [Google Scholar] [CrossRef]

- Tang, J.; Liu, G.Q.; Zhang, R.; Zhang, S.N.; Jin, L.H. Controlled Growth of YBCO Film with Tungsten Oxide Buffered Substrate. Mater. Lett. 2024, 375, 137256. [Google Scholar] [CrossRef]

- Maiorov, B.; Wang, H.; Foltyn, S.R.; Li, Y.; DePaula, R.; Stan, L.; Arendt, P.N.; Civale, L. Influence of Naturally Grown Nanoparticles at the Buffer Layer in the Flux Pinning in YBa2Cu3O7 Coated Conductors. Supercond. Sci. Technol. 2006, 19, 891–895. [Google Scholar] [CrossRef]

- Sparing, M.; Backen, E.; Freudenberg, T.; Hühne, R.; Rellinghaus, B.; Schultz, L.; Holzapfel, B. Artificial Pinning Centres in YBCO Thin Films Induced by Substrate Decoration with Gas-Phase-Prepared Y2O3 Nanoparticles. Supercond. Sci. Technol. 2007, 20, S239–S246. [Google Scholar] [CrossRef]

- Aytug, T.; Paranthaman, M.; Leonard, K.J.; Kim, K.; Ijaduola, A.O.; Zhang, Y.; Tuncer, E.; Thompson, J.R.; Christen, D.K. Enhanced Flux Pinning and Critical Currents in YBa2Cu3O7−δ Films by Nanoparticle Surface Decoration: Extension to Coated Conductor Templates. J. Appl. Phys. 2008, 104, 43906. [Google Scholar] [CrossRef]

- Jha, A.K.; Khare, N.; Pinto, R. Interface Engineering Using Ferromagnetic Nanoparticles for Enhancing Pinning in YBa2Cu3O7−δ Thin Film. J. Appl. Phys. 2011, 110, 113920. [Google Scholar] [CrossRef]

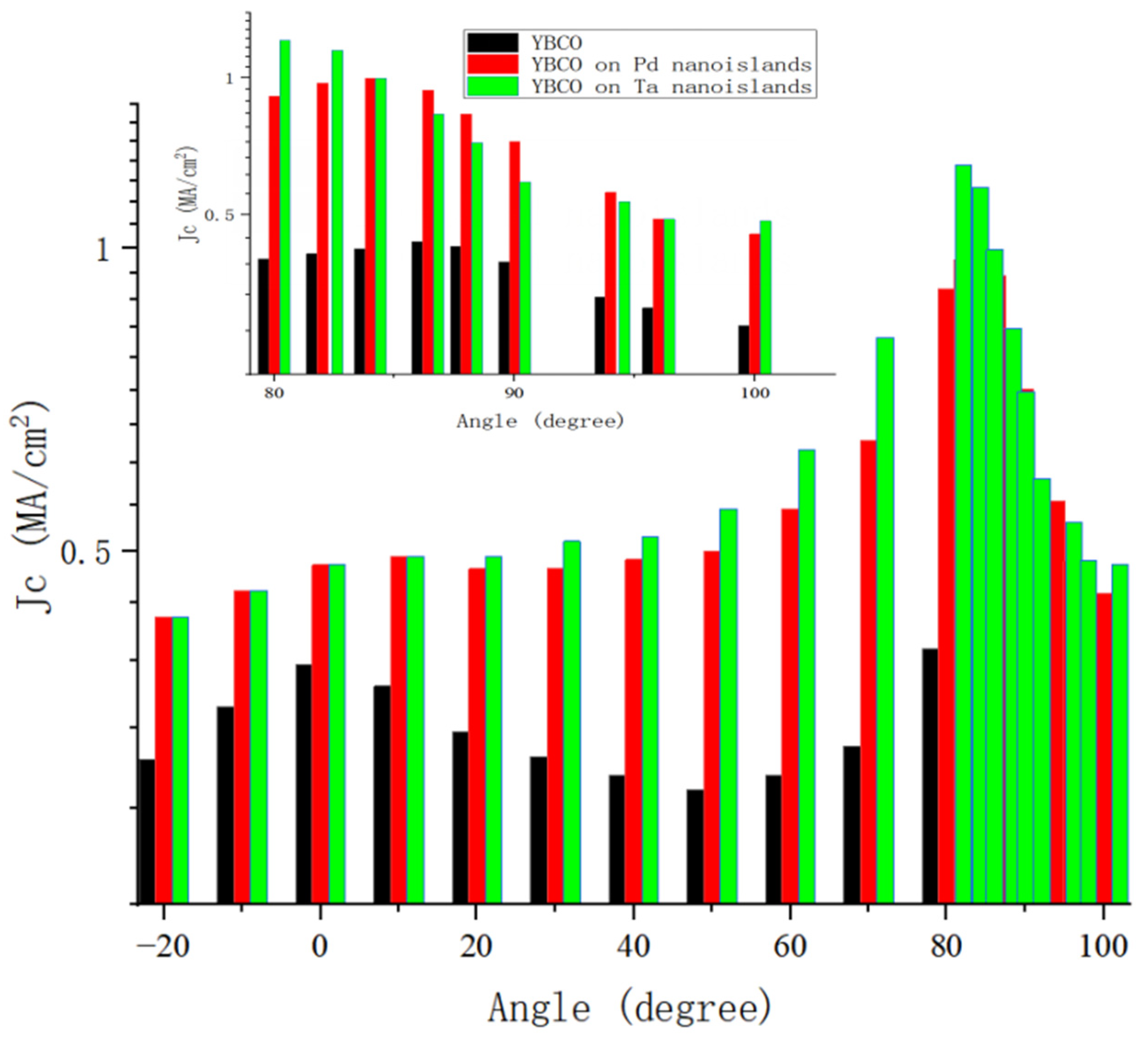

- Polat, Ö.; Ertuğrul, M.; Thompson, J.R.; Leonard, K.J.; Sinclair, J.W.; Paranthaman, M.P.; Wee, S.H.; Zuev, Y.L.; Xiong, X.; Selvamanickam, V.; et al. Superconducting Properties of YBa2Cu3O7−δ Films Deposited on Commercial Tape Substrates, Decorated with Pd or Ta Nano-Islands. Supercond. Sci. Technol. 2012, 25, 25018. [Google Scholar] [CrossRef]

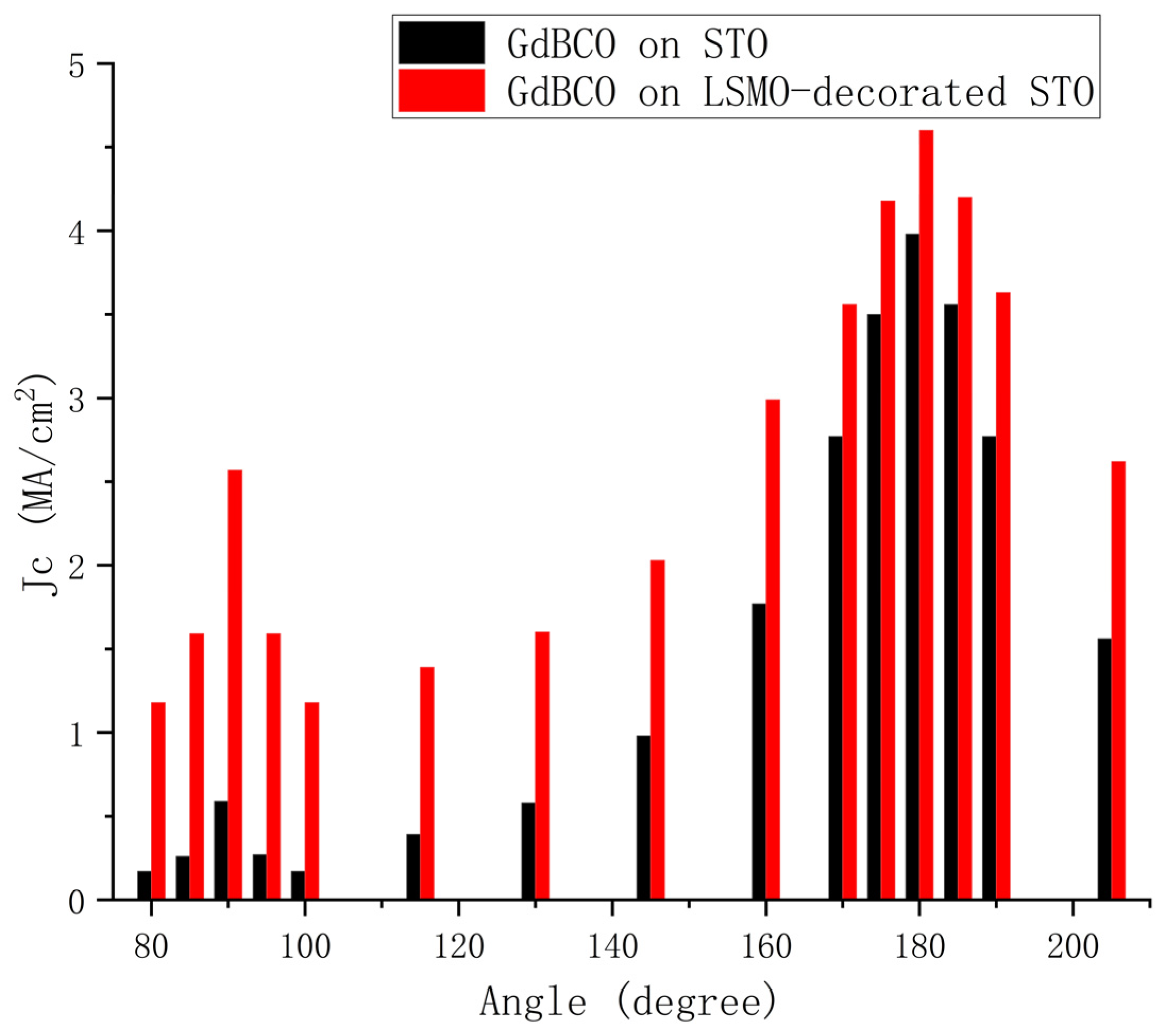

- Wang, Y.; Li, Y.; Liu, L.; Xu, D. Improvement of Flux Pinning in GdBa2Cu3O7−δ Thin Film by Nanoscale Ferromagnetic La0.67Sr0.33MnO3 Pretreatment of Substrate Surface. Ceram. Int. 2018, 44, 225–230. [Google Scholar] [CrossRef]

- Rizzo, F.; Piperno, L.; Augieri, A.; Meledin, A.; Feighan, J.; MacManus-Driscoll, J.L.; Celentano, G. Synergistic Strategies for Enhancing Flux Pinning in YBa2Cu3O7−x Thin Films at High Fields and Low Temperature. Phys. C Supercond. Its Appl. 2025, 630, 1354648. [Google Scholar] [CrossRef]

- Puig, T.; Gutierrez, J.; Obradors, X. Impact of High Growth Rates on the Microstructure and Vortex Pinning of High-Temperature Superconducting Coated Conductors. Nat. Rev. Phys. 2024, 6, 132–148. [Google Scholar] [CrossRef]

- Bartůněk, V.; Smrčková, O. Preparation of the Silver–Superconductor Composite by Deposition of the Silver Nanoparticles in the Bismuth Cuprate Superconductor. J. Supercond. Nov. Magn. 2011, 24, 1241–1244. [Google Scholar] [CrossRef]

- Dadras, S.; Gharehgazloo, Z. Effect of Au Nanoparticles Doping on Polycrystalline YBCO High Temperature Superconductor. Phys. B Condens. Matter 2016, 492, 45–49. [Google Scholar] [CrossRef]

- Shlyk, L.; Nenkov, K.; Krabbes, G.; Fuchs, G. Melt-Processed YBCO with Pt or Ce Additions: Comparison of Pinning Behavior. Phys. C Supercond. 2005, 423, 22–28. [Google Scholar] [CrossRef]

- Antončík, F.; Jankovský, O.; Hlásek, T.; Bartůněk, V. Nanosized Pinning Centers in the Rare Earth-Barium-Copper-Oxide Thin-Film Superconductors. Nanomaterials 2020, 10, 1429. [Google Scholar] [CrossRef]

- Cai, C.B.; Zhang, J.C.; Cao, S.X.; Hänisch, J.; Hühne, R.; Holzapfel, B. Growth-Controlled Precipitates for Flux Pinning Enhancement in YBa2Cu3O7−δ Films and Coated Conductors. Phys. C Supercond. 2007, 460–462, 1355–1356. [Google Scholar] [CrossRef]

- Rizzo, F.; Augieri, A.; Kursumovic, A.; Bianchetti, M.; Opherden, L.; Sieger, M.; Hühne, R.; Hänisch, J.; Meledin, A.; Van Tendeloo, G.; et al. Pushing the Limits of Applicability of REBCO Coated Conductor Films through Fine Chemical Tuning and Nanoengineering of Inclusions. Nanoscale 2018, 10, 8187–8195. [Google Scholar] [CrossRef]

- Bian, W.; Chen, Y.; Yin, X.; Tang, X.; Feng, Y.; Zhang, K.; Wu, H.; Li, L.; Hong, F.; Zhao, G.; et al. Manipulation of YBCO Film Properties by the Introduction of Perovskite BaTiO3 Nanodots as Substrate Decorations. J. Eur. Ceram. Soc. 2016, 36, 3417–3422. [Google Scholar] [CrossRef]

- Jha, A.K.; Matsumoto, K.; Horide, T.; Saini, S.; Mele, P.; Ichinose, A.; Yoshida, Y.; Awaji, S. Isotropic Enhancement in the Critical Current Density of YBCO Thin Films Incorporating Nanoscale Y2BaCuO5 Inclusions. J. Appl. Phys. 2017, 122, 93905. [Google Scholar] [CrossRef]

- Okram, G.S.; Muralidhar, M.; Murakami, M. The Effect of Gd2BaCuO5 Nanoparticles on Irreversibility Fields of (Nd–Sm–Gd)Ba2Cu3O7−δ. Supercond. Sci. Technol. 2005, 18, 1060–1064. [Google Scholar] [CrossRef]

- Haugan, T.; Barnes, P.N.; Wheeler, R.; Meisenkothen, F.; Sumption, M. Addition of Nanoparticle Dispersions to Enhance Flux Pinning of the YBa2Cu3O7−x Superconductor. Nature 2004, 430, 867–870. [Google Scholar] [CrossRef] [PubMed]

- Barnes, P.N.; Haugan, T.J.; Sumption, M.D.; Harrison, B.C. Pinning Enhancement of YBa2Cu3O7−δ Thin Films with Y2BaCuO5 Nanoparticulates. IEEE Trans. Appl. Supercond. 2005, 15, 3766–3769. [Google Scholar] [CrossRef]

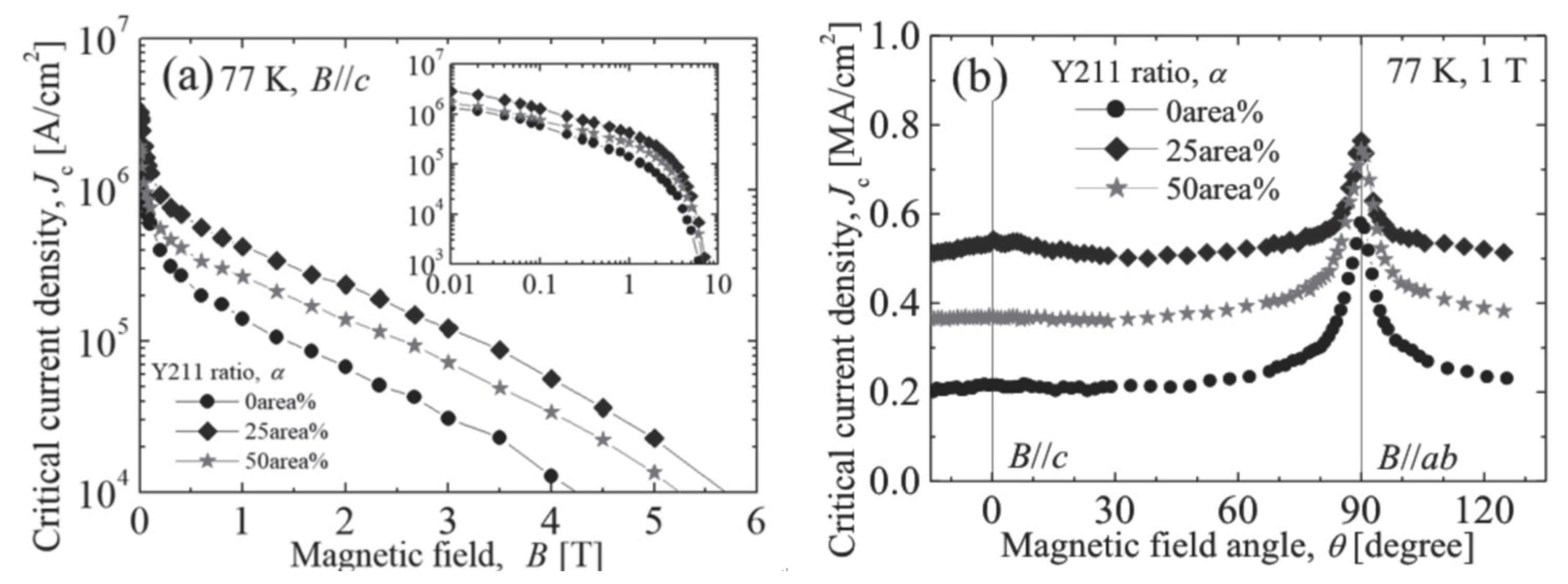

- Tsuchiya, Y.; Tajiri, S.; Ichino, Y.; Ichinose, A.; Yoshida, Y. Flux Pinning Properties in Y2BaCuO5-Doped YBa2Cu3Oy Films Fabricated with Vapor-Liquid-Solid Growth Method. J. Jpn. Inst. Met. Mater. 2019, 83, 335–340. [Google Scholar] [CrossRef]

- Gantepogu, C.S.; Yang, C.-M.; Ganesan, P.; Chen, I.-G.; Wang, M.-J.; MacManus-Driscoll, J.; Moon, S.-H.; Wang, C.; Wu, M.-K. Improvement of the Value and Anisotropy of Critical Current Density in GdBa2Cu3O7−δ Coated Conductors with Self-Assembled 3-Dimensional BaZrO3 Nanostructure. Mater. Today Phys. 2021, 20, 100455. [Google Scholar] [CrossRef]

- Aye, M.M.; Khan, M.Z.; Rivasto, E.; Tikkanen, J.; Huhtinen, H.; Paturi, P. Role of Columnar Defect Size in Angular Dependent Flux Pinning Properties of YBCO Thin Films. IEEE Trans. Appl. Supercond. 2019, 29, 8000805. [Google Scholar] [CrossRef]

- Jha, A.K.; Khare, N.; Pinto, R. Comparison of Flux Pinning Mechanism in Laser Ablated YBCO and YBCO:BaZrO3 Nanocomposite Thin Films. J. Supercond. Nov. Magn. 2012, 25, 377–380. [Google Scholar] [CrossRef]

- Wee, S.H.; Zuev, Y.L.; Cantoni, C.; Goyal, A. Engineering Nanocolumnar Defect Configurations for Optimized Vortex Pinning in High Temperature Superconducting Nanocomposite Wires. Sci. Rep. 2013, 3, 2310. [Google Scholar] [CrossRef]

- Sebastian, M.A.; Ebbing, C.; Zhang, D.; Jian, J.; Huang, J.; Zhang, Y.; Wang, H.; Ogunjimi, V.; Panth, M.; Gautam, B.; et al. Impact of Calcium Doping of YBa2Cu3O7−δ Multilayer Thin Films on the Flux Pinning Landscape at 65–5 K, 0–9 T for Various Applications. IEEE Trans. Appl. Supercond. 2023, 33, 8000606. [Google Scholar] [CrossRef]

- Panth, M.; Sebastian, M.A.; Zhang, D.; Ogunjimi, V.; Gautam, B.; Jian, J.; Huang, J.; Zhang, Y.; Haugan, T.; Wang, H.; et al. Multilayer YBa2Cu3O7−x/Ca0.3Y0.7Ba2Cu3O7−x Nanocomposite Films with 2–8% BaZrO3 Doping for High-Field Applications. IEEE Trans. Appl. Supercond. 2022, 32, 8001208. [Google Scholar] [CrossRef]

- Panth, M.; Ogunjimi, V.; Sebastian, M.A.; Gautam, B.; Haugan, T.; Wu, J. The Benefit of Ca in Improving Pinning of BaZrO3–Y2O3 Doubly-Doped YBa2Cu3O7−x/Ca0.3Y0.7Ba2Cu3O7−x Multilayer Nanocomposite Films. Mater. Res. Express 2023, 10, 46001. [Google Scholar] [CrossRef]

- Wu, J.; Ogunjimi, V.; Sebastian, M.A.; Panth, M.; Shen, J.; Moceri, M.; Aafiya, A.; Haugan, T.; Wang, H. Achieving High Jc in High Fields in Multilayer BZO/YBCO Thick Films. IEEE Trans. Appl. Supercond. 2025, 35, 7500106. [Google Scholar] [CrossRef]

- Aye, M.M.; Rivasto, E.; Rijckaert, H.; Palonen, H.; Huhtinen, H.; Van Driessche, I.; Paturi, P. Optimized BaZrO3 Nanorod Density in YBa2Cu3O6+x Matrix for High Field Applications. Supercond. Sci. Technol. 2022, 35, 75006. [Google Scholar] [CrossRef]

- Gondo, M.; Yoshida, M.; Yoshida, Y.; Ishimaru, M.; Horide, T.; Matsumoto, K.; Kita, R. Nanostructures and Flux Pinning Properties in YBa2Cu3O7−y Thin Films with Double Perovskite Ba2LuNbO6 Nanorods. J. Appl. Phys. 2021, 129, 195301. [Google Scholar] [CrossRef]

- Bartolomé, E.; Alcalà, J.; Vallès, F.; Puig, T.; Obradors, X.; Pompeo, N.; Alimenti, A.; Torokhtii, K.; Rizzo, F.; Augieri, A.; et al. Vortex Pinning Properties at Dc and Microwave Frequencies of YBa2Cu3O7−x Films with Nanorods and Nanoparticles. Supercond. Sci. Technol. 2020, 33, 74006. [Google Scholar] [CrossRef]

- Celentano, G.; Rizzo, F.; Augieri, A.; Mancini, A.; Pinto, V.; Rufoloni, A.; Vannozzi, A.; MacManus-Driscoll, J.L.; Feighan, J.; Kursumovic, A.; et al. YBa2Cu3O7−x Films with Ba2Y(Nb,Ta)O6 Nanoinclusions for High-Field Applications. Supercond. Sci. Technol. 2020, 33, 44010. [Google Scholar] [CrossRef]

- Okada, T.; Gaifullin, M.; Vyatkin, V.; Dao, H.T.; Veshchunov, I.; Petrykin, V.; Lee, S.; Awaji, S. Reduction of Jc Anisotropy in REBCO Coated Conductors via Bilayer Structure of Columnar and Random Pinning Centers. Supercond. Sci. Technol. 2025, 38, 55021. [Google Scholar] [CrossRef]

- Ichino, Y.; Sato, S.; Tsuchiya, Y.; Yoshida, Y. Effect on SmBa2Cu3O Films of Lattice Strain Induced by BaHfO3 Nanorods. Phys. C Supercond. Its Appl. 2020, 575, 1353692. [Google Scholar] [CrossRef]

- Popov, R.; Erbe, M.; Hänisch, J.; Holzapfel, B. Superconducting BaHfO3–GdBa2Cu3O7 Nanocomposite Thin Films: Influence of Growth Temperature and Deposition Rate on Transport Properties. IEEE Trans. Appl. Supercond. 2019, 29, 8001005. [Google Scholar] [CrossRef]

- Ito, T.; Ichino, Y.; Tsuchiya, Y.; Yasuda, K.; Ichinose, A.; Yoshida, Y. Enhancement of Ic of BaHfO3-Doped REBCO Thick Coated Conductor Using Vapor-Liquid-Solid Growth Technique. IEEE Trans. Appl. Supercond. 2021, 31, 6601304. [Google Scholar] [CrossRef]

- Ito, T.; Ichino, Y.; Tsuchiya, Y.; Yasuda, K.; Ichinose, A.; Yoshida, Y. Effect of Surface Liquid Layer during Film Growth on Morphology of BaHfO3 in YBa2Cu3Oy Coated Conductors Fabricated by Pulsed Laser Deposition. IEEE Trans. Appl. Supercond. 2021, 31, 6601205. [Google Scholar] [CrossRef]

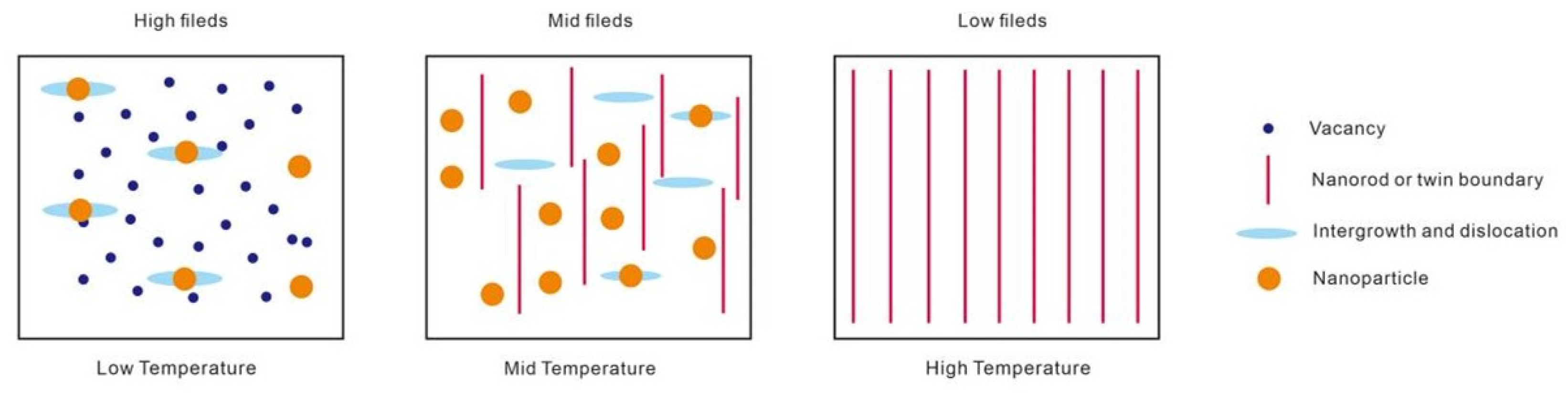

- Gautam, B.; Sebastian, M.A.; Chen, S.; Haugan, T.; Zhang, W.; Huang, J.; Wang, H.; Wu, J.Z. Microscopic Adaptation of BaHfO3 and Y2O3 Artificial Pinning Centers for Strong and Isotropic Pinning Landscape in YBa2Cu3O7–x Thin Films. Supercond. Sci. Technol. 2018, 31, 25008. [Google Scholar] [CrossRef]

- Horide, T.; Torigoe, K.; Ishimaru, M.; Kita, R.; Awaji, S.; Matsumoto, K. Simultaneous Achievement of High Jc and Suppressed Jc Anisotropy by Hybrid Pinning in YBa2Cu3O7 Three-Phase-Nanocomposite Film. Supercond. Sci. Technol. 2020, 33, 105003. [Google Scholar] [CrossRef]

- Horide, T.; Torigoe, K.; Kita, R.; Nakamura, R.; Ishimaru, M.; Awaji, S.; Matsumoto, K. Deposition-Temperature Dependence of Vortex Pinning Property in YBa2Cu3O7+BaHfO3 Films. Mater. Trans. 2020, 61, 449–454. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, M.; Tsuchiya, Y.; Okada, T.; Luo, J.; Awaji, S.; Wang, Y.; Zhao, Y. Co-Doping with BaSnO3 and BaHfO3 by Ultra-High Rate PLD Enabling Formation of High-Density Nanocolumns in EuBa2Cu3O7−δ Films. Supercond. Sci. Technol. 2025, 38, 5LT01. [Google Scholar] [CrossRef]

- Zhong, H.X.; Liu, X.M.; Boubeche, M.; Guo, Y.Q.; Li, M.J.; Bai, C.Y.; Liu, Z.Y.; Lu, Y.M.; Cai, C.B. Angular-Dependent Vortex Pinning Properties of YBa2Cu3O7−δ/Y2O3 Quasi-Multilayers. J. Supercond. Nov. Magn. 2018, 31, 55–59. [Google Scholar] [CrossRef]

- Ichino, Y.; Kusafuka, Y.; Ichinose, A.; Yoshida, Y. Peculiar Critical Current Density and Irreversibility Line in Double Perovskite Ba2SmNbO6-Doped SmBa2Cu3Oy Film Prepared by Nd:YAG Pulsed Laser Deposition. Jpn. J. Appl. Phys. 2017, 56, 73101. [Google Scholar] [CrossRef]

- Miura, S.; Yoshida, Y.; Ichino, Y.; Xu, Q.; Matsumoto, K.; Ichinose, A.; Awaji, S. Improvement in Jc Performance below Liquid Nitrogen Temperature for SmBa2Cu3Oy Superconducting Films with BaHfO3 Nano-Rods Controlled by Low-Temperature Growth. APL Mater. 2016, 4, 16102. [Google Scholar] [CrossRef]

- Zhao, M.; Wu, Y.; Xiang, H.; Liu, D.; Shi, J.; Tsuchiya, Y.; Okada, T.; Awaji, S.; Zhao, Y. Influence of Thickness on the Microstructure and Performance of BaHfO3-Doped EuBa2Cu3O7− Layers Grown by Ultra-Fast PLD Techniques. Appl. Surf. Sci. 2025, 694, 162791. [Google Scholar] [CrossRef]

- Murase, G.; Tsuchiya, Y.; Ichino, Y.; Yoshida, Y. Effects of Sm1+xBa2−xCu3Oy Films with Non-Stoichiometric Composition Fabricated by Combinatorial Pulsed Laser Deposition Method on the Superconducting Properties. J. Phys. Conf. Ser. 2019, 1293, 12032. [Google Scholar] [CrossRef]

- Khan, M.Z.; Malmivirta, M.; Zhao, Y.; Wu, X.; Jha, R.; Awana, V.P.S.; Huhtinen, H.; Paturi, P. Angular and Field Dependent Flux Pinning in Artificially Doped YBCO Films on IBAD-MgO Based Template. Phys. C Supercond. Its Appl. 2018, 555, 15–23. [Google Scholar] [CrossRef]

- Aye, M.M.; Rivasto, E.; Khan, M.Z.; Rijckaert, H.; Palonen, H.; Huhtinen, H.; Van Driessche, I.; Paturi, P. Multilayering BZO Nanocolumns with Different Defect Densities for YBCO High Field Applications. New J. Phys. 2021, 23, 113031. [Google Scholar] [CrossRef]

- Sebastian, M.A.; Gautam, B.; Ebbing, C.R.; Panasyuk, G.Y.; Susner, M.A.; Huang, J.; Zhang, W.; Wang, H.; Wu, J.Z.; Haugan, T.J. Comparison Study of the Flux Pinning Enhancement of YBa2Cu3O7−δ Thin Films with BaHfO3+Y2O3 Single- and Mixed-Phase Additions. IEEE Trans. Appl. Supercond. 2019, 29, 8002005. [Google Scholar] [CrossRef]

| Company | Technical Route | Substrate | Buffer Layer | Ic@77 K, Self-Field (A/cm-w) |

|---|---|---|---|---|

| SuperPower (Schenectady, NY, USA) | IBAD/MOCVD-REBCO | Hastelloy | Al2O3/Y2O3/MgO/LaMnO3 | 400 |

| Fujikura (Tokyo, Japan) | IBAD/PLD-GdBCO | Hastelloy | Al2O3/Y2O3/MgO/CeO2 | 725 |

| Shanghai Creative Superconductor Technology Corporation (Shanghai, China) | IBAD/MOD-REBCO | Hastelloy | Al2O3/Y2O3/MgO/LaMnO3 | 900 |

| Shanghai Superconductor Technology Corporation (Shanghai, China) | IBAD/PLD-REBCO | Hastelloy | Al2O3/Y2O3/MgO/CeO2 | 600 |

| SuNAM (Daejeon, Republic of Korea) | IBAD/RCE-GdBCO | Hastelloy | Al2O3/Y2O3/MgO/LaMnO3 | 700 |

| Eastern Superconductor Technology Corporation (Suzhou, China) | IBAD/MOCVD-REBCO | Hastelloy | Al2O3/Y2O3/MgO/LaMnO3 | >300 |

| Faraday Factory Japan (Sagamihara, Japan) | IBAD/PLD-REBCO | Hastelloy | Al2O3/Y2O3/MgO/LaMnO3 | 585 |

| Supermag Technology (Shanghai, China) | IBAD/PLD-REBCO | Hastelloy | Al2O3/Y2O3/MgO/CeO2 | >500 |

| RE Element | Tm3+ | Yb3+ | Er3+ | Dy3+ | Ho3+ | Y3+ | Gd3+ | Eu3+ | Sm3+ | Nd3+ |

|---|---|---|---|---|---|---|---|---|---|---|

| Ionic radius (Å) | 0.99 | 0.99 | 1.00 | 1.00 | 1.02 | 1.04 | 1.05 | 1.07 | 1.08 | 1.12 |

| Film | Film Deposition Process and Substrate | Thickness (µm) | Tc (K) | Jc @ Self-Field, 77 K (MA cm−2) | Reference (Ref.) |

|---|---|---|---|---|---|

| YGdBCO | multi-channel and multi beam PLD, C276/Al2O3/Y2O3/IBAD-MgO/CeO2 | 2.9 | 1.44 | [86] | |

| HoGdBCO | multi-channel and multi beam PLD, C276/Al2O3/Y2O3/IBAD-MgO/CeO2 | 0.9 | 3.9 | [86] | |

| GdBCO | PLD, MgO single crystals | 0.22–0.25 | 92.7 | 3.2 | [87] |

| YBCO | PLD, SrTiO3/LaMnO3 | 0.45 | 90.0 | 1.45 | [88] |

| YBCO | reel-to-reel PLD, stainless steel/YSZ/CeO2 | 0.7 | 90.5 | 2.7 | [89] |

| GdBCO | reel-to-reel PLD, Hastelloy/Al2O3/Y2O3/IBAD-MgO/ LaMnO3/CeO2 | 93.3 | 3.18 | [90] | |

| GdBCO | PLD, Hastelloy/Al2O3/Y2O3/IBAD-MgO/ LaMnO3/CeO2 | 2 | 3 | [91] | |

| Nd0.1Sm0.1Gd0.8BCO | PLD, STO single crystals | 92.0 | 2.5 | [92] | |

| NdErGdBCO | PLD, MgO single crystals | 0.5 | 92.5 | 3.18 | [93] |

| DyHoBCO | PLD, LAO single crystals | 0.5–0.6 | 90.3 | 1.25 | [94] |

| SmBCO | PLD, Hastelloy/Gd2Zr2O7/Y2O3/IBAD-MgO/LaMnO3/CeO2 | 0.5 | 93.1 | 3.0 | [95] |

| EuBCO | reel-to-reel PLD Hastelloy/Gd2Zr2O7/Y2O3/IBAD-MgO/LaMnO3/CeO2 | 0.5–0.55 | 93.4 | 5.7 | [96] |

| NdBCO | PLD, STO single crystals | 91.2 | 3.5 | [97] | |

| TmBCO | PLD, STO single crystals | 0.062 | 86 | 4.5 | [98] |

| ErBCO | PLD, STO single crystals | 89.7 | 1.0 | [99] | |

| HoBCO | PLD, Ni-alloy/CeO2/YSZ/CeO2 | 0.2 | ~90 | 5.6 | [100] |

| Film | Introduction of Nanoscale Secondary Phases and Dimension | Film Deposition Process and Substrate | Thickness (µm) | Tc (K) | Jc (MA cm−2) | Ref | ||

|---|---|---|---|---|---|---|---|---|

| High-Field, Low Temperature | Mid-Field, Mid Temperature | Self-Field, 77 K | ||||||

| YBCO | CeO2 nanoparticles (3D) | reel-to-reel PLD, C276/Al2O3/Y2O3/IBAD-MgO/CeO2 | 0.2 | 5.0 | [24] | |||

| YBCO | Y2O3 nanoparticles (3D) | PLD, STO single crystals | 0.28 | 90.0 | 3.6 | [147] | ||

| GdBCO | Gd2O3 nanoparticles (3D) | PLD, MgO single crystals | 0.23 | 93.3 | 3.66 (10 K, 8 T) 2.61 (10 K, 14 T) | 3.7 | [87] | |

| YBCO | Y211 nanoparticles (3D) | PLD, STO single crystals | 89.6 | 0.93 (65 K, 3 T) 0.49 (65 K, 7 T) | 2.3 | [121] | ||

| YBCO | Y211 nanoparticles (3D) | VLS, Hastelloy/Gd2Zr2O7/Y2O3/IBAD-MgO/LaMnO3/CeO2 | 0.4 | 91.3 | 2.9 | [125] | ||

| YBCO | BLNO nanocolumns (1D) | PLD, STO single crystals | 0.16 | 90.0 | 0.7 | [135] | ||

| SmBCO | BSNO nanocolumns (1D) | PLD, LAO single crystals | 0.5 | 90.4 | ~1.3 (65 K, 0.8 T) | 1.1 | [148] | |

| SmBCO | BHO nanocolumns (1D) | PLD, LAO single crystals | 0.26 | 91.5 | 18.06 (4.2 K, 8 T) 11.29 (4.2 K, 14 T) | 2.1 | [149] | |

| (Eu,Er)BCO | BHO nanocolumns (1D) and irradiation-induced nanoparticles (3D) | reel-to-reel PLD Hastelloy/Gd2Zr2O7/Y2O3/IBAD-MgO/LaMnO3/CeO2 | 0.5 | 91.7 | 2.20 (65 K, 3 T) 1.32 (65 K, 6 T) | 4.89 | [15] | |

| EuBCO | BHO nanocolumns (1D) and nanoparticles (3D) | reel-to-reel MPMT-PLD (facility), C276/Al2O3/Y2O3/IBAD-MgO/LaMnO3/CeO2 | 1.1 | 96.9 | 9.1 (4.2 K, 8 T) 5 (4.2 K, 14 T) | 2.8 (50 K, 3 T) | 2.59 | [150] |

| EuBCO | BHO nanocolumns (1D) and nanoparticles (3D) | reel-to-reel MPMT-PLD (facility), C276/Al2O3/Y2O3/IBAD-MgO/LaMnO3/CeO2 | 3.3 | 97.2 | 8.6 (4.2 K, 8 T) 5 (4.2 K, 14 T) | 2.6 (50 K, 3 T) | 1.39 | [150] |

| YBCO | BHO nanocolumns (1D) | VLS, Hastelloy/Al2O3/Y2O3/IBAD-MgO/LaMnO3/CeO2 | 90.0 | 0.37 (65 K, 3 T) 0.13 (65 K, 7 T) | 0.9 | [142] | ||

| Sm1.075Ba1.925Cu3Oy | BHO nanocolumns (1D) | PLD, Hastelloy/Al2O3/Y2O3/IBAD-MgO/CeO2 | 0.2 | 90.4 | 5.1 | [151] | ||

| YBCO | BCO nanoparticles (3D) | PLD, STO single crystals | 0.16 | 86.0 | 4.66 (10 K, 6 T) | 1.88 (40 K, 4 T) 1.74 (40 K, 6 T) | [152] | |

| GdBCO | BSO nanocolumns (1D) | reel-to-reel PLD, Hastelloy/Al2O3/Y2O3/IBAD-MgO/LaMnO3/CeO2 | 92.0 | 6.94 (4.2 K, 8 T) | 2.05 | [90] | ||

| YBCO | BZO nanocolumns (1D) | PLD, STO single crystals | 0.2 | 89.0 | 3.65 (10 K, 8 T) | 3.25 (40 K, 4 T) 2.31 (50 K, 8 T) 1.16 (65 K, 8 T) | [153] | |

| YBCO | BYNTO nanocolumns (1D) and Y2O3 nanoparticles (3D) | PLD, STO single crystals | 0.15–0.23 | 88.0 | 1.8 (65 K, 3 T) 0.88 (65 K, 5 T) | 3 | [136] | |

| YBCO | BHO nanocolumns (1D) and Y2O3 nanoparticles (3D) | PLD, STO single crystals | 0.16–0.20 | 88.5 | 5.32 (5 K, 8 T) | 2.57 (50 K, 3 T) 1.07 (50 K, 6 T) 0.9 (65 K, 3 T) | 3.7 | [154] |

| EuBCO | BSHO nanocolumns (1D) | reel-to-reel Ultra-high Rate PLD (facility), Hastelloy/Al2O3/Y2O3/IBAD-MgO/LaMnO3/CeO2 | 1 | 95.81 | 9.62 (4.2 K, 8 T) 6.32 (4.2 K, 14 T) | 4 (50 K, 3 T) | 2.6 | [146] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Z.; Chen, L.; Li, Y.; Xia, X.; Lin, G.; Hu, P.; Gong, D.; Wang, D.; Ma, Y. Recent Advances in Pulsed Laser Deposition of REBa2Cu3O7−δ High-Temperature Superconducting Coated Conductors and Artificial Flux Pinning. Materials 2025, 18, 4988. https://doi.org/10.3390/ma18214988

Guo Z, Chen L, Li Y, Xia X, Lin G, Hu P, Gong D, Wang D, Ma Y. Recent Advances in Pulsed Laser Deposition of REBa2Cu3O7−δ High-Temperature Superconducting Coated Conductors and Artificial Flux Pinning. Materials. 2025; 18(21):4988. https://doi.org/10.3390/ma18214988

Chicago/Turabian StyleGuo, Ziheng, Liangkang Chen, Yuxiang Li, Xinyue Xia, Guangyao Lin, Penghong Hu, Dongliang Gong, Dongliang Wang, and Yanwei Ma. 2025. "Recent Advances in Pulsed Laser Deposition of REBa2Cu3O7−δ High-Temperature Superconducting Coated Conductors and Artificial Flux Pinning" Materials 18, no. 21: 4988. https://doi.org/10.3390/ma18214988

APA StyleGuo, Z., Chen, L., Li, Y., Xia, X., Lin, G., Hu, P., Gong, D., Wang, D., & Ma, Y. (2025). Recent Advances in Pulsed Laser Deposition of REBa2Cu3O7−δ High-Temperature Superconducting Coated Conductors and Artificial Flux Pinning. Materials, 18(21), 4988. https://doi.org/10.3390/ma18214988